Investigating the Effects of Recycled Aggregate and Mineral Admixtures on the Mechanical Properties and Performance of Concrete

Abstract

1. Introduction

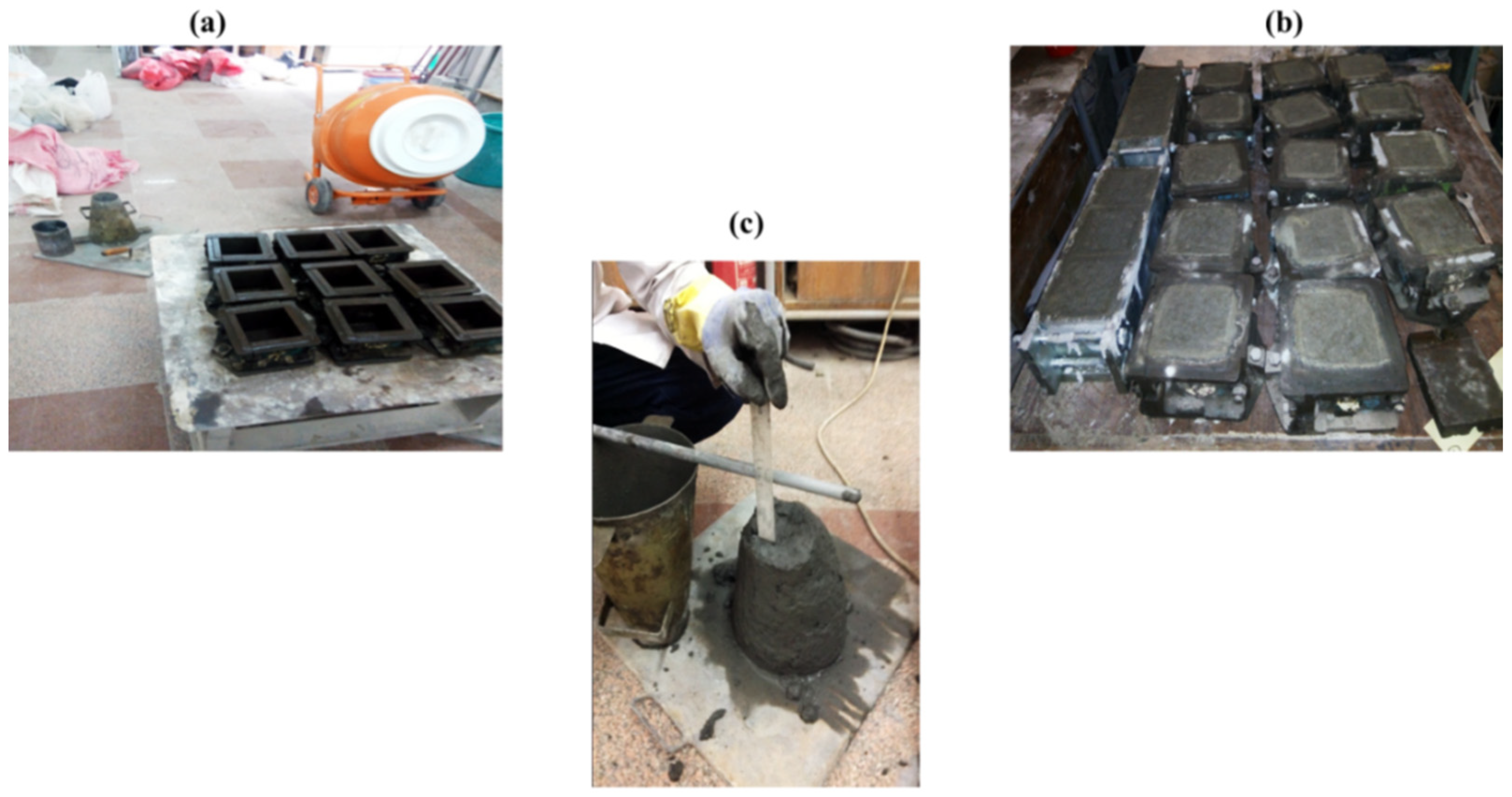

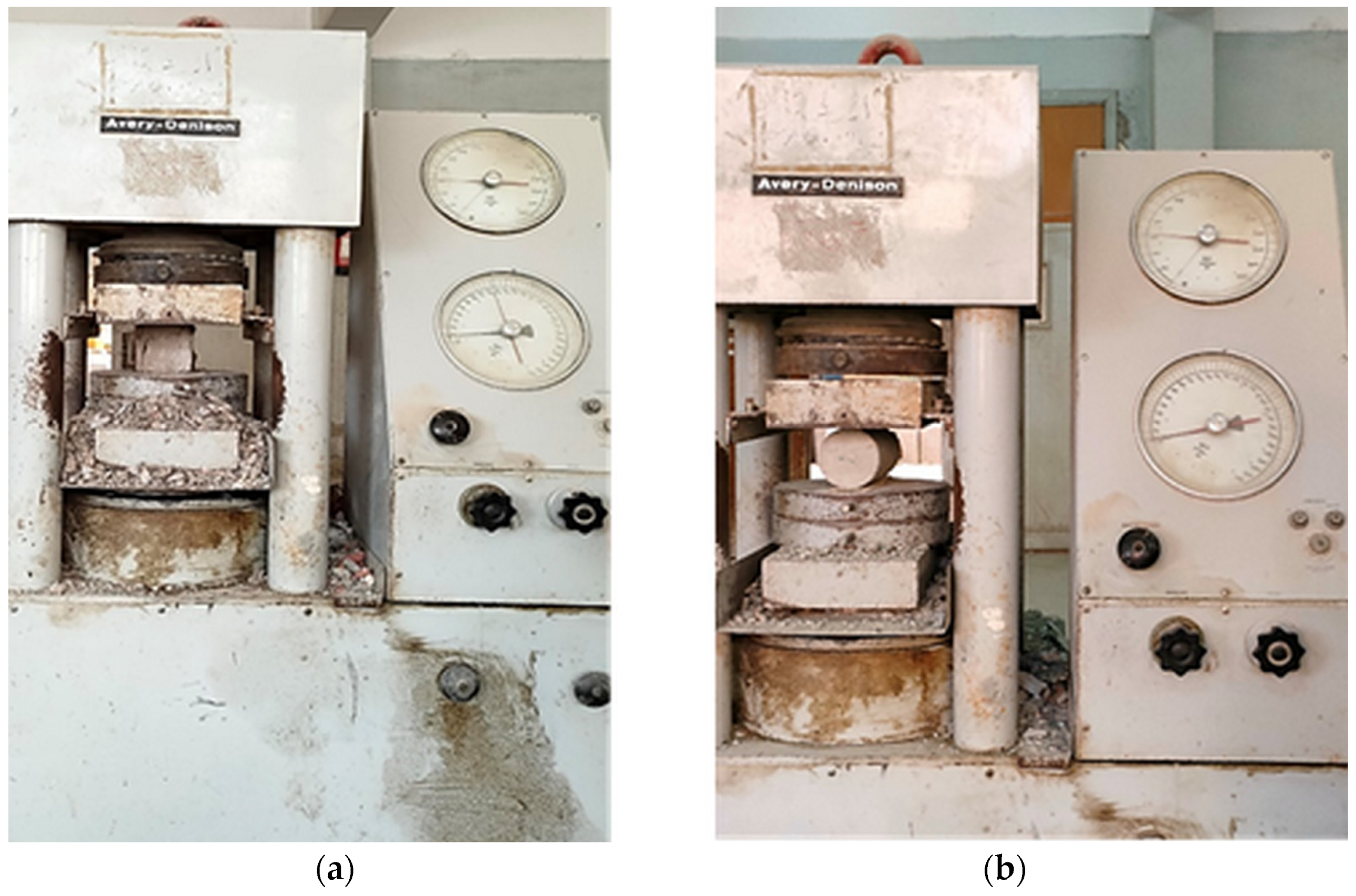

2. Materials and Methods

- (1)

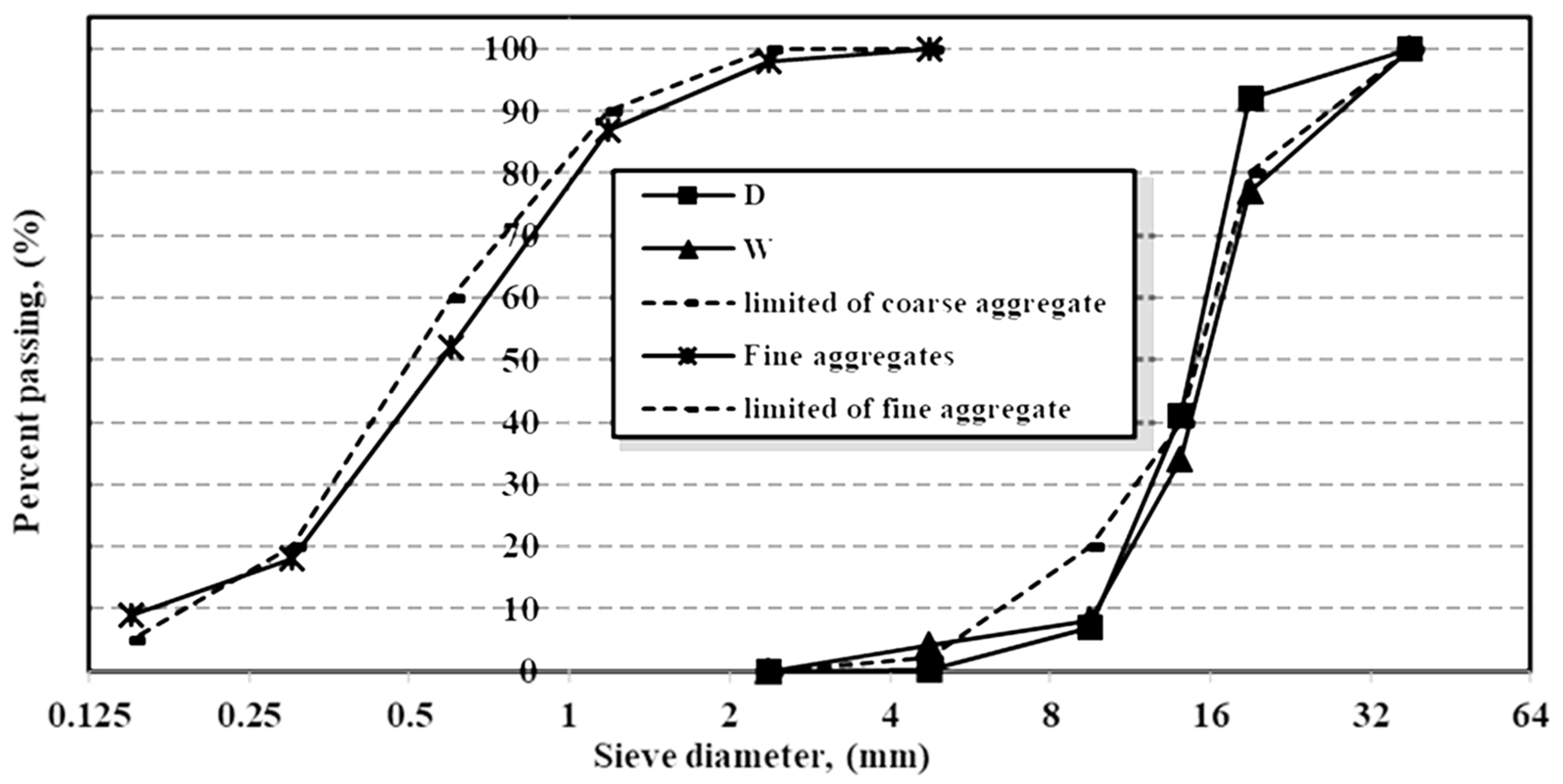

- (Egyptian Standard Specification No. 1109 2002).

- (2)

- (Egyptian Code of Practice for Reinforced Concrete No. 203 2017).

- (3)

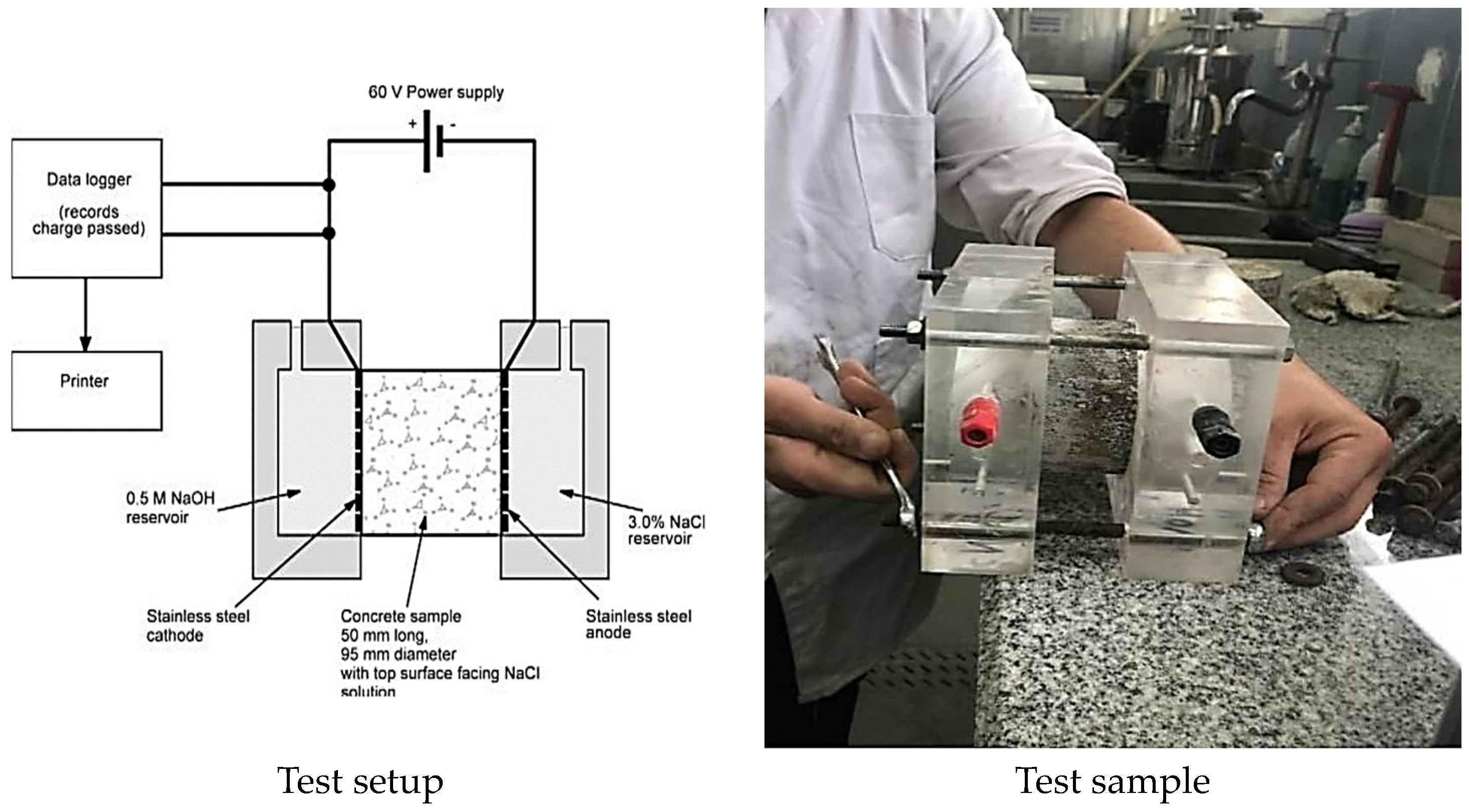

- (ASTM C637 2009).

3. Results and Discussions

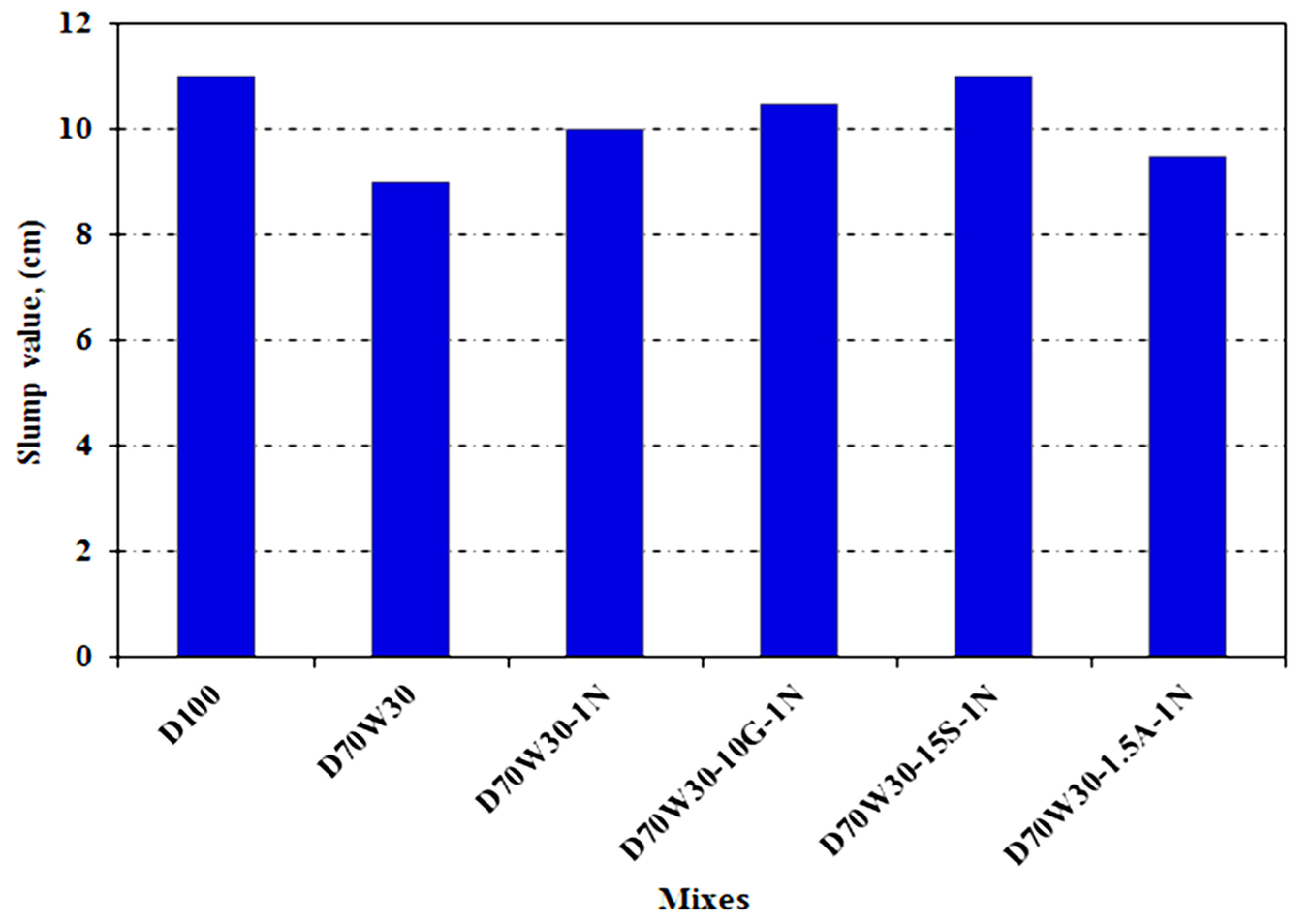

3.1. Workability

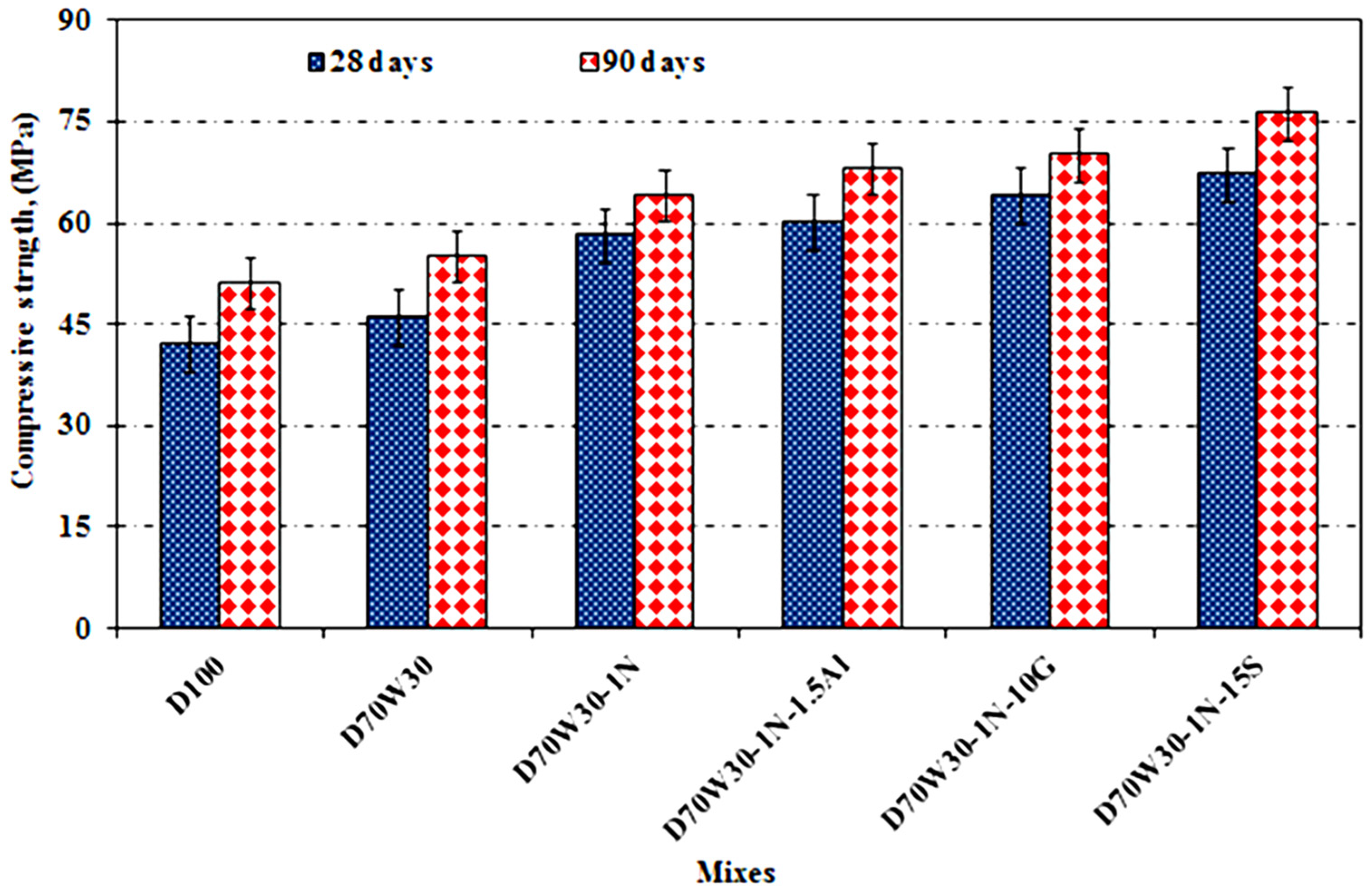

3.2. Compressive Strength

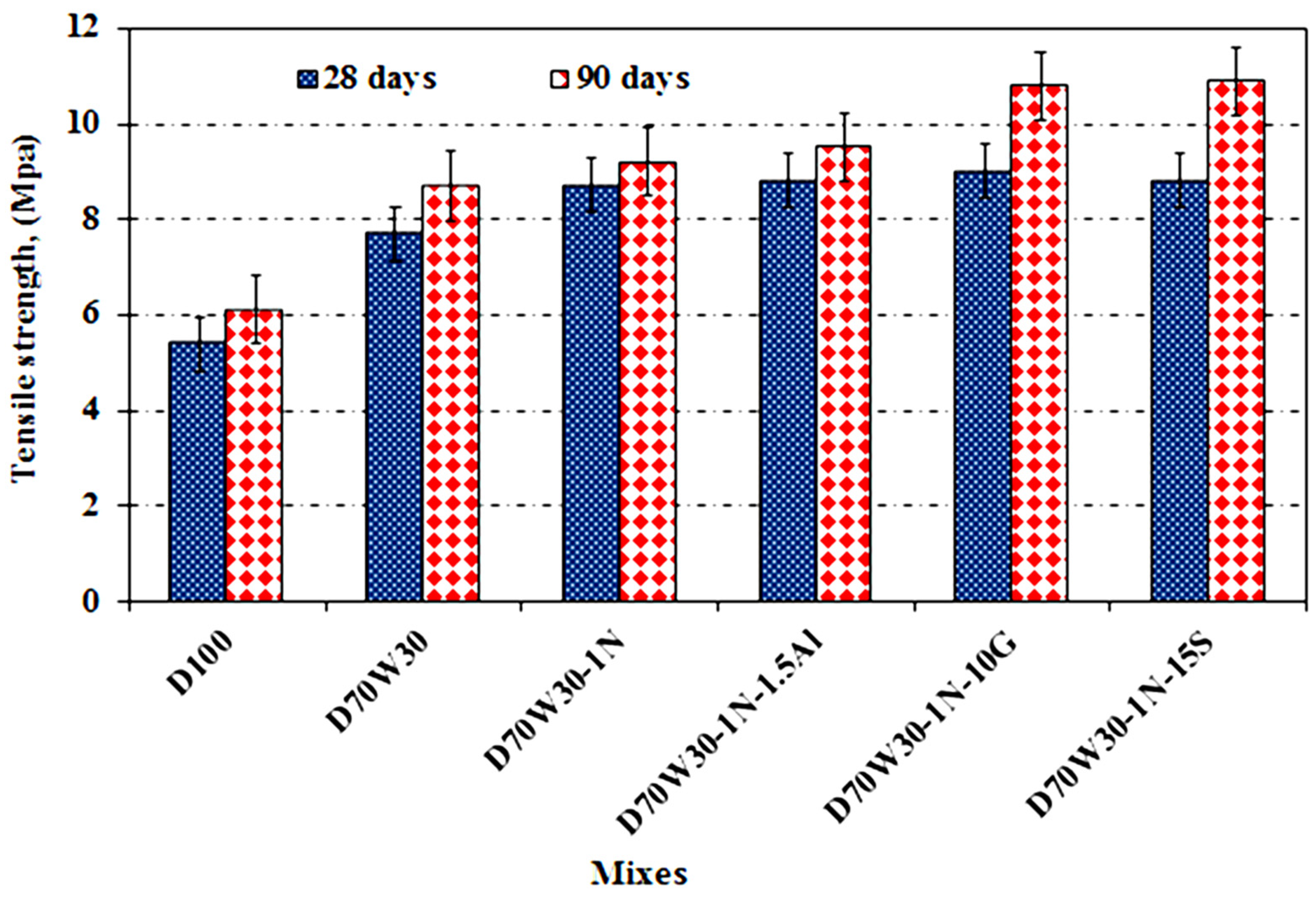

3.3. Tensile Splitting Strength

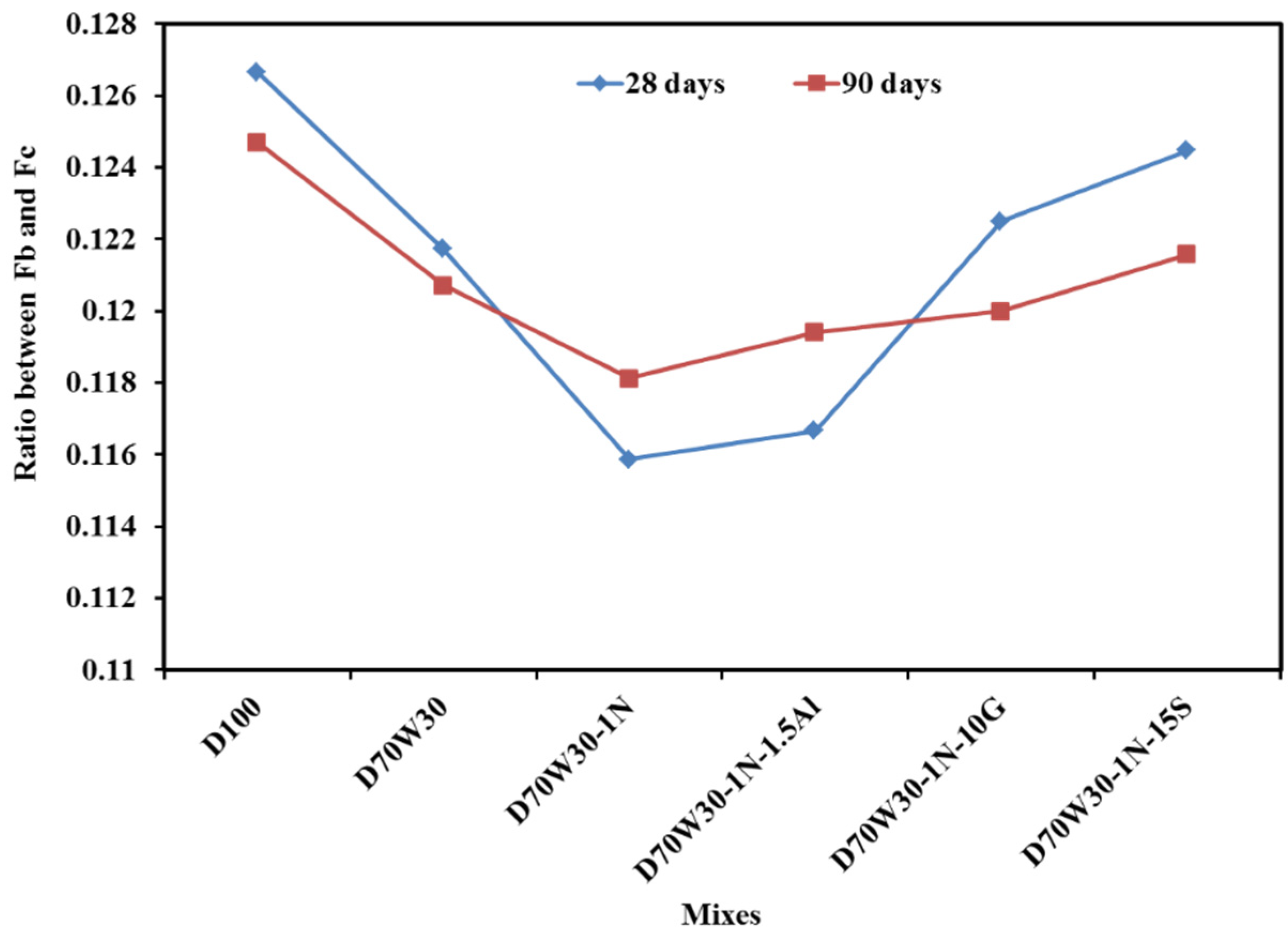

3.4. Flexural Strength

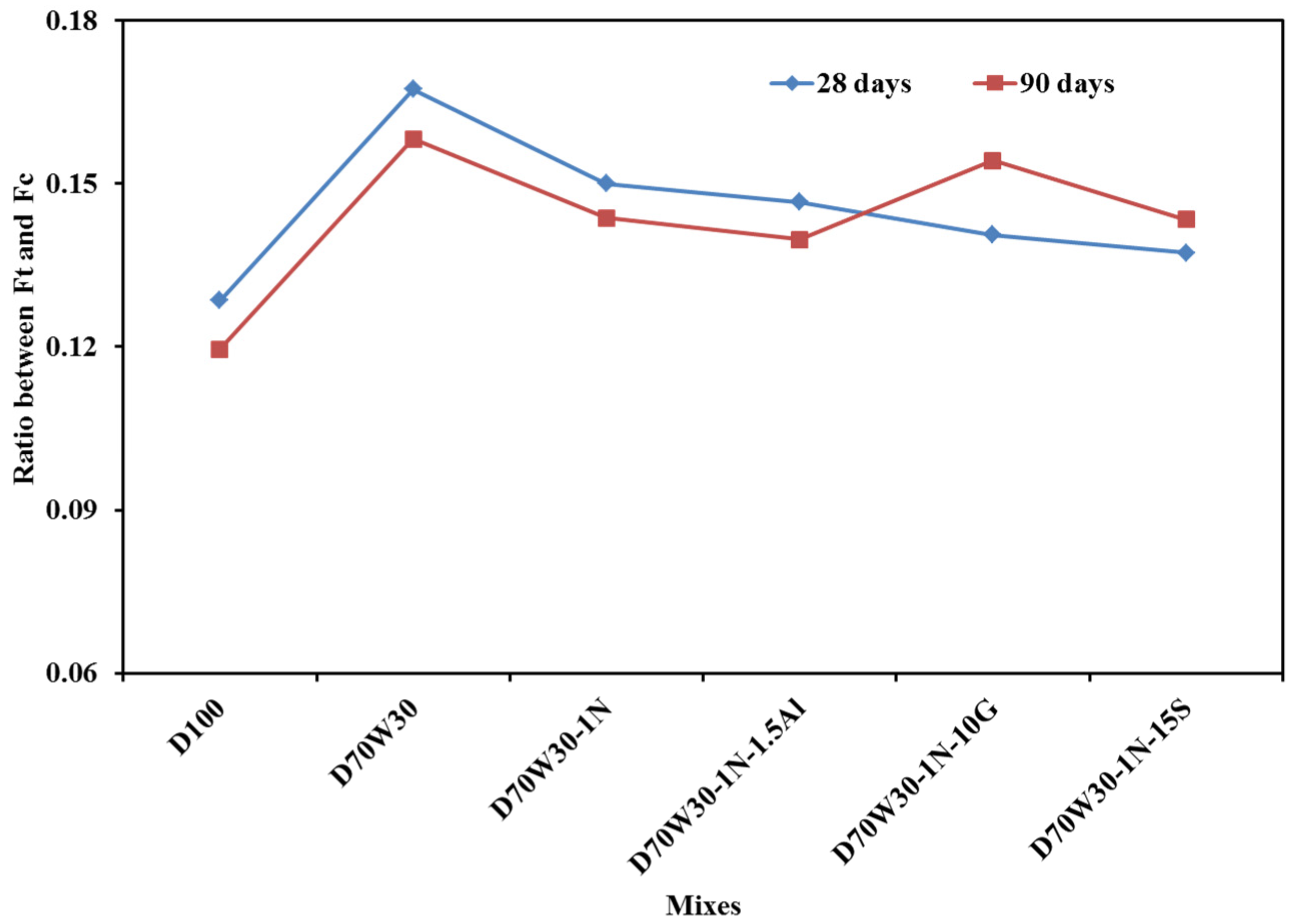

3.5. Strength Ratios

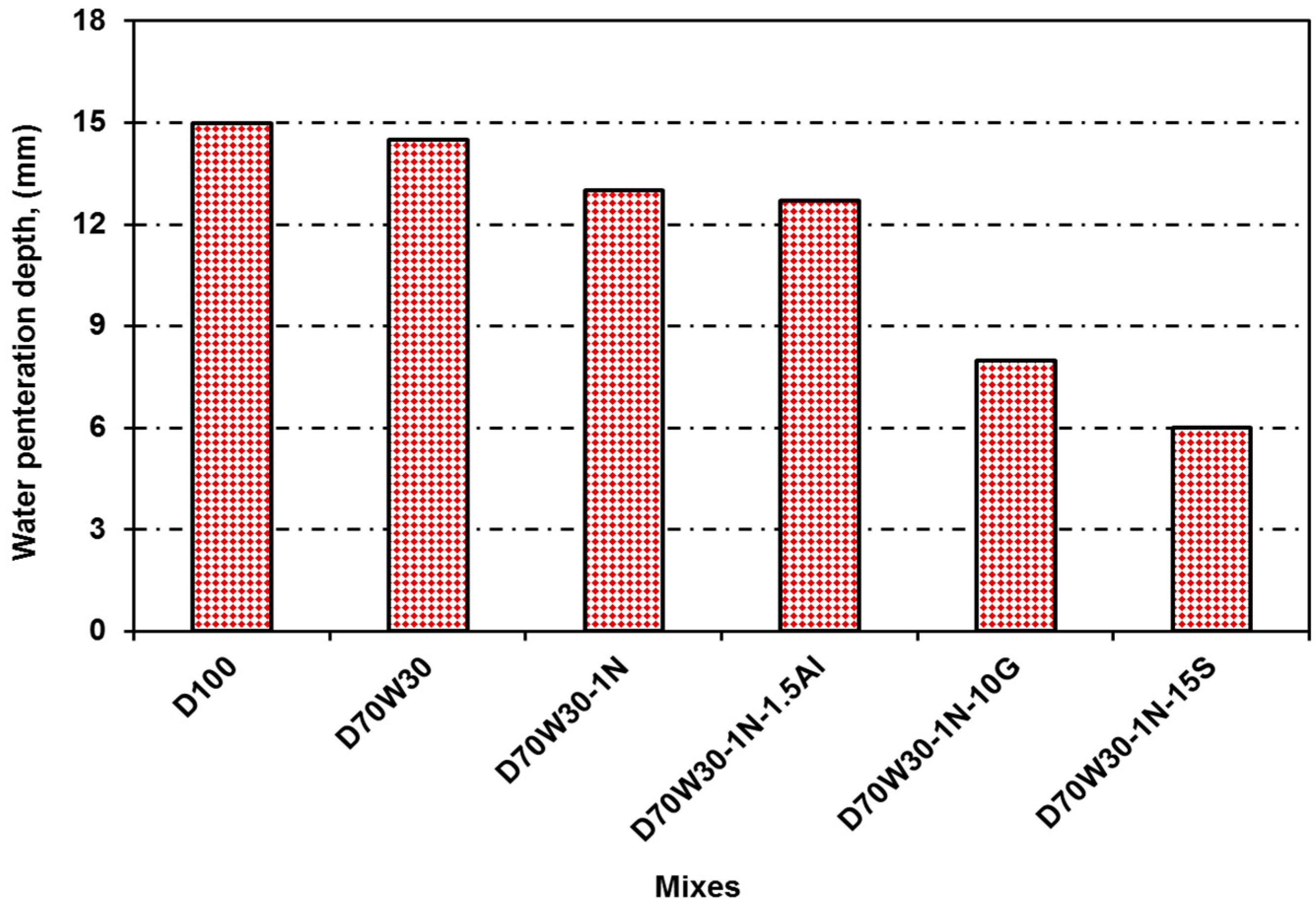

3.6. Water Permeability

3.7. Rapid Chloride Permeability

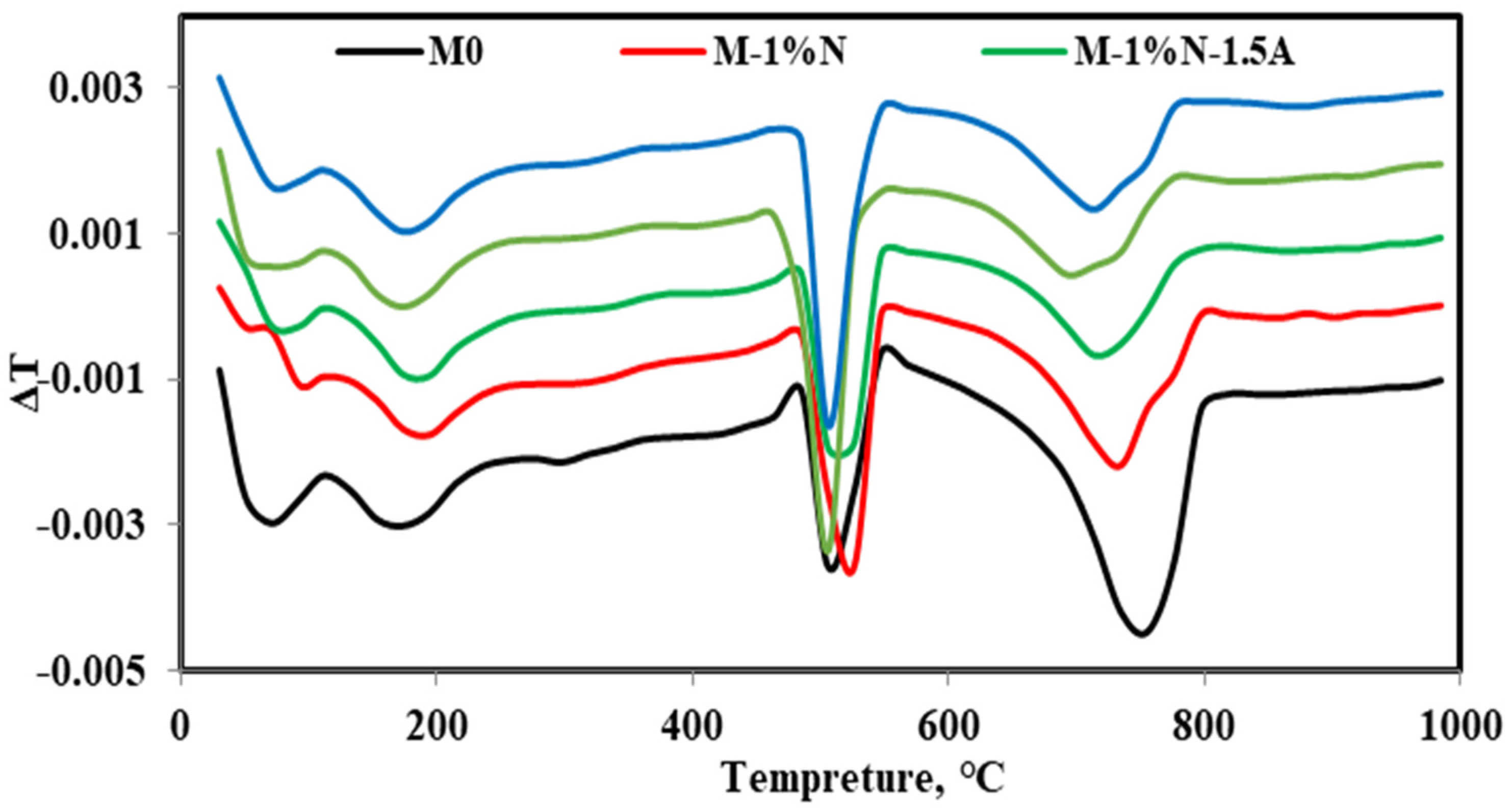

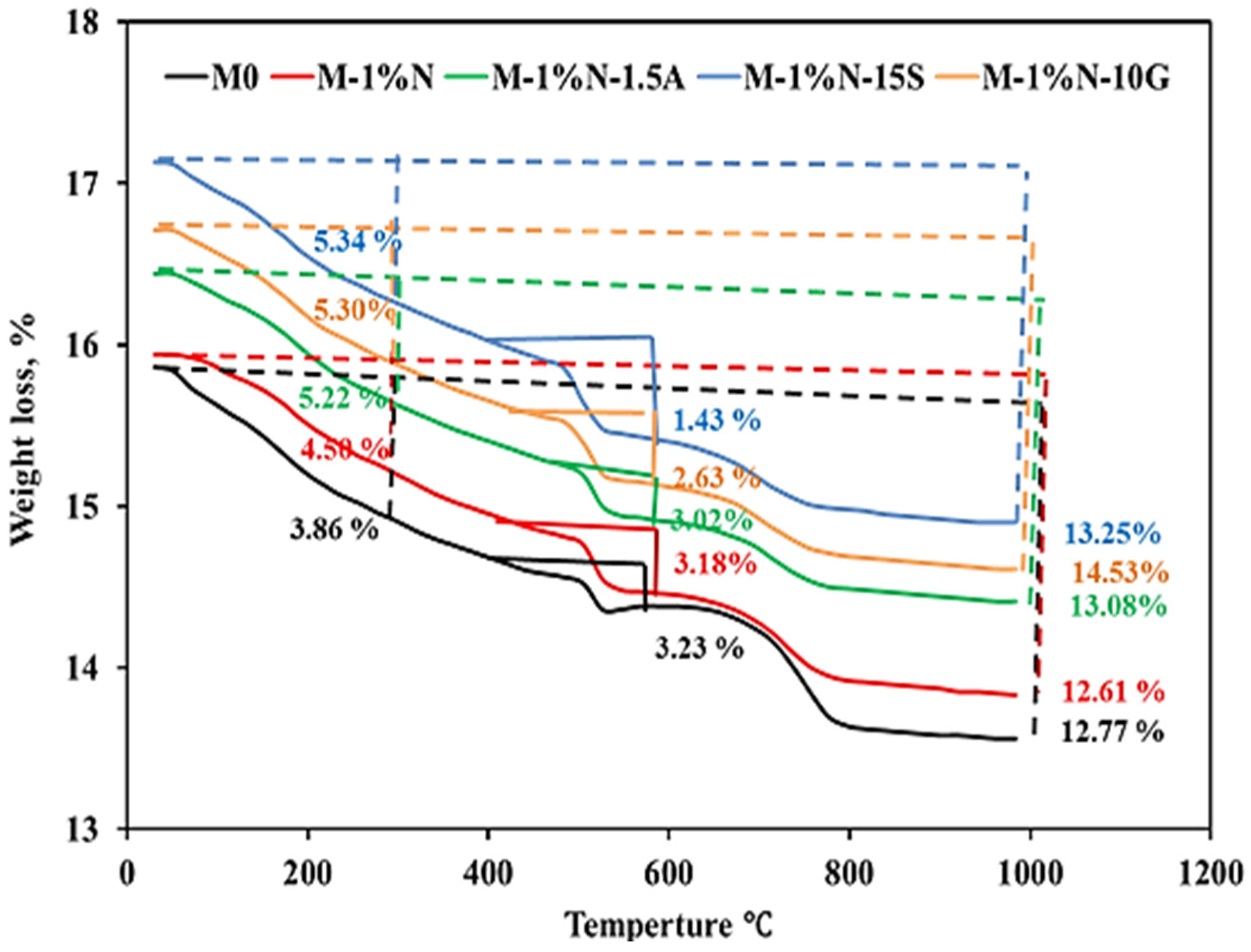

3.8. TGA/DTG Analysis

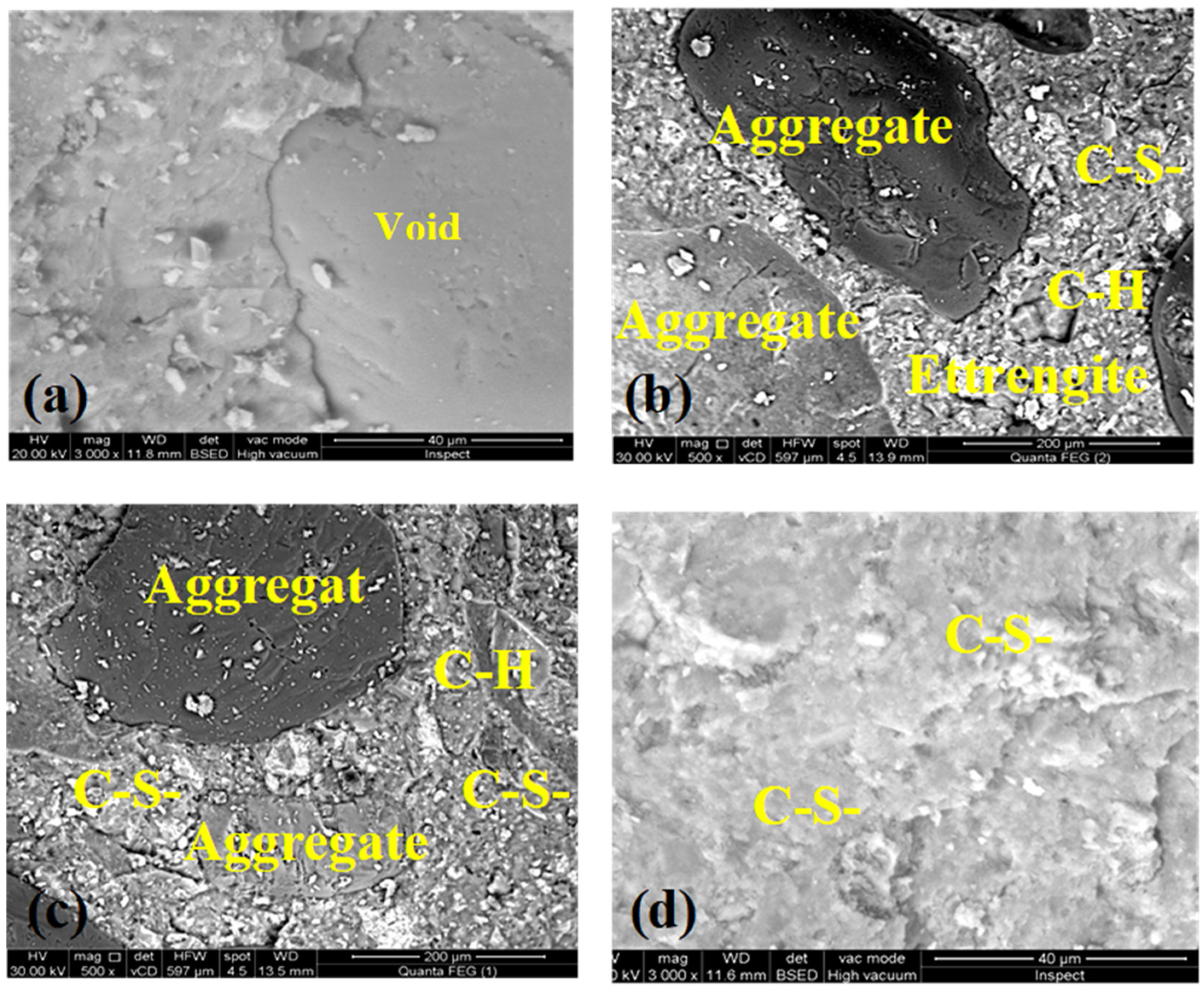

3.9. Microstructure Analysis

4. Conclusions

- (1)

- The slump value of dolomite concrete decreases as compared to recycled aggregate concrete. However, the addition of 1% NS binary cementing material increases the slump value of the concrete mix produced with recycled aggregate by approximately 11.1%.

- (2)

- The concrete mix with recycled aggregate has higher compressive, tensile, and flexural strength than dolomite aggregate because the recycled aggregate’s physical and mechanical characteristics improve upon interlocking with cement paste.

- (3)

- The strength increase is paired with a decrease in chloride penetration, indicating that microcracking affects both chloride penetration and compressive strength.

- (4)

- The inclusion of nanosilica and mineral admixtures in recycled aggregate concrete improves its mechanical strength.

- (5)

- The micrographs show that concrete mixes with recycled aggregate and mineral admixtures have a more compact microstructure compared to normal dolomite concrete due to an increased C-S-H phase and hydration products.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gharieb, M.; Rashed, A.M. An initial study of using sugar-beet waste as a cementitious material. Constr. Build. Mater. 2020, 250, 118843. [Google Scholar] [CrossRef]

- Sadek, D.M.; El-Attar, M.M. Development of High-Performance Green Concrete using Demolition and Industrial Wastes for Sustainable Construction Dina. J. Am. Sci. 2012, 8, 12–131. Available online: http://www.americanscience.org (accessed on 2 June 2023).

- Xu, J.H.; Fleiter, T.; Fan, Y.; Eichhammer, W. CO2 emissions reduction potential in China’s cement industry compared to IEA’s Cement Technology Roadmap up to 2050. Appl. Energy 2014, 130, 592–602. [Google Scholar] [CrossRef]

- Yadav, A.L.; Sairam, V.; Muruganandam, L.; Srinivasan, K. An overview of the influences of mechanical and chemical pro V cessing on sugarcane bagasse ash characterisation as a supplementary cementitious material. J. Clean. Prod. 2020, 245, 118854. [Google Scholar] [CrossRef]

- Yousef, M.M.; El-Sayed, H.A.; Kandeel, A.M.; Gharieb, M.; Aziz, A.A.A. Chloride-binders and their effect on the physico-mechanical properties of sulfate-resisting cement (SRC) hardened pastes upon exposure to seawater attack. Environ. Sci. Pollut. Res. 2022, 29, 20817–20828. [Google Scholar] [CrossRef]

- Khater, H.M.; Ramadan, W.; Gharieb, M. Impact of alkali-activated mortar incorporating different heavy metals on immobilization proficiency using gamma rays’ attenuation. Prog. Nucl. Energy. 2012, 137, 103729. [Google Scholar] [CrossRef]

- Porro, A.; Dolado, J.S.; Campillo, I.; Erkizia, E.D.; De Miguel, Y.; de Ibarra, Y.S.; Ayuela, A. Effects of nanosilica additions on cement pastes. In Applications of Nanotechnology in Concrete Design; Thomas Telford Publishing: London, UK, 2005; pp. 87–96. [Google Scholar] [CrossRef]

- Sun, H.; Zhang, X.; Zhao, P.; Liu, D. Effects of nano-Silica particle size on fresh state properties of cement paste. KSCE. J. Civ. Eng. 2021, 25, 2555–2566. [Google Scholar] [CrossRef]

- Wang, L.; Zheng, D.; Zhang, S.; Cui, H.; Li, D. Effect of nano-SiO2 on the hydration and microstructure of Portland cement. Nanomaterials 2016, 6, 241. [Google Scholar] [CrossRef]

- Guo, X.; Shi, H.; Wu, K. Effects of steel slag powder on workability and durability of concrete. J. Wuhan Univ. Technol. Sci. Ed. 2014, 29, 733–739. [Google Scholar] [CrossRef]

- Page, R.J.; Fanourakis, G.C. The Influence of Slag Fineness on the Workability of Cementitious Pastes. Concr. Bet. 2021, 120, 6–12. Available online: www.concretesociety.co.za (accessed on 18 November 2021).

- Collins, F.; Sanjayan, J.G. Early Age Strength and Workability of Slag Pastes Activated by NaOH and Na2CO3. Cem. Concr. Res. 1998, 28, 655–664. [Google Scholar] [CrossRef]

- Ann, K.Y.; Moon, H.Y.; Kim, Y.B.; Ryou, J. Durability of recycled aggregate concrete using pozzolanic materials. Waste Manag. 2008, 28, 993–999. [Google Scholar] [CrossRef]

- Correia, J.R.; De Brito, J.; Pereira, A.S. Effects on concrete durability of using recycled ceramic aggregates. Mater. Struct. Constr. 2006, 39, 169–177. [Google Scholar] [CrossRef]

- Tam VW, Y.; Le, K.N.; Evangelista AC, J.; Butera, A.; Tran CN, N.; Teara, A. Effect of fly ash and slag on concrete: Properties and emission analyses. Front. Eng. Manag. 2019, 6, 395–405. [Google Scholar] [CrossRef]

- Vesmawala, G.R.; Patil, Y.D.; Patil, M.V. A study on properties and effects of copper slag and marble dust in concrete. Int. J. Struct. Eng. 2018, 9, 91. [Google Scholar] [CrossRef]

- Ferraro, A.; Farina, I.; Race, M.; Colangelo, F.; Cioffi, R.; Fabbricino, M. Pre-treatments of MSWI fly-ashes: A comprehensive review to determine optimal conditions for their reuse and/or environmentally sustainable disposal. Rev. Environ. Sci. Biotechnol. 2019, 18, 453–471. [Google Scholar] [CrossRef]

- Kurda, R.; Silvestre, J.D.; de Brito, J. Life cycle assessment of concrete made with high volume of recycled concrete aggregates and fly ash. Resour. Conserv. Recycl. 2018, 139, 407–417. [Google Scholar] [CrossRef]

- Sandanayake, M.; Bouras, Y.; Haigh, R.; Vrcelj, Z. Current sustainable trends of using waste materials in concrete—A decade review. Sustainability 2020, 12, 9622. [Google Scholar] [CrossRef]

- Memon, M.U.; Memon, B.A.; Oad, M.; Chandio, F.A. Effect of Marble Dust on Compressive Strength of Recycled Aggregate Concrete. QUEST Res. J. 2020, 18, 11–18. [Google Scholar] [CrossRef]

- Rashad, A.; Gharieb, M.M. An investigation on the effect of sea sand on the properties of fly ash geopolymer mortars. Innov. Infrastruct. Solut. 2021, 6, 53. [Google Scholar] [CrossRef]

- Naji, A.J.; Mousa, M.A.; Malik, S.H. The Production of the Sustainable Concrete by using Different Types of plastic waste. J. Eng. Appl. Sci. 2019, 14, 5557–5560. [Google Scholar] [CrossRef]

- Fırat, S.; Kinuthia, J.; Abu-Tair, A. (Eds.) Proceedings of 3rd International Sustainable Buildings Symposium, (ISBS 2017); Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar] [CrossRef]

- Tavakoli, D.; Hashempour, M.; Heidari, A. Use of waste materials in concrete: A review. Pertanika J. Sci. Tech. 2018, 26, 499–522. [Google Scholar]

- Colangelo, F.; Petrillo, A.; Farina, I. Comparative environmental evaluation of recycled aggregates from construction and demolition wastes in Italy. Sci. Total Environ. 2021, 798, 149250. [Google Scholar] [CrossRef] [PubMed]

- Meena, R.V.; Jain, J.K.; Chouhan, H.S.; Beniwal, A.S. Use of waste ceramics to produce sustainable concrete: A review. Clean. Mater. 2022, 4, 100085. [Google Scholar] [CrossRef]

- Priya, S.; Kumar, S.S.S. Strength and Characteristics of Modified Concrete by Means of Industrial By-Products. Constr. Build. Mater. 2019, 21, 4618–4622. [Google Scholar] [CrossRef]

- Rashad, A.M.; Khafaga, S.A.; Gharieb, M. Valorization of fly ash as an additive for electric arc furnace slag geopolymer cement. Constr. Build. Mater. 2012, 294, 123570. [Google Scholar] [CrossRef]

- Manfredi, O.; Wuth, W.; Bohlinger, I. Characterizing the physical and chemical properties of aluminum dross. JOM 1997, 49, 48–51. [Google Scholar] [CrossRef]

- Elinwa, A.U.; Mbadike, E. The use of Aluminum waste for concrete production. J. Asian Archit. Build. Eng. 2011, 10, 217–220. [Google Scholar] [CrossRef]

- Seara-Paz, S.B.; González-Fonteboa, B.; Martínez-Abella, F.; González-Taboada, I. Time-dependent behavior of structural concrete made with recycled coarse aggregates. Creep and shrinkage. Constr. Build. Mater. 2016, 122, 95–109. [Google Scholar] [CrossRef]

- González-Fonteboa, B.; Martínez-Abella, F. Recycled aggregates concrete: Aggregate and mix properties. Mater. Constr. 2005, 55, 53–66. [Google Scholar] [CrossRef]

- Rashad, A.M.; Gharieb, M. Valorization of sugar beet waste as an additive for fly ash geopolymer cement cured at room temperature. J. Build. Eng. 2021, 44, 102989. [Google Scholar] [CrossRef]

- Kou, S.C.; Poon, C.S.; Agrela, F. Comparisons of natural and recycled aggregate concretes prepared with the addition of different mineral admixtures. Cem. Concr. Compos. 2011, 33, 788–795. [Google Scholar] [CrossRef]

- Corinaldesi, V.; Moriconi, G. Recycling of rubble from building demolition for low-shrinkage concretes. Waste Manag. 2010, 30, 655–659. [Google Scholar] [CrossRef]

- Corinaldesi, V.; Letelier, V.; Moriconi, G. Behaviour of beam-column joints made of recycled-aggregate concrete under cyclic loading. Constr. Build. Mater. 2011, 25, 1877–1882. [Google Scholar] [CrossRef]

- Higgins, D.D. Increased sulphate resistance of ggbs concrete in the presence of carbonate. Cem. Concr. Compos. 2003, 25, 913–919. [Google Scholar] [CrossRef]

- Han, B.; Zhang, L.; Jinping, O.; Han, B.; Zhang, L.; Ou, J. Smart and Multifunctional Concrete towards Sustainable Infrastructures; Springer: Singapore, 2017. [Google Scholar] [CrossRef]

- Jittabut, P.; Horpibulsuk, S. Physical and microstructure properties of geopolymer nanocomposite reinforced with carbon nanotubes. Mater. Today Proc. 2019, 17, 1682–1692. [Google Scholar] [CrossRef]

- Ahmad, S.S.E.; Elshami, A.; Fawzy, A. Behaviour of sustainable concrete modified with mineral admixtures and Nano-silica against aggressive media attacks. IOP Conf. Ser. Earth Environ. Sci. 2022, 1026, 012052. [Google Scholar] [CrossRef]

- Silva, R.V.; De Brito, J.; Neves, R.; Dhir, R. Prediction of chloride ion penetration of recycled aggregate concrete. Mater. Res. 2015, 18, 427–440. [Google Scholar] [CrossRef]

- Kou, S.; Poon, C.S. Compressive strength, pore size distribution and chloride-ion penetration of recycled aggregate concrete incorporating class-F fly ash. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2006, 21, 130–136. [Google Scholar] [CrossRef]

- Kou, S.C.; Poon, C.S.; Chan, D. Influence of Fly Ash as Cement Replacement on the Properties of Recycled Aggregate Concrete. J. Mater. Civil Eng. 2007, 19, 709–717. [Google Scholar] [CrossRef]

- Zhuang, C.; Chen, Y. The effect of nano-SiO2 on concrete properties—A review. Nanotechnol. Rev. 2019, 8, 562–572. [Google Scholar] [CrossRef]

- Muthu Kumar, E.; Ramamurthy, K. Effect of fineness and dosage of aluminum powder on the properties of moist-cured aerated concrete. Constr. Build. Mater. J. 2015, 95, 486–496. [Google Scholar] [CrossRef]

- Collins, F.; Lambert, F.; Duan, W.H. The influence of admixtures on the dispersion, workability, and strength of carbon nanotube OPC paste mixtures. Cem. Concr. Compos. 2012, 34, 1067–1074. [Google Scholar] [CrossRef]

- Sui, H.; Meng, Z. Research on the Resistance of Pier C45 Concrete to Chloride Ion Penetration. J. Phys. Conf. Ser. 2020, 1549, 032130. [Google Scholar] [CrossRef]

| Test | Test Results | E.S.S Limits | |

|---|---|---|---|

| Specific gravity | 3.15 | ------- | |

| Specific surface area (cm2/gm) | 3290 | ≥2750 | |

| Setting time (min) | Initial | 110 | ≥60 min |

| Final | 380 | ≤10 h | |

| Compressive strength 3 days (MPa) | 20.6 | ≥10 MPa | |

| Compressive strength 28 days (MPa) | 50.1 | ≥42.5 MPa | |

| Oxide Content, (%) | OPC | Nanosilica | Granite | Slag | Aluminum Waste |

|---|---|---|---|---|---|

| SiO2 | 21.33 | 95.22 | 69.50 | 36.66 | 16.40 |

| AL2O3 | 3.99 | 0.32 | 14.50 | 10.32 | 75.90 |

| Fe2O3 | 3.15 | 0.85 | 3.01 | 0.52 | 1.97 |

| CaO | 62.04 | 0.26 | 3.0 | 38.88 | 1.64 |

| MgO | 2.52 | 0.55 | 0.64 | 1.70 | 1.01 |

| SO3 | 2.70 | 0.20 | 0.19 | 2.16 | 0.12 |

| L.O.I. | 3.75 | 1.50 | 0.65 | 0.13 | 0.10 |

| Na2O | 0.26 | 0.37 | 3.46 | 0.45 | - |

| K20 | 0.22 | 0.51 | 4.29 | 1.02 | - |

| Cl− | 0.01 | 0.05 | 0.11 | 0.05 | 0.05 |

| TiO2 | - | - | 0.37 | 0.56 | - |

| TOTAL | 99.95 | 99.98 | 99.99 | 99.97 | 99.61 |

| Ins. Res | 0.66 | - | - | - | - |

| Na2OEq. | 0.41 | - | - | - | - |

| L.S.F | 0.90 | - | - | - | - |

| C3A | 5.22 | - | - | - | - |

| C3S | 51.40 | - | - | - | - |

| C2S | 22.47 | - | - | - | - |

| C4AF | 9.59 | - | - | - | - |

| Oxides, (%) | Dolomite | Recycled Dolomite Aggregate | Sand |

|---|---|---|---|

| SiO2 | 1.67 | 19.10 | 93.40 |

| Al2O3 | 0.07 | 2.45 | 2.03 |

| Fe2O3 | 0.01 | 1.50 | 0.98 |

| CaO | 35.54 | 37.61 | 0.71 |

| MgO | 17.51 | 8.87 | 0.25 |

| SO3 | 0.13 | 1.51 | 0.30 |

| Cl | - | 0.13 | 0.08 |

| Na2O | 0.04 | 0.49 | 0.38 |

| K2O | 0.02 | 0.16 | 0.64 |

| TiO2 | 0.01 | 0.19 | 0.17 |

| BaO | - | - | - |

| P2O5 | 0.01 | - | 0.06 |

| MnO | - | - | 0.03 |

| (L.O.I) | 44.99 | 27.83 | 0.74 |

| Total | 99.97 | 99.97 | 99.92 |

| Physical & Mechanical Properties | Sand | Coarse Aggregates | Limits of Coarse Aggregates | |

|---|---|---|---|---|

| Dolomite | Recycled Dolomite Aggregate | |||

| Specific gravity (g/cm3) | 2.65 | 2.61 | 2.41 | - |

| Unit weight (ton/m3) | 1.62 | 1.46 | 1.37 | - |

| Clay and fine materials (%) | 1.40 | 0.38 | - | ≤4(1) ≤10(3) |

| Water absorption (%) | - | 1.09 | 4.49 | ≤2.5(1) |

| Flakiness index (%) | - | 15.12 | 18.70 | ≤25(2) |

| Elongation index (%) | - | 13.79 | 9.20 | ≤25(2) |

| Abrasion resistance (%) | - | 19.32 | 25.84 | ≤30(2) |

| Impact value (%) | - | 15.52 | 19.31 | ≤45(1) |

| Composition | Concrete Ingredients (kg/m3) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| OPC | Slag | Granite | Aluminum Waste | Nanosilica | W | Fine Aggregates | Coarse Aggregates | SP | ||

| Sand | D | W | ||||||||

| D100 | 450 | - | - | - | - | 173 | 772 | 1544 | - | 8.1 |

| D70W30 | 450 | - | - | - | - | 173 | 772 | 1081 | 463 | 9.7 |

| D70W30-IN | 445.5 | - | - | - | 4.5 | 173 | 772 | 1081 | 463 | 9.5 |

| D70W30-1.5A-1N | 438.75 | - | - | 6.75 | 4.5 | 173 | 772 | 1081 | 463 | 9.6 |

| D70W30-10G-1N | 400.5 | - | 45 | - | 4.5 | 173 | 772 | 1081 | 463 | 9.4 |

| 70W30-15S-1N | 378 | 67.5 | - | - | 4.5 | 173 | 772 | 1081 | 463 | 9.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fawzy, A.; Elshami, A.; Ahmad, S. Investigating the Effects of Recycled Aggregate and Mineral Admixtures on the Mechanical Properties and Performance of Concrete. Materials 2023, 16, 5134. https://doi.org/10.3390/ma16145134

Fawzy A, Elshami A, Ahmad S. Investigating the Effects of Recycled Aggregate and Mineral Admixtures on the Mechanical Properties and Performance of Concrete. Materials. 2023; 16(14):5134. https://doi.org/10.3390/ma16145134

Chicago/Turabian StyleFawzy, Amal, Ahmed Elshami, and Seleem Ahmad. 2023. "Investigating the Effects of Recycled Aggregate and Mineral Admixtures on the Mechanical Properties and Performance of Concrete" Materials 16, no. 14: 5134. https://doi.org/10.3390/ma16145134

APA StyleFawzy, A., Elshami, A., & Ahmad, S. (2023). Investigating the Effects of Recycled Aggregate and Mineral Admixtures on the Mechanical Properties and Performance of Concrete. Materials, 16(14), 5134. https://doi.org/10.3390/ma16145134