Recent Advances in Additive Manufacturing of Soft Magnetic Materials: A Review

Abstract

:1. Introduction

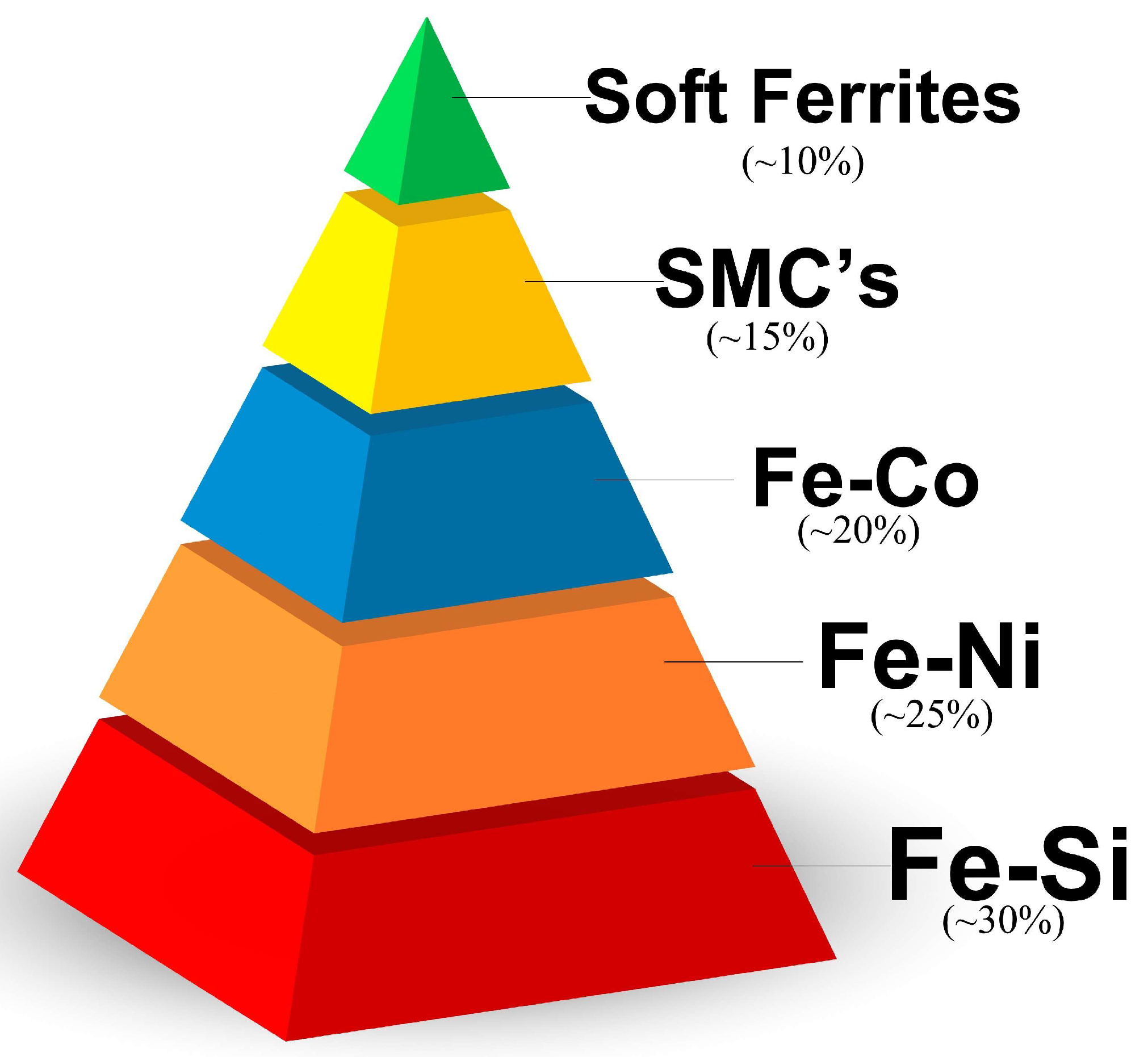

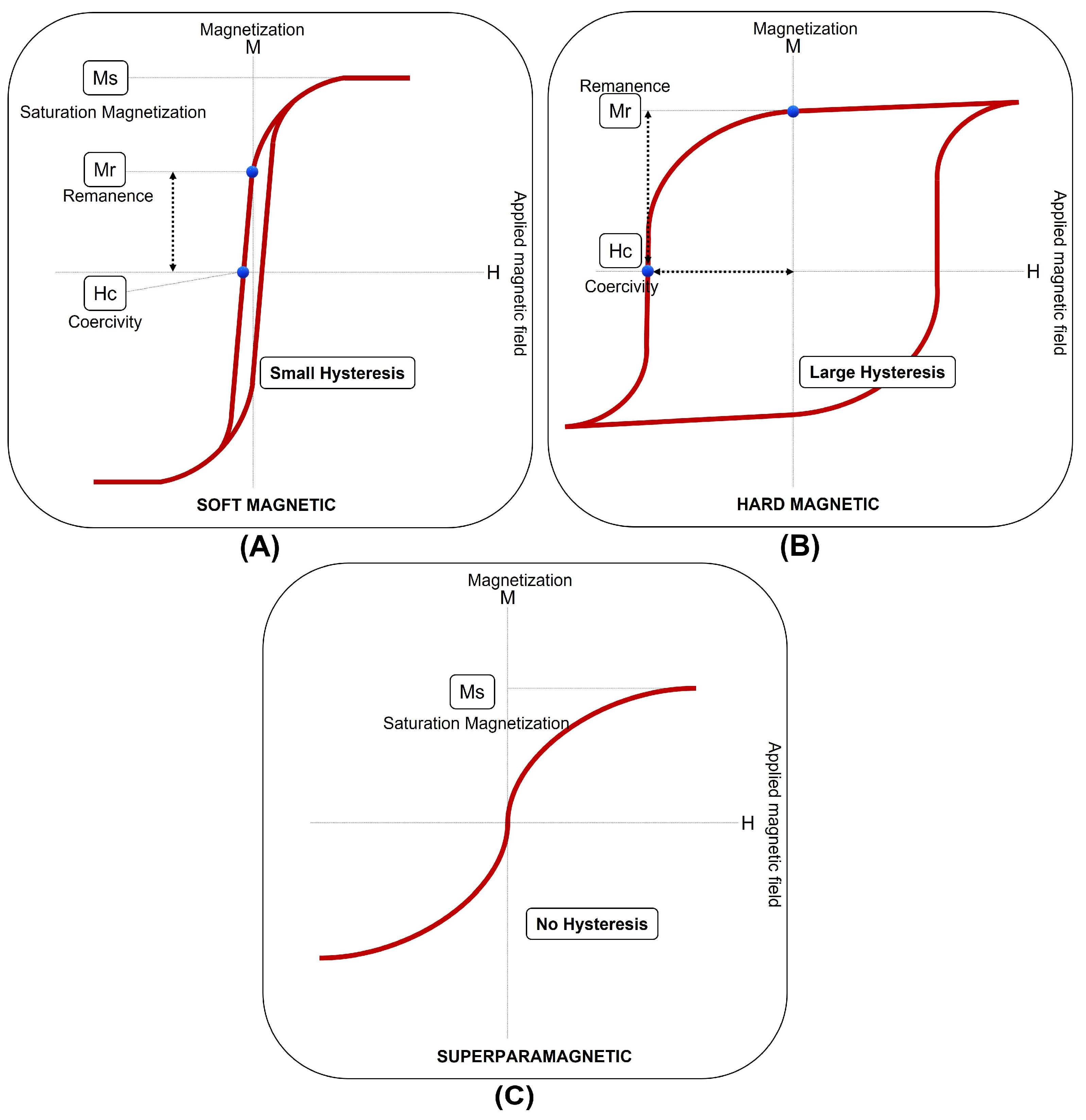

2. Overview of Soft Magnetic Materials

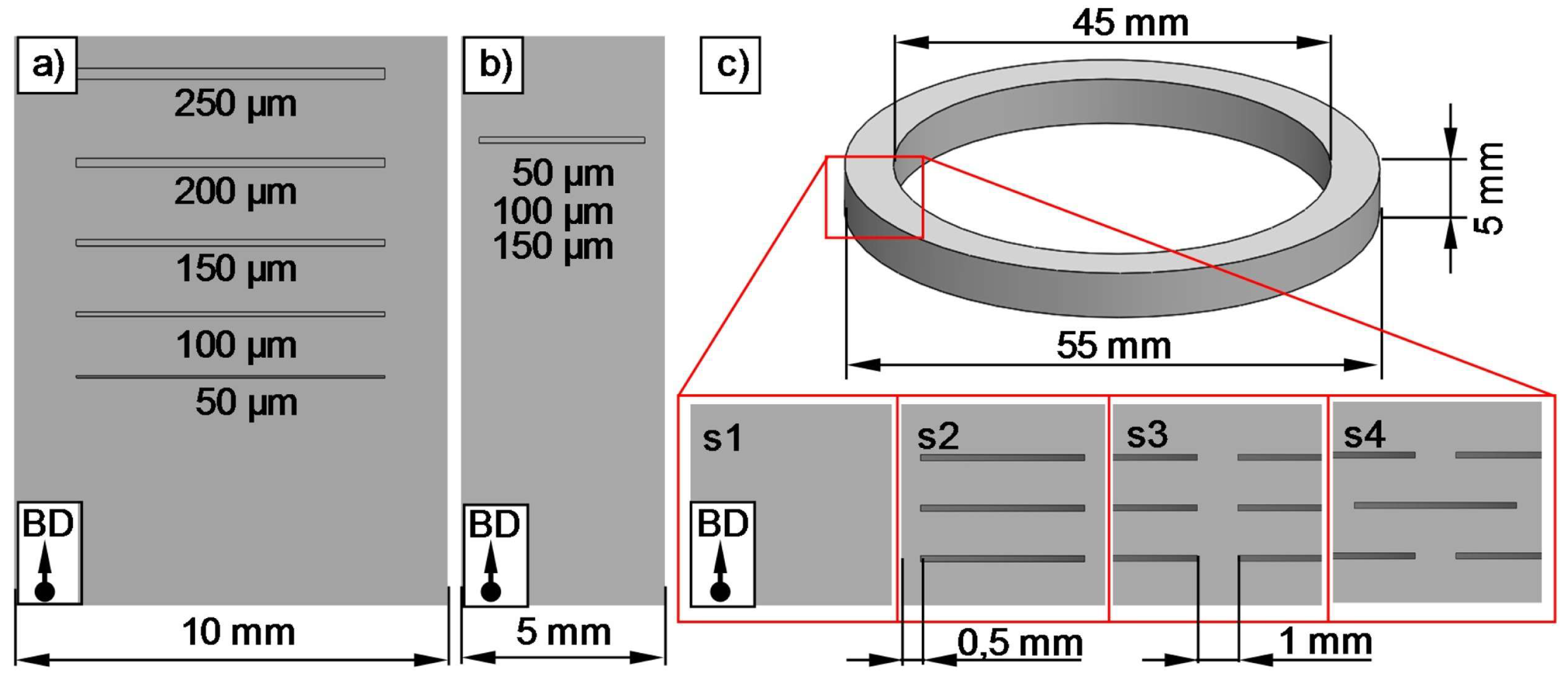

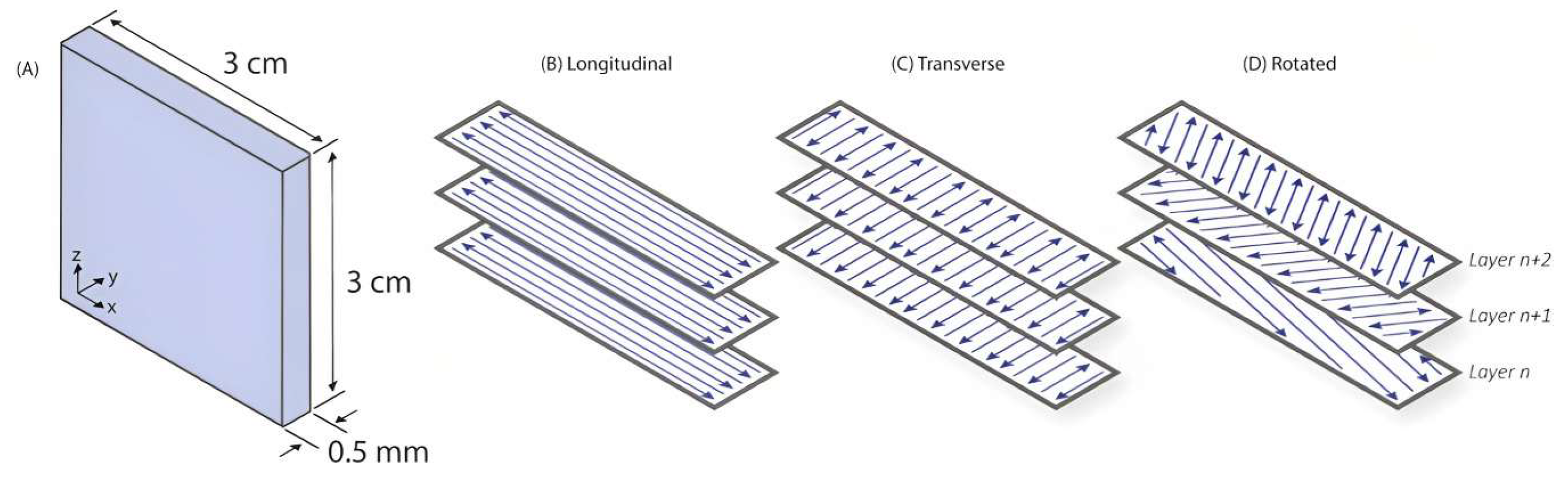

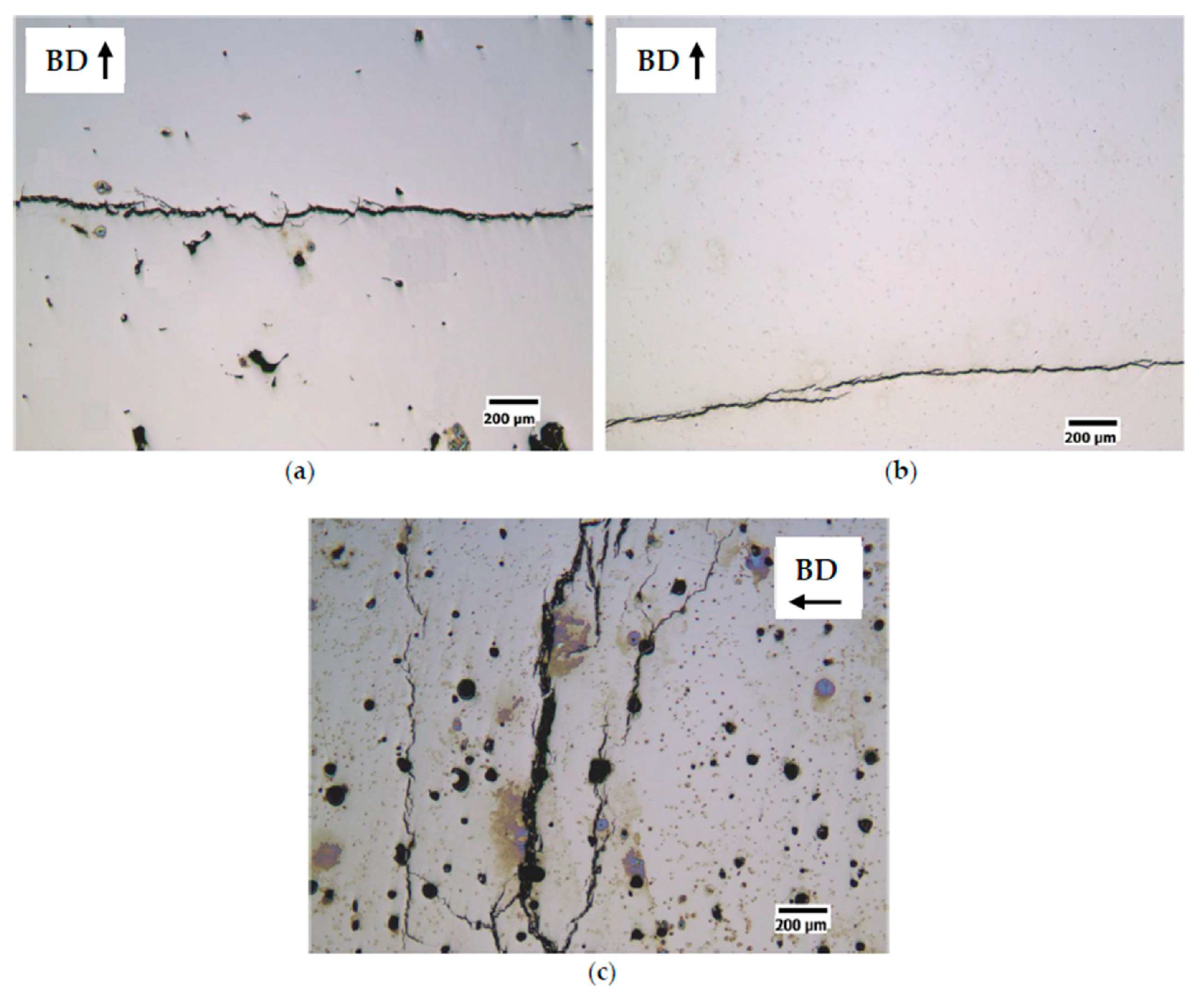

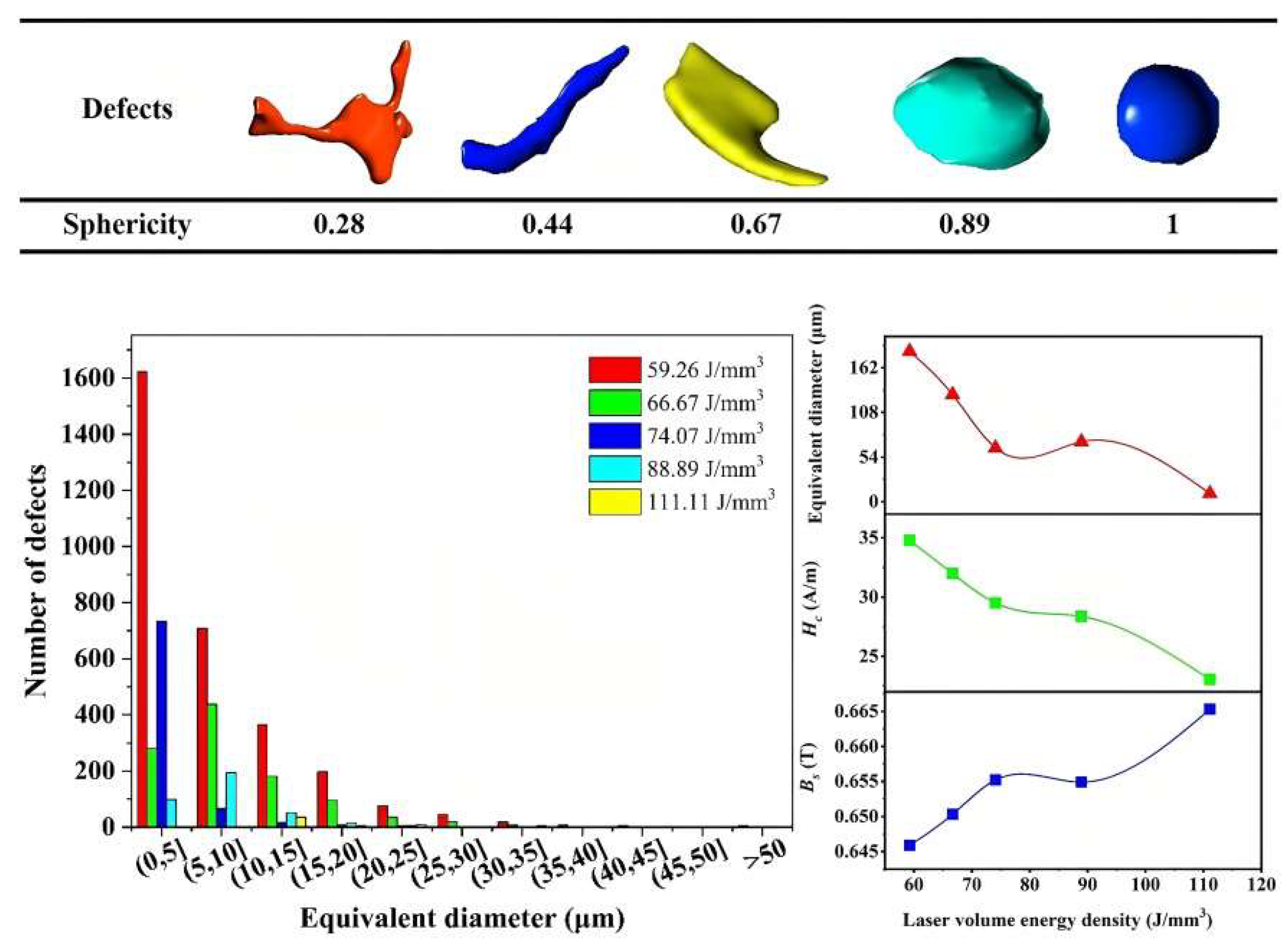

3. Fe–Si

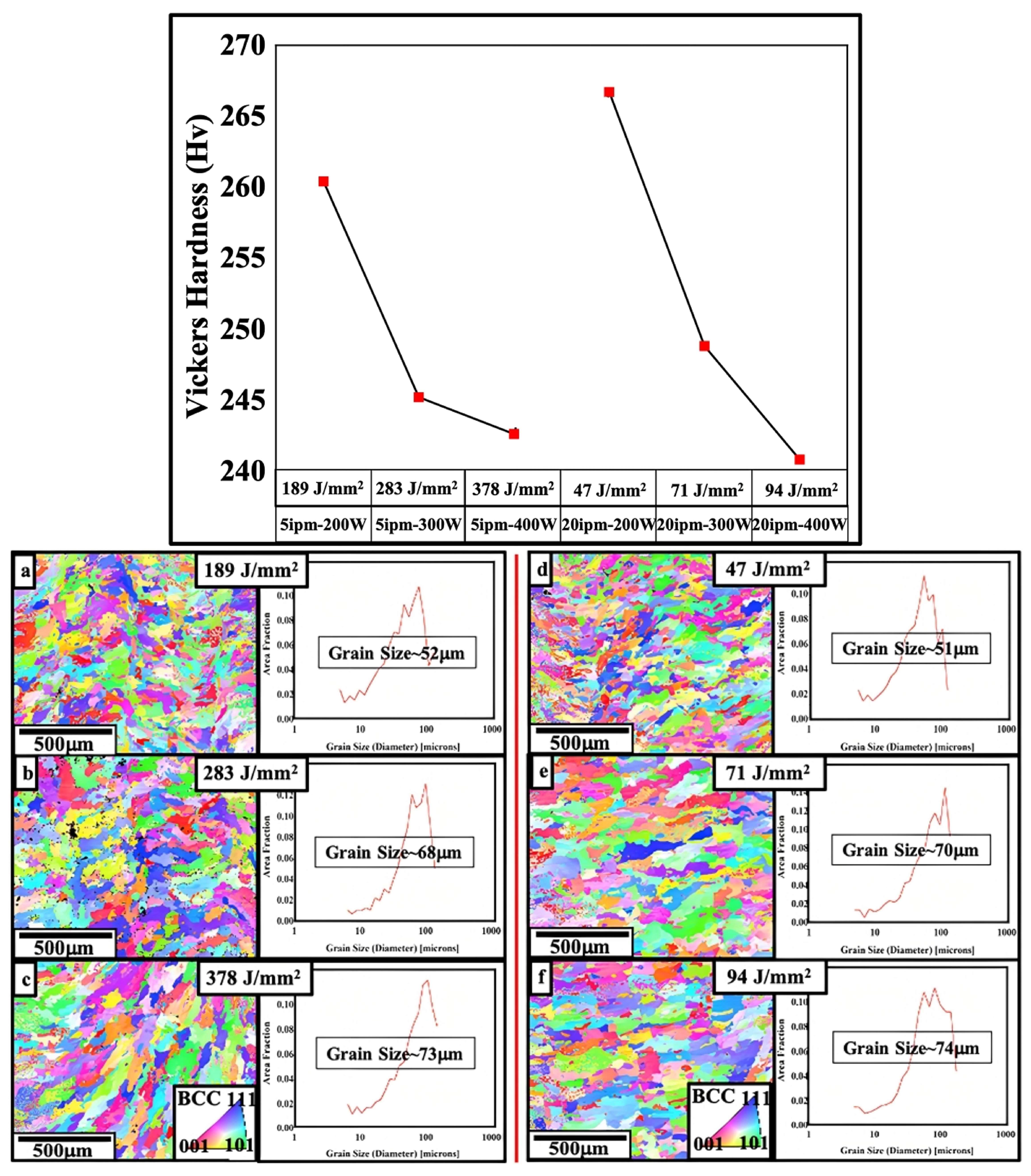

4. Fe–Ni

5. Fe–Co

6. Soft Magnetic Composites (SMCs)

7. Soft Ferrites

8. Novel Materials: High-Entropy Alloys (HEAs)

9. Summary and Outlook

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| AM | Additive Manufacturing |

| APD | Antiphase Domain |

| B | Flux Density |

| BCC | Body-centered Cubic |

| BJP | Binder Jetting Technology |

| Br | Remanence |

| CAD | Computed-Aided Design |

| DED | Directed Energy Deposition |

| E | Specific Energy/Specific Laser Energy |

| EDS | Energy-dispersive X-ray Spectroscopy |

| EBSD | Electron Backscatter Diffraction |

| EV | Input laser energy densities |

| FCC | Face Centered Cubic |

| HC | Coercivity |

| HCP | Hexagonal Close-packed |

| HEAs | High-entropy Alloys |

| HIPing | Hot Isostatic Pressing |

| HT | Heat Treatment |

| HV | Hardness Vickers |

| IPF | Inverse Pole Figures |

| k | Thermal Conductivity |

| LBM | Laser Beam Melting |

| L-DED | Laser-directed Energy Deposition |

| LENS | Laser-engineered Net Shaping |

| L-PBF | Laser Powder Bed Fusion |

| MIM | Metal Injection Molding |

| Mr | Relative Permeability |

| MRI | Magnetic Resonance Imaging |

| Ms or Bs | Saturation Magnetization |

| r | Electrical Resistivity |

| SEM | Scanning Electron Microscopy |

| SLM | Selective Laser Melting |

| SMCs | Soft Magnetic Composites |

| SMMs | Soft Magnetic Materials |

| SPS | Spark Plasma Sintering |

| TEM | Transmission electron microscopy |

| TO | Topological Optimization |

| XCT | X-ray computed tomography |

| Xm | Magnetic Susceptibility |

| XRD | X-ray Diffraction |

References

- Stornelli, G.; Gaggiotti, M.; Mancini, S.; Napoli, G.; Rocchi, C.; Tirasso, C.; Di Schino, A. Recrystallization and Grain Growth of AISI 904L Super-Austenitic Stainless Steel: A Multivariate Regression Approach. Metals 2022, 12, 200. [Google Scholar] [CrossRef]

- Stornelli, G.; Di Schino, A.; Mancini, S.; Montanari, R.; Testani, C.; Varone, A. Grain Refinement and Improved Mechanical Properties of EUROFER97 by Thermo-Mechanical Treatments. Appl. Sci. 2021, 11, 10598. [Google Scholar] [CrossRef]

- Di Schino, A.; Testani, C. Corrosion Behavior and Mechanical Properties of AISI 316 Stainless Steel Clad Q235 Plate. Metals 2020, 10, 552. [Google Scholar] [CrossRef]

- Di Schino, A.; Gaggiotti, M.; Testani, C. Heat Treatment Effect on Microstructure Evolution in a 7% Cr Steel for Forging. Metals 2020, 10, 808. [Google Scholar] [CrossRef]

- Stornelli, G.; Gaggia, D.; Rallini, M.; Di Schino, A. Heat Treatment Effect on Maraging Steel Manufactured by Laser Powder Bed Fusion Technology: Microstructure and Mechanical Properties. Acta Metall. Slovaca 2021, 27, 122–126. [Google Scholar] [CrossRef]

- Miranda-Pérez, A.F.; Rodríguez-Vargas, B.R.; Calliari, I.; Pezzato, L. Corrosion Resistance of GMAW Duplex Stainless Steels Welds. Materials 2023, 16, 1847. [Google Scholar] [CrossRef]

- Rodriguez, B.R.; Miranda, A.; Gonzalez, D.; Praga, R.; Hurtado, E. Maintenance of the Austenite/Ferrite Ratio Balance in GTAW DSS Joints Through Process Parameters Optimization. Materials 2020, 13, 780. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.; Zhang, Y.; Aghda, N.H.; Pillai, A.R.; Thakkar, R.; Nokhodchi, A.; Maniruzzaman, M. Emerging 3D Printing Technologies for Drug Delivery Devices: Current Status and Future Perspective. Adv. Drug Deliv. Rev. 2021, 174, 294–316. [Google Scholar] [CrossRef]

- Yin, H.; Qu, M.; Zhang, H.; Lim, Y. 3D Printing and Buildings: A Technology Review and Future Outlook. Technol. Archit. Des. 2018, 2, 94–111. [Google Scholar] [CrossRef]

- Lee, J.-Y.; An, J.; Chua, C.K. Fundamentals and Applications of 3D Printing for Novel Materials. Appl. Mater. Today 2017, 7, 120–133. [Google Scholar] [CrossRef]

- Gao, W.; Zhang, Y.; Ramanujan, D.; Ramani, K.; Chen, Y.; Williams, C.B.; Wang, C.C.L.; Shin, Y.C.; Zhang, S.; Zavattieri, P.D. The Status, Challenges, and Future of Additive Manufacturing in Engineering. Comput. Aided Des. 2015, 69, 65–89. [Google Scholar] [CrossRef]

- González-Henríquez, C.M.; Sarabia-Vallejos, M.A.; Sanz-Horta, R.; Rodriguez-Hernandez, J. Additive Manufacturing of Polymers: 3D and 4D Printing, Methodologies, Type of Polymeric Materials, and Applications. In Macromolecular Engineering; John Wiley & Sons, Ltd: Hoboken, NJ, USA, 2022; pp. 1–65. ISBN 9783527815562. [Google Scholar]

- Mahmood, A.; Akram, T.; Chen, H.; Chen, S. On the Evolution of Additive Manufacturing (3D/4D Printing) Technologies: Materials, Applications, and Challenges. Polymers 2022, 14, 4698. [Google Scholar] [CrossRef]

- Jung, S.; Kara, L.B.; Nie, Z.; Simpson, T.W.; Whitefoot, K.S. Is Additive Manufacturing an Environmentally and Economically Alternative for Mass Production? Environ. Sci. Technol. 2023, 57, 6373–6386. [Google Scholar] [CrossRef]

- Attaran, M. The Rise of 3-D Printing: The Advantages of Additive Manufacturing over Traditional Manufacturing. Bus. Horiz. 2017, 60, 677–688. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A.; Singh, R.P.; Suman, R.; Rab, S. Role of Additive Manufacturing Applications towards Environmental Sustainability. Adv. Ind. Eng. Polym. Res. 2021, 4, 312–322. [Google Scholar] [CrossRef]

- Ford, S.; Despeisse, M. Additive Manufacturing and Sustainability: An Exploratory Study of the Advantages and Challenges. J. Clean. Prod. 2016, 137, 1573–1587. [Google Scholar] [CrossRef]

- Prashar, G.; Vasudev, H.; Bhuddhi, D. Additive Manufacturing: Expanding 3D Printing Horizon in Industry 4.0. Int. J. Interact. Des. Manuf. 2022, 1–15. [Google Scholar] [CrossRef]

- Vafadar, A.; Guzzomi, F.; Rassau, A.; Hayward, K. Advances in Metal Additive Manufacturing: A Review of Common Processes, Industrial Applications, and Current Challenges. Appl. Sci. 2021, 11, 1213. [Google Scholar] [CrossRef]

- Mehrpouya, M.; Dehghanghadikolaei, A.; Fotovvati, B.; Vosooghnia, A.; Emamian, S.S.; Gisario, A. The Potential of Additive Manufacturing in the Smart Factory Industrial 4.0: A Review. Appl. Sci. 2019, 9, 3865. [Google Scholar] [CrossRef] [Green Version]

- May, G.; Psarommatis, F. Maximizing Energy Efficiency in Additive Manufacturing: A Review and Framework for Future Research. Energies 2023, 16, 4179. [Google Scholar] [CrossRef]

- Altıparmak, S.C.; Xiao, B. A Market Assessment of Additive Manufacturing Potential for the Aerospace Industry. J. Manuf. Process 2021, 68, 728–738. [Google Scholar] [CrossRef]

- Naseer, M.U.; Kallaste, A.; Asad, B.; Vaimann, T.; Rassõlkin, A. A Review on Additive Manufacturing Possibilities for Electrical Machines. Energies 2021, 14, 1940. [Google Scholar] [CrossRef]

- Rejeski, D.; Zhao, F.; Huang, Y. Research Needs and Recommendations on Environmental Implications of Additive Manufacturing. Addit. Manuf. 2018, 19, 21–28. [Google Scholar] [CrossRef] [Green Version]

- du Plessis, A.; Razavi, S.M.J.; Benedetti, M.; Murchio, S.; Leary, M.; Watson, M.; Bhate, D.; Berto, F. Properties and Applications of Additively Manufactured Metallic Cellular Materials: A Review. Prog. Mater. Sci. 2022, 125, 100918. [Google Scholar] [CrossRef]

- Buchanan, C.; Gardner, L. Metal 3D Printing in Construction: A Review of Methods, Research, Applications, Opportunities and Challenges. Eng. Struct. 2019, 180, 332–348. [Google Scholar] [CrossRef]

- Najmon, J.C.; Raeisi, S.; Tovar, A. 2—Review of Additive Manufacturing Technologies and Applications in the Aerospace Industry. In Additive Manufacturing for the Aerospace Industry; Froes, F., Boyer, R., Eds.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 7–31. ISBN 978-0-12-814062-8. [Google Scholar]

- Kustas, A.B.; Susan, D.F.; Monson, T. Emerging Opportunities in Manufacturing Bulk Soft-Magnetic Alloys for Energy Applications: A Review. JOM 2022, 74, 1306–1328. [Google Scholar] [CrossRef]

- Gutfleisch, O.; Willard, M.A.; Brück, E.; Chen, C.H.; Sankar, S.G.; Liu, J.P. Magnetic Materials and Devices for the 21st Century: Stronger, Lighter, and More Energy Efficient. Adv. Mater. 2011, 23, 821–842. [Google Scholar] [CrossRef]

- Żukowska, M.; Rad, M.A.; Górski, F. Additive Manufacturing of 3D Anatomical Models—Review of Processes, Materials and Applications. Materials 2023, 16, 880. [Google Scholar] [CrossRef]

- Lehmhus, D.; Aumund-Kopp, C.; Petzoldt, F.; Godlinski, D.; Haberkorn, A.; Zöllmer, V.; Busse, M. Customized Smartness: A Survey on Links between Additive Manufacturing and Sensor Integration. Procedia Technol. 2016, 26, 284–301. [Google Scholar] [CrossRef]

- Del Rosario, M.; Heil, H.S.; Mendes, A.; Saggiomo, V.; Henriques, R. The Field Guide to 3D Printing in Optical Microscopy for Life Sciences. Adv. Biol. 2022, 6, 2100994. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Tian, W.; Kan, C. When AI Meets Additive Manufacturing: Challenges and Emerging Opportunities for Human-Centered Products Development. J. Manuf. Syst. 2022, 64, 648–656. [Google Scholar] [CrossRef]

- Silveyra, J.M.; Ferrara, E.; Huber, D.L.; Monson, T.C. Soft Magnetic Materials for a Sustainable and Electrified World. Science 2018, 362, eaao0195. [Google Scholar] [CrossRef] [Green Version]

- Shokrollahi, H.; Janghorban, K. Soft Magnetic Composite Materials (SMCs). J. Mater. Process. Technol. 2007, 189, 1–12. [Google Scholar] [CrossRef]

- Babu, S.S. Thermo-Mechanical Processing. In Encyclopedia of Materials: Metals and Alloys; Caballero, F.G., Ed.; Elsevier: Oxford, UK, 2022; pp. 27–38. ISBN 978-0-12-819733-2. [Google Scholar]

- 6—Production and Casting of Aerospace Metals. In Introduction to Aerospace Materials; Mouritz, A.P. (Ed.) Woodhead Publishing: Sawston, UK, 2012; pp. 128–153. ISBN 978-1-85573-946-8. [Google Scholar]

- Litovchenko, I.; Akkuzin, S.; Polekhina, N.; Almaeva, K.; Moskvichev, E. Structural Transformations and Mechanical Properties of Metastable Austenitic Steel under High Temperature Thermomechanical Treatment. Metals 2021, 11, 645. [Google Scholar] [CrossRef]

- Lemke, J.N.; Simonelli, M.; Garibaldi, M.; Ashcroft, I.; Hague, R.; Vedani, M.; Wildman, R.; Tuck, C. Calorimetric Study and Microstructure Analysis of the Order-Disorder Phase Transformation in Silicon Steel Built by SLM. J. Alloys Compd. 2017, 722, 293–301. [Google Scholar] [CrossRef] [Green Version]

- Ming, K.; Jiang, S.; Niu, X.; Li, B.; Bi, X.; Zheng, S. High-Temperature Strength-Coercivity Balance in a FeCo-Based Soft Magnetic Alloy via Magnetic Nanoprecipitates. J. Mater. Sci. Technol. 2021, 81, 36–42. [Google Scholar] [CrossRef]

- Kuznetsov, D.D.; Kuznetsova, E.I.; Mashirov, A.V.; Loshachenko, A.S.; Danilov, D.V.; Mitsiuk, V.I.; Kuznetsov, A.S.; Shavrov, V.G.; Koledov, V.V.; Ari-Gur, P. Magnetocaloric Effect, Structure, Spinodal Decomposition and Phase Transformations Heusler Alloy Ni-Mn-In. Nanomaterials 2023, 13, 1385. [Google Scholar] [CrossRef]

- Cava, R.D.; Botta, W.J.; Kiminami, C.S.; Olzon-Dionysio, M.; Souza, S.D.; Jorge, A.M.; Bolfarini, C. Ordered Phases and Texture in Spray-Formed Fe–5wt%Si. J. Alloys Compd. 2011, 509, S260–S264. [Google Scholar] [CrossRef]

- Jang, P.; Lee, B.; Choi, G. Effects of Annealing on the Magnetic Properties of Fe–6.5%Si Alloy Powder Cores. J. Appl. Phys. 2008, 103, 07E743. [Google Scholar] [CrossRef]

- Urban, N.; Meyer, A.; Leckel, M.; Leder, M.; Franke, J. Additive Manufacturing of an Electric Drive a Feasability Study. In Proceedings of the 2018 International Symposium on Power Electronics, Electrical Drives, Automation and Motion (SPEEDAM), Amalfi, Italy, 20–22 June 2018; pp. 1327–1331. [Google Scholar]

- Yang, S.; Tang, Y.; Zhao, Y.F. A New Part Consolidation Method to Embrace the Design Freedom of Additive Manufacturing. J. Manuf. Process. 2015, 20, 444–449. [Google Scholar] [CrossRef] [Green Version]

- Atzeni, E.; Salmi, A. Economics of Additive Manufacturing for End-Usable Metal Parts. Int. J. Adv. Manuf. Technol. 2012, 62, 1147–1155. [Google Scholar] [CrossRef]

- Morales, C.; Merlin, M.; Fortini, A.; Fortunato, A. Direct Energy Depositions of a 17-4 PH Stainless Steel: Geometrical and Microstructural Characterizations. Coatings 2023, 13, 636. [Google Scholar] [CrossRef]

- Krings, A.; Cossale, M.; Tenconi, A.; Soulard, J.; Cavagnino, A.; Boglietti, A. Magnetic Materials Used in Electrical Machines: A Comparison and Selection Guide for Early Machine Design. IEEE Ind. Appl. Mag. 2017, 23, 21–28. [Google Scholar] [CrossRef] [Green Version]

- Mazeeva, A.K.; Staritsyn, M.V.; Bobyr, V.V.; Manninen, S.A.; Kuznetsov, P.A.; Klimov, V.N. Magnetic Properties of Fe–Ni Permalloy Produced by Selective Laser Melting. J. Alloys Compd. 2020, 814, 152315. [Google Scholar] [CrossRef]

- Lamichhane, T.N.; Sethuraman, L.; Dalagan, A.; Wang, H.; Keller, J.; Paranthaman, M.P. Additive Manufacturing of Soft Magnets for Electrical Machines—A Review. Mater. Today Phys. 2020, 15, 100255. [Google Scholar] [CrossRef]

- Yoshizawa, Y.; Oguma, S.; Yamauchi, K. New Fe-based Soft Magnetic Alloys Composed of Ultrafine Grain Structure. J. Appl. Phys. 1988, 64, 6044–6046. [Google Scholar] [CrossRef]

- Gheiratmand, T.; Madaah Hosseini, H.R.; Davami, P.; Sarafidis, C. Fabrication of FINEMET Bulk Alloy from Amorphous Powders by Spark Plasma Sintering. Powder Technol. 2016, 289, 163–168. [Google Scholar] [CrossRef]

- Geng, J.; Nlebedim, I.C.; Besser, M.F.; Simsek, E.; Ott, R.T. Bulk Combinatorial Synthesis and High Throughput Characterization for Rapid Assessment of Magnetic Materials: Application of Laser Engineered Net Shaping (LENSTM). JOM 2016, 68, 1972–1977. [Google Scholar] [CrossRef]

- Moghimian, P.; Poirié, T.; Habibnejad-Korayem, M.; Zavala, J.A.; Kroeger, J.; Marion, F.; Larouche, F. Metal Powders in Additive Manufacturing: A Review on Reusability and Recyclability of Common Titanium, Nickel and Aluminum Alloys. Addit. Manuf. 2021, 43, 102017. [Google Scholar] [CrossRef]

- Pham, T.; Kwon, P.; Foster, S. Additive Manufacturing and Topology Optimization of Magnetic Materials for Electrical Machines—A Review. Energies 2021, 14, 283. [Google Scholar] [CrossRef]

- Selema, A.; Ibrahim, M.N.; Sergeant, P. Metal Additive Manufacturing for Electrical Machines: Technology Review and Latest Advancements. Energies 2022, 15, 1076. [Google Scholar] [CrossRef]

- Mohd Yusuf, S.; Cutler, S.; Gao, N. Review: The Impact of Metal Additive Manufacturing on the Aerospace Industry. Metals 2019, 9, 1286. [Google Scholar] [CrossRef] [Green Version]

- Ladani, L.; Sadeghilaridjani, M. Review of Powder Bed Fusion Additive Manufacturing for Metals. Metals 2021, 11, 1391. [Google Scholar] [CrossRef]

- Nadzharyan, T.A.; Shamonin, M.; Kramarenko, E.Y. Theoretical Modeling of Magnetoactive Elastomers on Different Scales: A State-of-the-Art Review. Polymers 2022, 14, 4096. [Google Scholar] [CrossRef] [PubMed]

- Bastola, A.K.; Hossain, M. A Review on Magneto-Mechanical Characterizations of Magnetorheological Elastomers. Compos. B Eng. 2020, 200, 108348. [Google Scholar] [CrossRef]

- Kim, Y.; Zhao, X. Magnetic Soft Materials and Robots. Chem. Rev. 2022, 122, 5317–5364. [Google Scholar] [CrossRef]

- Zhukov, A.; Ipatov, M.; Corte-León, P.; Legarreta, L.G.; Churyukanova, M.; Blanco, J.M.; Gonzalez, J.; Taskaev, S.; Hernando, B.; Zhukova, V. Giant Magnetoimpedance in Rapidly Quenched Materials. J. Alloys Compd. 2020, 814, 152225. [Google Scholar] [CrossRef]

- Klenam, D.E.P.; Egowan, G.; Bodunrin, M.O.; van der Merwe, J.W.; Rahbar, N.; Soboyejo, W. Complex Concentrated Alloys: A Cornucopia of Possible Structural and Functional Applications. In Comprehensive Structural Integrity, 2nd ed.; Aliabadi, M.H.F., Soboyejo, W.O., Eds.; Elsevier: Oxford, UK, 2023; pp. 50–90. ISBN 978-0-323-91945-6. [Google Scholar]

- Jiles, D.C. Recent Advances and Future Directions in Magnetic Materials. Acta Mater. 2003, 51, 5907–5939. [Google Scholar] [CrossRef]

- Nakamura, H. The Current and Future Status of Rare Earth Permanent Magnets. Scr. Mater. 2018, 154, 273–276. [Google Scholar] [CrossRef]

- Coey, J.M.D. Hard Magnetic Materials: A Perspective. IEEE Trans. Magn. 2011, 47, 4671–4681. [Google Scholar] [CrossRef]

- Goll, D.; Kronmüller, H. High-Performance Permanent Magnets. Naturwissenschaften 2000, 87, 423–438. [Google Scholar] [CrossRef]

- Jeong, U.; Teng, X.; Wang, Y.; Yang, H.; Xia, Y. Superparamagnetic Colloids: Controlled Synthesis and Niche Applications. Adv. Mater. 2007, 19, 33–60. [Google Scholar] [CrossRef]

- Sezer, N.; Arı, İ.; Biçer, Y.; Koç, M. Superparamagnetic Nanoarchitectures: Multimodal Functionalities and Applications. J. Magn. Magn. Mater. 2021, 538, 168300. [Google Scholar] [CrossRef]

- Wei, X.; Jin, M.-L.; Yang, H.; Wang, X.-X.; Long, Y.-Z.; Chen, Z. Advances in 3D Printing of Magnetic Materials: Fabrication, Properties, and Their Applications. J. Adv. Ceram. 2022, 11, 665–701. [Google Scholar] [CrossRef]

- Jordán, D.; González-Chávez, D.; Laura, D.; León Hilario, L.M.; Monteblanco, E.; Gutarra, A.; Avilés-Félix, L. Detection of Magnetic Moment in Thin Films with a Home-Made Vibrating Sample Magnetometer. J. Magn. Magn. Mater. 2018, 456, 56–61. [Google Scholar] [CrossRef] [Green Version]

- Nisticò, R.; Cesano, F.; Garello, F. Magnetic Materials and Systems: Domain Structure Visualization and Other Characterization Techniques for the Application in the Materials Science and Biomedicine. Inorganics 2020, 8, 6. [Google Scholar] [CrossRef] [Green Version]

- Berthod, P. High-Temperature Extreme Alloys. In Encyclopedia of Materials: Metals and Alloys; Caballero, F.G., Ed.; Elsevier: Oxford, UK, 2022; pp. 311–322. ISBN 978-0-12-819733-2. [Google Scholar]

- Shahrubudin, N.; Lee, T.C.; Ramlan, R. An Overview on 3D Printing Technology: Technological, Materials, and Applications. Procedia Manuf. 2019, 35, 1286–1296. [Google Scholar] [CrossRef]

- Krings, A.; Boglietti, A.; Cavagnino, A.; Sprague, S. Soft Magnetic Material Status and Trends in Electric Machines. IEEE Trans. Ind. Electron. 2017, 64, 2405–2414. [Google Scholar] [CrossRef]

- Ruiz, D.; Venegas-Rebollar, V.; Anaya-Ruiz, G.; Moreno-Goytia, E.; Rodriguez-Rodrıguez, J. Design and Prototyping Medium-Frequency Transformers Featuring a Nanocrystalline Core for DC–DC Converters. Energies 2018, 11, 2081. [Google Scholar] [CrossRef] [Green Version]

- van Niekerk, D.; Schoombie, B.; Bokoro, P. Design of an Experimental Approach for Characterization and Performance Analysis of High-Frequency Transformer Core Materials. Energies 2023, 16, 3950. [Google Scholar] [CrossRef]

- Chakraborty, S.; Mandal, K.; Sakar, D.; Cremaschi, V.J.; Silveyra, J.M. Dynamic Coercivity of Mo-Doped FINEMETs. Phys. B Condens. Matter 2011, 406, 1915–1918. [Google Scholar] [CrossRef]

- Zhao, T.; Chen, C.; Wu, X.; Zhang, C.; Volinsky, A.A.; Hao, J. FeSiBCrC Amorphous Magnetic Powder Fabricated by Gas-Water Combined Atomization. J. Alloys Compd. 2021, 857, 157991. [Google Scholar] [CrossRef]

- Zhang, D.; Su, Y.; Yang, X.; Sun, H.; Guo, Z.; Wang, B.; Ma, C.; Dong, Z.; Zhu, L. Texture and Magnetic Property of Fe-6.5 Wt% Si Steel Strip with Cu-Rich Particles Modification. ACS Omega 2023, 8, 8461–8472. [Google Scholar] [CrossRef]

- Leuning, N.; Jaeger, M.; Schauerte, B.; Stöcker, A.; Kawalla, R.; Wei, X.; Hirt, G.; Heller, M.; Korte-Kerzel, S.; Böhm, L.; et al. Material Design for Low-Loss Non-Oriented Electrical Steel for Energy Efficient Drives. Materials 2021, 14, 6588. [Google Scholar] [CrossRef] [PubMed]

- Ouyang, G.; Chen, X.; Liang, Y.; Macziewski, C.; Cui, J. Review of Fe-6.5 wt%Si High Silicon Steel—A Promising Soft Magnetic Material for Sub-KHz Application. J. Magn. Magn. Mater. 2019, 481, 234–250. [Google Scholar] [CrossRef]

- Haines, M.P.; Rielli, V.V.; Primig, S.; Haghdadi, N. Powder Bed Fusion Additive Manufacturing of Ni-Based Superalloys: A Review of the Main Microstructural Constituents and Characterization Techniques. J. Mater. Sci. 2022, 57, 14135–14187. [Google Scholar] [CrossRef]

- Parivendhan, G.; Cardiff, P.; Flint, T.; Tukovic, Z.; Obeidi, M.; Brabazon, D.; Ivankovic, A. A Numerical Study of Processing Parameters and Their Effect on the Melt-Track Profile in Laser Powder Bed Fusion Processes. Addit. Manuf. 2023, 67, 103482. [Google Scholar] [CrossRef]

- Xue, M.; Chen, X.; Ji, X.; Xie, X.; Chao, Q.; Fan, G. Effect of Particle Size Distribution on the Printing Quality and Tensile Properties of Ti-6Al-4V Alloy Produced by LPBF Process. Metals 2023, 13, 604. [Google Scholar] [CrossRef]

- Averardi, A.; Cola, C.; Zeltmann, S.E.; Gupta, N. Effect of Particle Size Distribution on the Packing of Powder Beds: A Critical Discussion Relevant to Additive Manufacturing. Mater. Today Commun. 2020, 24, 100964. [Google Scholar] [CrossRef]

- Andreiev, A.; Hoyer, K.-P.; Dula, D.; Hengsbach, F.; Haase, M.; Gierse, J.; Zimmer, D.; Tröster, T.; Schaper, M. Soft-Magnetic Behavior of Laser Beam Melted FeSi3 Alloy with Graded Cross-Section. J. Mater. Process. Technol. 2021, 296, 117183. [Google Scholar] [CrossRef]

- Quercio, M.; Galbusera, F.; Pošković, E.; Franchini, F.; Ferraris, L.; Canova, A.; Gruosso, G.; Demir, A.G.; Previtali, B. Functional Characterization of L-PBF Produced FeSi2.9 Soft Magnetic Material. In Proceedings of the 2022 International Conference on Electrical Machines (ICEM), Valencia, Spain, 5–8 September 2022; pp. 531–537. [Google Scholar]

- Selema, A.; Beretta, M.; Van Coppenolle, M.; Tiismus, H.; Kallaste, A.; Ibrahim, M.N.; Rombouts, M.; Vleugels, J.; Kestens, L.A.I.; Sergeant, P. Evaluation of 3D-Printed Magnetic Materials For Additively-Manufactured Electrical Machines. J. Magn. Magn. Mater. 2023, 569, 170426. [Google Scholar] [CrossRef]

- Haines, M.P.; List, F.; Carver, K.; Leonard, D.N.; Plotkowski, A.; Fancher, C.M.; Dehoff, R.R.; Babu, S.S. Role of Scan Strategies and Heat Treatment on Grain Structure Evolution in Fe-Si Soft Magnetic Alloys Made by Laser-Powder Bed Fusion. Addit. Manuf. 2022, 50, 102578. [Google Scholar] [CrossRef]

- Martin, V.; Gillon, F.; Najjar, D.; Benabou, A.; Witz, J.-F.; Hecquet, M.; Quaegebeur, P.; Meersdam, M.; Auzene, D. MIM-like Additive Manufacturing of Fe3%Si Magnetic Materials. J. Magn. Magn. Mater. 2022, 564, 170104. [Google Scholar] [CrossRef]

- Tiismus, H.; Kallaste, A.; Naseer, M.U.; Vaimann, T.; Rassõlkin, A. Design and Performance of Laser Additively Manufactured Core Induction Motor. IEEE Access 2022, 10, 50137–50152. [Google Scholar] [CrossRef]

- Kumari, G.; Pham, T.Q.; Suen, H.; Rahman, T.; Kwon, P.; Foster, S.N.; Boehlert, C.J. Improving the Soft Magnetic Properties of Binder Jet Printed Iron-Silicon Alloy through Boron Addition. Mater. Chem. Phys. 2023, 296, 127181. [Google Scholar] [CrossRef]

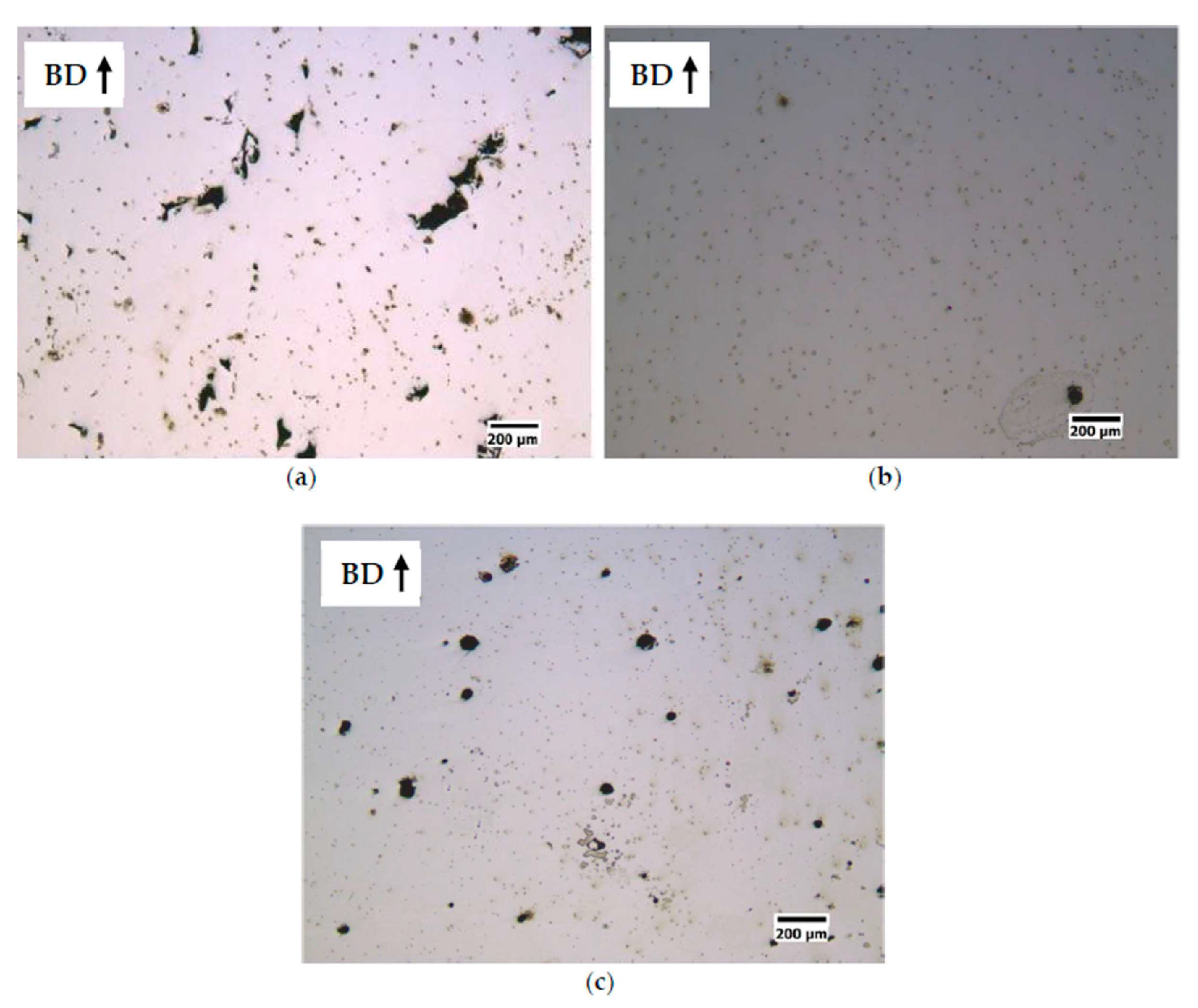

- Kang, N.; Li, Q.; El Mansori, M.; Yao, B.; Ma, F.; Lin, X.; Liao, H. Laser Powder Bed Fusion Processing of Soft Magnetic Fe–Ni–Si Alloys: Effect of Hot Isostatic Pressing Treatment. Chin. J. Mech. Eng. Addit. Manuf. Front. 2022, 1, 100054. [Google Scholar] [CrossRef]

- Garibaldi, M.; Ashcroft, I.; Simonelli, M.; Hague, R. Metallurgy of High-Silicon Steel Parts Produced Using Selective Laser Melting. Acta Mater. 2016, 110, 207–216. [Google Scholar] [CrossRef]

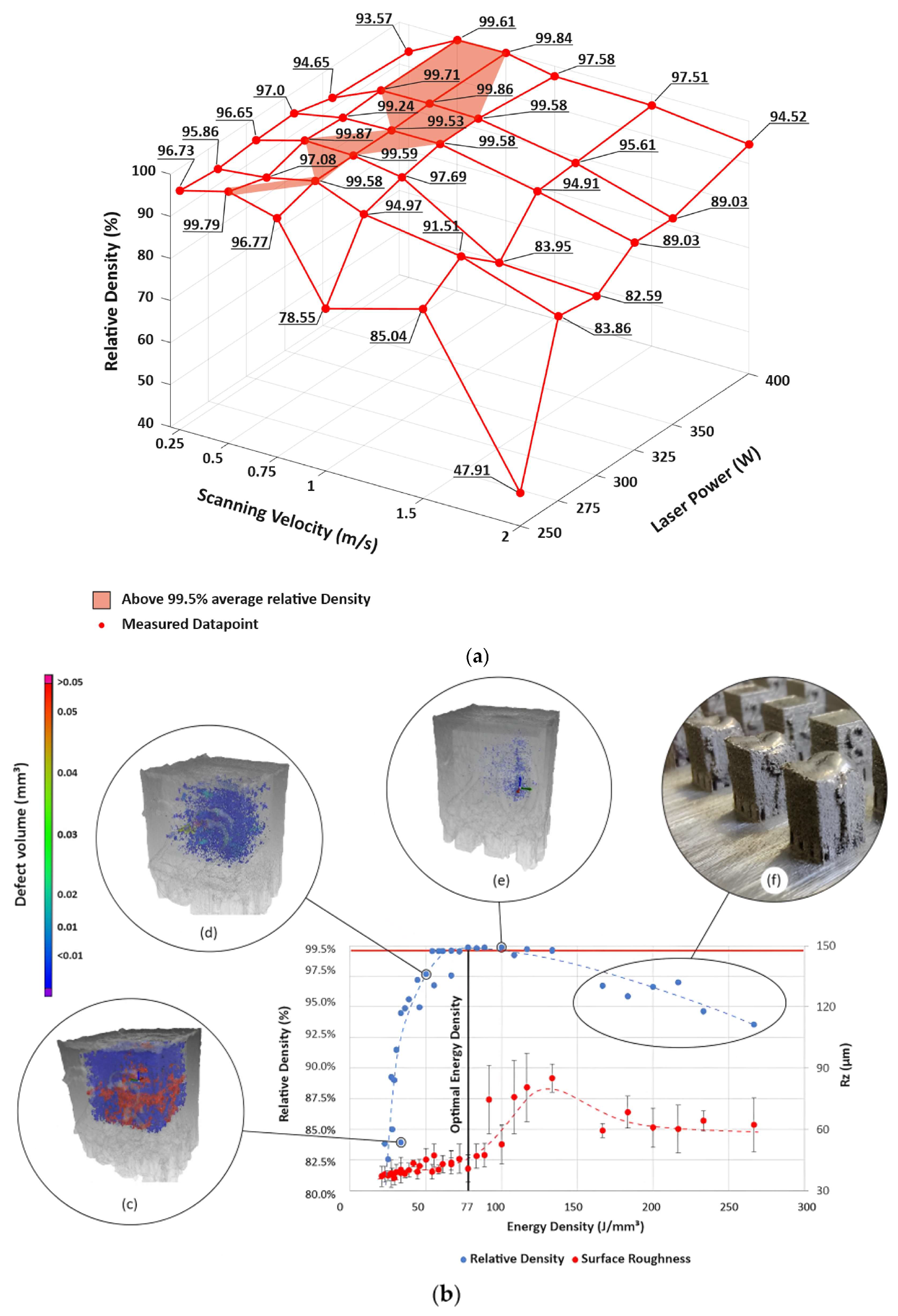

- Garibaldi, M.; Ashcroft, I.; Hillier, N.; Harmon, S.A.C.; Hague, R. Relationship between Laser Energy Input, Microstructures and Magnetic Properties of Selective Laser Melted Fe-6.9%wt Si Soft Magnets. Mater. Charact. 2018, 143, 144–151. [Google Scholar] [CrossRef]

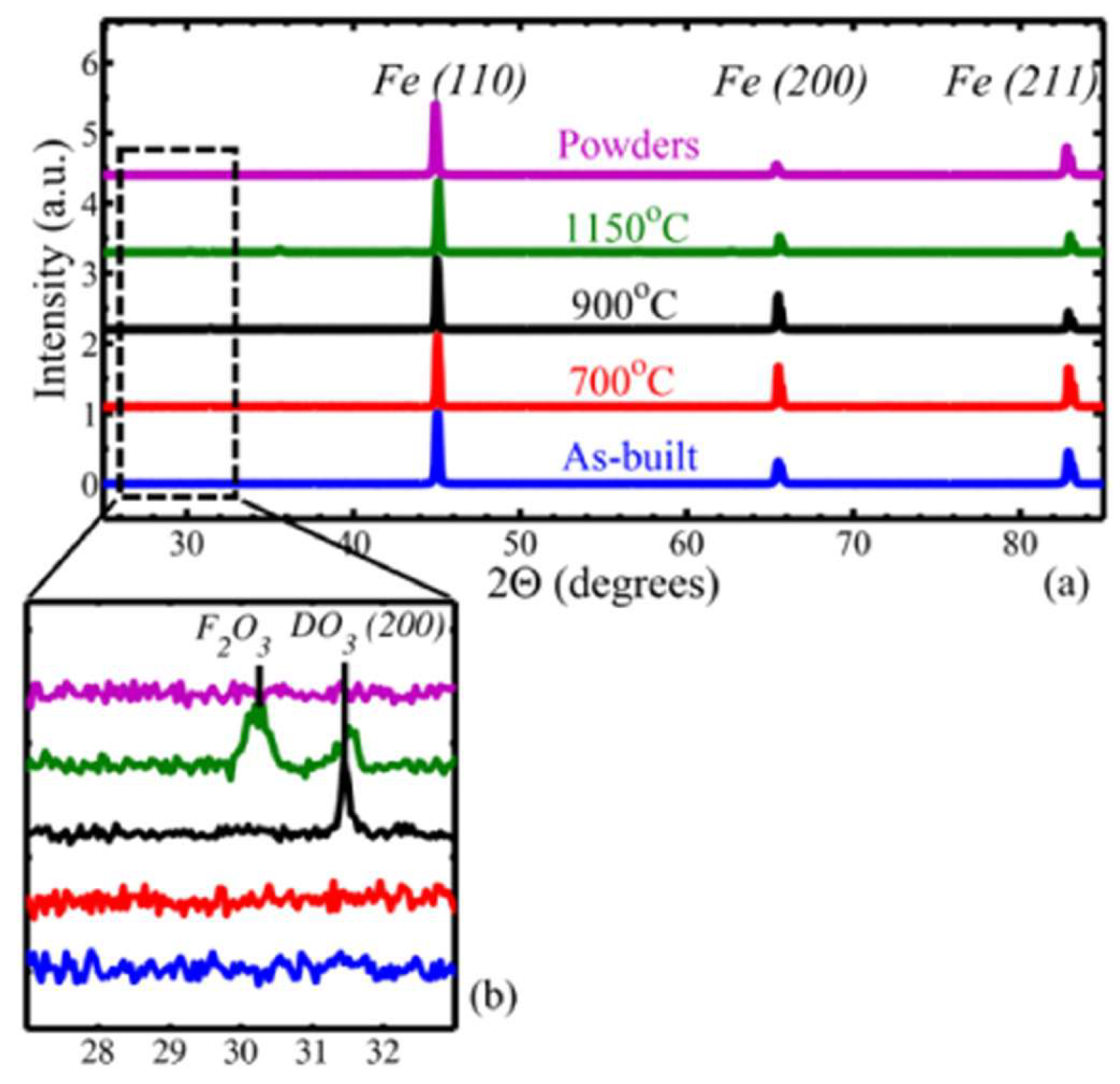

- Garibaldi, M.; Ashcroft, I.; Lemke, J.N.; Simonelli, M.; Hague, R. Effect of Annealing on the Microstructure and Magnetic Properties of Soft Magnetic Fe-Si Produced via Laser Additive Manufacturing. Scr. Mater. 2018, 142, 121–125. [Google Scholar] [CrossRef]

- Zaied, M.; Ospina-Vargas, A.; Buiron, N.; Favergeon, J.; Fenineche, N.-E. Additive Manufacturing of Soft Ferromagnetic Fe 6.5%Si Annular Cores: Process Parameters, Microstructure, and Magnetic Properties. IEEE Trans. Magn. 2022, 58, 2001420. [Google Scholar] [CrossRef]

- Di Schino, A.; Stornelli, G. Additive Manufacturing: A New Concept for End Users. The Case of Magnetic Materials. Acta Metall. Slovaca 2022, 28, 208–211. [Google Scholar] [CrossRef]

- Faba, A.; Riganti Fulginei, F.; Quondam Antonio, S.; Stornelli, G.; Di Schino, A.; Cardelli, E. Hysteresis Modelling in Additively Manufactured FeSi Magnetic Components for Electrical Machines and Drives. IEEE Trans. Ind. Electron. 2023, 1–9. [Google Scholar] [CrossRef]

- Stornelli, G.; Faba, A.; Di Schino, A.; Folgarait, P.; Ridolfi, M.R.; Cardelli, E.; Montanari, R. Properties of Additively Manufactured Electric Steel Powder Cores with Increased Si Content. Materials 2021, 14, 1489. [Google Scholar] [CrossRef]

- Stornelli, G.; Ridolfi, M.R.; Folgarait, P.; De Nisi, J.; Corapi, D.; Repitsch, C.; Di Schino, A. Feasibility Assessment of Magnetic Cores through Additive Manufacturing Techniques (Studio Di Fattibilità Della Fabbricazione Di Nuclei Ferromagnetici Attraverso Tecniche Di Manifattura Additiva). Metall. Ital. 2021, 113, 50–63. [Google Scholar]

- Seiler, N.; Kolb, D.; Schanz, J.; Goll, D.; Riegel, H. Influence of Modulated Laser Power on the Surface Topography and Microstructure in the Laser Powder Bed Fusion Process. Procedia CIRP 2022, 111, 693–696. [Google Scholar] [CrossRef]

- Agapovichev, A.V.; Khaimovich, A.I.; Erisov, Y.A.; Ryazanov, M. V Investigation of Soft Magnetic Material Fe-6.5Si Fracture Obtained by Additive Manufacturing. Materials 2022, 15, 8915. [Google Scholar] [CrossRef]

- Goll, D.; Schuller, D.; Martinek, G.; Kunert, T.; Schurr, J.; Sinz, C.; Schubert, T.; Bernthaler, T.; Riegel, H.; Schneider, G. Additive Manufacturing of Soft Magnetic Materials and Components. Addit. Manuf. 2019, 27, 428–439. [Google Scholar] [CrossRef]

- Chaudhary, V.; Sai Kiran Kumar Yadav, N.M.; Mantri, S.A.; Dasari, S.; Jagetia, A.; Ramanujan, R.V.; Banerjee, R. Additive Manufacturing of Functionally Graded Co–Fe and Ni–Fe Magnetic Materials. J. Alloys Compd. 2020, 823, 153817. [Google Scholar] [CrossRef]

- Chaudhary, V.; Borkar, T.; Mikler, C.V.; Gwalani, B.; Choudhuri, D.; Soni, V.; Alam, T.; Ramanujan, R.V.; Banerjee, R. Additively Manufactured Functionally Graded FeNi Based High Entropy Magnetic Alloys. In Proceedings of the 2018 IEEE International Magnetics Conference (INTERMAG), Singapore, 23–27 April 2018; p. 1. [Google Scholar]

- Yi, M.; Xu, B.-X.; Gutfleisch, O. Computational Study on Microstructure Evolution and Magnetic Property of Laser Additively Manufactured Magnetic Materials. Comput. Mech. 2019, 64, 917–935. [Google Scholar] [CrossRef] [Green Version]

- Mikler, C.V.; Chaudhary, V.; Borkar, T.; Soni, V.; Choudhuri, D.; Ramanujan, R.V.; Banerjee, R. Laser Additive Processing of Ni-Fe-V and Ni-Fe-Mo Permalloys: Microstructure and Magnetic Properties. Mater. Lett. 2017, 192, 9–11. [Google Scholar] [CrossRef]

- Mikler, C.V.; Chaudhary, V.; Borkar, T.; Soni, V.; Jaeger, D.; Chen, X.; Contieri, R.; Ramanujan, R.V.; Banerjee, R. Laser Additive Manufacturing of Magnetic Materials. JOM 2017, 69, 532–543. [Google Scholar] [CrossRef] [Green Version]

- Chaudhary, V.; Mantri, S.A.; Ramanujan, R.V.; Banerjee, R. Additive Manufacturing of Magnetic Materials. Prog. Mater. Sci. 2020, 114, 100688. [Google Scholar] [CrossRef]

- Yang, J.; Zhu, Q.; Wang, Z.; Xiong, F.; Li, Q.; Yang, F.; Li, R.; Ge, X.; Wang, M. Effects of Metallurgical Defects on Magnetic Properties of SLM NiFeMo Permalloy. Mater. Charact. 2023, 197, 112672. [Google Scholar] [CrossRef]

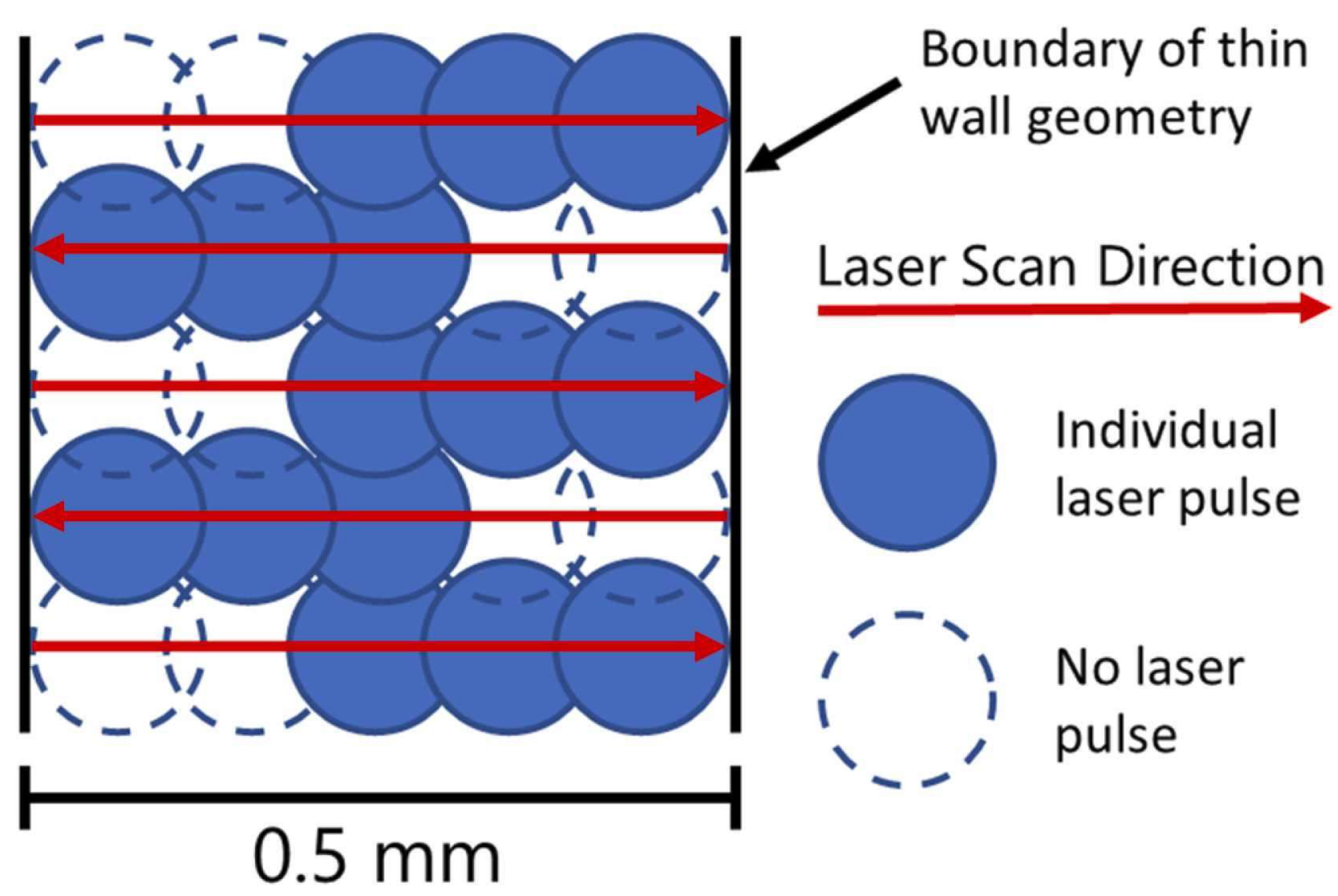

- Li, B.; Zhang, W.; Fu, W.; Xuan, F. Laser Powder Bed Fusion (L-PBF) 3D Printing Thin Overhang Walls of Permalloy for a Modified Honeycomb Magnetic-Shield Structure. Thin-Walled Struct. 2023, 182, 110185. [Google Scholar] [CrossRef]

- Kim, E.S.; Haftlang, F.; Ahn, S.Y.; Kwon, H.; Gu, G.H.; Kim, H.S. Mechanical and Magnetic Properties of Soft Magnetic Fe–Ni Permalloy Produced by Directed Energy Deposition Processes. J. Mater. Sci. 2022, 57, 17967–17983. [Google Scholar] [CrossRef]

- Kim, E.S.; Haftlang, F.; Ahn, S.Y.; Gu, G.H.; Kim, H.S. Effects of Processing Parameters and Heat Treatment on the Microstructure and Magnetic Properties of the In-Situ Synthesized Fe-Ni Permalloy Produced Using Direct Energy Deposition. J. Alloys Compd. 2022, 907, 164415. [Google Scholar] [CrossRef]

- Haftlang, F.; Kim, E.S.; Kim, H.S. Crystallographic-Orientation-Dependent Magnetic Properties of Fe–Ni Permalloy in-Situ Alloyed Using Additive Manufacturing. J. Mater. Process. Technol. 2022, 309, 117733. [Google Scholar] [CrossRef]

- Mohamed, A.E.-M.A.; Zou, J.; Sheridan, R.S.; Bongs, K.; Attallah, M.M. Magnetic Shielding Promotion via the Control of Magnetic Anisotropy and Thermal Post Processing in Laser Powder Bed Fusion Processed NiFeMo-Based Soft Magnet. Addit. Manuf. 2020, 32, 101079. [Google Scholar] [CrossRef]

- Kustas, A.B.; Susan, D.F.; Johnson, K.L.; Whetten, S.R.; Rodriguez, M.A.; Dagel, D.J.; Michael, J.R.; Keicher, D.M.; Argibay, N. Characterization of the Fe-Co-1.5V Soft Ferromagnetic Alloy Processed by Laser Engineered Net Shaping (LENS). Addit. Manuf. 2018, 21, 41–52. [Google Scholar] [CrossRef]

- Sundar, R.S.; Deevi, S.C. Soft Magnetic FeCo Alloys: Alloy Development, Processing, and Properties. Int. Mater. Rev. 2005, 50, 157–192. [Google Scholar] [CrossRef]

- Sreenivasulu, G.; Laletin, U.; Petrov, V.M.; Petrov, V.V.; Srinivasan, G. A Permendur-Piezoelectric Multiferroic Composite for Low-Noise Ultrasensitive Magnetic Field Sensors. Appl. Phys. Lett. 2012, 100, 173506. [Google Scholar] [CrossRef]

- Gould, H.L.B.; Wenny, D.H. Supermendur: A New Rectangular-Loop Magnetic Material. Electr. Eng. 1957, 76, 208–211. [Google Scholar] [CrossRef]

- Lindroos, T.; Riipinen, T.; Metsä-Kortelainen, S.; Pippuri-Mäkeläinen, J.; Manninen, A. Lessons Learnt—Additive Manufacturing of Iron Cobalt Based Soft Magnetic Materials. J. Magn. Magn. Mater. 2022, 563, 169977. [Google Scholar] [CrossRef]

- Riipinen, T.; Pippuri-Mäkeläinen, J.; Que, Z.; Metsä-Kortelainen, S.; Antikainen, A.; Lindroos, T. The Effect of Heat Treatment on Structure and Magnetic Properties of Additively Manufactured Fe-Co-V Alloys. Mater. Today Commun. 2023, 36, 106437. [Google Scholar] [CrossRef]

- Nartu, M.S.K.K.Y.; Dasari, S.; Sharma, A.; Chaudhary, V.; Varahabhatla, S.M.; Mantri, S.A.; Ivanov, E.; Ramanujan, R.V.; Dahotre, N.B.; Banerjee, R. Reducing Coercivity by Chemical Ordering in Additively Manufactured Soft Magnetic Fe–Co (Hiperco) Alloys. J. Alloys Compd. 2021, 861, 157998. [Google Scholar] [CrossRef]

- Kustas, A.B.; Fancher, C.M.; Whetten, S.R.; Dagel, D.J.; Michael, J.R.; Susan, D.F. Controlling the Extent of Atomic Ordering in Intermetallic Alloys through Additive Manufacturing. Addit. Manuf. 2019, 28, 772–780. [Google Scholar] [CrossRef]

- Borkar, T.; Conteri, R.; Chen, X.; Ramanujan, R.V.; Banerjee, R. Laser Additive Processing of Functionally-Graded Fe–Si–B–Cu–Nb Soft Magnetic Materials. Mater. Manuf. Process. 2017, 32, 1581–1587. [Google Scholar] [CrossRef]

- Conteri, R.; Borkar, T.; Nag, S.; Jaeger, D.; Chen, X.; Ramanujan, R.V.; Banerjee, R. Laser Additive Processing of Fe-Si-B-Cu-Nb Magnetic Alloys. J. Manuf. Process. 2017, 29, 175–181. [Google Scholar] [CrossRef]

- Dobrzanski, L.A.; Nowosielski, R.; Konieczny, J.; Przybył, A.; Wysłocki, J. Structure and Properties of Nanocrystalline Soft Magnetic Composite Materials with Silicon Polymer Matrix. J. Magn. Magn. Mater. 2005, 290–291, 1510–1512. [Google Scholar] [CrossRef]

- Nowosielski, R.; Wysłocki, J.J.; Wnuk, I.; Gramatyka, P. Nanocrystalline Soft Magnetic Composite Cores. J. Mater. Process. Technol. 2006, 175, 324–329. [Google Scholar] [CrossRef]

- Shokrollahi, H.; Janghorban, K. The Effect of Compaction Parameters and Particle Size on Magnetic Properties of Iron-Based Alloys Used in Soft Magnetic Composites. Mater. Sci. Eng. B 2006, 134, 41–43. [Google Scholar] [CrossRef]

- Chicinas, I.; Geoffroy, O.; Isnard, O.; Pop, V. Soft Magnetic Composite Based on Mechanically Alloyed Nanocrystalline Ni3Fe Phase. J. Magn. Magn. Mater. 2005, 290–291, 1531–1534. [Google Scholar] [CrossRef]

- Rimal, H.P.; Stornelli, G.; Faba, A.; Cardelli, E. Macromagnetic Approach to the Modeling in Time Domain of Magnetic Losses of Ring Cores of Soft Ferrites in Power Electronics. IEEE Trans. Power Electron. 2023, 38, 3559–3568. [Google Scholar] [CrossRef]

- Sharma, K.; Aggarwal, N.; Kumar, N.; Sharma, A. A Review Paper: Synthesis Techniques and Advance Application of Mn-Zn Nano-Ferrites. Mater. Today Proc. 2023, in press. [CrossRef]

- Liu, L.; Ge, T.; Ngo, K.D.T.; Mei, Y.; Lu, G.-Q. Ferrite Paste Cured with Ultraviolet Light for Additive Manufacturing of Magnetic Components for Power Electronics. IEEE Magn. Lett. 2018, 9, 5102705. [Google Scholar] [CrossRef]

- Liu, L.; Ge, T.; Yan, Y.; Ngo, K.D.T.; Lu, G.-Q. UV-Assisted 3D-Printing of Soft Ferrite Magnetic Components for Power Electronics Integration. In Proceedings of the 2017 International Conference on Electronics Packaging (ICEP), Yamagata, Japan, 19–22 April 2017; pp. 447–450. [Google Scholar]

- Andrews, C.E.; Chatham, M.P.; Dorman, S.F.; McCue, I.D.; Sopcisak, J.J.; Taheri, M.L. Additive Manufacturing of NiZnCu-Ferrite Soft Magnetic Composites. J. Mater. Res. 2021, 36, 3579–3590. [Google Scholar] [CrossRef]

- Tiismus, H.; Kallaste, A.; Vaimann, T.; Lind, L.; Virro, I.; Rassõlkin, A.; Dedova, T. Laser Additively Manufactured Magnetic Core Design and Process for Electrical Machine Applications. Energies 2022, 15, 3665. [Google Scholar] [CrossRef]

- Komatsubara, M.; Sadahiro, K.; Kondo, O.; Takamiya, T.; Honda, A. Newly Developed Electrical Steel for High-Frequency Use. J. Magn. Magn. Mater. 2002, 242–245, 212–215. [Google Scholar] [CrossRef]

- Haiji, H.; Okada, K.; Hiratani, T.; Abe, M.; Ninomiya, M. Magnetic Properties and Workability of 6.5% Si Steel Sheet. J. Magn. Magn. Mater. 1996, 160, 109–114. [Google Scholar] [CrossRef]

- Takada, Y.; Abe, M.; Masuda, S.; Inagaki, J. Commercial Scale Production of Fe-6.5 Wt. % Si Sheet and Its Magnetic Properties. J. Appl. Phys. 1988, 64, 5367–5369. [Google Scholar] [CrossRef]

- Cullity, B.D.; Graham, C.D. Introduction to Magnetic Materials; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2008; ISBN 9780470386323. [Google Scholar]

- Bozorth, R.M. IronSilicon Alloys. In Ferromagnetism; Wiley-IEEE Press: Hoboken, NJ, USA, 1978; pp. 67–101. [Google Scholar]

- Ustinovshikov, Y.; Sapegina, I. Morphology of Ordering Fe-Si Alloys. J. Mater. Sci. 2004, 39, 1007–1016. [Google Scholar] [CrossRef]

- Ghassemi, M. High Power Density Technologies for Large Generators and Motors for Marine Applications with Focus on Electrical Insulation Challenges. High Volt. 2020, 5, 7–14. [Google Scholar] [CrossRef]

- Maklakov, S.S.; Naboko, A.S.; Maklakov, S.A.; Bobrovskii, S.Y.; Polozov, V.I.; Zezyulina, P.A.; Osipov, A.V.; Ryzhikov, I.A.; Rozanov, K.N.; Filimonov, D.F.; et al. Amorphization of Thin Supermalloy Films Ni79Fe17Mo4 with Oxygen during Magnetron Sputtering. J. Alloys Compd. 2021, 854, 157097. [Google Scholar] [CrossRef]

- Li, B.; Fu, W.; Xu, H.; Qian, B.; Xuan, F. Additively Manufactured Ni-15Fe-5Mo Permalloy via Selective Laser Melting and Subsequent Annealing for Magnetic-Shielding Structures: Process, Micro-Structural and Soft-Magnetic Characteristics. J. Magn. Magn. Mater. 2020, 494, 165754. [Google Scholar] [CrossRef]

- Schönrath, H.; Spasova, M.; Kilian, S.O.; Meckenstock, R.; Witt, G.; Sehrt, J.T.; Farle, M. Additive Manufacturing of Soft Magnetic Permalloy from Fe and Ni Powders: Control of Magnetic Anisotropy. J. Magn. Magn. Mater. 2019, 478, 274–278. [Google Scholar] [CrossRef]

- Waeckerlé, T.; Demier, A.; Godard, F.; Fraisse, H. Evolution and Recent Developments of 80%Ni Permalloys. J. Magn. Magn. Mater. 2020, 505, 166635. [Google Scholar] [CrossRef]

- Hamler, A.; Goričan, V.; Šuštaršič, B.; Sirc, A. The Use of Soft Magnetic Composite Materials in Synchronous Electric Motor. J. Magn. Magn. Mater. 2006, 304, e816–e819. [Google Scholar] [CrossRef]

- Yoshida, S.; Mizushima, T.; Hatanai, T.; Inoue, A. Preparation of New Amorphous Powder Cores Using Fe-Based Glassy Alloy. IEEE Trans. Magn. 2000, 36, 3424–3429. [Google Scholar] [CrossRef]

- Hasegawa, R. Design and Fabrication of New Soft Magnetic Materials. J. Non Cryst. Solids 2003, 329, 1–7. [Google Scholar] [CrossRef]

- Louis, S.J.; Jan, B.; Willem, L.M. Manganese Zinc Ferrite Core. US Patent 2,551,711, 8 May 1951. [Google Scholar]

- Yeh, J.-W.; Chen, S.-K.; Lin, S.-J.; Gan, J.-Y.; Chin, T.-S.; Shun, T.-T.; Tsau, C.-H.; Chang, S.-Y. Nanostructured High-Entropy Alloys with Multiple Principal Elements: Novel Alloy Design Concepts and Outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Cantor, B.; Chang, I.T.H.; Knight, P.; Vincent, A.J.B. Microstructural Development in Equiatomic Multicomponent Alloys. Mater. Sci. Eng. A 2004, 375–377, 213–218. [Google Scholar] [CrossRef]

- Gan, G.-Y.; Ma, L.; Luo, D.-M.; Jiang, S.; Tang, B.-Y. Influence of Al Substitution for Sc on Thermodynamic Properties of HCP High Entropy Alloy Hf0.25Ti0.25Zr0.25Sc0.25-XAlx from First-Principles Investigation. Phys. B Condens. Matter 2020, 593, 412272. [Google Scholar] [CrossRef]

- Alijani, F.; Reihanian, M.; Gheisari, K. Study on Phase Formation in Magnetic FeCoNiMnV High Entropy Alloy Produced by Mechanical Alloying. J. Alloys Compd. 2019, 773, 623–630. [Google Scholar] [CrossRef]

- Guo, S.; Liu, C.T. Phase Stability in High Entropy Alloys: Formation of Solid-Solution Phase or Amorphous Phase. Prog. Nat. Sci. Mater. Int. 2011, 21, 433–446. [Google Scholar] [CrossRef] [Green Version]

- Wu, Z.; Wang, C.; Zhang, Y.; Feng, X.; Gu, Y.; Li, Z.; Jiao, H.; Tan, X.; Xu, H. The AC Soft Magnetic Properties of FeCoNixCuAl (1.0 ≤ x ≤ 1.75) High-Entropy Alloys. Materials 2019, 12, 4222. [Google Scholar] [CrossRef] [Green Version]

- Na, S.-M.; Lambert, P.K.; Jones, N.J. Hard Magnetic Properties of FeCoNiAlCuXTiX Based High Entropy Alloys. AIP Adv. 2021, 11, 015210. [Google Scholar] [CrossRef]

- Miracle, D.B.; Senkov, O.N. A Critical Review of High Entropy Alloys and Related Concepts. Acta Mater. 2017, 122, 448–511. [Google Scholar] [CrossRef] [Green Version]

- Chen, C.; Zhang, H.; Fan, Y.; Zhang, W.; Wei, R.; Wang, T.; Zhang, T.; Li, F. A Novel Ultrafine-Grained High Entropy Alloy with Excellent Combination of Mechanical and Soft Magnetic Properties. J. Magn. Magn. Mater. 2020, 502, 166513. [Google Scholar] [CrossRef]

- Zhao, C.C.; Inoue, A.; Kong, F.L.; Zhang, J.Y.; Chen, C.J.; Shen, B.L.; Al-Marzouki, F.; Greer, A.L. Novel Phase Decomposition, Good Soft-Magnetic and Mechanical Properties for High-Entropy (Fe0.25Co0.25Ni0.25Cr0.125Mn0.125)100–B (x = 9–13) Amorphous Alloys. J. Alloys Compd. 2020, 843, 155917. [Google Scholar] [CrossRef]

- Zhang, Q.; Xu, H.; Tan, X.H.; Hou, X.L.; Wu, S.W.; Tan, G.S.; Yu, L.Y. The Effects of Phase Constitution on Magnetic and Mechanical Properties of FeCoNi(CuAl) (x = 0–1.2) High-Entropy Alloys. J. Alloys Compd. 2017, 693, 1061–1067. [Google Scholar] [CrossRef]

- Feng, X.; Zheng, R.; Wu, Z.; Zhang, Y.; Li, Z.; Tan, X.; Xu, H. Study on a New High-Entropy Alloy Nd20Pr20La20Fe20Co10Al10 with Hard Magnetic Properties. J. Alloys Compd. 2021, 882, 160640. [Google Scholar] [CrossRef]

- Chen, H.; Gou, J.; Jia, W.; Song, X.; Ma, T. Origin of Hard Magnetism in Fe-Co-Ni-Al-Ti-Cu High-Entropy Alloy: Chemical Shape Anisotropy. Acta Mater. 2023, 246, 118702. [Google Scholar] [CrossRef]

- Radhakrishnan, M.; McKinstry, M.; Chaudhary, V.; Nartu, M.S.K.K.Y.; Krishna, K.V.M.; Ramanujan, R.V.; Banerjee, R.; Dahotre, N.B. Effect of Chromium Variation on Evolution of Magnetic Properties in Laser Direct Energy Additively Processed CoCrxFeNi Alloys. Scr. Mater. 2023, 226, 115269. [Google Scholar] [CrossRef]

- Zhou, R.; Liu, Y.; Zhou, C.; Li, S.; Wu, W.; Song, M.; Liu, B.; Liang, X.; Liaw, P.K. Microstructures and Mechanical Properties of C-Containing FeCoCrNi High-Entropy Alloy Fabricated by Selective Laser Melting. Intermetallics 2018, 94, 165–171. [Google Scholar] [CrossRef]

- Park, J.M.; Choe, J.; Kim, J.G.; Bae, J.W.; Moon, J.; Yang, S.; Kim, K.T.; Yu, J.-H.; Kim, H.S. Superior Tensile Properties of 1%C-CoCrFeMnNi High-Entropy Alloy Additively Manufactured by Selective Laser Melting. Mater. Res. Lett. 2020, 8, 1–7. [Google Scholar] [CrossRef] [Green Version]

- Nartu, M.S.K.K.Y.; Jagetia, A.; Chaudhary, V.; Mantri, S.A.; Ivanov, E.; Dahotre, N.B.; Ramanujan, R.V.; Banerjee, R. Magnetic and Mechanical Properties of an Additively Manufactured Equiatomic CoFeNi Complex Concentrated Alloy. Scr. Mater. 2020, 187, 30–36. [Google Scholar] [CrossRef]

- Yang, X.; Cui, X.; Jin, G.; Liu, J.; Chen, Y.; Liu, Z. Soft Magnetic Property of (Fe60Co35Ni5)78 Si6B12Cu1Mo3 Alloys by Laser Additive Manufacturing. J. Magn. Magn. Mater. 2018, 466, 75–80. [Google Scholar] [CrossRef]

| SMMs | Saturation Magnetization MS (T) | Relative Permeability μr | Core Resistivity r (μΩcm) | AM | Ref. | |

|---|---|---|---|---|---|---|

| Fe–Si | Fe–(2.9–3.7) Si | 2.10 | 25 | 20–50 | L-PBF, SLM | [87,88,89,90,91,92,93,94] |

| Fe–(6.5–6.9) Si | 1.9 | 11,000 | 85 | [95,96,97,98,99,100,101,102,103,104,105] | ||

| Fe–Ni | 0.60–1.10 | 8000–100,000 | - | L-PBF, SLM, DED | [106,107,108,109,110,111,112,113,114,115,116,117] | |

| Fe–Co | 2.4–2.5 | 20,000–60,000 | 45 | L-PBF, LENS | [118,119,120,121,122,123,124,125] | |

| SMCs | 0.50–1.30 | 6000–100,000 | 120–130 | SLM, DED, SPS | [52,126,127,128,129,130,131] | |

| Soft Ferrites | 0.32–0.545 | 350–20,000 | 107 × 109 | L-PBF, DED | [132,133,134,135,136] | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rodriguez-Vargas, B.R.; Stornelli, G.; Folgarait, P.; Ridolfi, M.R.; Miranda Pérez, A.F.; Di Schino, A. Recent Advances in Additive Manufacturing of Soft Magnetic Materials: A Review. Materials 2023, 16, 5610. https://doi.org/10.3390/ma16165610

Rodriguez-Vargas BR, Stornelli G, Folgarait P, Ridolfi MR, Miranda Pérez AF, Di Schino A. Recent Advances in Additive Manufacturing of Soft Magnetic Materials: A Review. Materials. 2023; 16(16):5610. https://doi.org/10.3390/ma16165610

Chicago/Turabian StyleRodriguez-Vargas, Bryan Ramiro, Giulia Stornelli, Paolo Folgarait, Maria Rita Ridolfi, Argelia Fabiola Miranda Pérez, and Andrea Di Schino. 2023. "Recent Advances in Additive Manufacturing of Soft Magnetic Materials: A Review" Materials 16, no. 16: 5610. https://doi.org/10.3390/ma16165610

APA StyleRodriguez-Vargas, B. R., Stornelli, G., Folgarait, P., Ridolfi, M. R., Miranda Pérez, A. F., & Di Schino, A. (2023). Recent Advances in Additive Manufacturing of Soft Magnetic Materials: A Review. Materials, 16(16), 5610. https://doi.org/10.3390/ma16165610