3D DEM Analysis of Particle Breakage Effect on Direct Shear Tests of Coarse Sand

Abstract

1. Introduction

2. Discrete Element Method for Particle Flow

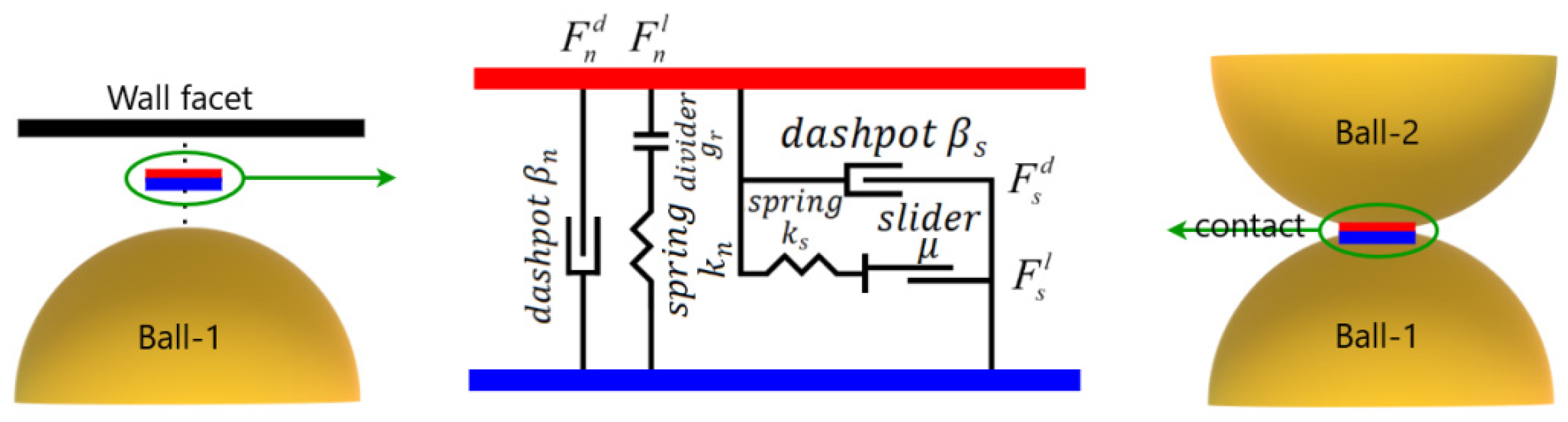

2.1. Particle Contact Model

2.1.1. Linear Model

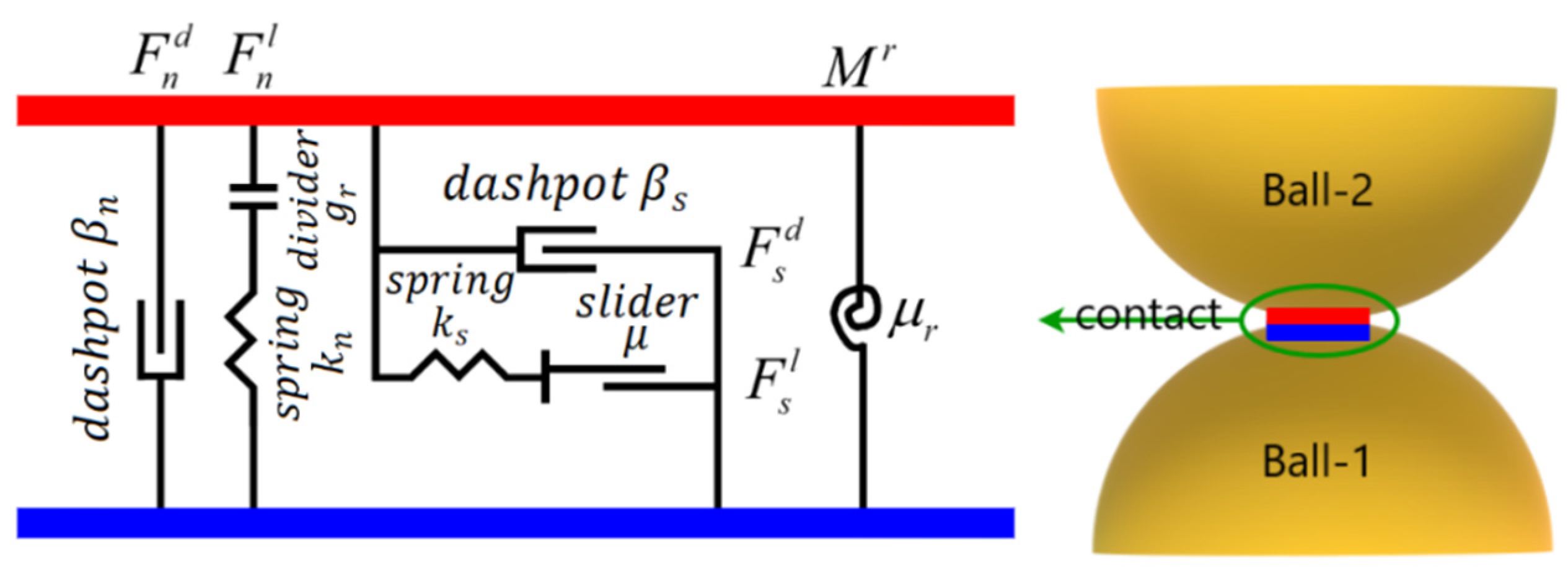

2.1.2. Rolling Resistance Linear Model

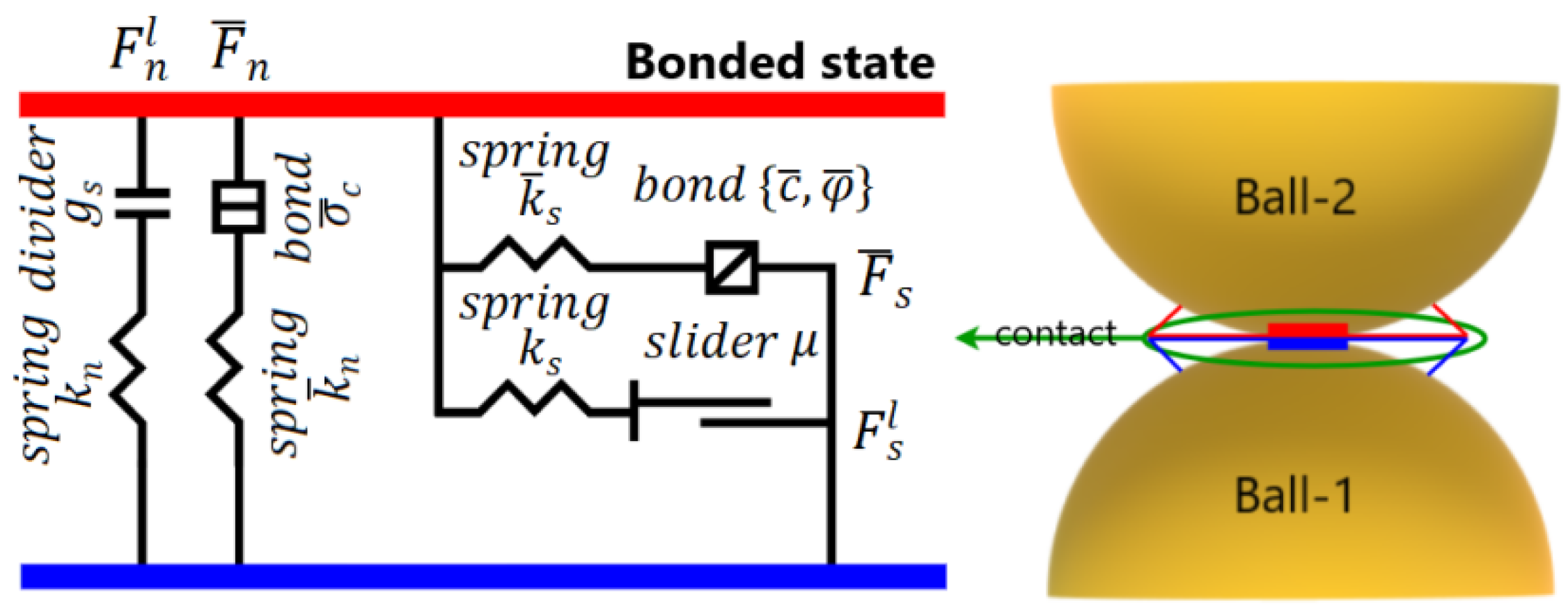

2.1.3. Linear Parallel-Bond Model

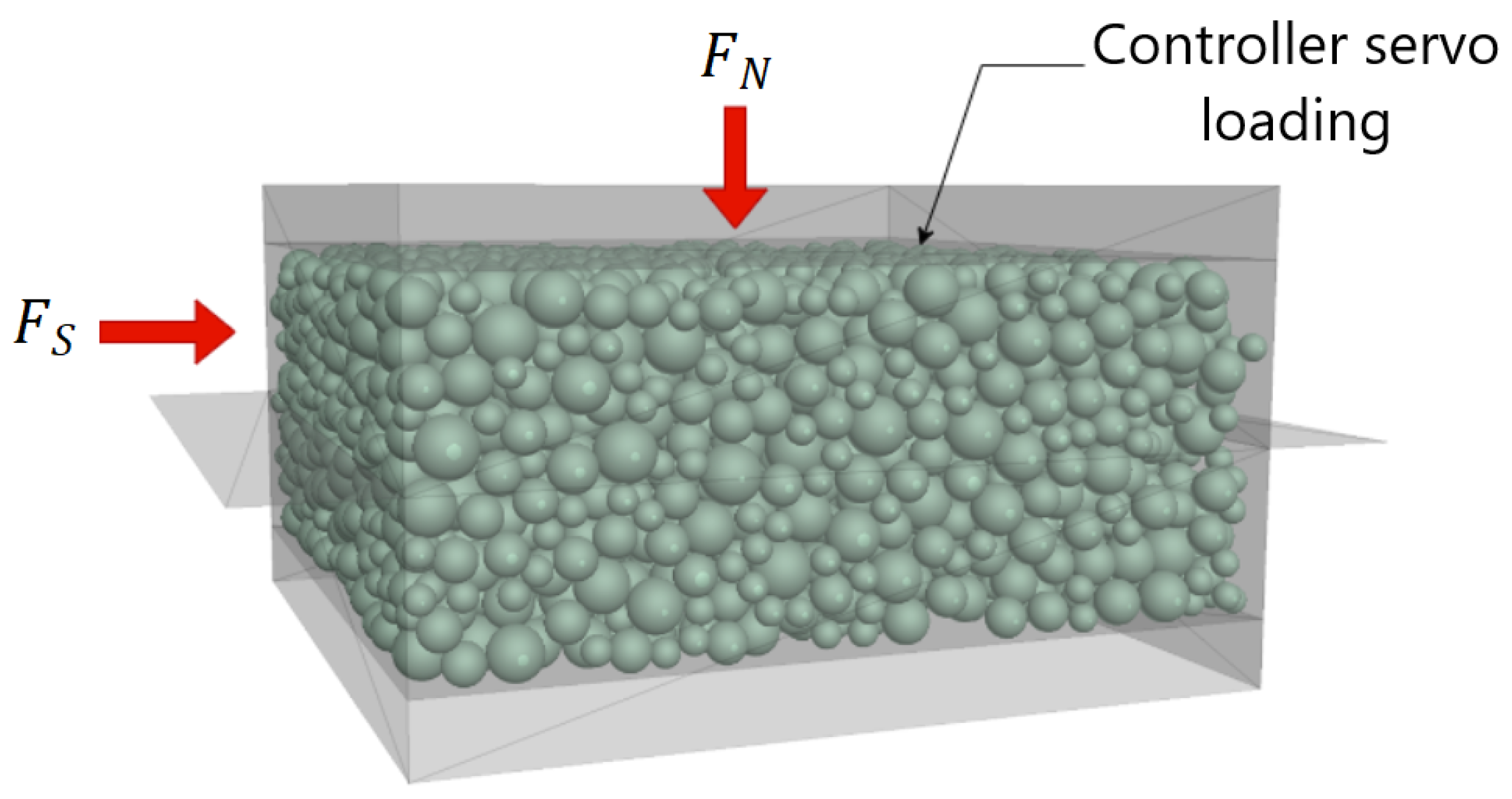

3. DEM Simulations of Direct Shear Test

3.1. Model Setup

3.2. Calibration and Validation Results

4. Particle Breakage on the Shear Band

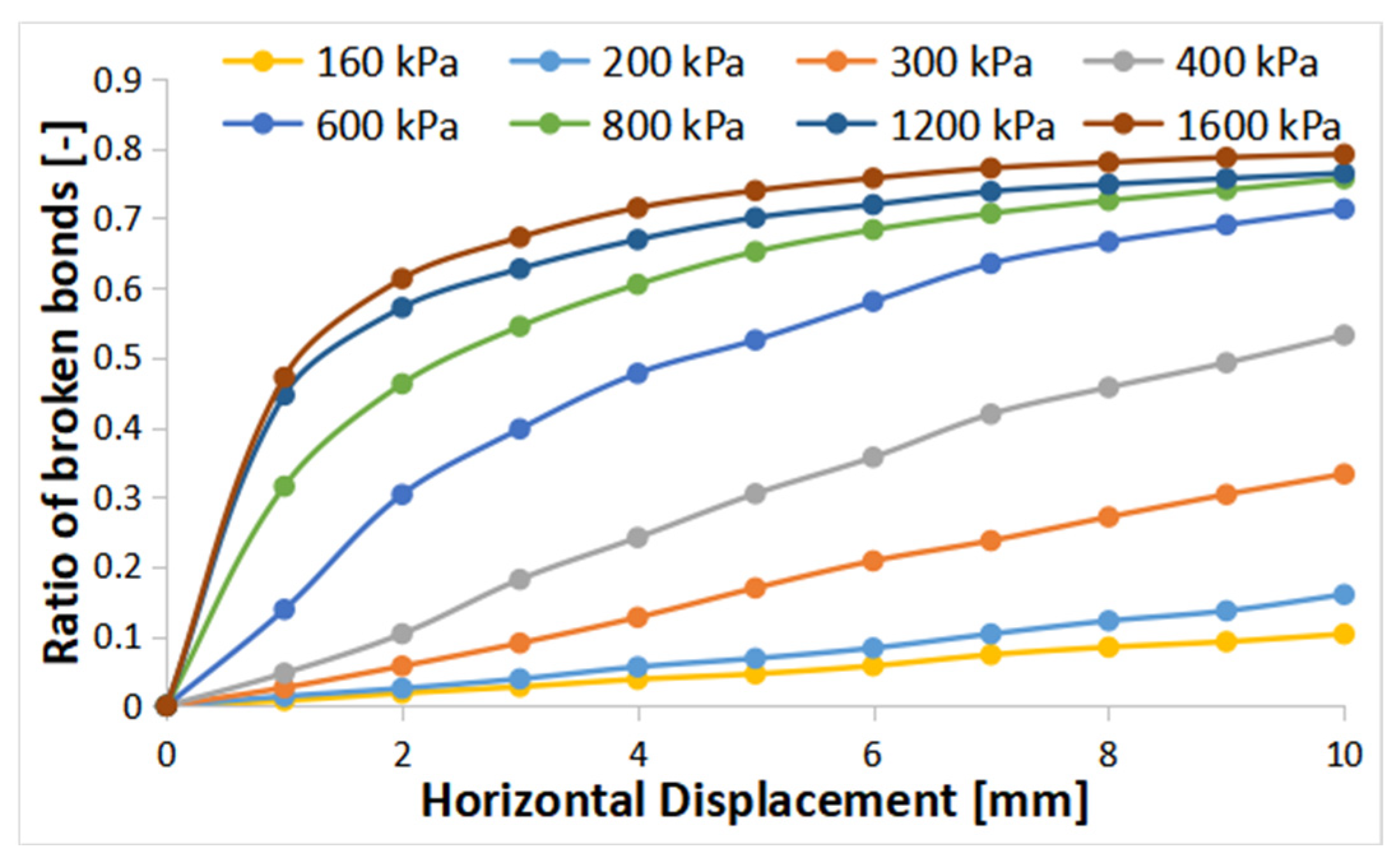

4.1. DST Tests with Various Normal Stresses

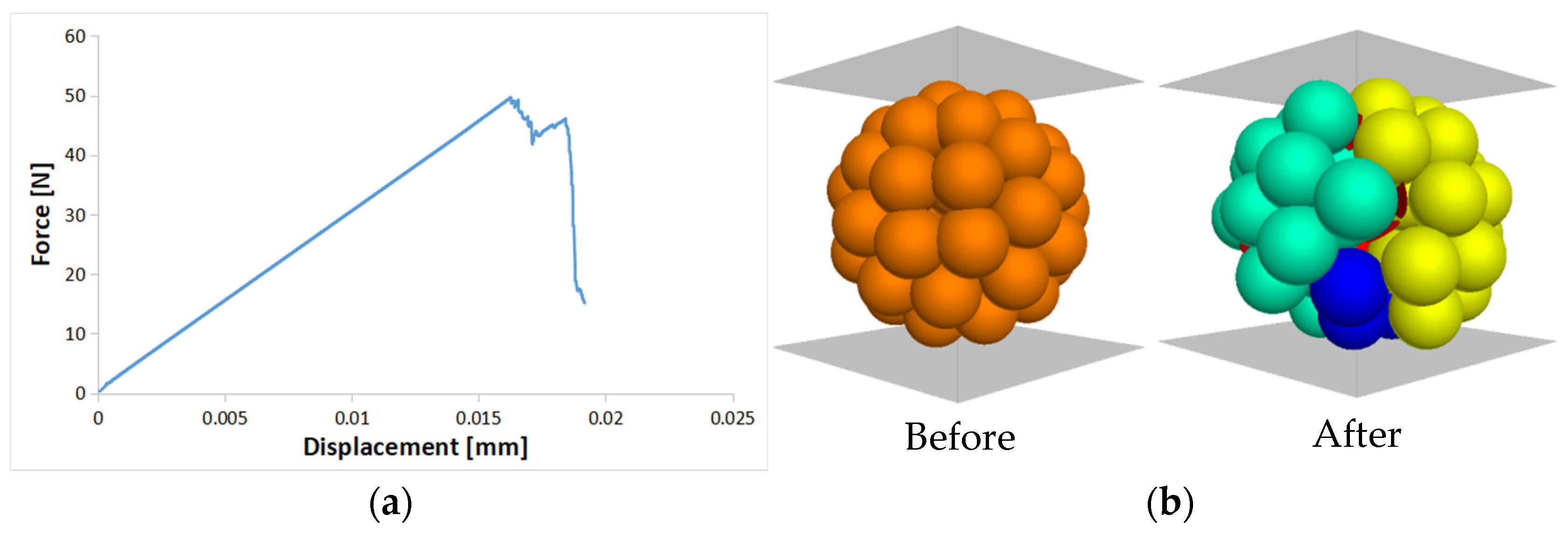

4.2. Single Grain Crushing Test

5. Results and Discussion

5.1. Shear Stress

5.2. Volumetric Strain

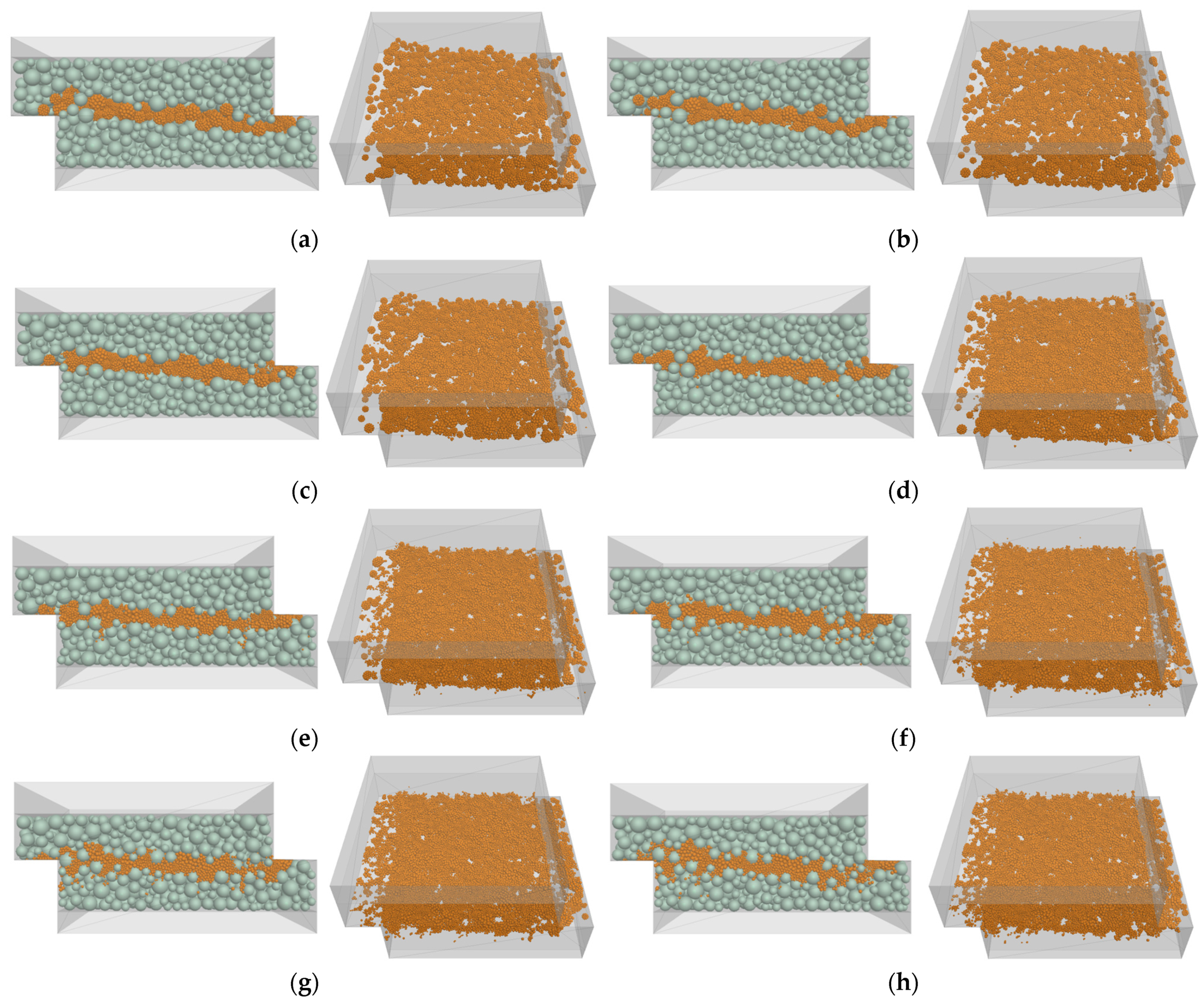

5.3. Visualization of Particle Crushing Evolution

6. Conclusions

- Particle crushing is essential to replicate the realistic behavior of sand, especially volumetric contraction, in high normal stress shear tests;

- With an increasing normal stress, the difference in the shear strength and volumetric strain of the crushable model and the non-crushable model increases;

- Crushable sand behaves similarly to non-crushable sand at low normal stresses, as long as the stress is not sufficient to cause particle crushing;

- Increasing the normal stress in DST causes a transition in the soil’s volumetric strain during shearing from dilative to contractive behavior for crushable sands;

- Particle breakage inside DST reduces shear strength and dilatancy, resulting in a less stiff shear stress–strain response;

- Shear stress increases with an increase in normal stress, regardless of whether crushable or non-crushable models are used;

- Particles on the shear band are partially crushed at peak shear stress, and further shearing produces finer particles along the shearing plane;

- 3D DEM simulations visually demonstrate the generation of smaller particles due to grain crushing, which fill pore spaces, thus reducing assembly dilatancy, and the effect of particle interlocking. At higher normal stress levels, the volumetric strain converges to a stable value;

- DEM simulations of DST which include crushable particles align well with laboratory experiments and provide physically realistic macro-scale results.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Almeida, M.; Jamiolkowski, M.; Peterson, R. Preliminary result of CPT tests in calcareous Quiou sand. In Proceedings of the International Symposium on Calibration Chamber Testing, New York, NY, USA, 28–29 June 1991; Elsevier: New York, NY, USA; pp. 41–53. [Google Scholar]

- Ahmed, S.M.; Agaiby, S.W.; Abdel-Rahman, A.H. A unified CPT–SPT correlation for non-crushable andcrushable cohesionless soils. Ain Shams Eng. J. 2014, 5, 63–73. [Google Scholar] [CrossRef]

- Angemeer, J.; Carlson, E.; Klick, J.H. Techniques and results of offshore pile load testing in calcareous soils. In Proceedings of the 5th Offshore Technology Conference, Houston, TX, USA, 5–7 November 1973; pp. 677–692. [Google Scholar] [CrossRef]

- Coop, M.R.; Airey, D.W. Carbonate sands. In Characterisation and Engineering Properties of Natural Soils; Tan, T.S., Ed.; Balkema: Rotterdam, The Netherlands, 2003; Volume 2, pp. 1049–1108. [Google Scholar]

- McDowell, G.R.; Bolton, M.D. Effect of particle size distribution on pile tip resistance in calcareous sand in the geotechnical centrifuge. Granul. Matter 2000, 2, 179–187. [Google Scholar] [CrossRef]

- White, D.J.; Bolton, M.D. Displacement and strain paths during plane-strain model pile installation in sand. Geotechnique 2004, 54, 375–397. [Google Scholar] [CrossRef]

- Mao, W.; Hamaguchi, H.; Koseki, J. Discrimination of Particle Breakage below Pile Tip after Model Pile Penetration in Sand Using Image Analysis. Int. J. Geomech. 2020, 20, 04019142. [Google Scholar] [CrossRef]

- Akili, W. Static cone penetration resistance of cemented sands: A laboratory investigation. In GeoCongress 2006: Geotechnical Engineering in the Information Technology Age; ASCE: Reston, VA, USA, 2006; pp. 1–6. [Google Scholar] [CrossRef]

- Donohue, S.; O’Sullivan, C.; Long, M. Particle breakage during cyclic triaxial loading of a carbonate sand. Géotechnique 2009, 59, 477–482. [Google Scholar] [CrossRef]

- Qadimi, A.; Coop, M.R. The undrained cyclic behaviour of a carbonate sand. Géotechnique 2007, 57, 739–750. [Google Scholar] [CrossRef]

- Yu, F. Particle breakage and the critical state of sands. Géotechnique 2017, 67, 713–719. [Google Scholar] [CrossRef]

- Nakata, Y.; Hyodo, M.; Hyde, A.F.L.; Kato, Y.; Murata, H. Microscopic particle crushing of sand subjected to high-pressure one-dimensional compression. Soils Found. 2001, 41, 69–82. [Google Scholar] [CrossRef]

- Giretti, D.; Fioravante, V.; Been, K.; Dickenson, S. Mechanical properties of a carbonate sand from a dredged hydraulic fill. G’eotechnique 2018, 68, 410–420. [Google Scholar] [CrossRef]

- Liu, E.; Chen, S.; Lai, Y.; Wei, W.; Fu, Z. Particle breakage of artificially crushable materials subject to drained cyclic triaxial loading. Soil Dyn. Earthq. Eng. 2016, 89, 262–268. [Google Scholar] [CrossRef]

- Coop, M.R.; Sorensen, K.K.; Freitas, T.B.; Georgoutsos, G. Particle breakage during shearing of a carbonate sand. Geotechnique 2004, 54, 157–163. [Google Scholar] [CrossRef]

- Wei, H.; Yin, M.; Zhao, T.; Yan, K.; Shen, J.; Meng, Q.; Wang, X.; He, J. Effect of particle breakage on the shear strength of calcareous sands. Mar. Geophys. Res. 2021, 42, 23. [Google Scholar] [CrossRef]

- Yu, F. Particle breakage and the drained shear behavior of sands. Int. J. Geomech. 2017, 17, 04017041. [Google Scholar] [CrossRef]

- Wang, H.; Cui, Y.J.; Zhang, F.; Liu, J.J. Effect of grain breakage on the compressibility of soils. Acta Geotech. 2022, 17, 769–778. [Google Scholar] [CrossRef]

- Tong, C.X.; Burton, G.J.; Zhang, S.; Sheng, D.C. Particle breakage of uniformly graded carbonate sands in dry/wet condition subjected to compression/shear tests. Acta Geotech. 2020, 15, 2379–2394. [Google Scholar] [CrossRef]

- Wei, H.; Zhao, T.; He, J.; Meng, Q.; Wang, X. Evolution of particle breakage for calcareous sands during ring shear tests. Int. J. Geomech. 2018, 18, 04017153. [Google Scholar] [CrossRef]

- Chandler, R.J.; Hamilton, P.S. On the measurement of the undrained strength of discontinuities in the direct shear box. Geotechnique 1999, 49, 615–620. [Google Scholar] [CrossRef]

- Wu, P.; Matsushima, K.; Tatsuoka, F. Effects of Specimen Size and Some Other Factors on the Strength and Deformation of Granular Soil in Direct Shear Tests. Geotech. Test. J. 2008, 31, 45–64. [Google Scholar] [CrossRef]

- Tarantino, A.; Hyde, A.F.L. An experimental investigation of work dissipation in crushable materials. Géotechnique 2005, 55, 575–584. [Google Scholar] [CrossRef]

- Qin, D.; Meng, Q.; Yan, K.; Qin, Q.; Huang, X.; Rao, P. Experimental study on particle size effect of shear strength and deformation of calcareous sand gravel. Rock Soil Mech. 2022, 43 (Suppl. S1), 331–338. [Google Scholar] [CrossRef]

- Jeong, S.W.; Park, S.S.; Fukuoka, H. Shear and Viscous Characteristics of Gravels in Ring Shear Tests. Geosci. J. 2018, 22, 11–17. [Google Scholar] [CrossRef]

- Hall, S.A.; Bornert, M.; Desrues, J.; Pannier, Y.; Lenoir, N.; Viggiani, G.; Bésuelle, P. Discrete and continuum analysis of localised deformation in sand using X-ray μCT and volumetric digital I mage correlation. Géotechnique 2010, 60, 315–322. [Google Scholar] [CrossRef]

- Kong, D.; Fonseca, J. Quantification of the morphology of shelly carbonate sands using 3D images. Géotechnique 2018, 68, 249–261. [Google Scholar] [CrossRef]

- Zhao, B.; Wang, J.; Coop, M.R.; Jiang, M. An investigation of single sand particle fracture using X-ray micro-tomography. Geotechnique 2015, 65, 625–641. [Google Scholar] [CrossRef]

- Seyyedan, S.M.; Mirghasemi, A.A.; Mohammadi, S. Numerical simulation of direct shear test on granular materials composed of breakable angular particles: A DEM-XFEM approach. Powder Technol. 2021, 391, 450–466. [Google Scholar] [CrossRef]

- Jeong, S.W.; Kighuta, K.; Lee, D.E.; Park, S.S. Numerical Analysis of Shear and Particle Crushing Characteristics in Ring Shear System Using the PFC2D. Materials 2021, 14, 229. [Google Scholar] [CrossRef]

- Nitka, M.; Grabowski, A. Shear band evolution phenomena in direct shear test modelled with DEM. Powder Technol. 2021, 391, 369–384. [Google Scholar] [CrossRef]

- Li, X.; Zhang, Z.; Yi, Y.; Wang, S. Experimental and DEM-Based Numerical Studies on the Shearing Characteristics of Talus-like Rock Mass. Materials 2022, 15, 6372. [Google Scholar] [CrossRef] [PubMed]

- PFC—Particle Flow Code; Version 7.0; Itasca Consulting Group, Inc.: Itasca, MN, USA, 2021.

- Cundall, P.A.; Strack, O.D.L. A discrete numerical model for granular assemblies. Géotechnique 1979, 29, 47–65. [Google Scholar] [CrossRef]

- Salazar, A.; Sáez, E.; Pardo, G. Modeling the direct shear test of a coarse sand using the 3D discrete element method with a rolling friction model. Comput. Geotech. 2015, 67, 83–93. [Google Scholar] [CrossRef]

- Moncada, M.; Betancourt, F.; Rodríguez, C.G.; Toledo, P. Effect of Particle Shape on Parameter Calibration for a Discrete Element Model for Mining Applications. Minerals 2023, 13, 40. [Google Scholar] [CrossRef]

- Li, J.; Zhang, J.; Yang, X.; Zhang, A.; Yu, M. Monte Carlo simulations of deformation behaviour of unbound granular materials based on a real aggregate library. Int. J. Pavement Eng. 2023, 24, 2165650. [Google Scholar] [CrossRef]

- Zhou, W.H.; Jing, X.Y.; Yin, Z.Y.; Geng, X. Effects of particle sphericity and initial fabric on the shearing behavior of soil-rough structural interface. Acta Geotech. 2019, 14, 1699–1716. [Google Scholar] [CrossRef]

- Cil, M.B.; Buscarnera, G. DEM assessment of scaling laws capturing the grain size dependence of yielding in granular soils. Granul. Matter. 2016, 18, 36. [Google Scholar] [CrossRef]

- Wen, R.; Tan, C.; Wu, Y.; Wang, C. Grain Size Effect on the Mechanical Behavior of Cohesionless Coarse-Grained Soils with the Discrete Element Method. Adv. Civ. Eng. 2018, 2018, 4608930. [Google Scholar] [CrossRef]

- Grabowski, A.; Nitka, M. 3D DEM simulations of basic geotechnical tests with early detection of shear localization. Stud. Geotech. Et Mech. 2020, 43, 48–64. [Google Scholar] [CrossRef]

- Benmebarek, M.A.; Movahedi Rad, M. Effect of Rolling Resistance Model Parameters on 3D DEM Modeling of Coarse Sand Direct Shear Test. Materials 2023, 16, 2077. [Google Scholar] [CrossRef]

- El Bied, A.; Sulem, J.; Martineaub, F. Microstructure of shear zones in Fontainebleau sandstone. Int. J. Rock Mech. Min. Sci. 2002, 39, 917–932. [Google Scholar] [CrossRef]

- He, H.; Zheng, J.; Li, Z. Accelerated simulations of direct shear tests by physics engine. Comp. Part. Mech. 2021, 8, 471–492. [Google Scholar] [CrossRef]

- Xu, W.J.; Li, C.Q.; Zhang, H.Y. DEM analyses of the mechanical behavior of soil and soil-rock mixture via the 3D direct shear test. Geomech. Eng. 2015, 9, 815–827. [Google Scholar] [CrossRef]

- Xu, W.J.; Liu, G.Y.; Yang, H. Study on the mechanical behavior of sands using 3D discrete element method with realistic particle models. Acta Geotech. 2020, 15, 2813–2828. [Google Scholar] [CrossRef]

- Kundu, S.; Stroisz, A.; Pradhan, S. A simple discrete-element-model of Brazilian test. Eur. Phys. J. B 2016, 89, 130. [Google Scholar] [CrossRef]

- JO, S.-A.; KIM, E.-K.; CHO, G.-C.; LEE, S.-W. Particle shape and crushing effects on direct shear behavior using dem. Soils Found. 2011, 51, 701–712. [Google Scholar] [CrossRef]

- Luo, R.; Zhu, F.; Liu, Q.; Zhang, S.; Wu, B.; Shang, Y.; Chen, Q. Experimental and Numerical Simulation Study on Shear Strength and Secondary Particle Breakage of Coarse Sand with Different Dry Densities. Geofluids 2022, 2022, 2249766. [Google Scholar] [CrossRef]

- Sassa, K.; Fukuoka, H.; Wang, G.; Ishikawa, N. Undrained Dynamic-Loading Ring-Shear Apparatus and Its Application to Landslide Dynamics. Landslides 2004, 1, 7–19. [Google Scholar] [CrossRef]

- Fukuoka, H.; Sassa, K.; Wang, G.; Sasaki, R. Observation of Shear Zone Development in Ring-Shear Apparatus with a Transparent Shear Box. Landslides 2006, 3, 239–251. [Google Scholar] [CrossRef]

| Particles Properties | ||

|---|---|---|

| Elementary particles size, | 2.4, 2.8, 3.2, 3.6, 4 | |

| Effective modulus of sand particle, | 2 | |

| Normal-to-shear stiffness ratio of sand particle | - | 1 |

| Density | 2600 | |

| Damping coefficient | - | 0.5 |

| Friction coefficient between sand particles, | - | 0.3 |

| Rolling resistance coefficient of sand particle, | - | 0.25 |

| Porosity | - | 0.41 |

| Effective modulus of wall particle, | 4 | |

| Normal-to-shear stiffness ratio between wall particle | - | 1 |

| Friction coefficient between sand particle and wall, | - | 0.0 |

| Particles Properties | ||

|---|---|---|

| Elementary particle size, | 0.46, 0.58, 0.64, 0.74, 0.84 | |

| Young’s modulus of the particle, | 2 | |

| Ratio of normal to shear stiffness of the particle, / | - | 1 |

| Density | ||

| Damping coefficient | - | |

| Particle friction angle coefficient, | - | 0.5 |

| Particle Friction coefficient, between particle and wall | - | 0 |

| Parallel bond properties | ||

| Installation gap, | ||

| Young’s modulus of the parallel bond, | ||

| Ratio of normal to shear stiffness of the parallel bond, / | - | |

| Friction angle of the parallel bond | ° | 20 |

| Tensile bond strength | MPa | |

| Cohesion bond strength | MPa | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Benmebarek, M.A.; Movahedi Rad, M.; Benmebarek, S. 3D DEM Analysis of Particle Breakage Effect on Direct Shear Tests of Coarse Sand. Materials 2023, 16, 5025. https://doi.org/10.3390/ma16145025

Benmebarek MA, Movahedi Rad M, Benmebarek S. 3D DEM Analysis of Particle Breakage Effect on Direct Shear Tests of Coarse Sand. Materials. 2023; 16(14):5025. https://doi.org/10.3390/ma16145025

Chicago/Turabian StyleBenmebarek, Mohamed Amine, Majid Movahedi Rad, and Sadok Benmebarek. 2023. "3D DEM Analysis of Particle Breakage Effect on Direct Shear Tests of Coarse Sand" Materials 16, no. 14: 5025. https://doi.org/10.3390/ma16145025

APA StyleBenmebarek, M. A., Movahedi Rad, M., & Benmebarek, S. (2023). 3D DEM Analysis of Particle Breakage Effect on Direct Shear Tests of Coarse Sand. Materials, 16(14), 5025. https://doi.org/10.3390/ma16145025