Factors Influencing the Expansion of Arch-Shaped Electromagnetic Railguns with Pre-Stressed Composite Barrels

Abstract

:1. Introduction

2. Materials and Methods

2.1. Winding–Loading Model

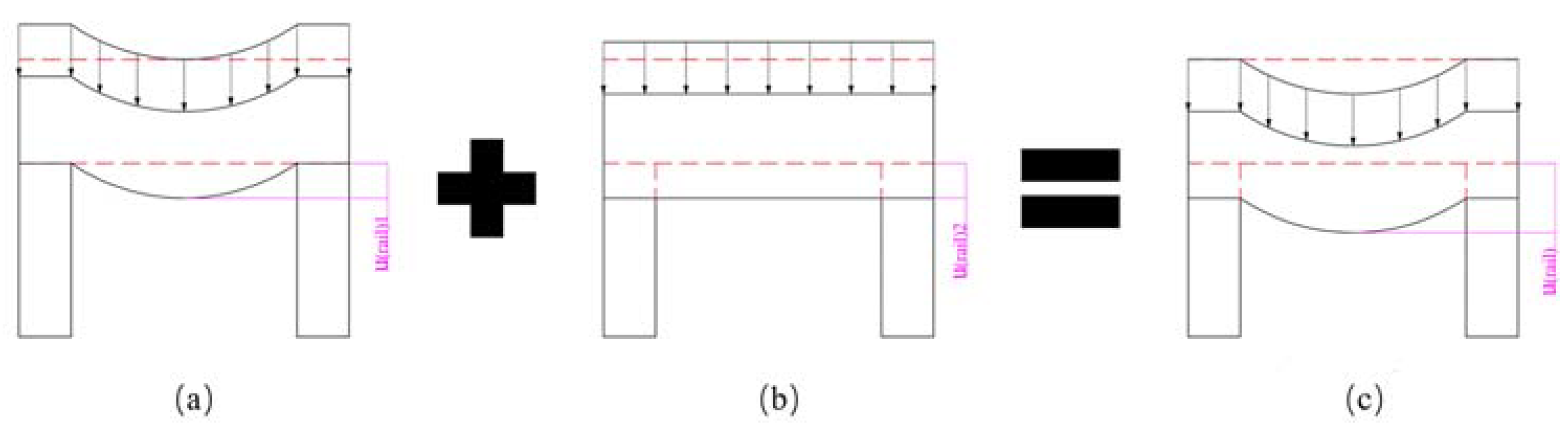

2.1.1. Rail Displacement Achieve during the Filament Winding Process

2.1.2. Rail Displacement Achieve during the Loading Process

- Hard contact. The rails and insulators are in contact but not bonded to each other. In this type of interaction, the area of contact decreases as the loading force increases. This can be attributed to the fact that the insulator deformation realized during the winding process is reversed completely. This occurs as the equivalent beam bends under the influence of the loading force. Consequently, the entire system cannot be approximated to an arch-shaped vessel.

- Bonded. The rails and insulators are bonded together using adhesives during the manufacturing process. In this scenario, the stress state of the insulation transitions from compressive to tensile as the deformation of the insulator recovers, and the loading force continues to increase. At this point, the strength of the bonded interface becomes the dominant factor. The interface breaks when it is unable to withstand the increasing force. The rails and insulators separate from each other under these conditions. After separation, similar observations were made for the previously mentioned case.

2.2. Finite Element Model for the Arch-Shaped EM Gun with a Pre-Stressed Composite Barrel

2.2.1. Modeling Technology

- Thermal parameter method. A critical challenge in modeling pre-stressed filament winding involves simulating the winding tension accurately. The thermal parameter method is proposed to address this issue. In the finite element model, a fictitious linear coefficient of thermal expansion, aligned along the fiber direction, is defined to reflect the material properties of the winding tapes. When a new layer is wound, the corresponding elements are activated and loaded with a fictitious temperature magnitude. This magnitude is defined as follows:

- Element birth and death strategy. Another significant challenge involves simulating the layer-by-layer winding process accurately. The element birth and death strategy is used to address this issue. This strategy involves the deactivation of elements over certain steps and the activation of the elements over specific steps. The method allows for the modification of the layer-by-layer winding process. However, when the elements representing the outer layers are deactivated during the initial steps, they can still be influenced by the deformation of the inner layers under tension, as depicted in Figure 6a. This can introduce certain errors during simulation. The real–fictitious element analysis strategy is proposed to overcome this issue. This method involves assigning fictitious elements, which have the same node numbers as the specified real elements, with different material properties. Negligible deformation of the real elements, caused by the activation of neighboring elements, can be realized by ensuring that the stiffness of the fictitious elements is significantly smaller than that of the real elements. This can be attributed to the low stiffness of the fictitious elements, as depicted in Figure 6b. Hence, the element birth and death method, coupled with the real–fictitious element analysis strategy, is suitable for accurately simulating the pre-stress winding process.

2.2.2. Model Establishment

3. Results and Discussion

3.1. Verification of the 3D FE Model

3.2. Mechanism of Pre-Stress Influences Railgun System

- Pre-stress is applied during the winding process through winding tension. This tension is transferred to external pressure on the outer surface of the curved part of the system, causing the deformation of the rails and the insulators.

- Contact pressure is generated at the interface between the rails and the insulators during winding procedure. The contact between the rails and the insulators is maintained during the loading process under conditions of deformation and the action of contact pressure. In other words, pre-stress is applied to the barrel to ensure that each component of the EM guns remains in contact during loading. This eventually helps maintain the stiffness and integrity of the system.

3.3. Factors Influencing the Extent of the Rail Expansion

3.3.1. Effect of Pre-Stress

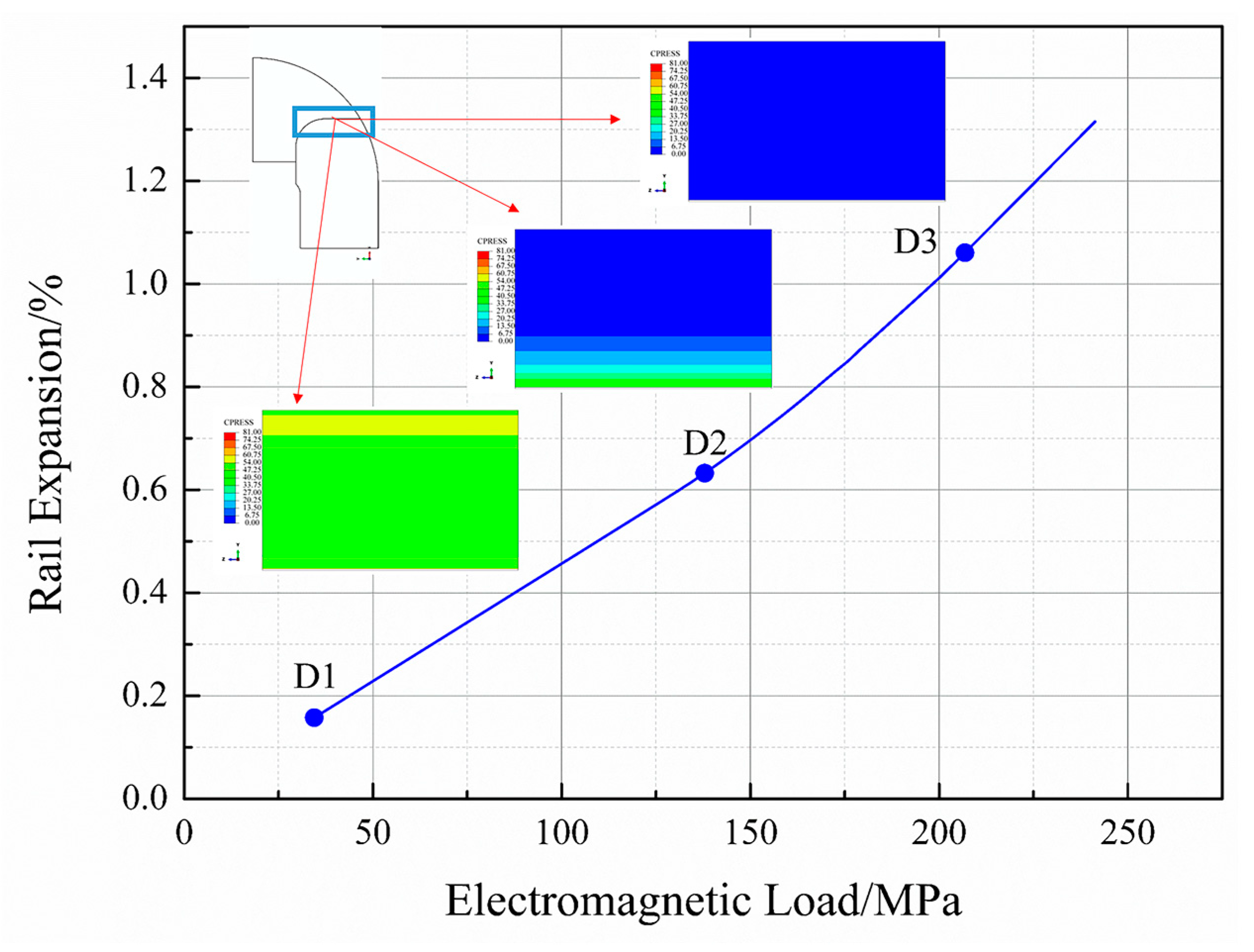

3.3.2. Effect of Electromagnetic Load

3.3.3. Effect of Insulator

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ma, W.; Lu, J.; Liu, Y. Research Progress and Challenges of Electromagnetic Launch Technology. Trans. China Electrotech. Soc. 2023, 38, 1–17. [Google Scholar] [CrossRef]

- Weldon, W.F.; Bacon, J.L.; Weeks, D.A.; Zowarka, R.C. Stiff Railguns. IEEE Trans. Magn. 1991, 27, 488–493. [Google Scholar] [CrossRef]

- Weeks, D.A.; Weldon, W.F.; Zowarka, R.C. Hypervelocity Macroparticle Accelerator Experiments at CEM-UT. IEEE Trans. Magn. 1991, 27, 85–90. [Google Scholar] [CrossRef]

- Weeks, D.A.; Weldon, W.F.; Zowarka, R.C. Plasma Armature Railgun Launcher Simulations at the University of Texas at Austin. IEEE Trans. Magn. 1989, 25, 580–586. [Google Scholar] [CrossRef]

- Susoeff, A.R.; Hawke, R.S.; Balk, J.K.; Hall, C.A.; McDonald, M.J. Fabrication Issues and Technology Development for HELEOS. IEEE Trans. Magn. 1989, 25, 541–545. [Google Scholar] [CrossRef]

- Cooper, K.P.; Jones, H.N.; Meger, R.A. Analysis of Railgun Barrel Material. IEEE Trans. Magn. 2007, 43, 120–125. [Google Scholar] [CrossRef]

- Du, X.; Liu, S.; Guan, J. Design and Experimental Study of a Curved Contact Quadrupole Railgun. Electronics 2022, 11, 3108. [Google Scholar] [CrossRef]

- Jin, L.; Lei, B.; Zhang, Q.; Zhu, R. Electromechanical Performance of Rails With Different Cross-Sectional Shapes in Railgun. IEEE Trans. Plasma Sci. 2015, 43, 1220–1224. [Google Scholar] [CrossRef]

- Du, X.; Liu, S.; Guan, J. Design and Performance Analysis of an Electromagnetic Railgun. J. Phys. Conf. Ser. 2022, 2378, 012008. [Google Scholar] [CrossRef]

- Liu, S.; Du, X.; Guan, J.; Shi, J. Research on Transient Contact Characteristics of the Hyperbolic Rail Augmented Quadrupole Launcher. IEEE Trans. Plasma Sci. 2022, 50, 3794–3801. [Google Scholar] [CrossRef]

- Du, X.; Liu, S.; Guan, J. Calculation Method of Projectile Movement Characteristics for Complex Structure Railgun. Wirel. Commun. Mob. Comput. 2022, 2022, 8966115. [Google Scholar] [CrossRef]

- Heydari, M.B.; Asgari, M.; Keshtkar, A. A Novel Structure of Augmented Railgun Using Multilayer Magnets and Sabots. IEEE Trans. Plasma Sci. 2019, 47, 3320–3326. [Google Scholar] [CrossRef]

- Liu, Y.; Guo, W.; Zhang, T.; Su, Z.; Fan, W.; Zhang, H. Influence of Contacting Schemes on Electromagnetic Force and Current Density Distribution in Armature. IEEE Trans. Plasma Sci. 2019, 47, 2726–2735. [Google Scholar] [CrossRef]

- Rackauskas, J.; Schneider, M.; Kacianauskas, R. Refining FE Structural Mechanics Simulations of a Railgun by Taking Into Account Electromagnetic Effects. IEEE Trans. Plasma Sci. 2018, 46, 4017–4022. [Google Scholar] [CrossRef]

- Tumonis, L.; Schneider, M.; Kacianauskas, R.; Vadluga, V. The Structural Mechanics of Rail Guns With Discrete Supports Showing the Influence of DES. IEEE Trans. Plasma Sci. 2011, 39, 144–148. [Google Scholar] [CrossRef]

- Chen, L.; He, J.; Xiao, Z.; Pan, Y. Augmentation of Current Ramp-Down Contact Pressure in C-Shaped Armature Railguns. IEEE Trans. Plasma Sci. 2011, 39, 48–52. [Google Scholar] [CrossRef]

- Tumonis, L.; Schneider, M.; Kaeianauskas, R.; Kaeeniauskas, A. Structural Mechanics of Railguns in the Case of Discrete Supports. IEEE Trans. Magn. 2009, 45, 474–479. [Google Scholar] [CrossRef]

- Xu, W.; Yuan, W.; Che, Y.; Fu, R.; Wang, J.; Zhang, D.; Yan, P. Velocity Precision Analysis With the Small Caliber Electromagnetic Launch. IEEE Trans. Plasma Sci. 2017, 45, 1394–1398. [Google Scholar] [CrossRef]

- Hric, G.R.; Odendaal, W.G. Improving Start-Up Contact Distribution Between Railgun Armature and Rails. IEEE Trans. Plasma Sci. 2016, 44, 1202–1207. [Google Scholar] [CrossRef]

- Chen, L.; He, J.; Xia, S.; Feng, D.; Tang, L. The Influence of Mechanical Preload on Muzzle Speed in Solid Armature Railgun. In Proceedings of the 2014 17th International Symposium on Electromagnetic Launch Technology, San Diego, CA, USA, 7–11 July 2014. [Google Scholar]

- Li, M.; Yan, P.; Yuan, W.; Sun, Y.; Shao, T.; Wang, J.; Zhou, Y. Simulations on Elastoplasticity of the Monolithic Aluminum Armature Under the Contact Force. IEEE Trans. Plasma Sci. 2011, 39, 426–430. [Google Scholar] [CrossRef]

- Hsieh, K.-T.; Satapathy, S.; Hsieh, M.-T. Effects of Pressure-Dependent Contact Resistivity on Contact Interfacial Conditions. IEEE Trans. Magn. 2009, 45, 313–318. [Google Scholar] [CrossRef]

- Johnson, A.J.; Moon, F.C. Elastic Waves in Electromagnetic Launchers. IEEE Trans. Magn. 2007, 43, 141–144. [Google Scholar] [CrossRef]

- Price, J.H.; Fahrenthold, E.P.; Fulcher CW, G.; Peterson, D.R.; Weldon, W.F.; Zowarka, R.C. Design and Testing of Large-Bore, Ultra-Stiff Railguns. IEEE Trans. Magn. 1989, 25, 460–466. [Google Scholar] [CrossRef]

- Noel, A.P.; Bauer, D.P. Laminated Barrel Axial Stiffness Assessment. IEEE Trans. Magn. 2001, 37, 3. [Google Scholar] [CrossRef]

- Werst, M.; Kitzmiller, J.; Zielinski, A.E. Rapid Fire Railgun for the Cannon Caliber Electromagnetic Gun System. In Digest of Technical Papers. In Proceedings of the Tenth IEEE International Pulsed Power Conference, Albuquerque, NM, USA, 10–13 July 1995; pp. 174–179. [Google Scholar]

- Wellman, G.W.; Schuler, K.W. Structural Consequences of Railgun Augmentation. IEEE Trans. Magn. 1989, 25, 593–598. [Google Scholar] [CrossRef]

- Yin, Q.; Zhang, H.; Li, H.; Yang, Y. Analysis of in-bore magnetic field in C-shaped armature railguns. Def. Technol. 2019, 15, 83–88. [Google Scholar] [CrossRef]

- Zu, L.; Xu, H.; Zhang, Q.; Jia, X.; Jin, S.; Li, D. Investigation on Mechanical Behavior of Composite Electromagnetic Gun Barrel Based on the High Tension Winding. Compos. Struct. 2020, 248, 112521. [Google Scholar] [CrossRef]

- Yin, D.; Li, B.; Xiao, H. Analysis for the Residual Prestress of Composite Barrel for Railgun with Tension Winding. Def. Technol. 2020, 16, 893–899. [Google Scholar] [CrossRef]

- Xiao, H.; Yin, D.; Lin, Q.; Li, B. Structural Optimum Design and Pre-stress Simulation of Fiber Housing for Railgun. Chin. J. High Press. Phys. 2018, 32, 152–158. [Google Scholar]

- Yin, D.; Xiao, H.; Li, B. Dynamics Response of Filament-Wound Composite Barrel for Rail Gun With Acceleration Load. IEEE Trans. Plasma Sci. 2018, 46, 1847–1854. [Google Scholar] [CrossRef]

- Xiao, H.; Yin, D.; Li, B. Research on Elastic Design About Filament Wound Barrel of Railgun. IEEE Trans. Plasma Sci. 2017, 45, 1414–1418. [Google Scholar] [CrossRef]

- Yin, D.; Li, B. Analysis of progressive damage of composite housing for railgun under winding prestress. Acta Armamentarii 2016, 37, 988–995. [Google Scholar]

- Xu, R.; Li, D.; Zhao, W.; Xu, W.; Yuan, W.; Yan, P. Research on Insulation Problems Under Multishot Experiments in Electromagnetic Rail Launcher. IEEE Trans. Plasma Sci. 2017, 45, 1353–1360. [Google Scholar] [CrossRef]

- Li, G.; Hong, X. The Stress Analysis of Obround Cross Section Pressure Vessel. Press. Vessel Technol. 2001, 6, 23–27. [Google Scholar]

- Root, J.; Olmstead, V.; Littlefield, A.; Truszkowska, K. An Analysis of EM Railgun Cross Section Designs; Defense Technical Information Center: Fort Belvoir, VA, USA, 2009.

| Materials | Modulus/GPa | Poisson’s Ratio |

|---|---|---|

| Copper | 104 | 0.34 |

| Item | G-10 | IM7/PEEK |

|---|---|---|

| E1/GPa | 24.63 | 172 |

| E2/GPa | 27.38 | 11.024 |

| E3/GPa | 11.49 | 11.024 |

| μ12 | 0.194 | 0.3 |

| μ13 | 0.455 | 0.3 |

| μ23 | 0.518 | 0.3 |

| G12/GPa | 5.52 | 5.5 |

| G13/GPa | 12.18 | 5.5 |

| G23/GPa | 12.18 | 1.35 |

| Materials of Insulator | Load Value of First Point/MPa | Load Value of Second Point/MPa |

|---|---|---|

| G-10 | 121.352 | 172.375 |

| S2/PEEK | 82.740 | 158.585 |

| NEXTEL/PEEK | 68.950 | 151.690 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Xiao, J.; Huan, D.; Yan, L. Factors Influencing the Expansion of Arch-Shaped Electromagnetic Railguns with Pre-Stressed Composite Barrels. Materials 2023, 16, 5535. https://doi.org/10.3390/ma16165535

Wang J, Xiao J, Huan D, Yan L. Factors Influencing the Expansion of Arch-Shaped Electromagnetic Railguns with Pre-Stressed Composite Barrels. Materials. 2023; 16(16):5535. https://doi.org/10.3390/ma16165535

Chicago/Turabian StyleWang, Junsheng, Jun Xiao, Dajun Huan, and Lei Yan. 2023. "Factors Influencing the Expansion of Arch-Shaped Electromagnetic Railguns with Pre-Stressed Composite Barrels" Materials 16, no. 16: 5535. https://doi.org/10.3390/ma16165535

APA StyleWang, J., Xiao, J., Huan, D., & Yan, L. (2023). Factors Influencing the Expansion of Arch-Shaped Electromagnetic Railguns with Pre-Stressed Composite Barrels. Materials, 16(16), 5535. https://doi.org/10.3390/ma16165535