The Effect of Sensitization on the Susceptibility of AISI 316L Biomaterial to Pitting Corrosion

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Potentiodynamic Polarization

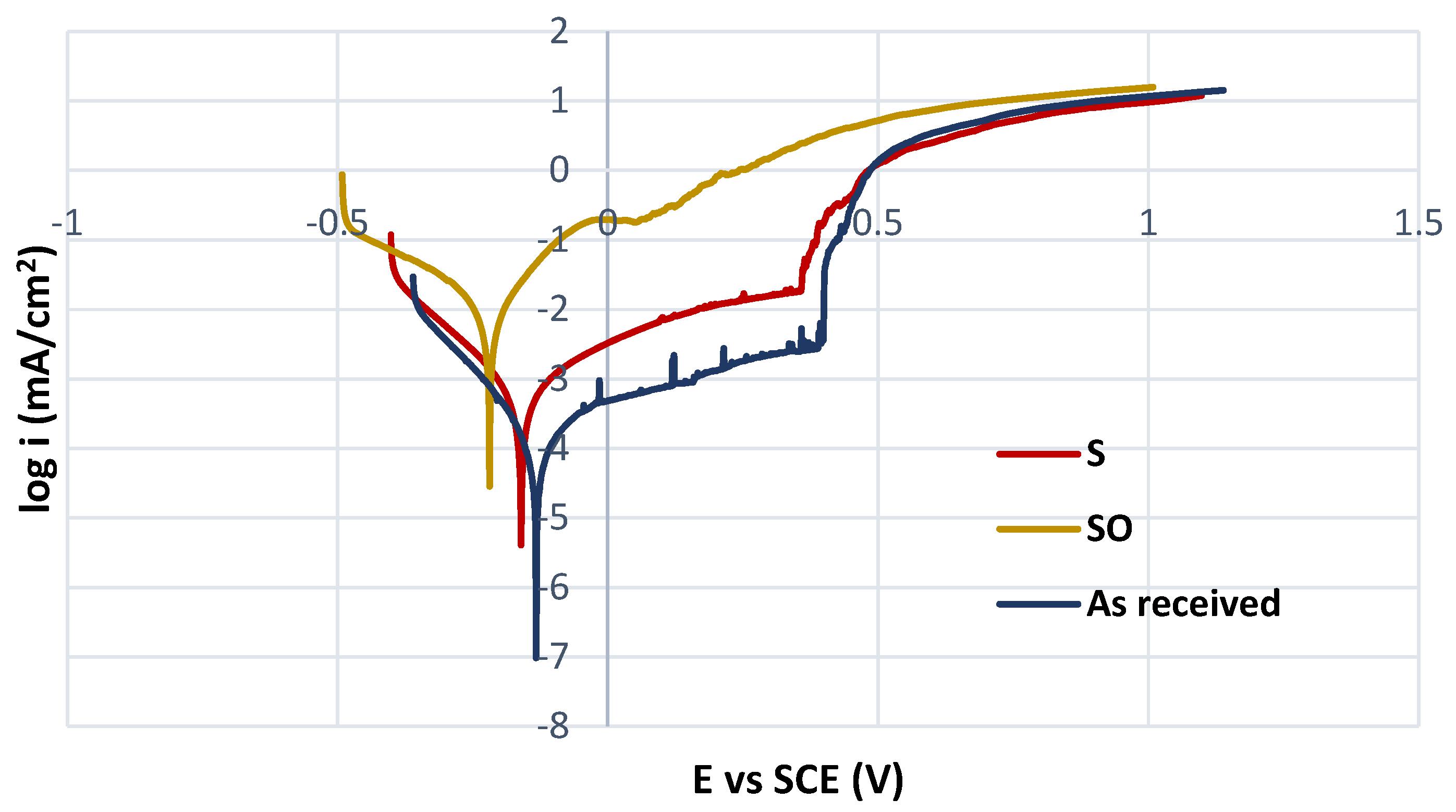

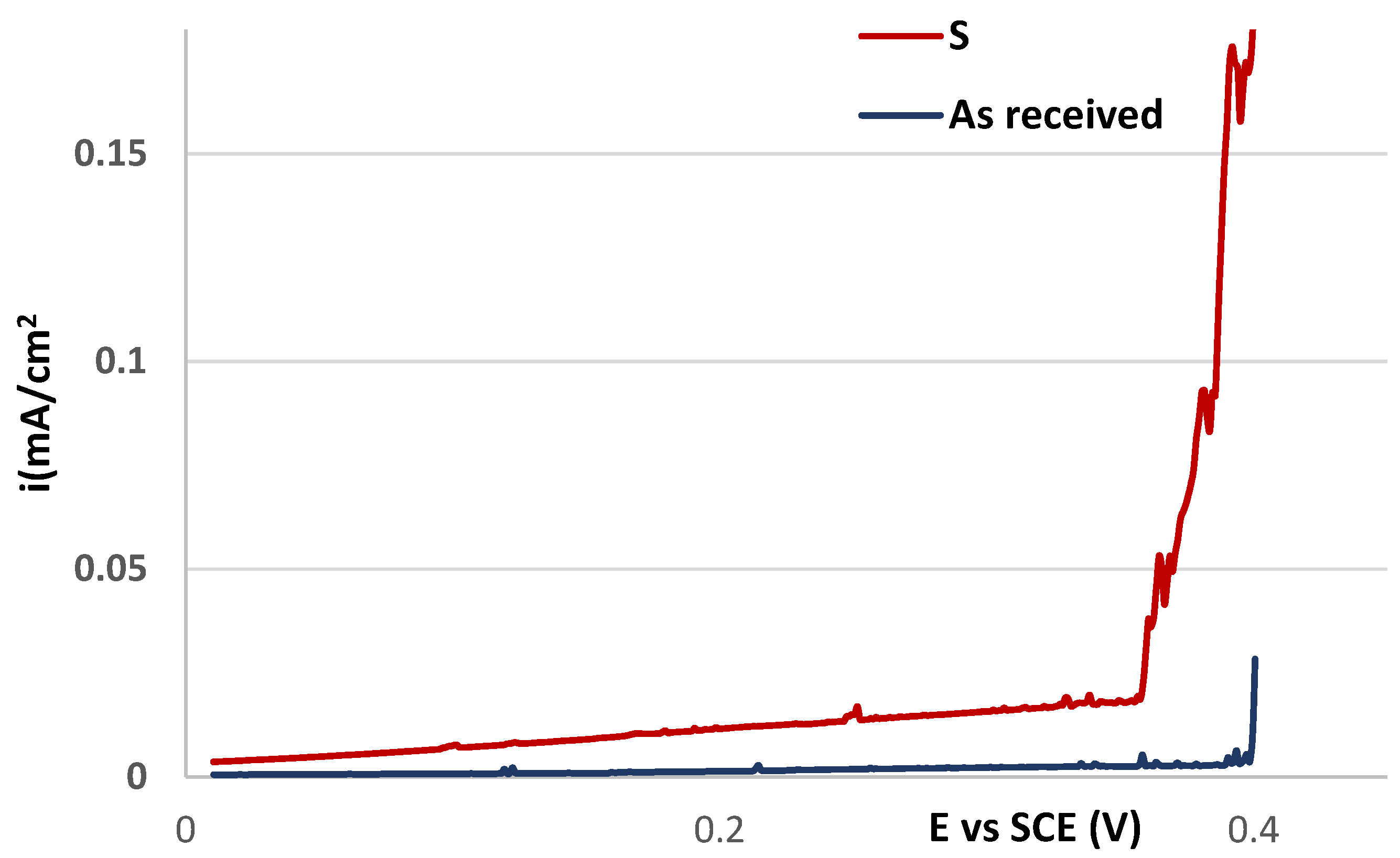

- Kartaman et al. [34] tested the corrosion resistance of sensitized (675 °C) and consequently mechanically polished AISI 316L SS specimens by PP in 0.01wt.% NaCl solution and recorded Ep = 0.391 V vs. SCE and also, similarly to us, higher passive current density compared to the as-received specimen. When partially different conditions [34] are taken into account (lower temperature and chloride concentration, different method of removing high-temperature oxides), the value of the Ep can be considered comparable to ours (0.36 ± 0.02 V vs. SCE)

- The impaired passive behavior and higher susceptibility to pitting of the welded AISI 316L SS in Hank’s and Ringer’s physiological solutions were confirmed by Farooq at al. [25].

- It should be emphasized that the pitting corrosion resistance of stainless steels strongly depends on the temperature. An increase in temperature by just a few degrees and also its fluctuation (e.g., during disease states) can lead to a significant deterioration of corrosion resistance [47]. The elevated temperature affects negatively the self-healing ability of the passive film. Diffusion rate of chloride ions through the passive film increases, making it easier to reach the raw metal surface. This enhanced diffusion contributes to a more rapid depassivation process; the pitting initiation and propagation are accelerated. This consequently leads to the sharp increase in current density [48]. The above-mentioned trend was documented by the authors of [41] who evaluated the corrosion resistance of sensitized AISI 304 steel in 1M acid NaCl solution at the temperatures of 20 and 50 °C. The conditions of sensitization were the same as in our study (650 °C/40 h). On the chemically treated surface (the same conditions as in our study) and at the 50 °C temperature, the authors noted a loss of passive behavior and an active anodic dissolution of the sensitized SS [41].

3.2. Exposure Immersion Test

4. Conclusions

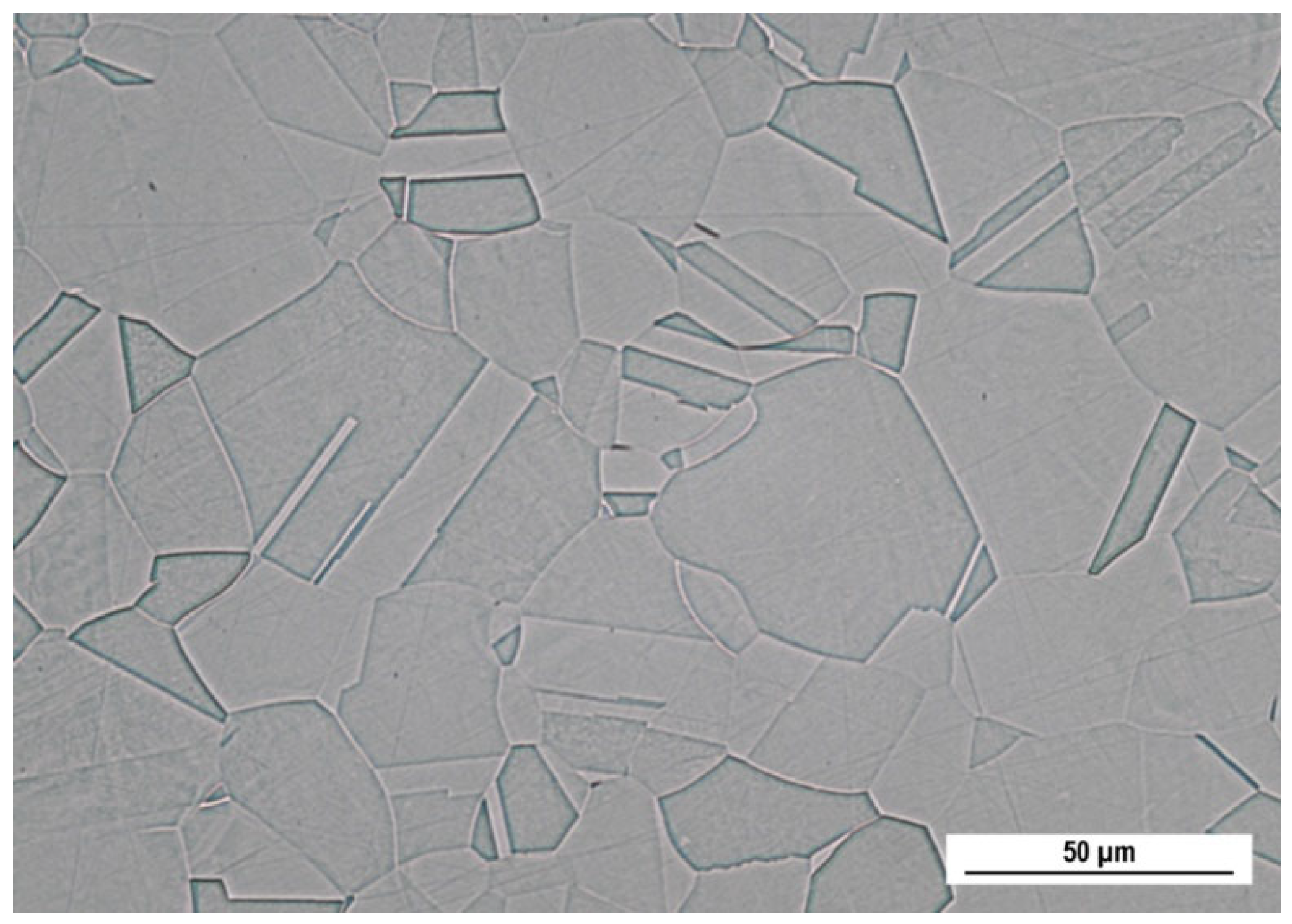

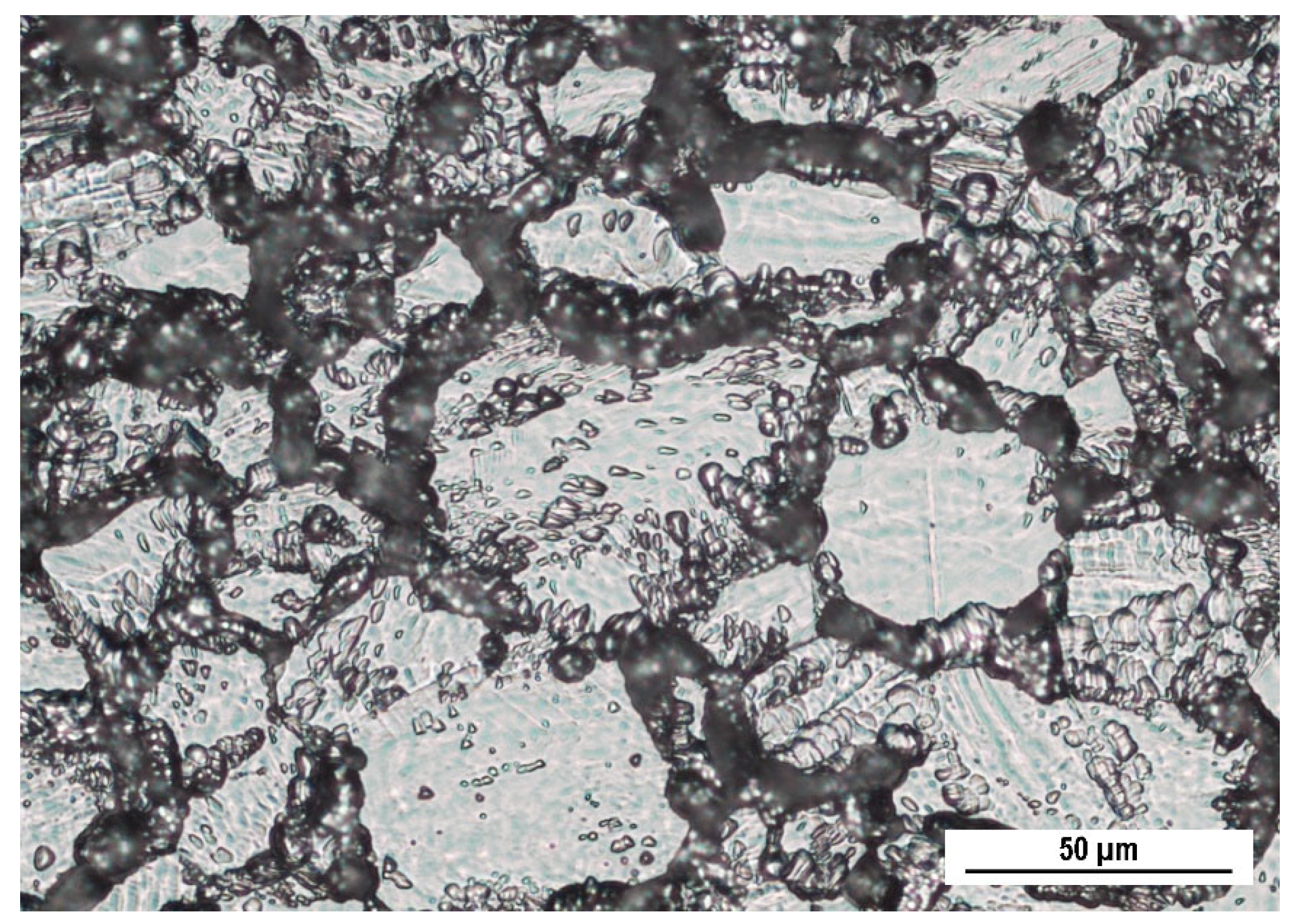

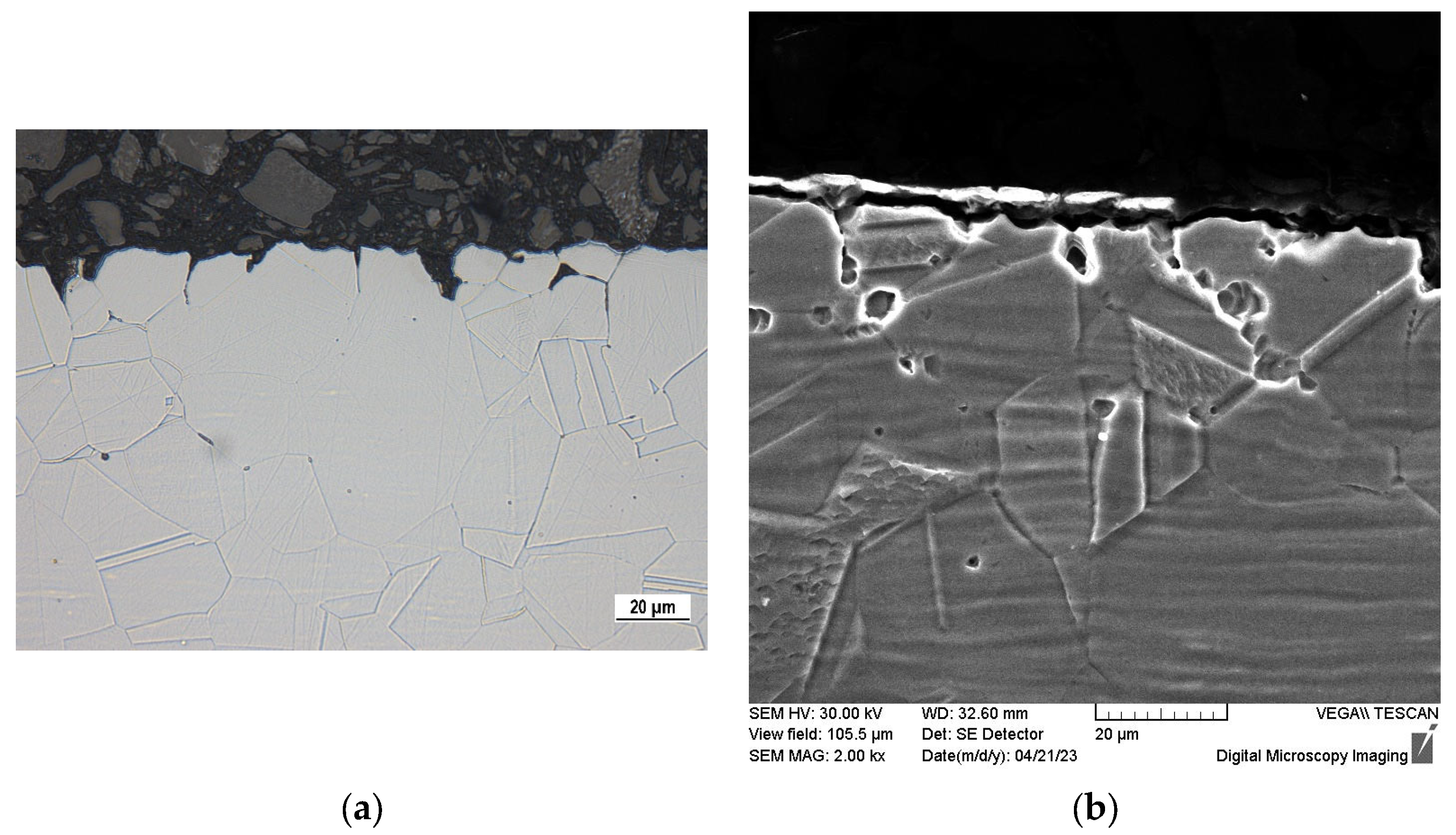

- Sensitization induced by the heat exposure of the experimental material (650 °C/40 h) was confirmed by “ditch” microstructure (Figure 2) observed after the electrochemical etching carried out according ASTM A262 practice A standard.

- The potentiodynamic polarization results showed a passive behavior of the sensitized material without high-temperature oxides (S type), but the pitting potential (Ep) and the corrosion potential (Ecorr) values were slightly lower compared to the as-received state (Table 4). This points to a higher susceptibility of the sensitized specimens to the pitting. According to the potentiodynamic polarization curve, the sensitized material with high-temperature oxides (SO type) showed an active anodic dissolution (Figure 3), which is unacceptable if it is intended for the internal human body environment.

- During the 50-day exposure immersion test in the simulated physiological solution, the sensitized specimens without high-temperature oxides (S type) were attacked by a local pitting corrosion with the pits situated in the grain boundaries (Figure 5). This confirmed the close relationship between sensitization and the pitting. The observed corrosion damage indicates a possible progress to deeper parts of the material along the grain boundaries.

- Based on the performed independent experiments, the sensitized AISI 316L biomaterial could represent a risk even after the chemical surface treatment, especially in the case of long-term implantation.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, Q.; Thouas, G.A. Metallic implant biomaterials. Mat. Sci. Eng. R 2015, 87, 1–57. [Google Scholar] [CrossRef]

- Dharadhar, S.; Majumdar, A.S. Biomaterials and Its Medical Applications. Available online: https://www.researchgate.net/publication/337341622_Biomaterials_and_Its_Medical_Applications (accessed on 15 May 2023).

- Paul, S. Application of Biomedical Engineering in Neuroscience, 1st ed.; Springer: Singapore, 2019; pp. 355–380. [Google Scholar]

- Tharani, K.S.; Prasanna, D.S.; Krithika, C.; Raghavan, R.N. Review of metallic biomaterials in dental applications. J. Pharm. Bioall. Sci. 2020, 12, 14–19. [Google Scholar] [CrossRef] [PubMed]

- Bazaka, O.; Bazaka, K.; Kingshott, P.; Crawford, R.J.; Ivanova, E.P. Chapter 1: Metallic Implants for Biomedical Applications. In The Chemistry of Inorganic Biomaterials; Royal Society of Chemistry: Croydon, UK, 2021; pp. 1–98. [Google Scholar]

- Pathote, D.; Jaiswal, D.; Singh, V.; Behera, C.K. Optimization of electrochemical corrosion behavior of 316L stainless steel as an effective biomaterial for orthopedic applications. Mater. Today Proc. 2022, 57, 265–269. [Google Scholar] [CrossRef]

- Souza, R.D.; Chattree, A.; Rajendran, S. Stainless Steel Alloys for Dental Application: Corrosion Behaviour in the Presence of Toothpaste Vicco. Pharma Chem. 2017, 9, 25–31. [Google Scholar]

- Loto, R.T. Study of the Corrosion Resistance of Type 304L and 316 Austenitic Stainless Steels in Acid Chloride Solution. Orient. J. Chem. 2017, 33, 1090–1096. [Google Scholar] [CrossRef]

- Petkovic, D.L.; Madic, M.J.; Radenkovic, G.M. The Effects of Passivation Parameters on Pitting Potential of Biomedical Stainless Steel. Chem. Ind. Chem. Eng. Q. 2017, 23, 121–129. [Google Scholar] [CrossRef]

- Szewcik-Nykiel, A. The influence of molybdenum on corrosion resistance of sintered austenitic stainless steels. Tech. Trans. 2015, 4, 131–142. [Google Scholar]

- Upadhyay, N.; Shankar, A.R.; Anandkumar, B.; George, R.P.; Pujar, M.G.; Philip, J.; Amarendra, G. Effect of Molybdenum on Pit Initiation Rate and Pit Growth Using Electrochemical Noise and Its Correlation with Confocal Laser Scanning Microscopic Studies. J. Mater. Eng. Perform. 2020, 29, 5337–5345. [Google Scholar] [CrossRef]

- Kolli, S. Sensitization in Austenitic Stainless Steels; University of Oulu Faculty of Technology: Tampere, Finland, 2020. [Google Scholar]

- Okpala, A.N.; Christian, A.; Amula, E. Effect of Sensitization on The Corrosion of Austenitic Stainless Steel in Fresh Water. J. Mech. Civ. Eng. 2016, 13, 133–137. [Google Scholar]

- Lipiński, T. Investigation of corrosion rate of X55CrMo14 stainless steel at 65% nitrate acid at 348 K. Prod. Eng. Arch. 2021, 27, 108–111. [Google Scholar] [CrossRef]

- Lou, X.; Snitzer, J. Sensitization of 316L stainless steel made by laser powder bed fusion additive manufacturing. Corrosion 2023, 79, 2. [Google Scholar]

- Reclaru, L.; Ardelean, L.C. Corrosion Susceptibility and Allergy Potential of Austenitic Stainless Steels. Materials 2020, 13, 4187. [Google Scholar] [CrossRef]

- Behbahani, K.M.; Pakshir, M. Effect of Different Degrees of Sensitization on the EIS Response of 316L and 316 SS in Transpassive Region. JMEPEG 2014, 23, 2283–2292. [Google Scholar] [CrossRef]

- McGuire, M.F. Stainless Steels for Design Engineers, 1st ed.; ASM International: Materials Park, OH, USA, 2008; pp. 151–185. [Google Scholar]

- Practical Guidelines for the Fabrication of Austenitic Stainless Steels. Available online: https://www.imoa.info/download_files/stainless-steel/Austenitics_fabrication.pdf (accessed on 25 April 2023).

- Sreevidya, N.; Abhijith, S.; Shaju, K.A.; Vinod, V.; Banerjee, I. Failure analysis of service exposed austenitic stainless steel pipelines. Eng. Fail. Anal. 2020, 108, 104337. [Google Scholar] [CrossRef]

- Ravi, S.; Parameswaran, P.; Ganeshkumar, J.; Sakthy, S.; Laha, K. Failure analysis of 316L austenitic stainless steel bellows used under dynamic sodium in a creep testing chamber. Eng. Fail. Anal. 2016, 59, 366–376. [Google Scholar] [CrossRef]

- Della Rovere, C.A.; Castro-Rebello, M.; Kuri, S.E. Corrosion behavior analysis of an austenitic stainless steel exposed to fire. Eng. Fail. Anal. 2013, 31, 40–47. [Google Scholar] [CrossRef]

- Chen, X.; Brox, D.; Assadsangabi, B.; Mohamed Ali, M.S.; Takahata, K. A stainless-steel-based implantable pressure sensor chip and its integration by microwelding. Sens. Actuator A Phys. 2017, 257, 134–144. [Google Scholar] [CrossRef]

- Ghumman, K.Z.; Ali, S.; Din, E.U.; Mubashar, A.; Khan, N.B.; Ahmed, S.W. Experimental investigation of effect of welding parameters on surface roughness, micro-hardness and tensile strength of AISI 316L stainless steel welded joints using 308L filler material by TIG welding. J. Mater. Res. Technol. 2022, 2, 220–236. [Google Scholar] [CrossRef]

- Farooq, A.; Azam, M.; Deen, K.M. Corrosion behavior of stainless steel weldments in physiological solutions. Mater. Res. Express 2018, 5, 015401. [Google Scholar] [CrossRef]

- Ely, K.J.; Hall, P.; Zhou, Y. Microwelding methods in medical components and devices. In Joining and Assembly of Medical Materials and Devices. In Woodhead Publishing Series in Biomaterials; Woodhead Publishing Limited: Sawston, UK, 2013; pp. 47–78, 79e. [Google Scholar]

- Kolli, S.; Javaheri, V.; Kömi, J.; Porter, D. On the Role of Grain Size and Carbon Content on the Sensitization and Desensitization Behavior of 301 Austenitic Stainless Steel. Metals 2019, 9, 1193. [Google Scholar] [CrossRef]

- Kolli, S.; Javaheri, V.; Ohligschläger, T.; Kömi, J.; Porter, D. The importance of steel chemistry and thermal history on the sensitization behavior in austenitic stainless steels: Experimental and modeling assessment. Mater. Today Commun. 2020, 24, 101088. [Google Scholar] [CrossRef]

- Lee, J.H.; Kim, K.T.; Pyoun, Y.S.; Kim, Y.S. Intergranular Corrosion Mechanism of Slightly-sensitized and UNSM-treated 316L Stainless Steel. Corros. Sci. Technol. 2016, 15, 26–236. [Google Scholar] [CrossRef]

- Kaur, H.; Singh, H. Improving pitting corrosion resistance of AISI 316L weld overlays via Inconel 82 additions. Mater. Today Proc. 2022, 62, A7–A13. [Google Scholar] [CrossRef]

- Ganesh, P.; Giri, R.; Kaul, P.; Sankar, R.; Tiwari, P.; Atulkar, A.; Porwal, R.K.; Dayal, R.K.; Kukreja, L.M. Studies on pitting corrosion and sensitization in laser rapid manufactured specimens of type 316L stainless steel. Mater. Des. 2012, 39, 509–521. [Google Scholar] [CrossRef]

- Vrsalović, L.; Paić, T.; Alar, V.; Stojanović, I.; Jakovljević, S. The effect of surface treatment AISI 316L welded joints on its corrosion behaviour in chloride solution. Met. Mater. 2016, 54, 167–174. [Google Scholar] [CrossRef]

- Chen, X.; Li, J.; Cheng, X.; Wang, H.; Huang, Z. Effect of heat treatment on microstructure, mechanical and corrosion properties of austenitic stainless steel 316L using arc additive manufacturing. Mater. Sci. Eng. A 2018, 715, 307–314. [Google Scholar] [CrossRef]

- Kartaman, A.M.; Nurlaily, E.; Putri, A.S.D.; Sihotang, J.C.; Kundari, N.A. Corrosion analysis of post-heat treatment and post-weld SS316 with electrokinetic reactivation and cyclic polarization method. J. Phys. Conf. Ser. 2020, 1436, 012104. [Google Scholar] [CrossRef]

- Lv, J.; Zhou, Z.; Wang, Z. Comparing the sensitization behavior and the corrosion resistance of the wrought and selective laser melted 316L stainless steels. Mater. Lett. 2022, 328, 133143. [Google Scholar]

- Taji, I.; Moayed, M.H.; Mirjalili, M. Correlation between sensitization and pitting corrosion of AISI 403 martensitic stainless steel. Corros. Sci. 2015, 92, 301–308. [Google Scholar] [CrossRef]

- Duan, Z.; Man, C.; Dong, C.; Cui, Z.; Kong, D.; Wang, L.; Wang, X. Pitting behavior of SLM 316L stainless steel exposed to chloride environments with different aggressiveness: Pitting mechanism induced by gas pores. Corros. Sci. 2020, 167, 108520. [Google Scholar] [CrossRef]

- ASTM International. Standard Practices for Detecting Susceptibility to Intergranular Attack in Austenitic Stainless Steels. Available online: http://www.tdqs.ru/static/doc/astm_a262_15.pdf (accessed on 20 February 2022).

- Cleaning and Descaling Stainless Steels. In A Designers’ Handbook Series N° 9001; Nickel Institute: Toronto, ON, USA, 2020; pp. 6–11.

- Štrbák, M.; Kajánek, D.; Knap, V.; Florková, Z.; Pastorková, J.; Hadzima, B.; Goraus, M. Effect of plasma electrolytic oxidation on the short-term corrosion behaviour of AZ91 magnesium alloy in aggressive chloride environment. Coatings 2022, 12, 566. [Google Scholar] [CrossRef]

- Zatkalíková, V.; Uhríčik, M.; Markovičová, L.; Kuchariková, L. Corrosion Behavior of Sensitized AISI 304 Stainless Steel in Acid Chloride Solution. Materials 2022, 15, 8543. [Google Scholar] [CrossRef]

- Bandson, A.V.; Patil, A.P.; Moon, A.P.; Khobragade, N.N. Intergranular Corrosion Behavior of Low-Nickel and 304 austenitic Stainless Steels. J. Mater. Eng. Perform. 2016, 25, 3615–3626. [Google Scholar]

- Abd Rashid, M.W.; Gakim, M.; Rosli, Z.M.; Azam, M.A. Formation of Cr23C6 during the Sensitization of AISI 304 Stainless Steel and its Effect to Pitting Corrosion. Int. J. Electrochem. Sci. 2012, 7, 9465–9477. [Google Scholar] [CrossRef]

- Elshawesh, F.; Elhoud, A. Role of heat tint on pitting corrosion of 304 austenitic stainless steel in chloride environment. In Proceedings of the EUROCORR 2004—Prevision a Long Terme etModelisation de la Corrosion, Nice, France, 12–16 September 2004. [Google Scholar]

- Mahajanam, S.; Heidersbach, K. Corrosion Studies of Heat-Tinted Austenitic Stainless Steel. Mater. Perform. 2021. Available online: https://nace.mydigitalpublication.com/publication/?i=704427&article_id=4006538&view=articleBrowser&ver=html5 (accessed on 4 June 2023).

- Zhang, C.Y.; Wei, Y.H.; Yang, J.; Emori, W.; Li, J. Effects of nitric acid passivation on the corrosion behavior of ZG06Cr13Ni4Mo stainless steel in simulated marine atmosphere. Mater. Corros. Werkst. Korros. 2020, 71, 1576–1590. [Google Scholar] [CrossRef]

- Szklarska–Smialowska, Z. Pitting and Crevice Corrosion, 1st ed.; NACE International: Houston, TX, USA, 2005; pp. 15–138. [Google Scholar]

- Ezuber, H.; Alshater, A.; Nisar, S.O.; Gonsalvez, A.; Aslam, S. Effect of Surface Finish on the Pitting Corrosion Behavior of Sensitized AISI 304 Austenitic Stainless Steel Alloys in 3.5% NaCl Solutions. Surf. Eng. Appl. Electrochem. 2018, 54, 73–80. [Google Scholar] [CrossRef]

- Cheng, C.Q.; Klinkenberg, L.I.; Ise, Y.; Zhao, J.; Tada, E.; Nishikata, A. Pitting corrosion of sensitised type 304 stainless steel under wet–dry cycling condition. Corros. Sci. 2017, 118, 217–226. [Google Scholar] [CrossRef]

- Voisin, T.; Shi, R.; Zhu, Y.; Qi, Z.; Wu, M.; Sen-Britain, S.; Zhang, Y.; Qiu, S.R.; Wang, Y.M.; Thomas, S.; et al. Pitting Corrosion in 316L Stainless Steel Fabricated by Laser Powder Bed Fusion Additive Manufacturing: A Review and Perspective. JOM 2022, 74, 4. [Google Scholar] [CrossRef]

- Rokosz, K.; Solecki, G.; Mori, G.; Fluch, R.; Kapp, M.; Lahtinen, J. Effect of Polishing on Electrochemical Behavior and Passive Layer Composition of Different Stainless Steels. Materials 2020, 13, 3402. [Google Scholar] [CrossRef]

- Zeidler, H.; Boettger-Hiller, F.; Edelmann, J.; Schubert, A. Surface finish machining of medical parts using Plasma Electrolytic Polishing. Procedia CIRP 2016, 49, 83–87. [Google Scholar] [CrossRef]

- Bell, T. How to Calculate the Rate of Metal Corrosion. Available online: https://www.thoughtco.com/corrosion-rate-calculator-2339697 (accessed on 3 May 2023).

| Cr | Ni | Mo | Mn | N | C | Si | P | S | Fe |

|---|---|---|---|---|---|---|---|---|---|

| 16.79 | 10.14 | 2.03 | 0.82 | 0.05 | 0.02 | 0.031 | 0.03 | 0.001 | balance |

| Component | Content (wt.%) | Temperature (°C) | Time (s) | Current Density (A.cm−2) |

|---|---|---|---|---|

| oxalic acid demineralized water | 10 90 | 20 ± 3 | 90 | 1.0 |

| Component | Volume (mL) | Temperature (°C) | Time (min) |

|---|---|---|---|

| HF HNO3 H2O | 2 15 to 100 mL | 50 | 10 |

| Type of Specimen | Specimen Designation |

|---|---|

| Sensitized after removal of high-temperature oxides | S |

| Sensitized with high-temperature oxides | SO |

| Original non-treated | As-received |

| Specimen Type | Corrosion Potential Ecorr (V vs. SCE) | Corrosion Current Density icorr (µA/cm2) | Pitting Potential Ep (V vs. SCE) |

|---|---|---|---|

| As-received | −0.13 ± 0.01 | - | 0.40 ± 0.02 |

| S | −0.17 ± 0.03 | - | 0.36 ± 0.02 |

| SO | −0.22 ± 0.04 | 13.95 ± 1.03 | - |

| Type of Surface | Average Mass Loss (mg) | Average Corrosion Rate (mm/y) |

|---|---|---|

| As-received | 0.08 ± 0.02 | 0.0007 ± 0.0001 |

| S | 0.11 ± 0.01 | 0.001 ± 0.0001 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zatkalíková, V.; Uhríčik, M.; Markovičová, L.; Pastierovičová, L.; Kuchariková, L. The Effect of Sensitization on the Susceptibility of AISI 316L Biomaterial to Pitting Corrosion. Materials 2023, 16, 5714. https://doi.org/10.3390/ma16165714

Zatkalíková V, Uhríčik M, Markovičová L, Pastierovičová L, Kuchariková L. The Effect of Sensitization on the Susceptibility of AISI 316L Biomaterial to Pitting Corrosion. Materials. 2023; 16(16):5714. https://doi.org/10.3390/ma16165714

Chicago/Turabian StyleZatkalíková, Viera, Milan Uhríčik, Lenka Markovičová, Lucia Pastierovičová, and Lenka Kuchariková. 2023. "The Effect of Sensitization on the Susceptibility of AISI 316L Biomaterial to Pitting Corrosion" Materials 16, no. 16: 5714. https://doi.org/10.3390/ma16165714

APA StyleZatkalíková, V., Uhríčik, M., Markovičová, L., Pastierovičová, L., & Kuchariková, L. (2023). The Effect of Sensitization on the Susceptibility of AISI 316L Biomaterial to Pitting Corrosion. Materials, 16(16), 5714. https://doi.org/10.3390/ma16165714