Additive Manufacturing of Advanced Ceramics Using Preceramic Polymers

Abstract

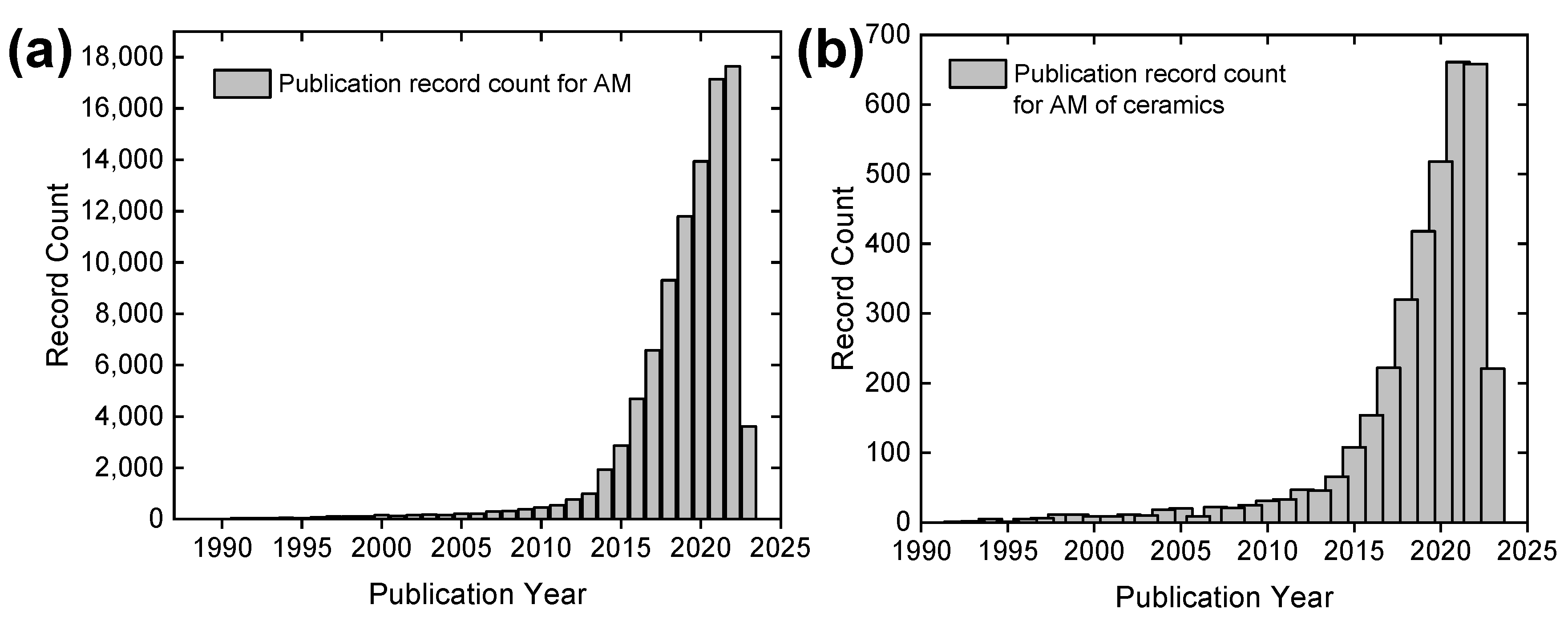

:1. Introduction

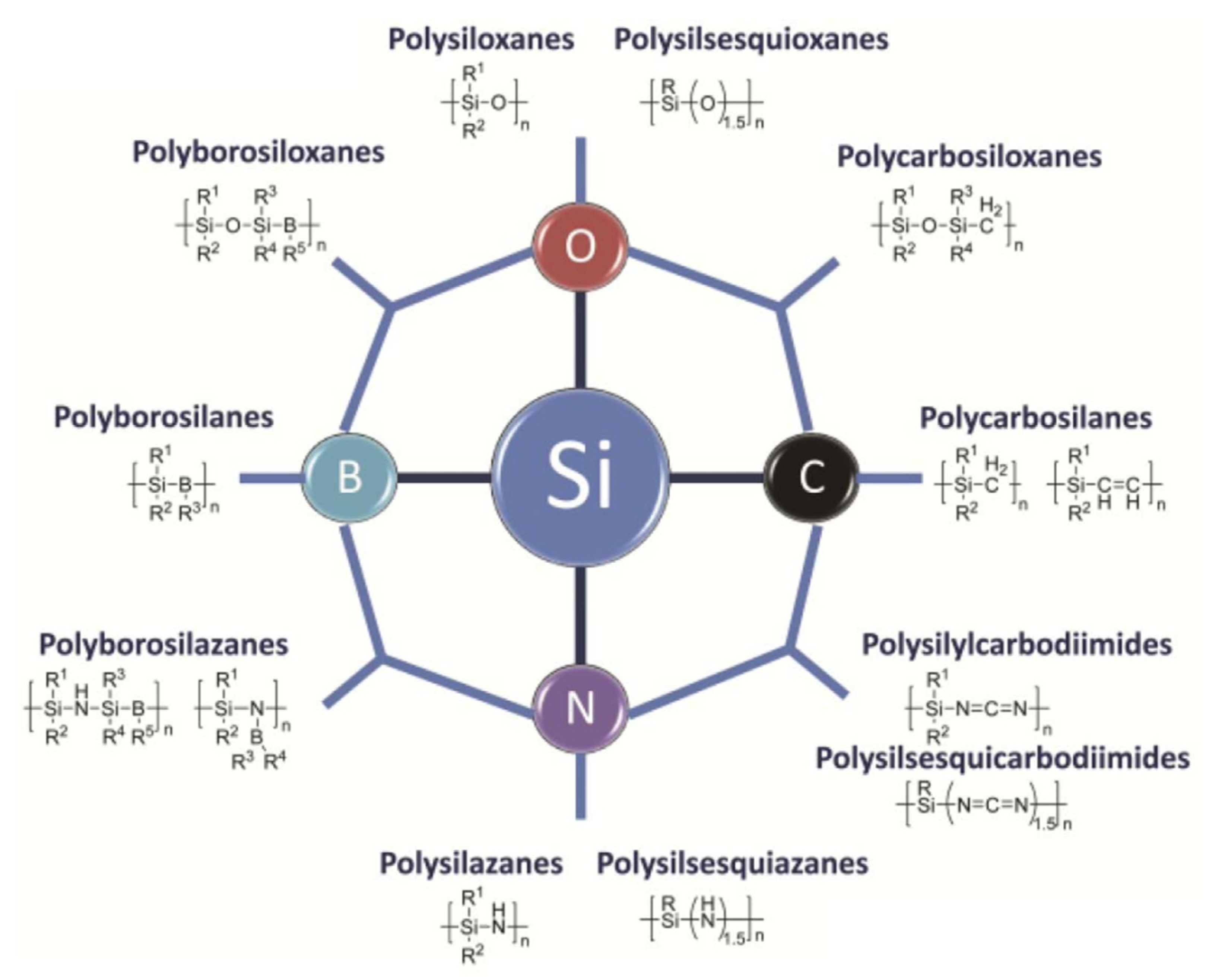

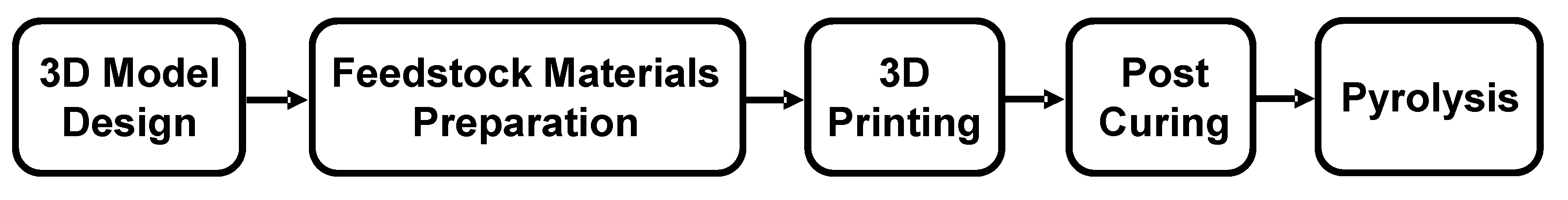

2. Preceramic Feedstock Materials for Additive Manufacturing

3. Additive Manufacturing for Preceramic Polymers

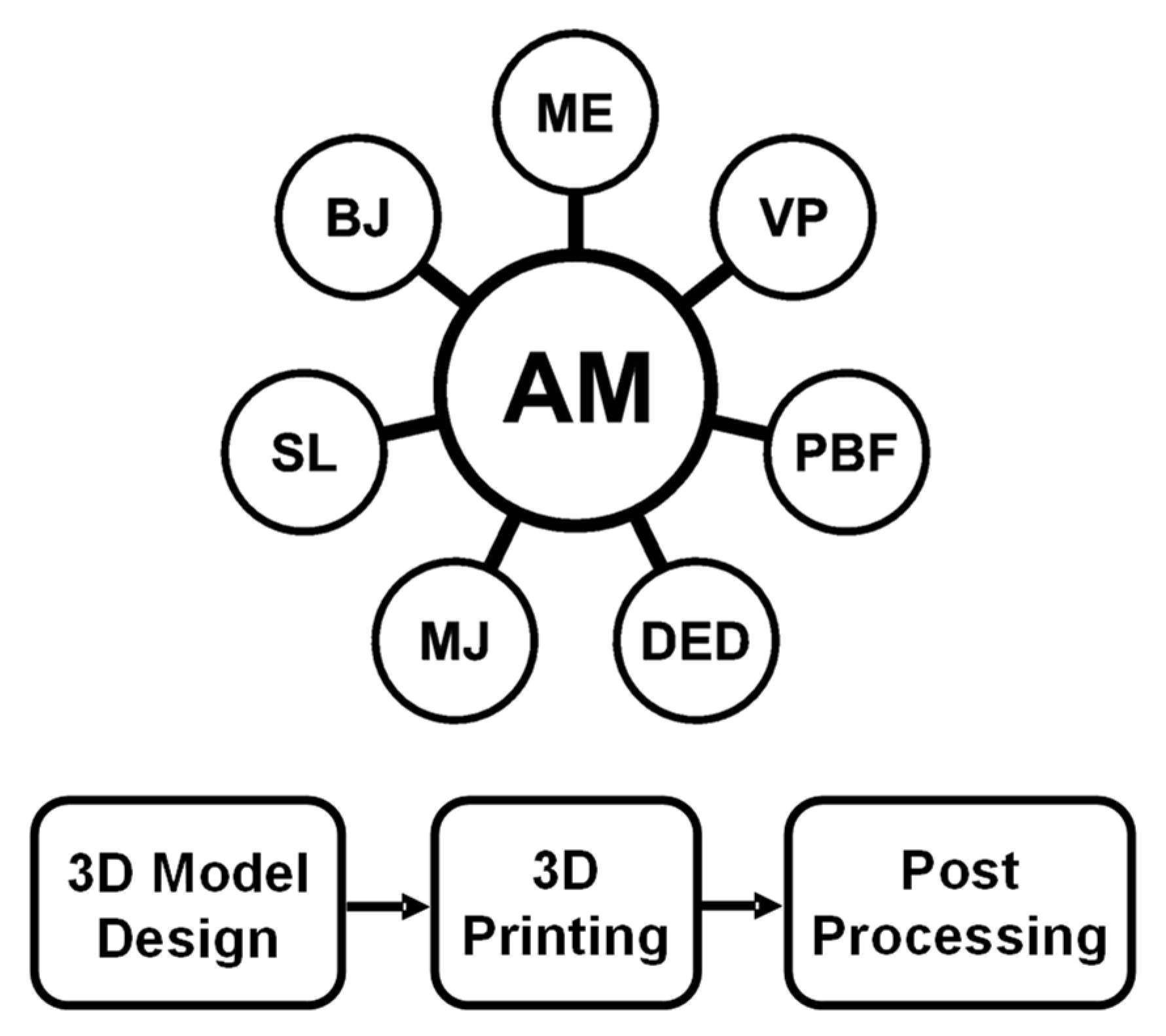

3.1. Additive Manufacturing Processes

3.2. Additive Manufacturing Processes for Preceramic Polymers

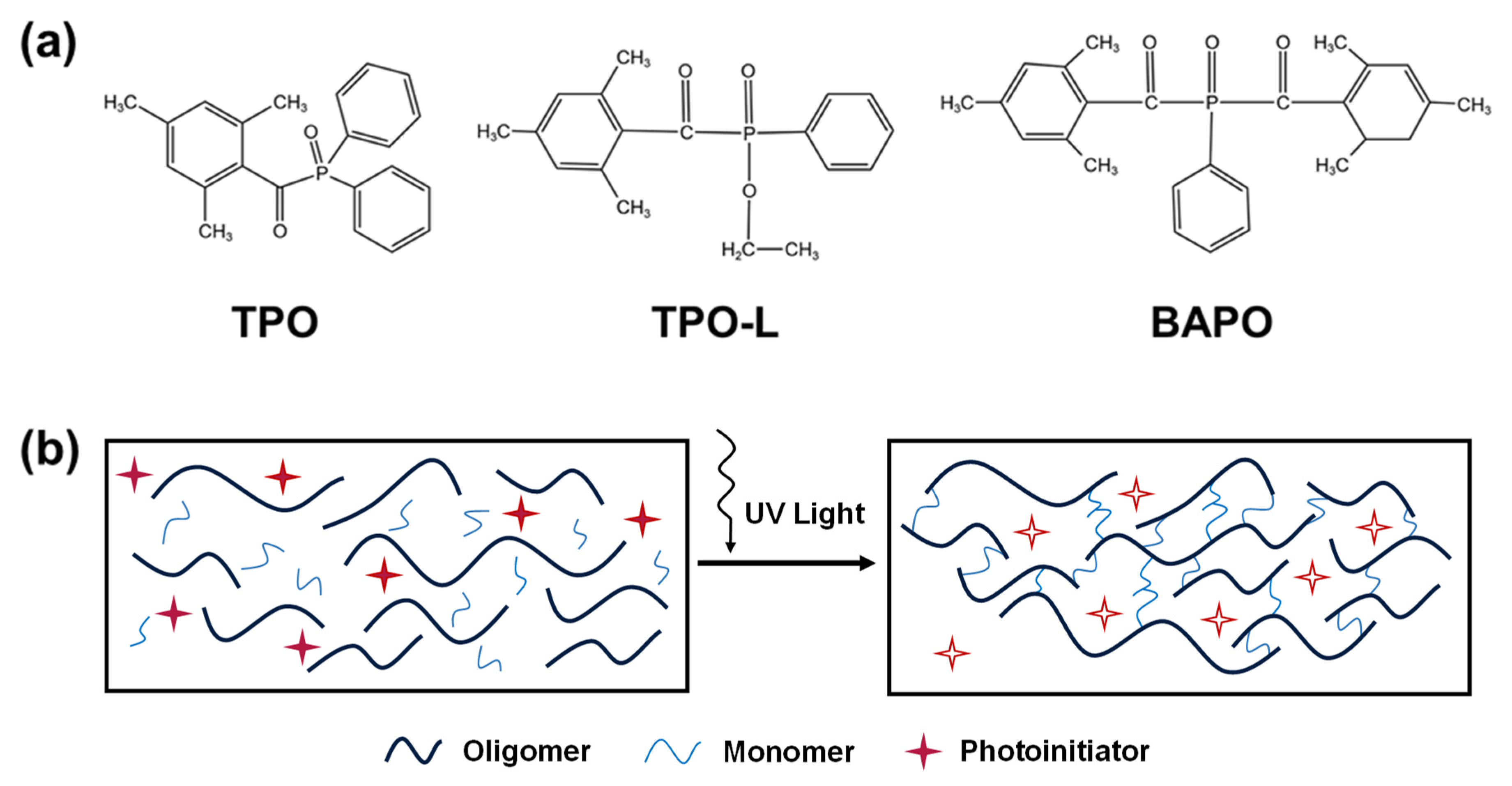

3.2.1. Vat Photopolymerization

- (i)

- Stereolithography (SLA)

- (ii)

- Digital Light Processing (DLP)

- (iii)

- Two-Photon Polymerization (2PP)

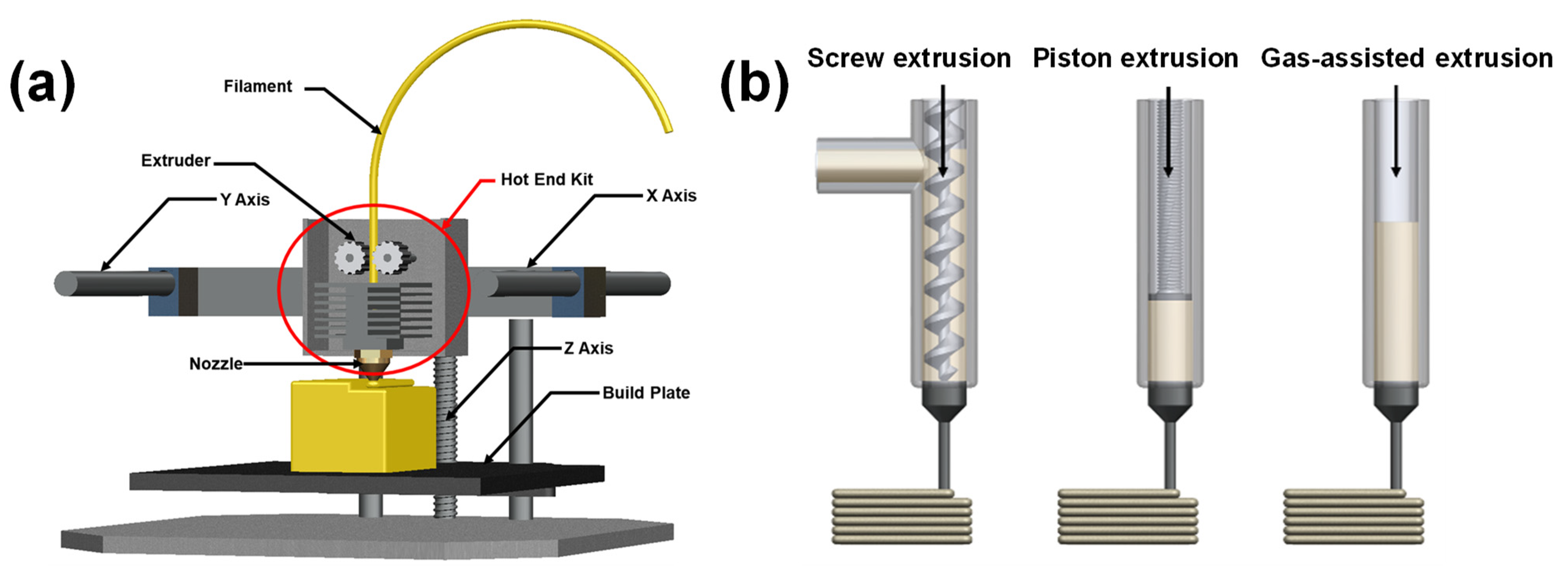

3.2.2. Material Extrusion (ME)

- (i)

- Fused Deposition Modeling (FDM)

- (ii)

- Direct Ink Writing (DIW)

3.2.3. Powder Bed Fusion (PBF)

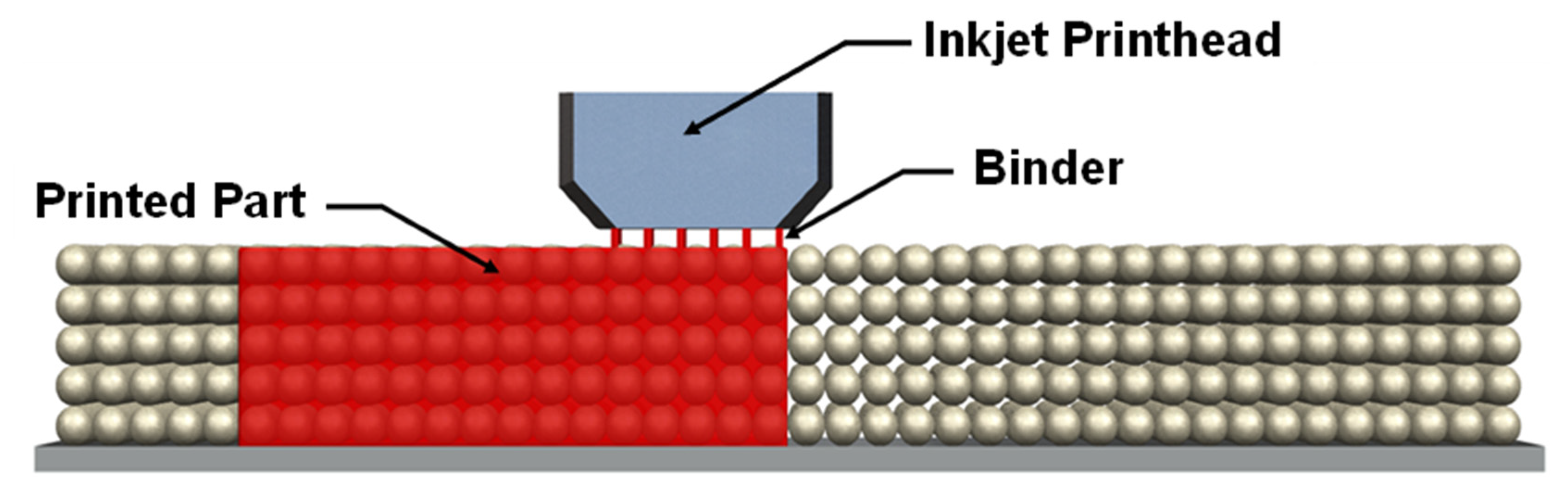

3.2.4. Binder Jetting

4. Future of AM Techniques for Printing Preceramic Materials

- (1)

- Advancing preceramic feedstocks for manufacturing functional components using the AM processes. With the rapid development of AM technologies and the urgent demands of advanced ceramic materials for various applications, such as high-temperature structure ceramics for hypersonic flight, electronic devices, thermal protection components, and healthcare devices, the development of preceramic feedstock materials for AM processes will continue to be one of the hot points for the fabrication of advanced ceramic components, especially the development of ceramic-based nanocomposites.

- (2)

- Enhancing versatile and multifunctional AM processes for manufacturing high-performance functional solid components. Integrating additional features, such as thermal energy, light, ultrasound waves, or other functions, during preceramic material printing may enable high-quality products with superior performance.

- (3)

- Developing highly dense near-net-shape advanced ceramic composites with low volumetric shrinkage and high performance is another hot topic. Volumetric shrinkage and porosity are still significant concerns for the pyrolyzed AM-fabricated ceramic components after pyrolysis, especially when preceramic polymer resins are adopted as feedstock materials. The addition of inert or active fillers or reinforcement materials has been demonstrated to effectively decrease the volumetric shrinkage of the printed ceramic components after pyrolysis and improve their properties. Exploring new composite feedstock materials for manufacturing near-net-shape high-quality ceramic components with superior performance properties using AM process is desired in the future.

5. Summary

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sciau, P.; Goudeau, P. Ceramics in Art and Archaeology: A Review of the Materials Science Aspects. Eur. Phys. J. B 2015, 88, 132. [Google Scholar] [CrossRef]

- Gnesin, G.G. Revisiting the History of Materials Science on the Origin and Development of Ceramic Technology. Powder Metall. Met. Ceram. 2012, 51, 496–501. [Google Scholar] [CrossRef]

- Chaudhary, R.P.; Parameswaran, C.; Idrees, M.; Rasaki, A.S.; Liu, C.; Chen, Z.; Colombo, P. Additive Manufacturing of Polymer-Derived Ceramics: Materials, Technologies, Properties and Potential Applications. Prog. Mater. Sci. 2022, 128, 100969. [Google Scholar] [CrossRef]

- Ayode Otitoju, T.; Ugochukwu Okoye, P.; Chen, G.; Li, Y.; Onyeka Okoye, M.; Li, S. Advanced Ceramic Components: Materials, Fabrication, and Applications. J. Ind. Eng. Chem. 2020, 85, 34–65. [Google Scholar] [CrossRef]

- Subbarao, E.C. Advanced Ceramics—An Overview. Sadhana 1988, 13, 1–11. [Google Scholar] [CrossRef]

- Corral, E.L.; Loehman, R.E. Ultra-High-Temperature Ceramic Coatings for Oxidation Protection of Carbon–Carbon Composites. J. Am. Ceram. Soc. 2008, 91, 1495–1502. [Google Scholar] [CrossRef]

- Huang, W.; Liang, J.; Zhuang, K.; Mao, S.; Zheng, Y.; Zhu, Y.; Tao, Q.; Yao, R. Realizing Load Bearing-Heat Insulation Integration of Lightweight Porosity-Controlled SiC(rGO) Bulk Ceramics via Precursor Route for Hypersonic Vehicles. Ceram. Int. 2022, 48, 31984–31994. [Google Scholar] [CrossRef]

- Francis, A. Biological Evaluation of Preceramic Organosilicon Polymers for Various Healthcare and Biomedical Engineering Applications: A Review. J. Biomed. Mater. Res. B Appl. Biomater. 2021, 109, 744–764. [Google Scholar] [CrossRef]

- Fu, S.; Liu, W.; Liu, S.; Zhao, S.; Zhu, Y. 3D Printed Porous β-Ca2SiO4 Scaffolds Derived from Preceramic Resin and Their Physicochemical and Biological Properties. Sci. Technol. Adv. Mater. 2018, 19, 495–506. [Google Scholar] [CrossRef] [Green Version]

- Schulz, M. Polymer Derived Ceramics in MEMS/NEMS—A Review on Production Processes and Application. Adv. Appl. Ceram. 2009, 108, 454–460. [Google Scholar] [CrossRef]

- Advanced Ceramics Market. Future Market Insights. 2022. Available online: https://www.futuremarketinsights.com/reports/advanced-ceramics-market (accessed on 20 May 2023).

- Gogotsi, G.A. Fracture Toughness of Ceramics and Ceramic Composites. Ceram. Int. 2003, 29, 777–784. [Google Scholar] [CrossRef]

- El Zoghbi, B.; Estevez, R.; Olagnon, C. Modeling and Numerical Investigation of Slow Crack Growth and Crack Arrest in Ceramic Polycrystals. Theor. Appl. Mech. Lett. 2013, 3, 051001. [Google Scholar] [CrossRef] [Green Version]

- Sommers, A.; Wang, Q.; Han, X.; T’Joen, C.; Park, Y.; Jacobi, A. Ceramics and Ceramic Matrix Composites for Heat Exchangers in Advanced Thermal Systems—A Review. Appl. Therm. Eng. 2010, 30, 1277–1291. [Google Scholar] [CrossRef]

- Bove, A.; Calignano, F.; Galati, M.; Iuliano, L. Photopolymerization of Ceramic Resins by Stereolithography Process: A Review. Appl. Sci. 2022, 12, 3591. [Google Scholar] [CrossRef]

- Gizowska, M.; Piątek, M.; Perkowski, K.; Antosik, A. Influence of Sintering Conditions and Nanosilicon Carbide Concentration on the Mechanical and Thermal Properties of Si3N4-Based Materials. Materials 2023, 16, 2079. [Google Scholar] [CrossRef] [PubMed]

- Peng, H.; Li, D.; Yang, Z.; Duan, W.; Jia, D.; Zhou, Y. Effects of Ti on the Microstructural Evolution and Mechanical Property of the SiBCN-Ti Composite Ceramics. Materials 2023, 16, 3560. [Google Scholar] [CrossRef]

- Wu, J.; Zhang, L.; Wang, W.; Su, R.; Gao, X.; Li, S.; Wang, G.; He, R. Microstructures, Mechanical Properties and Electromagnetic Wave Absorption Performance of Porous SiC Ceramics by Direct Foaming Combined with Direct-Ink-Writing-Based 3D Printing. Materials 2023, 16, 2861. [Google Scholar] [CrossRef]

- Evans, J.R.G. Seventy Ways to Make Ceramics. J. Eur. Ceram. Soc. 2008, 28, 1421–1432. [Google Scholar] [CrossRef]

- Yang, L.; Miyanaji, H. Ceramic Additive Manufacturing: A Review of Current Status and Challenges. In Proceedings of the 2017 International Solid Freeform Fabrication Symposium, University of Texas at Austin, Austin, TX, USA, 7–9 August 2017; pp. 652–679. [Google Scholar]

- Dilberoglu, U.M.; Gharehpapagh, B.; Yaman, U.; Dolen, M. The Role of Additive Manufacturing in the Era of Industry 4.0. Procedia Manuf. 2017, 11, 545–554. [Google Scholar] [CrossRef]

- Pelz, J.S.; Ku, N.; Meyers, M.A.; Vargas-Gonzalez, L.R. Additive Manufacturing of Structural Ceramics: A Historical Perspective. J. Mater. Res. Technol. 2021, 15, 670–695. [Google Scholar] [CrossRef]

- Anderson, I.E.; White, E.M.H.; Dehoff, R. Feedstock Powder Processing Research Needs for Additive Manufacturing Development. Curr. Opin. Solid State Mater. Sci. 2018, 22, 8–15. [Google Scholar] [CrossRef]

- Saunders, J.; Elbestawi, M.; Fang, Q. Ultrafast Laser Additive Manufacturing: A Review. J. Manuf. Mater. Process. 2023, 7, 89. [Google Scholar] [CrossRef]

- Bandyopadhyay, A.; Traxel, K.; Lang, M.; Juhasz, M.; Eliaz, N.; Bose, S. Alloy Design via Additive Manufacturing: Advantages, Challenges, Applications and Perspectives. Mater. Today 2022, 52, 207–224. [Google Scholar] [CrossRef]

- Pereira, T.; Kennedy, J.V.; Potgieter, J. A Comparison of Traditional Manufacturing vs Additive Manufacturing, the Best Method for the Job. Procedia Manuf. 2019, 30, 11–18. [Google Scholar] [CrossRef]

- Prakash, K.S.; Nancharaih, T.; Rao, V.V.S. Additive Manufacturing Techniques in Manufacturing—An Overview. Mater. Today Proc. 2018, 5, 3873–3882. [Google Scholar] [CrossRef]

- Wickramasinghe, S.; Do, T.; Tran, P. FDM-Based 3D Printing of Polymer and Associated Composite: A Review on Mechanical Properties, Defects and Treatments. Polymers 2020, 12, 1529. [Google Scholar] [CrossRef]

- Leontiou, A.; Georgopoulos, S.; Karabagias, V.K.; Kehayias, G.; Karakassides, A.; Salmas, C.E.; Giannakas, A.E. Three-Dimensional Printing Applications in Food Industry. Nanomanufacturing 2023, 3, 91–112. [Google Scholar] [CrossRef]

- 3D Printing Market Size, Share & Trends Analysis Report by Component (Hardware, Software, Services), by Printer Type, by Technology, by Software, by Application, by Vertical, by Region, and Segment Forecasts, 2023–2030. 2022. Available online: https://www.grandviewresearch.com/industry-analysis/3d-printing-industry-analysis (accessed on 12 May 2023).

- Wang, J.-C.; Dommati, H.; Hsieh, S.-J. Review of Additive Manufacturing Methods for High-Performance Ceramic Materials. Int. J. Adv. Manuf. Technol. 2019, 103, 2627–2647. [Google Scholar] [CrossRef]

- He, R.; Zhou, N.; Zhang, K.; Zhang, X.; Zhang, L.; Wang, W.; Fang, D. Progress and Challenges towards Additive Manufacturing of SIC Ceramic. J. Adv. Ceram. 2021, 10, 637–674. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, K.; Zhang, L.; Wang, W.; Li, Y.; He, R. Additive Manufacturing of Cellular Ceramic Structures: From Structure to Structure–Function Integration. Mater. Des. 2022, 215, 110470. [Google Scholar] [CrossRef]

- Gonzalez, J.A.; Mireles, J.; Lin, Y.; Wicker, R.B. Characterization of Ceramic Components Fabricated using Binder Jetting Additive Manufacturing Technology. Ceram. Int. 2016, 42, 10559–10564. [Google Scholar] [CrossRef] [Green Version]

- Wang, W.; Bai, X.; Zhang, L.; Jing, S.; Shen, C.; He, R. Additive Manufacturing of Csf/SiC Composites with High Fiber Content by Direct Ink Writing and Liquid Silicon Infiltration. Ceram. Int. 2022, 48, 3895–3903. [Google Scholar] [CrossRef]

- Chen, Q.; Juste, E.; Lasgorceix, M.; Petit, F.; Leriche, A. Binder Jetting Process with Ceramic Powders: Influence of Powder Properties and Printing Parameters. Open Ceram. 2022, 9, 100218. [Google Scholar] [CrossRef]

- Li, F.; Ji, X.; Wu, Z.; Qi, C.; Lai, J.; Xian, Q.; Sun, B. Digital Light Processing 3D Printing of Ceramic Shell for Precision Casting. Mater. Lett. 2020, 276, 128037. [Google Scholar] [CrossRef]

- Zhou, S.; Mei, H.; Chang, P.; Lu, M.; Cheng, L. Molecule Editable 3D Printed Polymer-Derived Ceramics. Coord. Chem. Rev. 2020, 422, 213486. [Google Scholar] [CrossRef]

- Chen, Z.; Li, Z.; Li, J.; Liu, C.; Lao, C.; Fu, Y.; Liu, C.; Li, Y.; Wang, P.; He, Y. 3D Printing of Ceramics: A Review. J. Eur. Ceram. Soc. 2019, 39, 661–687. [Google Scholar] [CrossRef]

- Wang, W.; Zhang, L.; Dong, X.; Wu, J.; Zhou, Q.; Li, S.; Shen, C.; Liu, W.; Wang, G.; He, R. Additive Manufacturing of Fiber Reinforced Ceramic Matrix Composites: Advances, Challenges, and Prospects. Ceram. Int. 2022, 48, 19542–19556. [Google Scholar] [CrossRef]

- Huang, R.-J.; Jiang, Q.-G.; Wu, H.-D.; Li, Y.-H.; Liu, W.-Y.; Lu, X.-X.; Wu, S.-H. Fabrication of Complex Shaped Ceramic Parts with Surface-Oxidized Si3N4 Powder via Digital Light Processing Based Stereolithography Method. Ceram. Int. 2019, 45, 5158–5162. [Google Scholar] [CrossRef]

- Zhang, F.; Li, Z.; Xu, M.; Wang, S.; Li, N.; Yang, J. A Review of 3D Printed Porous Ceramics. J. Eur. Ceram. Soc. 2022, 42, 3351–3373. [Google Scholar] [CrossRef]

- Sun, J.; Ye, D.; Zou, J.; Chen, X.; Wang, Y.; Yuan, J.; Liang, H.; Qu, H.; Binner, J.; Bai, J. A Review on Additive Manufacturing of Ceramic Matrix Composites. J. Mater. Sci. Technol. 2023, 138, 1–16. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, W.; Gao, X.; Li, S.; Gui, K.; Wang, G.; He, R. Additive Manufacturing of Continuous Carbon Fiber Reinforced High Entropy Ceramic Matrix Composites via Paper Laminating, Direct Slurry Writing, and Precursor Infiltration and Pyrolysis. Ceram. Int. 2023, 49, 7833–7841. [Google Scholar] [CrossRef]

- Ceramic Matrix Composites Market Size, Share & Trends Analysis Report by Product (Oxide, Silicon Carbide, Carbon), by Application (Aerospace, Defense, Energy & Power, Electrical & Electronics), by Region, and Segment Forecasts, 2023–2030. 2023. Available online: https://www.grandviewresearch.com/industry-analysis/global-ceramic-matrix-composites-market (accessed on 12 May 2023).

- Karadimas, G.; Salonitis, K. Ceramic Matrix Composites for Aero Engine Applications—A Review. Appl. Sci. 2023, 13, 3017. [Google Scholar] [CrossRef]

- Rathod, V.T.; Kumar, J.S.; Jain, A. Polymer and Ceramic Nanocomposites for Aerospace Applications. Appl. Nanosci. 2017, 7, 519–548. [Google Scholar] [CrossRef]

- Guo, Y.P.; Xue, Z.; Li, G.; Xu, R.; Lu, X. Effect of Rare Earth Y2O3 on the Corrosion and Friction Properties of Al2O3 Ceramic Coatings Prepared via Microarc Oxidation. Int. J. Electrochem. Sci. 2020, 15, 7682–7692. [Google Scholar] [CrossRef]

- Ghasemi-Kahrizsangi, S.; Gheisari Dehsheikh, H.; Boroujerdnia, M. Effect of Micro and Nano-Al2O3 Addition on the Microstructure and Properties of MgO-C Refractory Ceramic Composite. Mater. Chem. Phys. 2017, 189, 230–236. [Google Scholar] [CrossRef]

- Ye, F.; Zhang, L.; Yin, X.; Zhang, Y.; Kong, L.; Liu, Y.; Cheng, L. Dielectric and Microwave-Absorption Properties of SiC Nanoparticle/SiBCN Composite Ceramics. J. Eur. Ceram. Soc. 2014, 34, 205–215. [Google Scholar] [CrossRef]

- Tian, C.; Jiang, H.; Liu, N. Thermal Shock Behavior of Si3N4–TiN Nano-Composites. Int. J. Refract. Met. Hard Mater. 2011, 29, 14–20. [Google Scholar] [CrossRef]

- Fattahi, M.; Azizian-Kalandaragh, Y.; Delbari, S.A.; Sabahi Namini, A.; Ahmadi, Z.; Shahedi Asl, M. Nano-Diamond Reinforced ZrB2–SiC Composites. Ceram. Int. 2020, 46, 10172–10179. [Google Scholar] [CrossRef]

- Gao, C.; Feng, P.; Peng, S.; Shuai, C. Carbon Nanotube, Graphene and Boron Nitride Nanotube Reinforced Bioactive Ceramics for Bone Repair. Acta Biomater. 2017, 61, 1–20. [Google Scholar] [CrossRef]

- Hussain, S.; Faizan, M.; Vikraman, D.; Rabani, I.; Ali, B.; Kim, H.-S.; Jung, J.; Nam, K.-W. Eutectoid WxC Embedded WS2 Nanosheets as a Hybrid Composite Anode for Lithium-Ion Batteries. Ceram. Int. 2021, 47, 18646–18655. [Google Scholar] [CrossRef]

- Zocca, A.; Colombo, P.; Gomes, C.M.; Günster, J. Additive Manufacturing of Ceramics: Issues, Potentialities, and Opportunities. J. Am. Ceram. Soc. 2015, 98, 1983–2001. [Google Scholar] [CrossRef]

- Greil, P. Polymer Derived Engineering Ceramics. Adv. Eng. Mater. 2000, 2, 339–348. [Google Scholar] [CrossRef]

- Chantrell, P.G.; Popper, E.P. Inorganic Polymer and Ceramics. In Special Ceramics, 4th ed.; Popper, E.P., Ed.; Academic Press: New York, NY, USA, 1964; Volume 4, pp. 87–103. [Google Scholar]

- Fu, S.; Zhu, M.; Zhu, Y. Organosilicon Polymer-Derived Ceramics: An Overview. J. Adv. Ceram. 2019, 8, 457–478. [Google Scholar] [CrossRef] [Green Version]

- Colombo, P.; Mera, G.; Riedel, R.; Sorarù, G.D. Polymer-Derived Ceramics: 40 Years of Research and Innovation in Advanced Ceramics. J. Am. Ceram. Soc. 2010, 93, 1805–1837. [Google Scholar] [CrossRef]

- Xiong, H.; Chen, H.; Zhao, L.; Huang, Y.; Zhou, K.; Zhang, D. SiCw/SiCp reinforced 3D-SiC Ceramics Using Direct Ink Writing of Polycarbosilane-Based Solution: Microstructure, Composition and Mechanical Properties. J. Eur. Ceram. Soc. 2019, 39, 2648–2657. [Google Scholar] [CrossRef]

- Jana, P.; Santoliquido, O.; Ortona, A.; Colombo, P.; Sorarù, G.D. Polymer-Derived SiCN Cellular Structures from Replica of 3D Printed Lattices. J. Am. Ceram. Soc. 2018, 101, 2732–2738. [Google Scholar] [CrossRef] [Green Version]

- He, C.; Liu, X.; Ma, C.; Cao, Y.; Hou, F.; Yan, L.; Guo, A.; Liu, J. Digital Light Processing of Si-Based Composite Ceramics and Bulk Silica Ceramics from a High Solid Loading Polysiloxane/SiO2 Slurry. J. Eur. Ceram. Soc. 2021, 41, 7189–7198. [Google Scholar] [CrossRef]

- Xiao, J.; Jia, Y.; Liu, D.; Cheng, H. Three-Dimensional Printing of SiCN Ceramic Matrix Composites from Preceramic Polysilazane by Digital Light Processing. Ceram. Int. 2020, 46, 25802–25807. [Google Scholar] [CrossRef]

- Xia, A.; Yin, J.; Chen, X.; Liu, X.; Huang, Z. Polymer-Derived Si-Based Ceramics: Recent Developments and Perspectives. Crystals 2020, 10, 824. [Google Scholar] [CrossRef]

- Danko, G.A.; Silberglitt, R.; Colombo, P.; Pippel, E.; Woltersdorf, J. Comparison of Microwave Hybrid and Conventional Heating of Preceramic Polymers to Form Silicon Carbide and Silicon Oxycarbide Ceramics. J. Am. Ceram. Soc. 2000, 83, 1617–1625. [Google Scholar] [CrossRef]

- ASTM ISO/ASTM52900-21; Additive Manufacturing—General Principles—Fundamentals and Vocabulary. ASTM International: West Conshohocken, PA, USA, 2022. [CrossRef]

- Cao, L.; Bradford-Vialva, R.L.; Eckerle, R.M.; Herman, F.; Jones, C.; Klosterman, D.A. Development of Carbon Nanotube-Reinforced Nickel-Based Nanocomposites Using Laser Powder Bed Fusion. Adv. Eng. Mater. 2023, 25, 2201197. [Google Scholar] [CrossRef]

- Xiong, H.; Chen, H.; Chen, Z.; Xiong, X.; Zhang, D.; Zhou, K. 3D-SiC Decorated with SiC Whiskers: Chemical Vapor Infiltration on the Porous 3D-SiC Lattices Derived from Polycarbosilane-Based Suspensions. Ceram. Int. 2020, 46, 6234–6242. [Google Scholar] [CrossRef]

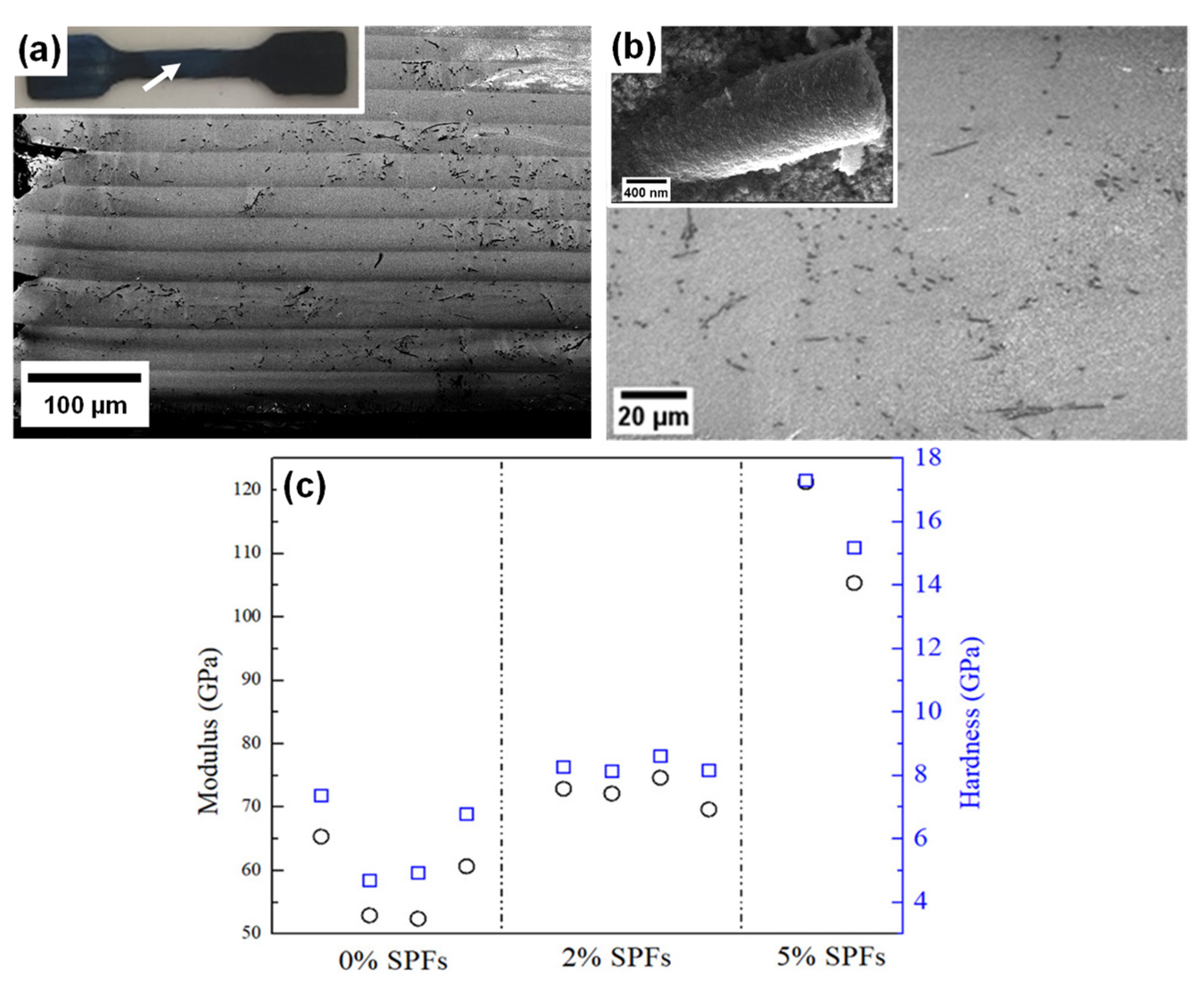

- Liu, H.; Mei, D.; Yu, S.; Qian, S.; Wang, Y. Direct Ink Writing of Chopped Carbon Fibers Reinforced Polymer Derived SiC Composites with Low Shrinkage and High Strength. J. Eur. Ceram. Soc. 2023, 43, 235–244. [Google Scholar] [CrossRef]

- Pagac, M.; Hajnys, J.; Ma, Q.-P.; Jancar, L.; Jansa, J.; Stefek, P.; Mesicek, J. A Review of Vat Photopolymerization Technology: Materials, Applications, Challenges, and Future Trends of 3D Printing. Polymers 2021, 13, 598. [Google Scholar] [CrossRef]

- Truxova, V.; Safka, J.; Seidl, M.; Kovalenko, I.; Volensky, L.; Ackermann, M. Ceramic 3D Printing: Comparison of SLA and DLP Technologies. MM Sci. J. 2020, 2020, 3905–3911. [Google Scholar] [CrossRef]

- Rumi, M.; Barlow, S.; Wang, J.; Perry, J.W.; Marder, S.R. Two-Photon Absorbing Materials and Two-Photon-Induced Chemistry. In Photoresponsive Polymers I. Advances in Polymer Science; Marder, S.R., Lee, K.S., Eds.; Springer: Berlin/Heidelberg, Germany, 2008; Volume 213, pp. 1–95. [Google Scholar] [CrossRef]

- Narayan, R.J.; Doraiswamy, A.; Chrisey, D.B.; Chichkov, B.N. Medical Prototyping Using Two Photon Polymerization. Mater. Today 2010, 13, 42–48. [Google Scholar] [CrossRef]

- Janusziewicz, R.; Tumbleston, J.R.; Quintanilla, A.L.; Mecham, S.J.; DeSimone, J.M. Layerless Fabrication with Continuous Liquid Interface Production. Proc. Natl. Acad. Sci. USA 2016, 113, 11703–11708. [Google Scholar] [CrossRef] [Green Version]

- He, C.; Ma, C.; Li, X.; Hou, F.; Yan, L.; Guo, A.; Liu, J. Continuous Fast 3D Printing of SiOC Ceramic Components. Addit. Manuf. 2021, 46, 102111. [Google Scholar] [CrossRef]

- Tumbleston, J.R.; Shirvanyants, D.; Ermoshkin, N.; Janusziewicz, R.; Johnson, A.R.; Kelly, D.; Chen, K.; Pinschmidt, R.; Rolland, J.P.; Ermoshkin, A.; et al. Continuous Liquid Interface Production of 3D Objects. Science 2015, 347, 1349–1352. [Google Scholar] [CrossRef]

- Huang, B.; Zhou, Y.; Wei, L.; Hu, R.; Zhang, X.; Coates, P.; Sefat, F.; Zhang, W.; Lu, C. Visible Light 3D Printing of High-Resolution Superelastic Microlattices of Poly(ethylene glycol) Diacrylate/Graphene Oxide Nanocomposites via Continuous Liquid Interface Production. Ind. Eng. Chem. Res. 2022, 61, 13052–13062. [Google Scholar] [CrossRef]

- Hsiao, K.; Lee, B.J.; Samuelsen, T.; Lipkowitz, G.; Kronenfeld, J.M.; Ilyn, D.; Shih, A.; Dulay, M.T.; Tate, L.; Shaqfeh, E.S.; et al. Single-Digit-Micrometer-Resolution Continuous Liquid Interface Production. Sci. Adv. 2022, 8, 46. [Google Scholar] [CrossRef] [PubMed]

- Zhou, X.; Hou, Y.; Lin, J. A review on the Processing Accuracy of Two-Photon Polymerization. AIP Adv. 2015, 5, 030701. [Google Scholar] [CrossRef]

- Park, S.-H.; Yang, D.-Y.; Lee, K.-S. Two-Photon Stereolithography for Realizing Ultraprecise Three-Dimensional Nano/Microdevices. Laser Photonics Rev. 2008, 3, 1–11. [Google Scholar] [CrossRef]

- Li, M.; Liu, Y.; Zhao, X.; Gao, R.; Li, Y.; Qu, S. High Sensitivity Fiber Acoustic Sensor Tip Working at 1550 nm Fabricated by Two-Photon Polymerization Technique. Sens. Actuators A Phys. 2017, 260, 29–34. [Google Scholar] [CrossRef]

- Ligon, S.C.; Liska, R.; Stampfl, J.; Gurr, M.; Mülhaupt, R. Polymers for 3D Printing and Customized Additive Manufacturing. Chem. Rev. 2017, 117, 10212–10290. [Google Scholar] [CrossRef] [Green Version]

- de Hazan, Y.; Penner, D. SiC and SiOC Ceramic Articles Produced by Stereolithography of Acrylate Modified Polycarbosilane Systems. J. Eur. Ceram. Soc. 2017, 37, 5205–5212. [Google Scholar] [CrossRef]

- Steyrer, B.; Neubauer, P.; Liska, R.; Stampfl, J. Visible Light Photoinitiator for 3D-Printing of Tough Methacrylate Resins. Materials 2017, 10, 1445. [Google Scholar] [CrossRef] [Green Version]

- Ou, J.; Huang, M.; Wu, Y.; Huang, S.; Lu, J.; Wu, S. Additive Manufacturing of Flexible Polymer-Derived Ceramic Matrix Composites. Virtual Phys. Prototyp. 2023, 18, e2150230. [Google Scholar] [CrossRef]

- Zhu, N.; Hou, Y.; Yang, W.; Wen, G.; Zhong, C.; Wang, D.; Liu, Y.; Zhang, L. Preparation of Complex SiOC Ceramics by a Novel Photocurable Precursor with Liquid Crystal Display (LCD) 3D Printing Technology. J. Eur. Ceram. Soc. 2022, 42, 3204–3212. [Google Scholar] [CrossRef]

- Kollep, M.; Konstantinou, G.; Madrid-Wolff, J.; Boniface, A.; Hagelüken, L.; Sasikumar, P.V.W.; Blugan, G.; Delrot, P.; Loterie, D.; Brugger, J.; et al. Tomographic Volumetric Additive Manufacturing of Silicon Oxycarbide Ceramics. Adv. Eng. Mater. 2022, 24, 2101345. [Google Scholar] [CrossRef]

- He, C.; Liu, X.; Ma, C.; Li, X.; Hou, F.; Yan, L.; Guo, A.; Liu, J. Digital Light Processing Fabrication of Mullite Component Derived from Preceramic Precusor Using Photosensitive Hydroxysiloxane as the Matrix and Alumina Nanoparticles as the Filler. J. Eur. Ceram. Soc. 2021, 41, 5570–5577. [Google Scholar] [CrossRef]

- He, C.; Cao, Y.; Ma, C.; Liu, X.; Hou, F.; Yan, L.; Guo, A.; Liu, J. Digital Light Processing of Complex-Shaped 3D-Zircon (ZrSiO4) Ceramic Components from a Photocurable Polysiloxane/ZrO2 Slurry. Ceram. Int. 2021, 47, 32905–32914. [Google Scholar] [CrossRef]

- Cao, Y.; Xu, X.; Qin, Z.; He, C.; Yan, L.; Hou, F.; Liu, J.; Guo, A. Vat Photopolymerization 3D Printing of Thermal Insulating Mullite Fiber-Based Porous Ceramics. Addit. Manuf. 2022, 60, 103235. [Google Scholar] [CrossRef]

- Li, S.; Zhang, Y.; Zhao, T.; Han, W.; Duan, W.; Wang, L.; Dou, R.; Wang, G. Additive Manufacturing of SiBCN/Si3N4w Composites from Preceramic Polymers by Digital Light Processing. RSC Adv. 2020, 10, 5681–5689. [Google Scholar] [CrossRef] [Green Version]

- O’Masta, M.R.; Stonkevitch, E.; Porter, K.A.; Bui, P.P.; Eckel, Z.C.; Schaedler, T.A. Additive Manufacturing of Polymer-Derived Ceramic Matrix Composites. J. Am. Ceram. Soc. 2020, 103, 6712–6723. [Google Scholar] [CrossRef]

- Wang, X.; Schmidt, F.; Hanaor, D.; Kamm, P.H.; Li, S.; Gurlo, A. Additive Manufacturing of Ceramics from Preceramic Polymers: A Versatile Stereolithographic Approach Assisted by Thiol-Ene Click Chemistry. Addit. Manuf. 2019, 27, 80–90. [Google Scholar] [CrossRef] [Green Version]

- Brinckmann, S.A.; Young, J.C.; Fertig, R.S.; Frick, C.P. Effect of Print Direction on Mechanical Properties of 3D Printed Polymer-Derived Ceramics and Their Precursors. Mater. Lett. X 2023, 17, 100179. [Google Scholar] [CrossRef]

- Al-Ajrash, S.M.N.; Browning, C.; Eckerle, R.; Cao, L. Initial Development of Preceramic Polymer Formulations for Additive Manufacturing. Mater. Adv. 2021, 2, 1083–1089. [Google Scholar] [CrossRef]

- Bagheri, A.; Jin, J. Photopolymerization in 3D Printing. ACS Appl. Polym. Mater. 2019, 1, 593–611. [Google Scholar] [CrossRef] [Green Version]

- Xiong, S.; Liu, J.; Cao, J.; Li, Z.; Idrees, M.; Lin, X.; Long, Z.; Liu, Z.; Wang, P.; Liu, C.; et al. 3D Printing of Crack-Free Dense Polymer-Derived Ceramic Monoliths and Lattice Skeletons with Improved Thickness and Mechanical Performance. Addit. Manuf. 2022, 57, 102964. [Google Scholar] [CrossRef]

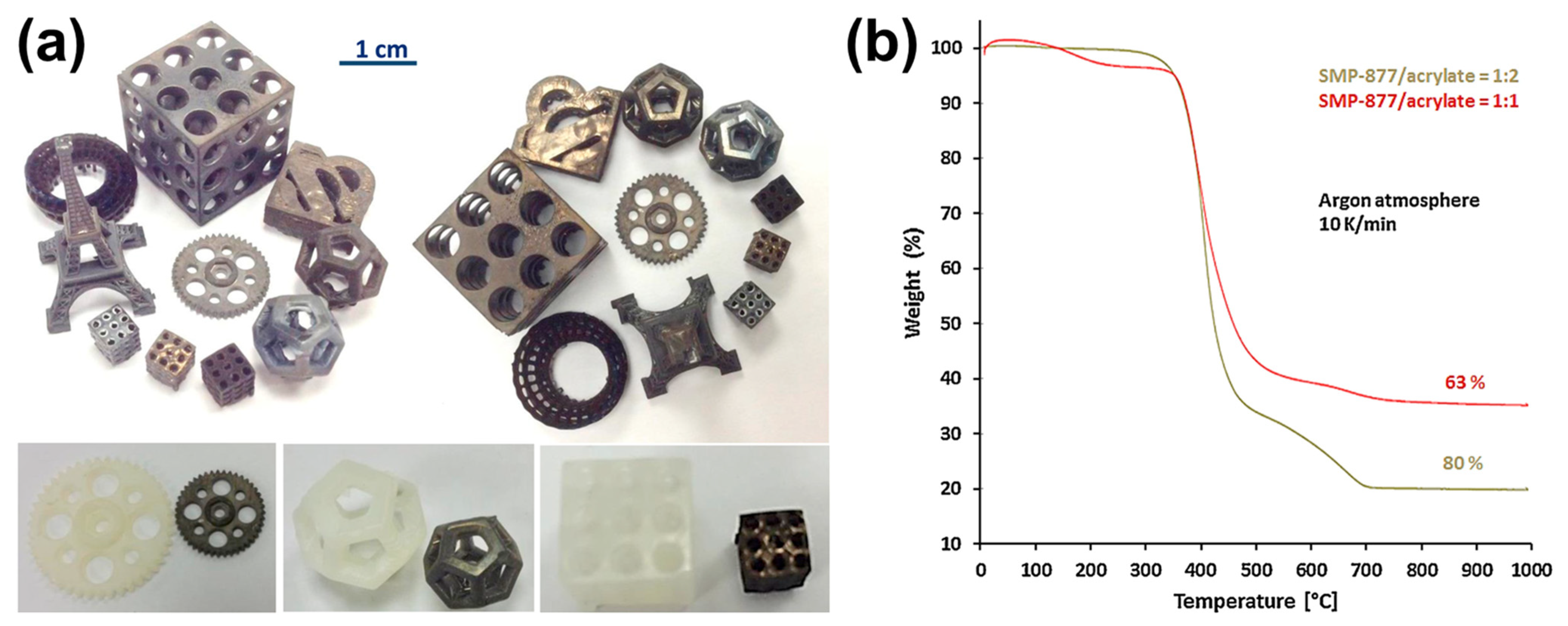

- Eckel, Z.C.; Zhou, C.; Martin, J.H.; Jacobsen, A.J.; Carter, W.B.; Schaedler, T.A. Additive Manufacturing of Polymer-Derived Ceramics. Science 2016, 351, 58–62. [Google Scholar] [CrossRef] [Green Version]

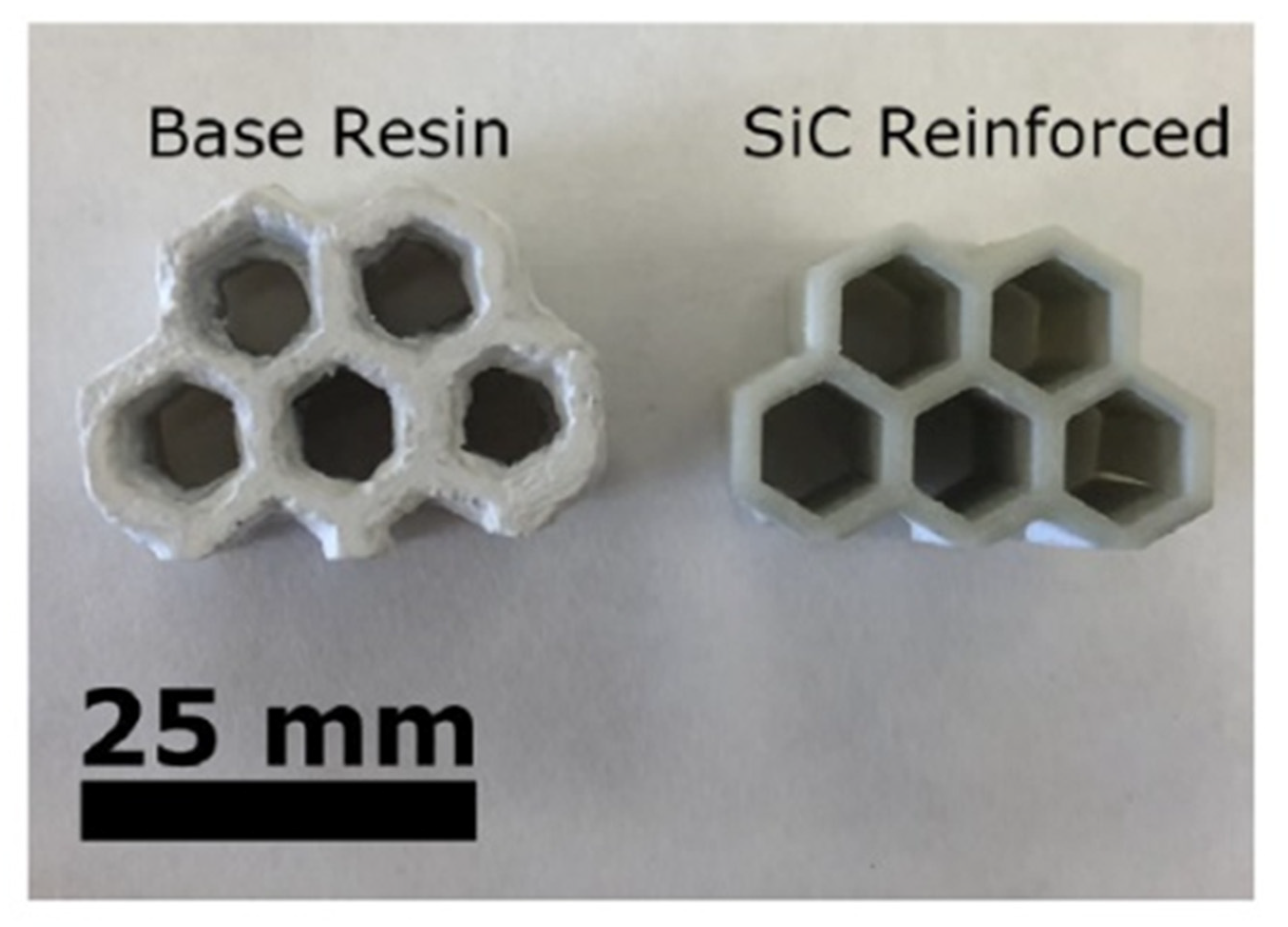

- Brinckmann, S.A.; Patra, N.; Yao, J.; Ware, T.H.; Frick, C.P.; Fertig, R.S., III. Stereolithography of SiOC Polymer-Derived Ceramics Filled with SiC Micronwhiskers. Adv. Eng. Mater. 2018, 20, 1800593. [Google Scholar] [CrossRef]

- Xu, X.; Li, P.; Ge, C.; Han, W.; Zhao, D.; Zhang, X. 3D Printing of Complex-Type SiOC Ceramics Derived from Liquid Photosensitive Resin. ChemistrySelect 2019, 4, 6862–6869. [Google Scholar] [CrossRef]

- Kotz, F.; Arnold, K.; Bauer, W.; Schild, D.; Keller, N.; Sachsenheimer, K.; Nargang, T.M.; Richter, C.; Helmer, D.; Rapp, B.E. Three-Dimensional Printing of Transparent Fused Silica Glass. Nature 2017, 544, 337–339. [Google Scholar] [CrossRef] [PubMed]

- Franchin, G.; Maden, H.; Wahl, L.; Baliello, A.; Pasetto, M.; Colombo, P. Optimization and Characterization of Preceramic Inks for Direct Ink Writing of Ceramic Matrix Composite Structures. Materials 2018, 11, 515. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Eichhorn, F.; Kellermann, S.; Betke, U.; Fey, T. Phase Evolution, Filler-Matrix Interactions, and Piezoelectric Properties in Lead Zirconate Titanate (PZT)-Filled Polymer-Derived Ceramics (PDCs). Materials 2020, 13, 1520. [Google Scholar] [CrossRef] [Green Version]

- Colombo, P.; Gambaryan-Roisman, T.; Scheffler, M.; Buhler, P.; Greil, P. Conductive Ceramic Foams from Preceramic Polymers. J. Am. Ceram. Soc. 2001, 84, 2265–2268. [Google Scholar] [CrossRef]

- Zocca, A.; Gomes, C.M.; Staude, A.; Bernardo, E.; Günster, J.; Colombo, P. SiOC Ceramics with Ordered Porosity by 3D-Printing of a Preceramic Polymer. J. Mater. Res. 2013, 28, 2243–2252. [Google Scholar] [CrossRef]

- Corcione, C.E.; Greco, A.; Montagna, F.; Licciulli, A.; Maffezzoli, A. Silica Moulds Built by Stereolithography. J. Mater. Sci. 2005, 40, 4899–4904. [Google Scholar] [CrossRef]

- Greil, P. Active-Filler-Controlled Pyrolysis of Preceramic Polymers. J. Am. Ceram. Soc. 1995, 78, 835–848. [Google Scholar] [CrossRef]

- Bernardo, E.; Fiocco, L.; Parcianello, G.; Storti, E.; Colombo, P. Advanced Ceramics from Preceramic Polymers Modified at the Nano-Scale: A Review. Materials 2014, 7, 1927–1956. [Google Scholar] [CrossRef]

- Kemp, J.W.; Diaz, A.A.; Malek, E.C.; Croom, B.P.; Apostolov, Z.D.; Kalidindi, S.R.; Compton, B.G.; Rueschhoff, L.M. Direct Ink Writing of ZrB2-SiC Chopped Fiber Ceramic Composites. Addit. Manuf. 2021, 44, 102049. [Google Scholar] [CrossRef]

- Tethon 3D Company. Available online: https://tethon3d.com (accessed on 12 May 2023).

- Xiao, J.; Liu, D.; Cheng, H.; Jia, Y.; Zhou, S.; Zu, M. Carbon Nanotubes as Light Absorbers in Digital Light Processing Three-Dimensional Printing of SiCN Ceramics from Preceramic Polysilazane. Ceram. Int. 2020, 46, 19393–19400. [Google Scholar] [CrossRef]

- Gyak, K.-W.; Vishwakarma, N.K.; Hwang, Y.-H.; Kim, J.; Yun, H.; Kim, D.-P. 3D-Printed Monolithic SiCN Ceramic Microreactors from a Photocurable Preceramic Resin for the High Temperature Ammonia Cracking Process. React. Chem. Eng. 2019, 4, 1393–1399. [Google Scholar] [CrossRef]

- Huang, M.; Wu, Y.; Ou, J.; Huang, Y.; Wang, J.; Wu, S. 3D-Printing of Polymer-derived SiCN Ceramic Matrix Composites by Digital Light Processing. J. Eur. Ceram. Soc. 2022, 42, 5476–5483. [Google Scholar] [CrossRef]

- Schmidt, J.; Altun, A.A.; Schwentenwein, M.; Colombo, P. Complex Mullite Structures Fabricated via Digital Light Processing of a Preceramic Polysiloxane with Active Alumina Fillers. J. Eur. Ceram. Soc. 2019, 39, 1336–1343. [Google Scholar] [CrossRef]

- Cooperstein, I.; Shukrun, E.; Press, O.; Kamyshny, A.; Magdassi, S. Additive Manufacturing of Transparent Silica Glass from Solutions. ACS Appl. Mater. Interfaces 2018, 10, 18879–18885. [Google Scholar] [CrossRef]

- Fu, Y.; Chen, Z.; Xu, G.; Wei, Y.; Lao, C. Preparation and Stereolithography 3D Printing of Ultralight and Ultrastrong ZrOC Porous Ceramics. J. Alloys Compd. 2019, 789, 867–873. [Google Scholar] [CrossRef]

- Li, S.; Duan, W.; Zhao, T.; Han, W.; Wang, L.; Dou, R.; Wang, G. The Fabrication of SiBCN Ceramic Components from Preceramic Polymers by Digital Light Processing (DLP) 3D Printing Technology. J. Eur. Ceram. Soc. 2018, 38, 4597–4603. [Google Scholar] [CrossRef]

- Brigo, L.; Schmidt, J.E.M.; Gandin, A.; Michieli, N.; Colombo, P.; Brusatin, G. 3D Nanofabrication of SiOC Ceramic Structures. Adv. Sci. 2018, 5, 1800937. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Park, S.; Lee, D.-H.; Ryoo, H.-I.; Lim, T.-W.; Yang, D.-Y.; Kim, D.-P. Fabrication of Three-Dimensional SiC Ceramic Microstructures with Near-Zero Shrinkage via Dual Crosslinking Induced Stereolithography. Chem. Commun. 2009, 4880–4882. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zanchetta, E.; Cattaldo, M.; Franchin, G.; Schwentenwein, M.; Homa, J.; Brusatin, G.; Colombo, P. Stereolithography of SiOC Ceramic Microcomponents. Adv. Mater. 2016, 28, 370–376. [Google Scholar] [CrossRef] [PubMed]

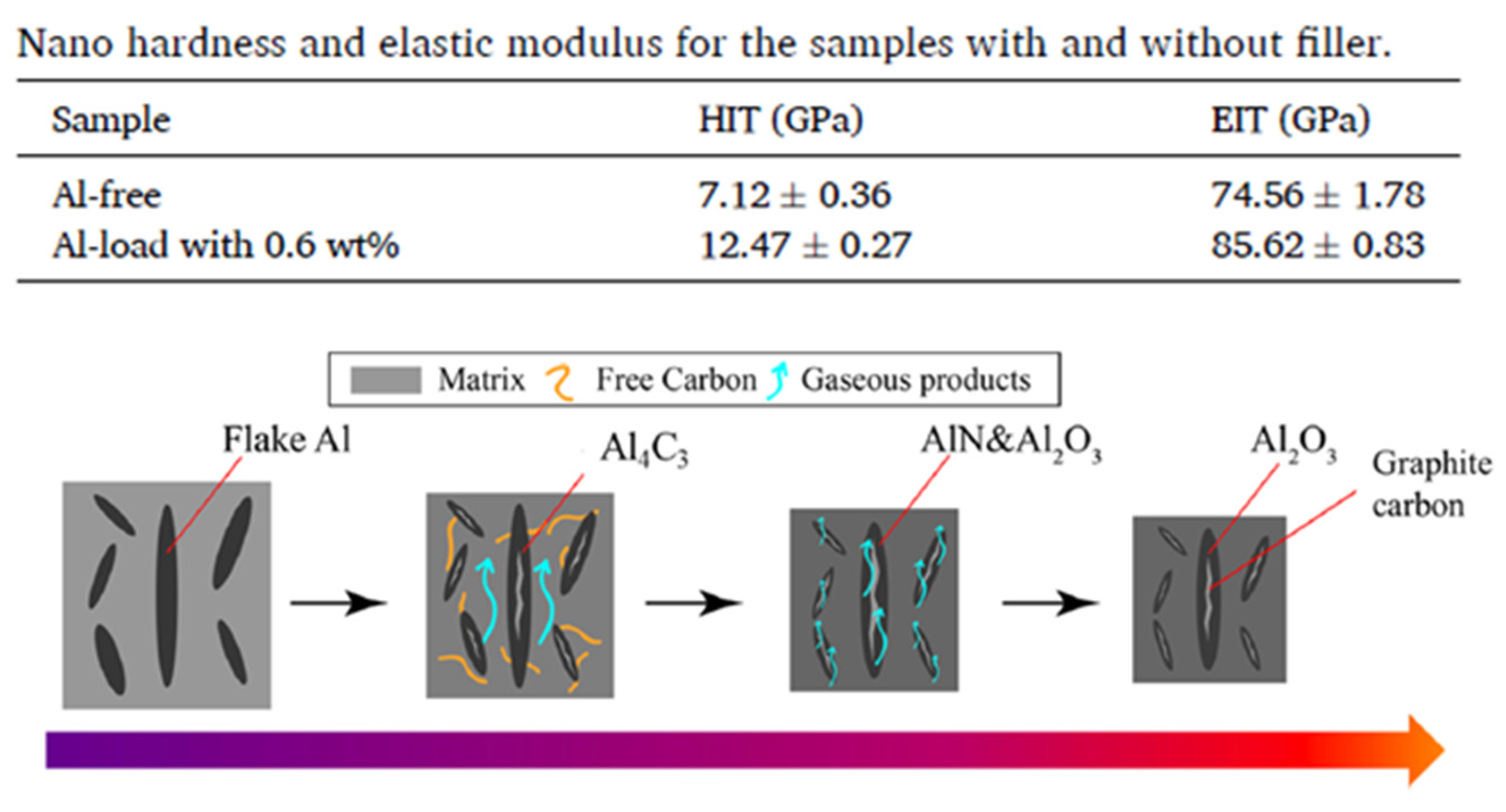

- Cheng, Y.; Huang, H.; Xi, X.; Deng, Y.; Zhang, H.; Wang, C.; Lin, H. Vinyl Polysilazane Based Photo-Curable Resin Derived Ceramics Manufactured by Digital Light Processing with Al Flake as the Active Filler. J. Eur. Ceram. Soc. 2023, 43, 332–340. [Google Scholar] [CrossRef]

- Al-Ajrash, S.M.N.; Browning, C.; Eckerle, R.; Cao, L. Innovative Procedure for 3D Printing of Hybrid Silicon Carbide/Carbon Fiber Nanocomposites. Nano Select 2021, 2, 2201–2208. [Google Scholar] [CrossRef]

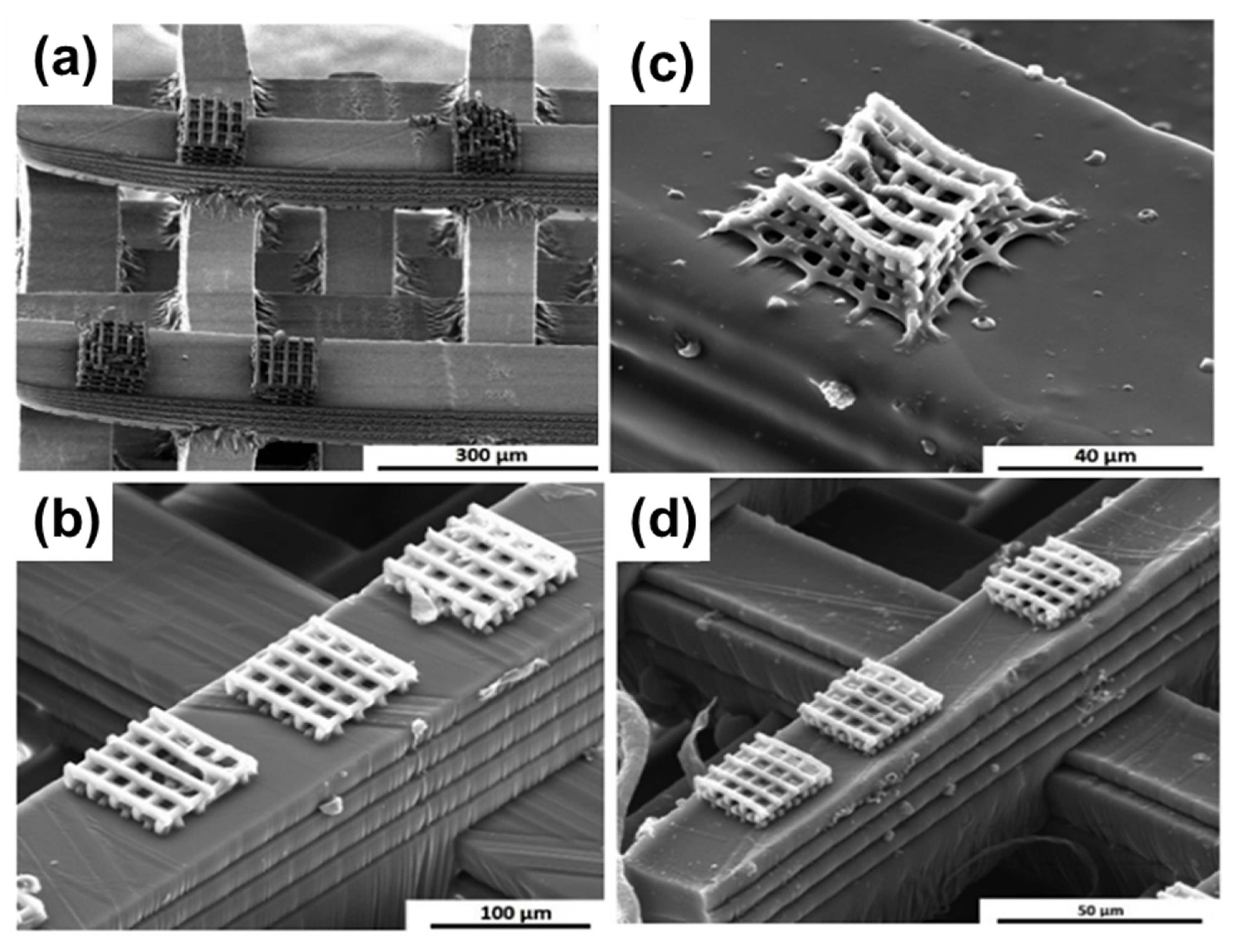

- Schmidt, J.; Brigo, L.; Gandin, A.; Schwentenwein, M.; Colombo, P.; Brusatin, G. Multiscale Ceramic Components from Preceramic Polymers by Hybridization of Vat Polymerization-Based Technologies. Addit. Manuf. 2019, 30, 100913. [Google Scholar] [CrossRef]

- Lao, Z.; Xia, N.; Wang, S.; Xu, T.; Wu, X.; Zhang, L. Tethered and Untethered 3D Microactuators Fabricated by Two-Photon Polymerization: A Review. Micromachines 2021, 12, 465. [Google Scholar] [CrossRef]

- Liew, L.-A.; Zhang, W.; Bright, V.M.; An, L.; Dunn, M.L.; Raj, R. Fabrication of SiCN Ceramic MEMS Using Injectable Polymer-Precursor Technique. Sens. Actuators A Phys. 2001, 89, 64–70. [Google Scholar] [CrossRef]

- Hassanin, H.; Essa, K.; Elshaer, A.; Imbaby, M.; El-Mongy, H.H.; El-Sayed, T.A. Micro-Fabrication of Ceramics: Additive Manufacturing and Conventional Technologies. J. Adv. Ceram. 2021, 10, 1–27. [Google Scholar] [CrossRef]

- Konstantinou, G.; Kakkava, E.; Hagelüken, L.; Warriam Sasikumar, P.V.; Wang, J.; Makowska, M.G.; Blugan, G.; Nianias, N.; Marone, F.; Van Swygenhoven, H.; et al. Additive Micro-Manufacturing of Crack-Free PDCs by Two-Photon Polymerization of a Single, Low-Shrinkage Preceramic Resin. Addit. Manuf. 2020, 35, 101343. [Google Scholar] [CrossRef]

- Gonzalez-Gutierrez, J.; Cano, S.; Schuschnigg, S.; Kukla, C.; Sapkota, J.; Holzer, C. Additive Manufacturing of Metallic and Ceramic Components by the Material Extrusion of Highly-Filled Polymers: A Review and Future Perspectives. Materials 2018, 11, 840. [Google Scholar] [CrossRef] [Green Version]

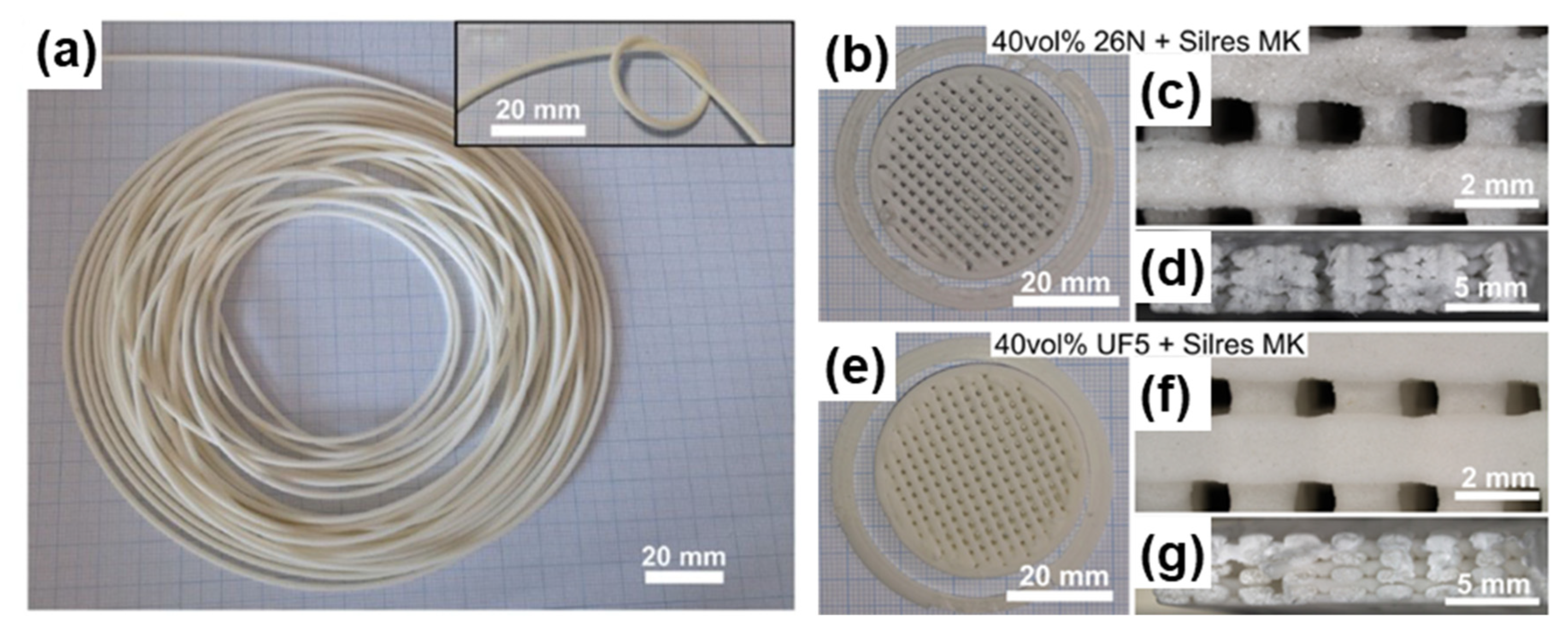

- Gorjan, L.; Tonello, R.; Sebastian, T.; Colombo, P.; Clemens, F. Fused Deposition Modeling of Mullite Structures from a Preceramic Polymer and γ-Alumina. J. Eur. Ceram. Soc. 2019, 39, 2463–2471. [Google Scholar] [CrossRef]

- Zhao, L.; Wang, X.; Xiong, H.; Zhou, K.; Zhang, D. Optimized Preceramic Polymer for 3D Structured Ceramics via Fused Deposition Modeling. J. Eur. Ceram. Soc. 2021, 41, 5066–5074. [Google Scholar] [CrossRef]

- Solís Pinargote, N.W.; Smirnov, A.; Peretyagin, N.; Seleznev, A.; Peretyagin, P. Direct Ink Writing Technology (3D Printing) of Graphene-Based Ceramic Nanocomposites: A Review. Nanomaterials 2020, 10, 1300. [Google Scholar] [CrossRef] [PubMed]

- Romanczuk-Ruszuk, E.; Sztorch, B.; Pakuła, D.; Gabriel, E.; Nowak, K.; Przekop, R.E. 3D Printing Ceramics—Materials for Direct Extrusion Process. Ceramics 2023, 6, 364–385. [Google Scholar] [CrossRef]

- Xiong, H.; Zhao, L.; Chen, H.; Wang, X.; Zhou, K.; Zhang, D. 3D SiC Containing Uniformly Dispersed, Aligned SiC Whiskers: Printability, Microstructure and Mechanical Properties. J. Alloys Compd. 2019, 809, 151824. [Google Scholar] [CrossRef]

- Pierin, G.; Grotta, C.; Colombo, P.; Mattevi, C. Direct Ink Writing of Micrometric SiOC Ceramic Structures Using a Preceramic Polymer. J. Eur. Ceram. Soc. 2016, 36, 1589–1594. [Google Scholar] [CrossRef]

- Sarraf, F.; Hadian, A.; Churakov, S.V.; Clemens, F. EVA-PVA Binder System for Polymer Derived Mullite Made by Material Extrusion Based Additive Manufacturing. J. Eur. Ceram. Soc. 2023, 43, 530–541. [Google Scholar] [CrossRef]

- Sarraf, F.; Abbatinali, E.; Gorjan, L.; Sebastian, T.; Colombo, P.; Churakov, S.V.; Clemens, F. Effect of MgO Sintering Additive on Mullite Structures Manufactured by Fused Deposition Modeling (FDM) Technology. J. Eur. Ceram. Soc. 2021, 41, 6677–6686. [Google Scholar] [CrossRef]

- Mei, H.; Yan, Y.; Feng, L.; Dassios, K.G.; Zhang, H.; Cheng, L. First Printing of Continuous Fibers into Ceramics. J. Am. Ceram. Soc. 2019, 102, 3244–3255. [Google Scholar] [CrossRef]

- Yan, Y.; Mei, H.; Zhang, M.; Jin, Z.; Fan, Y.; Cheng, L.; Zhang, L. Key Role of Interphase in Continuous Fiber 3D Printed Ceramic Matrix Composites. Compos. Part A Appl. Sci. Manuf. 2022, 162, 107127. [Google Scholar] [CrossRef]

- Chen, H.; Wang, X.; Xue, F.; Huang, Y.; Zhou, K.; Zhang, D. 3D Printing of SiC Ceramic: Direct Ink Writing with a Solution of Preceramic Polymers. J. Eur. Ceram. Soc. 2018, 38, 5294–5300. [Google Scholar] [CrossRef]

- Bowen, J.J.; Mooraj, S.; Goodman, J.A.; Peng, S.; Street, D.P.; Roman-Manso, B.; Davidson, E.C.; Martin, K.L.; Rueschhoff, L.M.; Schiffres, S.N.; et al. Hierarchically Porous Ceramics via Direct Writing of Preceramic Polymer-Triblock Copolymer Inks. Mater. Today 2022, 58, 71–79. [Google Scholar] [CrossRef]

- Colombo, P.; Schmidt, J.; Franchin, G.; Zocca, A.; Günster, J. Additive Manufacturing Techniques for Fabricating Complex Ceramic Components from Preceramic Polymers. Am. Ceram. Soc. Bull. 2017, 96, 16–23. [Google Scholar]

- Farkash, M.; Brandon, D.G. Whisker Alignment by Slip Extrusion. Mater. Sci. Eng. A 1994, 177, 269–275. [Google Scholar] [CrossRef]

- Shahzad, A.; Lazoglu, I. Direct Ink Writing (DIW) of Structural and Functional Ceramics: Recent Achievements and Future Challenges. Compos. B Eng. 2021, 225, 109249. [Google Scholar] [CrossRef]

- Herschel, W.H. Consistency of Rubber Benzene Solutions. Ind. Eng. Chem. 1924, 16, 927. [Google Scholar] [CrossRef]

- Lewis, J.A. Direct Ink Writing of 3D Functional Materials. Adv. Funct. Mater. 2006, 16, 2193–2204. [Google Scholar] [CrossRef]

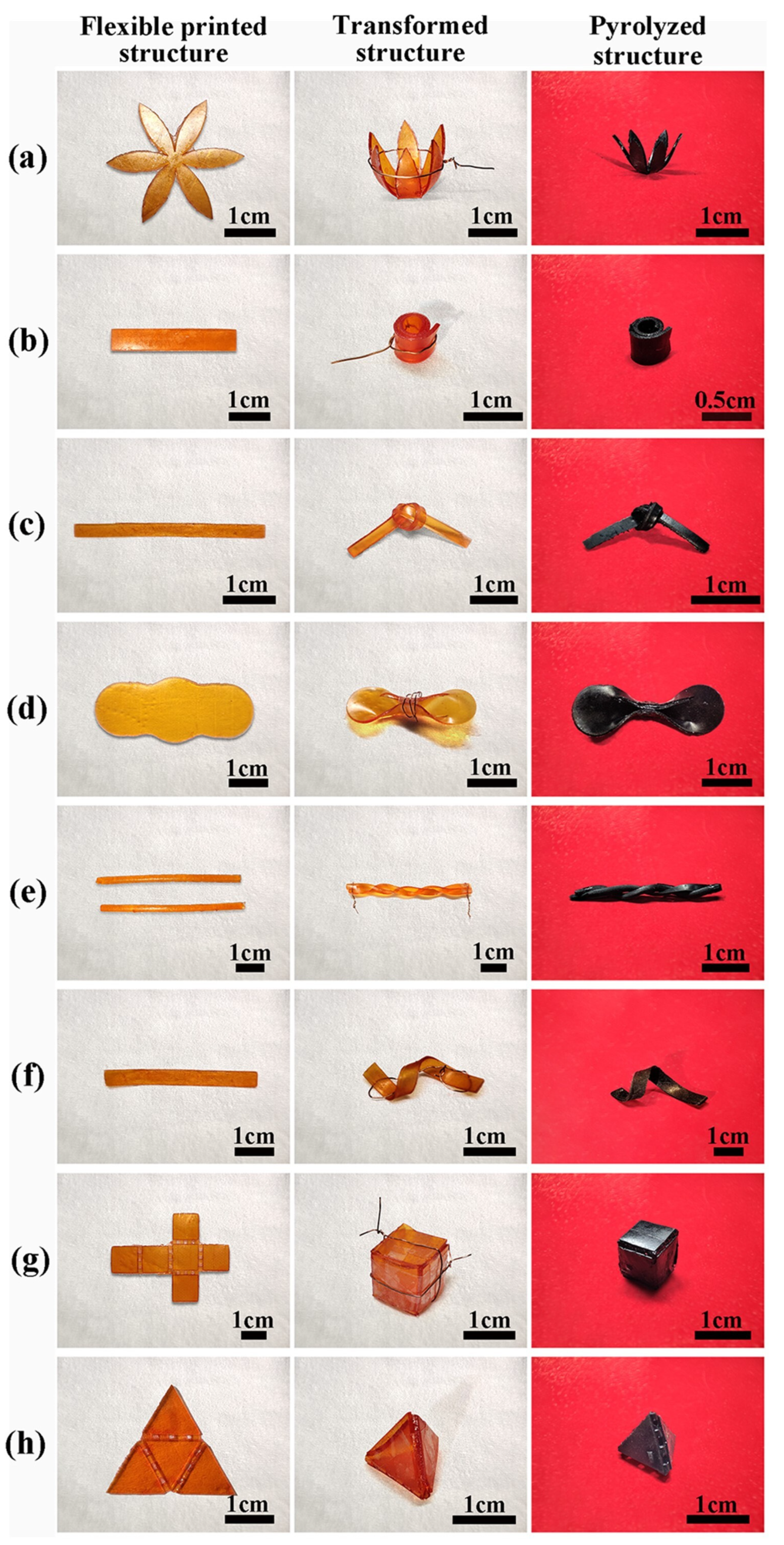

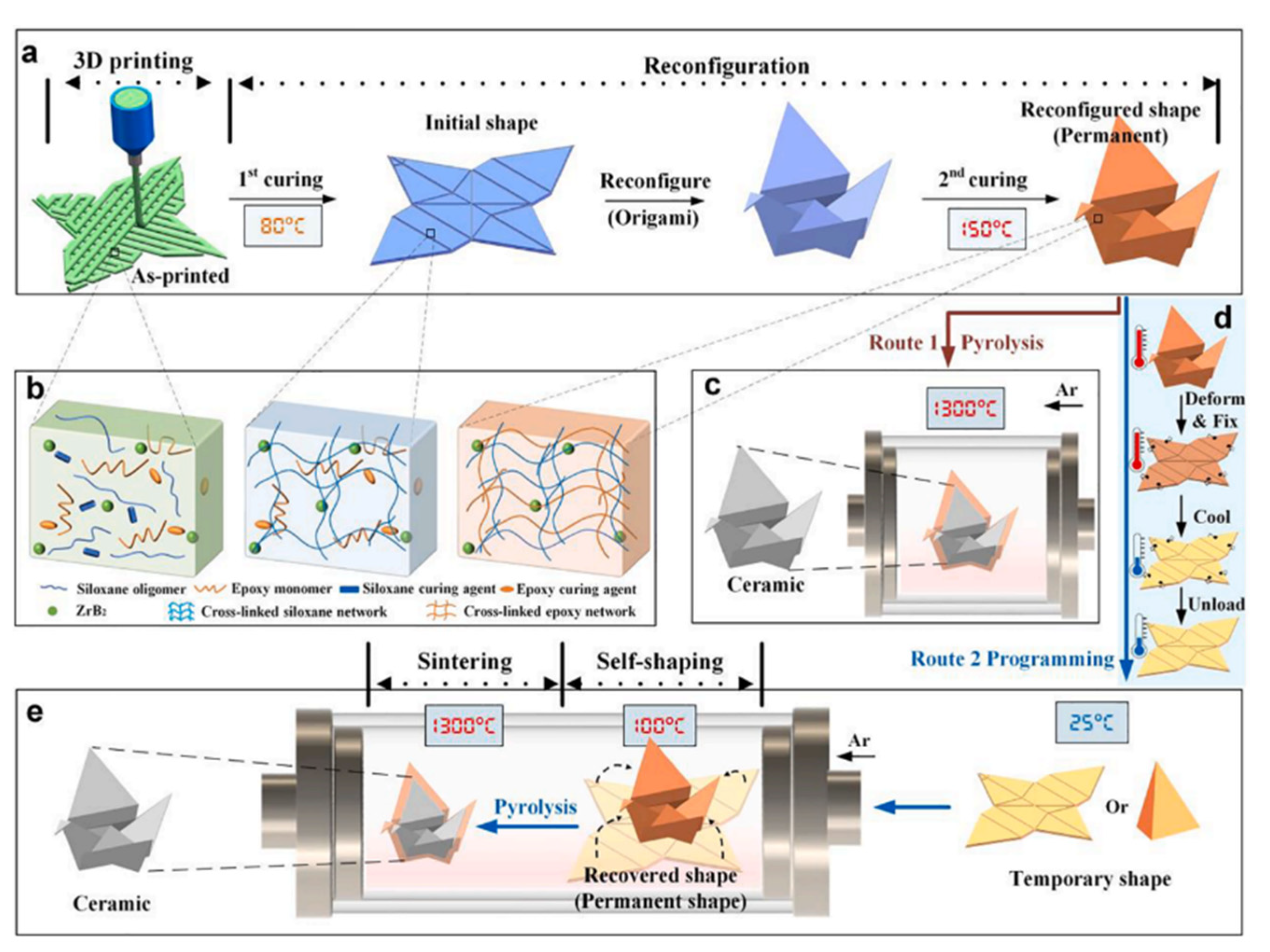

- Chen, S.; Li, J.; Shi, H.; Chen, X.; Liu, G.; Meng, S.; Lu, J. Lightweight and Geometrically Complex Ceramics Derived from 4D Printed Shape Memory Precursor with Reconfigurability and Programmability for Sensing and Actuation Applications. Chem. Eng. J. 2023, 455, 140655. [Google Scholar] [CrossRef]

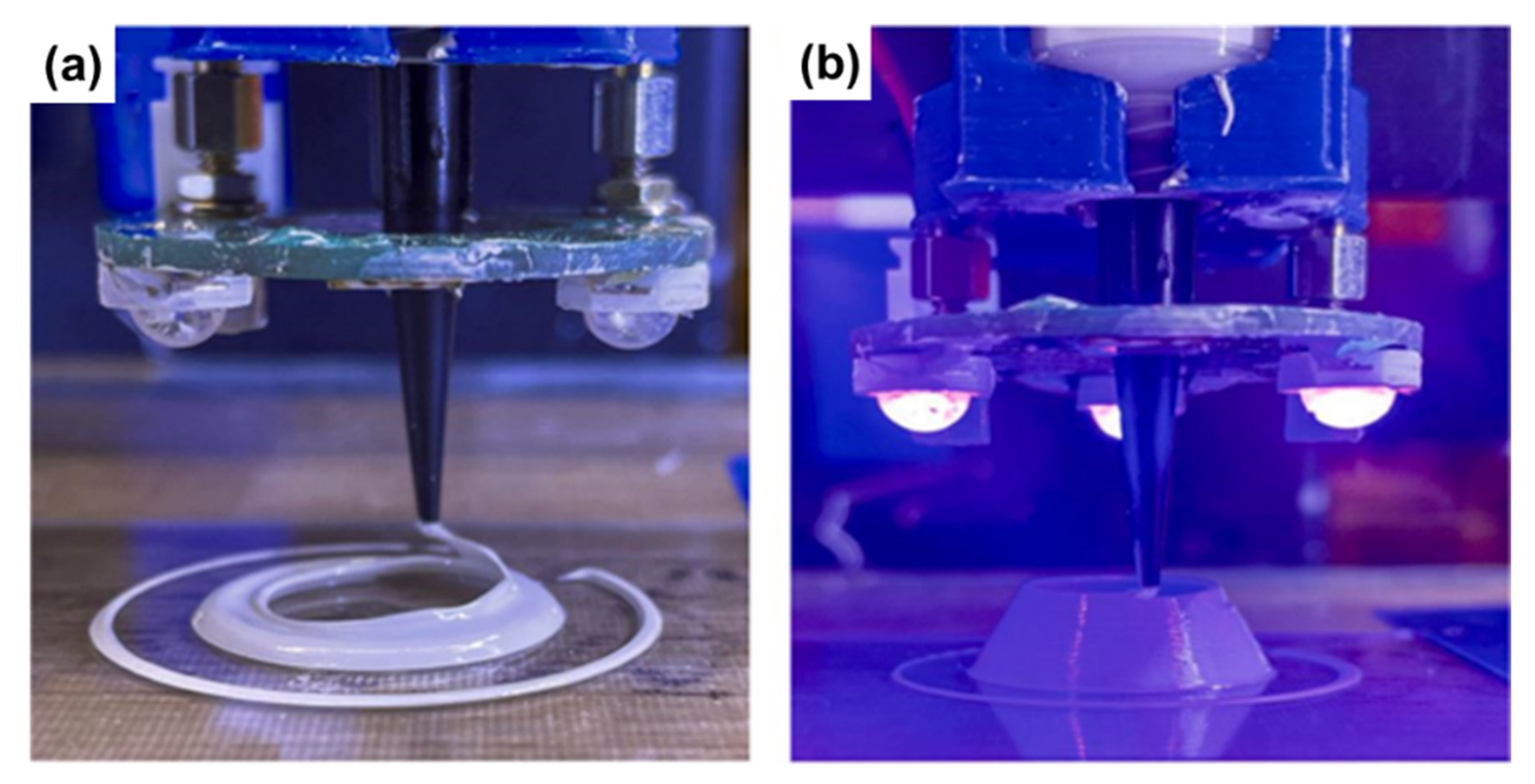

- Clarkson, C.M.; Wyckoff, C.; Parvulescu, M.J.S.; Rueschhoff, L.M.; Dickerson, M.B. UV-Assisted Direct Ink Writing of Si3N4/SiC Preceramic Polymer Suspensions. J. Eur. Ceram. Soc. 2022, 42, 3374–3382. [Google Scholar] [CrossRef]

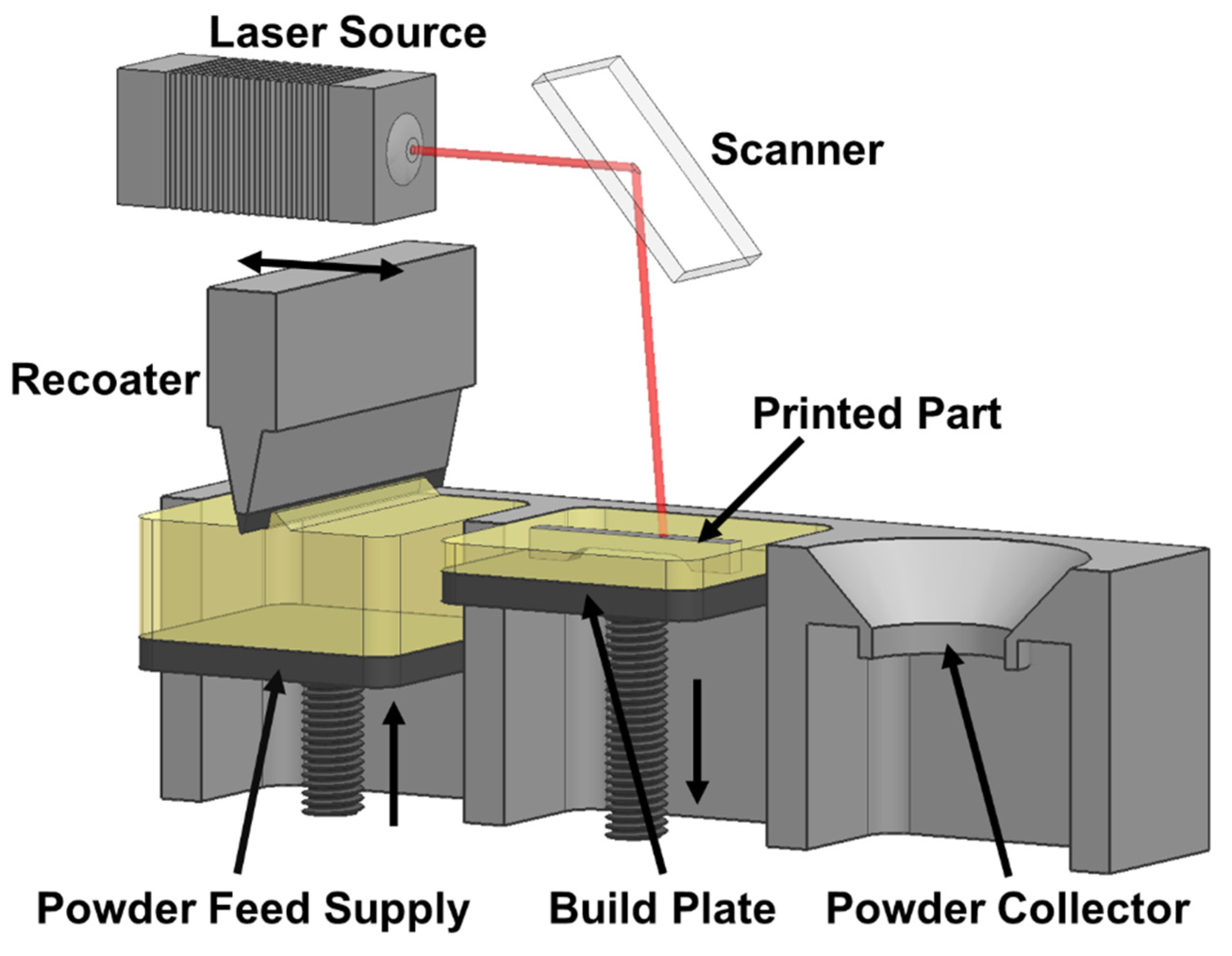

- Rajamani, D.; Balasubramanian, E. Investigation of Sintering Parameters on Viscoelastic Behaviour of Selective Heat Sintered HDPE Parts. J. Appl. Sci. Eng. 2019, 22, 391–402. [Google Scholar] [CrossRef]

- Tolochko, N.K.; Khlopkov, Y.V.; Mozzharov, S.E.; Ignatiev, M.B.; Laoui, T.; Titov, V.I. Absorptance of Powder Materials Suitable for Laser Sintering. Rapid Prototyp. J. 2000, 6, 155–161. [Google Scholar] [CrossRef]

- Friedel, T.; Travitzky, N.; Niebling, F.; Scheffler, M.; Greil, P. Fabrication of Polymer Derived Ceramic Parts by Selective Laser Curing. J. Eur. Ceram. Soc. 2005, 25, 193–197. [Google Scholar] [CrossRef]

| VP Processes | Preceramic Feedstock Material Composition | Ceramic | Ref. |

|---|---|---|---|

| SLA | Vinylmethoxysiloxane + PEGDA + SiC whisker | SiCw/SiOC | [99] |

| Multifunctional acrylic + Silicone acrylate + SiO2 powder | SiO2 | [106] | |

| DLP | PSZ + VHPCS + PETA + HDDA + CNT | CNT/SiCN | [111] |

| PVSZ + 2-Isocyanatoethyl methacrylate + SiO2 NP | SiO2/SiCN | [112] | |

| PSZ + TMPTA + Si3N4 powder + Si3N4 whisker | Si3N4/SiCN | [113] | |

| Polysiloxane (RC 711) + Al2O3 powder | Mullite | [114] | |

| Epoxy-acrylic siloxane (self-synthesized) + Hydroxyl silicone oil | SiOC | [115] | |

| Hydroxysiloxane + Al2O3 nanopowder | Mullite | [88] | |

| Epoxy-acrylic siloxane (self-synthesized) + ZrO2 micro powder + ZrO2 nano powder | ZrSiO4 | [89] | |

| Polysiloxane + HDDA + TMPTA + Phenolic resin | SiOC | [97] | |

| TEOS + APTMS | SiO2 (transparent) | [115] | |

| PVSA + HDDA + TMPTA + 3-(Trimethoxysilyl) propyl methacrylate | SiOC | [86] | |

| Zirconium n-propoxide + Methylacrylic acid +TMPTA | ZrOC | [116] | |

| Polyborosilazane + Acrylate resin | SiBCN | [117] | |

| 2PP | Polysiloxane (RC 711) | SiOC | [118] |

| Allylhydridopolycarbosilane | SiC | [119] |

| ME Processes | Preceramic Feedstock Material Composition | Ceramic | Ref. |

|---|---|---|---|

| FDM | Al2O3 powder + SILRES® MK + EVA + PVA + MgO | Mullite | [135] |

| Al2O3 powder + SILRES® MK + MgO | Mullite | [136] | |

| SILRES® MK + Polycaprolactone + PLA + Carbon fiber | CF/SiC + SiOC | [137] | |

| SILRES® MK + Carbon fiber | CF/SiOC | [138] | |

| DIW | PCS | SiC | [139] |

| Calcium carbonate + Polysiloxane | β-Ca2SiO4 | [9] | |

| Polycarbosilane + SiC whisker | SiCw/SiC | [133] | |

| PCS + SiC whisker + SiC powder | SiCw + SiCp/SiC | [60] | |

| PCS + Chopped carbon fiber | CF/SiC | [69] | |

| PCS + ZrB2 + SiC fiber | ZrB2 + SiCf/SiC | [109] | |

| PCS + PMMA + Poly(n-butyl acrylate) + Pentaerythritol tetrakis(3-mercaptopropionate) | SiC/SiOC | [140] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Han, J.; Liu, C.; Bradford-Vialva, R.L.; Klosterman, D.A.; Cao, L. Additive Manufacturing of Advanced Ceramics Using Preceramic Polymers. Materials 2023, 16, 4636. https://doi.org/10.3390/ma16134636

Han J, Liu C, Bradford-Vialva RL, Klosterman DA, Cao L. Additive Manufacturing of Advanced Ceramics Using Preceramic Polymers. Materials. 2023; 16(13):4636. https://doi.org/10.3390/ma16134636

Chicago/Turabian StyleHan, Jinchen, Chang Liu, Robyn L. Bradford-Vialva, Donald A. Klosterman, and Li Cao. 2023. "Additive Manufacturing of Advanced Ceramics Using Preceramic Polymers" Materials 16, no. 13: 4636. https://doi.org/10.3390/ma16134636

APA StyleHan, J., Liu, C., Bradford-Vialva, R. L., Klosterman, D. A., & Cao, L. (2023). Additive Manufacturing of Advanced Ceramics Using Preceramic Polymers. Materials, 16(13), 4636. https://doi.org/10.3390/ma16134636