Ohmic Contact to n-GaN Using RT-Sputtered GaN:O

Abstract

:1. Introduction

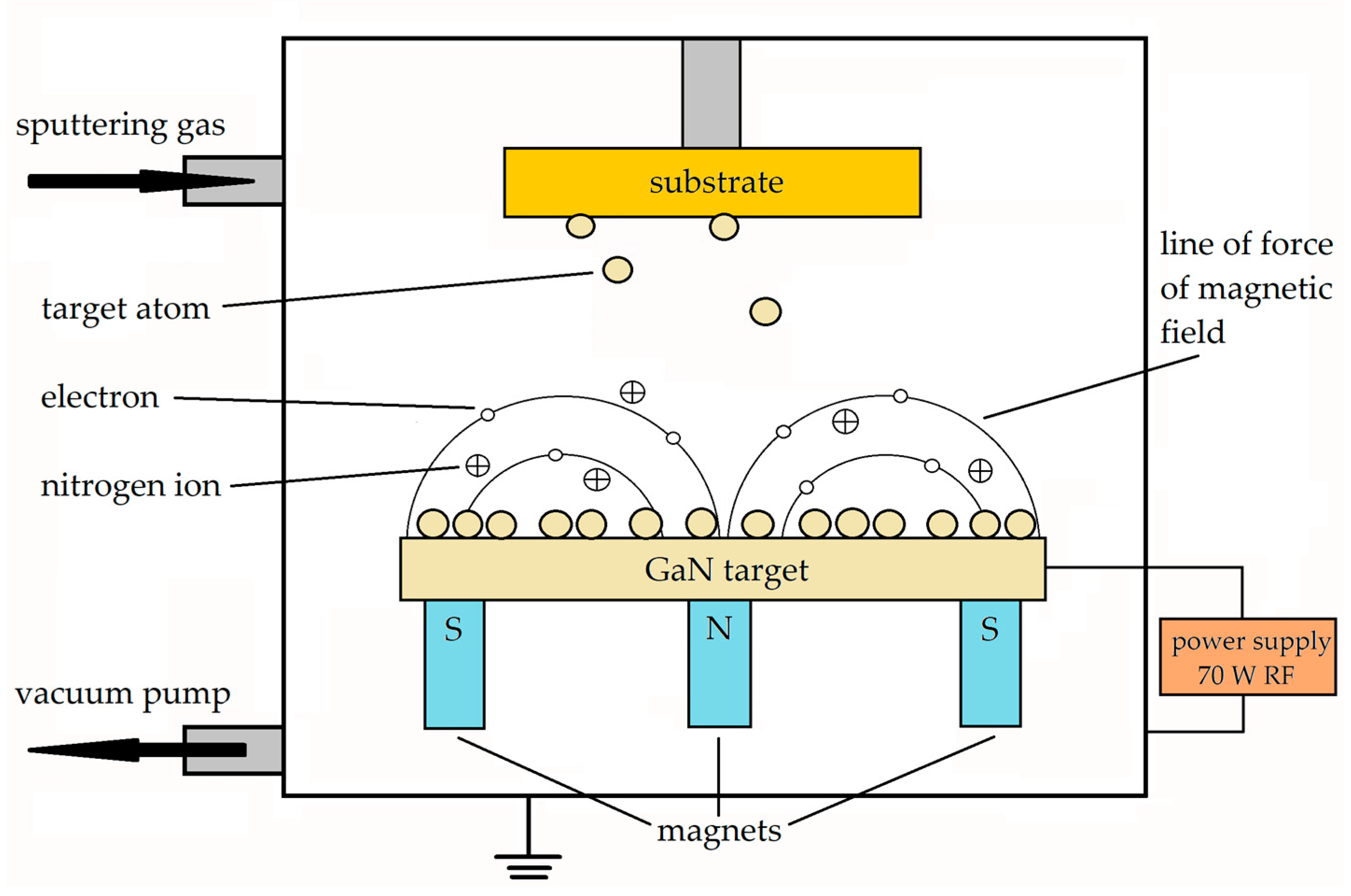

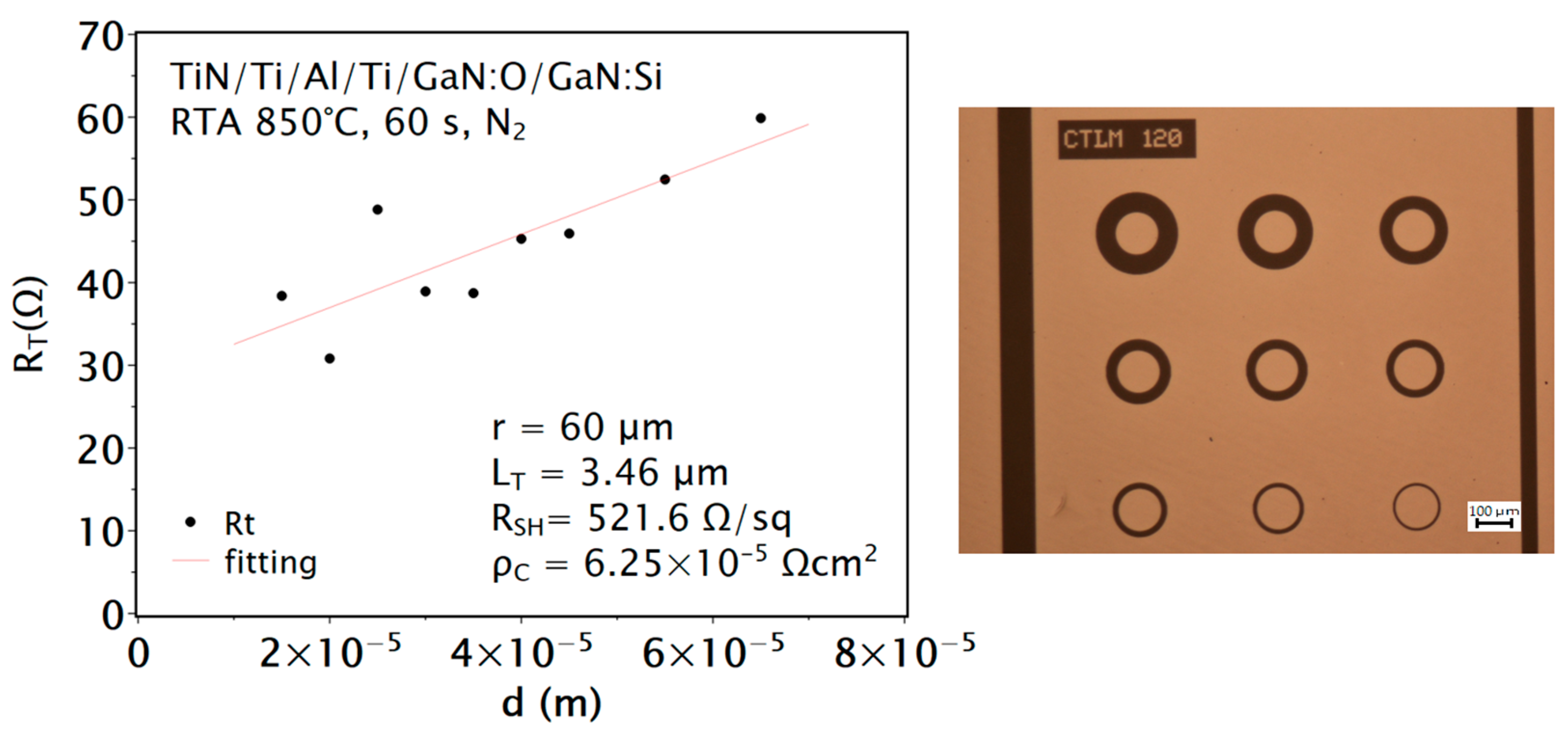

2. Materials and Methods

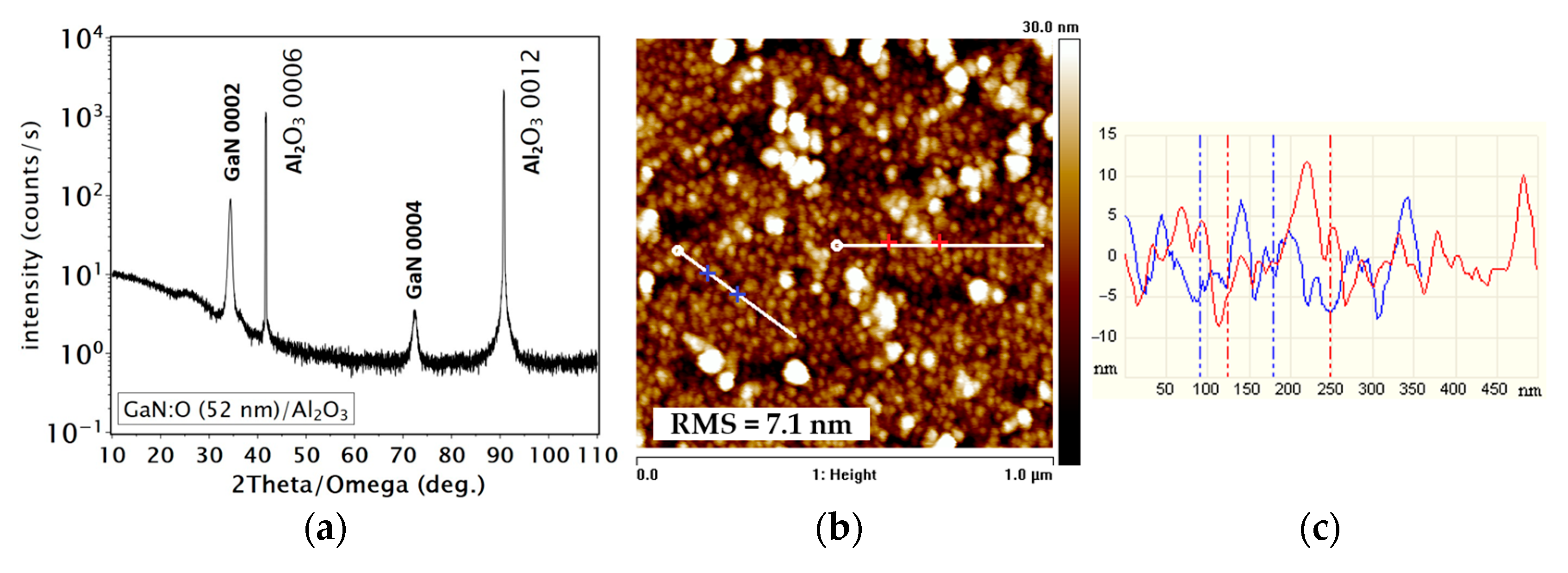

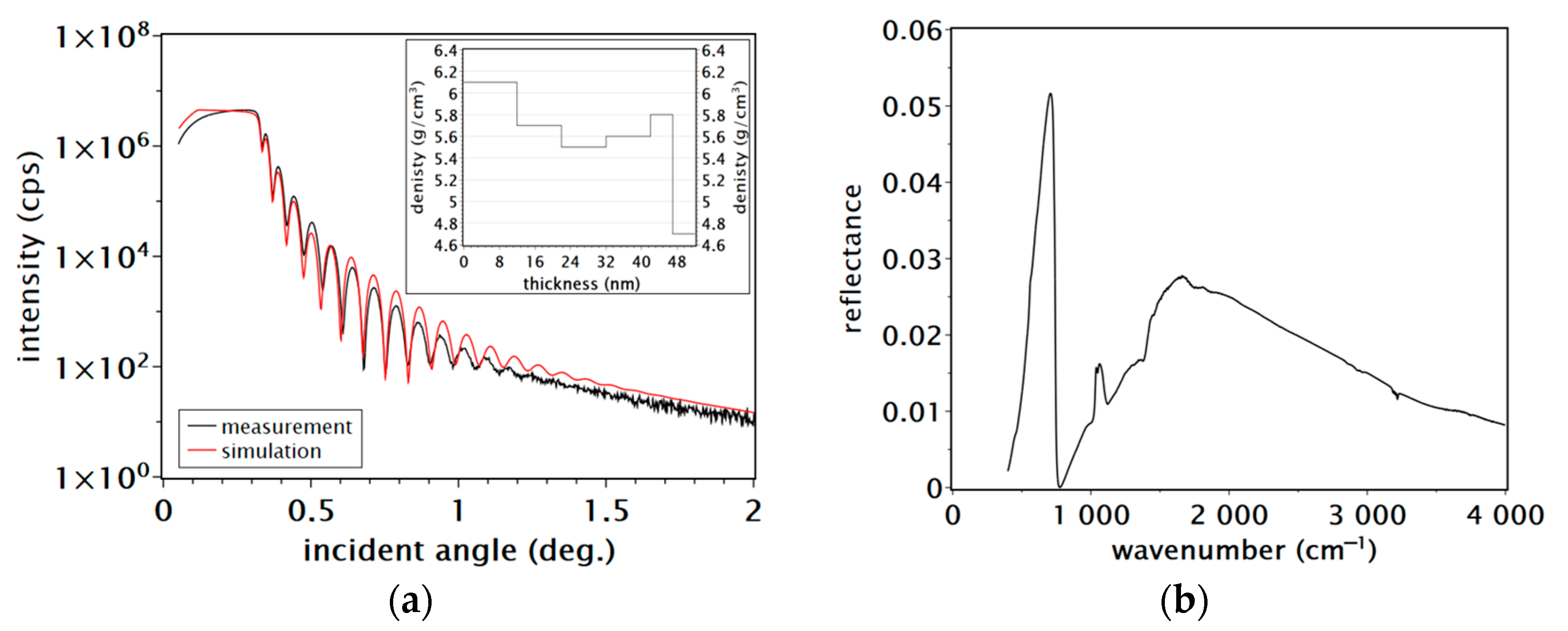

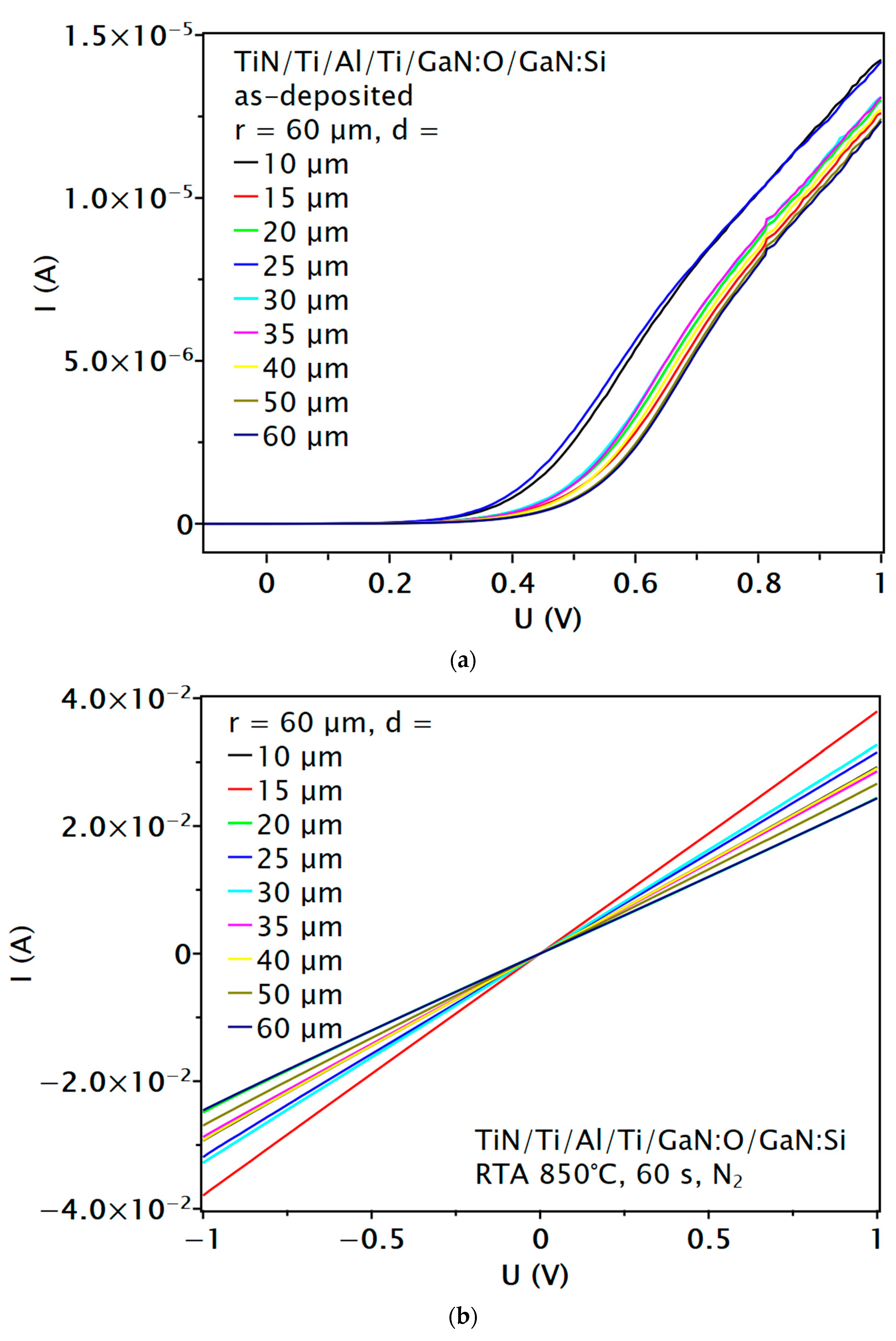

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Meneghini, M.; De Santi, C.; Abid, I.; Buffolo, M.; Cioni, M.; Khadar, R.A.; Nela, L.; Zagni, N.; Chini, A.; Medjdoub, F.; et al. GaN-based power devices: Physics, reliability and perspectives. J. Appl. Phys. 2021, 130, 181101. [Google Scholar] [CrossRef]

- Whiting, P.G.; Rudawski, N.G.; Holzworth, M.R.; Pearton, S.J.; Jones, K.S.; Liu, L.; Kang, T.S.; Ren, F. Nanocrack formation in AlGaN/GaN high electron mobility transistors utilizing Ti/Al/Ni/Au ohmic contacts. Microelectron. Reliab. 2017, 70, 41–48. [Google Scholar] [CrossRef]

- Guo, J.; Cao, Y.; Lian, C.; Zimmermann, T.; Li, G.; Verma, J.; Gao, X.; Guo, S.; Saunier, P.; Wistey, M.; et al. Metal-face InAlN/AlN/GaN high electron mobility transistors with regrown ohmic contacts by molecular beam epitaxy. Phys. Status Solidi A 2011, 208, 1617–1619. [Google Scholar] [CrossRef]

- Greco, G.; Iucolano, F.; Roccaforte, F. Ohmic contacts to Gallium Nitride materials. Appl. Surf. Sci. 2016, 383, 324–345. [Google Scholar] [CrossRef]

- Mohammad, S.N. Contact mechanism and design principles for alloyed ohmic contacts to n-GaN. J. Appl. Phys. 2004, 95, 7940–7953. [Google Scholar] [CrossRef]

- Iucolano, F.; Roccaforte, F.; Alberti, A.; Bongiorno, C.; Di Franco, S.; Raineri, V. Temperature dependence of the specific resistance in Ti/Al/Ni/Au contacts on n-type GaN. J. Appl. Phys. 2006, 100, 123706. [Google Scholar] [CrossRef]

- Upadhyay, P.; Meer, M.; Takhar, K.; Khachariya, D.; Kumar, S.A.; Banerjee, D.; Ganguly, S.; Laha, A.; Saha, D. Improved Ohmic contact to GaN and AlGaN/GaN two-dimensional electron gas using trap assisted tunneling by B implantation. Phys. Status Solidi B 2015, 252, 989–995. [Google Scholar] [CrossRef]

- Nomoto, K.; Toyoda, Y.; Satoh, M.; Inada, T.; Nakamura, T. Characterization of silicon ion-implanted GaN and AlGaN. Nucl. Instrum. Methods Phys. Res. B 2012, 272, 125–127. [Google Scholar] [CrossRef]

- Wojtasiak, W.; Góralczyk, M.; Gryglewski, D.; Zajac, M.; Kucharski, R.; Prystawko, P.; Piotrowska, A.; Ekielski, M.; Kaminska, E.; Taube, A.; et al. AlGaN/GaN High Electron Mobility Transistors on Semi-Insulating Ammono-GaN Substrates with Regrown Ohmic Contacts. Micromachines 2018, 9, 546. [Google Scholar] [CrossRef] [Green Version]

- Guo, J.; Li, J.G.; Faria, F.; Cao, Y.; Wang, R.; Verma, J.; Gao, X.; Guo, S.; Beam, E.; Ketterson, A.; et al. MBE-regrown ohmics in InAlN HEMTs with a regrowth interface resistance of 0.05 Ω·mm. IEEE Electron. Device Lett. 2012, 33, 525–527. [Google Scholar] [CrossRef]

- Wang, C.; Zhao, M.D.; He, Y.L.; Zheng, X.F.; Wei, X.X.; Mao, W.; Zhang, J.; Hao, Y. Optimization of ohmic contact for AlGaN/GaN HEMT by introducing patterned etching in ohmic area. Solid State Electron. 2017, 129, 114–119. [Google Scholar] [CrossRef]

- Pampili, P.; Parbrook, P.J. Doping of III-nitride materials. Mater. Sci. Semicond. Process. 2017, 62, 180–191. [Google Scholar] [CrossRef]

- Watson, I.M. Metal organic vapour phase epitaxy of AlN, GaN, InN and their alloys: A key chemical technology for advanced device applications. Coord. Chem. Rev. 2013, 257, 2120–2141. [Google Scholar] [CrossRef]

- Ueno, K.; Arakawa, Y.; Kobayashi, A.; Ohta, J.; Fujioka, H. Highly conductive Ge-doped GaN epitaxial layers prepared by pulsed sputtering. Appl. Phys. Express. 2017, 10, 101002. [Google Scholar] [CrossRef]

- Yi, G.C.; Wessels, B.W. Compensation of n-type GaN. Appl. Phys. Lett. 1996, 69, 3028–3030. [Google Scholar] [CrossRef]

- Kirste, R.; Hoffmann, M.P.; Sachet, E.; Bobea, M.; Bryan, Z.; Bryan, I.; Nenstiel, C.; Hoffmann, A.; Maria, J.-P.; Collazo, R.; et al. Ge doped GaN with controllable high carrier concentration for plasmonic applications. Appl. Phys. Lett. 2013, 103, 242107. [Google Scholar] [CrossRef]

- Junaid, M.; Lundin, D.; Palisaitis, J.; Hsiao, C.-L.; Darakchieva, V.; Jensen, J.; Persson, P.O.A.; Sandstrom, P.; Lai, W.-J.; Chen, L.-C.; et al. Two-domain formation during the epitaxial growth of GaN(0001) on c-plane Al2O3(0001) by high power impulse magnetron sputtering. J. Appl. Phys. 2011, 110, 123519. [Google Scholar] [CrossRef]

- Arakawa, Y.; Ueno, K.; Imabeppu, H.; Kobayashi, A.; Ohta, J.; Fujioka, H. Electrical properties of Si-doped GaN prepared using pulsed sputtering. Appl. Phys. Lett. 2017, 110, 042103. [Google Scholar] [CrossRef] [Green Version]

- Shinoda, H.; Mutsukura, N. Structural properties of GaN layers grown on Al2O3 (0001) and GaN/Al2O3 template by reactive radio-frequency magnetron sputter epitaxy. Vacuum 2016, 125, 133–140. [Google Scholar] [CrossRef] [Green Version]

- Junaid, M.; Hsiao, C.-L.; Palisaitis, J.; Jensen, J.; Persson, P.O.Å.; Hultman, L.; Birch, J. Electronic-grade GaN(0001)/Al2O3(0001) grown by reactive DC-magnetron sputter epitaxy using a liquid Ga target. Appl. Phys. Lett. 2011, 98, 141915. [Google Scholar] [CrossRef] [Green Version]

- Polyakov, A.Y.; Lee, I.-H. Deep traps in GaN-based structures as affecting the performance of GaN devices. Mater. Sci. Eng. R Rep. 2015, 94, 1–56. [Google Scholar] [CrossRef]

- Lund, C.; Nakamura, S.; DenBaars, S.P.; Mishra, U.K.; Keller, S. Growth of high purity N-polar (In,Ga)N films. J. Cryst. Growth 2017, 464, 127–131. [Google Scholar] [CrossRef]

- Sintonen, S.; Kivisaari, P.; Pimputkar, S.; Suihkonen, S.; Schulz, T.; Speck, J.S.; Nakamura, S. Incorporation and effects of impurities in different growth zones within basic ammonothermal GaN. J. Cryst. Growth 2016, 456, 43–50. [Google Scholar] [CrossRef] [Green Version]

- Zajac, M.; Kucharski, R.; Grabianska, K.; Gwardys-Bak, A.; Puchalski, A.; Wasik, D.; Litwin-Staszewska, E.; Piotrzkowski, R.; Domagala, J.Z.; Bockowski, M. Basic ammonothermal growth of Gallium Nitride—State of the art, challenges, perspectives. Prog. Cryst. Growth Charact. Mater. 2018, 64, 63–74. [Google Scholar] [CrossRef]

- Yin, M.L.; Zou, C.W.; Li, M.; Liu, C.S.; Guo, L.P.; Fu, D.J. Middle-frequency magnetron sputtering for GaN growth. Nucl. Instrum. Methods Phys. Res. B Beam Interact. Mater. At. 2007, 262, 189–193. [Google Scholar] [CrossRef]

- Akazawa, H. Target-quality dependent crystallinity of sputter-deposited LiNbO3 films: Observation of impurity segregation. Thin Solid Films 2009, 517, 5786–5792. [Google Scholar] [CrossRef]

- Kikuma, T.; Tominaga, K.; Furutani, K.; Kusaka, K.; Hanabusa, T.; Mukai, T. GaN films deposited by planar magnetron sputtering. Vacuum 2002, 66, 233–237. [Google Scholar] [CrossRef]

- Junaid, M.; Sandström, P.; Palisaitis, J.; Darakchieva, V.; Hsiao, C.-L.; Persson, P.O.Å.; Hultman, L.; Birch, J. Stress evolution during growth of GaN(0001)/Al2O3(0001) by reactive dc magnetron sputter epitaxy. J. Phys. D Appl. Phys. 2014, 47, 145301. [Google Scholar] [CrossRef]

- Masłyk, M.; Borysiewicz, M.A.; Wzorek, M.; Wojciechowski, T.; Kwoka, M.; Kaminska, E. Influence of absolute argon and oxygen flow values at a constant ratio on the growth of Zn/ZnO nanostructures obtained by DC reactive magnetron sputtering. Appl. Surf. Sci. 2016, 389, 287–293. [Google Scholar] [CrossRef]

- Qian, D. Plasma edge and its application to infrared measurement and detection. J. Appl. Phys. 1993, 74, 3061–3064. [Google Scholar] [CrossRef]

- Charache, G.W.; DePoy, D.M.; Raynolds, J.E.; Baldasaro, P.F.; Miyano, K.E.; Holden, T.; Pollak, F.H.; Sharps, P.R.; Timmons, M.L.; Geller, C.B.; et al. Moss–Burstein and plasma reflection characteristics of heavily doped n-type InxGa1−xAs and InPyAs1−y. J. Appl. Phys. 1999, 86, 452–458. [Google Scholar] [CrossRef]

- Giehler, M.; Ramsteiner, M.; Brandt, O.; Yang, H.; Ploog, K.H. Optical phonons of hexagonal and cubic GaN studied by infrared transmission and Raman spectroscopy. Appl. Phys. Lett. 1995, 67, 733–735. [Google Scholar] [CrossRef]

- Hsueh, K.-P.; Chiang, K.-C.; Hsin, Y.-M.; Wang, C.-J. Investigation of Cr- and Al-based metals for the reflector and Ohmic contact on n-GaN in GaN flip-chip light-emitting diodes. Appl. Phys. Lett. 2006, 89, 191122. [Google Scholar] [CrossRef]

- Lee, M.-L.; Sheu, J.-K.; Hu, C.C. Nonalloyed Cr⁄Au-based Ohmic contacts to n-GaN. Appl. Phys. Lett. 2007, 91, 182106. [Google Scholar] [CrossRef] [Green Version]

- Schroder, D.K. Semiconductor Material and Device Characterization, 3rd ed.; Wiley & Sons Inc.: Hoboken, NJ, USA, 2006. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maslyk, M.; Prystawko, P.; Kaminska, E.; Grzanka, E.; Krysko, M. Ohmic Contact to n-GaN Using RT-Sputtered GaN:O. Materials 2023, 16, 5574. https://doi.org/10.3390/ma16165574

Maslyk M, Prystawko P, Kaminska E, Grzanka E, Krysko M. Ohmic Contact to n-GaN Using RT-Sputtered GaN:O. Materials. 2023; 16(16):5574. https://doi.org/10.3390/ma16165574

Chicago/Turabian StyleMaslyk, Monika, Pawel Prystawko, Eliana Kaminska, Ewa Grzanka, and Marcin Krysko. 2023. "Ohmic Contact to n-GaN Using RT-Sputtered GaN:O" Materials 16, no. 16: 5574. https://doi.org/10.3390/ma16165574

APA StyleMaslyk, M., Prystawko, P., Kaminska, E., Grzanka, E., & Krysko, M. (2023). Ohmic Contact to n-GaN Using RT-Sputtered GaN:O. Materials, 16(16), 5574. https://doi.org/10.3390/ma16165574