Effect of Nano Ni Particles on the Microstructure and Thermophysical Properties of Sn–Bi–Zn Heat Transfer and Heat Storage Alloys

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

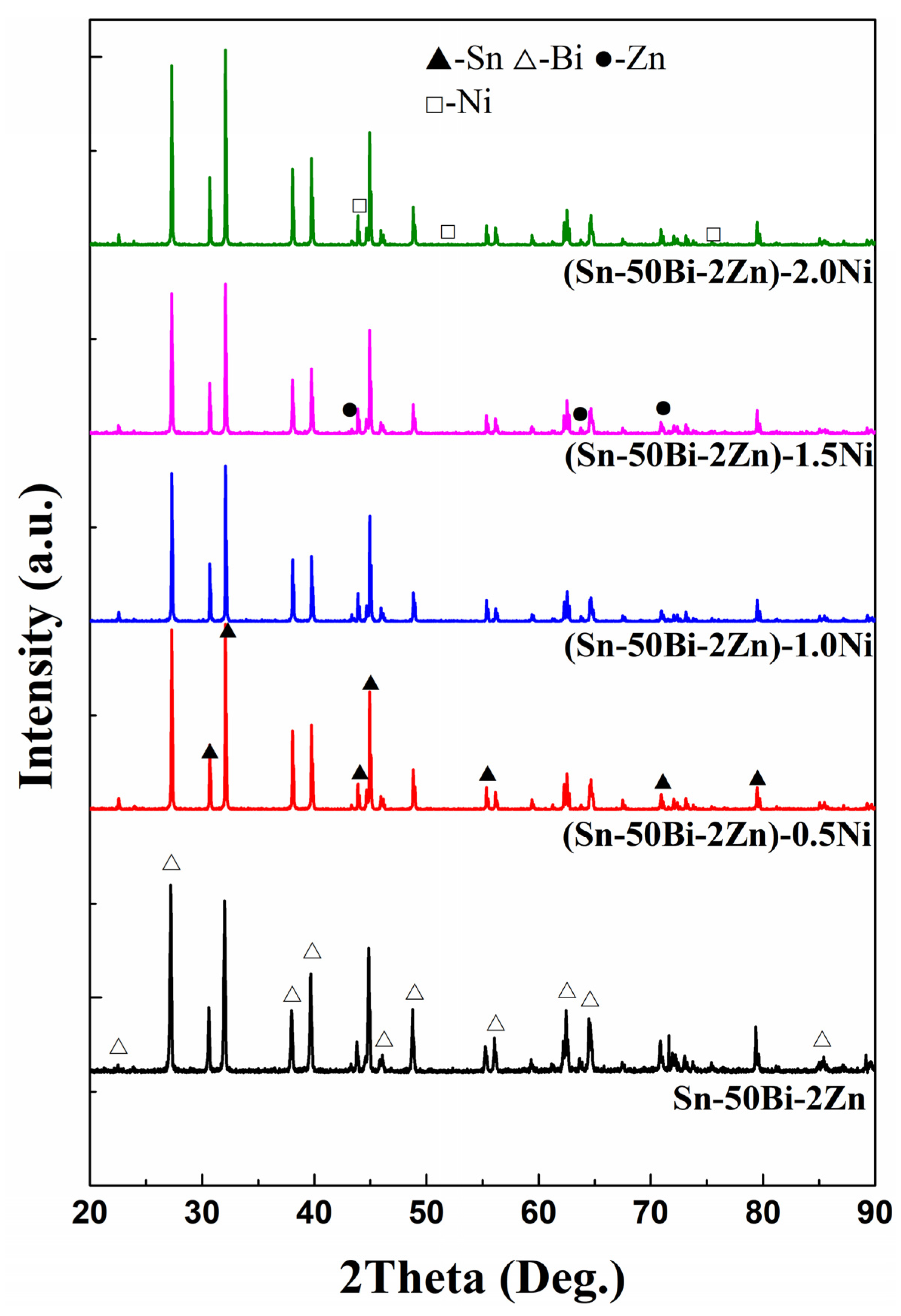

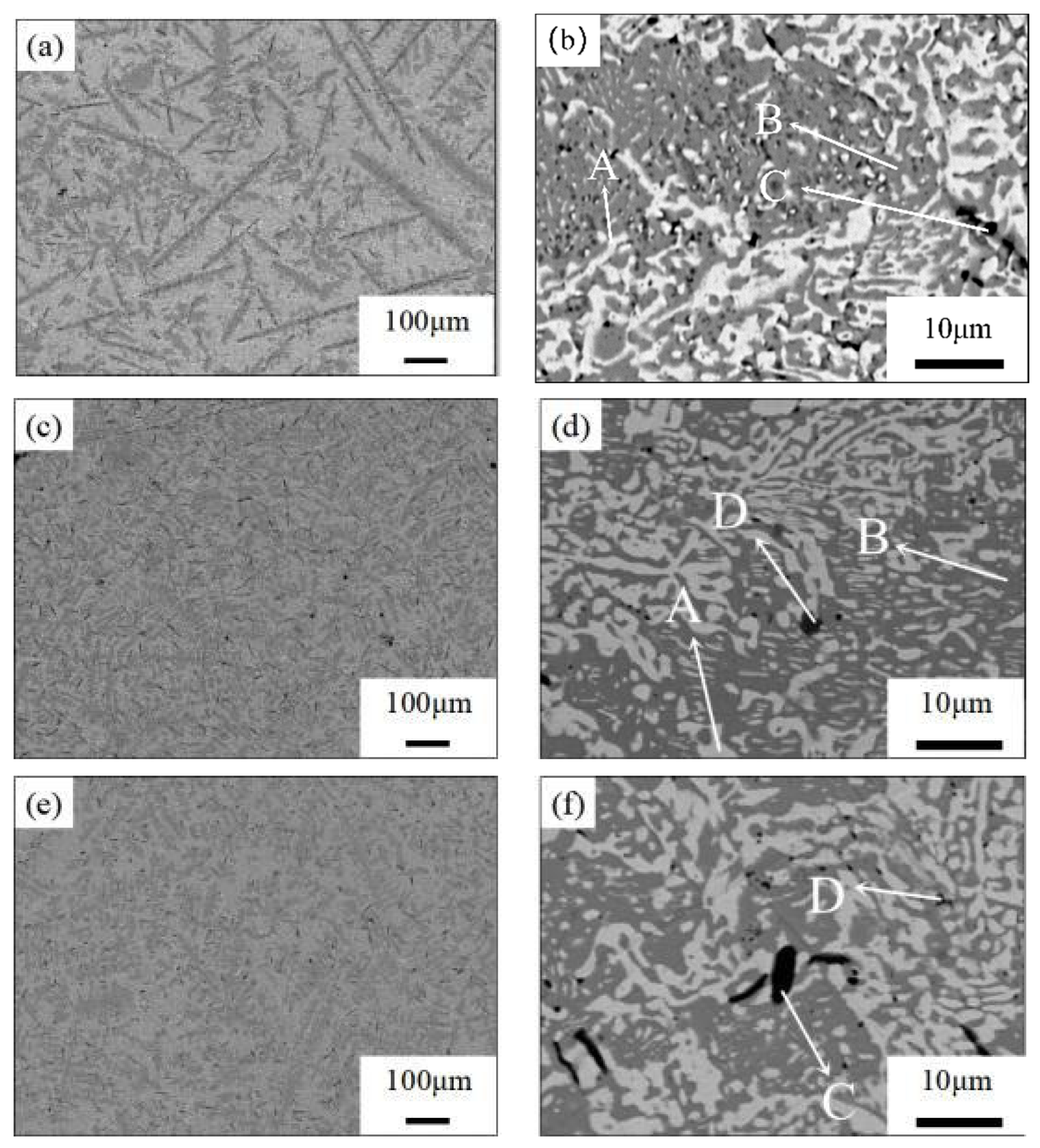

3.1. XRD and EPMA Analysis

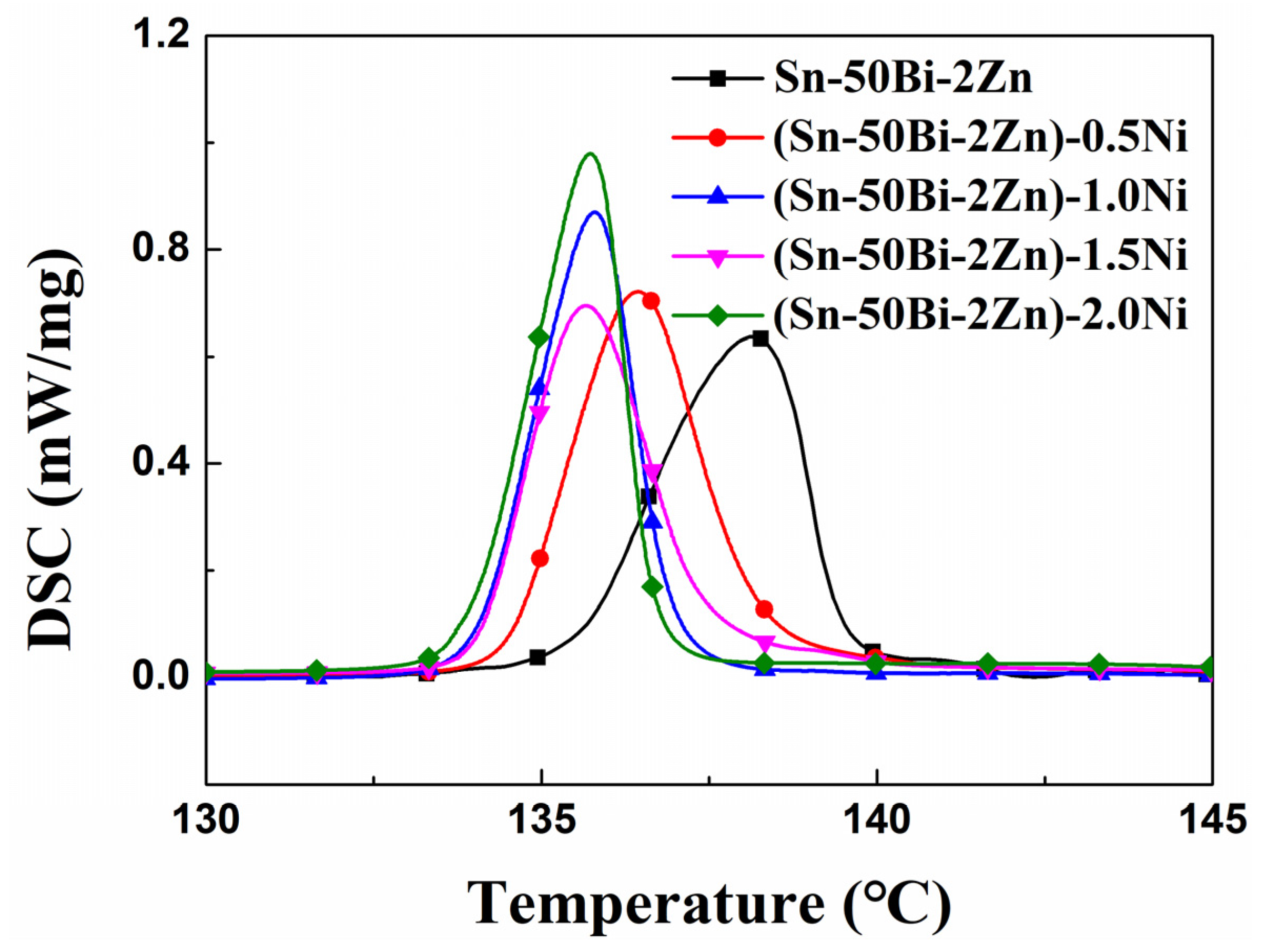

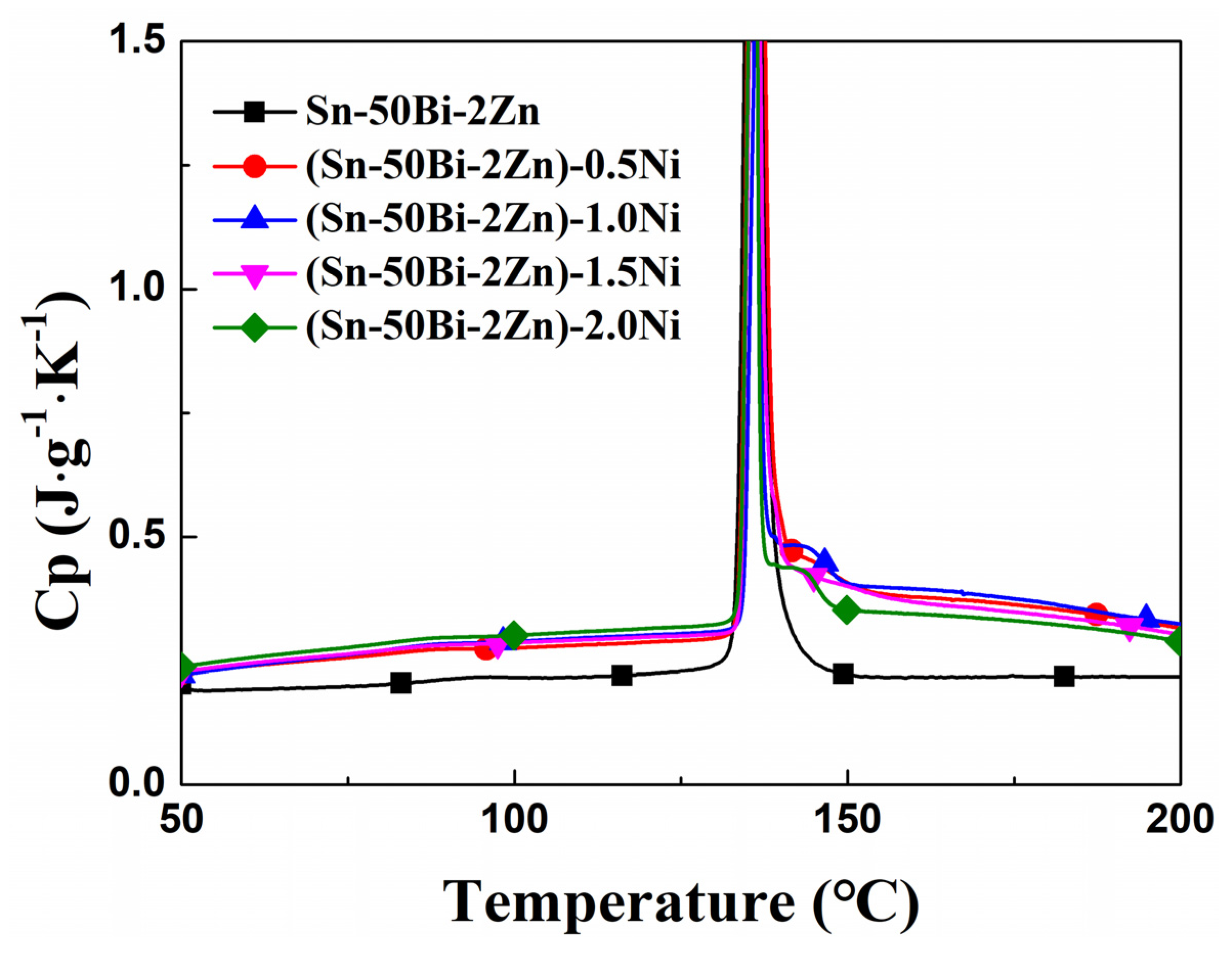

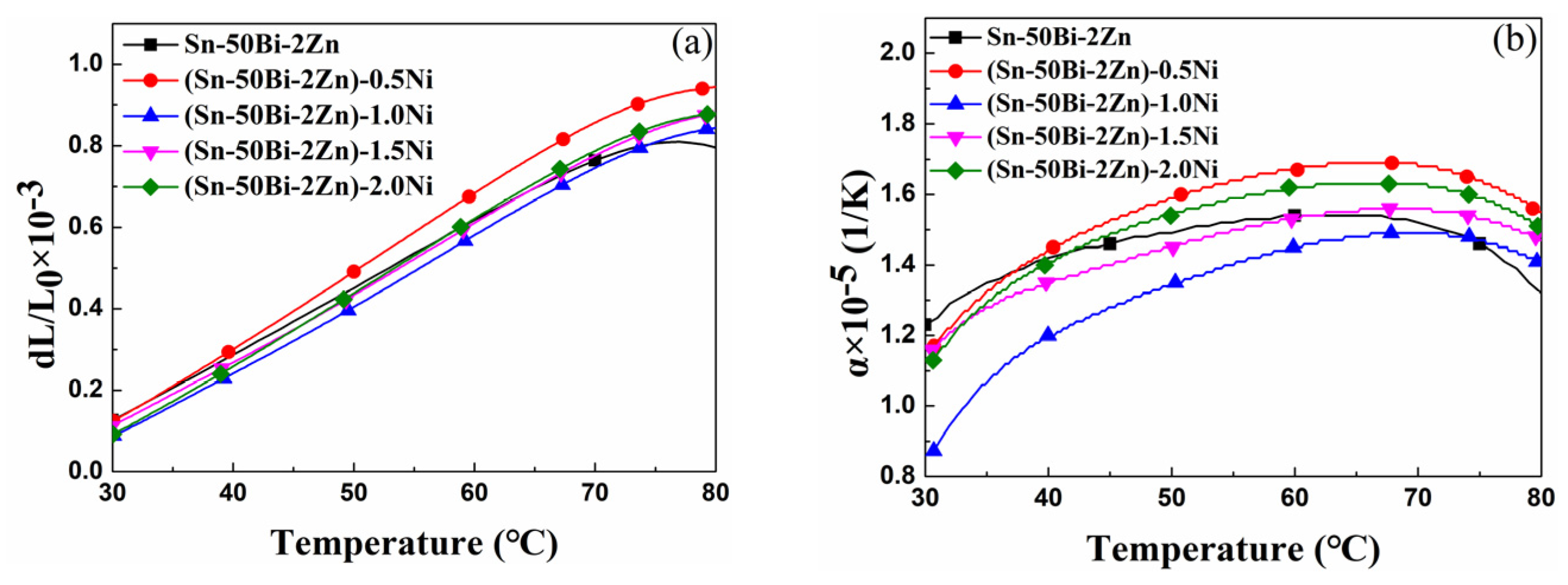

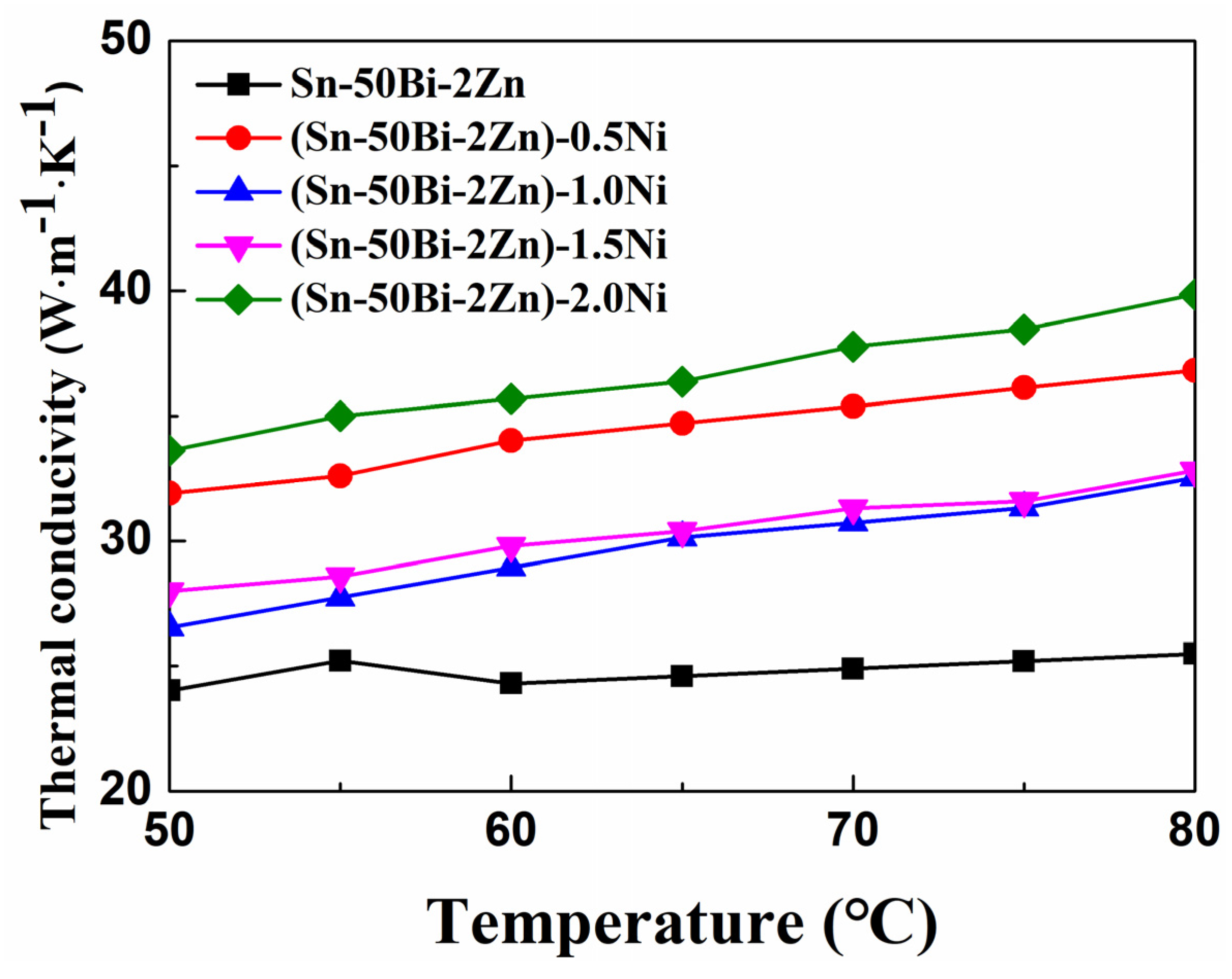

3.2. Thermophysical Properties

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- He, Y.; Qiu, Y.; Wang, K.; Yuan, F.; Wang, W.; Li, M.; Guo, J. Perspective of concentrating solar power. Energy 2020, 198, 117373. [Google Scholar] [CrossRef]

- Far, B.E.; Rizvi, S.; Nayfeh, Y.; Shin, D. Study of viscosity and heat capacity characteristics of molten salt nanofluids for thermal energy storage. Sol. Energy Mater. Sol. Cells 2020, 210, 110503. [Google Scholar] [CrossRef]

- Pérez-Valseca, A.D.; Aguilar-Madera, C.G.; Herrera-Hernández, E.C.; Espinosa-Paredes, G. Upscaled heat transfer coefficients for a liquid metal-cooled fast nuclear reactor. Int. J. Heat Mass Transf. 2021, 165, 120622. [Google Scholar] [CrossRef]

- Benoit, H.; Spreafico, L.; Gauthier, D.; Flamant, G. Review of heat transfer fluids in tube-receivers used in concentrating solar thermal systems: Properties and heat transfer coefficients. Renew. Sustain. Energy Rev. 2016, 55, 298–315. [Google Scholar] [CrossRef]

- Chen, Y.; Zhao, C. Thermophysical properties of Ca(NO3)2-NaNO3-KNO3 mixtures for heat transfer and thermal storage. Sol. Energy 2017, 146, 172–179. [Google Scholar] [CrossRef]

- Cheng, X.; Li, G.; Yu, G.; Li, Y.; Han, J. Effect of expanded graphite and carbon nanotubes on the thermal performance of stearic acid phase change materials. J. Mater. Sci. 2017, 52, 12370–12379. [Google Scholar] [CrossRef]

- Rao, K.; Prabhu, K.N. Compositional and Bath Temperature Effects on Heat Transfer During Quenching in Molten NaNO3–KNO3 Salt Mixtures. J. Mater. Eng. Perform. 2020, 29, 1860–1868. [Google Scholar] [CrossRef]

- Li, Y.; Xu, X.; Wang, X.; Li, P.; Hao, Q.; Xiao, B. Survey and Evaluation of Equations for Thermophysical Properties of Binary/Ternary Eutectic Salts from NaCl, KCl, MgCl2, CaCl2, ZnCl2, for Heat Transfer and Thermal Storage Fluids in CSP. Sol. Energy 2017, 152, 57–79. [Google Scholar] [CrossRef]

- Giaconia, A.; Iaquaniello, G.; Metwally, A.; Caputo, G.; Balog, I. Experimental demonstration and analysis of a CSP plant with molten salt heat transfer fluid in parabolic troughs. Sol. Energy 2020, 211, 622–632. [Google Scholar] [CrossRef]

- Hosseini, S.A.; Romano, G.; Greaney, P.A. Enhanced thermoelectric performance of polycrystalline Si0.8Ge0.2 alloys through the addition of nanoscale porosity. Nanomaterials 2021, 11, 2591. [Google Scholar] [CrossRef] [PubMed]

- Sorokin, A.P.; Kuzina, Y.A. Physical Modeling of Hydrodynamic and Heat Transfer Processes in Liquid-Metal Cooled Nuclear Power Facilities. Therm. Eng. 2019, 128, 277–286. [Google Scholar] [CrossRef]

- Salyan, S.; Praveen, B.; Singh, H.; Suresh, S.; Reddy, A.S. Liquid Metal Gallium in Metal Inserts for Solar Thermal Energy Storage: A Novel Heat Transfer Enhancement Technique. Sol. Energy Mater. Sol. Cells 2019, 208, 110365. [Google Scholar] [CrossRef]

- Blancorodríguez, P.; Rodríguezaseguinolaza, J.; Risueño, E.; Tello, M. Thermophysical Characterization of Mg–51%Zn Eutectic Metal Alloy: A Phase Change Material for Thermal Energy Storage in Direct Steam Generation Applications. Energy 2014, 72, 414–420. [Google Scholar] [CrossRef]

- Fang, D.; Sun, Z.; Li, Y.; Cheng, X. Preparation, Microstructure and Thermal Properties of Mg, Bi Alloys as Phase Change Materials for Thermal Energy Storage. Appl. Therm. Eng. 2016, 92, 187–193. [Google Scholar] [CrossRef]

- Gancarz, T.; Berent, K. The applications of Cu substrate in liquid metal cooling systems. Mater. Lett. 2018, 227, 116–119. [Google Scholar] [CrossRef]

- Mondragón, R.; Juliá, J.E.; Cabedo, L.; Navarrete, N. On the relationship between the specific heat enhancement of salt-based nanofluids and the ionic exchange capacity of nanoparticles. Sci. Rep. 2018, 8, 7532. [Google Scholar] [CrossRef]

- Li, Z.; Cui, L.; Li, B.; Du, X. Enhanced heat conduction in molten salt containing nanoparticles: Insights from molecular dynamics. Int. J. Heat Mass Transf. 2020, 153, 119578. [Google Scholar] [CrossRef]

- Seo, J.; Mostafavi, A.; Shin, D. Molecular dynamics study of enhanced specific heat by molten salt eutectic (Li2CO3-K2CO3) doped with SiO2 nanoparticles. Int. J. Multiscale Comput. Eng. 2018, 16, 321–333. [Google Scholar] [CrossRef]

- Ahmed, S.F.; Khalid, M.; Walvekar, R.; Vaka, M.; Mubarak, N.M.; Chamkha, A.; Khalid, M. Investigating the effect of graphene on eutectic salt properties for thermal energy storage. Mater. Res. Bull. 2019, 119, 110568. [Google Scholar] [CrossRef]

- Huang, Y.; Cheng, X.; Li, Y.; Yu, G.; Xu, K.; Li, G. Effect of in-situ synthesized nano-MgO on thermal properties of NaNO3-KNO3. Sol. Energy 2018, 160, 208–215. [Google Scholar] [CrossRef]

- Han, Z.X.; Ram, M.K.; Kamal, R.; Alamro, T.; Goswami, D.Y.; Jotshi, C. Characterization of molten salt doped with different size nanoparticles of Al2O3. Int. J. Energy Res. 2019, 43, 3732–3745. [Google Scholar] [CrossRef]

- Wang, Q.M.; Cheng, X.M.; Li, Y.Y.; Yu, G.M.; Liu, Z. Microstructures and thermal properties of Sn–Bi–Pb–Zn alloys as heat storage and transfer materials. Rare Met. 2019, 38, 350–358. [Google Scholar] [CrossRef]

- ASTM E1269-11; Standard Test Method for Determining Specific Heat Capacity by Differential Scanning Calorime-Try. American National Standards Institute (ANSI): New York, NY, USA, 2011.

- ASTM E831-06; Standard Test Method for Linear Thermal Expansion of Solid Materials by Thermomechanical Analysis. American National Standards Institute (ANSI): New York, NY, USA, 2006.

- Shen, H.H.; Zhang, J.W.; Hu, J.T.; Zhang, J.C.; Mao, Y.W.; Xiao, H.Y.; Zhou, X.S.; Zu, X.T. A novel TiZrHfMoNb high-entropy alloy for solar thermal energy storage. Nanomaterials 2019, 9, 248. [Google Scholar] [CrossRef] [PubMed]

- Skwarek, A.; Krammer, O.; Hurtony, T.; Ptak, P.; Gorecki, K.; Wronski, S.; Straubinger, D.; Witek, K.; Illes, B. Application of ZnO Nanoparticles in Sn99Ag0.3 Cu0.7-Based Composite Solder Alloys. Nanomaterials 2021, 11, 1545. [Google Scholar] [CrossRef] [PubMed]

- Zhang, B.B.; Tao, N.R.; Lu, K. A high strength and high electrical conductivity bulk Cu-Ag alloy strengthened with nanotwins. Scr. Mater. 2017, 129, 39–43. [Google Scholar] [CrossRef]

- Tong, X.; You, G.; Ding, Y.; Xue, H.; Wang, Y.; Guo, W. Effect of grain size on low-temperature electrical resistivity and thermal conductivity of pure magnesium. Mater. Lett. 2018, 229, 261–264. [Google Scholar] [CrossRef]

- Mao, J.; Wang, Y.; Kim, H.S.; Liu, Z.; Saparamadu, U.; Tian, F.; Dahal, K.; Sun, J.; Chen, S.; Liu, W.; et al. High thermoelectric power factor in Cu–Ni alloy originate from potential barrier scattering of twin boundaries. Nano Energy 2015, 17, 279–289. [Google Scholar] [CrossRef]

- Pan, S.; Guan, Z.; Li, X. Unusual thermal performance in Cu-60Ag by WC nanoparticles. Mater. Sci. Eng. B 2021, 265, 115010. [Google Scholar] [CrossRef]

- Lu, L.; Shen, Y.; Chen, X.; Qian, L.; Lu, K. Ultrahigh strength and high electrical conductivity in copper. Science 2004, 304, 422–426. [Google Scholar] [CrossRef]

| Samples | Designed Compounds | XRF Results (wt.%) | |||

|---|---|---|---|---|---|

| Sn | Bi | Zn | Ni | ||

| A1 | Sn–50Bi–2Zn | 48.29 | 49.57 | 2.14 | 0 |

| A2 | (Sn–50Bi–2Zn)–0.5Ni | 47.86 | 49.71 | 1.91 | 0.52 |

| A3 | (Sn–50Bi–2Zn)–1.0Ni | 47.65 | 49.52 | 1.87 | 0.97 |

| A4 | (Sn–50Bi–2Zn)–1.5Ni | 47.63 | 48.99 | 1.86 | 1.52 |

| A5 | (Sn–50Bi–2Zn)–2.0Ni | 47.77 | 48.42 | 1.83 | 1.98 |

| Elemental Composition | A | B | C | D | E | F | G |

|---|---|---|---|---|---|---|---|

| Sn | 0 | 93.24 | 20.20 | 59.52 | 22.84 | 16.88 | 48.61 |

| Bi | 100 | 4.86 | 16.35 | 0 | 67.62 | 12.27 | 14.35 |

| Zn | 0 | 1.90 | 63.45 | 40.48 | 0 | 50.82 | 5.83 |

| Ni | 0 | 0 | 0 | 0 | 9.54 | 22.16 | 31.21 |

| Phase composition | Bi-rich | Sn-rich | Zn-rich | Sn + Zn | Bi + Ni | NiZn | Sn + Ni |

| Samples | Melting Temperature/(°C) | Melting Enthalpy/(J·g−1) | ||

|---|---|---|---|---|

| Onset | Peak | End | ΔHm | |

| A1 | 135.49 | 138.15 | 139.47 | 47.62 |

| A2 | 134.48 | 136.44 | 138.26 | 47.07 |

| A3 | 134.02 | 135.79 | 136.94 | 46.45 |

| A4 | 134.04 | 135.66 | 137.51 | 45.24 |

| A5 | 133.91 | 135.73 | 136.65 | 48.14 |

| Samples | The Average Specific Heat Capacity (J·g−1·K−1) | |

|---|---|---|

| Solid State | Liquid State | |

| A1 | 0.21 | 0.22 |

| A2 | 0.25 | 0.36 |

| A3 | 0.25 | 0.38 |

| A4 | 0.26 | 0.35 |

| A5 | 0.27 | 0.33 |

| Samples | Thermal Diffusivity (mm2/s) |

|---|---|

| A1 | 18.19 |

| A2 | 17.18 |

| A3 | 14.61 |

| A4 | 14.73 |

| A5 | 16.94 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Q.; Cheng, X.; Wang, X.; Yang, T.; Cheng, Q.; Liu, Z.; Lv, Z. Effect of Nano Ni Particles on the Microstructure and Thermophysical Properties of Sn–Bi–Zn Heat Transfer and Heat Storage Alloys. Materials 2023, 16, 5325. https://doi.org/10.3390/ma16155325

Wang Q, Cheng X, Wang X, Yang T, Cheng Q, Liu Z, Lv Z. Effect of Nano Ni Particles on the Microstructure and Thermophysical Properties of Sn–Bi–Zn Heat Transfer and Heat Storage Alloys. Materials. 2023; 16(15):5325. https://doi.org/10.3390/ma16155325

Chicago/Turabian StyleWang, Qingmeng, Xiaomin Cheng, Xiuli Wang, Tao Yang, Qianju Cheng, Zhi Liu, and Zean Lv. 2023. "Effect of Nano Ni Particles on the Microstructure and Thermophysical Properties of Sn–Bi–Zn Heat Transfer and Heat Storage Alloys" Materials 16, no. 15: 5325. https://doi.org/10.3390/ma16155325

APA StyleWang, Q., Cheng, X., Wang, X., Yang, T., Cheng, Q., Liu, Z., & Lv, Z. (2023). Effect of Nano Ni Particles on the Microstructure and Thermophysical Properties of Sn–Bi–Zn Heat Transfer and Heat Storage Alloys. Materials, 16(15), 5325. https://doi.org/10.3390/ma16155325