Zn-Doped Calcium Magnesium Phosphate Bone Cement Based on Struvite and Its Antibacterial Properties

Abstract

:1. Introduction

2. Materials and Methods

2.1. Synthesis of Cement Materials

2.2. Characterization of the Materials

2.3. Mechanical Testing

2.4. Dissolution Assays

2.5. Testing of Antibacterial Properties

2.6. Testing of Cytocompatibility

3. Results

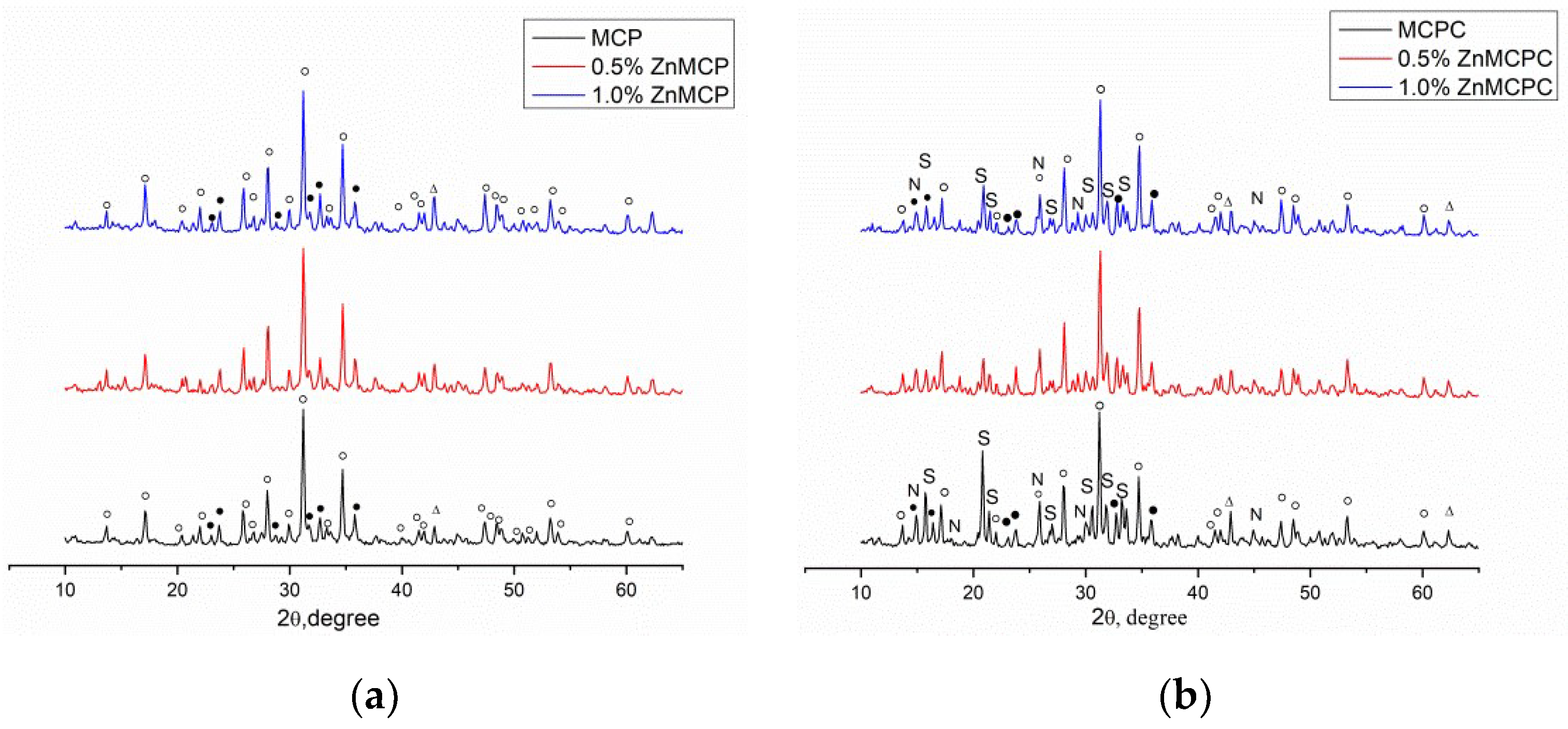

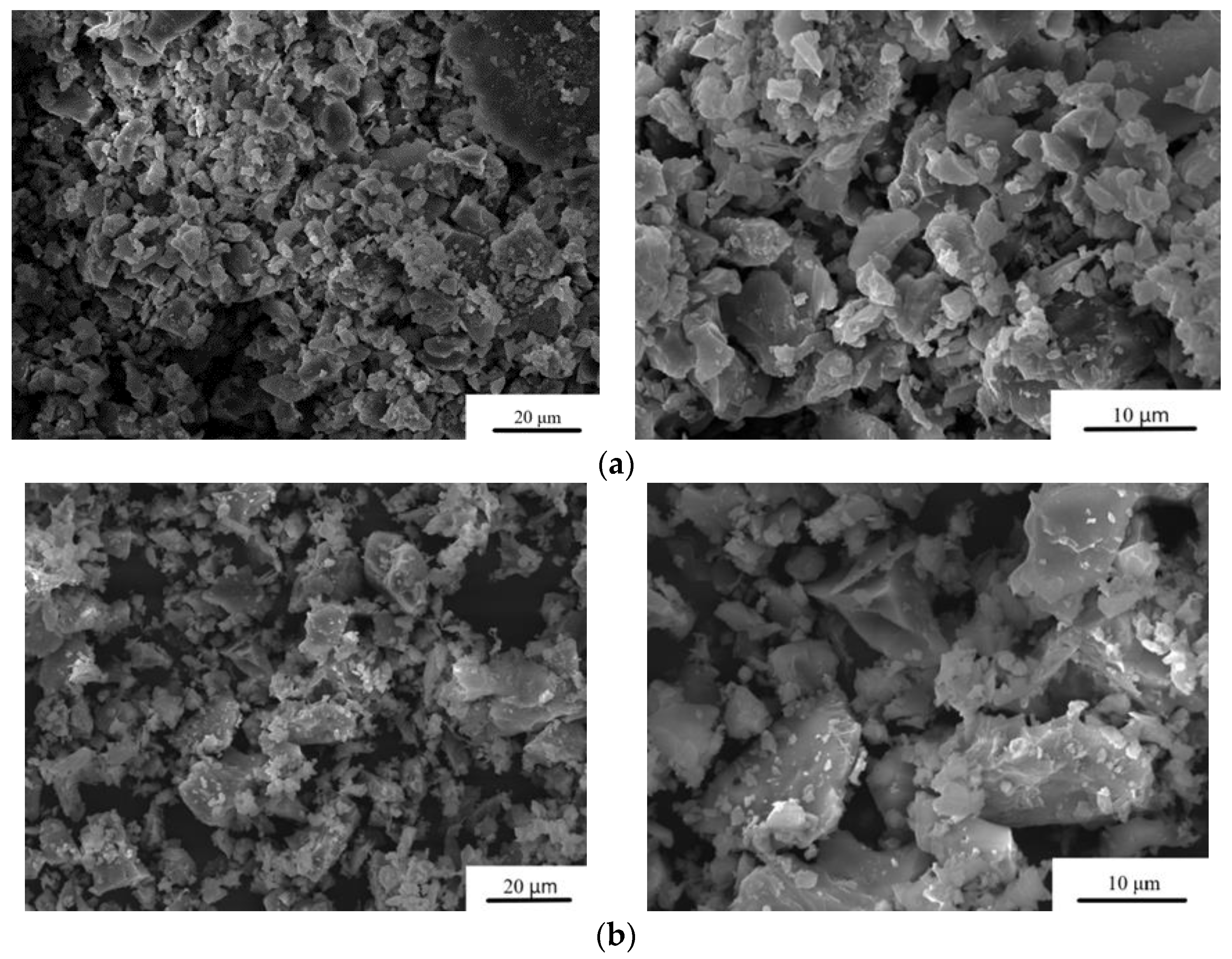

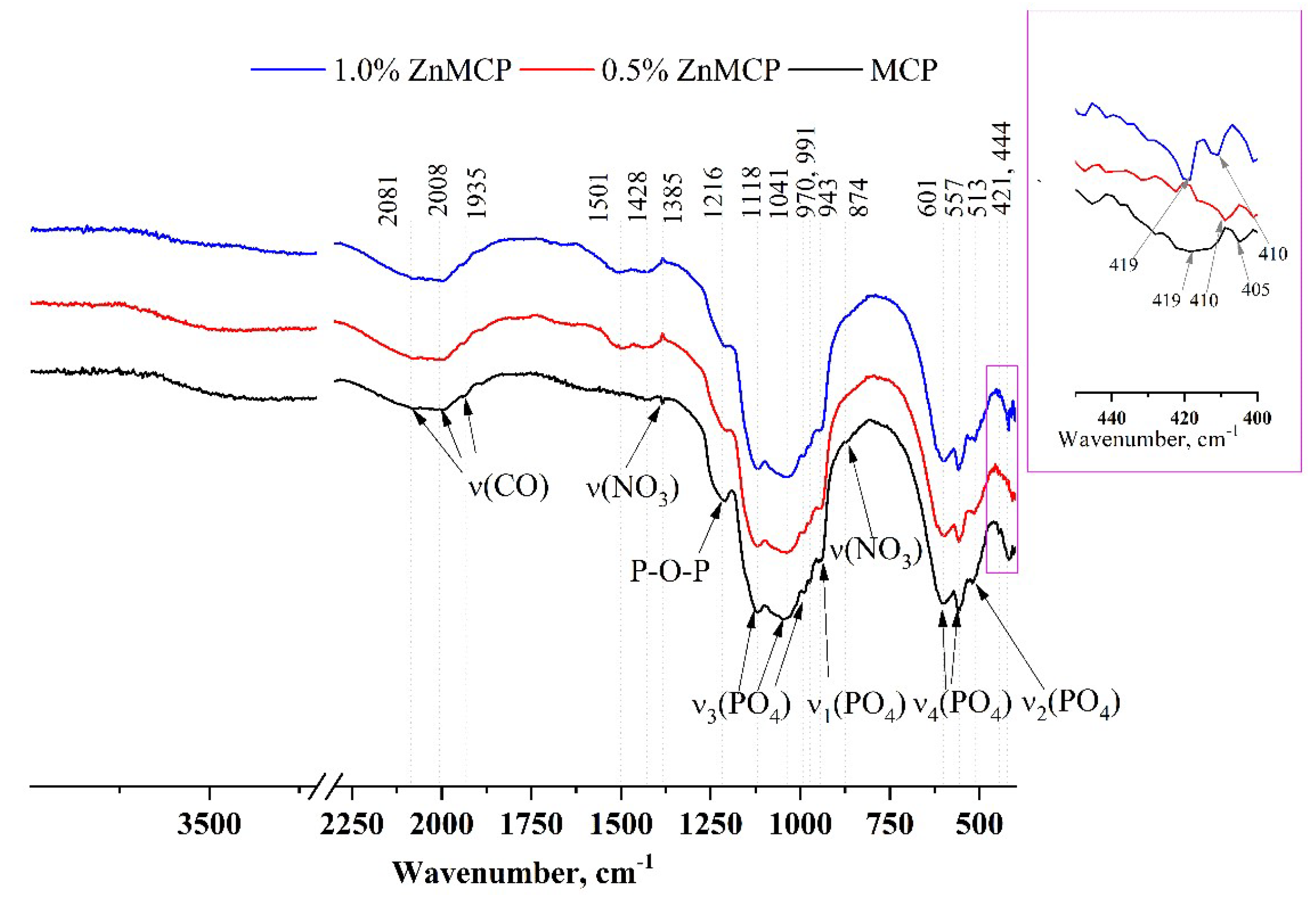

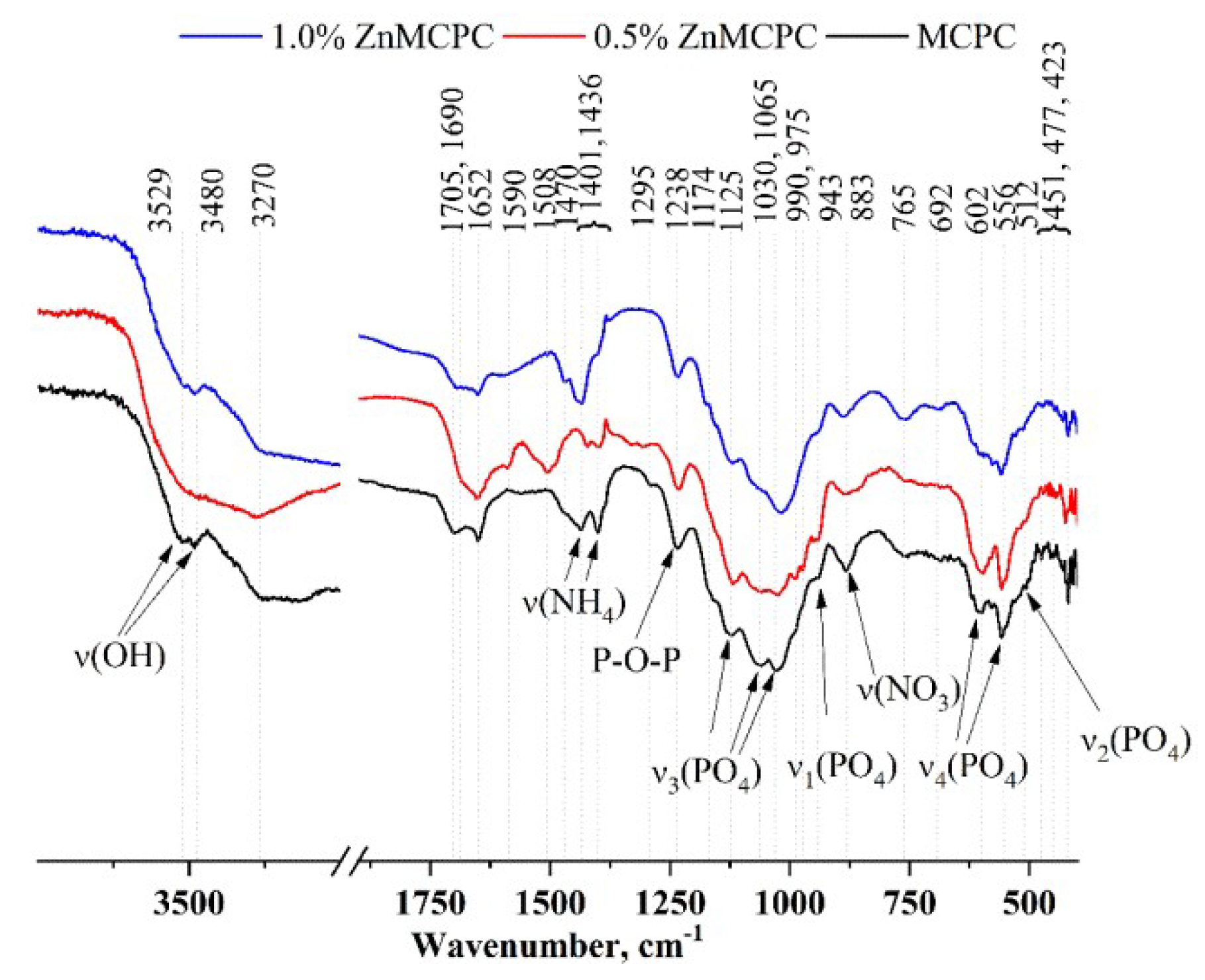

3.1. Characterization of the Cement Powders

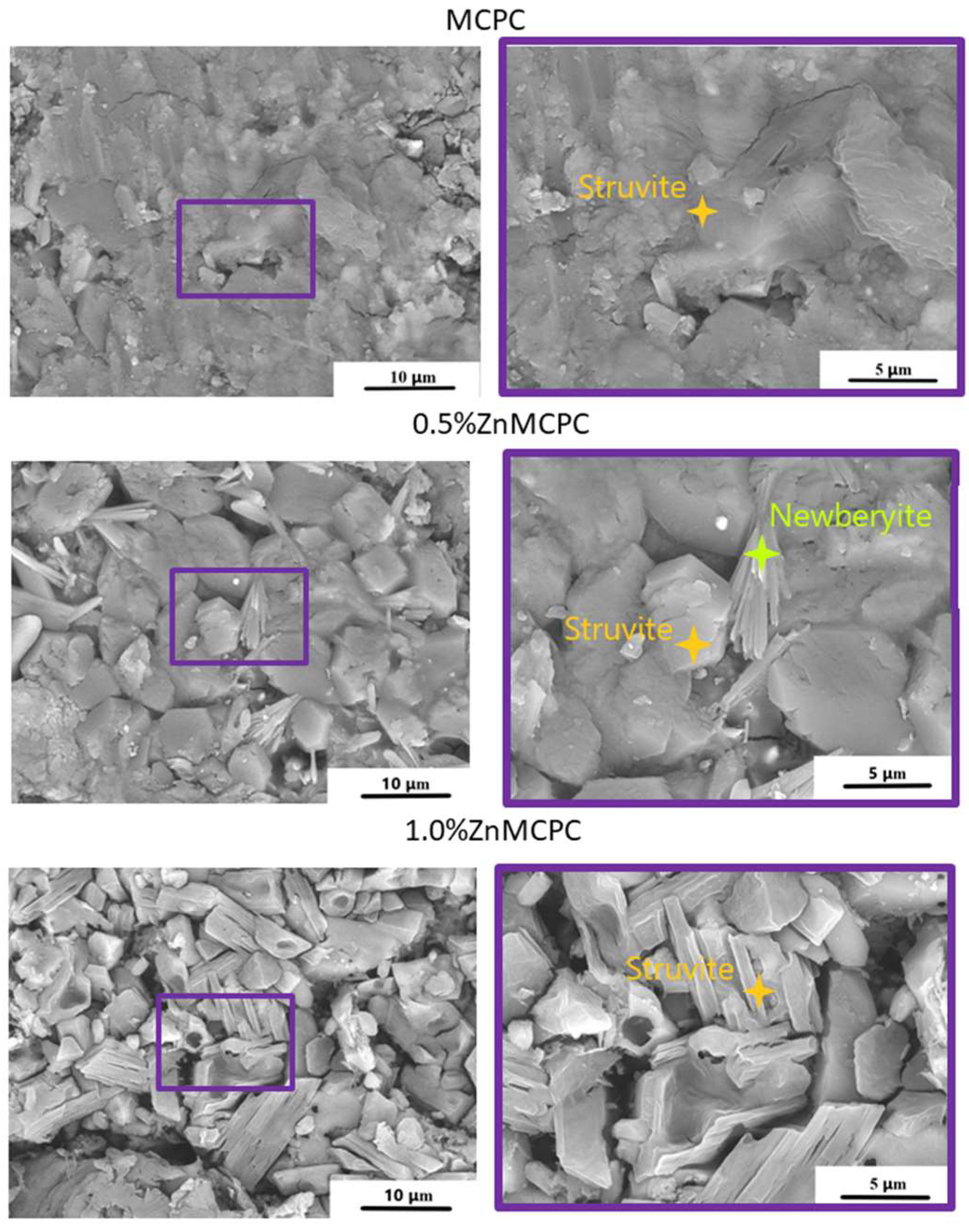

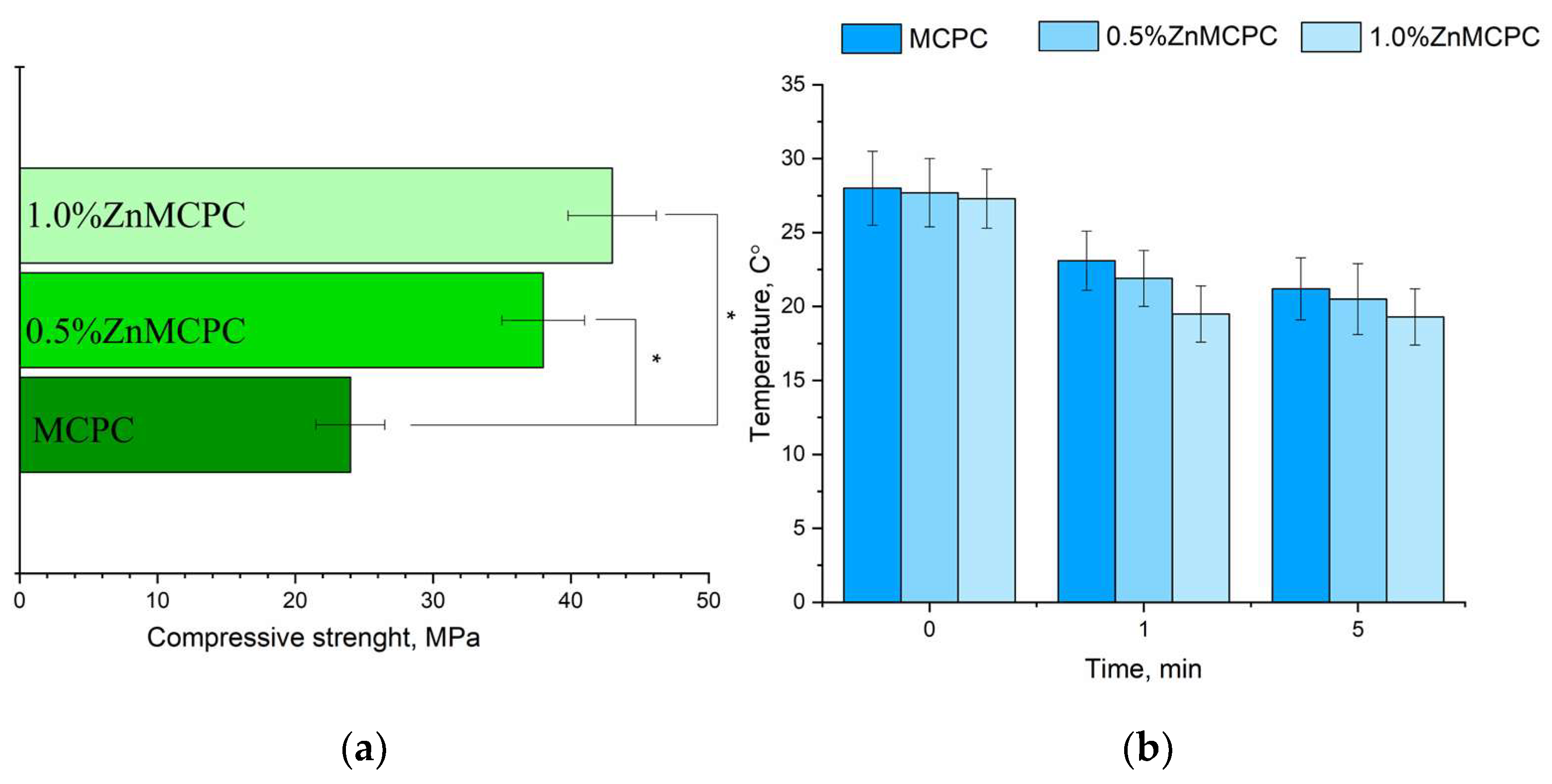

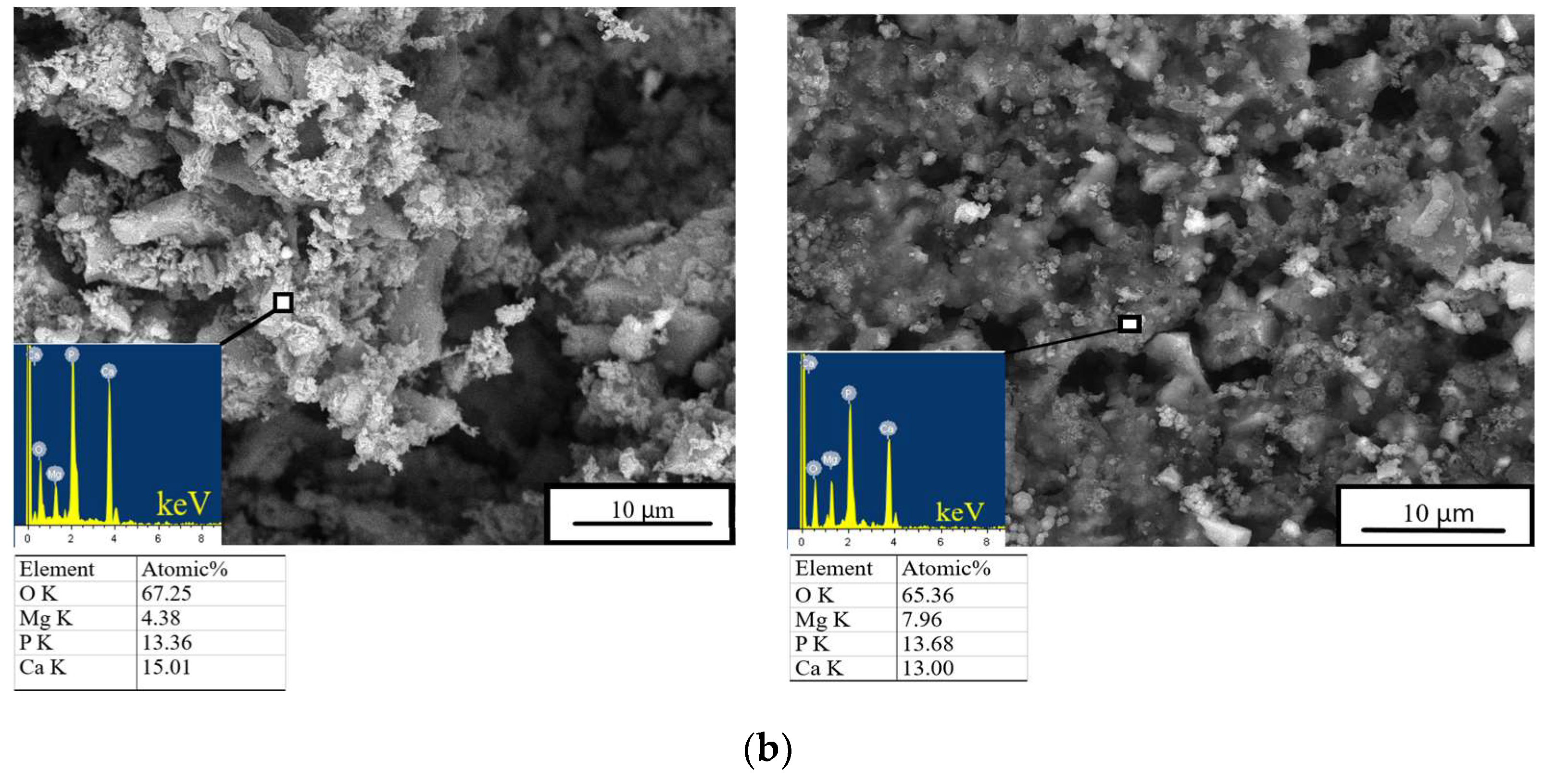

3.2. Characterization of the Cement Materials

2MgNH4PO4∙6H2O + (1 − x)MgHPO4·3H2O + xCaHPO4·2H2O

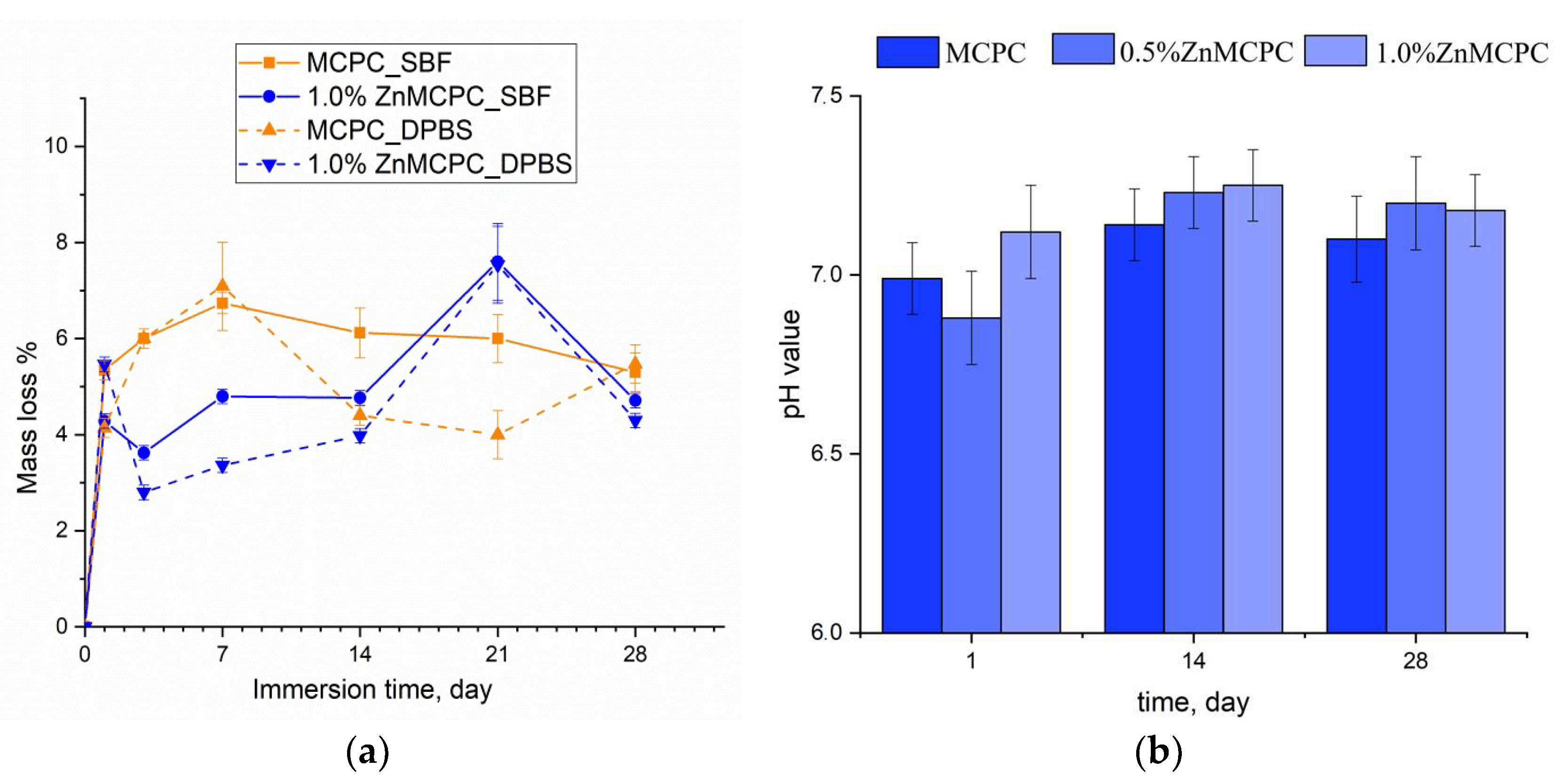

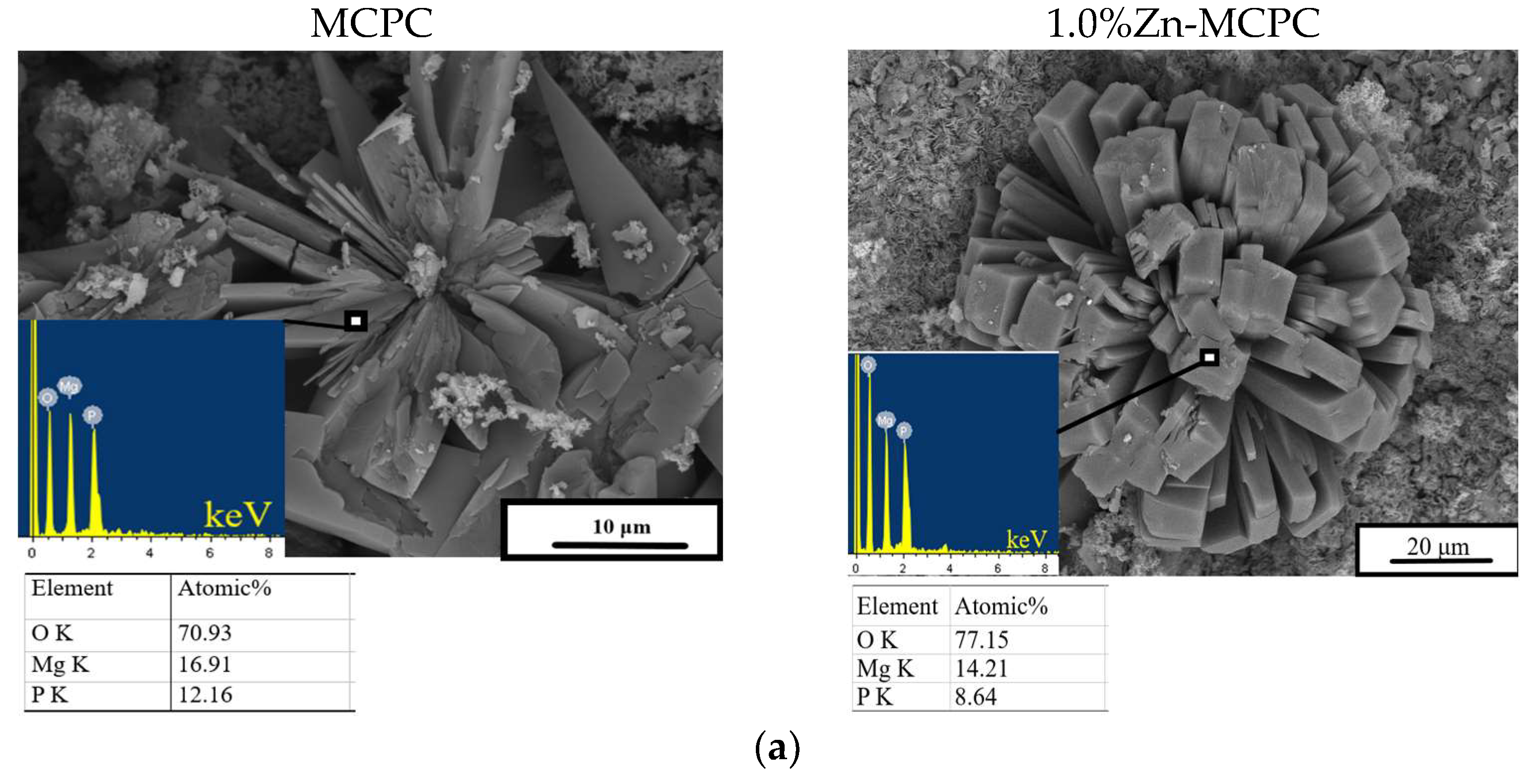

3.3. In Vitro Dissolution Assays

3.4. Antibacterial Properties

3.5. Cytocompatibility of the Bone Cement Samples

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shinde, A.; Deore, G.; Navsariwala, K.P.; Tabassum, H.; Wani, M. We are all aging, and here’s why. Aging Med. 2022, 5, 211–231. [Google Scholar] [CrossRef] [PubMed]

- Chakhtoura, M.; Dagher, H.; Sharara, S.; Ajjour, S.; Chamoun, N.; Cauley, J.; Mahfoud, Z.; Boudreau, R.; El Hajj Fuleihan, G. Systematic review of major osteoporotic fracture to hip fracture incidence rate ratios worldwide: Implications for Fracture Risk Assessment Tool (FRAX)-derived estimates. J. Bone Miner. Res. 2021, 36, 1942–1956. [Google Scholar] [CrossRef] [PubMed]

- Segura-Palleres, I.; Sobrero, F.; Roccia, F.; de Oliveira Gorla, L.F.; Pereira-Filho, V.A.; Gallafassi, D.; Faverani, L.P.; Romeo, I.; Bojino, A.; Copelli, C.; et al. Characteristics and age-related injury patterns of maxillofacial fractures in children and adolescents: A multicentric and prospective study. Dent. Traumatol. 2022, 38, 213–222. [Google Scholar] [CrossRef] [PubMed]

- Moukengue, B.; Lallier, M.; Marchandet, L.; Baud’huin, M.; Verrecchia, F.; Ory, B.; Lamoureux, F. Origin and Therapies of Osteosarcoma. Cancers 2022, 14, 3503. [Google Scholar] [CrossRef]

- Salgado-Peralvo, A.O.; Mateos-Moreno, M.V.; Velasco-Ortega, E.; Peña-Cardelles, J.F.; Kewalramani, N. Preventive antibiotic therapy in bone augmentation procedures in oral implantology: A systematic review. J. Stomatol. Oral Maxillofac. Surg. 2022, 123, 74–80. [Google Scholar] [CrossRef]

- Bassetti, S.; Tschudin-Sutter, S.; Egli, A.; Osthoff, M. Optimizing antibiotic therapies to reduce the risk of bacterial resistance. Eur. J. Intern. Med. 2022, 99, 7–12. [Google Scholar] [CrossRef]

- Ke Ren, A.D. Drug Delivery Strategies for Treating Osteoporosis. Orthop. Muscular Syst. 2014, s2, 8–11. [Google Scholar] [CrossRef]

- Al-Husinat, L.; Jouryyeh, B.; Al Sharie, S.; Al Modanat, Z.; Jurieh, A.; Al Hseinat, L.; Varrassi, G. Bone Cement and Its Anesthetic Complications: A Narrative Review. J. Clin. Med. 2023, 12, 2105. [Google Scholar] [CrossRef]

- Choryfek, P. Vertebroplasty and kyphoplasty—advantages and disadvantages used bone cement of PMMA. J. Achiev. Mater. Manuf. Eng. 2019, 92, 36–49. [Google Scholar] [CrossRef]

- Vezenkova, A.; Locs, J. Sudoku of porous, injectable calcium phosphate cements—Path to osteoinductivity. Bioact. Mater. 2022, 17, 109–124. [Google Scholar] [CrossRef]

- Kaiser, F.; Schröter, L.; Stein, S.; Krüger, B.; Weichhold, J.; Stahlhut, P.; Ignatius, A.; Gbureck, U. Accelerated bone regeneration through rational design of magnesium phosphate cements. Acta Biomater. 2022, 145, 358–371. [Google Scholar] [CrossRef]

- Wu, J.; Liu, F.; Wang, Z.; Liu, Y.; Zhao, X.; Fang, C.; Leung, F.; Yeung, K.W.K.; Wong, T.M. The Development of a Magnesium-Releasing and Long-Term Mechanically Stable Calcium Phosphate Bone Cement Possessing Osteogenic and Immunomodulation Effects for Promoting Bone Fracture Regeneration. Front. Bioeng. Biotechnol. 2022, 9, 803723. [Google Scholar] [CrossRef]

- Goldberg, M.A.; Krohicheva, P.A.; Fomin, A.S.; Khairutdinova, D.R.; Antonova, O.S.; Baikin, A.S.; Smirnov, V.V.; Fomina, A.A.; Leonov, A.V.; Mikheev, I.V.; et al. Insitu magnesium calcium phosphate cements formation: From one pot powders precursors synthesis to in vitro investigations. Bioact. Mater. 2020, 5, 644–658. [Google Scholar] [CrossRef]

- Liu, J.; Liao, J.; Li, Y.; Yang, Z.; Ying, Q.; Xie, Y.; Zhou, A. Bioactive tetracalcium phosphate/magnesium phosphate composite bone cement for bone repair. J. Biomater. Appl. 2019, 34, 239–249. [Google Scholar] [CrossRef]

- Tseng, T.H.; Chang, C.H.; Chen, C.L.; Chiang, H.; Hsieh, H.Y.; Wang, J.H.; Young, T.H. A simple method to improve the antibiotic elution profiles from polymethylmethacrylate bone cement spacers by using rapid absorbable sutures. BMC Musculoskelet. Disord. 2022, 23, 916. [Google Scholar] [CrossRef]

- Anis, H.K.; Sodhi, N.; Faour, M.; Klika, A.K.; Mont, M.A.; Barsoum, W.K.; Higuera, C.A.; Molloy, R.M. Effect of Antibiotic-Impregnated Bone Cement in Primary Total Knee Arthroplasty. J. Arthroplasty 2019, 34, 2091–2095. [Google Scholar] [CrossRef]

- Hu, M.H.; Chu, P.Y.; Huang, S.M.; Shih, B.S.; Ko, C.L.; Hu, J.J.; Chen, W.C. Injectability, Processability, Drug Loading, and Antibacterial Activity of Gentamicin-Impregnated Mesoporous Bioactive Glass Composite Calcium Phosphate Bone Cement In Vitro. Biomimetics 2022, 7, 121. [Google Scholar] [CrossRef]

- Köse, N.; Asfuroğlu, Z.M.; Köse, A.; Şahintürk, V.; Gürbüz, M.; Doğan, A. Silver ion-doped calcium phosphate-based bone-graft substitute eliminates chronic osteomyelitis: An experimental study in animals. J. Orthop. Res. 2021, 39, 1390–1401. [Google Scholar] [CrossRef]

- Krokhicheva, P.A.; Goldberg, M.A.; Fomin, A.S.; Khayrutdinova, D.R.; Antonova, O.S.; Baikin, A.S.; Konovalov, A.A.; Leonov, A.V.; Mikheev, I.V.; Merzlyak, E.M.; et al. Enhanced bone repair by silver-doped magnesium calcium phosphate bone cements. Ceram. Int. 2023, 49, 19249–19264. [Google Scholar] [CrossRef]

- Fiore, M.; Sambri, A.; Zucchini, R.; Giannini, C.; Donati, D.M.; De Paolis, M. Silver-coated megaprosthesis in prevention and treatment of peri-prosthetic infections: A systematic review and meta-analysis about efficacy and toxicity in primary and revision surgery. Eur. J. Orthop. Surg. Traumatol. 2021, 31, 201–220. [Google Scholar] [CrossRef]

- Molenda, M.; Kolmas, J. The Role of Zinc in Bone Tissue Health and Regeneration—A Review. Biol. Trace Elem. Res. 2023. online ahead of print. [Google Scholar] [CrossRef] [PubMed]

- Qiao, Y.; Zhang, W.; Tian, P.; Meng, F.; Zhu, H.; Jiang, X.; Liu, X.; Chu, P.K. Stimulation of bone growth following zinc incorporation into biomaterials. Biomaterials 2014, 35, 6882–6897. [Google Scholar] [CrossRef]

- Su, Y.; Wang, K.; Gao, J.; Yang, Y.; Qin, Y.X.; Zheng, Y.; Zhu, D. Enhanced cytocompatibility and antibacterial property of zinc phosphate coating on biodegradable zinc materials. Acta Biomater. 2019, 98, 174–185. [Google Scholar] [CrossRef] [PubMed]

- Ijaz, M.; Zafar, M.; Islam, A.; Afsheen, S.; Iqbal, T. A Review on Antibacterial Properties of Biologically Synthesized Zinc Oxide Nanostructures. J. Inorg. Organomet. Polym. Mater. 2020, 30, 2815–2826. [Google Scholar] [CrossRef]

- Uysal, I.; Yilmaz, B.; Evis, Z. Zn-doped hydroxyapatite in biomedical applications. J. Aust. Ceram. Soc. 2021, 57, 869–897. [Google Scholar] [CrossRef]

- Hill, W.L.; Faust, G.T.; Reynolds, D.S. The Binary System P2O5-2CaO.P2O5. Part I. Am. J. Sci. 1944, 242, 457–477. [Google Scholar] [CrossRef]

- ISO 9917-1:2007; Dentistry—Water-Based Cements—Part 1: Powder/Liquid Acid-Base Cements. International Organization for Standardization: Cham, Switzerland, 2007.

- Kokubo, T.; Takadama, H. How useful is SBF in predicting in vivo bone bioactivity? Biomaterials 2006, 27, 2907–2915. [Google Scholar] [CrossRef]

- Devi, K.B.; Tripathy, B.; Roy, A.; Lee, B.; Kumta, P.N.; Nandi, S.K.; Roy, M. In Vitro Biodegradation and in Vivo Biocompatibility of Forsterite Bio-Ceramics: Effects of Strontium Substitution. ACS Biomater. Sci. Eng. 2019, 5, 530–543. [Google Scholar] [CrossRef]

- GOST ISO 20645-2014; Textile Products. Determination of Antibacterial Activity. Diffusive Test in Agar Plate. International Organization for Standardization: Cham, Switzerland, 2014.

- Mosmann, T. Rapid Colorimetric Assay for Cellular Growth and Survival: Application to Proliferation and Cytotoxicity Assays Tim. J. lmmunol. Methods 1983, 65, 55–63. [Google Scholar] [CrossRef]

- Shannon, R.D. Revised Effective Ionic Radii and Systematic Studies of Interatomie Distances in Halides and Chaleogenides. Acta Crystallogr. 1976, A32, 751–767. [Google Scholar] [CrossRef]

- Lee, G.H.; Makkar, P.; Paul, K.; Lee, B.T. Incorporation of BMP-2 loaded collagen conjugated BCP granules in calcium phosphate cement based injectable bone substitutes for improved bone regeneration. Mater. Sci. Eng. C 2017, 77, 713–724. [Google Scholar] [CrossRef]

- Mestres, G.; Ginebra, M.P. Novel magnesium phosphate cements with high early strength and antibacterial properties. Acta Biomater. 2011, 7, 1853–1861. [Google Scholar] [CrossRef]

- Babaie, E.; Lin, B.; Bhaduri, S.B. A new method to produce macroporous Mg-phosphate bone growth substitutes. Mater. Sci. Eng. C 2017, 75, 602–609. [Google Scholar] [CrossRef]

- Wagh, A.S.; Jeong, S.Y. Chemically Bonded Phosphate Ceramics: I, A Dissolution Model of Formation. J. Am. Ceram. Soc. 2003, 86, 1838–1844. [Google Scholar] [CrossRef]

- Graziani, V.; Fosca, M.; Egorov, A.A.; Zobkov, Y.V.; Fedotov, A.Y.; Baranchikov, A.E.; Ortenzi, M.; Caminiti, R.; Komlev, V.S.; Rau, J.V. Zinc-releasing calcium phosphate cements for bone substitute materials. Ceram. Int. 2016, 42, 17310–17316. [Google Scholar] [CrossRef]

- Haque, M.A.; Chen, B. Research progresses on magnesium phosphate cement: A review. Constr. Build. Mater. 2019, 211, 885–898. [Google Scholar] [CrossRef]

- Moseke, C.; Saratsis, V.; Gbureck, U. Injectability and mechanical properties of magnesium phosphate cements. J. Mater. Sci. Mater. Med. 2011, 22, 2591–2598. [Google Scholar] [CrossRef]

- Tansel, B.; Lunn, G.; Monje, O. Struvite formation and decomposition characteristics for ammonia and phosphorus recovery: A review of magnesium-ammonia-phosphate interactions. Chemosphere 2018, 194, 504–514. [Google Scholar] [CrossRef]

- Boistelle, R.; Abbona, F.; Lundager Madsen, H.E. On the transformation of struvite into newberyite in aqueous systems. Phys. Chem. Miner. 1983, 9, 216–222. [Google Scholar] [CrossRef]

- Liu, J.; Jin, H.; Gu, C.; Yang, Y. Effects of zinc oxide nanoparticles on early-age hydration and the mechanical properties of cement paste. Constr. Build. Mater. 2019, 217, 352–362. [Google Scholar] [CrossRef]

- Fadeeva, I.V.; Goldberg, M.A.; Preobrazhensky, I.I.; Mamin, G.V.; Davidova, G.A.; Agafonova, N.V.; Fosca, M.; Russo, F.; Barinov, S.M.; Cavalu, S.; et al. Improved cytocompatibility and antibacterial properties of zinc-substituted brushite bone cement based on β-tricalcium phosphate. J. Mater. Sci. Mater. Med. 2021, 32, 99. [Google Scholar] [CrossRef] [PubMed]

- Klammert, U.; Reuther, T.; Blank, M.; Reske, I.; Barralet, J.E.; Grover, L.M.; Kübler, A.C.; Gbureck, U. Phase composition, mechanical performance and in vitro biocompatibility of hydraulic setting calcium magnesium phosphate cement. Acta Biomater. 2010, 6, 1529–1535. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Shi, F.; Zhao, D.; Yan, Y. Effect of ZnO-doped magnesium phosphate cements on osteogenic differentiation of mBMSCs in vitro. J. Appl. Biomater. Funct. Mater. 2022, 20, 22808000221136369. [Google Scholar] [CrossRef] [PubMed]

- Marques, C.F.; Olhero, S.; Abrantes, J.C.C.; Marote, A.; Ferreira, S.; Vieira, S.I.; Ferreira, J.M.F. Biocompatibility and antimicrobial activity of biphasic calcium phosphate powders doped with metal ions for regenerative medicine. Ceram. Int. 2017, 43, 15719–15728. [Google Scholar] [CrossRef]

- Cockerill, I.; Su, Y.; Sinha, S.; Qin, Y.X.; Zheng, Y.; Young, M.L.; Zhu, D. Porous zinc scaffolds for bone tissue engineering applications: A novel additive manufacturing and casting approach. Mater. Sci. Eng. C 2020, 110, 110738. [Google Scholar] [CrossRef]

- Ishikawa, K.; Miyamoto, Y.; Yuasa, T.; Ito, A.; Nagayama, M.; Suzuki, K. Fabrication of Zn containing apatite cement and its initial evaluation using human osteoblastic cells. Biomaterials 2002, 23, 423–428. [Google Scholar] [CrossRef]

- Singh, S.S.; Roy, A.; Lee, B.; Banerjee, I.; Kumta, P.N. Synthesis, characterization, and in-vitro cytocompatibility of amorphous β-tri-calcium magnesium phosphate ceramics. Mater. Sci. Eng. C 2016, 67, 636–645. [Google Scholar] [CrossRef]

| Cement Powder Name | Phase Composition, wt.% * | Particle Size Distribution (μm) | Zn2+ Content, wt.% ** (ICP) | ||||

|---|---|---|---|---|---|---|---|

| Whitlockite Ca2.589Mg0.411(PO4)2 | Stanfieldite Mg3Ca3(PO4)4 | MgO | D10 | D50 | D90 | ||

| MCPC | 42 | 29 | 29 | 1.0 | 7.9 | 21.6 | 0 |

| 0.5%Zn-MCPC | 38 | 29 | 33 | 0.3 | 13.3 | 32.9 | 0.501 |

| 1.0%Zn-MCPC | 39 | 22 | 39 | 0.5 | 18.0 | 36.4 | 0.911 |

| Set Cement Name | Phase Composition, wt.% | ||||

|---|---|---|---|---|---|

| Whitlockite Ca2.589Mg0.411(PO4)2 | Stanfieldite Mg3Ca3(PO4)4 | MgO | Struvite MgNH4PO4 ·6H2O | NewberyiteMgHPO4 ·3H2O | |

| MCPC | 5 | 4 | 3 | 88 | - |

| 0.5%Zn-MCPC | 8 | 6 | 3 | 58 | 25 |

| 1.0%Zn-MCPC | 7 | 5 | 2 | 68 | 18 |

| Samples | Concentration of Test Culture, 108 Colony-Forming Units/mL (10 Units in BSS) | ||

|---|---|---|---|

| Growth Inhibition Zone, mm | Bacterial Growth under Sample | Assessment | |

| S. aureus ATCC 6538 | |||

| MCPC | 3 | Completely inhibited | Sufficient effect |

| 0.5%Zn-MCPC | 7 | Completely inhibited | Sufficient effect |

| 1.0%Zn-MCPC | 8 | Completely inhibited | Sufficient effect |

| E. coli XL1-Blue | |||

| MCPC | 0 | Growth was observed | Insufficient effect |

| 0.5%Zn-MCPC | 1 | Completely inhibited | Sufficient effect |

| 1.0%Zn-MCPC | 2 | Completely inhibited | Sufficient effect |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Krokhicheva, P.A.; Goldberg, M.A.; Fomin, A.S.; Khayrutdinova, D.R.; Antonova, O.S.; Baikin, A.S.; Leonov, A.V.; Merzlyak, E.M.; Mikheev, I.V.; Kirsanova, V.A.; et al. Zn-Doped Calcium Magnesium Phosphate Bone Cement Based on Struvite and Its Antibacterial Properties. Materials 2023, 16, 4824. https://doi.org/10.3390/ma16134824

Krokhicheva PA, Goldberg MA, Fomin AS, Khayrutdinova DR, Antonova OS, Baikin AS, Leonov AV, Merzlyak EM, Mikheev IV, Kirsanova VA, et al. Zn-Doped Calcium Magnesium Phosphate Bone Cement Based on Struvite and Its Antibacterial Properties. Materials. 2023; 16(13):4824. https://doi.org/10.3390/ma16134824

Chicago/Turabian StyleKrokhicheva, Polina A., Margarita A. Goldberg, Alexander S. Fomin, Dinara R. Khayrutdinova, Olga S. Antonova, Alexander S. Baikin, Aleksander V. Leonov, Ekaterina M. Merzlyak, Ivan V. Mikheev, Valentina A. Kirsanova, and et al. 2023. "Zn-Doped Calcium Magnesium Phosphate Bone Cement Based on Struvite and Its Antibacterial Properties" Materials 16, no. 13: 4824. https://doi.org/10.3390/ma16134824

APA StyleKrokhicheva, P. A., Goldberg, M. A., Fomin, A. S., Khayrutdinova, D. R., Antonova, O. S., Baikin, A. S., Leonov, A. V., Merzlyak, E. M., Mikheev, I. V., Kirsanova, V. A., Sviridova, I. K., Akhmedova, S. A., Sergeeva, N. S., Barinov, S. M., & Komlev, V. S. (2023). Zn-Doped Calcium Magnesium Phosphate Bone Cement Based on Struvite and Its Antibacterial Properties. Materials, 16(13), 4824. https://doi.org/10.3390/ma16134824