Study on the Influences of Adding Rare Earth Ce on the Precipitation Behaviors of TiN Inclusions in 20CrMnTi

Abstract

1. Introduction

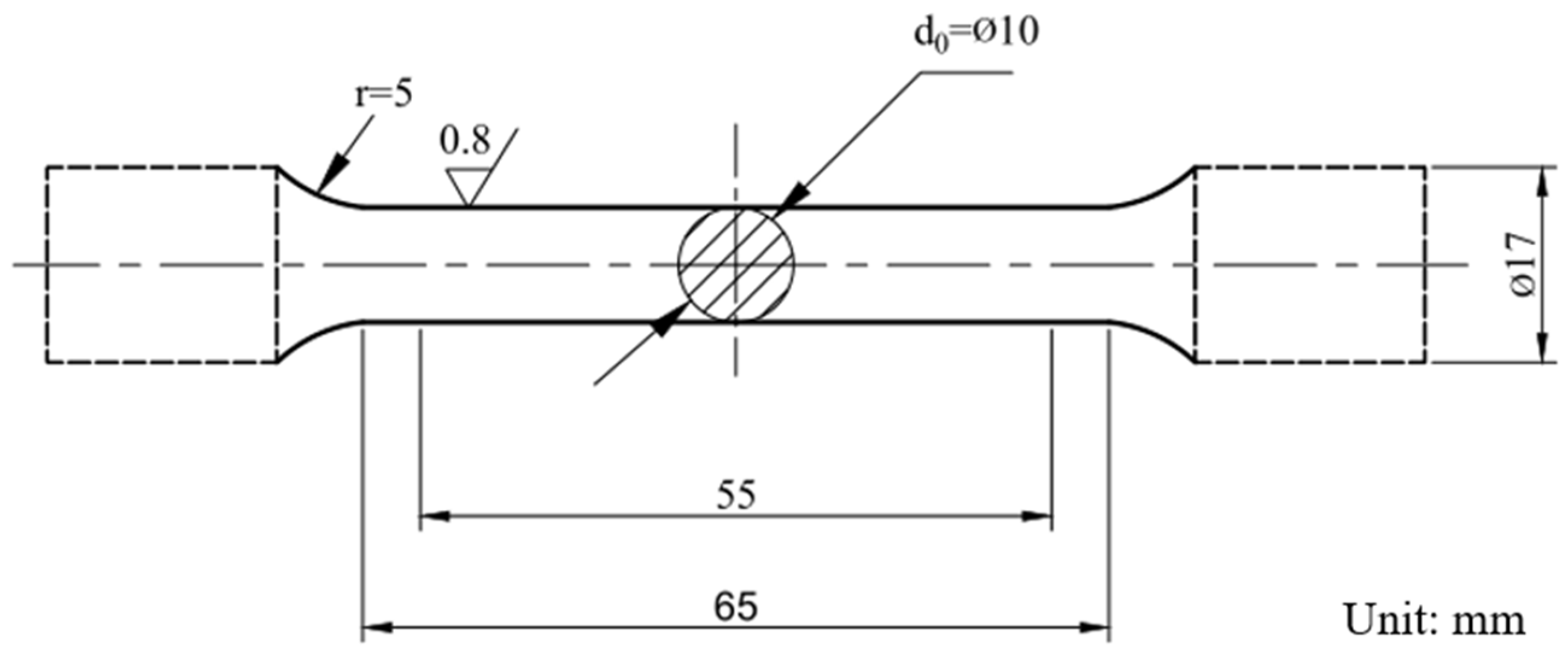

2. Materials and Methods

3. Results and Discussion

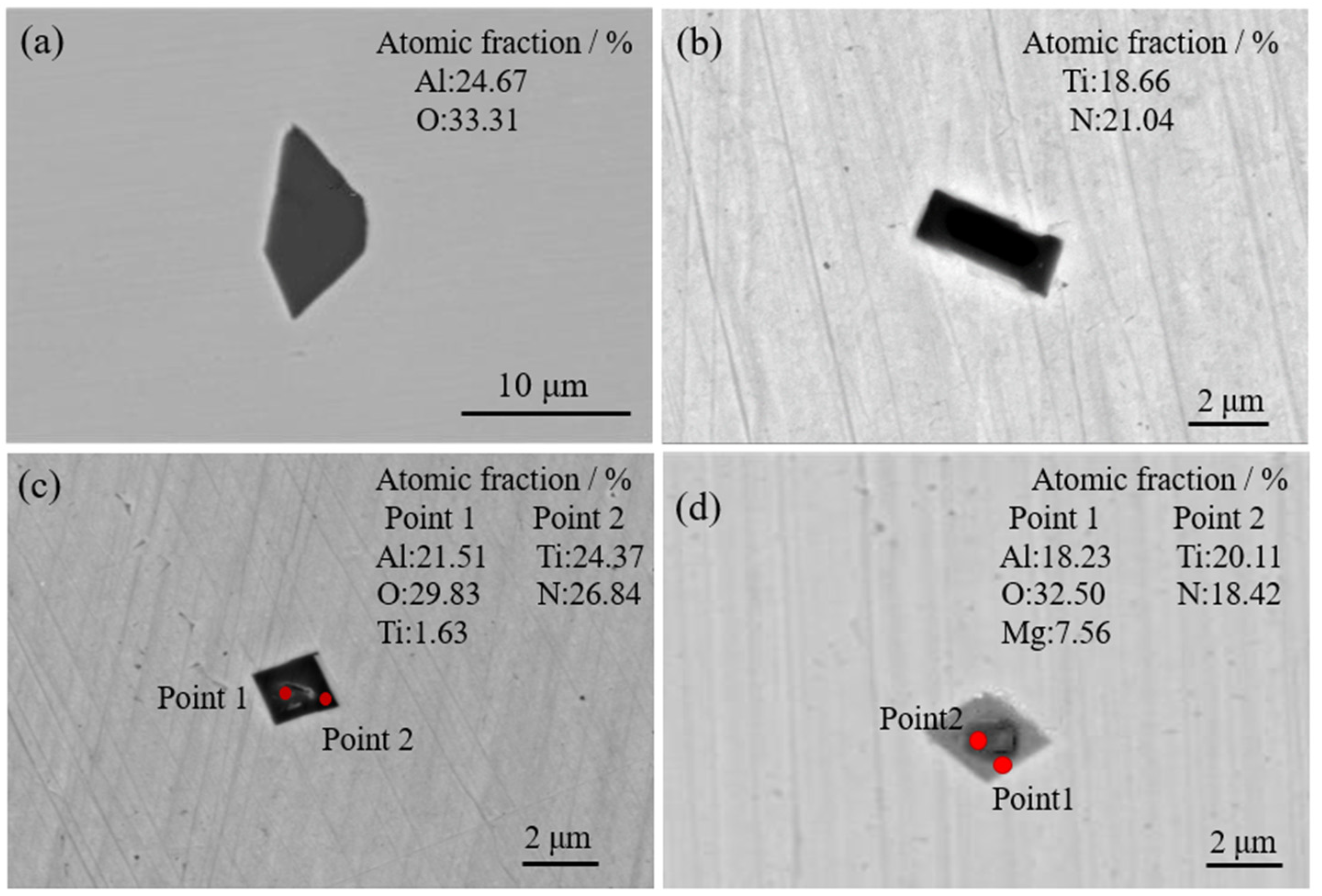

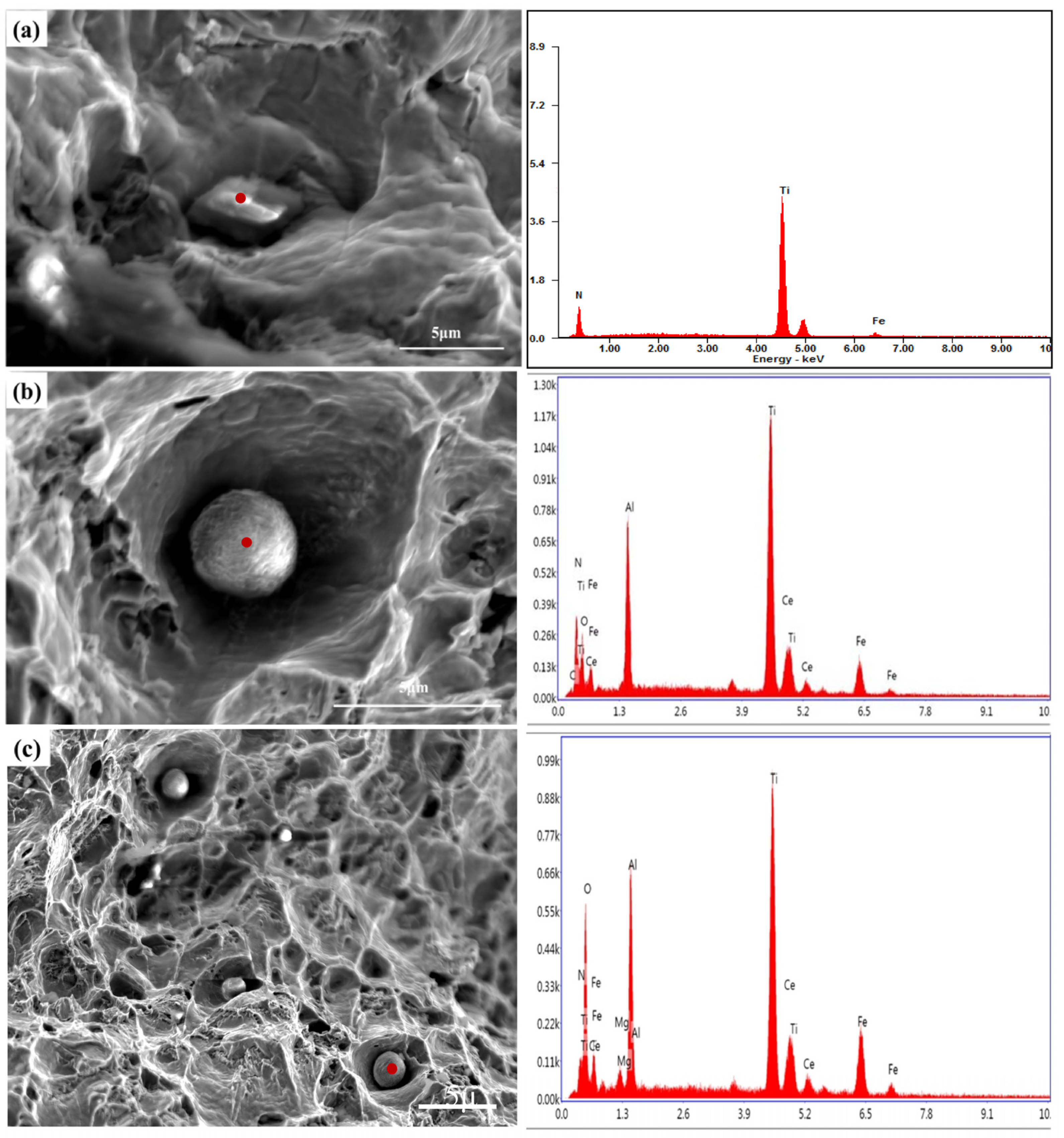

3.1. Morphologies and Compositions of the Inclusions Containing TiN in 20CrMnTi

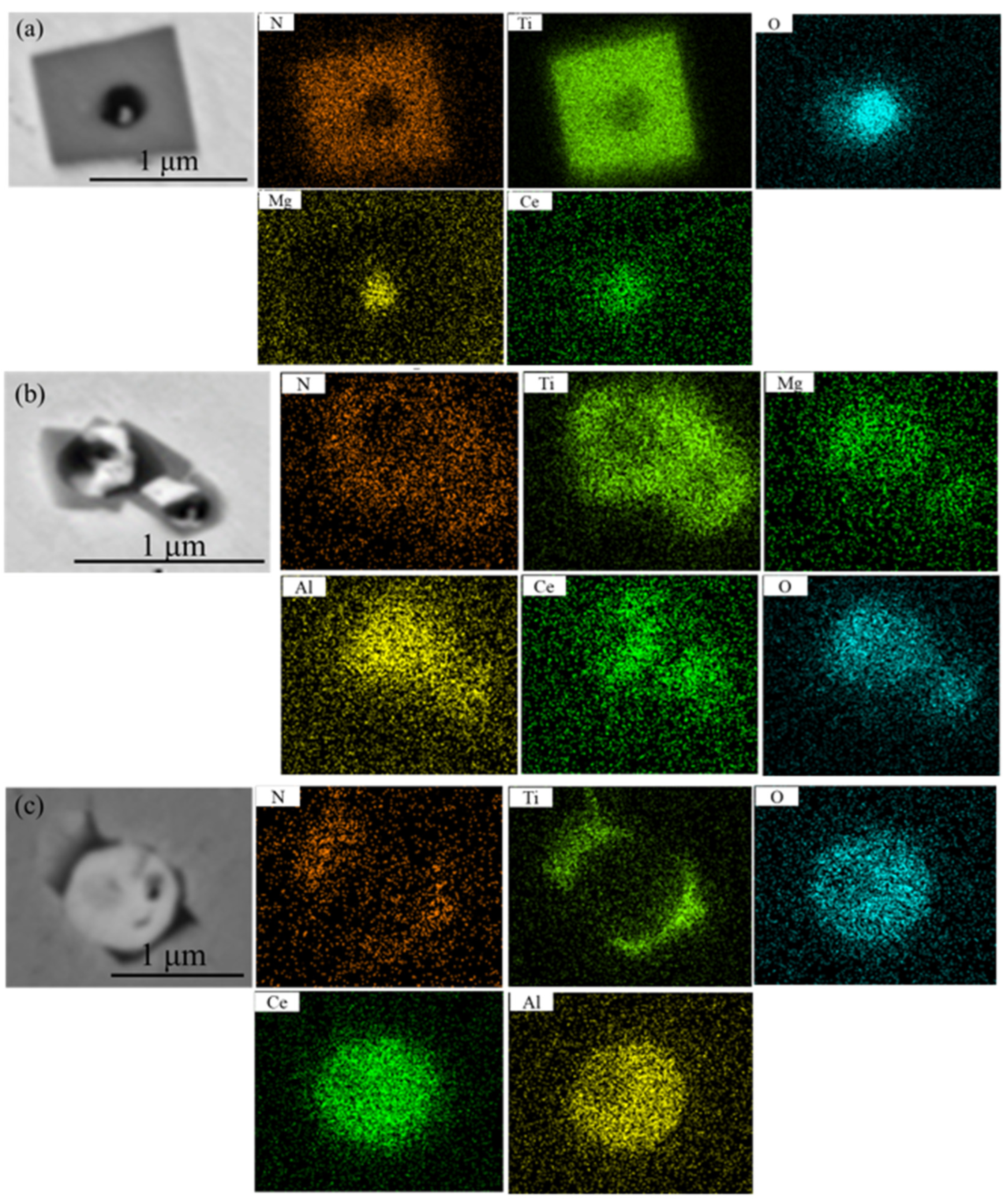

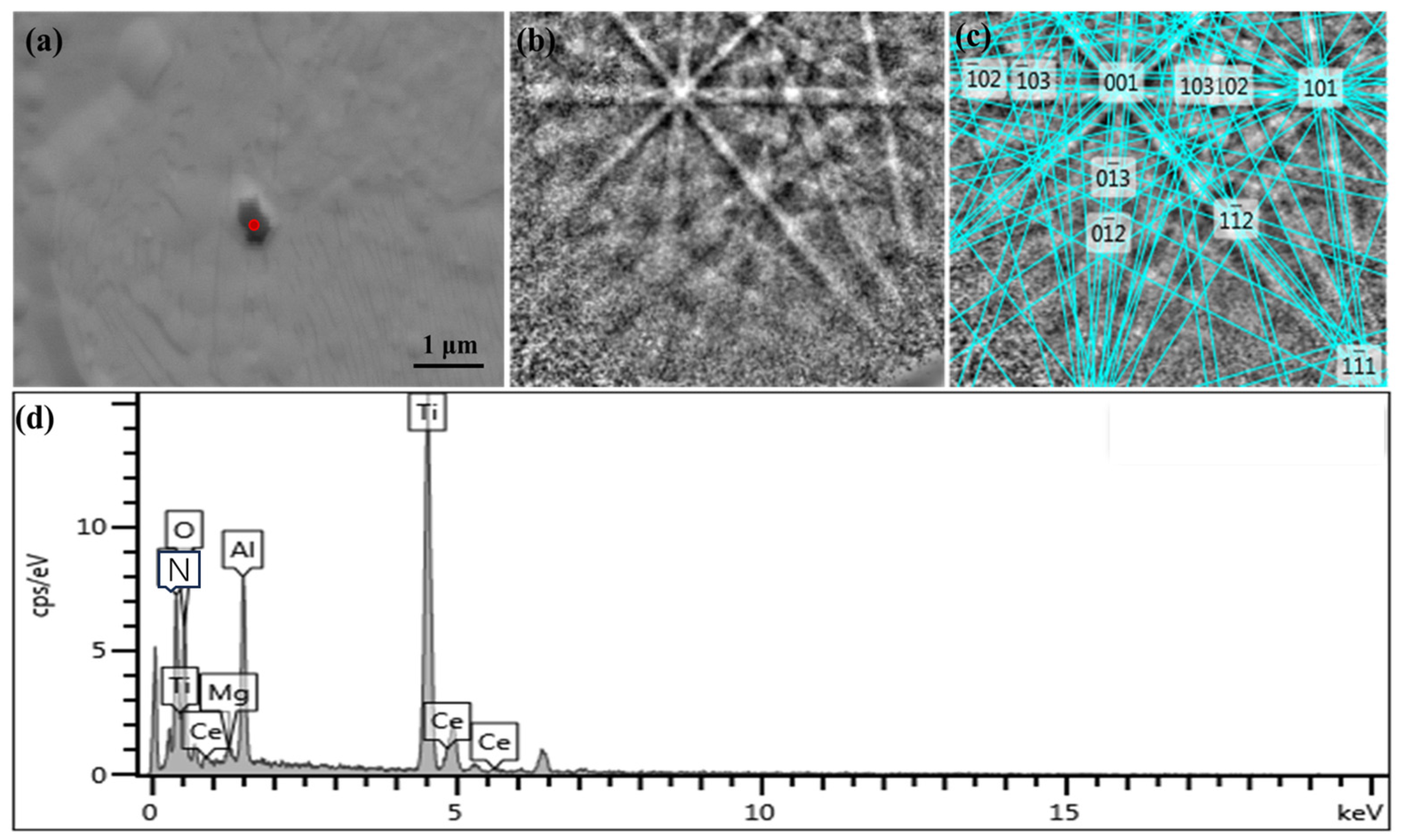

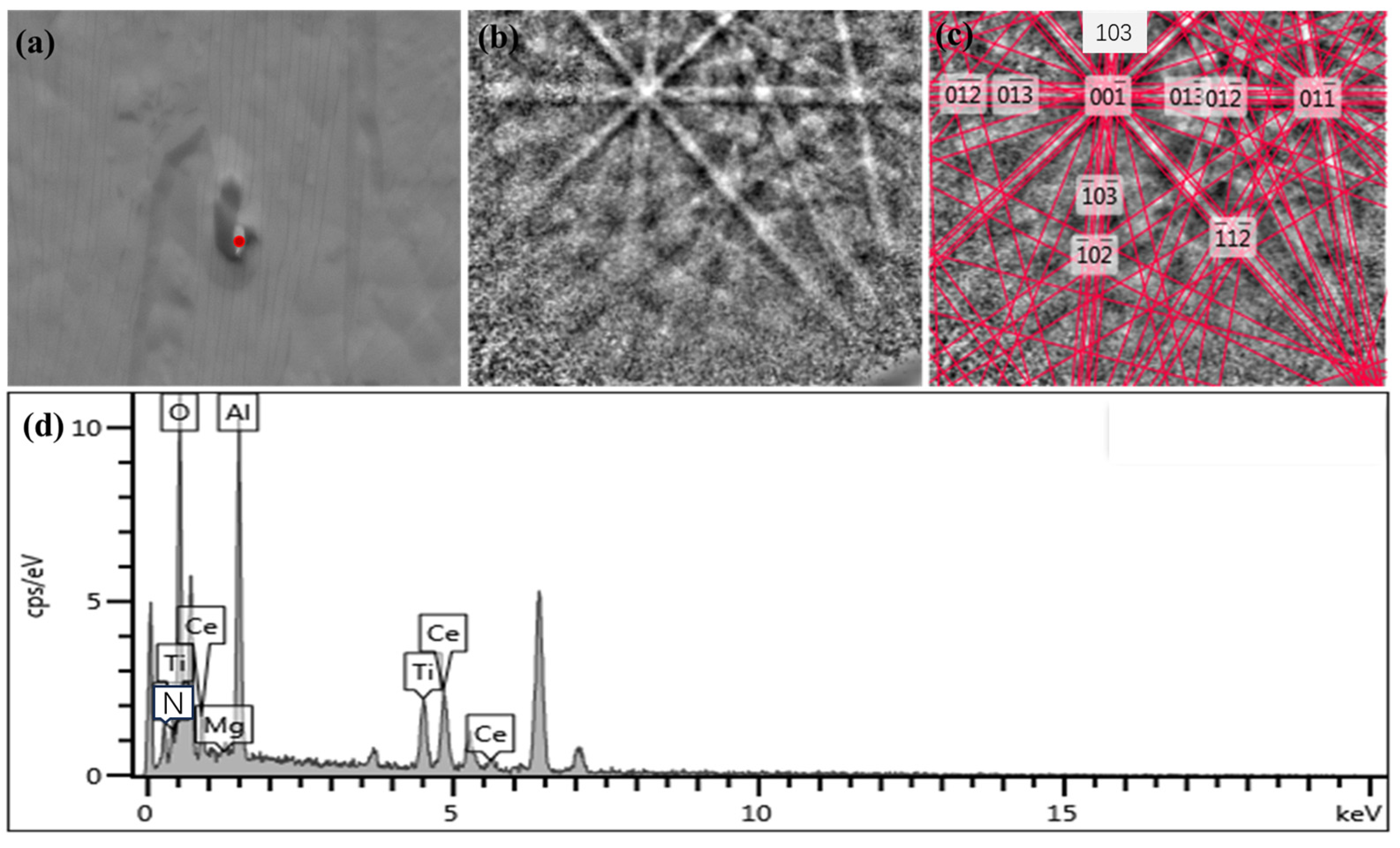

3.2. Morphologies and Compositions of the Inclusions Containing TiN in 20CrMnTiCe

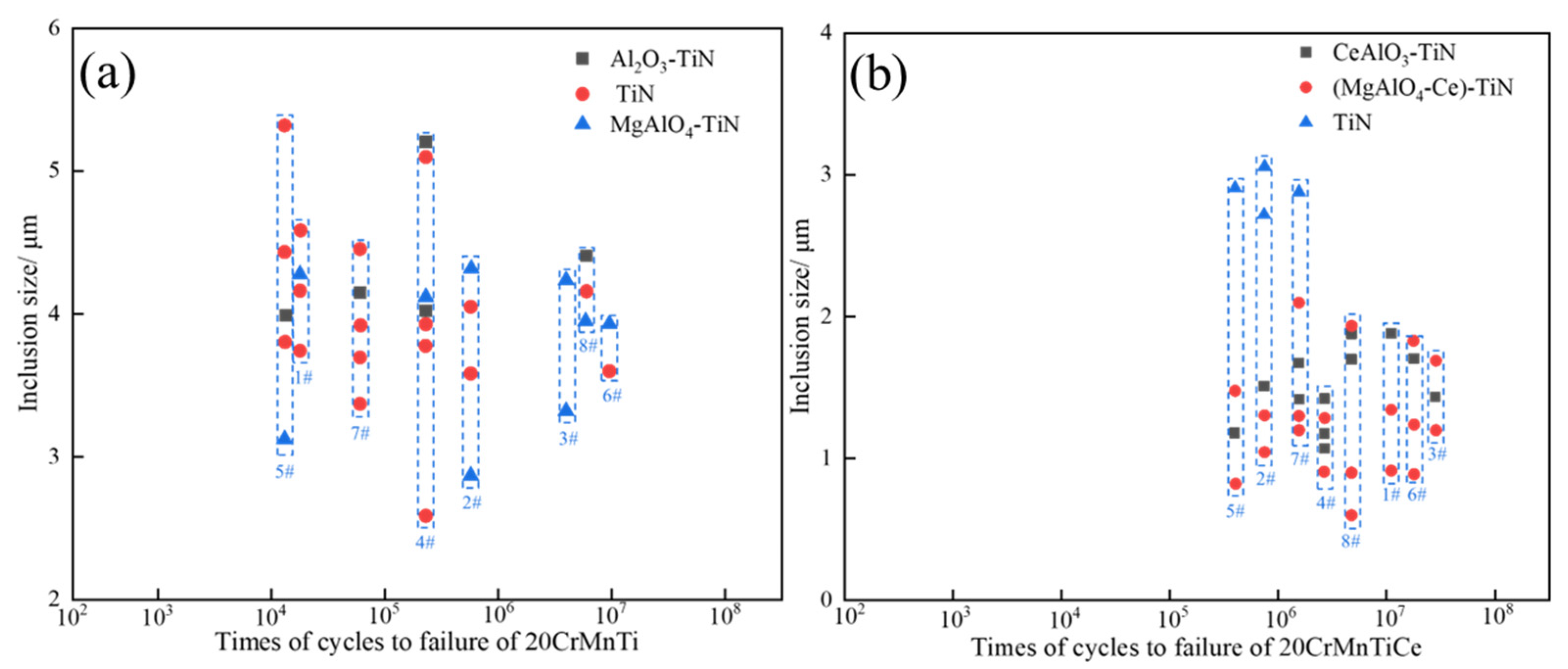

3.3. Effects of Ce on the Quantities and Sizes of the Inclusions Containing TiN in Steels

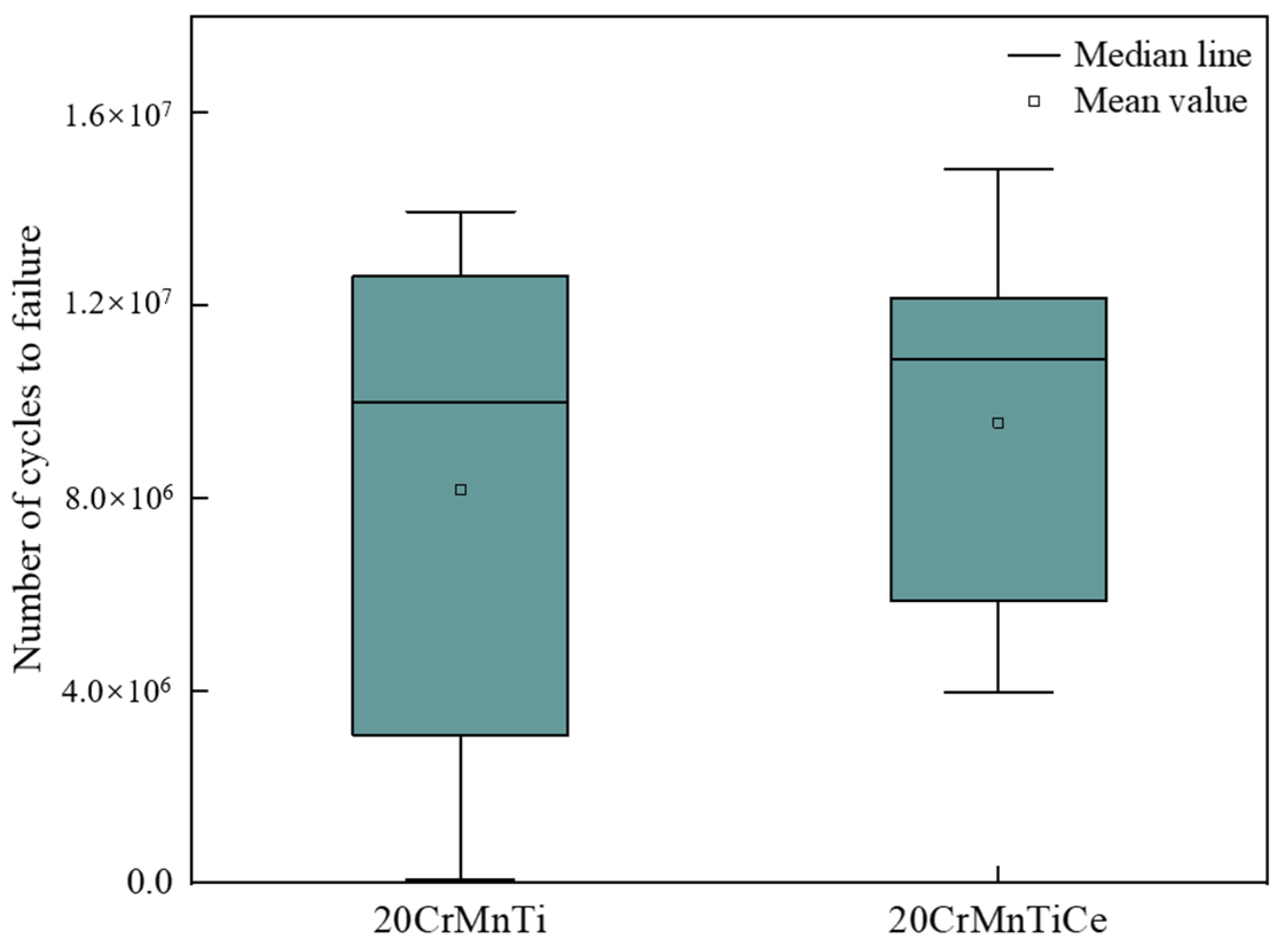

3.4. Effects of Ce on Fatigue Properties of the Steels

4. Conclusions

- (1)

- The main inclusions in 20CrMnTi are TiN, Al2O3, Al2O3-TiN, and MgAlO4-TiN, among which the inclusions containing TiN are mostly square or diamond-shaped, and the pure TiN inclusions account for 60% of the total inclusions. After the addition of rare earth Ce, the main titanium inclusions of 20CrMnTiCe are TiN, MgAlO4-TiN, and CeAlO3-TiN, among which pure TiN inclusions account for 36.7% of the total inclusions. The generated MgAlO4-TiN and CeAlO3-TiN are spherical, indicating that rare earth Ce can modify some TiN inclusions.

- (2)

- The sizes of Al2O3 and TiN in 20CrMnTi are concentrated in 2–5 μm. The composite inclusions of Al2O3-TiN and MgAlO4-TiN are concentrated in sizes ranging from 4 to 10 μm, and their proportion is 14.3%. After adding rare earth Ce, the sizes of MgAlO4-TiN and CeAlO3-TiN less than 2 μm accounted for 63.3%. Rare earth Ce can refine the inclusions containing TiN in 20CrMnTi.

- (3)

- The average fatigue lives of 20CrMnTi do not reach 107 times, and the deviations between the maximum and minimum fatigue lives are great, while large-sized TiN is the main inclusion affecting the fatigue performance. The addition of Ce can modify TiN inclusions, forming spherical and small-sized composite inclusions of (MgAlO4Ce)-TiN and (CeAlO3)-TiN. The average fatigue lives exceed 107 times, and the deviations of the fatigue lives are smaller than those of 20CrMnTi.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, X.; Tang, J.Y. Effect of 20CrMnTi material compositions fluctuation on gear performance after carburizing and quenching process. J. Cent. South Univ. 2017, 48, 1979–1987. [Google Scholar]

- Wang, X.; Wei, X.; Yang, X.; Cheng, Z.; Wang, W. Atomic diffusion of gradient ultrafine structured surface layer produced by T10 steel rubbing against 20CrMnTi steel. Wear 2013, 304, 118–125. [Google Scholar] [CrossRef]

- Zhu, Y.; Lu, Y.-M.; Huang, C.-W.; Liang, Y.-L. The effect of TiN inclusions on the fracture mechanism of 20CrMnTi steel with lath martensite. Mater. Res. Express 2020, 7, 036509. [Google Scholar] [CrossRef]

- Li, Y.; Cheng, G.; Lu, J.; Sun, J. Characteristics and Formation Mechanism of Complex TiN Inclusions in 20CrMnTi Gear Steel. ISIJ Int. 2022, 62, 2266–2275. [Google Scholar] [CrossRef]

- Zhang, M.; Wang, Z.; Feng, X.L.; Xie, L.Z.; Liu, A.J.; Liu, N. Research on fatigue of 20CrMnTi steel gear. Heat Treat. 2017, 32, 9–12. [Google Scholar]

- Li, Y.; Cheng, G.G.; Lu, J.L.; Sun, J. Characteristics and distribution of TiN inclusions in 20CrMnTi gear steel. China Metall. 2020, 30, 28–34. [Google Scholar]

- Wang, X.Y. Study on Control of Non-Metallic Inclusions in 20CrMnTi Gear Steel; Northeastern University: Shenyang, China, 2018. [Google Scholar]

- Fang, Y.R.; Wang, C.R.; Xu, Y.H.; Hu, Y.J.; Zhan, D.P. Research on inclusions in billet of 20CrMnTiH gear steel. J. Liaoning Inst. Sci. Technol. 2021, 23, 4–7. [Google Scholar]

- Tang, J.; Hu, X.; Lai, F.; Guo, X.; Qu, S.; He, R.; Qin, S.; Li, J. Evolution of Fretting Wear Behaviors and Mechanisms of 20CrMnTi Steel after Carburizing. Metals 2020, 10, 179. [Google Scholar] [CrossRef]

- Wang, J.B.; Ding, J.; Song, K.; Zhang, X.D.; Wang, L.S. Dynamic Stress Response of 20CrMnTi Steel under Impact Load with Modified J-C Ontogenetic Model Considering Adiabatic Temperature Rise. Mech. Strength 2019, 41, 1066–1070. [Google Scholar]

- Wang, D.K. Research on Flow Behaviors and Microstructure Evolutions during Warm/Hot Deformation in 20CrMnTi Low-Alloy Steel; Huazhong University of Science & Technology: Wuhan, China, 2020. [Google Scholar]

- Yuan, S.; Liang, G. Dissolving behaviour of second phase particles in Nb–Ti microalloyed steel. Mater. Lett. 2009, 63, 2324–2326. [Google Scholar] [CrossRef]

- Shi, Z.; Wang, R.; Hang, S.; Feng, C.; Wang, Q.; Yang, C. Effect of nitrogen content on the second phase particles in V–Ti microalloyed shipbuilding steel during weld thermal cycling. Mater. Des. 2016, 96, 241–250. [Google Scholar] [CrossRef]

- Wang, J.; Peng, J.; Zhang, F.; Li, Y.; Zhang, X.; An, S. Effects of Ce-Modified TiN Inclusions on the Fatigue Properties of Gear Steel 20CrMnTi. Crystals 2023, 13, 1071. [Google Scholar] [CrossRef]

- Cheng, L. Study on Evolution and Control of Inclusions in 20CrMnTi Gear Steel; Northeastern University: Shenyang, China, 2020. [Google Scholar]

- Qi, H.Q. Study on the Effect of Composition Optimization of 20CrMnTi Steel on Microstructure and Contact Fatigue Life; Kunming University Of Science And Technology: Kunming, China, 2010. [Google Scholar]

- Yan, W.; Shan, Y.Y.; Yang, K. Effect of TiN inclusions on the impact toughness of low-carbon microalloyed steels. Met. Mater. Trans. A 2006, 37, 2147–2158. [Google Scholar] [CrossRef]

- Kim, W.-Y.; Jo, J.-O.; Chung, T.-I.; Kim, D.-S.; Pak, J.-J. Thermodynamics of Titanium, Nitrogen and TiN Formation in Liquid Iron. ISIJ Int. 2007, 47, 1082–1089. [Google Scholar] [CrossRef]

- Yin, X.; Sun, Y.; Yang, Y.; Bai, X.; Barati, M.; Mclean, A. Formation of Inclusions in Ti-Stabilized 17Cr Austenitic Stainless Steel. Met. Mater. Trans. B 2016, 47, 3274–3284. [Google Scholar] [CrossRef]

- Ma, W.-J.; Bao, Y.-P.; Zhao, L.-H.; Wang, M. Control of the precipitation of TiN inclusions in gear steels. Int. J. Miner. Met. Mater. 2014, 21, 234–239. [Google Scholar] [CrossRef]

- Yang, C.; Luan, Y.; Li, D.; Li, Y. Effects of rare earth elements on inclusions and impact toughness of high-carbon chromium bearing steel. J. Mater. Sci. Technol. 2019, 35, 1298–1308. [Google Scholar] [CrossRef]

- Ahn, J.-H.; Jung, H.-D.; Im, J.-H.; Jung, K.H.; Moon, B.-M. Influence of the addition of gadolinium on the microstructure and mechanical properties of duplex stainless steel. Mater. Sci. Eng. A 2016, 658, 255–262. [Google Scholar] [CrossRef]

- Zhou, D.G.; Jie, F.U.; Chen, X.C. Precipitation behavior of TiN in bearingsteel. J. Mater. Sci. Technol. 2003, 19, 184–186. [Google Scholar] [CrossRef]

- Yin, X.; Sun, Y.; Yang, Y.; Deng, X.; Barati, M.; McLean, A. Effect of alloy addition on inclusion evolution in stainless steels. Ironmak. Steelmak. 2016, 44, 152–158. [Google Scholar] [CrossRef]

- Liu, H.Y.; Wang, H.L.; Li, L.; Zheng, J.Q.; Li, Y.H.; Zeng, X.Y. Investigation of Ti inclusions in wire cord steel. Ironmak. Steelmak. 2011, 38, 53–58. [Google Scholar] [CrossRef]

- Qu, T.-P.; Tian, J.; Chen, K.-L.; Xu, Z.; Wang, D.-Y. Precipitation behaviour of TiN in Nb-Ti containing alloyed steel during the solidification process. Ironmak. Steelmak. 2017, 46, 353–358. [Google Scholar] [CrossRef]

| Literature | <5 μm | >5 μm |

|---|---|---|

| Li et al. [6] | main | many |

| Wang et al. [7] | 74.11% | 25.89% |

| Fang et al. [8] | average size ≤ 5 μm | |

| Samples | C | Si | Mn | Al | Cr | Ti | Mg | O | N | Ce | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|

| (wt/%) | (ppm) | ||||||||||

| 20CrMnTi | 0.24 | 0.18 | 0.95 | 0.011 | 1.02 | 0.052 | 138 | 44 | 50 | / | Bal. |

| 20CrMnTi-Ce | 0.25 | 0.20 | 0.93 | 0.010 | 1.00 | 0.054 | 130 | 33 | 47 | 62 | Bal. |

| Steel | <2 μm | 2–5 μm | 5–10 μm |

|---|---|---|---|

| Proportion/% | |||

| 20CrMnTi | 45.9 | 39.8 | 14.3 |

| 20CrMnTiCe | 76.6 | 19.2 | 4.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Peng, J.; Liu, L.; Zhang, F.; Peng, J.; Tang, H.; Zheng, J.; An, S. Study on the Influences of Adding Rare Earth Ce on the Precipitation Behaviors of TiN Inclusions in 20CrMnTi. Materials 2023, 16, 5598. https://doi.org/10.3390/ma16165598

Wang J, Peng J, Liu L, Zhang F, Peng J, Tang H, Zheng J, An S. Study on the Influences of Adding Rare Earth Ce on the Precipitation Behaviors of TiN Inclusions in 20CrMnTi. Materials. 2023; 16(16):5598. https://doi.org/10.3390/ma16165598

Chicago/Turabian StyleWang, Jian, Jun Peng, Lixia Liu, Fang Zhang, Jihua Peng, Hao Tang, Jie Zheng, and Shengli An. 2023. "Study on the Influences of Adding Rare Earth Ce on the Precipitation Behaviors of TiN Inclusions in 20CrMnTi" Materials 16, no. 16: 5598. https://doi.org/10.3390/ma16165598

APA StyleWang, J., Peng, J., Liu, L., Zhang, F., Peng, J., Tang, H., Zheng, J., & An, S. (2023). Study on the Influences of Adding Rare Earth Ce on the Precipitation Behaviors of TiN Inclusions in 20CrMnTi. Materials, 16(16), 5598. https://doi.org/10.3390/ma16165598