Enhancing Surface Temperature Uniformity in a Liquid Silicone Rubber Injection Mold with Conformal Heating Channels

Abstract

:1. Introduction

2. Experimental Details

3. Results and Discussion

4. Conclusions

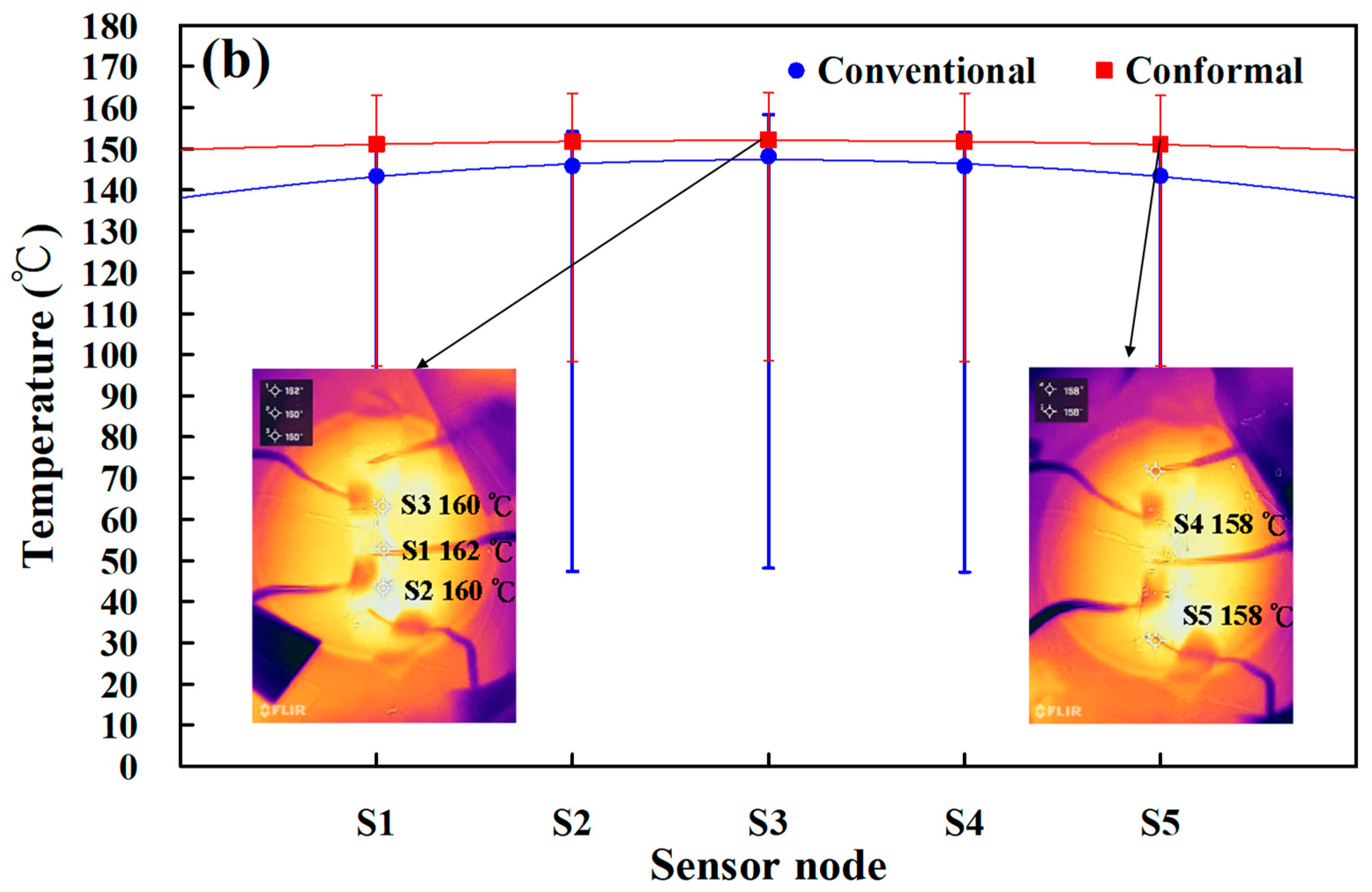

- The uniformity of the mold surface for LSR injection mold with the conformal heating channel was better than for the mold with the conventional heating channel.

- The experimental results showed that the average temperature of the mold surface (y) could be predicted by the heating oil temperature (x) according to the prediction equation of y = −0.7999x2 + 19.477x + 40.13 with a correlation coefficient of 0.9984.

- The experimental results showed that the trend of the average temperature of five sensor modes was consistent with the simulation results.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

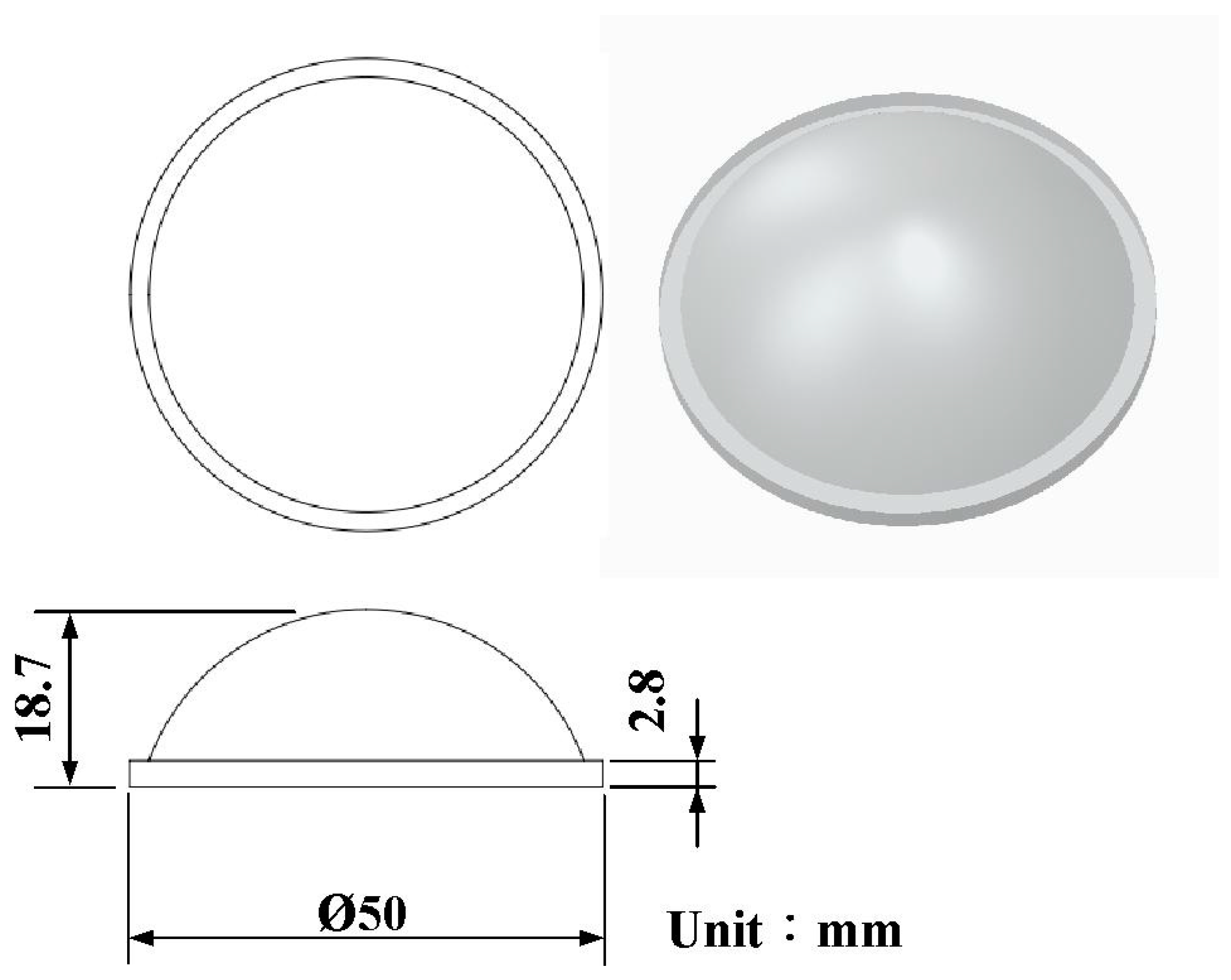

- Kuo, C.-C.; Tasi, Q.-Z.; Hunag, S.-H.; Tseng, S.-F. Development of an Injection Mold with High Energy Efficiency of Vulcanization for Liquid Silicone Rubber Injection Molding of the Fisheye Optical Lens. Polymers 2023, 15, 2869. [Google Scholar] [CrossRef] [PubMed]

- Kuo, C.-C.; Lin, J.-X. A cost-effective method for rapid manufacturing polymer rapid tools used for liquid silicone rubber injection molding. Int. J. Adv. Manuf. Technol. 2019, 104, 1159–1170. [Google Scholar] [CrossRef]

- Kuo, C.-C.; Lin, J.-X. Fabrication of the Fresnel lens with liquid silicone rubber using rapid injection mold. Int. J. Adv. Manuf. Technol. 2019, 101, 615–625. [Google Scholar] [CrossRef]

- Rey, T.; Le Cam, J.-B.; Chagnon, G.; Favier, D.; Rebouah, M.; Razan, F.; Robin, E.; Didier, P.; Heller, L.; Faure, S.; et al. An original architectured NiTi silicone rubber structure for biomedical applications. Mater. Sci. Eng. C 2014, 45, 184–190. [Google Scholar] [CrossRef]

- Ou, H.; Sahli, M.; Barrière, T.; Gelin, J.C. Multiphysics modelling and experimental investigations of the filling and curing phases of bi-injection moulding of thermoplastic polymer/liquid silicone rubbers. Int. J. Adv. Manuf. Technol. 2017, 92, 3871–3882. [Google Scholar] [CrossRef]

- Zhang, Y.; Liu, W.; Zhou, Q.; Meng, Y.; Zhong, Y.; Xu, J.; Xiao, C.; Zhang, G.; Zhang, Y. Effects of Vinyl Functionalized Silica Particles on Thermal and Mechanical Properties of Liquid Silicone Rubber Nanocomposites. Polymers 2023, 15, 1224. [Google Scholar] [CrossRef]

- Magaña, H.; Becerra, C.D.; Serrano-Medina, A.; Palomino, K.; Palomino-Vizcaíno, G.; Olivas-Sarabia, A.; Bucio, E.; Cornejo-Bravo, J.M. Radiation Grafting of a Polymeric Prodrug onto Silicone Rubber for Potential Medical/Surgical Procedures. Polymers 2020, 12, 1297. [Google Scholar] [CrossRef]

- Guo, J.; Wang, X.; Wang, J.; Chen, C.; Liu, Y.; Fan, W.; Jia, Z. Study on the Anticondensation Characteristics of Liquid Silicone Rubber Temperature-Control Coatings. Polymers 2019, 11, 1282. [Google Scholar] [CrossRef]

- Wu, J.-K.; Zheng, K.-W.; Wang, Q.-Y.; Nie, X.-C.; Wang, R.; Xu, J.-T. Binary Promoter Improving the Moderate-Temperature Adhesion of Addition-Cured Liquid Silicone Rubber for Thermally Conductive Potting. Materials 2022, 15, 5211. [Google Scholar] [CrossRef]

- Marl, S.; Giesen, R.-U.; Heim, H.-P. Liquid Silicone Rubber Foamed with Thermoplastic Expandable Microspheres. Materials 2022, 15, 3779. [Google Scholar] [CrossRef]

- Woitschach, F.; Kloss, M.; Schlodder, K.; Borck, A.; Grabow, N.; Reisinger, E.C.; Sombetzki, M. In Vitro Study of the Interaction of Innate Immune Cells with Liquid Silicone Rubber Coated with Zwitterionic Methyl Methacrylate and Thermoplastic Polyurethanes. Materials 2021, 14, 5972. [Google Scholar] [CrossRef] [PubMed]

- Shang, N.; Chen, Q.; Wei, X. Preparation and Dielectric Properties of SiC/LSR Nanocomposites for Insulation of High Voltage Direct Current Cable Accessories. Materials 2018, 11, 403. [Google Scholar] [CrossRef]

- Kaitainen, S.; Kutvonen, A.; Suvanto, M.; Pakkanen, T.T.; Lappalainen, R.; Myllymaa, S. Liquid silicone rubber (LSR)-based dry bioelectrodes: The effect of surface micropillar structuring and silver coating on contact impedance. Sens. Actuators A Phys. 2014, 206, 22–29. [Google Scholar] [CrossRef]

- Seitz, V.; Arzt, K.; Mahnel, S.; Rapp, C.; Schwaminger, S.; Hoffstetter, M.; Wintermantel, E. Improvement of adhesion strength of self-adhesive silicone rubber on thermoplastic substrates—Comparison of an atmospheric pressure plasma jet (APPJ) and a Pyrosil® flame. Int. J. Adhes. Adhes. 2016, 66, 65–72. [Google Scholar] [CrossRef]

- Liu, T.; Zeng, X.; Fang, W.; Lai, X.; Li, H. Synthesis of a novel hydantoin-containing silane and its effect on the tracking and bacteria resistance of addition-cure liquid silicone rubber. Appl. Surf. Sci. 2017, 423, 630–640. [Google Scholar] [CrossRef]

- Harkousa, A.; Colomines, G.; Leroyb, E.; Mousseaua, P.; Deterrea, R. The kinetic behavior of Liquid Silicone Rubber: A comparison between thermal and rheological approaches based on gel point determination. React. Funct. Polym. 2016, 101, 20–27. [Google Scholar] [CrossRef]

- Qiu, J.; Lai, X.; Fang, W.; Li, H.; Zeng, X. An efficient strategy for simultaneously improving tracking resistance and flame retardancy of addition-cure liquid silicone rubber. Polym. Degrad. Stab. 2017, 144, 176–186. [Google Scholar] [CrossRef]

- Mackiewicz, E.; Wejrzanowski, T.; Adamczyk-Cieślak, B.; Oliver, G.J. Polymer–Nickel Composite Filaments for 3D Printing of Open Porous Materials. Materials 2022, 15, 1360. [Google Scholar] [CrossRef]

- Kosiński, P.; Żach, P. Verification of Fatigue Damage and Prognosis Related to Degradation of Polymer-Ceramic. Materials 2021, 14, 5147. [Google Scholar] [CrossRef]

- Mohammed, A.H.; Kovacev, N.; Elshaer, A.; Melaibari, A.A.; Iqbal, J.; Hassanin, H.; Essa, K.; Memić, A. Preparation of Polylactic Acid/Calcium Peroxide Composite Filaments for Fused Deposition Modelling. Polymers 2023, 15, 2229. [Google Scholar] [CrossRef]

- Balani, S.B.; Mokhtarian, H.; Salmi, T.; Coatanéa, E. An Investigation of the Influence of Viscosity and Printing Parameters on the Extrudate Geometry in the Material Extrusion Process. Polymers 2023, 15, 2202. [Google Scholar] [CrossRef] [PubMed]

- Khan, K.; Gudainiyan, J.; Iqbal, M.; Jamal, A.; Amin, M.N.; Mohammed, I.; Al-Faiad, M.A.; Abu-Arab, A.M. Modelling Compression Strength of Waste PET and SCM Blended Cementitious Grout Using Hybrid of LSSVM Models. Materials 2022, 15, 5242. [Google Scholar] [CrossRef] [PubMed]

- Skowrońska, B.; Chmielewski, T.; Kulczyk, M.; Skiba, J.; Przybysz, S. Microstructural Investigation of a Friction-Welded 316L Stainless Steel with Ultrafine-Grained Structure Obtained by Hydrostatic Extrusion. Materials 2021, 14, 1537. [Google Scholar] [CrossRef]

- Li, K.; Zhou, T.; Liu, B.-H. Internet-based intelligent and sustainable manufacturing: Developments and challenges. Int. J. Adv. Manuf. Technol. 2020, 108, 1767–1791. [Google Scholar] [CrossRef]

- Rahman, M.A.; Ali, A.; Rahamathulla, M.; Salam, S.; Hani, U.; Wahab, S.; Warsi, M.H.; Yusuf, M.; Ali, A.; Mittal, V.; et al. Fabrication of Sustained Release Curcumin-Loaded Solid Lipid Nanoparticles (Cur-SLNs) as a Potential Drug Delivery System for the Treatment of Lung Cancer: Optimization of Formulation and In Vitro Biological Evaluation. Polymers 2023, 15, 542. [Google Scholar] [CrossRef]

- Varghese, S.A.; Pulikkalparambil, H.; Promhuad, K.; Srisa, A.; Laorenza, Y.; Jarupan, L.; Nampitch, T.; Chonhenchob, V.; Harnkarnsujarit, N. Renovation of Agro-Waste for Sustainable Food Packaging: A Review. Polymers 2023, 15, 648. [Google Scholar] [CrossRef]

- Morales, M.A.; Maranon, A.; Hernandez, C.; Michaud, V.; Porras, A. Colombian Sustainability Perspective on Fused Deposition Modeling Technology: Opportunity to Develop Recycled and Biobased 3D Printing Filaments. Polymers 2023, 15, 528. [Google Scholar] [CrossRef]

- Kumar, L.; Jain, P.K.; Sharma, A.K. A fuzzy goal programme–based sustainable Greenfield supply network design for tyre retreading industry. Int. J. Adv. Manuf. Technol. 2020, 108, 2855–2880. [Google Scholar] [CrossRef]

- Bae, K.; Moon, H.-S.; Park, Y.; Jo, I.; Lee, J. Influence of Tempering Temperature and Time on Microstructure and Mechanical Properties of Additively Manufactured H13 Tool Steel. Materials 2022, 15, 8329. [Google Scholar] [CrossRef]

- Meylan, B.; Calderon, I.; Wasmer, K. Optimization of Process Parameters for the Laser Polishing of Hardened Tool Steel. Materials 2022, 15, 7746. [Google Scholar] [CrossRef]

- Wang, B.; Wang, Y.; Li, C.; Gao, A. Evolution and Regulation of Radial Structure of PAN Pre-Oxidized Fiber Based on the Fine Denier Model. Materials 2022, 15, 1409. [Google Scholar] [CrossRef] [PubMed]

- Sahu, M.; Narasimhan, L.; Raichur, A.M.; Sover, A.; Ciobanu, R.C.; Lucanu, N.; Aradoaei, M. Improving Fracture Toughness of Tetrafunctional Epoxy with Functionalized 2D Molybdenum Disulfide Nanosheets. Polymers 2021, 13, 4440. [Google Scholar] [CrossRef] [PubMed]

- Nakonieczny, D.S.; Martynková, G.S.; Hundáková, M.; Kratošová, G.; Holešová, S.; Kupková, J.; Pazourková, L.; Majewska, J. Alkali-Treated Alumina and Zirconia Powders Decorated with Hydroxyapatite for Prospective Biomedical Applications. Materials 2022, 15, 1390. [Google Scholar] [CrossRef] [PubMed]

- Houssat, M.; Villeneuve-Faure, C.; Lahoud Dignat, N.; Locatelli, M.-L.; Cambronne, J.-P. Temperature Influence on PI/Si3N4 Nanocomposite Dielectric Properties: A Multiscale Approach. Polymers 2021, 13, 1936. [Google Scholar] [CrossRef] [PubMed]

- Hameed, A.R.; Majdoub, H.; Jabrail, F.H. Effects of Surface Morphology and Type of Cross-Linking of Chitosan-Pectin Microspheres on Their Degree of Swelling and Favipiravir Release Behavior. Polymers 2023, 15, 3173. [Google Scholar] [CrossRef]

- Ferrari, M.; Lettieri, E.; Pontoriero, D.I.K.; Vallittu, P.; Cagidiaco, E.F. Particulate Filler and Discontinuous Fiber Filler Resin Composite’s Adaptation and Bonding to Intra-Radicular Dentin. Polymers 2023, 15, 3180. [Google Scholar] [CrossRef]

- Lafirenza, M.; Guerra, M.G.; Lavecchia, F. A layerwise monitoring methodology based on blue laser line profilometer for Material Extrusion processes. Int. J. Adv. Manuf. Technol. 2023, 127, 5421–5436. [Google Scholar] [CrossRef]

- Čermák, A.; Simonović, K.; Bondarev, A.; Kožmín, P.; Syrovátka, Š.; Polcar, T.; Syrovátka, J. Femtosecond laser texturing of DLC-based coatings by DLW method with sub-micrometer precision. Int. J. Adv. Manuf. Technol. 2022, 121, 8479–8494. [Google Scholar] [CrossRef]

- Jatti, V.S.; Sefene, E.M.; Jatti, A.V.; Mishra, A.; Dhabale, R.D. Synthesis and characterization of diamond-like carbon coatings for drill bits using plasma-enhanced chemical vapor deposition. Int. J. Adv. Manuf. Technol. 2023, 127, 4081–4096. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kuo, C.-C.; Tasi, Q.-Z.; Huang, S.-H.; Tseng, S.-F. Enhancing Surface Temperature Uniformity in a Liquid Silicone Rubber Injection Mold with Conformal Heating Channels. Materials 2023, 16, 5739. https://doi.org/10.3390/ma16175739

Kuo C-C, Tasi Q-Z, Huang S-H, Tseng S-F. Enhancing Surface Temperature Uniformity in a Liquid Silicone Rubber Injection Mold with Conformal Heating Channels. Materials. 2023; 16(17):5739. https://doi.org/10.3390/ma16175739

Chicago/Turabian StyleKuo, Chil-Chyuan, Qing-Zhou Tasi, Song-Hua Huang, and Shih-Feng Tseng. 2023. "Enhancing Surface Temperature Uniformity in a Liquid Silicone Rubber Injection Mold with Conformal Heating Channels" Materials 16, no. 17: 5739. https://doi.org/10.3390/ma16175739

APA StyleKuo, C.-C., Tasi, Q.-Z., Huang, S.-H., & Tseng, S.-F. (2023). Enhancing Surface Temperature Uniformity in a Liquid Silicone Rubber Injection Mold with Conformal Heating Channels. Materials, 16(17), 5739. https://doi.org/10.3390/ma16175739