Influence of the Resin System and Sand Type on the Infiltration of 3D-Printed Sand Tools

Abstract

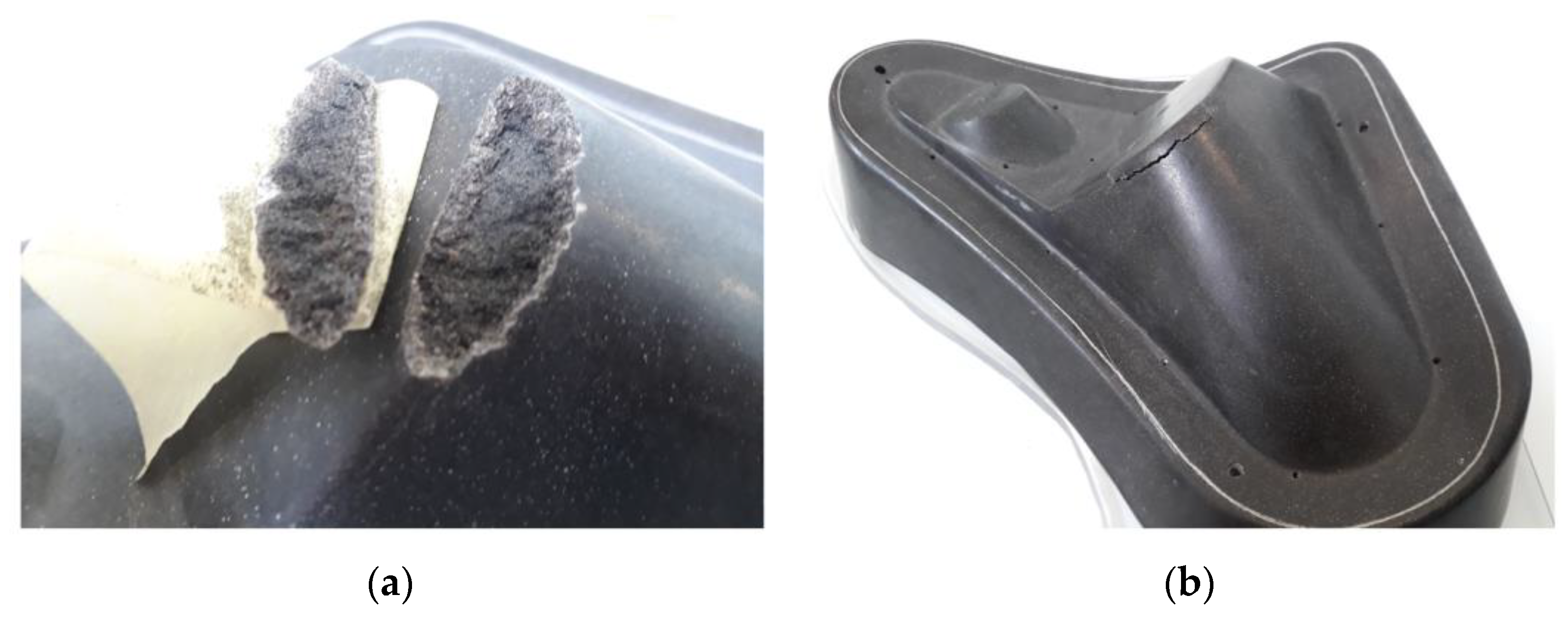

1. Introduction

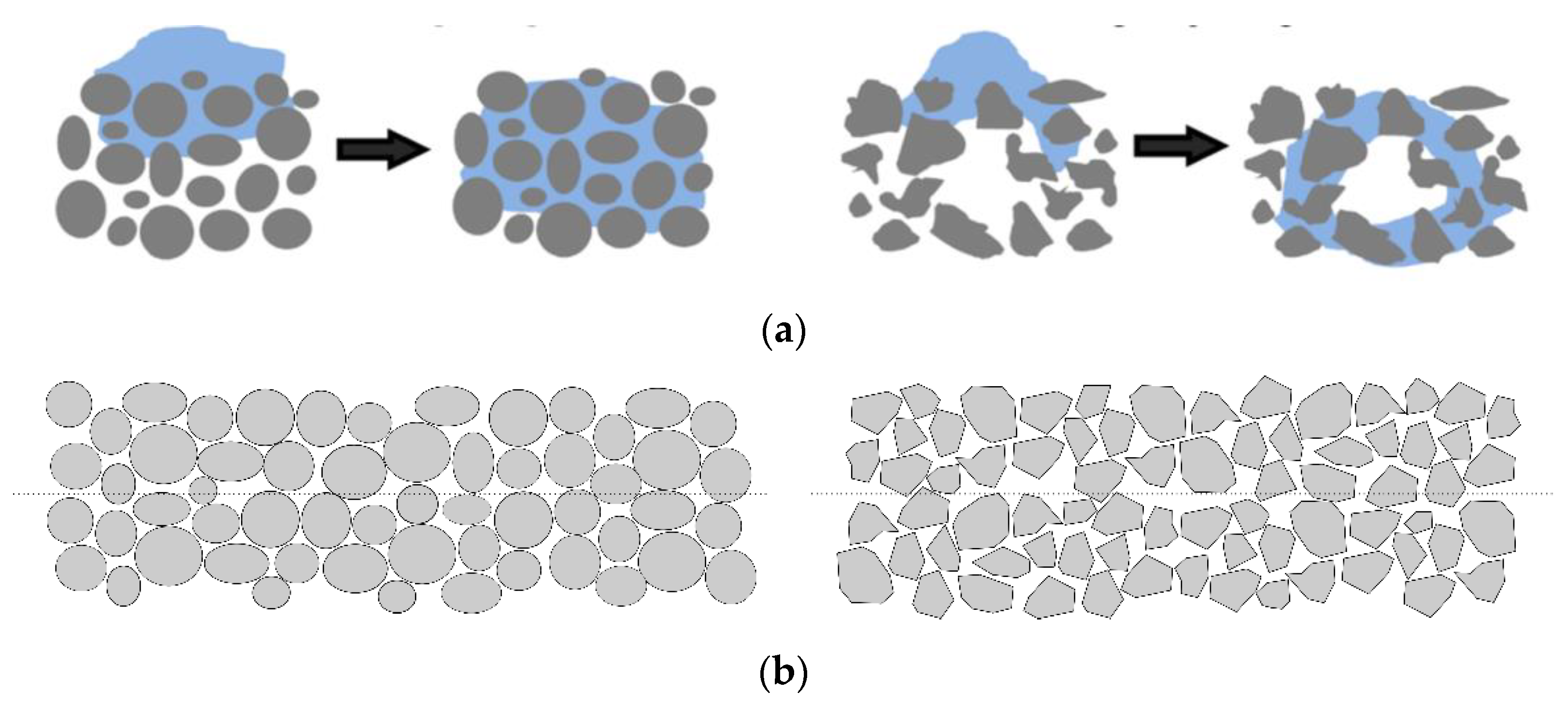

2. Theory on Infiltration of Porous Substrates

3. Materials and Methods

3.1. Materials

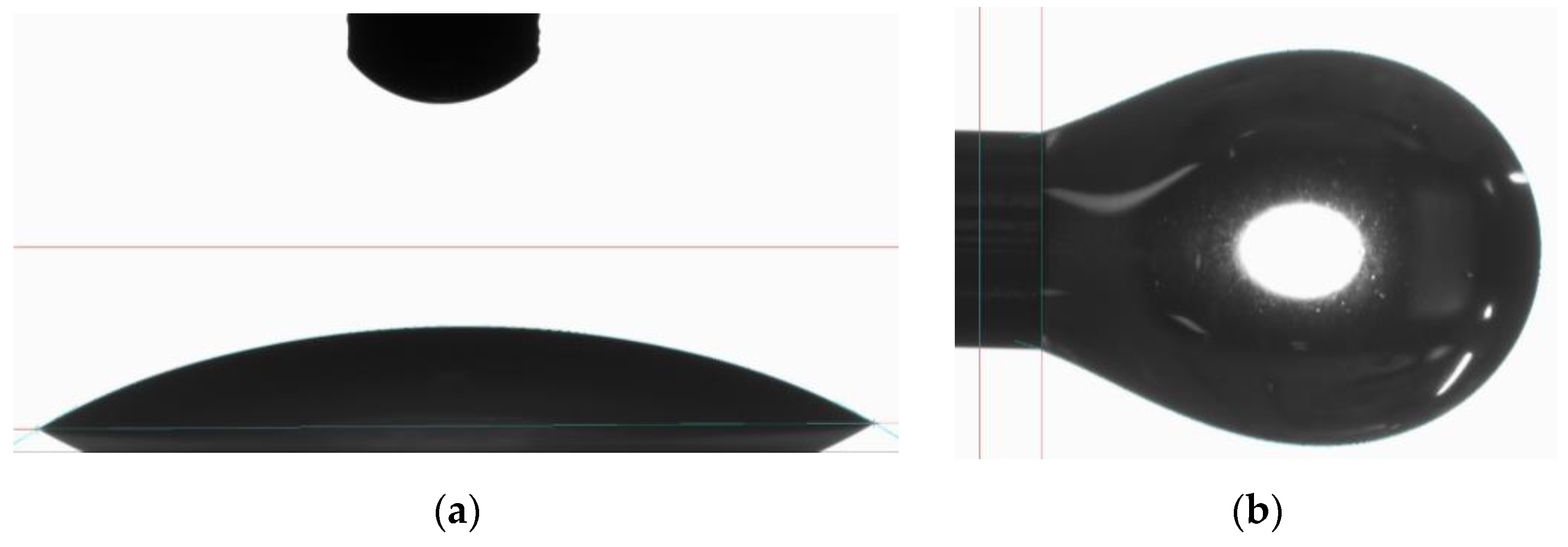

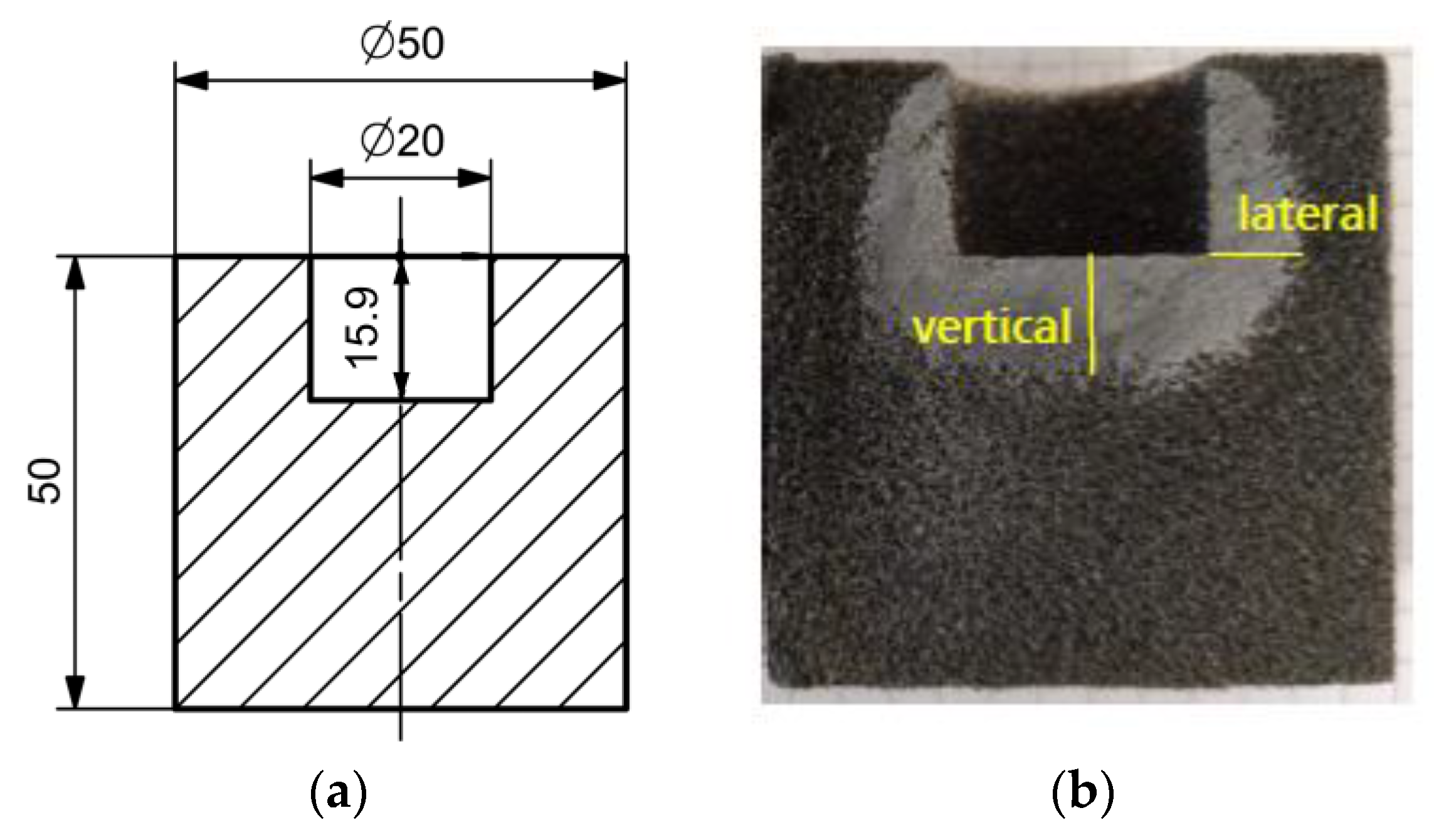

3.2. Specimen and Experimental Method

3.3. Examination Methods

4. Results and Discussion

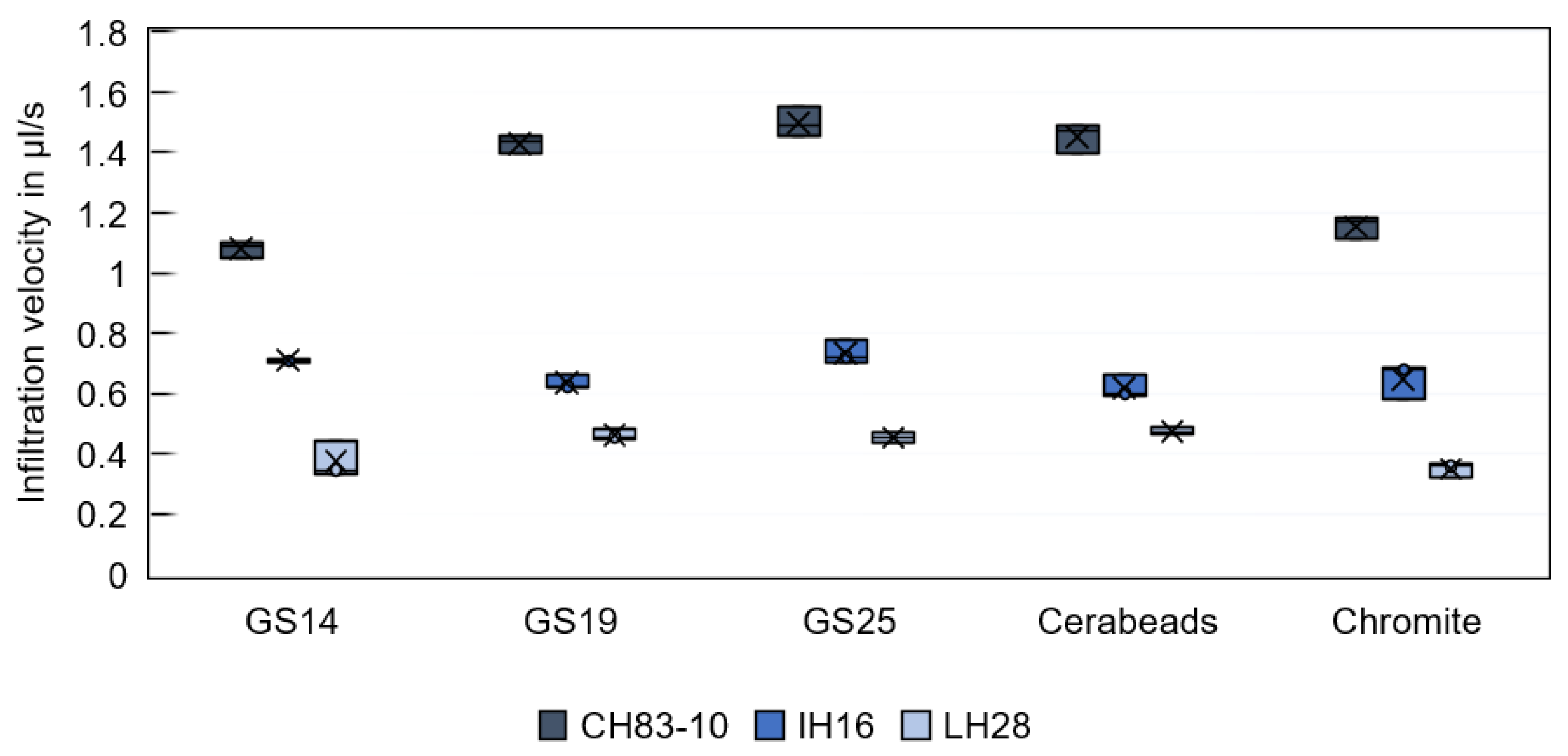

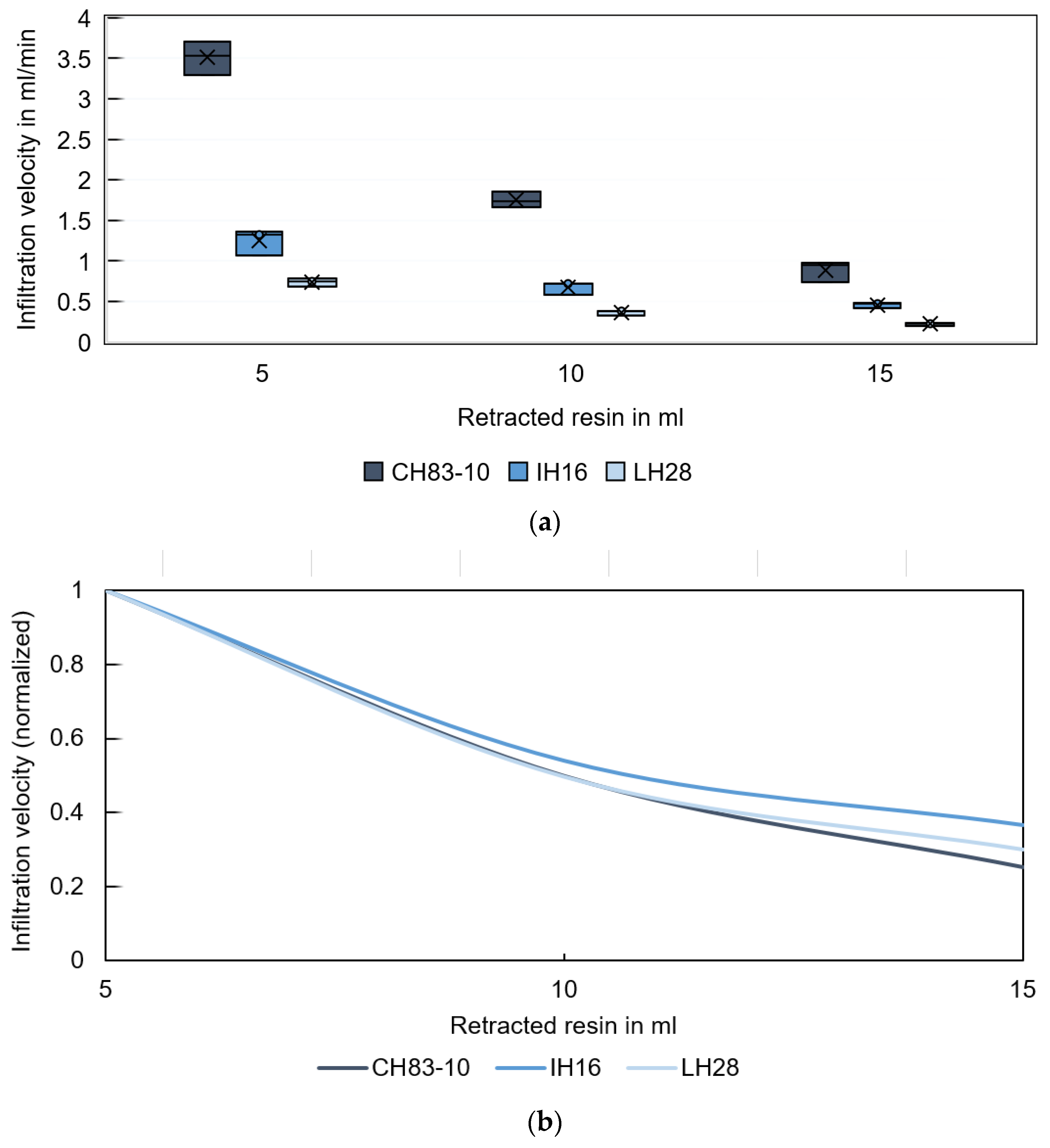

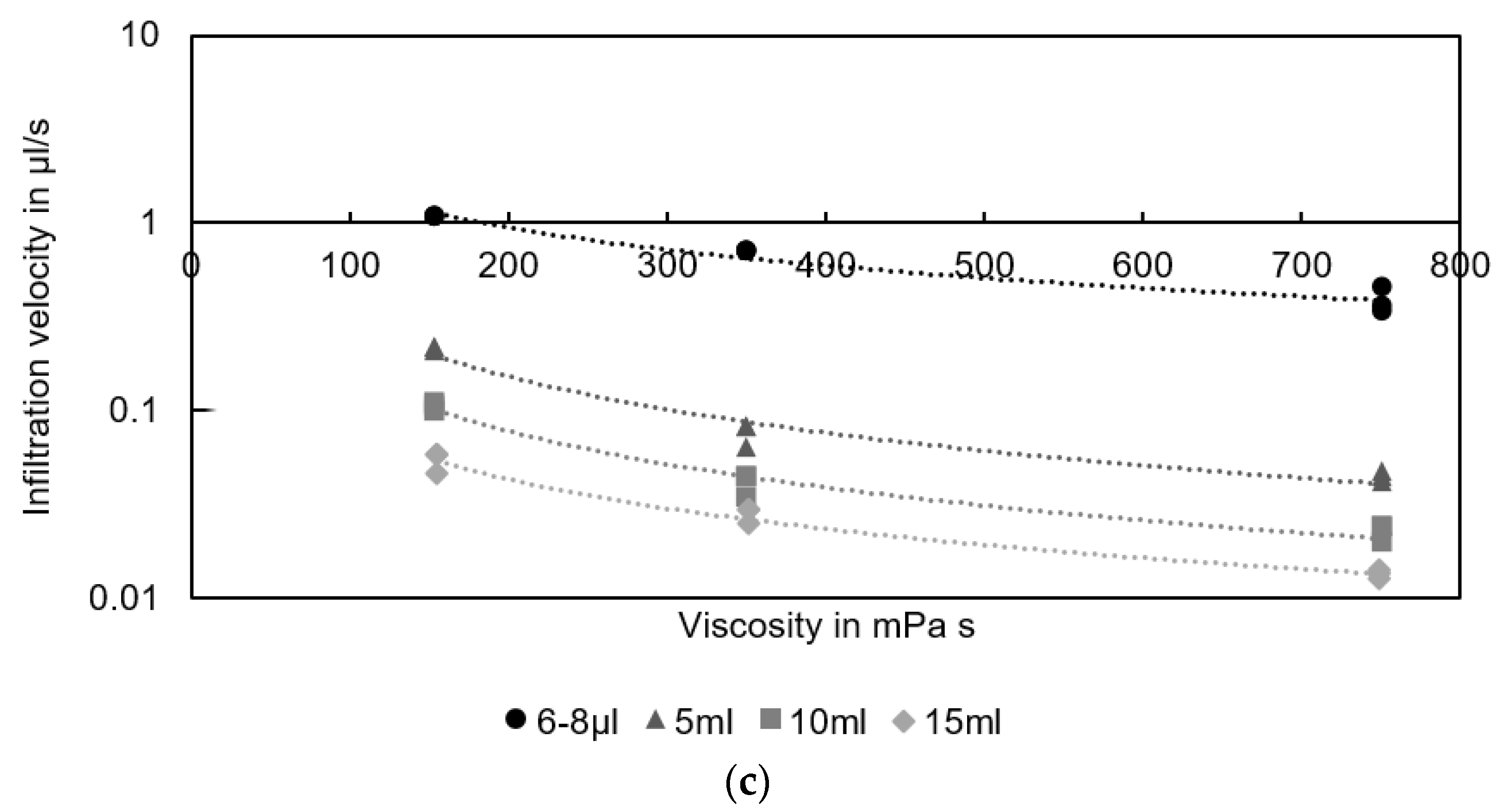

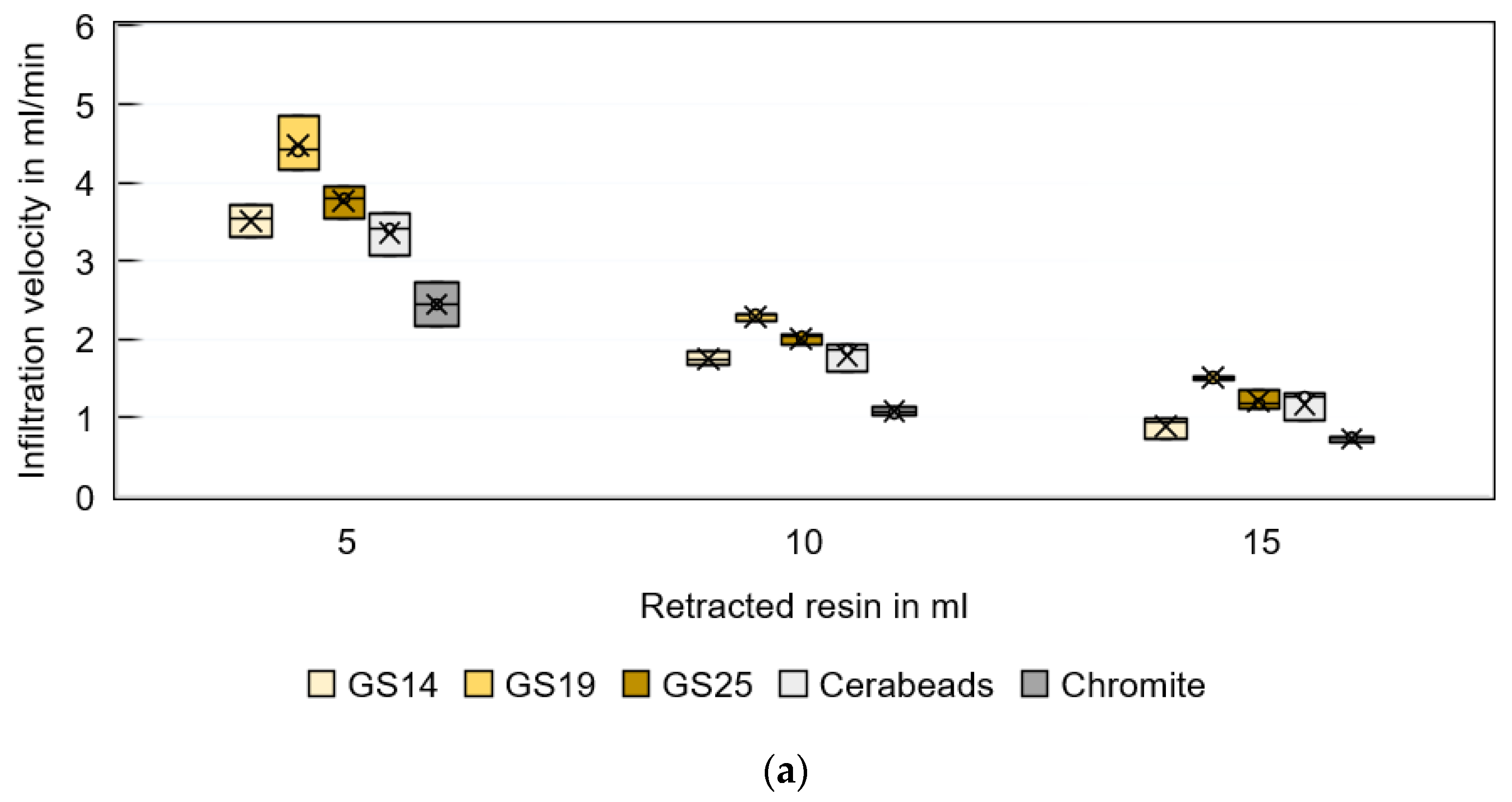

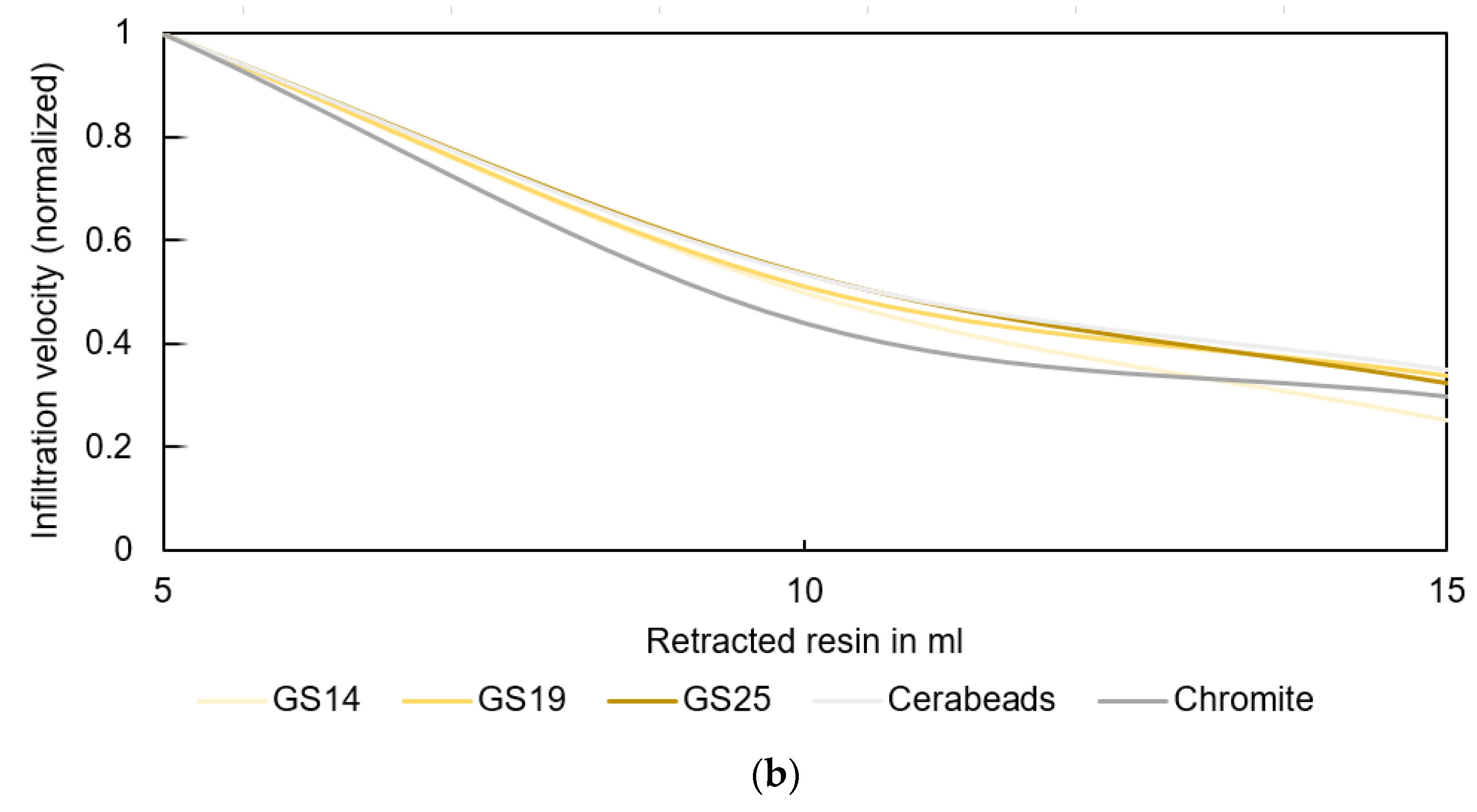

4.1. Infiltration Velocity

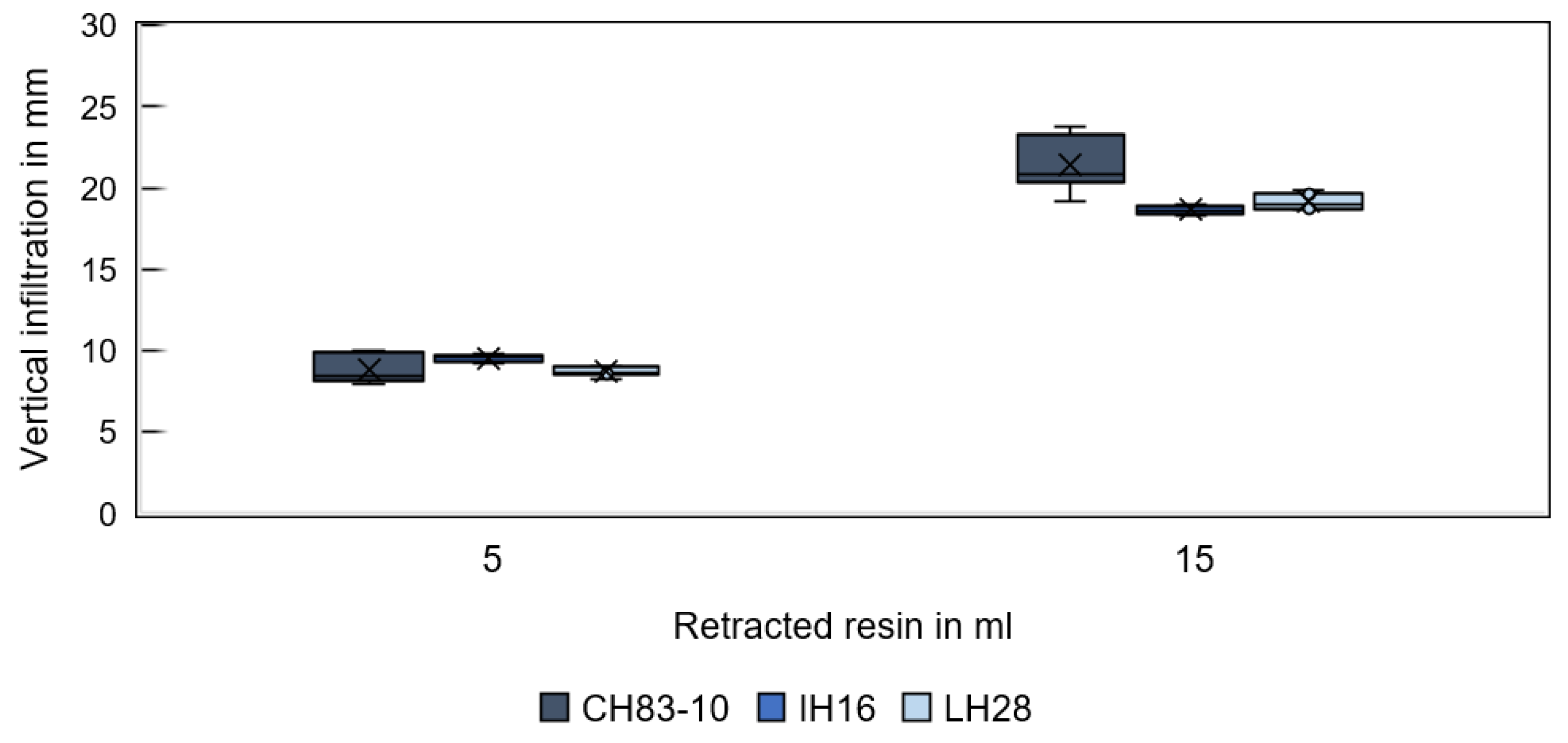

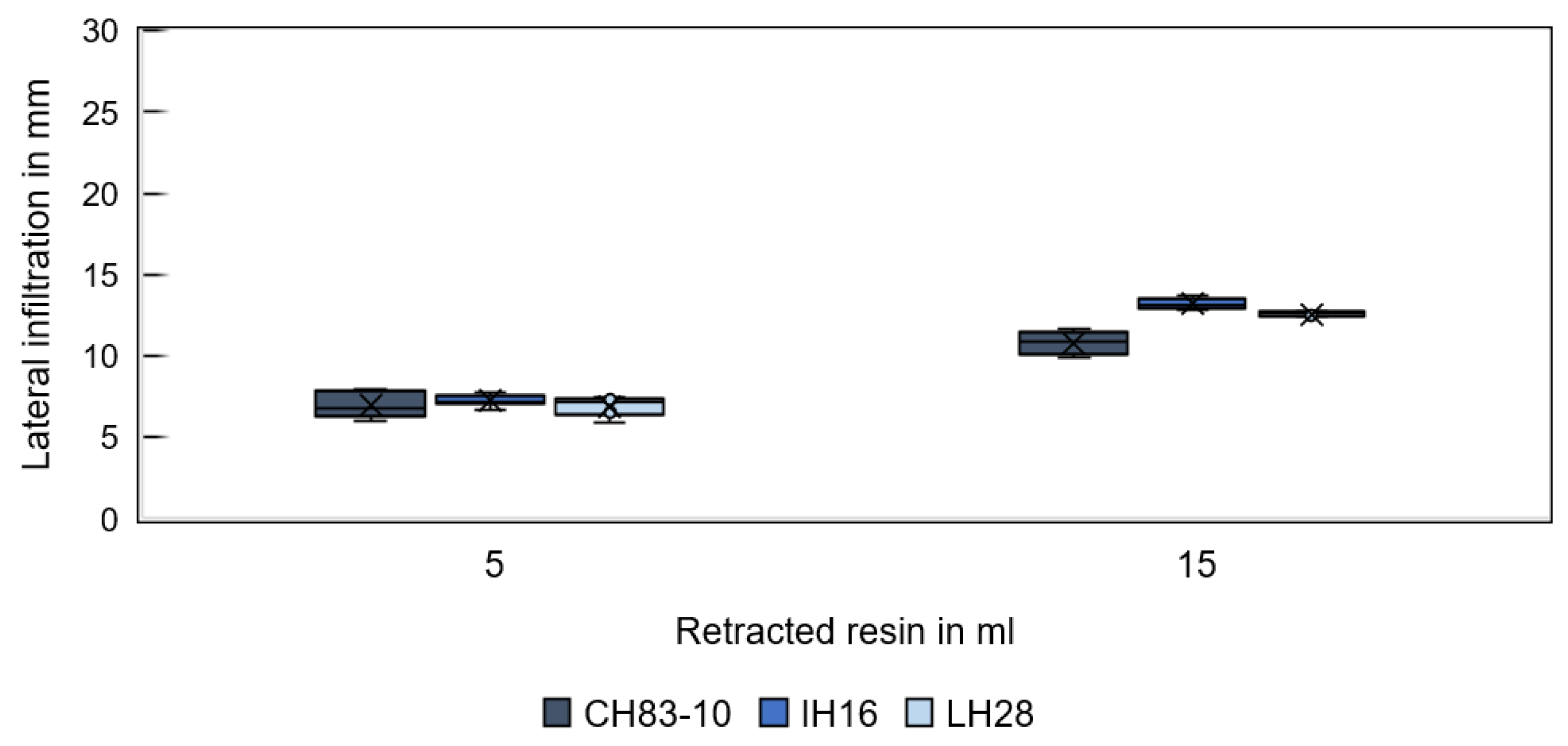

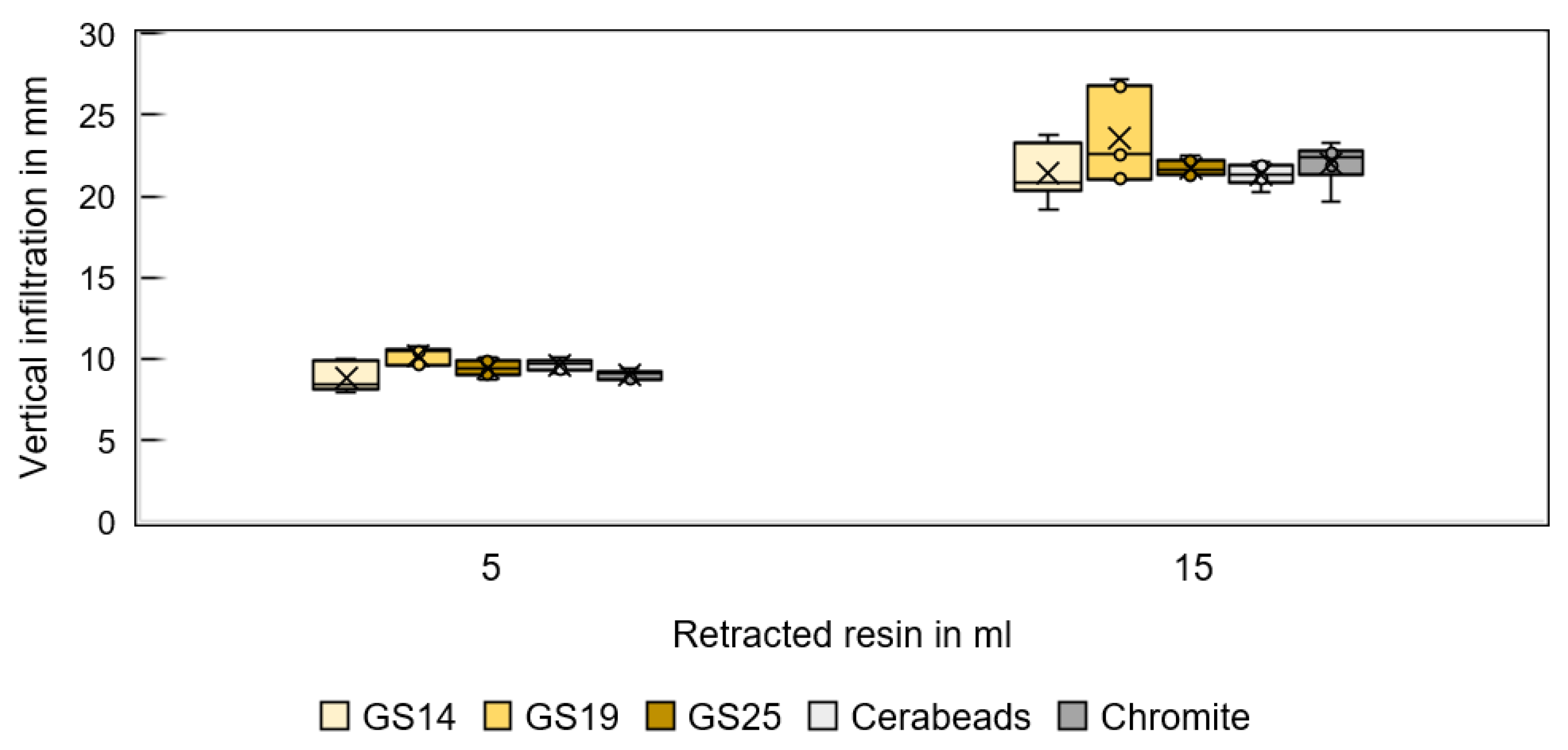

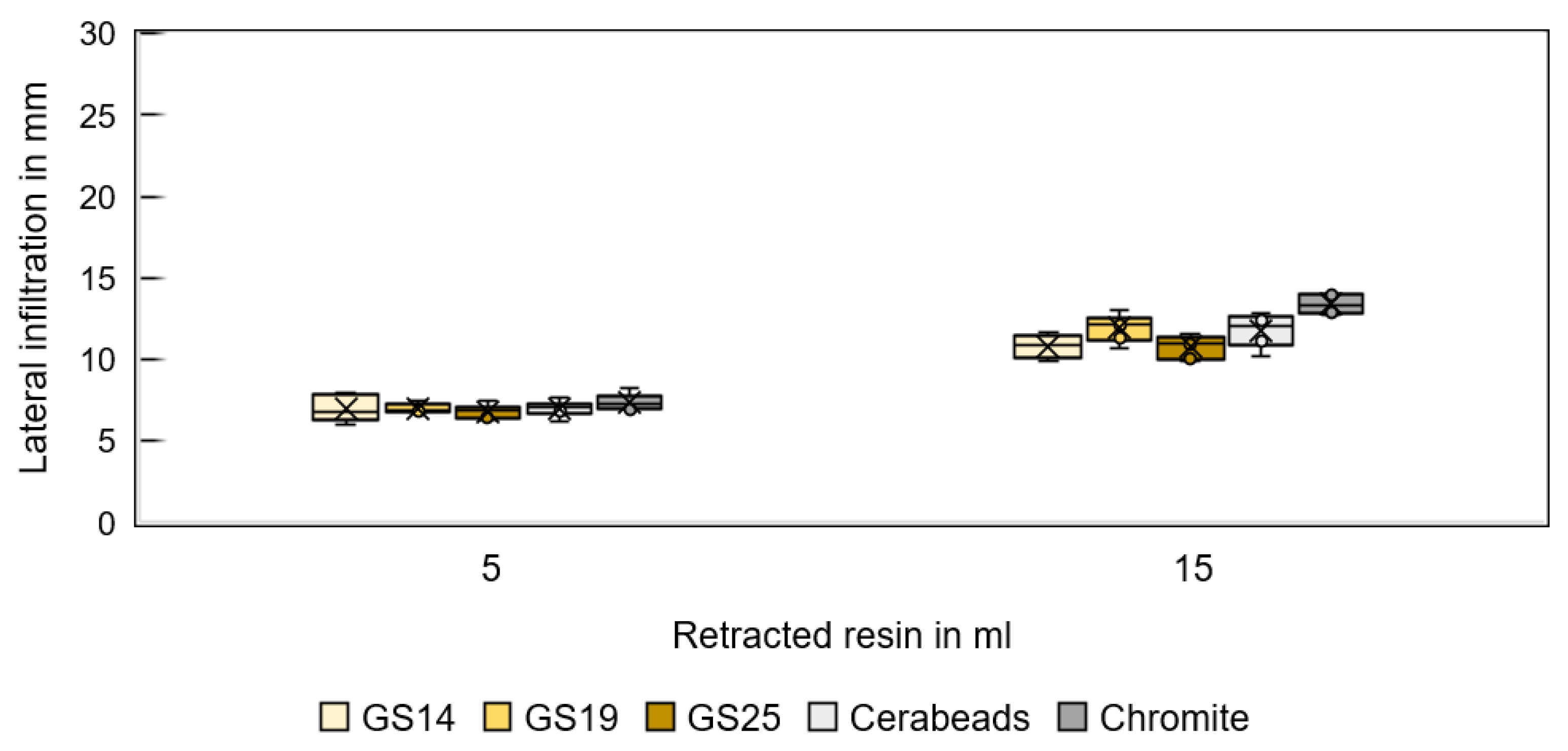

4.2. Infiltration Depth

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Taha, I.; Abdellatif, M.H.; Dietz, P. Infiltration and Coating of Rapid Prototyping Parts. Adv. Eng. Mater. 2005, 7, 91–96. [Google Scholar] [CrossRef]

- Gohn, A.M.; Brown, D.; Mendis, G.; Forster, S.; Rudd, N.; Giles, M. Mold inserts for injection molding prototype applications fabricated via material extrusion additive manufacturing. Addit. Manuf. 2022, 51, 102595. [Google Scholar] [CrossRef]

- Wohlers, T.T.; Campbell, I.; Diegel, O.; Huff, R.; Kowen, J. Wohlers Report 2022: 3D Printing and Additive Manufacturing Global State of the Industry; Wohlers Associates: Fort Collins, CO, USA, 2022. [Google Scholar]

- Moshiri, M.; Charles, A.; Elkaseer, A.; Scholz, S.; Mohanty, S.; Tosello, G. An Industry 4.0 framework for tooling production using metal additive manufacturing-based first-time-right smart manufacturing system. Procedia CIRP 2020, 93, 32–37. [Google Scholar] [CrossRef]

- Fette, M.; Sander, P.; Wulfsberg, J.; Zierk, H.; Herrmann, A.; Stoess, N. Optimized and Cost-efficient Compression Molds Manufactured by Selective Laser Melting for the Production of Thermoset Fiber Reinforced Plastic Aircraft Components. Procedia CIRP 2015, 35, 25–30. [Google Scholar] [CrossRef]

- Brøtan, V.; Berg, O.Å.; Sørby, K. Additive Manufacturing for Enhanced Performance of Molds. Procedia CIRP 2016, 54, 186–190. [Google Scholar] [CrossRef]

- Asnafi, N. Application of Laser-Based Powder Bed Fusion for Direct Metal Tooling. Metals 2021, 11, 458. [Google Scholar] [CrossRef]

- Salmi, A.; Calignano, F.; Galati, M.; Atzeni, E. An integrated design methodology for components produced by laser powder bed fusion (L-PBF) process. Virtual Phys. Prototyp. 2018, 13, 191–202. [Google Scholar] [CrossRef]

- Bajaj, P.; Hariharan, A.; Kini, A.; Kürnsteiner, P.; Raabe, D.; Jägle, E.A. Steels in additive manufacturing: A review of their microstructure and properties. Mater. Sci. Eng. A 2020, 772, 138633. [Google Scholar] [CrossRef]

- Junk, S.; Schrock, S.; Schröder, W. Additive tooling for thermoforming a cowling of an UAV using binder jetting. AIP Conf. Proc. 2019, 2113, 150001. [Google Scholar]

- Leal, R.; Barreiros, F.M.; Alves, L.; Romeiro, F.; Vasco, J.C.; Santos, M.; Marto, C. Additive manufacturing tooling for the automotive industry. Int. J. Adv. Manuf. Technol. 2017, 92, 1671–1676. [Google Scholar] [CrossRef]

- Chimento, J.; Jason Highsmith, M.; Crane, N. 3D printed tooling for thermoforming of medical devices. Rapid Prototyp. J. 2011, 17, 387–392. [Google Scholar] [CrossRef]

- Modi, Y.K. Calcium sulphate based 3D printed tooling for vacuum forming of medical devices: An experimental evaluation. Mater. Technol. 2018, 33, 642–650. [Google Scholar] [CrossRef]

- Bhandari, S. Feasibility of Using 3D Printed Molds for Thermoforming Thermoplastic Composites. Master’s Thesis, University of Maine, Orono, ME, USA, 2017. Available online: https://www.researchgate.net/publication/317399630_Feasibility_of_using_3D_printed_molds_for_thermoforming_thermoplastic_composites (accessed on 21 June 2023).

- Han, L.; Gilmer, D.B.; Elliott, A.; Saito, T. Spray coating for washout tooling by binder jet additive manufacturing. Compos. Part B Eng. 2023, 250, 110436. [Google Scholar] [CrossRef]

- Warden, G.F. Development of an Additive Manufacturing Compression Molding Process for Low Cost In-House Prototyping. 2018. Available online: https://digitalcommons.calpoly.edu/imesp/249 (accessed on 21 June 2023).

- Bere, P.; Neamtu, C.; Udroiu, R. Novel Method for the Manufacture of Complex CFRP Parts Using FDM-based Molds. Polymers 2020, 12, 2220. [Google Scholar] [CrossRef]

- Hassen, A.A.; Springfield, R.; Lindahl, J.; Post, B.; Kunc, V. The durability of large-scale additive manufacturing composite molds. CAMX 2016, 2016, 26–29. Available online: https://www.researchgate.net/publication/324391116 (accessed on 23 June 2023).

- Yeole, P.; Herring, C.; Hassen, A.; Kunc, V.; Stratton, R.; Vaidya, U. Improve durability and surface quality of additively manufactured molds using carbon fiber prepreg. Polym. Compos. 2021, 42, 2101–2111. [Google Scholar] [CrossRef]

- Erhard, P.; Hartmann, C.; Li, R.; Volk, W.; Günther, D. Advanced Procedures for Series Production with 3D-Printed Core Packages. Inter. Metalcast. 2023, 1–12. [Google Scholar] [CrossRef]

- Erhard, P.; Angenoorth, J.; Vogt, J.; Spiegel, J.; Ettemeyer, F.; Volk, W.; Günther, D. Characterization of Slurry-Cast Layer Compounds for 3D Printing of High Strength Casting Cores. Materials 2021, 14, 6149. [Google Scholar] [CrossRef]

- Upadhyay, M.; Sivarupan, T.; El Mansori, M. 3D printing for rapid sand casting—A review. J. Manuf. Process. 2017, 29, 211–220. [Google Scholar] [CrossRef]

- Porter, Q.; Moghadasi, M.; Pei, Z.; Ma, C. Dense and strong ceramic composites via binder jetting and spontaneous infiltration. Ceram. Int. 2023, 49, 17363–17370. [Google Scholar] [CrossRef]

- Chen, Q.; Juste, E.; Lasgorceix, M.; Lefebvre, G.; Tenailleau, C.; Duployer, B.; Grossin, D.; Petit, F.; Leriche, A. Post-infiltration to improve the density of binder jetting ceramic parts. IOP Conf. Ser. Mater. Sci. Eng. 2022, 42, 7134–7148. [Google Scholar] [CrossRef]

- Zhang, J.; Wu, J.-M.; Liu, H.; Zhang, Y.-Z.; Ye, C.-S.; Shi, Y.-S. Infiltration of silica slurry into silica-based ceramic cores prepared by selective laser sintering based on pre-sintering. Ceram. Int. 2023, in press. [CrossRef]

- Garzón, E.O.; Alves, J.L.; Neto, R.J. Post-process Influence of Infiltration on Binder Jetting Technology. In Materials Design and Applications. Advanced Structured Materials; Silva, L., Ed.; Springer: Cham, Switzerland, 2017; Volume 65. [Google Scholar] [CrossRef]

- Maravola, M.; Conner, B.; Walker, J.; Cortes, P. Epoxy infiltrated 3D printed ceramics for composite tooling applications. Addit. Manuf. 2019, 25, 59–63. [Google Scholar] [CrossRef]

- Günther, D.; Erhard, P.; Schwab, S.; Taha, I. 3D Printed Sand Tools for Thermoforming Applications of Carbon Fiber Reinforced Composites-A Perspective. Materials 2021, 14, 4639. [Google Scholar] [CrossRef] [PubMed]

- Ayres, T.J.; Sama, S.R.; Joshi, S.B.; Manogharan, G.P. Influence of resin infiltrants on mechanical and thermal performance in plaster binder jetting additive manufacturing. Addit. Manuf. 2019, 30, 100885. [Google Scholar]

- Guo, A.; Wang, J.; Tang, R.; Kong, H.; Kong, D.; Qu, P.; Wang, S.; Wang, H.; Hu, Y. Insights into the effects of epoxy resin infiltration on powder aging issue induced by powder recycling in powder bed fusion of Nylon12 materials. J. Mater. Res. Technol. 2023, 23, 3151–3165. [Google Scholar] [CrossRef]

- Mostafaei, A.; Elliott, A.M.; Barnes, J.E.; Li, F.; Tan, W.; Cramer, C.L.; Nandwana, P.; Chmielus, M. Binder jet 3D printing—Process parameters, materials, properties, modeling, and challenges. Prog. Mater. Sci. 2020, 40, 100707. [Google Scholar] [CrossRef]

- Prakoso, A.T.; Basri, H.; Adanta, D.; Yani, I.; Ammarullah, M.I.; Akbar, I.; Ghazali, F.A.; Syahrom, A.; Kamarul, T. The Effect of Tortuosity on Permeability of Porous Scaffold. Biomedicines 2023, 11, 427. [Google Scholar] [CrossRef]

- Seymour, A.J.; Shin, S.; Heilshorn, S.C. 3D Printing of Microgel Scaffolds with Tunable Void Fraction to Promote Cell Infiltration. Adv. Healthc. Mater. 2021, 10, e2100644. [Google Scholar] [CrossRef]

- Wudy, K.; Drummer, D. Infiltration Behavior of Thermosets for Use in a Combined Selective Laser Sintering Process of Polymers. JOM 2019, 71, 920–927. [Google Scholar] [CrossRef]

- Washburn, E.W. The Dynamics of Capillary Flow. Phys. Rev. 1921, 17, 273–283. [Google Scholar] [CrossRef]

- Denesuk, M.; Smith, G.L.; Zelinski, B.; Kreidl, N.J.; Uhlmann, D.R. Capillary Penetration of Liquid Droplets into Porous Materials. J. Colloid Interface Sci. 1993, 158, 114–120. [Google Scholar] [CrossRef]

- Holman, R.K.; Cima, M.J.; Uhland, S.A.; Sachs, E. Spreading and infiltration of inkjet-printed polymer solution droplets on a porous substrate. J. Colloid Interface Sci. 2002, 249, 432–440. [Google Scholar] [CrossRef] [PubMed]

- Holman, R.K. Effects of the Polymeric Binder System in Slurry-Based Three Dimensional Printing of Ceramics. Ph.D. Thesis, Department of Materials Science and Engineering, Massachusetts Institute of Technology, Cambridge, MA, USA, 2001. Available online: http://hdl.handle.net/1721.1/8448 (accessed on 23 June 2023).

- Erhard, P.; Seidel, A.; Vogt, J.; Volk, W.; Günther, D. Evaluation and optimisation of a slurry-based layer casting process in additive manufacturing using multiphase simulations and spatial reconstruction. Prod. Eng. Res. Dev. 2022, 16, 43–54. [Google Scholar] [CrossRef]

- Schneider, C.A.; Rasband, W.S.; Eliceiri, K.W. NIH Image to ImageJ: 25 years of image analysis. Nat. Methods 2012, 9, 671–675. [Google Scholar] [CrossRef] [PubMed]

- Chu, X.; Mariño, M.A. Determination of ponding condition and infiltration into layered soils under unsteady rainfall. J. Hydrol. 2005, 313, 195–207. [Google Scholar] [CrossRef]

- Herrada, M.A.; Gutiérrez-Martin, A.; Montanero, J.M. Modeling infiltration rates in a saturated/unsaturated soil under the free draining condition. J. Hydrol. 2014, 515, 10–15. [Google Scholar] [CrossRef]

- Feng, G.L.; Letey, J.; Wu, L. Water Ponding Depths Affect Temporal Infiltration Rates in a Water-Repellent Sand. Soil Sci. Soc. Am. J. 2001, 65, 315–320. [Google Scholar] [CrossRef]

- Schulze, D. Powders and Bulk Solids: Behavior, Characterization, Storage and Flow; Springer: Berlin/Heidelberg, Germany, 2014; Available online: http://worldcatlibraries.org/wcpa/oclc/261225514 (accessed on 11 May 2023).

- Utela, B.; Storti, D.; Anderson, R.; Ganter, M. A review of process development steps for new material systems in three dimensional printing (3DP). J. Manuf. Process. 2008, 10, 96–104. [Google Scholar] [CrossRef]

- Chen, Z.; Li, Z.; Li, J.; Liu, C.; Lao, C.; Fu, Y.; Liu, C.; Li, Y.; Wang, P.; He, Y. 3D printing of ceramics: A review. IOP Conf. Ser. Mater. Sci. Eng. 2019, 39, 661–687. [Google Scholar] [CrossRef]

- Recknagel, U.; Dahlmann, M. Spezialsande—Formgrundstoffe für die moderne Kern- und Formherstellung. Giess. Rundsch. 2009, 2009, 9–17. [Google Scholar]

- Hapgood, K.P.; Litster, J.D.; Biggs, S.R.; Howes, T. Drop penetration into porous powder beds. J. Colloid Interface Sci. 2002, 253, 353–366. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Z.; Buchanan, F.; Mitchell, C.; Dunne, N. Printability of calcium phosphate: Calcium sulfate powders for the application of tissue engineered bone scaffolds using the 3D printing technique. Mater. Sci. Eng. C Mater. Biol. Appl. 2014, 38, 1–10. [Google Scholar] [CrossRef] [PubMed]

| Identification | Particulate Material | Manufacturing Method | Morphology | Medium Grain Size in µm | Printed Part Porosity in % |

|---|---|---|---|---|---|

| GS14 1 | Quartz sand | Mined & ground | Edge-rounded | 130 | 51.7 |

| GS19 1 | Quartz sand | Mined & ground | Edge-rounded | 196 | 50.5 |

| GS25 1 | Quartz sand | Mined & ground | Edge-rounded | 242 | 49.4 |

| Cerabeads ES650 2 | Sintered mullite | Sintered | Round | 200 | 49.8 |

| Chromite 3 | Chromite sand | Ground | Angular | 210 | 49.0 |

| Identification Resin/Hardener | Mixed Viscosity @25 °C in mPa s | Pot Life @100 g, 25 °C in min | Compressive Strength in MPa |

|---|---|---|---|

| Biresin CR83/CH83-10 4 | 155 | 300 | 131 |

| IH16/Fast hardener 5 | 350 | 55 | 135 |

| LH28-1/TM 5 | 750 | 300 | 95 |

| CH83-10 | IH16 | LH28 | |

|---|---|---|---|

| Average contact angle in [°] | 27.5 | 31.0 | 29.4 |

| Average surface tension (average tolerance) in [mN/m] | 30.6 (0.11) | 29.3 (0.33) | 35.8 (0.25) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Erhard, P.; Taha, I.; Günther, D. Influence of the Resin System and Sand Type on the Infiltration of 3D-Printed Sand Tools. Materials 2023, 16, 5549. https://doi.org/10.3390/ma16165549

Erhard P, Taha I, Günther D. Influence of the Resin System and Sand Type on the Infiltration of 3D-Printed Sand Tools. Materials. 2023; 16(16):5549. https://doi.org/10.3390/ma16165549

Chicago/Turabian StyleErhard, Patricia, Iman Taha, and Daniel Günther. 2023. "Influence of the Resin System and Sand Type on the Infiltration of 3D-Printed Sand Tools" Materials 16, no. 16: 5549. https://doi.org/10.3390/ma16165549

APA StyleErhard, P., Taha, I., & Günther, D. (2023). Influence of the Resin System and Sand Type on the Infiltration of 3D-Printed Sand Tools. Materials, 16(16), 5549. https://doi.org/10.3390/ma16165549