Topological Design of Two-Dimensional Phononic Crystals Based on Genetic Algorithm

Abstract

:1. Introduction

2. Simulation Models and Calculation Methods

3. Topological Optimization Design of Binary Microstructural Phononic Crystals

3.1. Algorithmic Description of Binary Materials

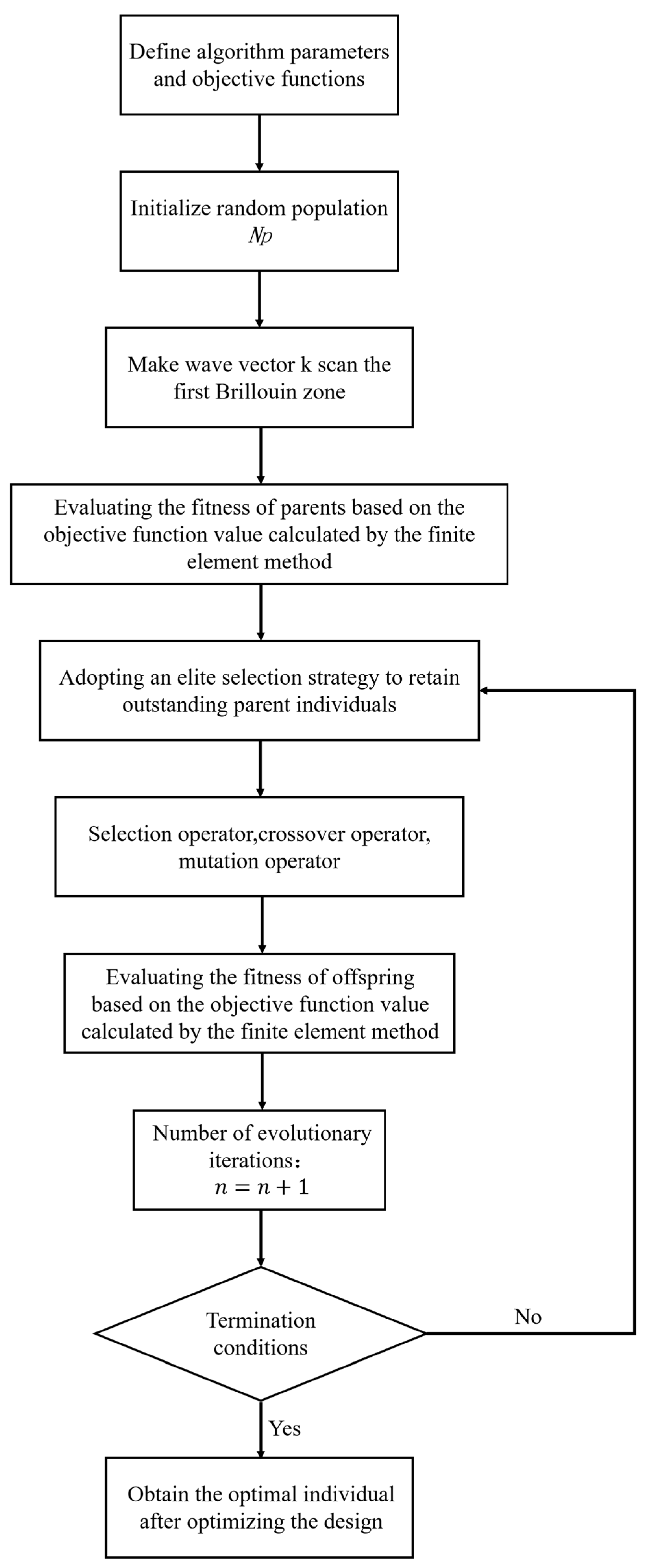

3.2. Improved Genetic Algorithm

- (1)

- The generation of the initial population.

- (2)

- The fitness functions.

- (3)

- The determination of genetic operators.

- (4)

- The termination conditions.

4. Results and Discussions

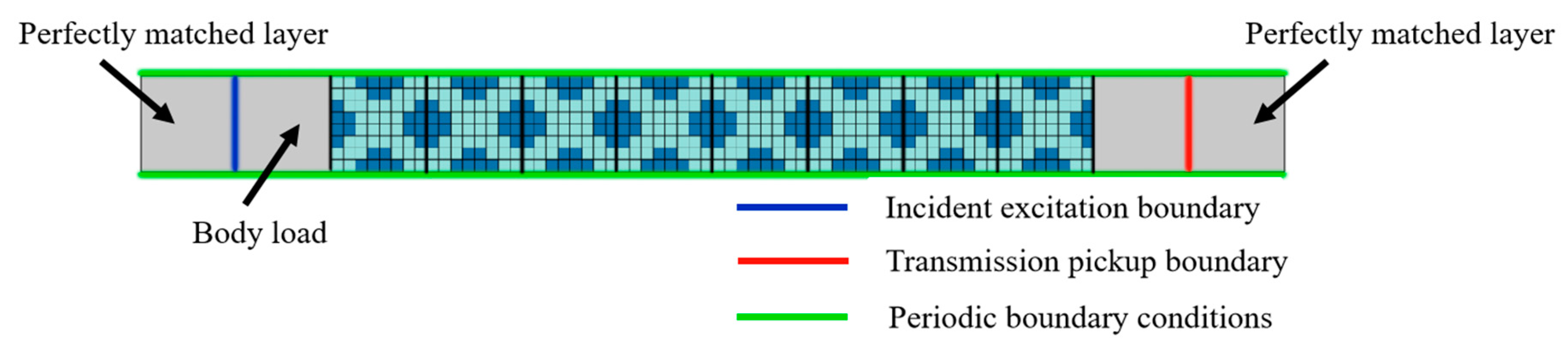

4.1. Transmission Loss

- (1)

- Materials with large impedance differences are more likely to exhibit bandgaps.

- (2)

- According to the band-gap mechanism of phononic crystals, it is known that the center frequency of the lowest bandgap generated by Bragg-type phononic crystals is approximately c/2a, where c is the elastic wave velocity and the lattice size. Therefore, phononic crystals based on Bragg scattering mechanisms are more likely to generate medium-to-high frequency bandgaps, while localized resonance mechanisms, with their ability to control large wavelengths through small dimensions, are more likely to open bandgaps at lower frequencies.

- (3)

- For locally resonant phononic crystals, the frequency range can be controlled by adjusting the effective spring constant of the unit-cell structure and the block mass of the scatterers, as indicated by the frequency formula of the spring-mass oscillator model.

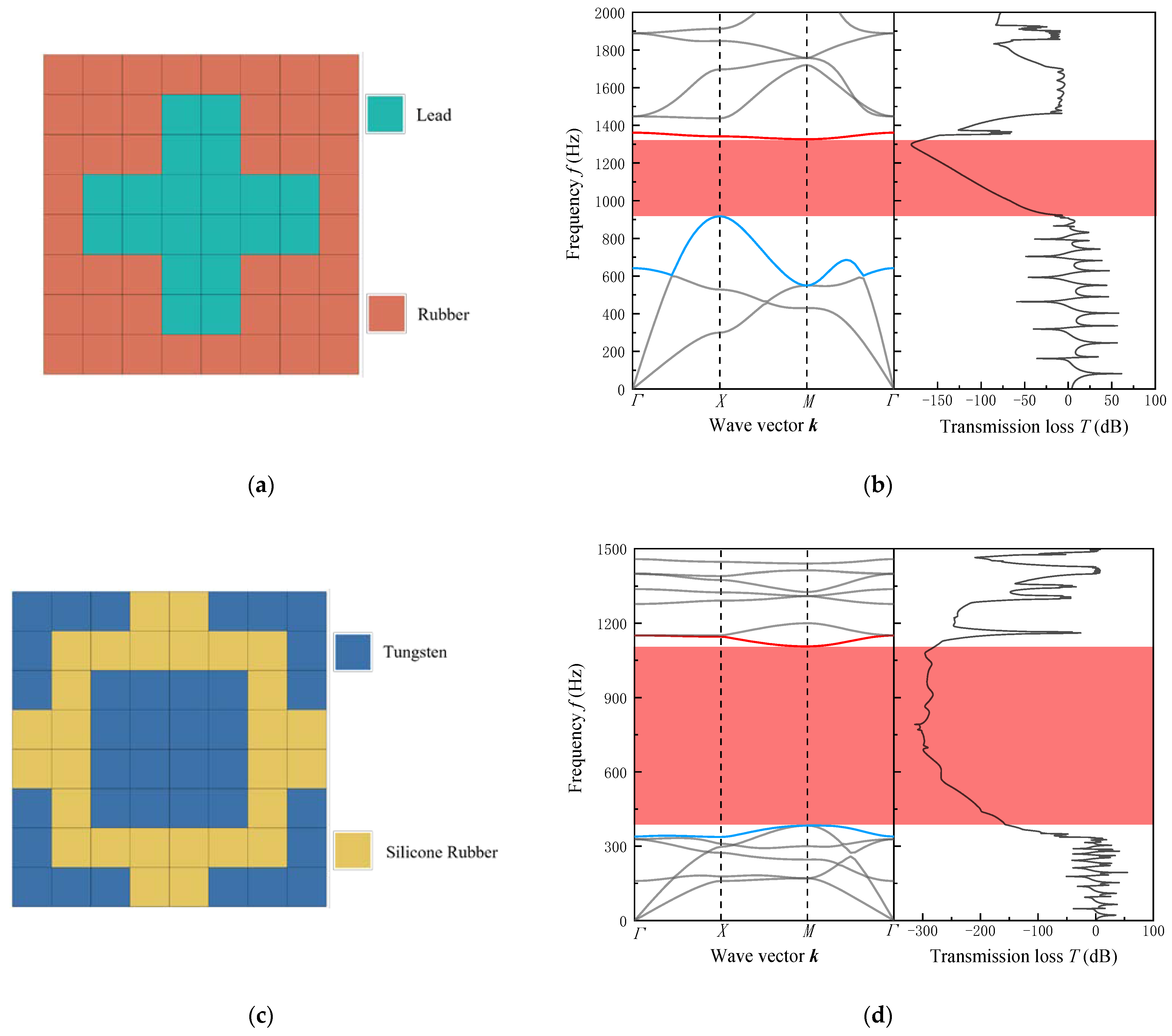

4.2. Case 1: Maximizing Relative Bandwidth in the Specified Mid–Low Frequency Range

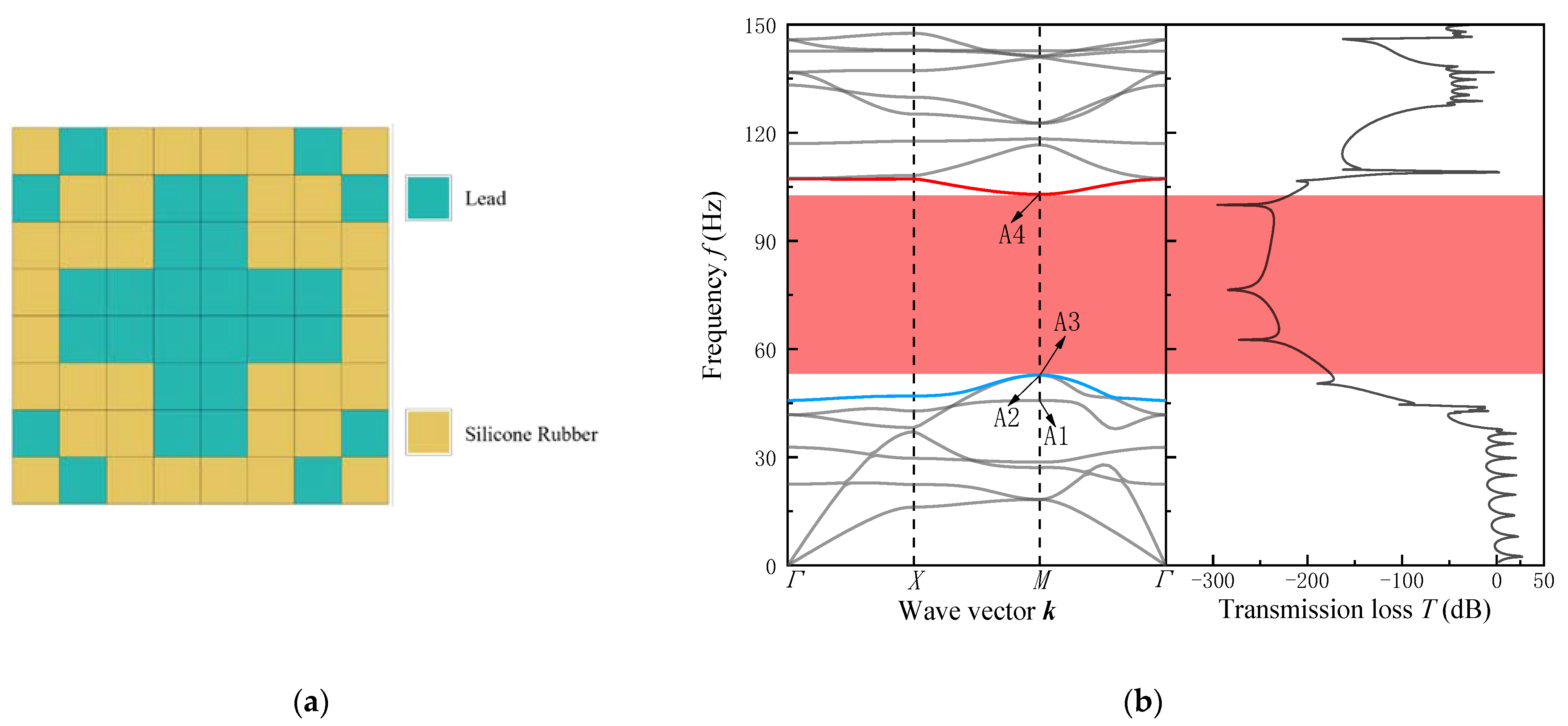

4.3. Case 2: Maximizing Relative Bandwidth in the Specified Ultra-Low Frequency Range

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, T.T.; Tian, L.Q.; Ma, W.L. Research Progress of Phononic Crystals in the Field of Vibration and Noise Reduction in Marine Engineering. Ship Stand. Eng. 2022, 55, 22. (In Chinese) [Google Scholar]

- Ruan, Y.D.; Liang, X.; Hua, X.Y.; Zhang, C.; Xia, H.; Cheng, L. Isolating Low-Frequency Vibration From Power Systems on a Ship Using Spiral Phononic Crystals. Ocean. Eng. 2021, 225, 108804. [Google Scholar] [CrossRef]

- Shao, J.; Yang, J.; Wu, X.; Zeng, T. Nonlinear Energy Sink Applied for Low-Frequency Noise Control Inside Acoustic Cavities: A Review. Vib. Act. Control. 2021, 40, 1453–1472. [Google Scholar] [CrossRef]

- La Paglia, I.; Rapino, L.; Ripamonti, F.; Corradi, R.; Simone, B. An in-Plane Flexible Ring Model for the Analysis of the Free and Forced Response of a Rolling Tyre. In Internoise 2022—51st International Congress and Exposition on Noise Control Engineering; Institute of Noise Control Engineering: Washington, DC, USA, 2023; Volume 265, pp. 5133–5140. [Google Scholar]

- Chauhan, V.; Darpe, A.; Bijwe, J. Susceptibility of Eco-Friendly Brake-Pads to Noise-Vibration Emanation Due to Siloxane Treatment on Alumina Particles. Appl. Acoust. 2022, 185, 108377. [Google Scholar] [CrossRef]

- Huang, H.B.; Wu, J.H.; Huang, X.R.; Yang, M.L.; Ding, W.P. A Generalized Inverse Cascade Method to Identify and Optimize Vehicle Interior Noise Sources. J. Sound. Vib. 2020, 467, 115062. [Google Scholar] [CrossRef]

- Shi, G.T.; Yang, L.; Zhang, X.A.; Zhang, X.Y. Influence of Vehicle Suspension System Parameters on Acoustic Radiation Characteristics of Rubber Floating Plate Structure. In Second International Conference on Rail Transportation; American Society of Civil Engineers: Reston, VA, USA, 2021; pp. 166–175. [Google Scholar]

- Song, Y.B.; Wen, J.H.; Tian, H.; Lu, X.Y.; Li, Z.C.; Feng, L.P. Vibration and Sound Properties of Metamaterial Sandwich Panels with Periodically Attached Resonators: Simulation and Experiment Study. J. Sound. Vib. 2020, 489, 115644. [Google Scholar] [CrossRef]

- Jin, Y.; Jia, X.-Y.; Wu, Q.-Q.; He, X.; Yu, G.-C.; Wu, L.-Z.; Luo, B. Design of Vibration Isolators by Using the Bragg Scattering and Local Resonance Band Gaps in a Layered Honeycomb Meta-Structure. J. Sound. Vib. 2022, 521, 116721. [Google Scholar] [CrossRef]

- Ahmed, R.; Ahmed, H. Influence of Resonator Configuration on Band Gap Range in Acoustic Metamaterials. In Proceedings of the 2021 12th International Conference on Mechanical and Aerospace Engineering (ICMAE), Athens, Greece, 16–19 July 2021; pp. 339–342. [Google Scholar]

- Liao, G.X.; Luan, C.C.; Wang, Z.W.; Liu, J.P.; Yao, X.H.; Fu, J.Z. Acoustic Metamaterials: A Review of Theories, Structures, Fabrication Approaches, and Applications. Adv. Mater. Technol. 2021, 6, 2000787. [Google Scholar] [CrossRef]

- Pires, F.A.; Sangiuliano, L.; Denayer, H.; Deckers, E.; Desmet, W.; Claeys, C. The Use of Locally Resonant Metamaterials to Reduce Flow-Induced Noise and Vibration. J. Sound. Vib. 2022, 535, 117106. [Google Scholar] [CrossRef]

- Xu, G.G.; Sun, X.W.; Li, R.S.; Zhang, Z.R.; Song, T.; Liu, Z.J. The Low-Frequency Bandgap Characteristics of a New Three-Dimensional Multihole Phononic Crystal. Appl. Phys. A 2021, 127, 812. [Google Scholar] [CrossRef]

- Zhou, P.; Wan, S.; Wang, X.; Fu, J.D.; Zhu, Y.B. A Novel Hybrid Composite Phononic Crystal Plate with Multiple Vibration Band Gaps at Low Frequencies. Phys. B Condens. Matter 2021, 623, 413366. [Google Scholar] [CrossRef]

- Xuan, C.M.; Xu, W.K.; Yang, Z.; Qi, W.C.; Wang, W. Broadband Tunable Elastic Metastructure Based on One-Dimensional Phononic Crystal. J. Appl. Phys. 2021, 129, 245102. [Google Scholar] [CrossRef]

- Yan, W.; Zhang, G.; Gao, Y.W. Investigation on the Tunability of the Band Structure of Two-Dimensional Magnetorheological Elastomers Phononic Crystals Plate. J. Magn. Magn. Mater. 2022, 544, 168704. [Google Scholar] [CrossRef]

- Park, S.; Jeon, W. Ultra-Wide Low-Frequency Band Gap in a Tapered Phononic Beam. J. Sound. Vib. 2021, 499, 115977. [Google Scholar] [CrossRef]

- Miao, L.C.; Li, C.; Lei, L.J.; Fang, H.L.; Liang, X.D. A New Periodic Structure Composite Material with Quasi-Phononic Crystals. Phys. Lett. A 2020, 384, 126594. [Google Scholar] [CrossRef]

- Wu, K.; Hu, H.Y.; Wang, L.F.; Gao, Y.Q. Parametric Optimization of an Aperiodic Metastructure Based on Genetic Algorithm. Int. J. Mech. Sci. 2022, 214, 106878. [Google Scholar] [CrossRef]

- Chen, L.Y.; Guo, Y.J.; Yi, H. Optimization Study of Bandgaps Properties for Two-Dimensional Chiral Phononic Crystals Base on Lightweight Design. Phys. Lett. A 2021, 388, 127054. [Google Scholar] [CrossRef]

- Zhao, C.Y.; Zheng, J.Y.; Sang, T.; Wang, L.C.; Yi, Q.; Wang, P. Computational Analysis of Phononic Crystal Vibration Isolators via FEM Coupled with the Acoustic Black Hole Effect to Attenuate Railway-Induced Vibration. Constr. Build. Mater. 2021, 283, 122802. [Google Scholar] [CrossRef]

- Panahi, E.; Hosseinkhani, A.; Khansanami, M.F.; Younesian, D.; Ranjbar, M. Novel Cross Shape Phononic Crystals with Broadband Vibration Wave Attenuation Characteristic: Design, Modeling and Testing. Thin. Wall. Struct. 2021, 163, 107665. [Google Scholar] [CrossRef]

- Pan, Y.; Liu, R.; Bin, G.F.; He, X.H. Vibration and Noise Reduction of Phononic Crystal Structure Laid on the Noise Transmission Path of Axial Piston Pump. Appl. Acoust. 2022, 200, 109075. [Google Scholar] [CrossRef]

- Shao, H.B.; He, H.; He, C.; Chen, G.P. Study on the Band Gap Optimization and Defect State of Two-Dimensional Honeycomb Phononic Crystals. J. Mater. Res. 2020, 35, 3021–3030. [Google Scholar] [CrossRef]

- Cui, R.X.; Zhou, J.S.; Gong, D. Band Gap and Vibration Reduction Properties of Damped Rail with Two-Dimensional Honeycomb Phononic Crystals. Shock Vib. 2021, 2021, 8814962. [Google Scholar] [CrossRef]

- Li, C.; Zhang, S.F.; Gao, L.Y.; Huang, W.; Liu, Z.X. Vibration Attenuation Investigations on a Distributed Phononic Crystals Beam for Rubber Concrete Structures. Math. Probl. Eng. 2021, 2021, 9982376. [Google Scholar] [CrossRef]

- Meng, H.; Bailey, N.; Chen, Y.; Wang, L.; Ciampa, F.; Fabro, A.; Chronopoulos, D.; Elmadih, W. 3D Rainbow Phononic Crystals for Extended Vibration Attenuation Bands. Sci. Rep. 2020, 10, 18989. [Google Scholar] [CrossRef]

- Wu, Q.B.; He, J.J.; Chen, W.J.; Li, Q.H.; Liu, S.T. Topology Optimization of Phononic Crystal with Prescribed Band Gaps. Comput. Methods Appl. Mech. Eng. 2023, 412, 116071. [Google Scholar] [CrossRef]

- Li, X.F.; Cheng, S.L.; Wang, R.; Yan, Q.; Wang, B.; Sun, Y.T.; Yan, H.; Zhao, Q.X.; Xin, Y.J. Design of Novel Two-Dimensional Single-Phase Chiral Phononic Crystal Assembly Structures and Study of Bandgap Mechanism. Results Phys. 2023, 48, 106431. [Google Scholar] [CrossRef]

- Wen, G.L.; Ou, H.F.; Liu, J. Ultra-Wide Band gap in a Two-Dimensional Phononic Crystal with Hexagonal Lattices. Mater. Today Commun. 2020, 24, 10977. [Google Scholar] [CrossRef]

- Sharma, A.K.; Kosta, M.; Shmuel, G.; Amir, O. Gradient-Based Topology Optimization of Soft Dielectrics as Tunable Phononic Crystals. Compos. Struct. 2022, 280, 114846. [Google Scholar] [CrossRef]

- Zhang, X.P.; Li, Y.; Wang, Y.G.; Luo, Y.J. Ultra-Wide Low-Frequency Bandgap Design of Acoustic Metamaterial via Multi-Material Topology Optimization. Compos. Struct. 2023, 306, 116584. [Google Scholar] [CrossRef]

- Li, W.B.; Meng, F.; Chen, Y.F.; Li, Y.F.; Huang, X.D. Topology Optimization of Photonic and Phononic Crystals and Metamaterials: A Review. Adv. Theor. Simul. 2019, 2, 1900017. [Google Scholar] [CrossRef]

- Yang, L.; Chen, J.; Yang, N.; Li, B.W. Significant reduction of graphene thermal conductivity by phononic crystal structure. Int. J. Heat. Mass. Tran. 2015, 91, 428–432. [Google Scholar] [CrossRef] [Green Version]

- Xie, G.F.; Ju, Z.F.; Zhou, K.K.; Wei, X.L.; Guo, Z.X.; Cai, Y.Q.; Zhang, G. Ultra-low thermal conductivity of two-dimensional phononic crystals in the incoherent regime. Npj Comput. Mater. 2018, 4, 21. [Google Scholar] [CrossRef] [Green Version]

- Aryana, K.; Stahley, J.B.; Parvez, N.; Kim, K.; Zanjani, M.B. Superstructures of multielement colloidal molecules: Efficient pathways to construct reconfigurable photonic and phononic crystals. Adv. Theor. Simul. 2019, 2, 1800198. [Google Scholar] [CrossRef]

- Ren, K.; Liu, X.J.; Chen, S.; Chen, Y.; Tang, W.C.; Zhang, G. Remarkable reduction of interfacial thermal resistance in nanophononic heterostructures. Adv. Funct. Mater. 2020, 30, 2004003. [Google Scholar] [CrossRef]

- Zhao, C.Y.; Cheung, C.F.; Xu, P. High-efficiency sub-microscale uncertainty measurement method using pattern recognition. ISA Trans. 2020, 101, 503–514. [Google Scholar] [CrossRef]

- Deng, W.Y.; Zhang, Y.J.; Tang, Y.; Li, Q.H.; Yi, Y.Q. A neural network-based adaptive power-sharing strategy for hybrid frame inverters in a microgrid. Front. Energy Res. 2023, 10, 1082948. [Google Scholar] [CrossRef]

- Gueorguiev, G.K.; Pacheco, J.M. Shapes of cagelike metal carbide clusters: First-principles calculations. Phys. Rev. B 2003, 68, 241401. [Google Scholar] [CrossRef]

- Wick, C.D.; Dang, L.X. Recent advances in understanding transfer ions across aqueous interfaces. Chem. Phys. Lett. 2008, 458, 1–5. [Google Scholar] [CrossRef]

- Zhang, Y.; He, Y.; Wang, H.W.; Sun, L.; Su, Y.K. Ultra-broadband mode size converter using on-chip metamaterial-based Luneburg lens. Acs. Photonics 2020, 8, 202–208. [Google Scholar] [CrossRef]

- Bendsøe, M.P.; Kikuchi, N. Generating Optimal Topologies in Structural Design Using a Homogenization Method. Comput. Method. Appl. Mech. Eng. 1988, 71, 197. [Google Scholar] [CrossRef]

- Bendsøe, M.P. Optimal Shape Design as a Material Distribution Problem. Struct. Multidiscip. Optim. 1989, 1, 193. [Google Scholar] [CrossRef]

- Zhou, M.; Rozvany, G.I.N. The COC Algorithm, Part II: Topological, Geometrical and Generalized Shape Optimization. Comput. Method. Appl. Mech. Eng. 1991, 89, 309. [Google Scholar] [CrossRef]

- Wang, M.Y.; Wang, X.M.; Guo, D.M. A Level Set Method for Structural Topology Optimization. Comput. Method. Appl. Mech. Eng. 2003, 192, 227. [Google Scholar] [CrossRef]

- Allaire, G.; Jouve, F.; Toader, A.M. A Level-Set Method for Shape Optimization. Comptes Rendus Math. 2002, 334, 1125. [Google Scholar] [CrossRef]

- Allaire, G.; Jouve, F.; Toader, A.M. Structural Optimization Using Sensitivity Analysis and a Level-Set Method. J. Comput. Phys. 2004, 194, 363. [Google Scholar] [CrossRef] [Green Version]

- Huang, X.; Xie, Y.M. Convergent and Mesh-Independent Solutions for the Bi-Directional Evolutionary Structural Optimization Method. Finite Elem. Anal. Des. 2007, 43, 1039. [Google Scholar] [CrossRef]

- Huang, X.; Xie, Y.M. Bi-Directional Evolutionary Topology Optimization of Continuum Structures with One or Multiple Materials. Comput. Mech. 2009, 43, 393. [Google Scholar] [CrossRef]

- Holland, J.H. Adaptation in Natural and Artificial Systems: An Introductory Analysis with Applications to Biology, Control, and Artificial Intelligence; MIT Press: Cambridge, MA, USA, 1992; p. 26570. [Google Scholar]

- Sigmund, O.; Søndergaard, J. Systematic Design of Phononic Band–Gap Materials and Structures by Topology Optimization. Ser. A Math. Phys. Eng. Sci. 2003, 361, 1001. [Google Scholar] [CrossRef]

- Gazonas, G.A.; Weile, D.S.; Wildman, R.; Mohan, A. Genetic Algorithm Optimization of Phononic Bandgap Structures. Int. J. Solids Struct. 2006, 43, 5851. [Google Scholar] [CrossRef] [Green Version]

- Hussein, M.I.; Hamza, K.; Hulbert, G.M.; Scott, R.A.; Saitou, K. Multiobjective Evolutionary Optimization of Periodic Layered Materials for Desired Wave Dispersion Characteristics. Struct. Multidiscip. Optim. 2006, 31, 60. [Google Scholar] [CrossRef] [Green Version]

- Hussein, M.I.; Hamza, K.; Hulbert, G.M.; Saitou, K. Optimal Synthesis of 2D Phononic Crystals for Broadband Frequency Isolation. Wave Random Complex 2007, 17, 491. [Google Scholar] [CrossRef]

- Bilal, O.R.; Hussein, M.I. Optimization of Phononic Crystals for the Simultaneous Attenuation of out-of-Plane and in-Plane Waves. In Proceedings of the ASME 2011 International Mechanical Engineering Congress and Exposition, Denver, CO, USA, 11–17 November 2011; Volume 54945, p. 969. [Google Scholar]

- Dong, H.W.; Su, X.X.; Wang, Y.S.; Zhang, C. Topological Optimization of Two-Dimensional Phononic Crystals Based on the Finite Element Method and Genetic Algorithm. Struct. Multidiscip. Optim. 2014, 50, 593. [Google Scholar] [CrossRef]

- Liu, Z.F.; Wu, B.; He, C.F. Band-Gap Optimization of Two-Dimensional Phononic Crystals Based on Genetic Algorithm and FPWE. Wave Random Complex 2014, 24, 286. [Google Scholar] [CrossRef]

- Katoch, S.; Chauhan, S.S.; Kumar, V. A Review on Genetic Algorithm: Past, Present, and Future. Multimed. Tools Appl. 2021, 80, 8091–8126. [Google Scholar] [CrossRef]

- Cheng, Q.; Guo, H.; Yuan, T.; Sun, P.; Guo, F.X.; Wang, Y.S. Topological Design of Square Lattice Structure for Broad and Multiple Band Gaps in Low-Frequency Range. Extreme Mech. Lett. 2020, 35, 100632. [Google Scholar] [CrossRef]

- Zhang, D.B.; Zhao, J.F.; Bonello, B.; Li, L.; Wei, J.X.; Pan, Y.D.; Zhong, Z. Air-Coupled Method to Investigate the Lowest-Order Antisymmetric Lamb Mode in Stubbed and Air-Drilled Phononic Plates. Aip. Adv. 2016, 6, 085021. [Google Scholar] [CrossRef]

| Material | Young Modulus E/1010 Pa | Density ρ/kg·m−3 | Poisson Ratio μ |

|---|---|---|---|

| Tungsten | 35.41 | 19,100 | 0.35 |

| Lead | 4.08 | 11,600 | 0.37 |

| Aluminum | 7.76 | 2730 | 0.35 |

| Epoxy Resin | 0.435 | 1180 | 0.37 |

| Rubber | 9.942 × 10−5 | 1600 | 0.47 |

| Silicone Rubber | 1.175 × 10−5 | 1300 | 0.47 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wen, X.; Kang, L.; Sun, X.; Song, T.; Qi, L.; Cao, Y. Topological Design of Two-Dimensional Phononic Crystals Based on Genetic Algorithm. Materials 2023, 16, 5606. https://doi.org/10.3390/ma16165606

Wen X, Kang L, Sun X, Song T, Qi L, Cao Y. Topological Design of Two-Dimensional Phononic Crystals Based on Genetic Algorithm. Materials. 2023; 16(16):5606. https://doi.org/10.3390/ma16165606

Chicago/Turabian StyleWen, Xiaodong, Lei Kang, Xiaowei Sun, Ting Song, Liangwen Qi, and Yue Cao. 2023. "Topological Design of Two-Dimensional Phononic Crystals Based on Genetic Algorithm" Materials 16, no. 16: 5606. https://doi.org/10.3390/ma16165606

APA StyleWen, X., Kang, L., Sun, X., Song, T., Qi, L., & Cao, Y. (2023). Topological Design of Two-Dimensional Phononic Crystals Based on Genetic Algorithm. Materials, 16(16), 5606. https://doi.org/10.3390/ma16165606