Fluidity and Strength of Loess-Based Quick Consolidated Backfill Material with One High-Water Content

Abstract

1. Introduction

2. Orthogonal Test Schemes and Test Results

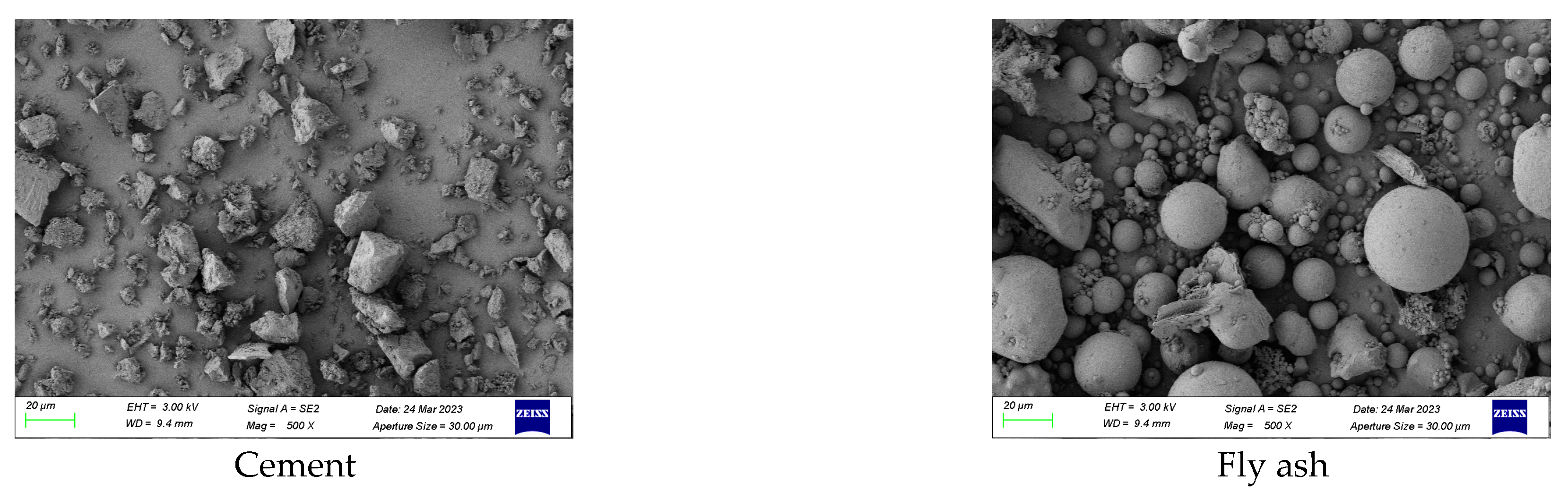

2.1. Experimental Raw Material Analysis

2.2. Experimental Scheme Design

2.3. Experimental Procedure

- (1)

- Brush the inner surface of the three-gang mold with lubricating oil before the experiment to ensure that the test piece is relatively intact after demolding;

- (2)

- Weigh the corresponding mass of raw materials according to Table 2, and mix them with water in the mixing bucket;

- (3)

- Pour out some mixed materials and perform initial setting time testing in the beaker. When the beaker is tilted at 45°, there is no obvious flow trace of the material in the cup, which is considered the initial setting of the material (Figure 2a);

- (4)

- Conduct the flow spread test on a smooth glass plate. Apply butter to the bottom of the flow spread cylinder and place it on the glass plate. Pour the mixed filling material into the cylinder to two-thirds of the total height, lift the cylinder and measure the material spread using a tape measure (Figure 2b);

- (5)

- After the material is mixed, it is poured into the standard mold, appropriately vibrated to eliminate air bubbles in the slurry, and stands for three days. Using an air gun to demold the test piece, the demolded specimen is placed in a constant temperature and humidity curing box for curing (Figure 2c,d);

- (6)

- After curing, the specimen is placed on the MTS electro-hydraulic servo-motor machine for the direct shear and uniaxial compressive tests (Figure 2f,g).

3. Significance Analysis of Fluidity

3.1. Factors Influencing the Initial Setting Time

3.2. Factors Influencing the Diffusivity

4. Significance Analysis of Strength

4.1. Factors Influencing the Compressive Strength

4.2. Factors Influencing the Shear Strength

5. Analytical Model for Characteristic Parameters of Fluidity and Strength

5.1. Changes in Characteristic Parameters under Influences of Each Single Factor

5.2. Analytical Model of Characteristic Parameters

6. Conclusions

- (i).

- By conducting orthogonal tests, taking the mass concentration of loess water, the content of high-water-content materials, the cement content, and the content of fly ash as four factors, for each of which four levels were set, sixteen groups of mix designs were tested. After testing the fluidity and strength characteristics, the analysis revealed that the initial setting time, diffusivity, compressive strength, and shear strength of the loess material were distributed in ranges of 13~33 min, 400~580 mm, 0.917~3.605 MPa, and 0.360~0.722 MPa, respectively;

- (ii).

- For the initial setting time, the four factors were listed in descending order as A > D > B > C, wherein all four factors showed lower significance. The four factors were ranked such that A > B > C > D according to their influences on the diffusivity, indicative of the mass concentration of loess water being the main factor influencing the diffusivity. With regard to the compressive strength, the four factors were ranked such that A > C > D > B, implying that the mass concentration of loess water and the cement content were the main factors influencing the uniaxial compressive strength. The four factors were ranked such that A > C > D > B according to their influences on the shear strength, which means that the mass concentration of loess water and the content of cement were the main factors influencing the shear strength;

- (iii).

- Mathematical relationships of factors A, B, C, and D with the fluidity and strength indices were fitted.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zheng, L.H.; Zhou, Y.J.; Zhang, L.M.; Mao, D.G.; Ma, Y.D. Experimental research on load-bearing characteristics of gangue polymer backfilling material. J. Coal Sci. Technol. 2022, 50, 222–229. [Google Scholar]

- Lin, H.F.; Zhai, Y.L.; Li, S.G.; Li, L.; Bai, Y. Research on mechanics and permeability characteristics of similar material of solid-gas coupling based on orthogonal design. J. China Coal Soc. 2016, 41, 672–679. [Google Scholar]

- Chang, Q.L.; Yuan, C.L.; Wang, Y.Z.; Zhang, B.; Zhou, H.Q. Semi-convex mechnical analysis on stability of step coal wall in fully mechanized mining with paste filling. J. China Univ. Min. Technol. 2022, 51, 46–55. [Google Scholar]

- Huang, P.; Zhang, J.X.; Guo, Y.M.; Li, M.; Zhang, Q. Viscoelastic effect of deep gangue backfill body and time-dependent deformation characteristics of roof in deep mining. J. China Univ. Min. Technol. 2021, 50, 489–497. [Google Scholar]

- Xuan, Z.J.; Chang, Q.L. Study on floor failure mechanism of paste backfill mining and division area control technology. J. Saf. Coal Min. 2022, 53, 210–217. [Google Scholar]

- Yu, W.J.; Wan, X.; Liu, F.F.; Wang, Z. Experimental study on red clay paste backfilling material and its physical characteristics. J. Coal Sci. Technol. 2021, 49, 61–68. [Google Scholar]

- Sun, X.K. Research on paste backfilling mining technology of coal mining under buildings, water bodies and railways. J. Coal Sci. Technol. 2021, 49, 218–224. [Google Scholar]

- Wang, Y.Y.; Yu, Z.Q.; Cui, L.H. Experimental study on compressive behavior of cemented paste backfilling material with different water contents. J. Coal Sci. Technol. 2022, 50, 219–224. [Google Scholar]

- Hao, Z. Comprehensive assessment on the geological disasters in small pit goaf. J. Geo. Res. 2019, 28, 394–400. [Google Scholar]

- Feng, G.R.; Hou, S.Y.; Liang, C.H.; Bai, J.W.; Zhang, Y.J. Basic theories and key technologies of rock strata control for residual coal resources mining under complex conditions. J. Coal Sci. Technol. 2020, 48, 144–149. [Google Scholar]

- Feng, G.R.; Li, Q.D.; Qi, T.Y.; Guo, Y.X.; Ran, H.Y. Assessing static stability of cemented coal gangue backfill with ultrasonic pulse velocity method. J. Min. Saf. Eng. 2020, 37, 1231–1237. [Google Scholar]

- Wu, L.L.; Kang, T.H.; Yin, B.; Du, M.Z. Microcalorimetric test and analysis of hydration heat of fly ash paste-filling material. J. China Coal Soc. 2015, 40, 2801–2806. [Google Scholar]

- Liu, P.L.; Zhang, H.X.; Cui, F.; Sun, K.H.; Sun, W.M. Technology and practice of mechanized backfill mining for water protection with aeolian sand paste-like. J. China Coal Soc. 2017, 42, 118–126. [Google Scholar]

- Shao, X.P.; Tao, Y.Q.; Liu, E.S.; Zhao, B.C.; Li, X. Study and application of paste-like filling mining parameters of shallow buried coal seam in Northern Shaanxi. J. Coal Sci. Technol. 2021, 49, 63–70. [Google Scholar]

- Li, N.L.; Yi, Q.M.; Zhang, H.; An, B.F.; Wang, D.D. Research on physical and mechanical properties of mixed solid filling materials with aeolian sand and loess. J. Coal Technol. 2021, 40, 20–24. [Google Scholar]

- Bai, J.W.; Cui, B.Q.; Qi, T.Y.; Zhu, W.B.; Wang, K. Fundamental theory for rock strata control of key pillar-side backfilling. J. China Coal Soc. 2021, 46, 424–438. [Google Scholar]

- Feng, C.G.; Gao, G.R.; Feng, X.H. Experimental study on cement-bonded loess as filling material for old open areas of coal mines. J. China Coal. 2021, 38, 1–6. [Google Scholar]

- Fernández-Jiménez, A.; Palomo, A. Characterisation of fly ashes. Potential reactivity as alkaline cements. J. Fuel 2003, 82, 2259–2265. [Google Scholar] [CrossRef]

- Oggeri, C.; Oreste, P.; Spagnoli, G. Creep behaviour of two-component grout and interaction with segmental lining in tunnelling. J. Tunn. Undergr. Space Technol. 2022, 119, 104216. [Google Scholar] [CrossRef]

- Huang, P.; Spearing, S.; Ju, F.; Jessu, K.V.; Wang, Z.; Ning, P. Control effects of five common solid waste backfilling materials on in situ strata of gob. J. Energ. 2019, 12, 154. [Google Scholar] [CrossRef]

- Chen, K. Experimental Design and Analysis; Tsinghua University Press: Beijing, China, 2005. [Google Scholar]

- Feng, G.M.; Ding, Y.; Zhu, H.J. Experimental study on ultra-high water filling material and its structure for mining. J. China Univ. Min. Technol. 2010, 39, 813–819. [Google Scholar]

- Feng, G.M. Research and Application of Ultra-High Water Filling Materials and Filling Mining. Ph.D. Thesis, China University of Mining and Technology, Xuzhou, China, 2009. [Google Scholar]

| Number of Level Groups | A. Loess Mass Concentration | B. High-Water Content | C. Cement Content | D. Fly Ash Content |

|---|---|---|---|---|

| 1 | 140:260 (concentration 35.00%) | 12 | 28 | 20 |

| 2 | 160:240 (concentration 40.00%) | 16 | 34 | 25 |

| 3 | 180:220 (concentration 45.00%) | 20 | 40 | 30 |

| 4 | 200:200 (concentration 50.00%) | 24 | 46 | 35 |

| Number of Experimental Groups | Influencing Factors | Test Results | |||||||

|---|---|---|---|---|---|---|---|---|---|

| A | B | C | D | Initial Coagulation Time/min | Diffusion /mm | Compressive Strength/MPa | Shear Strength/MPa | Overall Rating | |

| 1 | 0.35 | 12 | 28 | 20 | 28.00 | 58.00 | 2.13 | 0.41 | 22.135 |

| 2 | 0.35 | 16 | 34 | 25 | 28.00 | 56.70 | 1.39 | 0.43 | 21.630 |

| 3 | 0.35 | 20 | 40 | 30 | 16.00 | 56.30 | 1.93 | 0.40 | 18.658 |

| 4 | 0.35 | 24 | 46 | 35 | 17.00 | 47.80 | 1.85 | 0.48 | 16.783 |

| 5 | 0.40 | 12 | 34 | 30 | 13.00 | 51.00 | 1.29 | 0.51 | 16.450 |

| 6 | 0.40 | 16 | 28 | 35 | 23.00 | 53.70 | 1.07 | 0.41 | 19.545 |

| 7 | 0.40 | 20 | 46 | 20 | 17.00 | 49.30 | 1.71 | 0.62 | 17.158 |

| 8 | 0.40 | 24 | 40 | 25 | 17.00 | 47.70 | 1.25 | 0.46 | 16.603 |

| 9 | 0.45 | 12 | 40 | 35 | 33.00 | 45.70 | 1.73 | 0.50 | 20.233 |

| 10 | 0.45 | 16 | 46 | 30 | 18.00 | 48.70 | 2.42 | 0.50 | 17.405 |

| 11 | 0.45 | 20 | 28 | 25 | 20.00 | 46.70 | 0.92 | 0.36 | 16.995 |

| 12 | 0.45 | 24 | 34 | 20 | 20.00 | 43.30 | 2.40 | 0.47 | 16.543 |

| 13 | 0.50 | 12 | 46 | 25 | 15.00 | 41.20 | 2.65 | 0.72 | 14.893 |

| 14 | 0.50 | 16 | 40 | 20 | 17.00 | 42.30 | 3.03 | 0.66 | 15.748 |

| 15 | 0.50 | 20 | 34 | 35 | 18.00 | 40.20 | 3.61 | 0.64 | 15.613 |

| 16 | 0.50 | 24 | 28 | 30 | 13.00 | 40.70 | 1.62 | 0.59 | 13.978 |

| Factor | Initial Coagulation Time/min | Diffusion/mm | ||||||||||

| A | B | C | D | A | B | C | D | |||||

| k1 | 22.250 | 22.2500 | 21 | 20.5 | 54.70 | 48.976 | 49.77 | 48.23 | ||||

| k2 | 17.500 | 21.5000 | 19.75 | 20 | 50.42 | 50.35 | 47.80 | 48.08 | ||||

| k3 | 22.750 | 17.7500 | 20.75 | 15 | 46.10 | 48.13 | 48.00 | 49.18 | ||||

| k4 | 15.750 | 16.7500 | 16.75 | 22.75 | 41.10 | 44.86 | 46.75 | 46.85 | ||||

| R | 7 | 5.5 | 4.25 | 7.75 | 13.60 | 5.48 | 3.02 | 2.33 | ||||

| Factor | Compressive Strength/MPa | Shear Strength/MPa | Overall Rating | |||||||||

| A | B | C | D | A | B | C | D | A | B | C | D | |

| k1 | 1.8235 | 1.9492 | 1.4332 | 2.3140 | 0.4303 | 0.5355 | 0.4405 | 0.5385 | 19.801 | 18.428 | 18.161 | 17.896 |

| k2 | 1.330 | 1.980 | 2.1710 | 1.5532 | 0.5005 | 0.4980 | 0.5142 | 0.4938 | 17.438 | 18.582 | 17.559 | 17.532 |

| k3 | 1.8660 | 2.0390 | 1.9855 | 1.8142 | 0.4572 | 0.5048 | 0.5053 | 0.4990 | 17.793 | 17.106 | 17.810 | 16.623 |

| k4 | 2.7260 | 1.7773 | 2.1557 | 2.0640 | 0.6515 | 0.5013 | 0.5795 | 0.5082 | 15.057 | 15.972 | 16.559 | 18.043 |

| R | 1.3960 | 0.2617 | 0.7378 | 0.7607 | 0.2212 | 0.0375 | 0.139 | 0.0448 | 5.554 | 2.820 | 2.037 | 2.721 |

| Source of Variation | Sum of Squared Deviations | Degree of Freedom | Variance | F-Value | Fα | Significance Level |

|---|---|---|---|---|---|---|

| A | 144.688 | 3 | 48.229 | F0.01(3,15) = 5.417 F0.05(3,15) = 3.287 F0.10(3,15) = 2.490 F0.25(3,15) = 1.520 | --- | |

| B | 88.688 | 3 | 29.563 | --- | ||

| C | 45.688 | 3 | 15.229 | --- | ||

| D | 128.188 | 3 | 42.729 | --- | ||

| Error e | 78.688 | 3 | 26.229 | |||

| Correct errors e | 485.938 | 15 | 32.396 | |||

| Sum | 485.938 |

| Source of Variation | Sum of Squared Deviations | Degree of Freedom | Variance | F-Value | Fα | Significance Level |

|---|---|---|---|---|---|---|

| A | 93.847 | 3 | 31.282 | 3.324 | F0.01(3,3) = 29.457 F0.05(3,3) = 9.277 F0.10(3,3) = 5.391 F0.25(3,3) = 2.356 | o |

| B | 205.445 | 3 | 68.482 | 7.278 | * | |

| C | 96.573 | 3 | 32.191 | 3.421 | o | |

| D | 82.922 | 3 | 27.641 | 2.937 | o | |

| Error e | 28.229 | 3 | 9.410 | |||

| Sum | 507.017 |

| Source of Variation | Sum of Squared Deviations | Degree of Freedom | Variance | F-Value | Fα | Significance Level |

|---|---|---|---|---|---|---|

| A | 4.036 | 3 | 1.3452 | 3.932 | F0.01(3,12) = 5.953 F0.05(3,12) = 3.490 F0.10(3,12) = 2.606 F0.25(3,12) = 1.561 | ** |

| B | 0.152 | 3 | 0.0505 | --- | ||

| C | 1.434 | 3 | 0.4778 | --- | ||

| D | 1.281 | 3 | 0.4270 | --- | ||

| Error e | 1.240 | 3 | 0.4133 | |||

| Correct errors e | 4.106 | 12 | 0.3422 | |||

| Sum | 8.141 |

| Source of Variation | Sum of Squared Deviations | Degree of Freedom | Variance | F-Value | Fα | Significance Level |

|---|---|---|---|---|---|---|

| A | 0.1170 | 3 | 0.0390 | 30.974 | F0.01(3,9) = 6.992 F0.05(3,9) = 3.863 F0.10(3,9) = 2.813 F0.25(3,9) = 1.632 | *** |

| C | 0.0040 | 3 | 0.0013 | --- | ||

| D | 0.0388 | 3 | 0.0129 | 10.271 | *** | |

| 0.0048 | 3 | 0.0016 | --- | |||

| Error e | 0.0025 | 3 | 0.0008 | |||

| Correct errors e | 0.0113 | 9 | 0.0013 | |||

| Sum | 0.1670 |

| Factor | Index | Fitted Relationship | General Formula | Degree of Fit R2 |

|---|---|---|---|---|

| Yellow mud quality Concentration (PA) | Initial coagulation time | 0.92 | ||

| Diffusion | 0.98 | |||

| Compressive strength | 0.99 | |||

| Tensile strength | 0.99 | |||

| High-water content (PB) | Initial coagulation time | 0.96 | ||

| Diffusion | 0.99 | |||

| Compressive strength | 0.99 | |||

| Tensile strength | 0.99 | |||

| Cement content (PC) | Initial coagulation time | 0.99 | ||

| Diffusion | 0.99 | |||

| Compressive strength | 0.99 | |||

| Tensile strength | 0.99 | |||

| Fly ash content (PD) | Initial coagulation time | 0.99 | ||

| Diffusion | 0.99 | |||

| Compressive strength | 0.99 | |||

| Tensile strength | 0.99 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cui, C.; An, B.; Cui, H.; Yi, Q.; Wang, J. Fluidity and Strength of Loess-Based Quick Consolidated Backfill Material with One High-Water Content. Materials 2023, 16, 5544. https://doi.org/10.3390/ma16165544

Cui C, An B, Cui H, Yi Q, Wang J. Fluidity and Strength of Loess-Based Quick Consolidated Backfill Material with One High-Water Content. Materials. 2023; 16(16):5544. https://doi.org/10.3390/ma16165544

Chicago/Turabian StyleCui, Chenghao, Baifu An, Heng Cui, Qiaomei Yi, and Jiale Wang. 2023. "Fluidity and Strength of Loess-Based Quick Consolidated Backfill Material with One High-Water Content" Materials 16, no. 16: 5544. https://doi.org/10.3390/ma16165544

APA StyleCui, C., An, B., Cui, H., Yi, Q., & Wang, J. (2023). Fluidity and Strength of Loess-Based Quick Consolidated Backfill Material with One High-Water Content. Materials, 16(16), 5544. https://doi.org/10.3390/ma16165544