The Effect of Fe Addition on the Curie Temperature and Magnetic Entropy of the Gd45Co50Al5 Amorphous Alloy

Abstract

1. Introduction

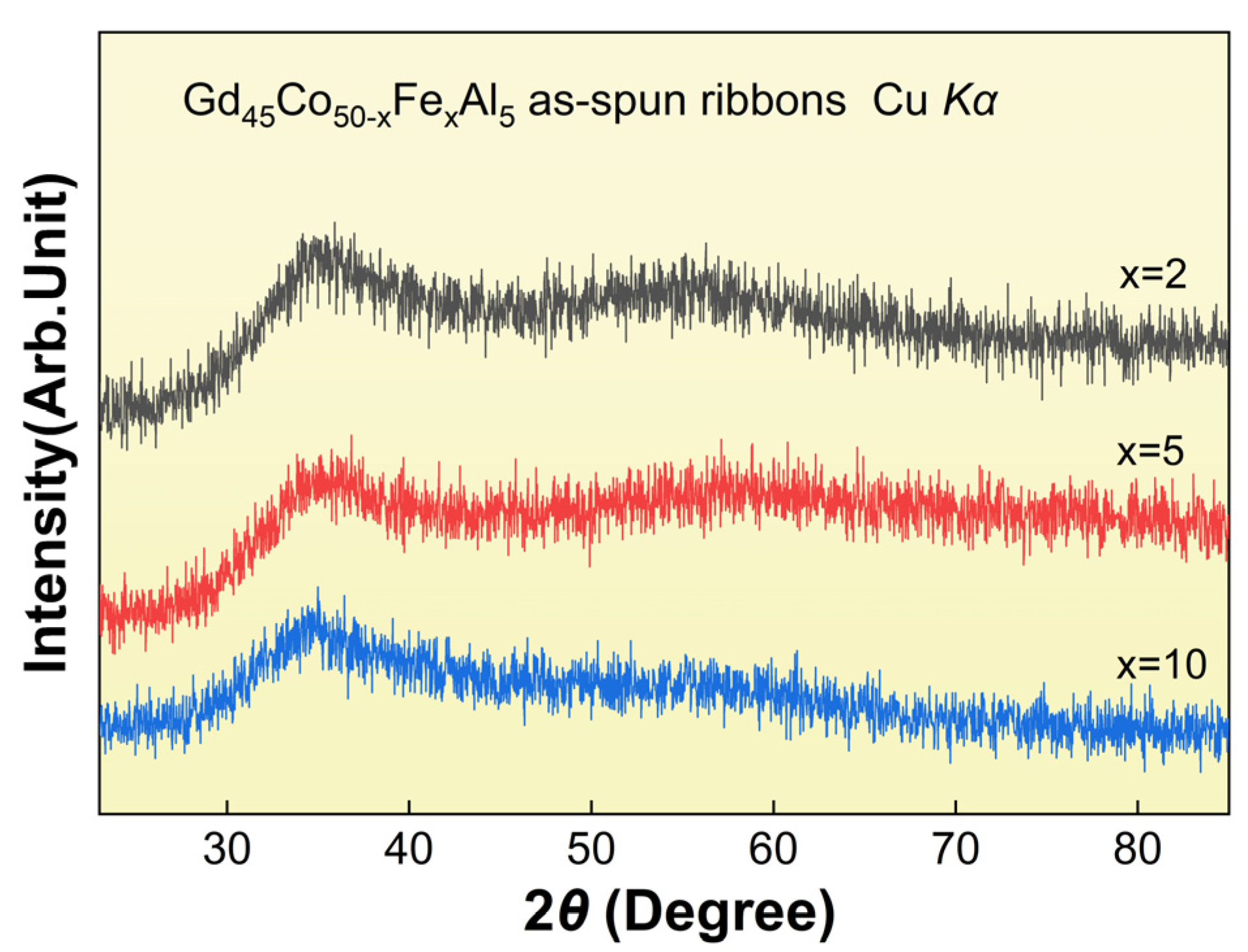

2. Materials and Methods

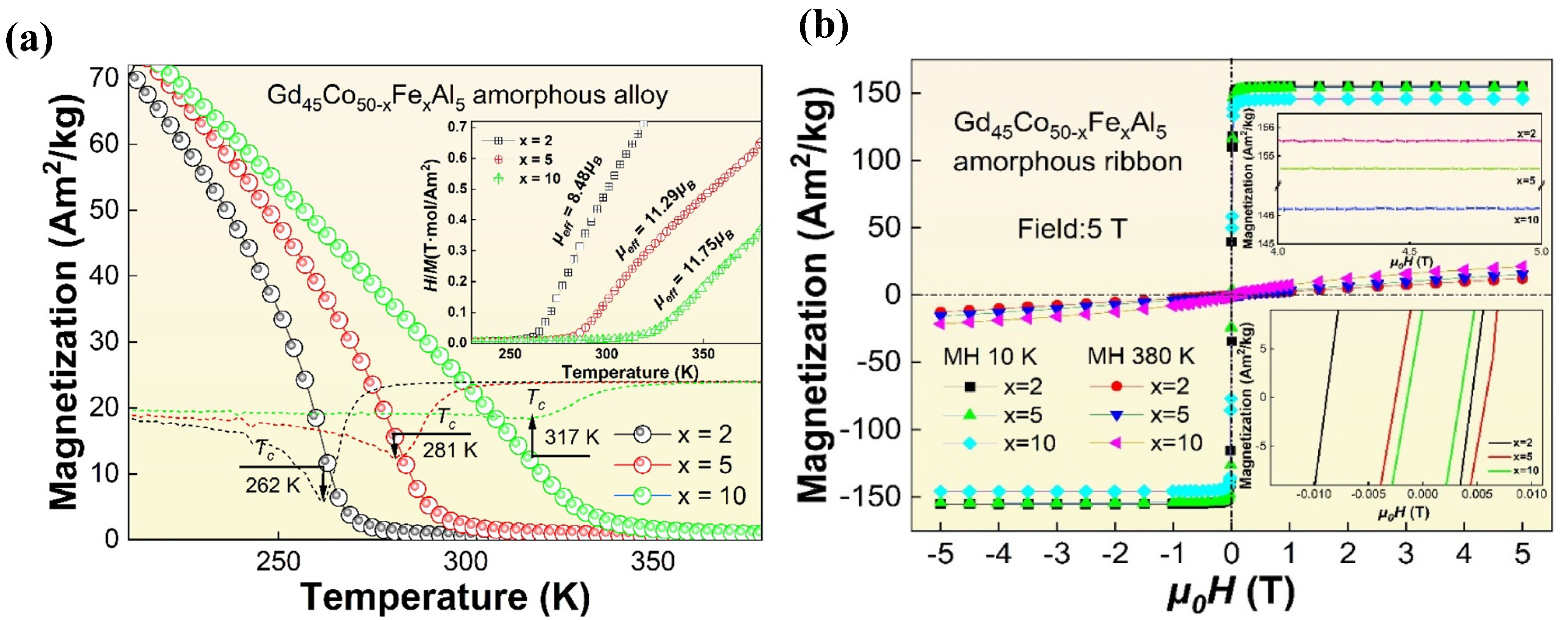

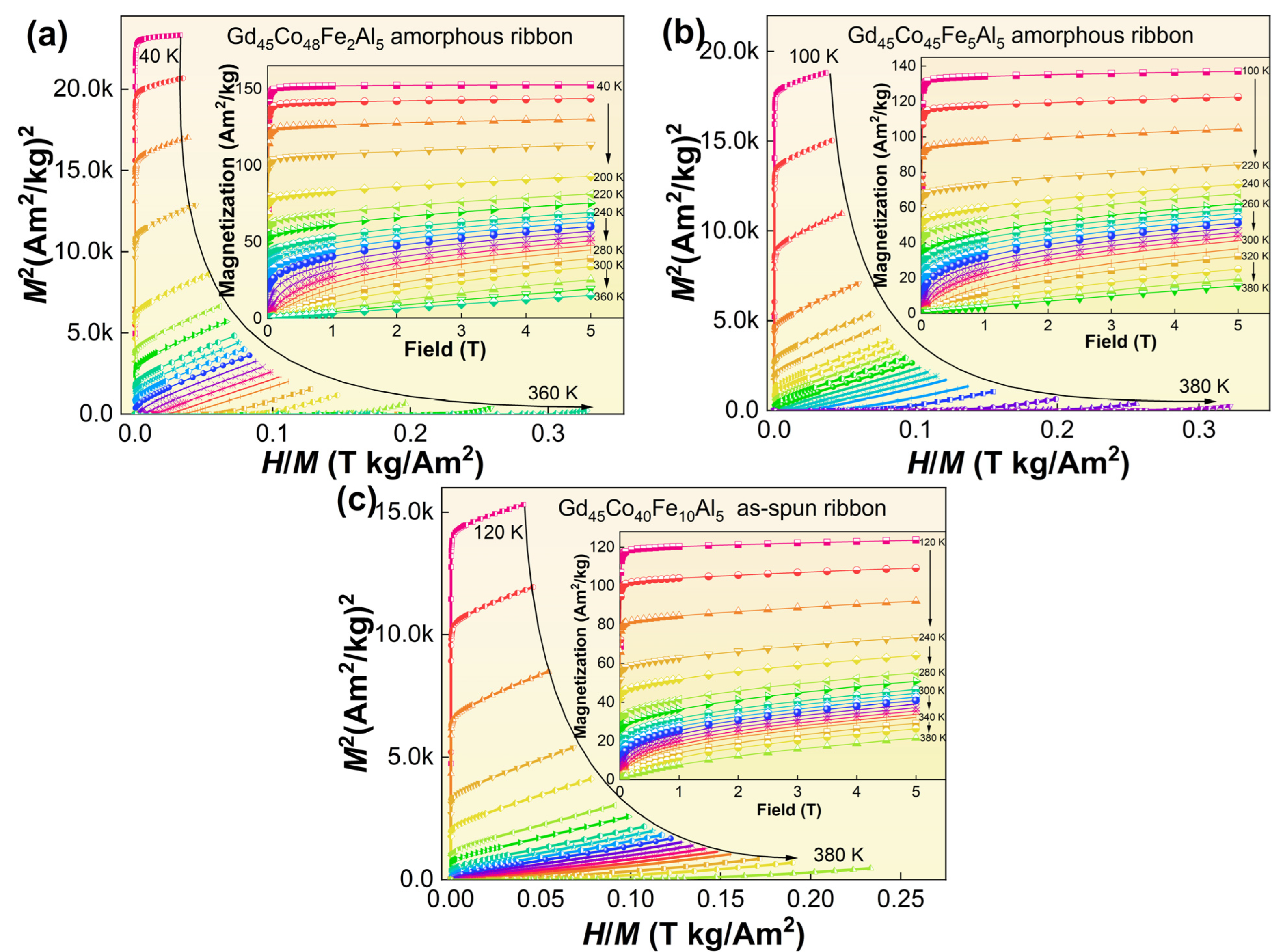

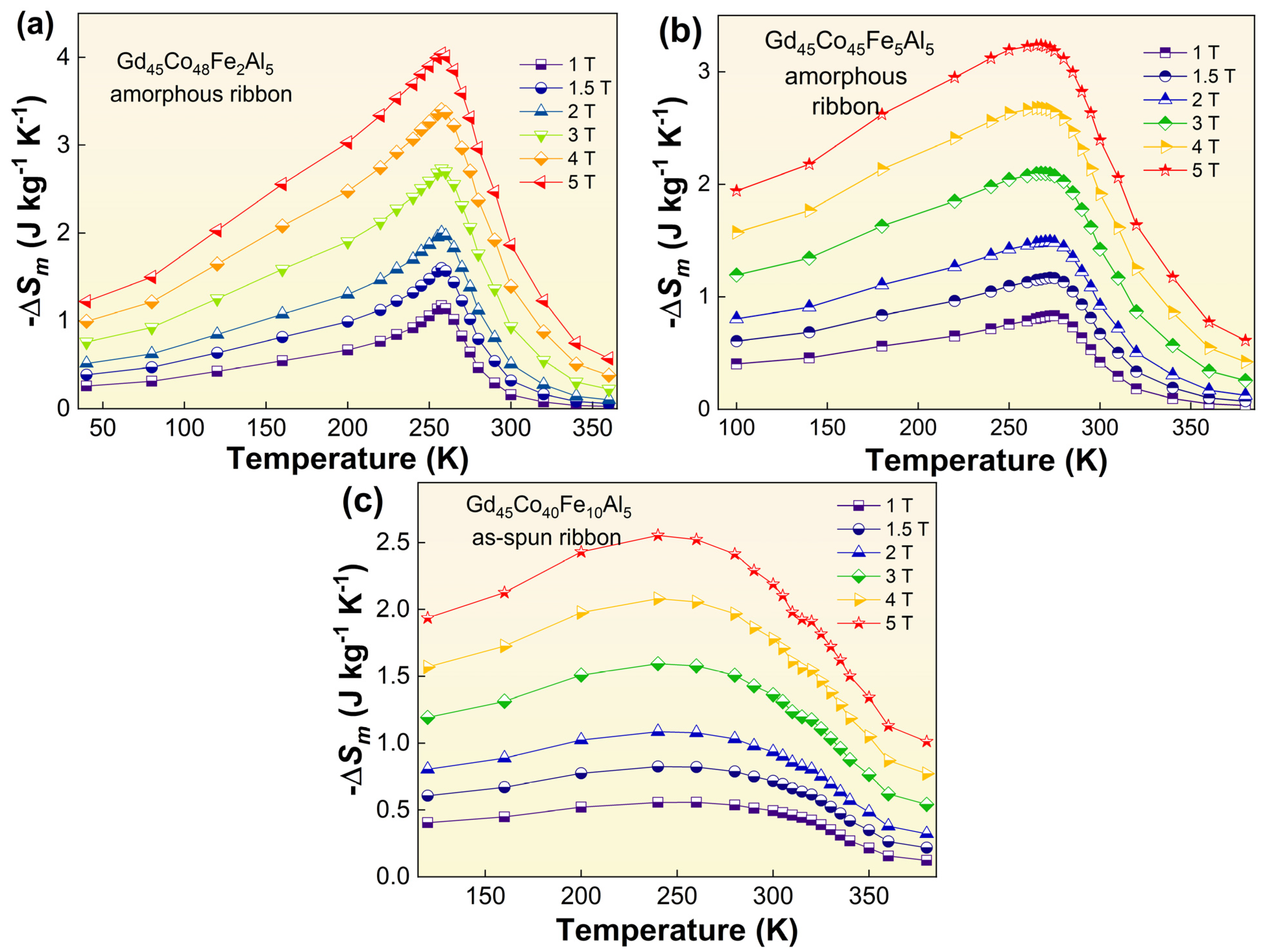

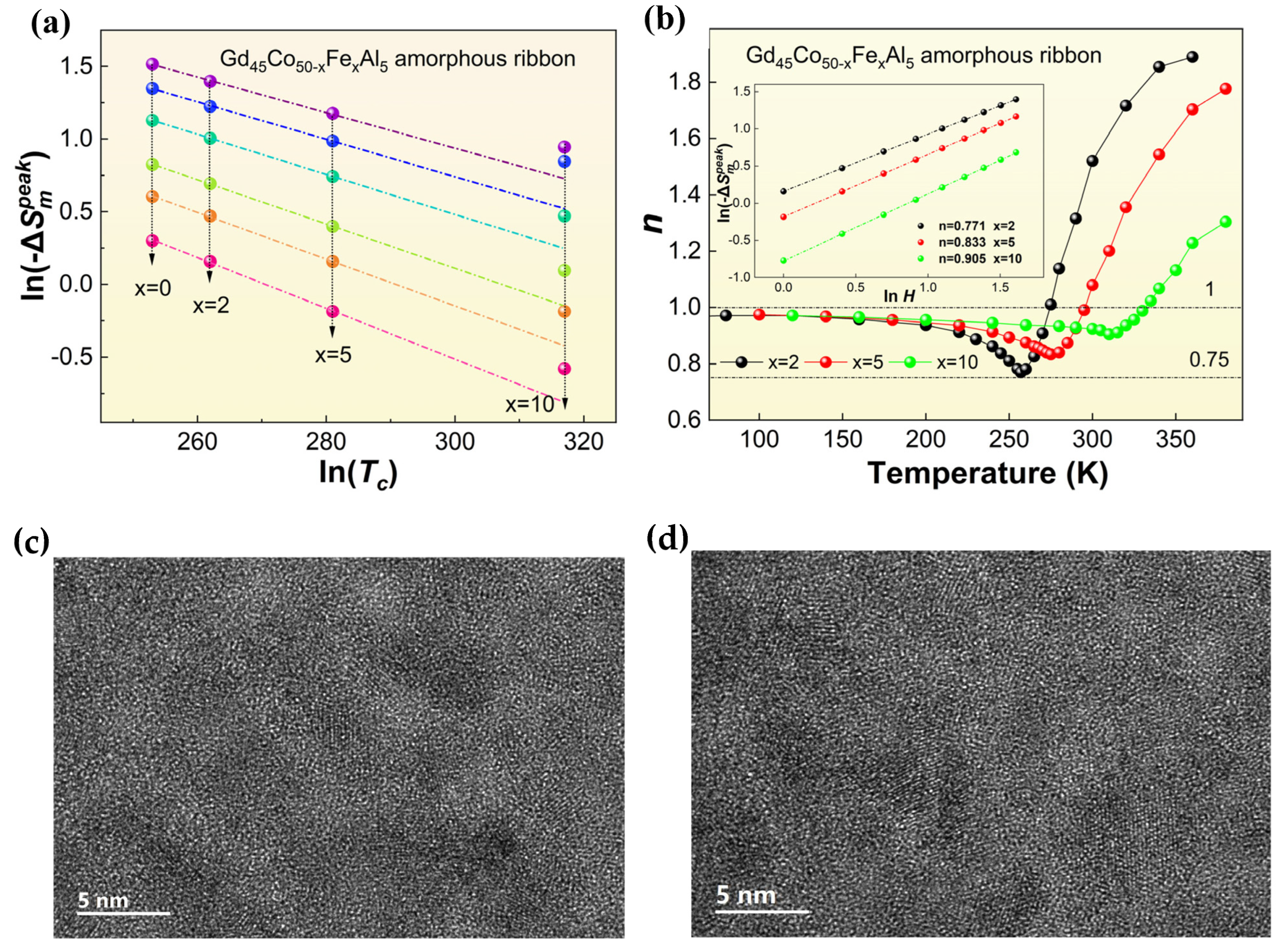

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gutfleisch, O.; Willard, M.A.; Bruck, E.; Chen, C.H.; Sankar, S.G.; Liu, J.P. Magnetic materials and devices for the 21st Century: Stronger, lighter, and more energy efficient. Adv. Mater. 2011, 23, 821–842. [Google Scholar] [CrossRef]

- Kitanovski. Energy Applications of Magnetocaloric Materials. Adv. Energy Mater. 2020, 10, 1903741. [Google Scholar] [CrossRef]

- Franco, V.; Blazquez, J.S.; Ipus, J.J.; Law, J.Y.; Moreno-Ramírez, L.M.; Conde, A. Magnetocaloric effect: From materials research to refrigeration devices. Prog. Mater. Sci. 2018, 93, 112–232. [Google Scholar]

- Shen, B.G.; Sun, J.R.; Hu, F.X.; Zhang, H.W.; Cheng, Z.H. Recent progress in exploring magnetocaloric materials. Adv. Mater. 2009, 21, 4545–4564. [Google Scholar] [CrossRef]

- Tegus, O.; Bruck, E.; Buschow, K.H.J.; de Boer, F.R. Transition-metal-based magnetic refrigerants for room-temperature applications. Nature 2002, 415, 150–152. [Google Scholar] [CrossRef]

- de Oliveira, N.A.; von Ranke, P.J. Theoretical aspects of the magnetocaloric effect. Phys. Rep. 2010, 489, 89–159. [Google Scholar] [CrossRef]

- Gschneidner, A.; Pecharsky, V.K. Magnetocaloric materials. Ann. Rev. Mater. Sci. 2000, 30, 387–429. [Google Scholar] [CrossRef]

- Gschneidner, K.A.; Pecharsky, V.K.; Tsokol, A.O. Recent developments in magnetocaloric materials. Rep. Prog. Phys. 2005, 68, 1479–1539. [Google Scholar] [CrossRef]

- Yu, B.F.; Gao, Q.; Zhang, B.; Meng, X.Z.; Chen, Z. Review on research of room temperature magnetic refrigeration. Int. J. Refig. 2003, 26, 622–636. [Google Scholar] [CrossRef]

- Li, H.X.; Lu, Z.C.; Wang, S.L.; Wu, Y.; Lu, Z.P. Fe-based bulk metallic glasses: Glass formation, fabrication, properties and applications. Prog. Mater. Sci. 2019, 103, 235–318. [Google Scholar] [CrossRef]

- Luo, Q.; Wang, W.H. Magnetocaloric effect in rare earth-based bulk metallic glasses. J. Alloys Compd. 2010, 495, 209–216. [Google Scholar] [CrossRef]

- Huo, J.T.; Zhao, D.Q.; Bai, H.Y.; Axinte, E.; Wang, W.H. Giant magnetocaloric effect in Tm-based bulk metallic glasses. J. Non-Cryst. Solids 2013, 359, 1–4. [Google Scholar] [CrossRef]

- Luo, Q.; Tang, M.B.; Shen, J. Tuning the magnetocaloric response of Er-based metallic glasses by varying structural order in disorder. J. Magn. Magn. Mater. 2016, 401, 406–411. [Google Scholar] [CrossRef]

- Wang, X.; Wang, Q.; Tang, B.Z.; Yu, P.; Xia, L.; Ding, D. Large magnetic entropy change and adiabatic temperature rise of a ternary Gd34Ni33Al33 metallic glass. J. Rare. Earth 2021, 39, 998–1002. [Google Scholar] [CrossRef]

- Fu, H.; Zhang, X.Y.; Yu, H.J.; Teng, B.H.; Zu, X.T. Large magnetic entropy change of Gd-based ternary bulk metallic glass in liquid-nitrogen temperature range. Solid State Commun. 2008, 145, 15–17. [Google Scholar] [CrossRef]

- Zhang, H.Y.; Li, R.; Zhang, L.; Zhang, T. Tunable magnetic and magnetocaloric properties in heavy rare-earth based metallic glasses through the substitution of similar elements. J. Appl. Phys. 2014, 115, 133903. [Google Scholar] [CrossRef]

- Huo, J.T.; Wang, J.Q.; Wang, W.H. Denary high entropy metallic glass with large magnetocaloric effect. J. Alloys Compd. 2019, 776, 202–206. [Google Scholar] [CrossRef]

- Xia, L.; Wu, C.; Chen, S.H.; Chan, K.C. Magneto-caloric effect of a Gd50Co50 amorphous alloy near the freezing point of water. AIP Adv. 2015, 5, 097122. [Google Scholar] [CrossRef]

- Wu, C.; Ding, D.; Xia, L.; Chan, K.C. Achieving tailorable magneto-caloric effect in the Gd-Co binary amorphous alloys. AIP. Advs. 2016, 6, 035302. [Google Scholar] [CrossRef]

- Liu, G.L.; Zhao, D.Q.; Bai, H.Y.; Wang, W.H.; Pan, M.X. Room temperature table-like magnetocaloric effect in amorphous Gd50Co45Fe5 ribbon. J. Phys. D Appl. Phys. 2016, 49, 055004. [Google Scholar] [CrossRef]

- Tang, B.Z.; Guo, D.Q.; Ding, D.; Xia, L.; Chan, K.C. Large adiabatic temperature rise above the water ice point of a minor Fe substituted Gd50Co50 amorphous alloy. J. Non-Cryst. Solids 2017, 464, 30–33. [Google Scholar] [CrossRef]

- Huang, L.W.; Tang, B.Z.; Ding, D.; Wang, X.; Xia, L. Achieving high adiabatic temperature change at room temperature in a Gd48Co50Fe2 amorphous alloy. J. Alloys Compd. 2019, 811, 152003. [Google Scholar] [CrossRef]

- Tang, B.Z.; Liu, X.P.; Li, D.M.; Yu, P.; Xia, L. Effect of Ni substitution on the formability and magnetic properties of Gd50Co50 amorphous alloy. Chin. Phys. B 2020, 29, 056401. [Google Scholar] [CrossRef]

- Blundell, S. Magnetism in Condensed Matter; Oxford University Press: New York, NY, USA, 2001. [Google Scholar]

- Banerjee, S.K. On a generalised approach to first and second order magnetic transitions. Phys. Lett. 1964, 12, 16. [Google Scholar] [CrossRef]

- Yu, P.; Zhang, J.Z.; Xia, L. Effect of boron on the magneto-caloric effect in Fe91−xZr9Bx(x = 3, 4, 5) amorphous alloys. J. Mater. Sci. 2017, 52, 13948–13955. [Google Scholar] [CrossRef]

- Wang, X.; Wang, Q.; Tang, B.Z.; Ding, D.; Cui, L.; Xia, L. Magnetic and magneto-caloric properties of the amorphous Fe(92−x)Zr(8)B(x) ribbons. Mater 2020, 13, 5334. [Google Scholar] [CrossRef]

- Gan, L.H.; Ma, L.Y.; Tang, B.Z.; Ding, D.; Xia, L. Effect of Co substitution on the glass forming ability and magnetocaloric effect of Fe88Zr8B4 amorphous alloys. Sci. China-Phys. Mech. Astron. 2017, 60, 076121. [Google Scholar] [CrossRef]

- Chen, L.S.; Zhang, J.Z.; Wen, L.; Yu, P.; Xia, L. Outstanding magnetocaloric effect of Fe88−xZr8B4Smx (x = 0, 1, 2, 3) amorphous alloys. Sci. China-Phys. Mech. Astron. 2018, 61, 056121. [Google Scholar] [CrossRef]

- Peng, J.X.; Tang, B.Z.; Wang, Q.; Bai, C.; Wu, Y.; Chen, Q.X.; Li, D.M.; Ding, D.; Xia, L.; Guo, X.L.; et al. Effect of heavy rare-earth (Dy, Tb, Gd) addition on the glass-forming ability and magneto-caloric properties of Fe89Zr7B4 amorphous alloy. J. Alloys Compd. 2022, 925, 166707. [Google Scholar] [CrossRef]

- Wang, X.; Tang, B.Z.; Wang, Q.; Yu, P.; Ding, D.; Xia, L. Co50Gd48−xFe2Nix amorphous alloys with high adiabatic temperature rise near the hot end of a domestic magnetic refrigerator. J. Non-Cryst. Solids 2020, 544, 120146. [Google Scholar] [CrossRef]

- Belo, J.H.; Amaral, J.S.; Pereira, A.M.; Amaral, V.S.; Araújo, J.P. On the Curie temperature dependency of the magnetocaloric effect. Appl. Phys. Lett. 2012, 100, 242407. [Google Scholar] [CrossRef]

- Franco, V.; Blázquez, J.S.; Conde, A. Field dependence of the magnetocaloric effect in materials with a second order phase transition: A master curve for the magnetic entropy change. Appl. Phys. Lett. 2006, 89, 222512. [Google Scholar] [CrossRef]

- Law, J.Y.; Franco, V.; Moreno-Ramírez, L.M.; Conde, A.; Karpenkov, D.Y.; Radulov, I.; Skokov, K.P.; Gutfleisch, O. A quantitative criterion for determining the order of magnetic phase transitions using the magnetocaloric effect. Nat. Commun. 2018, 9, 2680. [Google Scholar] [CrossRef]

- Zhang, Z.Y.; Tang, Q.; Wang, F.C.; Zhang, H.Y.; Zhou, Y.X.; Xia, A.L.; Li, H.L.; Chen, S.S.; Li, W.H. Tailorable magnetocaloric effect by Fe substitution in Gd-(Co, Fe) amorphous alloy. Intermetallics 2019, 111, 106500. [Google Scholar] [CrossRef]

- Yu, P.; Zhang, N.Z.; Cui, Y.T.; Wen, L.; Zeng, Z.Y.; Xia, L. Achieving an enhanced magneto-caloric effect by melt spinning a Gd55Co25Al20 bulk metallic glass into amorphous ribbons. J. Alloy Compd. 2016, 655, 353–356. [Google Scholar] [CrossRef]

- Xia, L.; Guan, Q.; Ding, D.; Tang, M.B.; Dong, Y.D. Magneto-caloric response of the Gd60Co25Al15 metallic glasses. Appl. Phys. Lett. 2014, 105, 192402. [Google Scholar] [CrossRef]

- Guan, Q.; Yu, P.; Chan, K.C.; Xia, L. Improvement of glass forming ability and magnetic properties of a Gd55Al20Co25 bulk metallic glass by minor Fe substitution for Co. Mod. Phys. Lett. B 2015, 29, 1550198. [Google Scholar] [CrossRef]

- Wu, C.; Yu, P.; Xia, L. Glass forming ability and magnetic properties of a Gd55Ni25Al18Zn2 bulk metallic glass. J. Non-Cryst. Solids 2015, 422, 23–25. [Google Scholar] [CrossRef]

| Samples | Tc (K) | −ΔSmpeak * (J/(kg·K)) | RC (J/kg) | Ref. | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1 T | 1.5 T | 2 T | 3 T | 4 T | 5 T | 2 T | 5 T | |||

| Gd45Co50Al5 | 253 | 1.35 | 1.83 | 2.28 | 3.09 | 3.85 | 4.55 | 260 | 728 | Present work |

| Gd45Co48Fe2Al5 | 262 | 1.17 | 1.60 | 2.00 | 2.73 | 3.40 | 4.04 | 274 | 723 | |

| Gd45Co45Fe5Al5 | 281 | 0.83 | 1.17 | 1.49 | 2.10 | 2.68 | 3.24 | ~300 | ~740 | |

| Gd45Co40Fe10Al5 | 317 | 0.56 | 0.83 | 1.10 | 1.60 | 2.33 | 2.57 | ~310 | ~770 | |

| Gd50Co50 | 267 | 1.38 | 2.36 | 3.16 | 3.92 | 4.6 | 212.8 | 685.9 | [18] | |

| Gd50Co48Fe2 | 277 | 2.24 | 4.44 | ~700 | [21] | |||||

| Co50Gd49Fe1 | 283 | 2.32 | 4.4 | 226.7 | 680 | [22] | ||||

| Co50Gd48Fe2 | 297 | 1.98 | 3.96 | ~241 | ~674 | |||||

| Co50Gd49Ni1 | 273 | 2.53 | 4.90 | 263.2 | 684.6 | [23] | ||||

| Co50Gd48Ni2 | 280 | 2.26 | 4.46 | 239.3 | 685.8 | |||||

| Co50Gd47Fe2Ni1 | 302 | 1.85 | 3.73 | ~211 | ~620 | [31] | ||||

| Co50Gd46Fe2Ni2 | 310 | 1.59 | 3.28 | ~231 | ~670 | |||||

| Fe88Zr8B4 | 291 | 1.5 | 2.81 | 200 | 551 | [27] | ||||

| Fe87Co1Zr8B4 | 317 | 1.61 | 3.24 | ~600 | [28] | |||||

| Fe87Zr8B4Sm1 | 308 | 1.65 | 3.27 | >550 | [29] | |||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, L.; Tang, B.; Fu, W.; Lu, Y.; Fu, Y.; Ding, D.; Xia, L.; Yu, P. The Effect of Fe Addition on the Curie Temperature and Magnetic Entropy of the Gd45Co50Al5 Amorphous Alloy. Materials 2023, 16, 4571. https://doi.org/10.3390/ma16134571

Li L, Tang B, Fu W, Lu Y, Fu Y, Ding D, Xia L, Yu P. The Effect of Fe Addition on the Curie Temperature and Magnetic Entropy of the Gd45Co50Al5 Amorphous Alloy. Materials. 2023; 16(13):4571. https://doi.org/10.3390/ma16134571

Chicago/Turabian StyleLi, Luyi, Benzhen Tang, Weijie Fu, Ying Lu, Yunqing Fu, Ding Ding, Lei Xia, and Peng Yu. 2023. "The Effect of Fe Addition on the Curie Temperature and Magnetic Entropy of the Gd45Co50Al5 Amorphous Alloy" Materials 16, no. 13: 4571. https://doi.org/10.3390/ma16134571

APA StyleLi, L., Tang, B., Fu, W., Lu, Y., Fu, Y., Ding, D., Xia, L., & Yu, P. (2023). The Effect of Fe Addition on the Curie Temperature and Magnetic Entropy of the Gd45Co50Al5 Amorphous Alloy. Materials, 16(13), 4571. https://doi.org/10.3390/ma16134571