Asymmetric TMO–Metal–TMO Structure for Enhanced Efficiency and Long-Term Stability of Si-Based Heterojunction Solar Cells

Abstract

:1. Introduction

2. Experimental Section

2.1. Material and Sample Preparation

2.2. Characterization

3. Results and Discussion

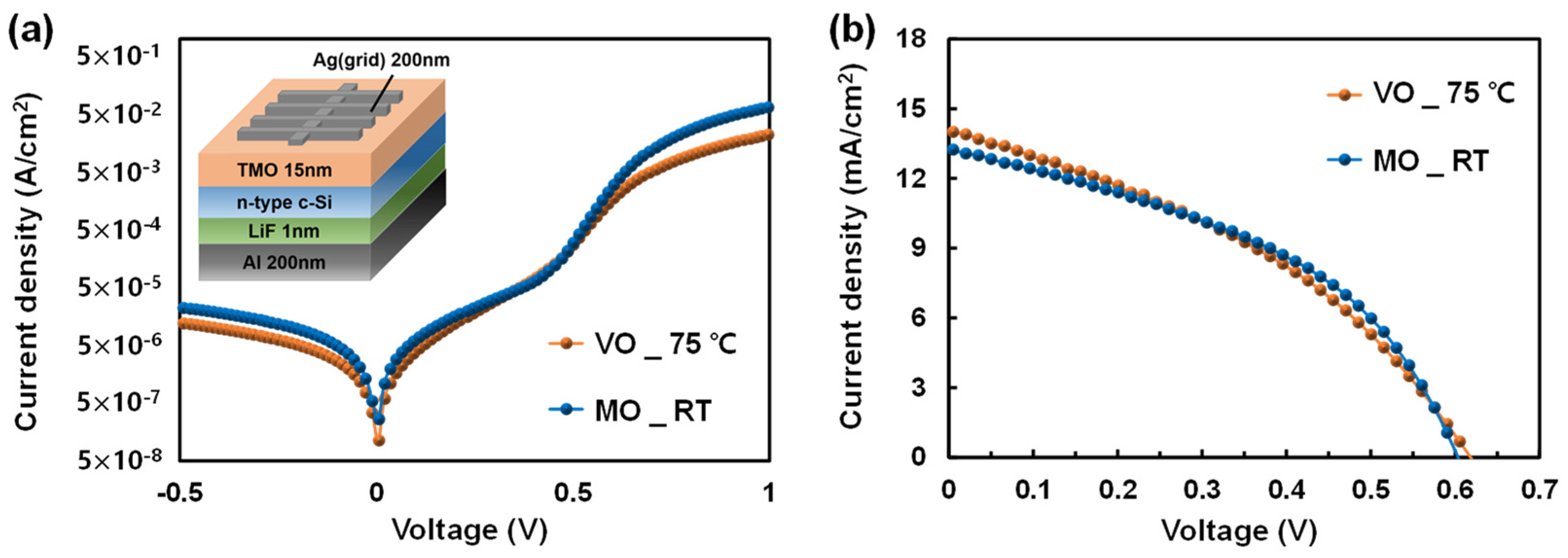

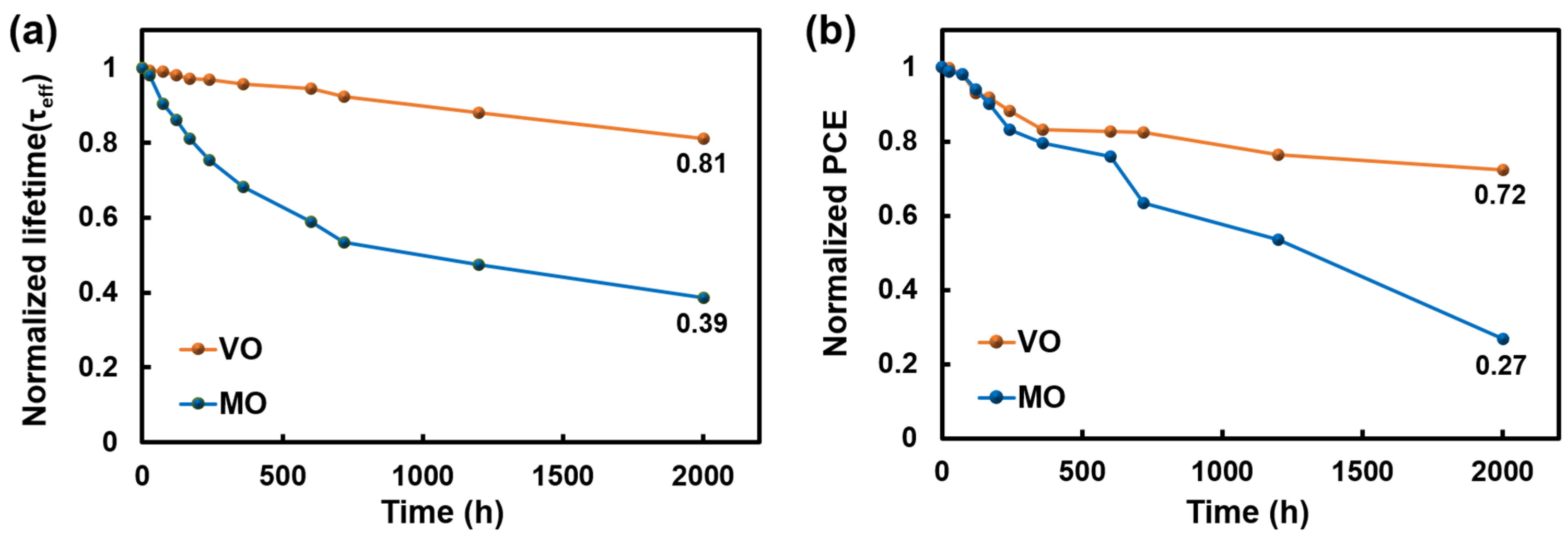

3.1. Effect of TMO on the Performance of TMO/Si HSCs

3.2. Effect of TMO Thickness on TMT/Si HSC Performance

3.3. Comparison between Asymmetric and Symmetric TMT/Si HSCs

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yoshikawa, K.; Kawasaki, H.; Yoshida, W.; Irie, T.; Konishi, K.; Nakano, K.; Uto, T.; Adachi, D.; Kanematsu, M.; Uzu, H. Silicon heterojunction solar cell with interdigitated back contacts for a photoconversion efficiency over 26%. Nat. Energy 2017, 2, 17032. [Google Scholar] [CrossRef]

- Wilson, G.M.; Al-Jassim, M.; Metzger, W.K.; Glunz, S.W.; Verlinden, P.; Xiong, G.; Mansfield, L.M.; Stanbery, B.J.; Zhu, K.; Yan, Y. The 2020 photovoltaic technologies roadmap. J. Phys. D Appl. Phys. 2020, 53, 493001. [Google Scholar] [CrossRef]

- Dai, H.; Yang, L.; He, S. <50-μm thin crystalline silicon heterojunction solar cells with dopant-free carrier-selective contacts. Nano Energy 2019, 64, 103930. [Google Scholar]

- Gao, P.; Ding, K.; Wang, Y.; Ruan, K.; Diao, S.; Zhang, Q.; Sun, B.; Jie, J. Crystalline Si/graphene quantum dots heterojunction solar cells. J. Phys. Chem. C 2014, 118, 5164–5171. [Google Scholar] [CrossRef]

- Cruz, A.; Wang, E.-C.; Morales-Vilches, A.B.; Meza, D.; Neubert, S.; Szyszka, B.; Schlatmann, R.; Stannowski, B. Effect of front TCO on the performance of rear-junction silicon heterojunction solar cells: Insights from simulations and experiments. Sol. Energy Mater. Sol. Cells 2019, 195, 339–345. [Google Scholar] [CrossRef]

- Niemelä, J.-P.; Macco, B.; Barraud, L.; Descoeudres, A.; Badel, N.; Despeisse, M.; Christmann, G.; Nicolay, S.; Ballif, C.; Kessels, W.M. Rear-emitter silicon heterojunction solar cells with atomic layer deposited ZnO: Al serving as an alternative transparent conducting oxide to In2O3: Sn. Sol. Energy Mater. Sol. Cells 2019, 200, 109953. [Google Scholar] [CrossRef]

- Gerling, L.G.; Mahato, S.; Morales-Vilches, A.; Masmitja, G.; Ortega, P.; Voz, C.; Alcubilla, R.; Puigdollers, J. Transition metal oxides as hole-selective contacts in silicon heterojunctions solar cells. Sol. Energy Mater. Sol. Cells 2016, 145, 109–115. [Google Scholar] [CrossRef] [Green Version]

- Messmer, C.; Bivour, M.; Schön, J.; Hermle, M. Requirements for efficient hole extraction in transition metal oxide-based silicon heterojunction solar cells. J. Appl. Phys. 2018, 124, 085702. [Google Scholar] [CrossRef]

- He, J.; Wan, Y.; Gao, P.; Tang, J.; Ye, J. Over 16.7% efficiency organic-silicon heterojunction solar cells with solution-processed dopant-free contacts for both polarities. Adv. Funct. Mater. 2018, 28, 1802192. [Google Scholar] [CrossRef]

- Rafique, S.; Abdullah, S.M.; Shahid, M.M.; Ansari, M.O.; Sulaiman, K. Significantly improved photovoltaic performance in polymer bulk heterojunction solar cells with graphene oxide/PEDOT: PSS double decked hole transport layer. Sci. Rep. 2017, 7, 39555. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; Chen, Q.; Duan, H.-S.; Zhou, H.; Yang, Y.M.; Chen, H.; Luo, S.; Song, T.-B.; Dou, L.; Hong, Z. A dopant-free organic hole transport material for efficient planar heterojunction perovskite solar cells. J. Mater. Chem. A 2015, 3, 11940–11947. [Google Scholar] [CrossRef]

- Liu, Y.; Hong, Z.; Chen, Q.; Chen, H.; Chang, W.H.; Yang, Y.; Song, T.B. Perovskite solar cells employing dopant-free organic hole transport materials with tunable energy levels. Adv. Mater. 2016, 28, 440–446. [Google Scholar] [CrossRef] [PubMed]

- Wu, W.; Bao, J.; Jia, X.; Liu, Z.; Cai, L.; Liu, B.; Song, J.; Shen, H. Dopant-free back contact silicon heterojunction solar cells employing transition metal oxide emitters. Phys. Status Solidi (RRL) Rapid Res. Lett. 2016, 10, 662–667. [Google Scholar] [CrossRef]

- Mehmood, H.; Nasser, H.; Tauqeer, T.; Turan, R. Simulation of silicon heterostructure solar cell featuring dopant-free carrier-selective molybdenum oxide and titanium oxide contacts. Renew. Energy 2019, 143, 359–367. [Google Scholar] [CrossRef]

- Almora, O.; Gerling, L.G.; Voz, C.; Alcubilla, R.; Puigdollers, J.; Garcia-Belmonte, G. Superior performance of V2O5 as hole selective contact over other transition metal oxides in silicon heterojunction solar cells. Sol. Energy Mater. Sol. Cells 2017, 168, 221–226. [Google Scholar] [CrossRef] [Green Version]

- Gerling, L.G.; Mahato, S.; Voz, C.; Alcubilla, R.; Puigdollers, J. Characterization of transition metal oxide/silicon heterojunctions for solar cell applications. Appl. Sci. 2015, 5, 695–705. [Google Scholar] [CrossRef] [Green Version]

- Masmitjà, G.; Ortega, P.; Puigdollers, J.; Gerling, L.; Martín, I.; Voz, C.; Alcubilla, R. Interdigitated back-contacted crystalline silicon solar cells with low-temperature dopant-free selective contacts. J. Mater. Chem. A 2018, 6, 3977–3985. [Google Scholar] [CrossRef] [Green Version]

- Lu, M.; Das, U.; Bowden, S.; Hegedus, S.; Birkmire, R. Optimization of interdigitated back contact silicon heterojunction solar cells: Tailoring hetero-interface band structures while maintaining surface passivation. Prog. Photovolt. Res. Appl. 2011, 19, 326–338. [Google Scholar] [CrossRef]

- Yu, C.; Xu, S.; Yao, J.; Han, S. Recent advances in and new perspectives on crystalline silicon solar cells with carrier-selective passivation contacts. Crystals 2018, 8, 430. [Google Scholar] [CrossRef] [Green Version]

- Gerling, L.G.; Masmitja, G.; Ortega, P.; Voz, C.; Alcubilla, R.; Puigdollers, J. Passivating/hole-selective contacts based on V2O5/SiOx stacks deposited at ambient temperature. Energy Procedia 2017, 124, 584–592. [Google Scholar] [CrossRef]

- Gerling, L.G.; Voz, C.; Alcubilla, R.; Puigdollers, J. Origin of passivation in hole-selective transition metal oxides for crystalline silicon heterojunction solar cells. J. Mater. Res. 2017, 32, 260–268. [Google Scholar] [CrossRef] [Green Version]

- Young, D.L.; Nemeth, W.; Grover, S.; Norman, A.; Lee, B.G.; Stradins, P. Carrier-selective, passivated contacts for high efficiency silicon solar cells based on transparent conducting oxides. In Proceedings of the 2014 IEEE 40th Photovoltaic Specialist Conference (PVSC), Denver, CO, USA, 8–13 June 2014; pp. 1–5. [Google Scholar]

- Feldmann, F.; Simon, M.; Bivour, M.; Reichel, C.; Hermle, M.; Glunz, S. Carrier-selective contacts for Si solar cells. Appl. Phys. Lett. 2014, 104, 181105. [Google Scholar] [CrossRef]

- Jeong, G.S.; Jung, Y.-C.; Park, N.Y.; Yu, Y.-J.; Lee, J.H.; Seo, J.H.; Choi, J.-Y. Stoichiometry and Morphology Analysis of Thermally Deposited V2O5−x Thin Films for Si/V2O5−x Heterojunction Solar Cell Applications. Materials 2022, 15, 5243. [Google Scholar] [CrossRef]

- Gao, P.; Yang, Z.; He, J.; Yu, J.; Liu, P.; Zhu, J.; Ge, Z.; Ye, J. Dopant-free and carrier-selective heterocontacts for silicon solar cells: Recent advances and perspectives. Adv. Sci. 2018, 5, 1700547. [Google Scholar] [CrossRef] [Green Version]

- Dauwe, S.; Mittelstädt, L.; Metz, A.; Hezel, R. Experimental evidence of parasitic shunting in silicon nitride rear surface passivated solar cells. Prog. Photovolt. Res. Appl. 2002, 10, 271–278. [Google Scholar] [CrossRef]

- Reeves, G.; Harrison, H. Obtaining the specific contact resistance from transmission line model measurements. IEEE Electron Device Lett. 1982, 3, 111–113. [Google Scholar] [CrossRef]

- Ros Costals, E. Transparent electrodes based on ultra-thin dielectric-metal-dielectric multilayer structures. Master’s Thesis, Universitat Politècnica de Catalunya, Barcelona, Spain, 2019. [Google Scholar]

- Akdemir, O.; Zolfaghari Borra, M.; Nasser, H.; Turan, R.; Bek, A. MoOx/Ag/MoOx multilayers as hole transport transparent conductive electrodes for n-type crystalline silicon solar cells. Int. J. Energy Res. 2020, 44, 3098–3109. [Google Scholar] [CrossRef]

- Hornauer, H.; Vancea, J.; Reiss, G.; Hoffmann, H. Thickness dependence of the work function in double-layer metallic films. Z. Für Phys. B Condens. Matter 1989, 77, 399–407. [Google Scholar] [CrossRef] [Green Version]

- Kim, J.H.; Lee, J.; Kim, J.H.; Hwang, C.; Lee, C.; Park, J.Y. Work function variation of MoS2 atomic layers grown with chemical vapor deposition: The effects of thickness and the adsorption of water/oxygen molecules. Appl. Phys. Lett. 2015, 106, 251606. [Google Scholar] [CrossRef] [Green Version]

- Meyer, J.; Hamwi, S.; Kröger, M.; Kowalsky, W.; Riedl, T.; Kahn, A. Transition metal oxides for organic electronics: Energetics, device physics and applications. Adv. Mater. 2012, 24, 5408–5427. [Google Scholar] [CrossRef]

- Li, Y.; Phattalung, S.N.; Limpijumnong, S.; Kim, J.; Yu, J. Formation of oxygen vacancies and charge carriers induced in the n-type interface of a LaAlO3 overlayer on SrTiO3 (001). Phys. Rev. B 2011, 84, 245307. [Google Scholar] [CrossRef]

- Liu, L.; Mei, Z.; Tang, A.; Azarov, A.; Kuznetsov, A.; Xue, Q.-K.; Du, X. Oxygen vacancies: The origin of n-type conductivity in ZnO. Phys. Rev. B 2016, 93, 235305. [Google Scholar] [CrossRef] [Green Version]

- Glunz, S.W.; Biro, D.; Rein, S.; Warta, W. Field-effect passivation of the SiO2Si interface. J. Appl. Phys. 1999, 86, 683–691. [Google Scholar] [CrossRef]

- He, J.; Gao, P.; Ling, Z.; Ding, L.; Yang, Z.; Ye, J.; Cui, Y. High-efficiency silicon/organic heterojunction solar cells with improved junction quality and interface passivation. ACS Nano 2016, 10, 11525–11531. [Google Scholar] [CrossRef]

- Park, N.Y.; Jeong, G.S.; Yu, Y.-J.; Jung, Y.-C.; Lee, J.H.; Seo, J.H.; Choi, J.-Y. Photovoltaic Device Application of a Hydroquinone-Modified Conductive Polymer and Dual-Functional Molecular Si Surface Passivation Technology. Polymers 2022, 14, 478. [Google Scholar] [CrossRef]

- McIntosh, K.R.; Black, L.E. On effective surface recombination parameters. J. Appl. Phys. 2014, 116, 014503. [Google Scholar] [CrossRef] [Green Version]

| Sample | Jsc (mA/cm2) | Voc (mV) | FF (%) | Rsh (Ω·cm2) | Rs (Ω·cm2) | PCE (%) |

|---|---|---|---|---|---|---|

| VO_75 °C | 14.09 | 618 | 37.81 | 14,102 | 5.65 | 3.29 ± 0.09 |

| MO_RT | 13.29 | 603 | 43.20 | 13,291 | 3.54 | 3.46 ± 0.11 |

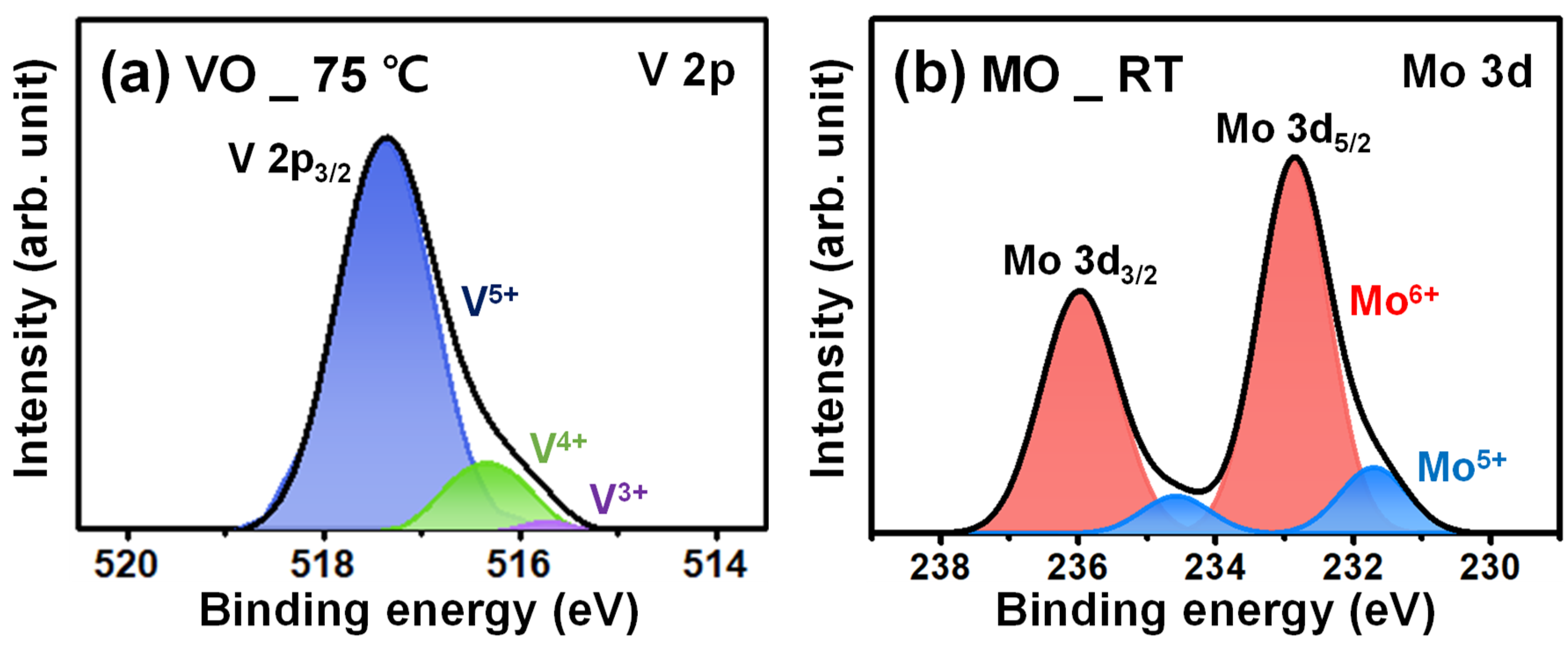

| Sample | Ratio of V Oxidation State (%) | Sample | Ratio of Mo Oxidation State (%) | |||

|---|---|---|---|---|---|---|

| V5+ | V4+ | V3+ | Mo6+ | Mo5+ | ||

| VO (@ 75 °C) | 88.3 | 10.5 | 1.2 | MO (@ RT) | 80.5 | 19.5 |

| MO Thickness | Jsc (mA/cm2) | Voc (mV) | FF (%) | Rsh (Ω·cm2) | Rs (Ω·cm2) | PCE (%) |

|---|---|---|---|---|---|---|

| 8 nm | 14.07 | 606 | 44.73 | 14,089 | 2.10 | 3.81 ± 0.05 |

| 15 nm | 14.16 | 605 | 42.84 | 14,166 | 3.39 | 3.67 ± 0.06 |

| 30 nm | 12.68 | 607 | 45.16 | 12,666 | 3.57 | 3.48 ± 0.09 |

| MO/Ag/VO | Jsc (mA/cm2) | Voc (mV) | FF (%) | Rsh (Ω·cm2) | Rs (Ω·cm2) | PCE (%) |

|---|---|---|---|---|---|---|

| 8 nm/15 nm/15 nm | 17.54 | 537 | 48.36 | 17,566 | 6.31 | 4.56 ± 0.17 |

| 8 nm/15 nm/35 nm | 20.40 | 552 | 45.37 | 20,394 | 4.19 | 5.11 ± 0.14 |

| 8 nm/15 nm/55 nm | 23.24 | 574 | 56.78 | 23,207 | 2.91 | 7.57 ± 0.07 |

| 8 nm/15 nm/75 nm | 21.08 | 573 | 27.57 | 21,051 | 12.46 | 3.33 ± 0.06 |

| Sample Structures | Jsc (mA/cm2) | Voc (mV) | FF (%) | Rsh (Ω·cm2) | Rs (Ω·cm2) | PCE (%) |

|---|---|---|---|---|---|---|

| VO 8 nm/Ag 15 nm/VO 55 nm (VAV) | 11.11 | 591 | 37.76 | 11,146 | 5.47 | 2.48 ± 0.05 |

| MO 8 nm/Ag 15 nm/MO 55 nm (MAM) | 19.42 | 547 | 59.22 | 19,411 | 2.54 | 6.29 ± 0.22 |

| VO 8 nm/Ag 15 nm/MO 55 nm (VAM) | 18.20 | 579 | 45.90 | 18,313 | 7.85 | 4.84 ± 0.18 |

| MO 8 nm/Ag 15 nm/VO 55 nm (MAV) | 23.24 | 574 | 56.78 | 23,207 | 2.91 | 7.57 ± 0.07 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jung, Y.-C.; Yu, Y.-J.; Kim, Y.-K.; Lee, J.H.; Seo, J.H.; Choi, J.-Y. Asymmetric TMO–Metal–TMO Structure for Enhanced Efficiency and Long-Term Stability of Si-Based Heterojunction Solar Cells. Materials 2023, 16, 5550. https://doi.org/10.3390/ma16165550

Jung Y-C, Yu Y-J, Kim Y-K, Lee JH, Seo JH, Choi J-Y. Asymmetric TMO–Metal–TMO Structure for Enhanced Efficiency and Long-Term Stability of Si-Based Heterojunction Solar Cells. Materials. 2023; 16(16):5550. https://doi.org/10.3390/ma16165550

Chicago/Turabian StyleJung, Yoon-Chae, Young-Jin Yu, Yu-Kyung Kim, Jin Hee Lee, Jung Hwa Seo, and Jea-Young Choi. 2023. "Asymmetric TMO–Metal–TMO Structure for Enhanced Efficiency and Long-Term Stability of Si-Based Heterojunction Solar Cells" Materials 16, no. 16: 5550. https://doi.org/10.3390/ma16165550

APA StyleJung, Y.-C., Yu, Y.-J., Kim, Y.-K., Lee, J. H., Seo, J. H., & Choi, J.-Y. (2023). Asymmetric TMO–Metal–TMO Structure for Enhanced Efficiency and Long-Term Stability of Si-Based Heterojunction Solar Cells. Materials, 16(16), 5550. https://doi.org/10.3390/ma16165550