Performance Analysis of High-Performance Concrete Materials in Civil Construction

Abstract

:1. Introduction

2. Materials and Methods

2.1. Characteristics of High-Performance Concrete

2.2. Test Methods

3. Results

3.1. Mechanical Characteristics of High-Performance Concrete Materials

3.2. Durability Characteristics of High-Performance Concrete Materials

4. Discussions

- (1)

- In this paper, the ratio of mineral powder to fly ash is 3:2, and different amounts are mixed in the concrete. With the increase in the admixture, the slump and expansion of concrete decreased rapidly and then slowly, and the admixture of 60% was the turning point. With the increase in the mineral powder–fly ash composite mineral admixture, the compressive strength and flexural strength of concrete first decreased and then decreased rapidly. When the admixture is 0–30%, the change in concrete strength is not evident. When the admixture exceeds 30%, the compressive strength and flexural strength of concrete decrease rapidly. After mixing mineral powder, the shrinkage of concrete changes greatly in one day, and the larger the dosage the smaller the shrinkage of concrete. Generally, 35% of mineral powder–fly ash composite mineral admixture is used;

- (2)

- A certain proportion of fly ash and mineral powder admixture can directly improve the early crack resistance of high-performance concrete; fly ash can enhance the crack resistance of concrete and reduce shrinkage and cracking, but the role of mineral powder is not evident. When the composite mineral admixture is incorporated into concrete, the corrosion resistance of concrete will be more than 88%, whereas the corrosion resistance of concrete with fly ash alone is less than 81%. After more than 300 freezing and thawing cycles, the relative dynamic modulus of C50 high-performance concrete will be more than 95%, and the relative dynamic modulus of concrete with a single admixture of fly ash is higher than that of concrete with a single admixture of mineral powder. Composite mineral admixture helps to improve the impermeability of concrete, which will reach the grade of P17. Admixture of only one mineral admixture is also effective in improving the impermeability of concrete, which reaches the grades of P11 and P13 for (KF)-only and (FMH)-only concretes. An admixture of mineral admixtures helps to improve the durability of concrete.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Seleem, H.E.D.H.; Rashad, A.M.; El-Sabbagh, B.A. Durability and strength evaluation of high-performance concrete in marine structures. Constr. Build. Mater. 2010, 24, 878–884. [Google Scholar] [CrossRef]

- Yeh, I.C. Modeling of strength of high-performance concrete using artificial neural networks. Cem. Concr. Res. 1998, 28, 1797–1808. [Google Scholar] [CrossRef]

- Marvila, M.T.; de Azevedo, A.R.G.; de Matos, P.R.; Monteiro, S.N.; Vieira, C.M.F. Materials for production of high and ultra-high-performance concrete: Review and perspective of possible novel materials. Materials 2021, 14, 4304. [Google Scholar] [CrossRef]

- Guo, X.L.; Shi, H.S. Thermal treatment and utilization of flue gas desulphurization gypsum as an admixture in cement and concrete. Constr. Build. Mater. 2008, 22, 1471–1476. [Google Scholar] [CrossRef]

- Li, Y.F.; Liu, Y.; Du, R.Q.; Kong, F.Y. Effect of steel slag powder on the durability of high performance concrete. Adv. Mater. Res. 2009, 79, 175–178. [Google Scholar] [CrossRef]

- Zhang, Y.; Cai, J.D.; Xu, S.L.; Yue, C.X. Experimental investigation of effect of admmixture on concrete strength and frost-resistance. In Proceedings of the 2011 International Conference on Electric Technology and Civil Engineering (ICETCE) 2011, Lushan, China, 22–24 April 2011; IEEE: Piscataway, NJ, USA, 2021; pp. 2180–2183. [Google Scholar]

- Zong, X. Research on the Application of Compound Admixture in the Freezing Mine Shaft Lining Concrete. Adv. Mater. Res. 2011, 250, 1252–1255. [Google Scholar] [CrossRef]

- He, Z.M.; Liu, J.Z. Chloride Ions Penetration Resistance of New-Old Concrete. Adv. Mater. Res. 2012, 366, 518–521. [Google Scholar] [CrossRef]

- Li, Y.F.; Wang, Q.X.; Guo, H.X. Shrinkage Cracking Ring Tests of Concrete with Compound Mineral Admixtures. Appl. Mech. Mater. 2013, 325, 59–62. [Google Scholar] [CrossRef]

- Yu, Y.; Yu, J.; Ge, Y. Water and chloride permeability research on ordinary cement mortar and concrete with compound admixture and fly ash. Constr. Build. Mater. 2016, 127, 556–564. [Google Scholar] [CrossRef]

- Lu, S.; Li, J.; Luo, Z.; Yang, X.; Gu, Q.; Liu, X. Effects of Compound Rust Inhibitor on the Performance of Concrete with a Large Amount of Mineral Admixtures. Rev. Compos. Matériaux Avancés 2020, 30, 109–114. [Google Scholar] [CrossRef]

- Vejmelkova, E.; Pavlikova, M.; Keppert, M.; Keršner, Z.; Rovnaníková, P.; Ondráček, M.; Černý, R. High performance concrete with Czech metakaolin: Experimental analysis of strength, toughness and durability characteristics. Constr. Build. Mater. 2010, 24, 1404–1411. [Google Scholar] [CrossRef]

- Mateckova, P.; Bilek, V.; Sucharda, O. Comparative Study of High-Performance Concrete Characteristics and Loading Test of Pretensioned Experimental Beams. Crystals 2021, 11, 427. [Google Scholar] [CrossRef]

- Pedro, D.; De Brito, J.; Evangelista, L. Evaluation of high-performance concrete with recycled aggregates: Use of densified silica fume as cement replacement. Constr. Build. Mater. 2017, 147, 803–814. [Google Scholar] [CrossRef]

- Deepa, C.; SathiyaKumari, K.; Sudha, V.P. Prediction of the compressive strength of high-performance concrete mix using tree-based modeling. Int. J. Comput. Appl. 2010, 6, 18–24. [Google Scholar] [CrossRef]

- Al-Jabri, K.S.; Hisada, M.; Al-Oraimi, S.K.; Al-Saidy, A.H. Copper slag as sand replacement for high performance concrete. Cem. Concr. Compos. 2009, 31, 483–488. [Google Scholar] [CrossRef]

- Zhang, P.; Wan, J.; Wang, K.; Li, Q. Influence of nano-SiO2 on properties of fresh and hardened high performance concrete: A state-of-the-art review. Constr. Build. Mater. 2017, 148, 648–658. [Google Scholar] [CrossRef]

- Kim, J.; Nam, B.H.; Al Muhit, B.A.; Tasneem, K.M.; An, J. Effect of Chemical Treatment of MSWI Bottom Ash for Its Use in Concrete. Mag. Concr. Res. 2015, 67, 179–186. [Google Scholar] [CrossRef]

- Zhang, Y.; Sun, W.; Liu, S. Study on the hydration heat of binder paste in high-performance concrete. Cem. Concr. Res. 2002, 32, 1483–1488. [Google Scholar] [CrossRef]

- Xu, Y.; Ahmad, W.; Ahmad, A.; Ostrowski, K.A.; Dudek, M.; Aslam, F.; Joyklad, P. Computation of high-performance concrete compressive strength using standalone and ensembled machine learning techniques. Materials 2021, 14, 7034. [Google Scholar] [CrossRef]

- Erdal, H.I.; Karakurt, O.; Namli, E. High performance concrete compressive strength forecasting using ensemble models based on discrete wavelet transform. Eng. Appl. Artif. Intell. 2013, 26, 1246–1254. [Google Scholar] [CrossRef]

- Kurdi, A.; Khoury, S.; Abbas, R. A new concrete for the 21 century: Reactive powder concrete. Alex. Eng. J. 2001, 40, 893–909. [Google Scholar]

| Mixing Amount (%) | Amount of per Square Meter (kg/m3) | ||||||

|---|---|---|---|---|---|---|---|

| Cement (kg) | Fly Ash (kg) | Mineral Powder (kg) | Sand (kg) | Gravel (kg) | Water (kg) | Additive (kg) | |

| 0 | 470 | 0 | 0 | 500 | 1000 | 165 | 4.8 |

| 15 | 410 | 25 | 35 | 500 | 1000 | 165 | 4.8 |

| 30 | 350 | 50 | 70 | 500 | 1000 | 165 | 4.8 |

| 45 | 260 | 90 | 120 | 500 | 1000 | 165 | 4.8 |

| 60 | 180 | 120 | 170 | 500 | 1000 | 165 | 4.8 |

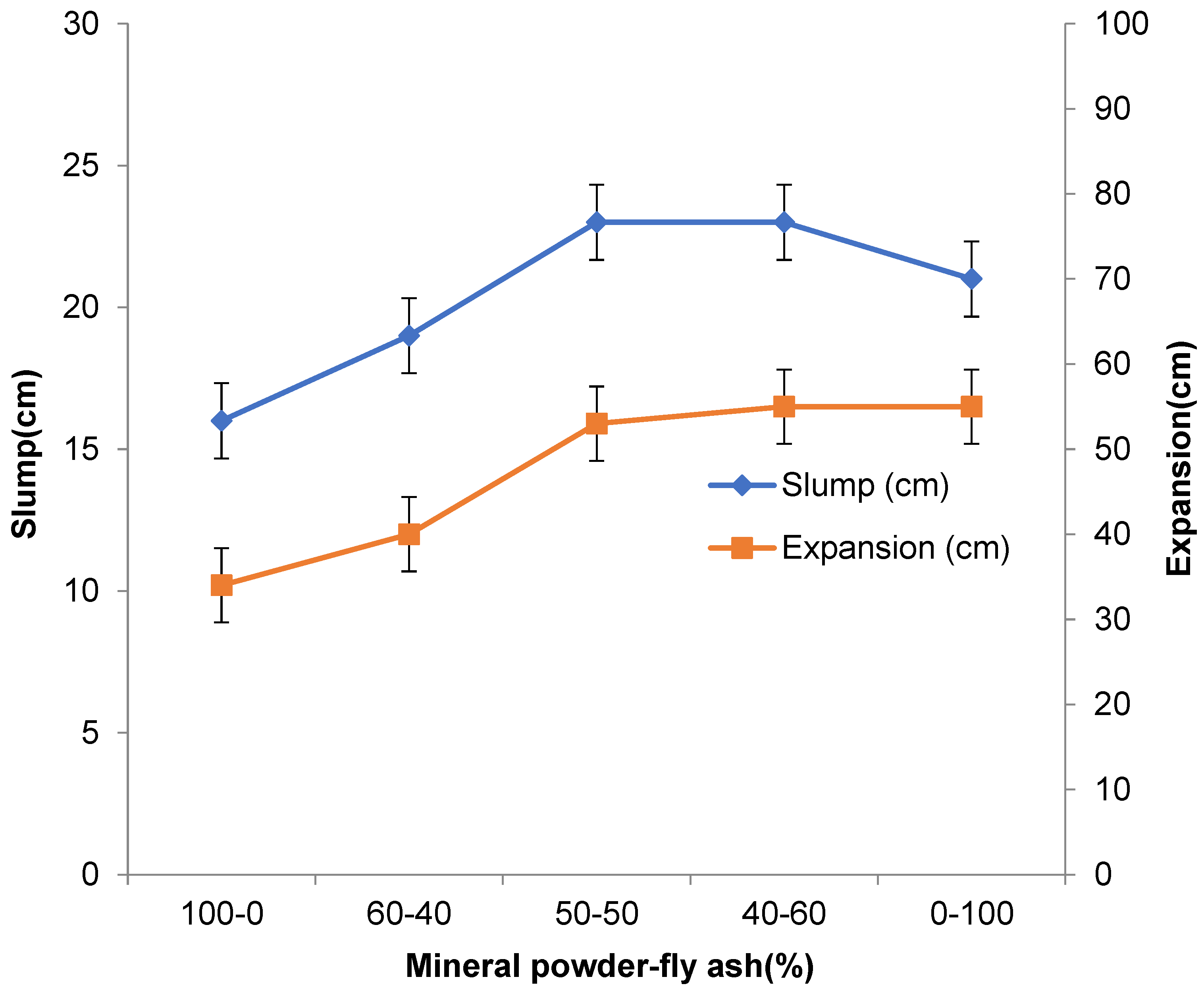

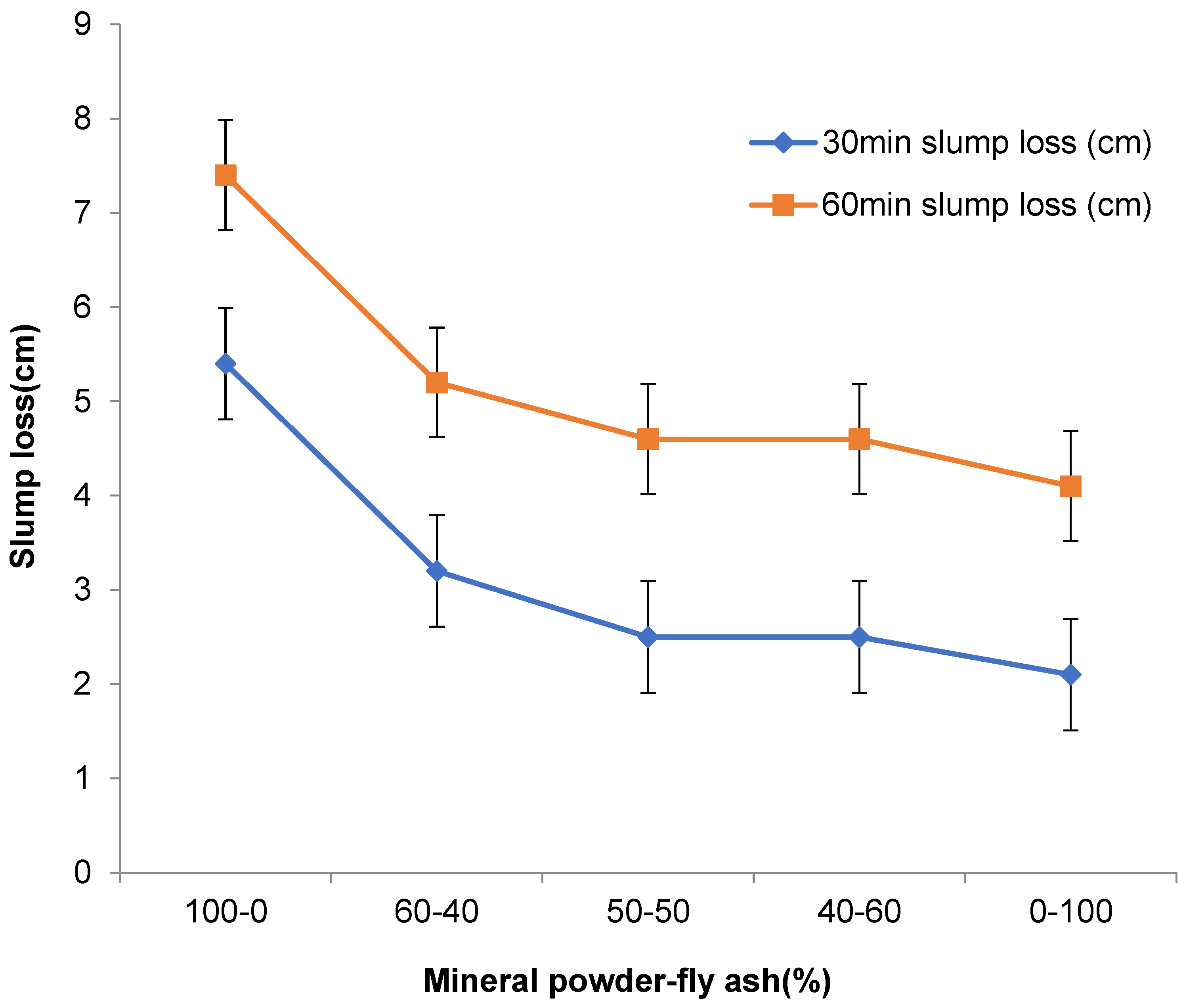

| Mineral Powder-Fly Ash (%) | Slump (cm) | Expansion (cm) | 30 min Slump Loss (cm) | 60 min Slump Loss (cm) |

|---|---|---|---|---|

| 100–0 | 16 | 34 | 5.4 | 7.4 |

| 60–40 | 19 | 40 | 3.2 | 5.2 |

| 50–50 | 23 | 53 | 2.5 | 4.6 |

| 40–60 | 23 | 55 | 2.5 | 4.6 |

| 0–100 | 21 | 55 | 2.1 | 4.1 |

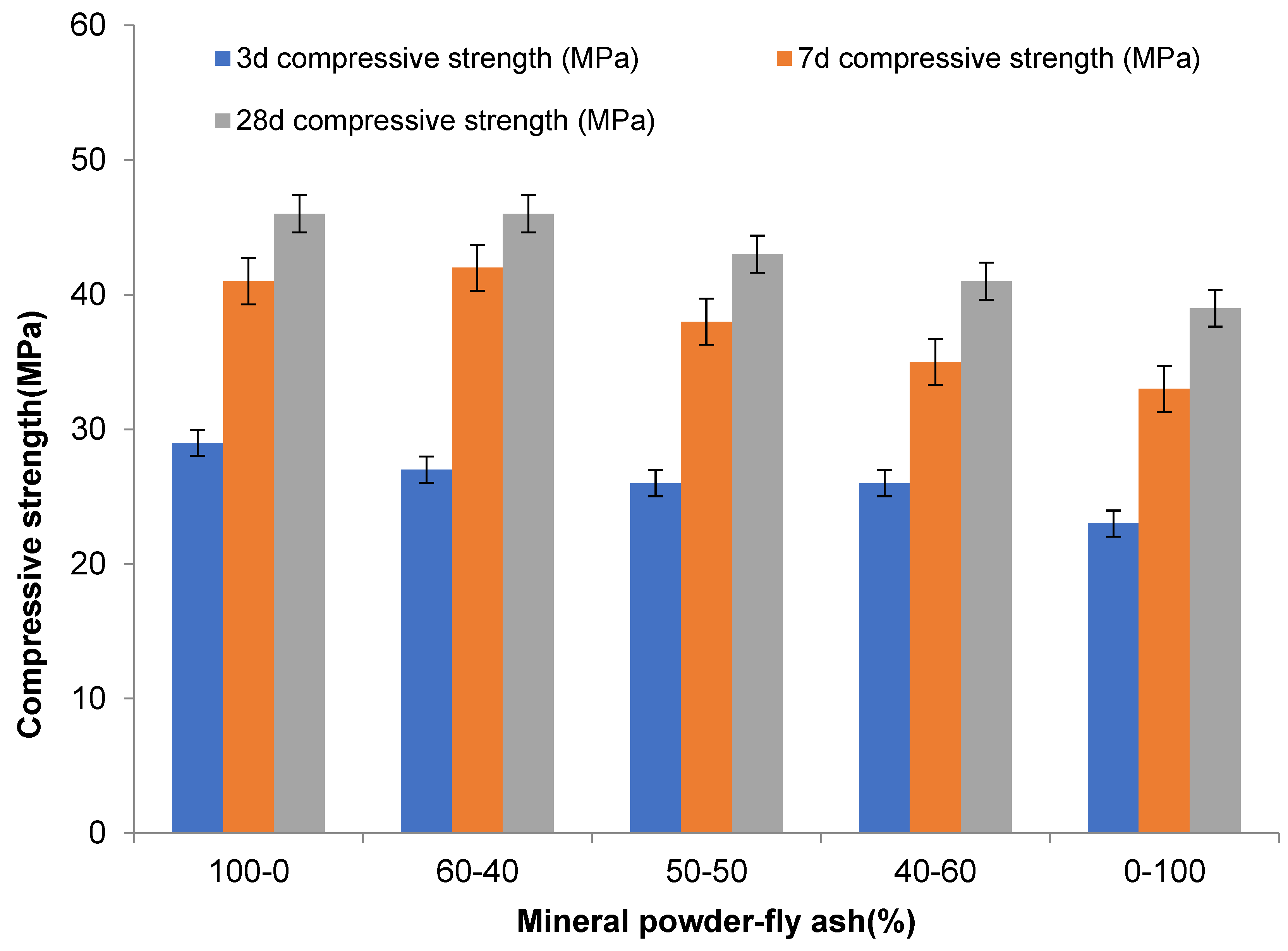

| Mineral Powder-Fly Ash (%) | 3 d Compressive Strength (MPa) | 7 d Compressive Strength (MPa) | 28 d Compressive Strength (MPa) | 7 d Flexural Strength (MPa) | 7 d Flexural Strength (MPa) | 28 d Flexural Strength (MPa) |

|---|---|---|---|---|---|---|

| 100–0 | 29 | 41 | 46 | 4.5 | 5.6 | 6.1 |

| 60–40 | 27 | 42 | 46 | 4.0 | 5.1 | 5.8 |

| 50–50 | 26 | 38 | 43 | 3.7 | 4.7 | 5.2 |

| 40–60 | 26 | 35 | 41 | 3.4 | 4.2 | 4.8 |

| 0–100 | 23 | 33 | 39 | 3.0 | 3.6 | 4.6 |

| NO. | Cracking Time (h) | Average Cracking Area (mm2) | Number of Cracks per Unit Area (piece/m2) | Total Cracking Area per Unit Area (mm2/m2) |

|---|---|---|---|---|

| (Mixed with FMH + KF) | 19 | 21 | 8 | 203 |

| (Mixed with FMH) | 14 | 30 | 11 | 300 |

| (Mixed with KF) | 10 | 124 | 16 | 1754 |

| (Reference sample) | 7 | 141 | 19 | 2250 |

| NO. | 28 d Corrosion Resistance Coefficient | 7 d Corrosion Resistance Coefficient |

|---|---|---|

| (Mixed with FMH + KF) | 88 | 89 |

| (Mixed with FMH) | 74 | 81 |

| (Mixed with KF) | 86 | 82 |

| (Reference sample) | 73 | 75 |

| NO. | Freeze Cycles (times) | ||||

|---|---|---|---|---|---|

| 50 | 100 | 150 | 200 | 250 | |

| Relative Elastic Modulus (%) | |||||

| (Mixed with FMH + KF) | 99 | 98 | 97 | 96 | 95 |

| (Mixed with FMH) | 95 | 94 | 90 | 88 | 85 |

| (Mixed with KF) | 91 | 88 | 83 | 79 | 76 |

| (Reference sample) | 84 | 81 | 78 | 70 | 51 |

| Test Result | Reference Sample | (Mixed with KF) | (Mixed with FMH) | (Mixed with FMH + KF) |

|---|---|---|---|---|

| The water pressure of the third specimen when it seeps (MPa) | 0.7 | 1.3 | 1.5 | 1.9 |

| Water seepage grade | P5 | P11 | P13 | P17 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, Y.; Zhou, T. Performance Analysis of High-Performance Concrete Materials in Civil Construction. Materials 2023, 16, 5711. https://doi.org/10.3390/ma16165711

Han Y, Zhou T. Performance Analysis of High-Performance Concrete Materials in Civil Construction. Materials. 2023; 16(16):5711. https://doi.org/10.3390/ma16165711

Chicago/Turabian StyleHan, Yongguang, and Tianhua Zhou. 2023. "Performance Analysis of High-Performance Concrete Materials in Civil Construction" Materials 16, no. 16: 5711. https://doi.org/10.3390/ma16165711

APA StyleHan, Y., & Zhou, T. (2023). Performance Analysis of High-Performance Concrete Materials in Civil Construction. Materials, 16(16), 5711. https://doi.org/10.3390/ma16165711