Interlocking Evaluation of Mesoscopic Skeleton with the Compaction Degree of Hot-Mix Asphalt

Abstract

:1. Introduction

2. Materials and Test Methods

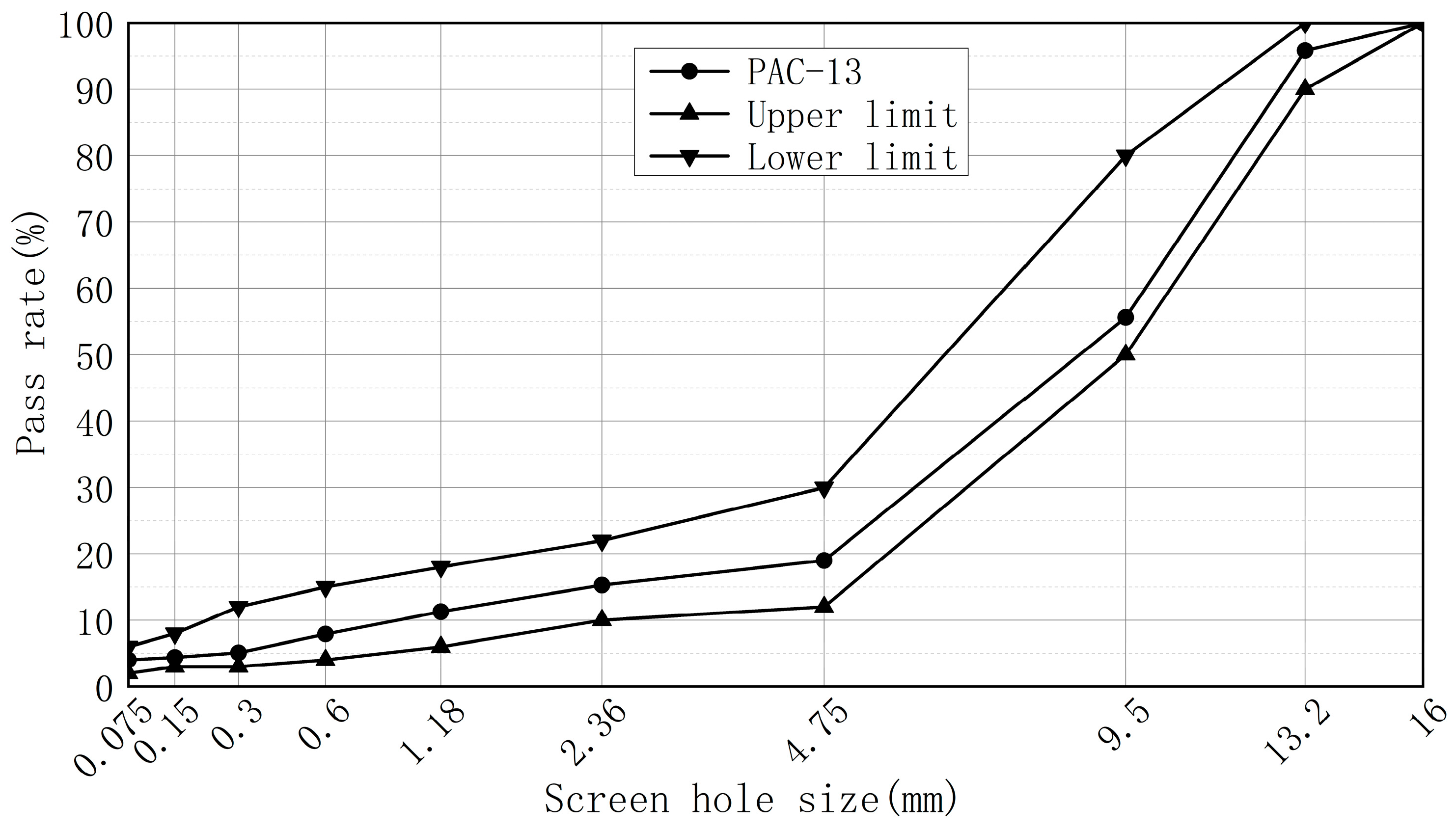

2.1. Materials

2.2. Specimen Preparation for Different Compaction Processes

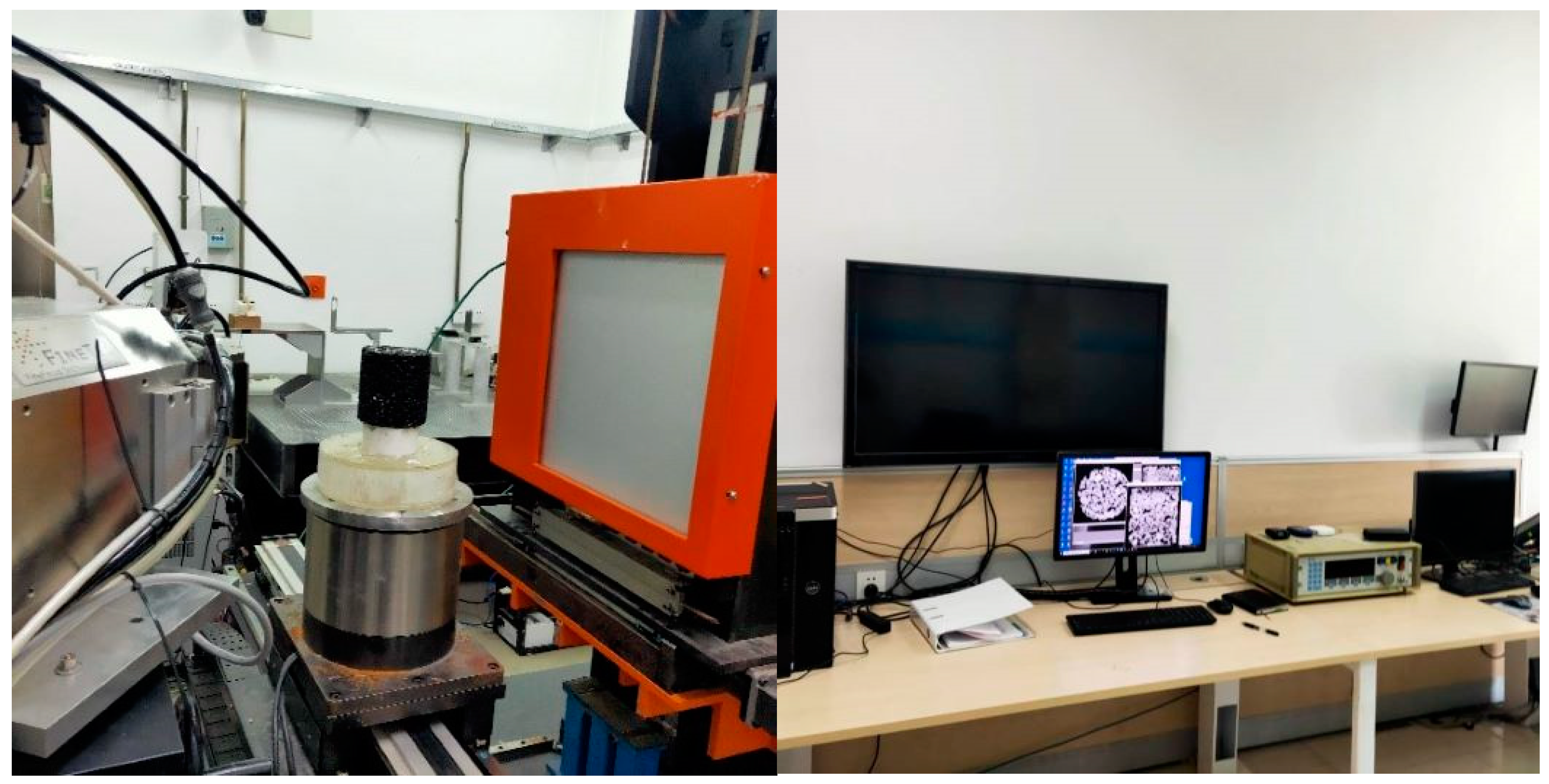

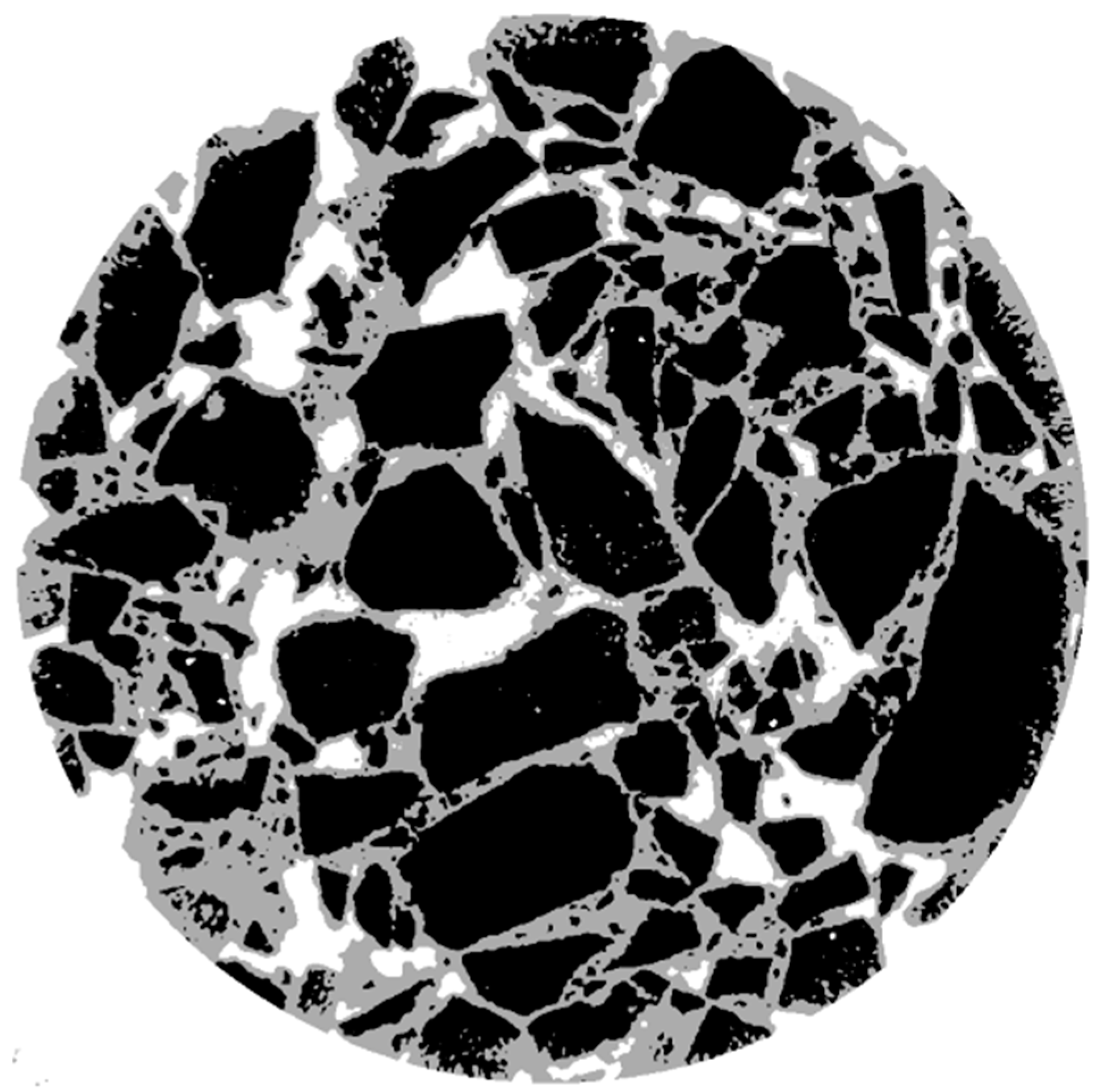

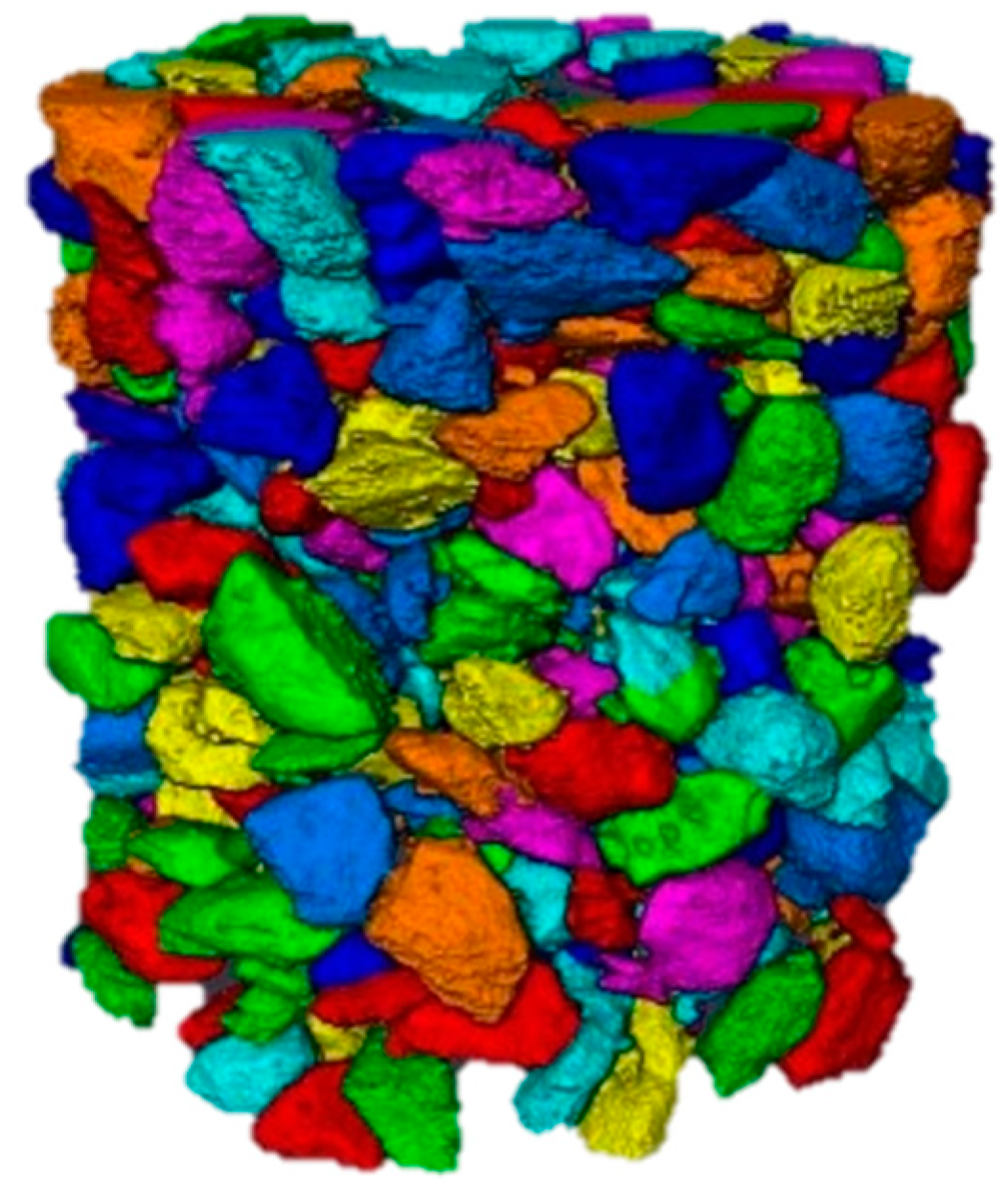

2.3. Digital Image Acquisition and Processing of Asphalt Mixtures

2.4. Parameters of the Aggregate

2.4.1. Coordination Number

2.4.2. Centroid Distribution

2.4.3. Spindle Inclination

2.4.4. Anisotropy of the Fabric Tensor

3. Experimental Results & Discussion

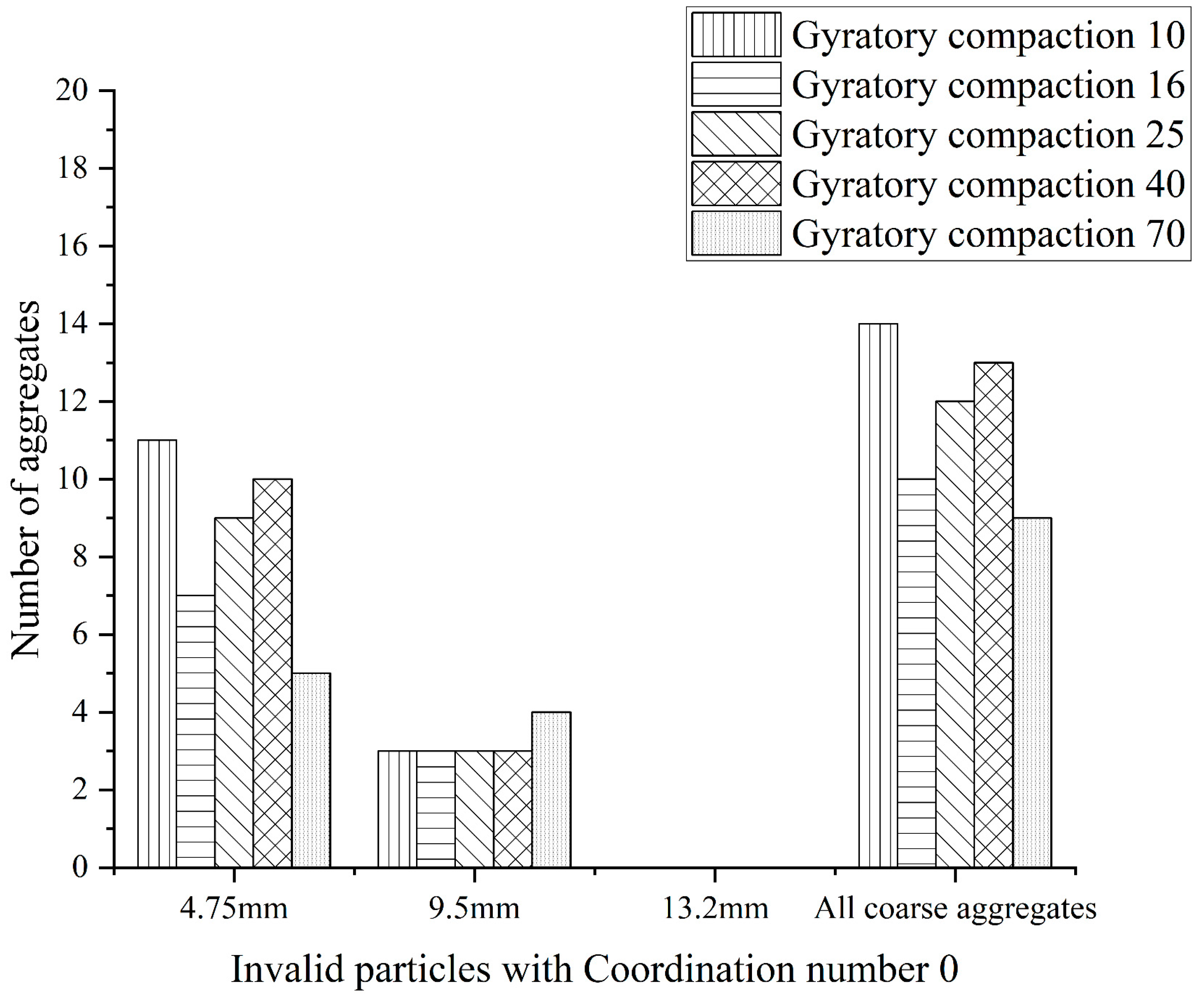

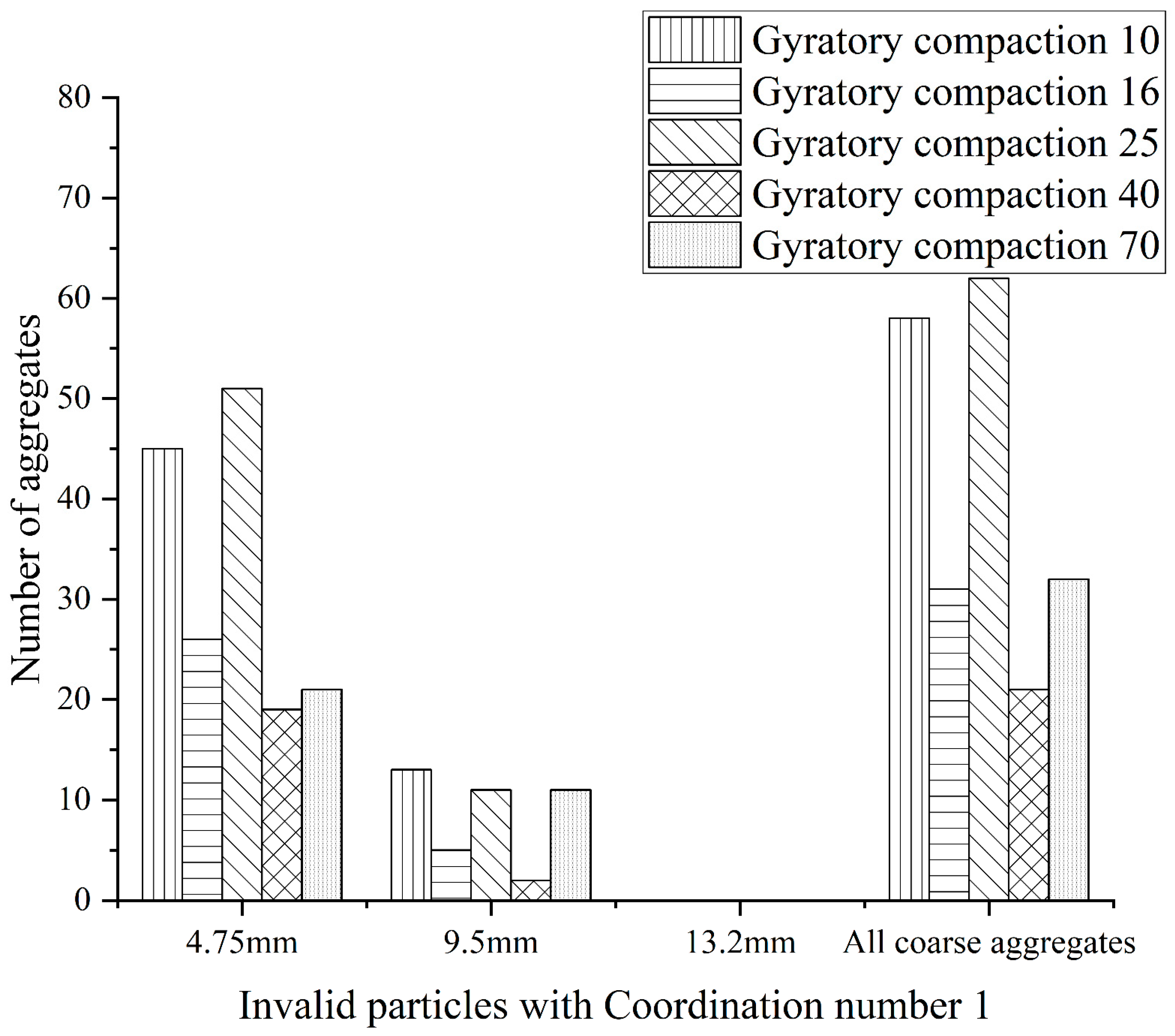

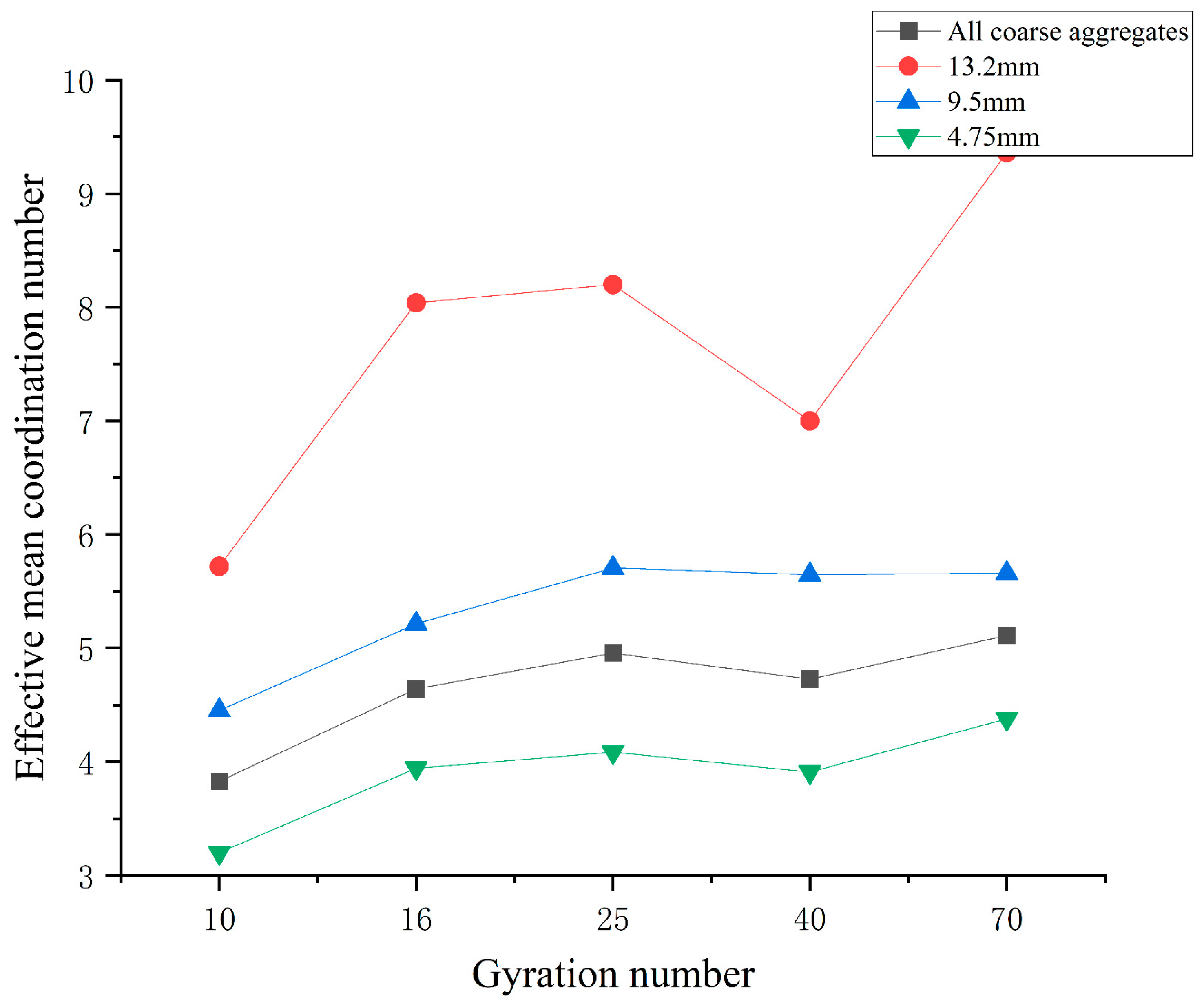

3.1. Coordination Number

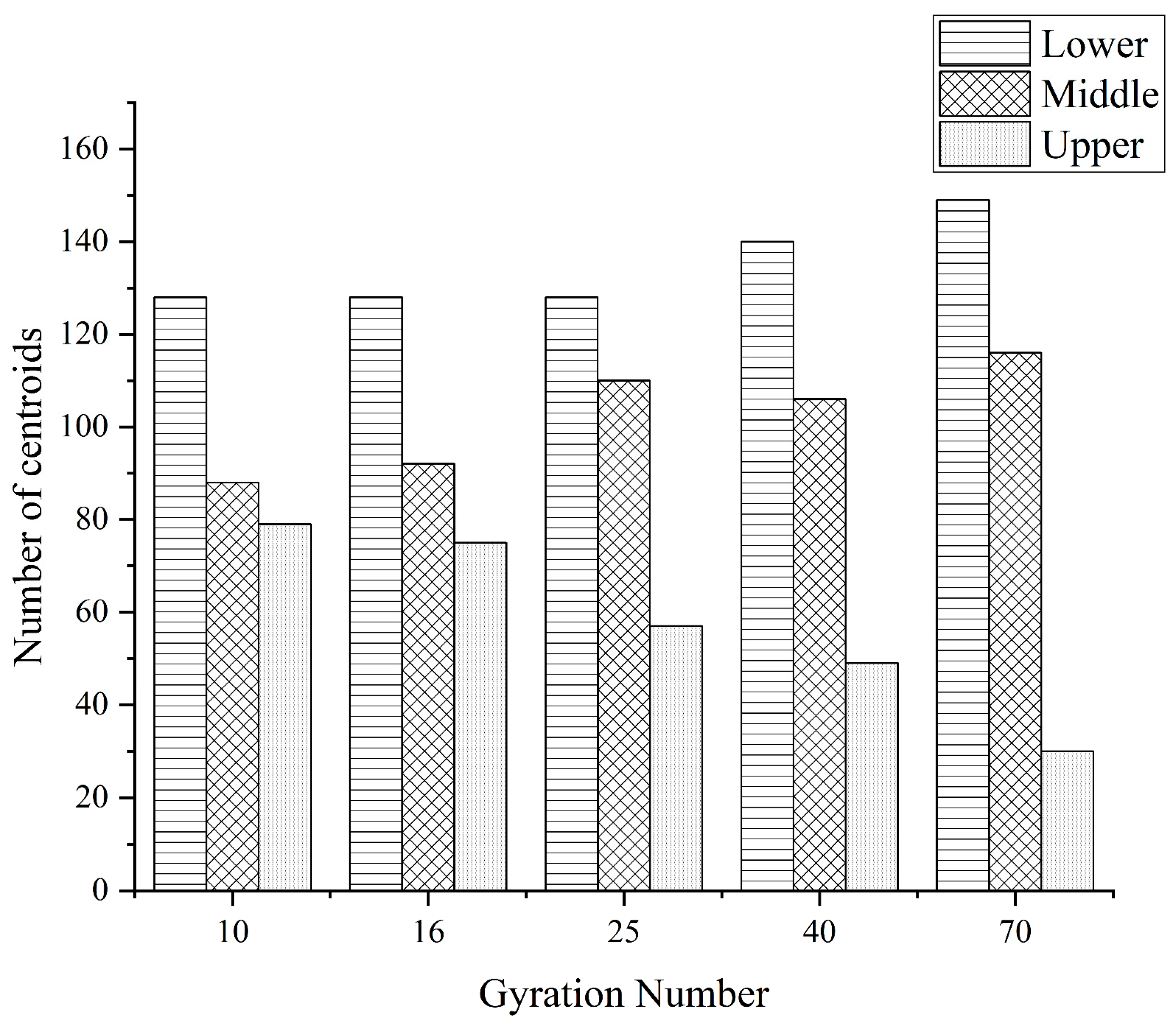

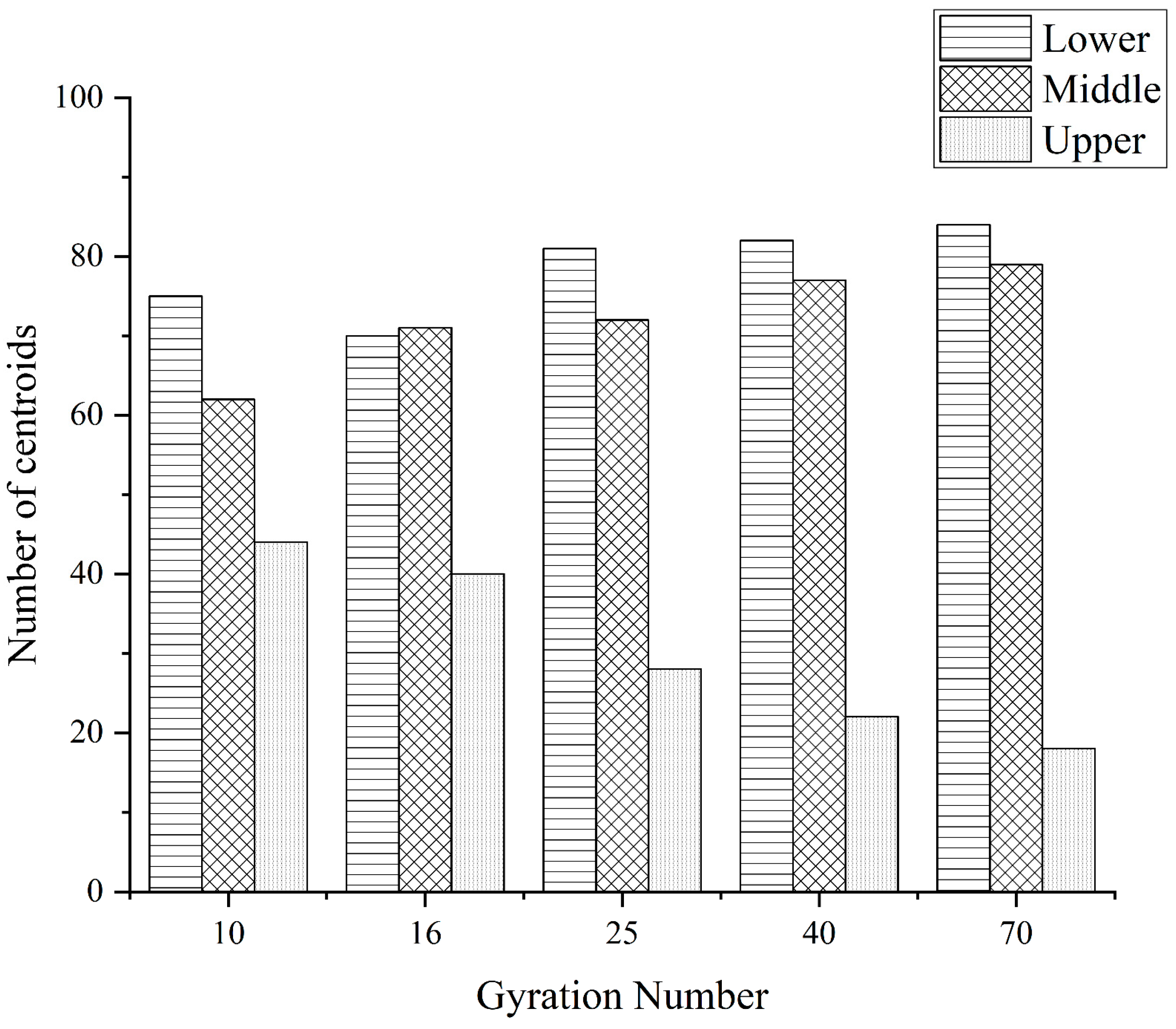

3.2. Centroid Distribution

3.3. Spindle Inclination

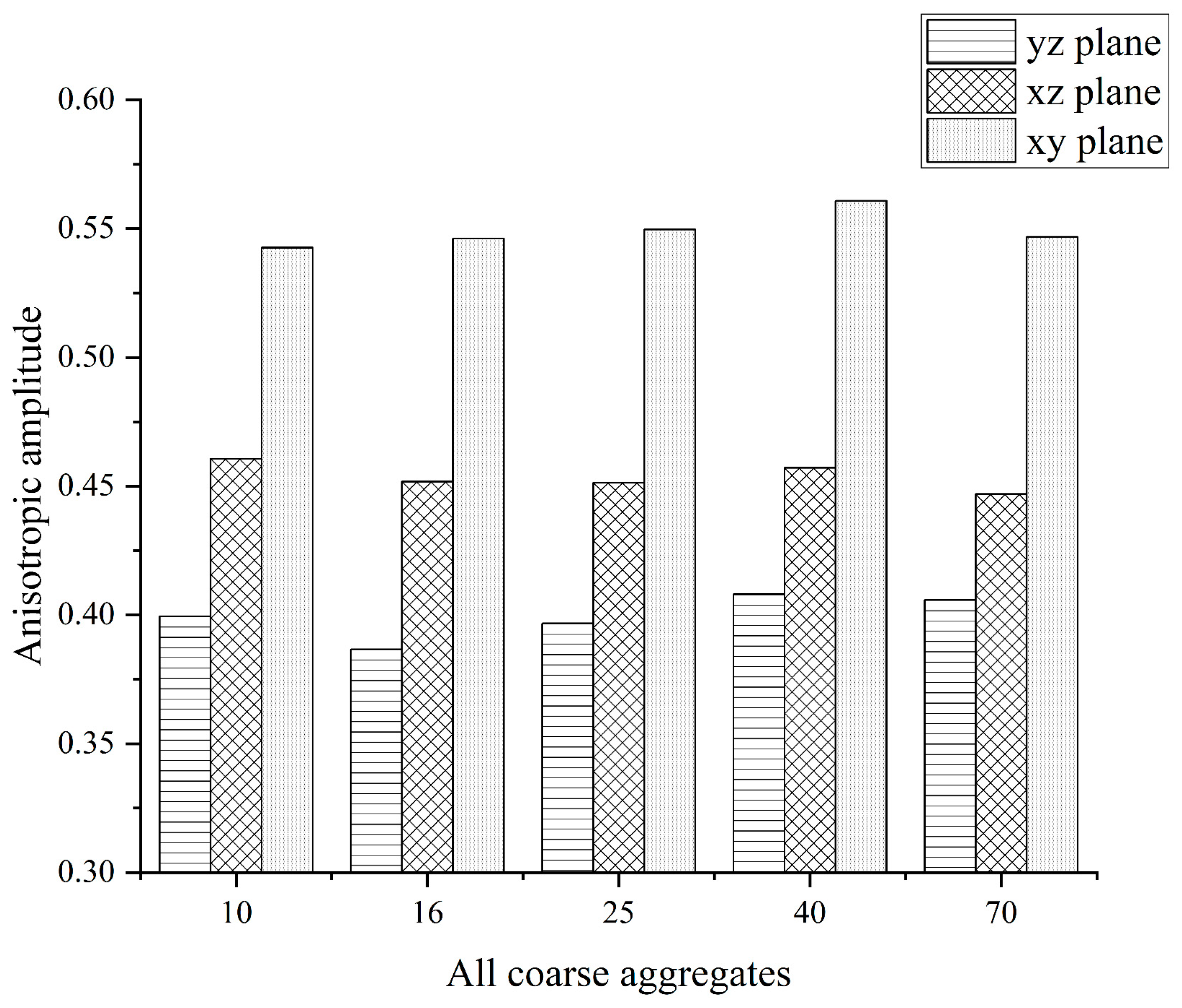

3.4. Anisotropy of the Fabric Tensor

4. Conclusions

- (1)

- The “coordination number” of the specimen in different compaction processes is greatly related to the size of the aggregate, and the larger the aggregate size, the greater the possibility of producing “effective particles”. With the increase of the number of compaction, the “effective average coordination number” of each grade aggregate will increase accordingly, when the compaction number increases to 25~40 times, the skeleton structure of the asphalt mixture is relatively stable, the rearrangement phenomenon between the particles is not easy to occur, and the change of the “effective average coordination number” is relatively stable and the fluctuation is small.

- (2)

- The distribution of centroids of different compaction processes of specimens has the following characteristics: with the increase of the number of compaction times, the number of centroids in the upper layer of the specimen continues to decrease, and the number of centroids in the middle and lower layers continues to increase.

- (3)

- The frequency distribution curve of the spindle inclination angle of the specimen with different compaction times is 0°~180° and shows a Gaussian distribution state, especially in the range of 80°~100°, which is the most distributed. With the increase in the number of compactions, the standard deviation of the Gaussian distribution decreases, and the inclination angle of the aggregate spindle tends to be more and more in the range of 80° to 100°, indicating that there are more and more coarse aggregates for “lying flat”, and the skeleton structure is becoming more and more stable.

- (4)

- In different compaction processes, the anisotropic amplitude of the fabric tensor of the xy plane is significantly greater than that of the xz plane and the yz plane. Before the rotational compaction 40 times, as the number of compactions increased, the amplitude of xy plane anisotropy increased significantly. After 40 compressions, the change tends to stop. It is stated that a compaction of 40 times is a critical number of compactions at which the skeleton structure of the mixture may have reached initial stability.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, Z.; Huang, S.; Zhang, K. Accurate detection method for compaction uniformity of asphalt pavement. Constr. Build. Mater. 2017, 145, 88–97. [Google Scholar] [CrossRef]

- Chen, B.; Yu, X.; Dong, F.; Zheng, C.; Ding, G.; Wu, W. Compaction Quality Evaluation of Asphalt Pavement Based on Intelligent Compaction Technology. J. Constr. Eng. Manag. 2021, 147, 04021099. [Google Scholar] [CrossRef]

- Pouranian, M.R.; Haddock, J.E. Determination of voids in the mineral aggregate and aggregate skeleton characteristics of asphalt mixtures using a linear-mixture packing model. Constr. Build. Mater. 2018, 188, 292–304. [Google Scholar] [CrossRef]

- Zhao, Y.; Zhang, K.; Zhang, Y.; Luo, Y.; Wang, S. Prediction of air voids of asphalt layers by intelligent algorithm. Constr. Build. Mater. 2022, 317, 125908. [Google Scholar] [CrossRef]

- Zhao, X.; Niu, D.; Niu, Y.; Hu, B.; Chen, X.; Liu, P. Effect of compaction parameter on aggregate particle migration and compaction mechanism using 2D image analysis. Constr. Build. Mater. 2023, 382, 131298. [Google Scholar] [CrossRef]

- Pei, Y.; Guo, Y.; Shen, A.; Mao, S. Uniformity evaluation of asphalt pavements in hot and humid areas based on ground-penetrating radar. Constr. Build. Mater. 2023, 384, 131432. [Google Scholar] [CrossRef]

- Dessouky, S.; Pothuganti, A.; Walubita, L.F.; Rand, D. Laboratory Evaluation of the Workability and Compactability of Asphaltic Materials prior to Road Construction. J. Mater. Civ. Eng. 2013, 25, 810–818. [Google Scholar] [CrossRef]

- Cai, X.; Wu, K.H.; Huang, W.K.; Wan, C. Study on the correlation between aggregate skeleton characteristics and rutting performance of asphalt mixture. Constr. Build. Mater. 2018, 179, 294–301. [Google Scholar] [CrossRef]

- Li, P.; Su, J.; Ma, S.; Dong, H. Effect of aggregate contact condition on skeleton stability in asphalt mixture. Int. J. Pavement Eng. 2020, 21, 196–202. [Google Scholar] [CrossRef]

- Airey, G.D.; Collop, A.C. Mechanical and structural assessment of laboratory- and field-compacted asphalt mixtures. Int. J. Pavement Eng. 2016, 17, 50–63. [Google Scholar] [CrossRef]

- Guo, H.; Zhao, Y.; Zhang, D.; Shang, M. Study of movement of coarse aggregates in the formation process of asphalt mixture in the laboratory. Constr. Build. Mater. 2016, 111, 743–750. [Google Scholar] [CrossRef]

- Xing, C.; Xu, H.; Tan, Y.; Liu, X.; Ye, Q. Mesostructured property of aggregate disruption in asphalt mixture based on digital image processing method. Constr. Build. Mater. 2019, 200, 781–789. [Google Scholar] [CrossRef]

- Onifade, I.; Jelagin, D.; Guarin, A.; Birgisson, B.; Kringos, N. Asphalt Internal Structure Characterization with X-Ray Computed Tomography and Digital Image Processing. In Multi-Scale Modeling and Characterization of Infrastructure Materials; Springer: Dordrecht, The Netherlands, 2013. [Google Scholar]

- Moghadas Nejad, F.; Motekhases, F.Z.; Zakeri, H.; Wang, L.-J.; Monaghan, J.M. An Image Processing Approach to Asphalt Concrete Feature Extraction. J. Ind. Intell. Inf. 2014, 3, 54–60. [Google Scholar] [CrossRef]

- Masad, E.; Muhunthan, B.; Shashidhar, N.; Harman, T. Internal Structure Characterization of Asphalt Concrete Using Image Analysis. J. Comput. Civ. Eng. 1999, 13, 88–95. [Google Scholar] [CrossRef]

- Roohi Sefidmazgi, N.; Bahia, H.U. Effect of compaction conditions on aggregate packing using 2-dimensional image analysis and the relation to performance of HMA. Mater. Struct. 2014, 47, 1313–1324. [Google Scholar] [CrossRef]

- Yohana Ribas, C.; Padilha Thives, L. Evaluation of effect of compaction method on the macrostructure of asphalt mixtures through digital image processing under Brazilian conditions. Constr. Build. Mater. 2019, 228, 116821. [Google Scholar] [CrossRef]

- Huang, J.; Pei, J.; Li, Y.; Yang, H.; Li, R.; Zhang, J.; Wen, Y. Investigation on aggregate particles migration characteristics of porous asphalt concrete (PAC) during vibration compaction process. Constr. Build. Mater. 2020, 243, 118153. [Google Scholar] [CrossRef]

- Zhao, Z.; Jiang, J.; Ni, F.; Ma, X. 3D-Reconstruction and characterization of the pore microstructure within the asphalt FAM using the X-ray micro-computed tomography. Constr. Build. Mater. 2021, 272, 121764. [Google Scholar] [CrossRef]

- Enríquez-León, A.J.; Souza, T.D.D.; Aragão, F.T.S.; Pereira, A.M.B.; Nogueira, L.P. Characterization of the air void content of fine aggregate matrices within asphalt concrete mixtures. Constr. Build. Mater. 2021, 300, 124214. [Google Scholar] [CrossRef]

- Coleri, E.; Harvey, J.T.; Yang, K.; Boone, J.M. Investigation of asphalt concrete rutting mechanisms by X-ray computed tomography imaging and micromechanical finite element modeling. Mater. Struct. 2013, 46, 1027–1043. [Google Scholar] [CrossRef]

- Sefidmazgi, N.R.; Tashman, L.; Bahia, H. Internal structure characterization of asphalt mixtures for rutting performance using imaging analysis. Road Mater. Pavement Des. 2012, 13 (Suppl. S1), 21–37. [Google Scholar] [CrossRef]

- Masad, E.; Muhunthan, B.; Shashidhar, N.; Harman, T. Quantifying Laboratory Compaction Effects on the Internal Structure of Asphalt Concrete. Transp. Res. Rec. 1999, 1681, 179–185. [Google Scholar] [CrossRef]

- Coenen, A.R.; Kutay, M.E.; Sefidmazgi, N.R.; Bahia, H.U. Aggregate structure characterisation of asphalt mixtures using two-dimensional image analysis. Road Mater. Pavement Des. 2012, 13, 433–454. [Google Scholar] [CrossRef]

- Tashman, L.; Masad, E.; D’Angelo, J.; Bukowski, J.; Harman, T. X-ray Tomography to Characterize Air Void Distribution in Superpave Gyratory Compacted Specimens. Int. J. Pavement Eng. 2002, 3, 19–28. [Google Scholar] [CrossRef]

- Zhu, X.; Qian, G.; Yu, H.; Yao, D.; Shi, C.; Zhang, C. Evaluation of coarse aggregate movement and contact unbalanced force during asphalt mixture compaction process based on discrete element method. Constr. Build. Mater. 2022, 328, 27004. [Google Scholar] [CrossRef]

- Liu, T.; Zhang, X.-N.; Li, Z.; Chen, Z.-Q. Research on the homogeneity of asphalt pavement quality using X-ray computed tomography (CT) and fractal theory. Constr. Build. Mater. 2014, 68, 587–598. [Google Scholar] [CrossRef]

- Zelelew, H.; Mahmoud, E.; Papagiannakis, A.T. Micromechanical Simulation of the Permanent Deformation Properties of Asphalt Concrete Mixtures. In Multi-Scale Modeling and Characterization of Infrastructure Materials; Springer: Dordrecht, The Netherlands, 2013. [Google Scholar]

- Vadood, M.; Johari, M.S.; Rahaei, A.R. Introducing a simple method to determine aggregate gradation of hot mix asphalt using image processing. Int. J. Pavement Eng. 2014, 15, 142–350. [Google Scholar] [CrossRef]

- Zelelew, H.M.; Almuntashri, A.; Again, S.; Papagiannakis, A.T. An improved image processing technique for asphalt concrete X-ray CT images. Road Mater. Pavement Des. 2013, 14, 341–359. [Google Scholar] [CrossRef]

- Guarin, A.; Roque, R.; Kim, S.; Sirin, O. Disruption factor of asphalt mixtures. Int. J. Pavement Eng. 2013, 14, 472–485. [Google Scholar] [CrossRef]

- JTG E20-2011; Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. 2011. Available online: https://www.chinesestandard.net/PDF/English.aspx/JTGE20-2011 (accessed on 24 August 2023).

- JTG F40-2004; Technical Specifications for Construction of Highway Asphalt Pavements. 2009. Available online: https://www.chinesestandard.net/PDF/English.aspx/JTGF40-2004 (accessed on 24 August 2023).

- JTG E42-2005; Test Methods of Aggregate for Highway Engineering. 2005. Available online: https://www.chinesestandard.net/PDF/English.aspx/JTGE42-2005 (accessed on 24 August 2023).

- Xue-Feng, L.I.; Wang, Q.; Liu, J.F.; Wei, W.; Fan-Chao, M. Quantitative Description of Microscopic Fabric Based on Sand Particle Shapes. China J. Highw. Transp. 2016, 29, 29. [Google Scholar]

| Aggregate specifications (mm) | 16–13.2 | 13.2–9.5 | 9.5–4.75 | 4.75–2.36 |

| apparent density (g/cm3) | 2.774 | 2.758 | 2.792 | 2.772 |

| Aggregate specifications (mm) | 2.38–1.18 | 1.18–0.6 | 0.6–0.3 | 0.3–0.15 | 0.15–0.075 |

| apparent density (g/cm3) | 2.643 | 2.655 | 2.725 | 2.631 | 2.522 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gong, X.; Liu, Z.; Qian, G.; Liu, Z. Interlocking Evaluation of Mesoscopic Skeleton with the Compaction Degree of Hot-Mix Asphalt. Materials 2023, 16, 5879. https://doi.org/10.3390/ma16175879

Gong X, Liu Z, Qian G, Liu Z. Interlocking Evaluation of Mesoscopic Skeleton with the Compaction Degree of Hot-Mix Asphalt. Materials. 2023; 16(17):5879. https://doi.org/10.3390/ma16175879

Chicago/Turabian StyleGong, Xiangbing, Ziming Liu, Guoping Qian, and Zhiyang Liu. 2023. "Interlocking Evaluation of Mesoscopic Skeleton with the Compaction Degree of Hot-Mix Asphalt" Materials 16, no. 17: 5879. https://doi.org/10.3390/ma16175879

APA StyleGong, X., Liu, Z., Qian, G., & Liu, Z. (2023). Interlocking Evaluation of Mesoscopic Skeleton with the Compaction Degree of Hot-Mix Asphalt. Materials, 16(17), 5879. https://doi.org/10.3390/ma16175879