High-Temperature Corrosion Behavior of Selected HVOF-Sprayed Super-Alloy Based Coatings in Aggressive Environment at 800 °C

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

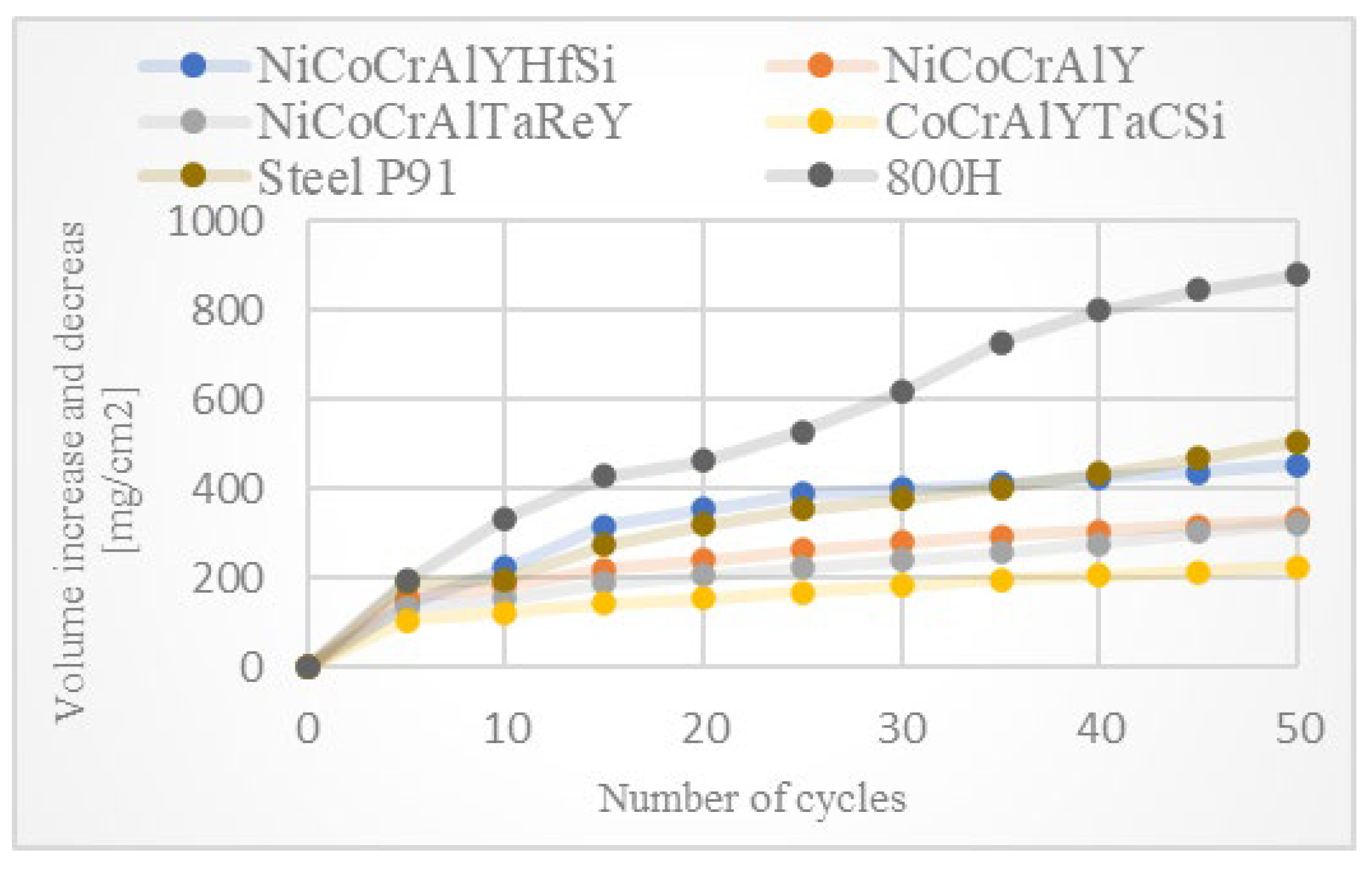

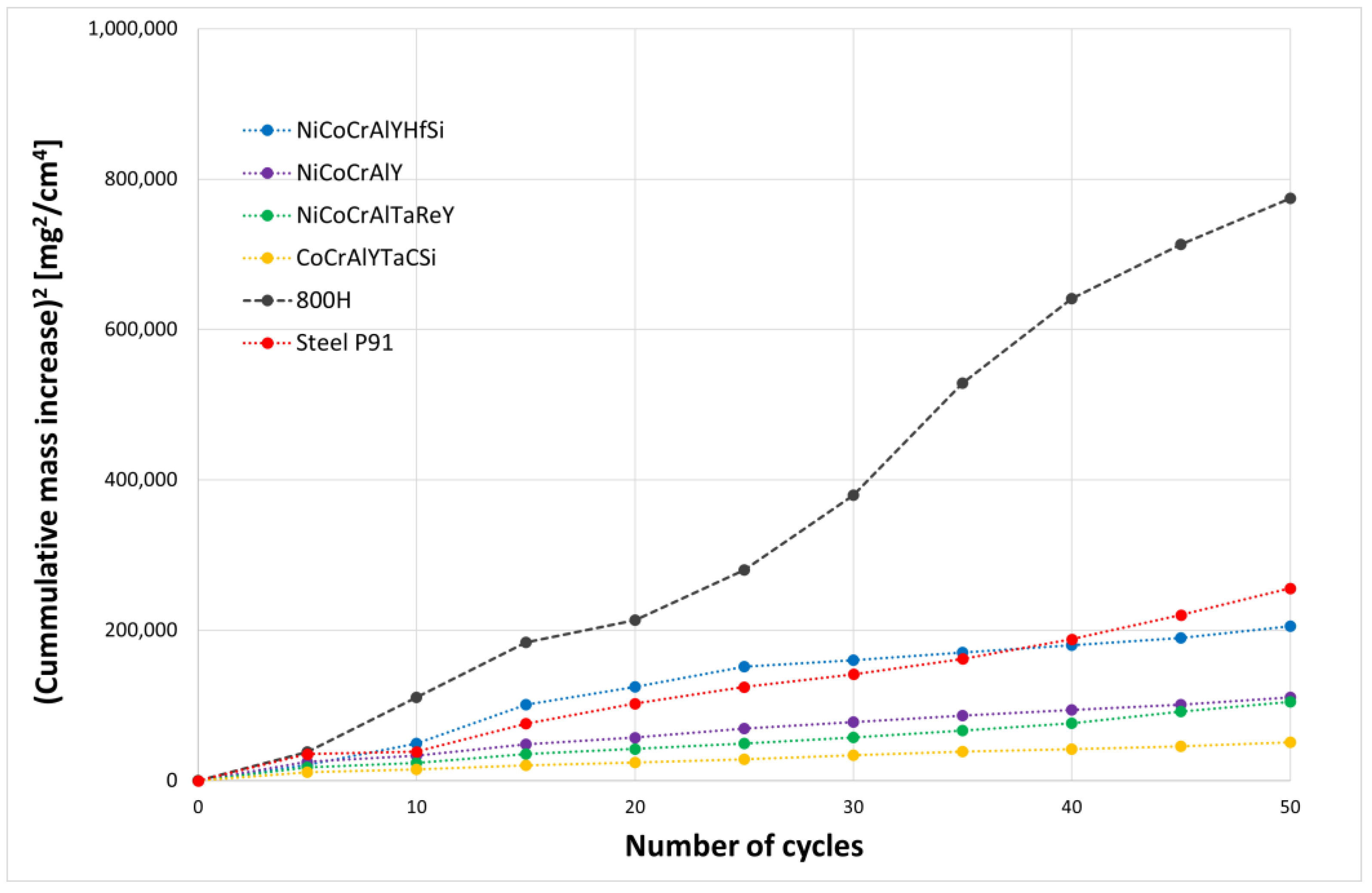

3.1. Corrosion Kinetics

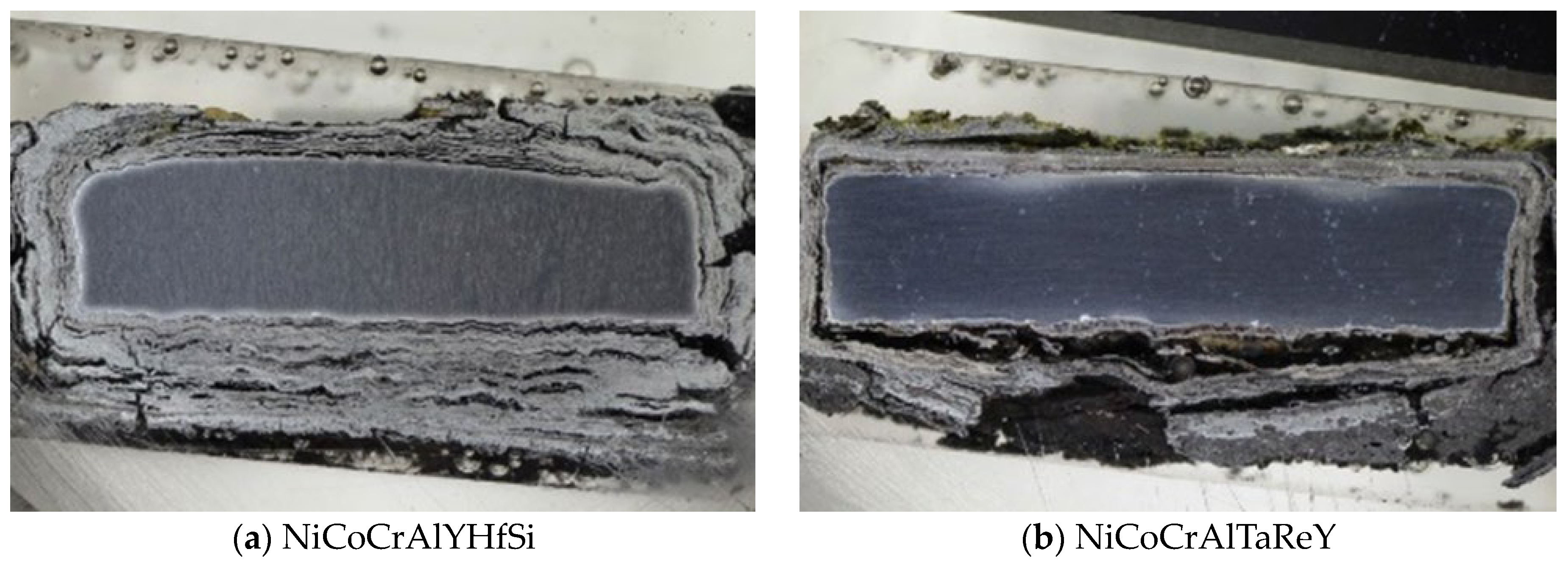

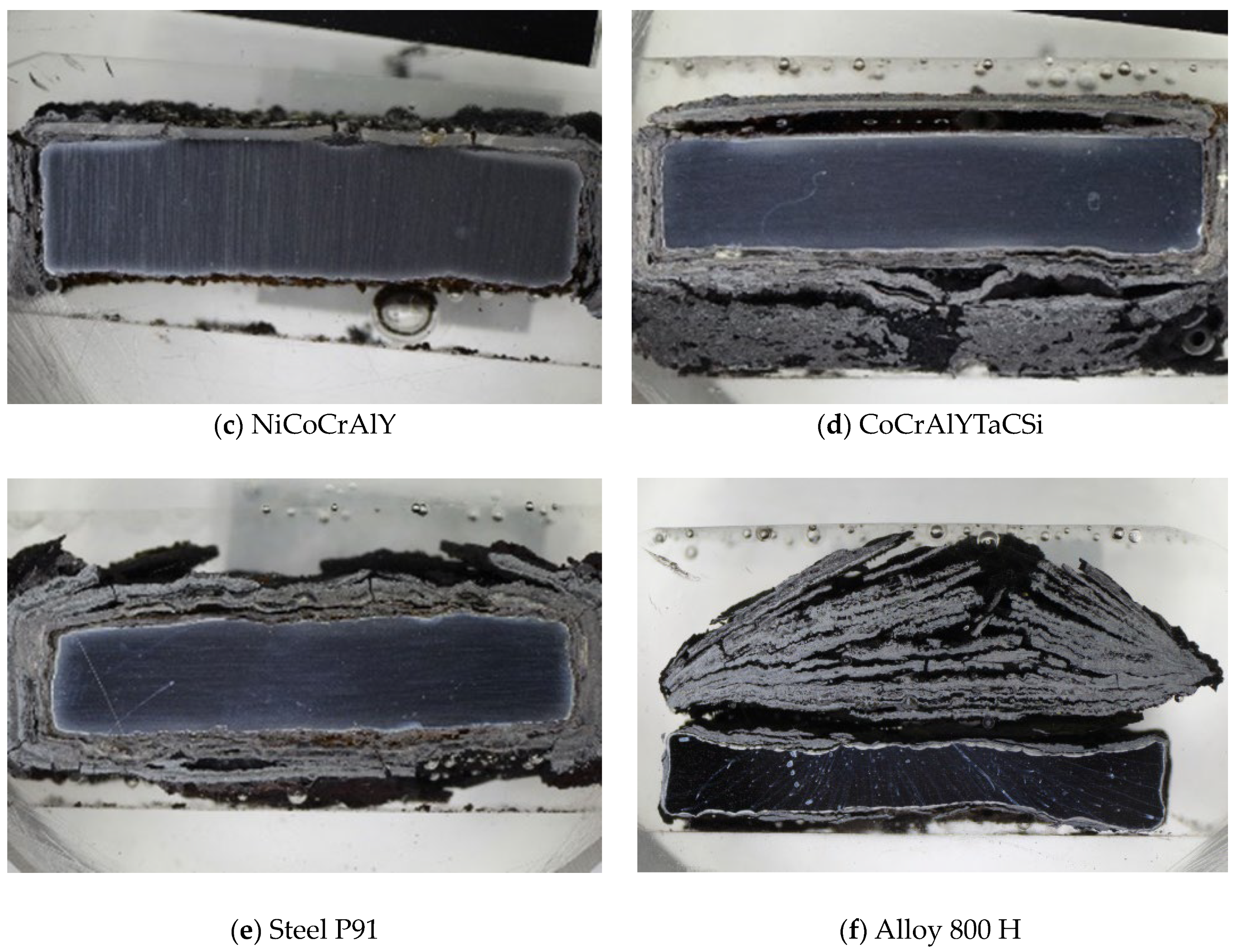

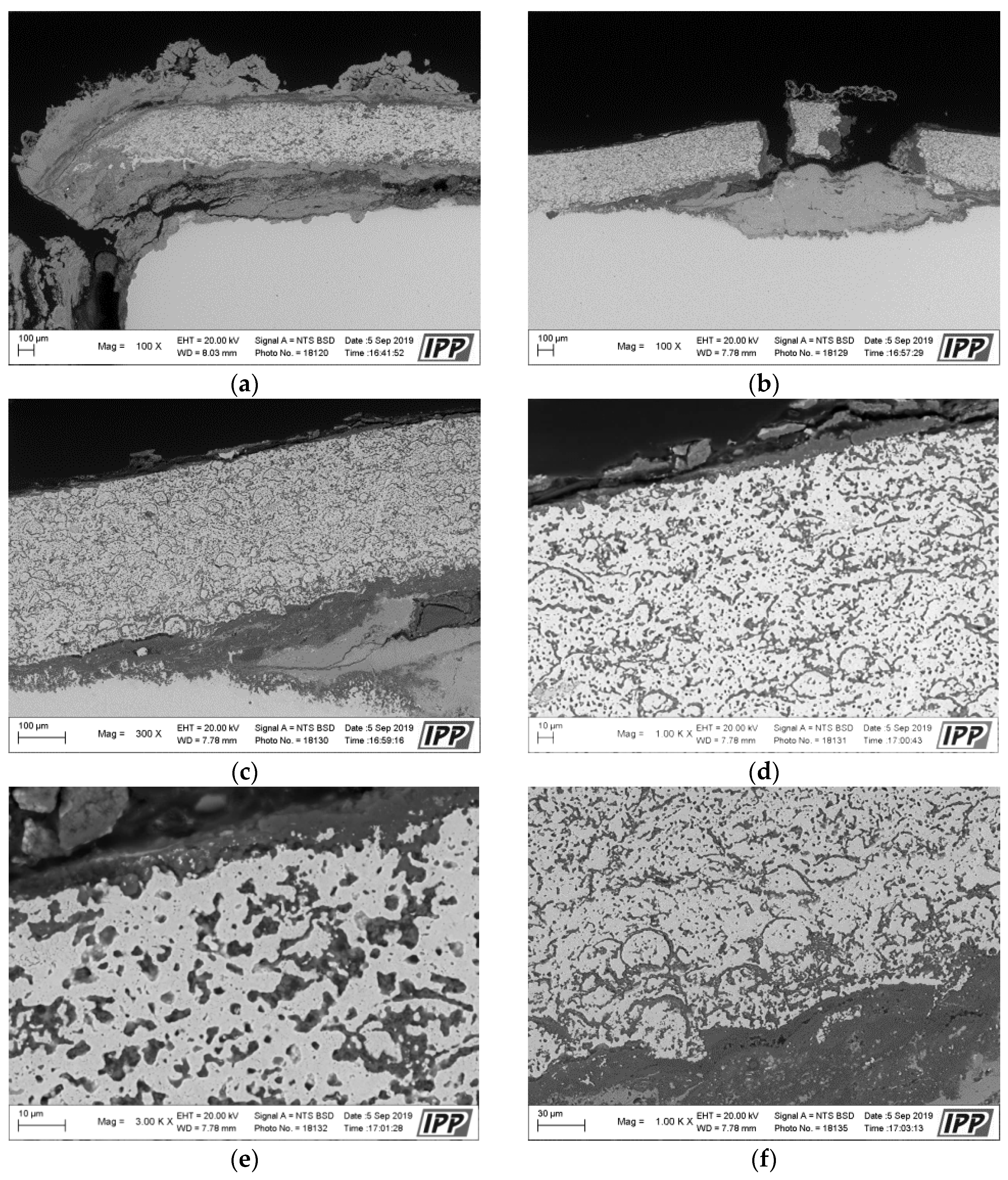

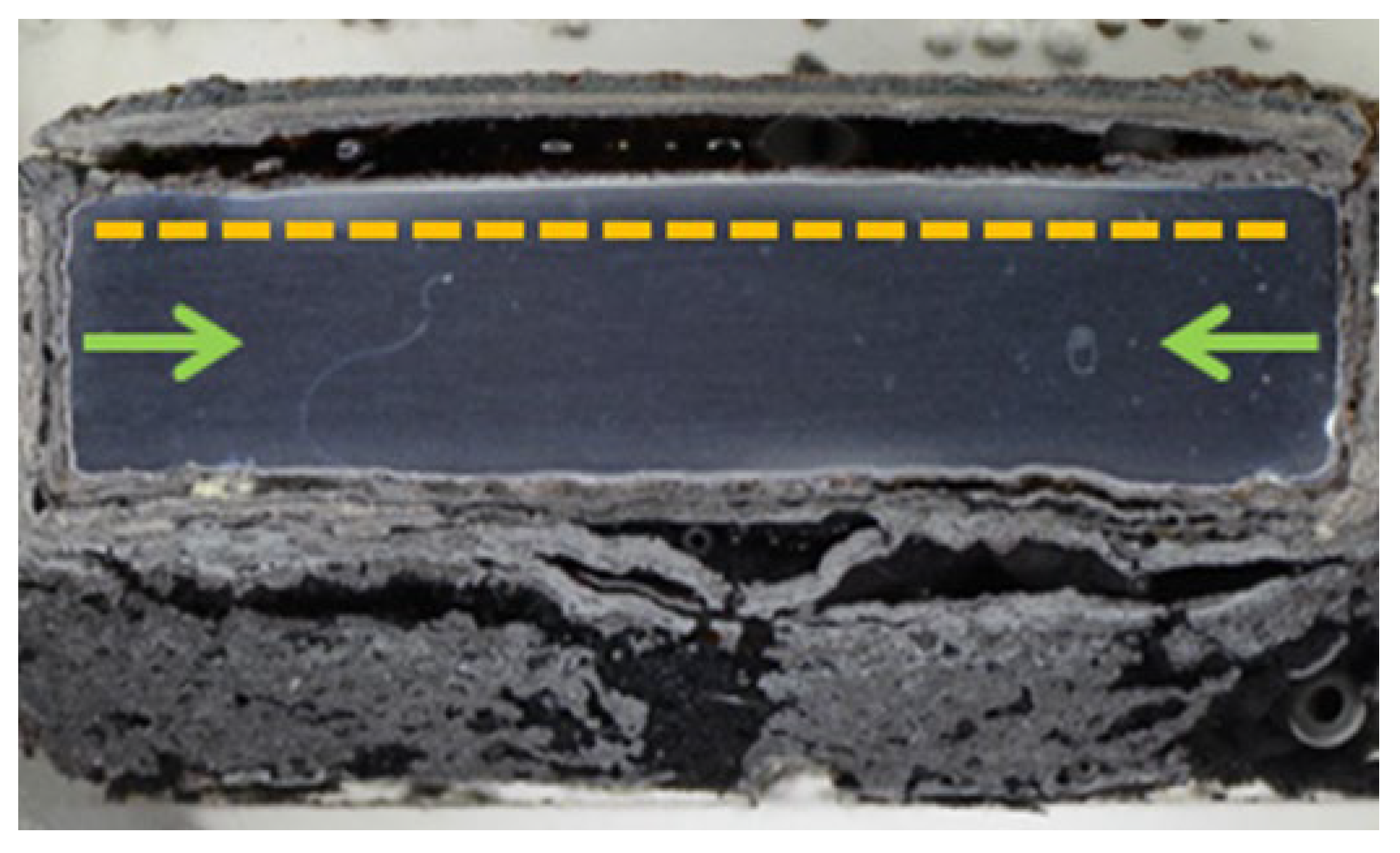

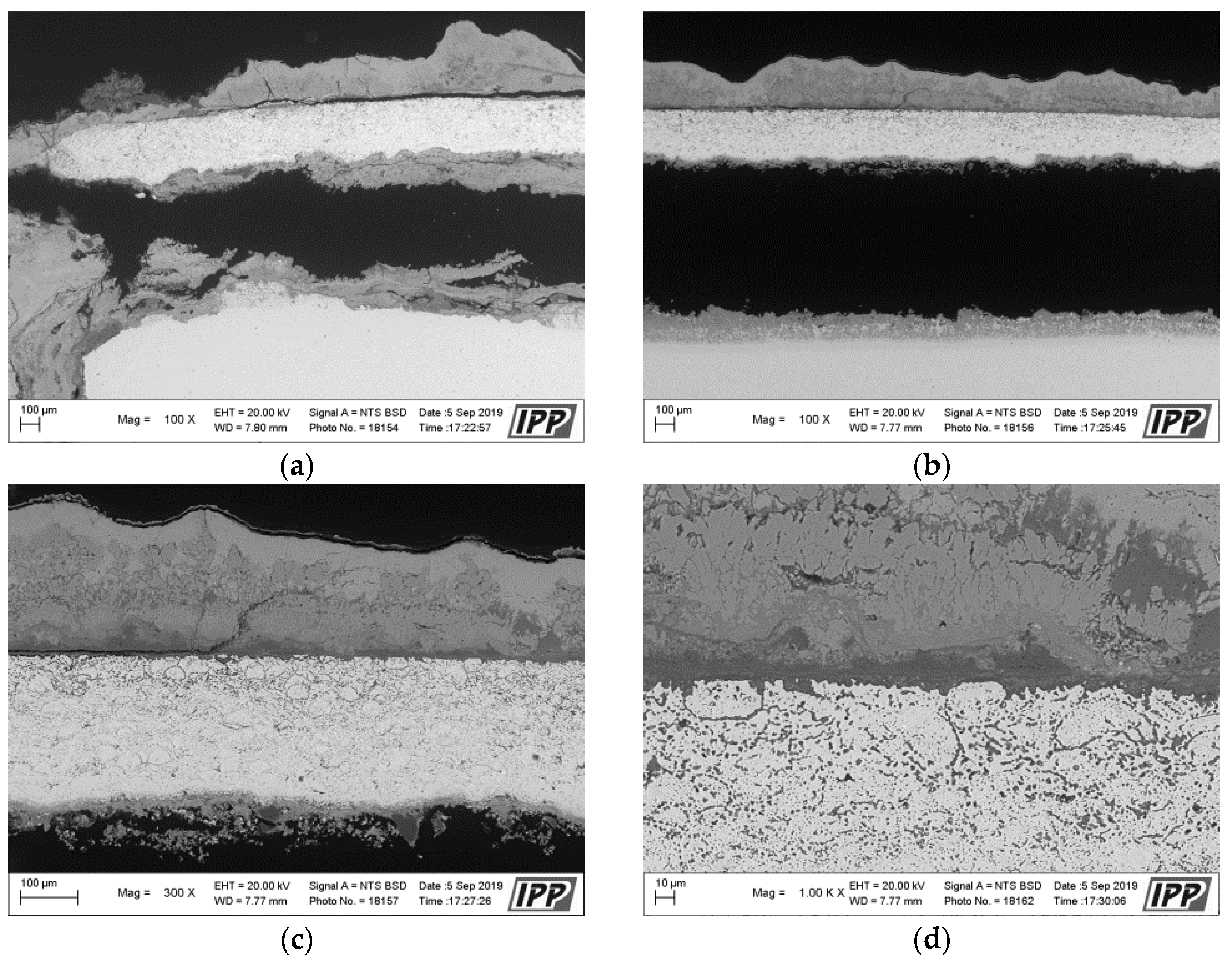

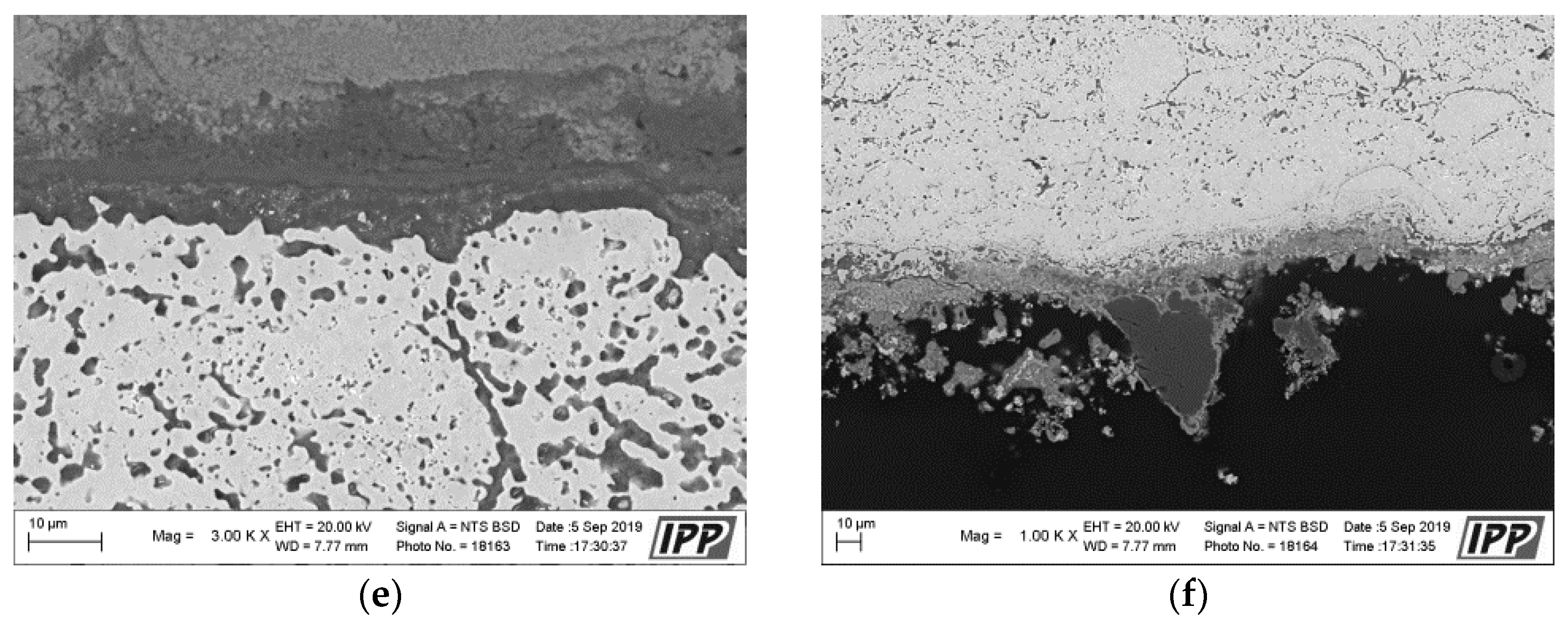

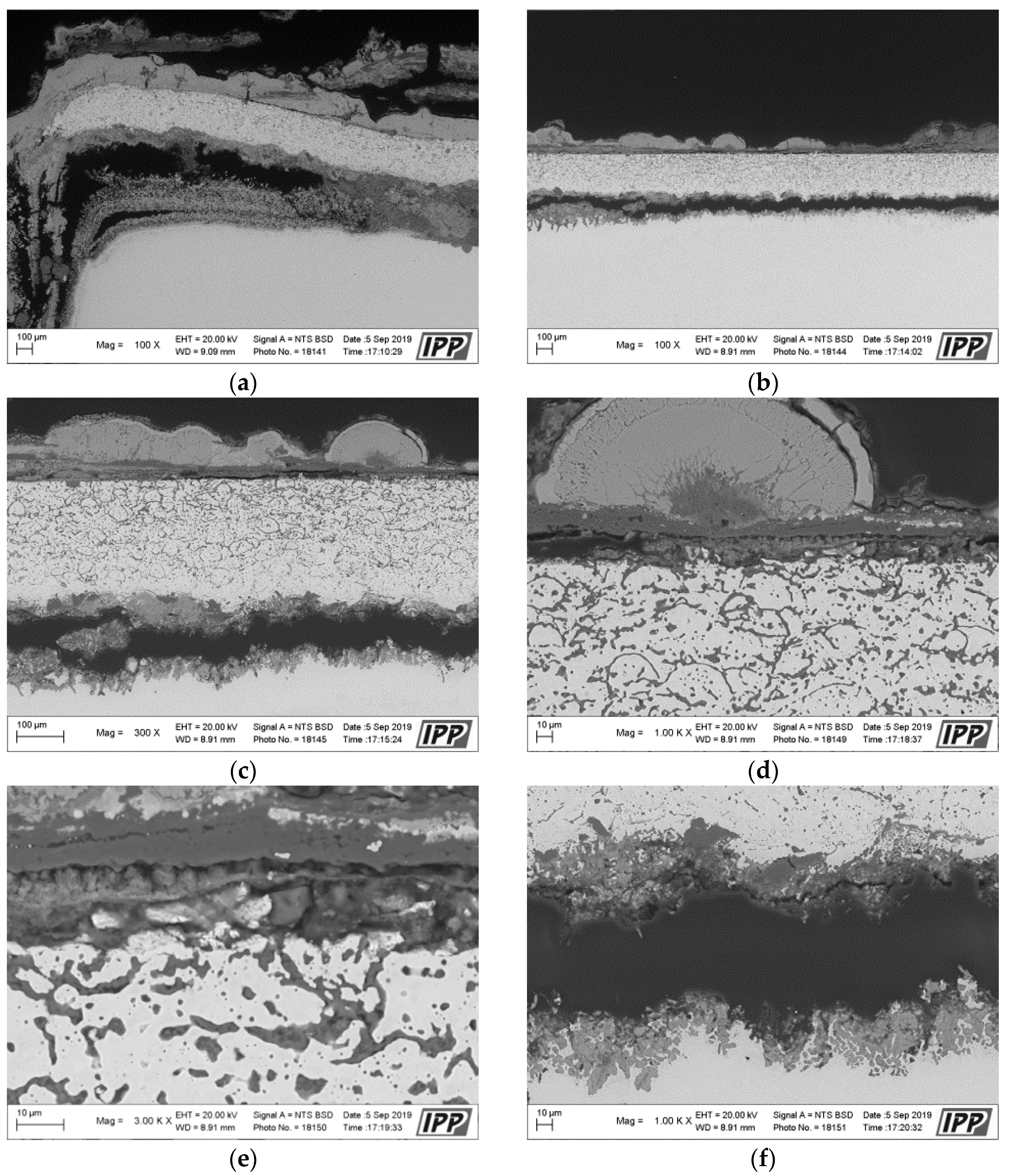

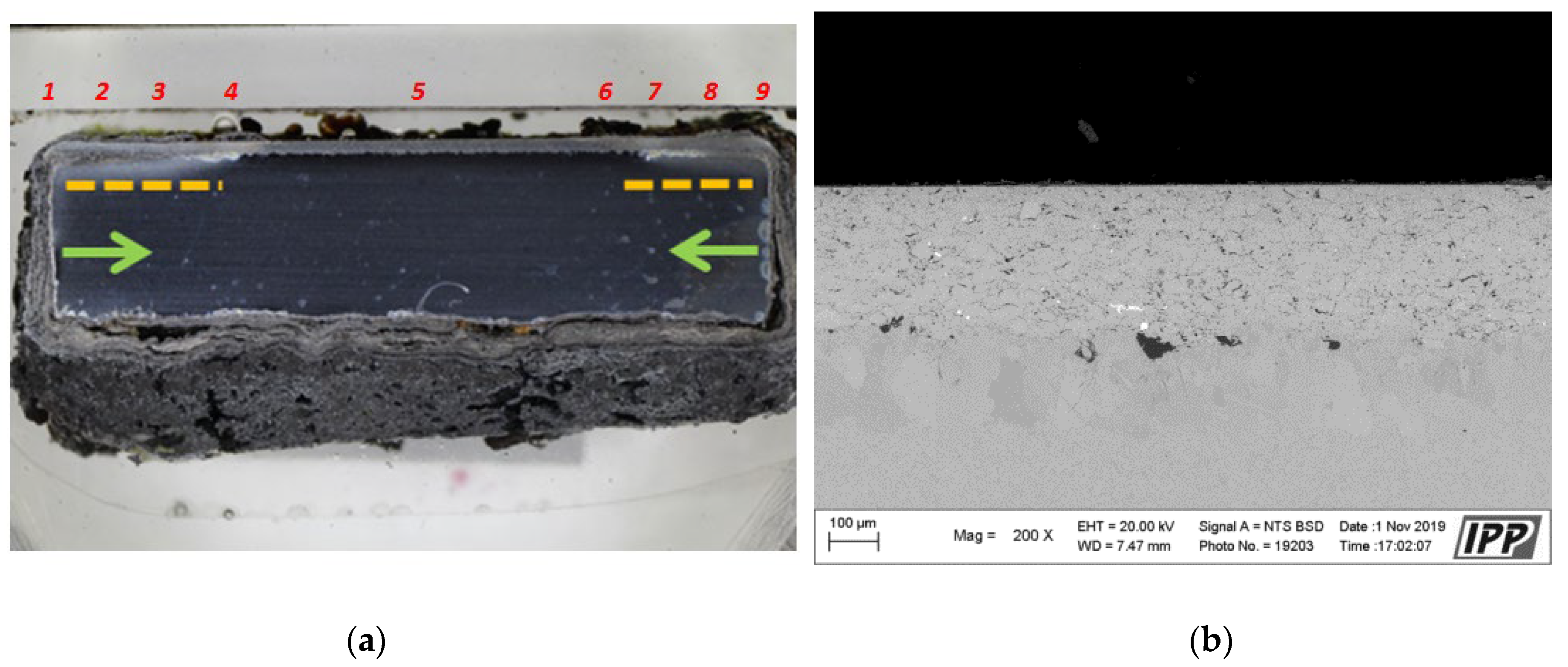

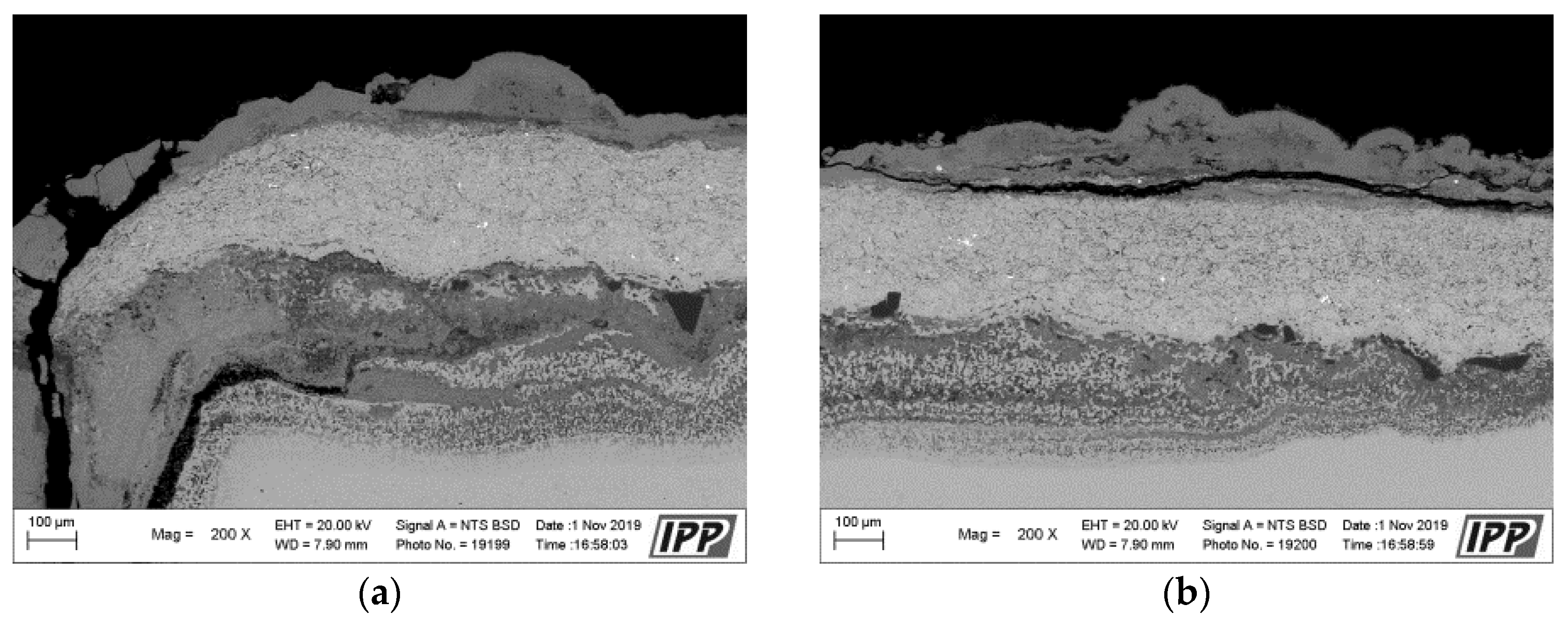

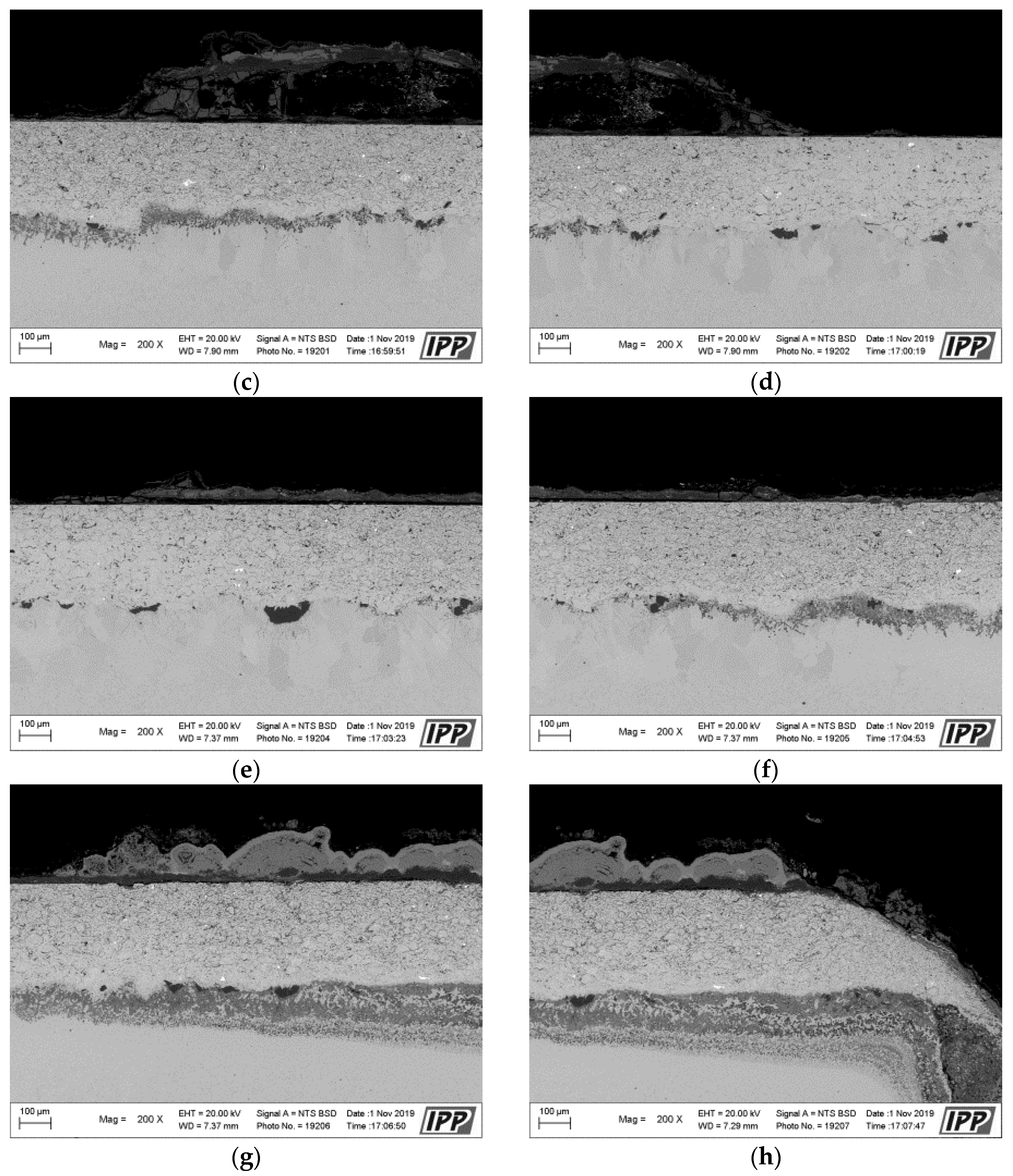

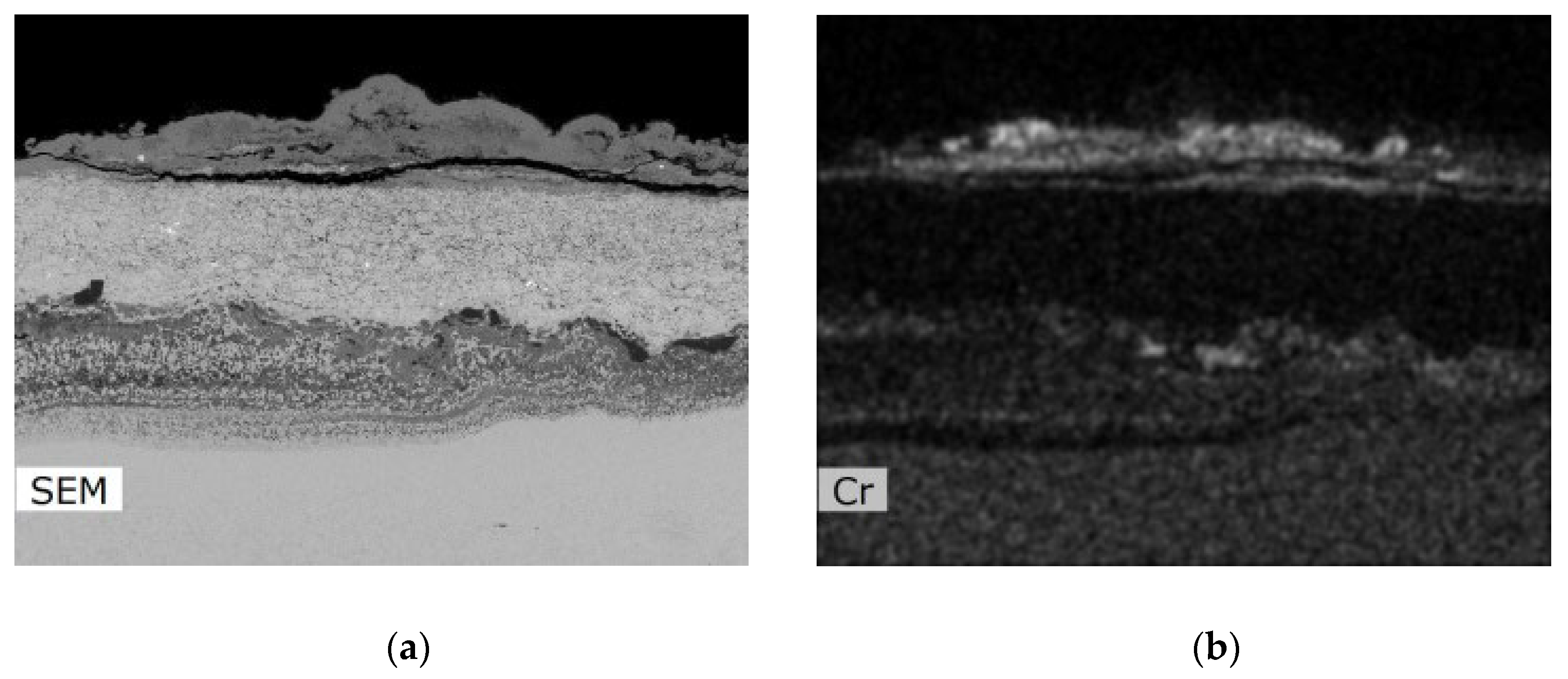

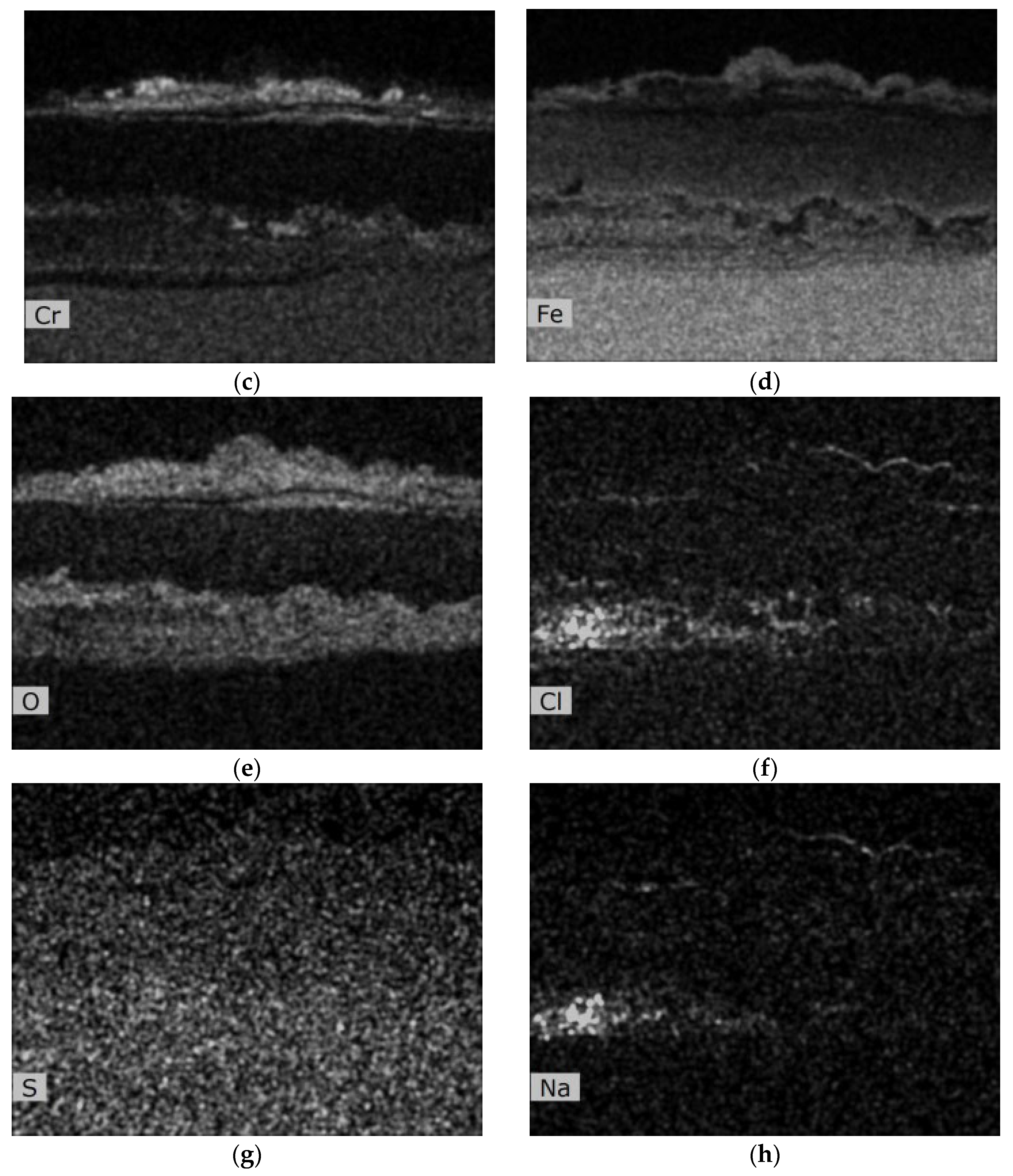

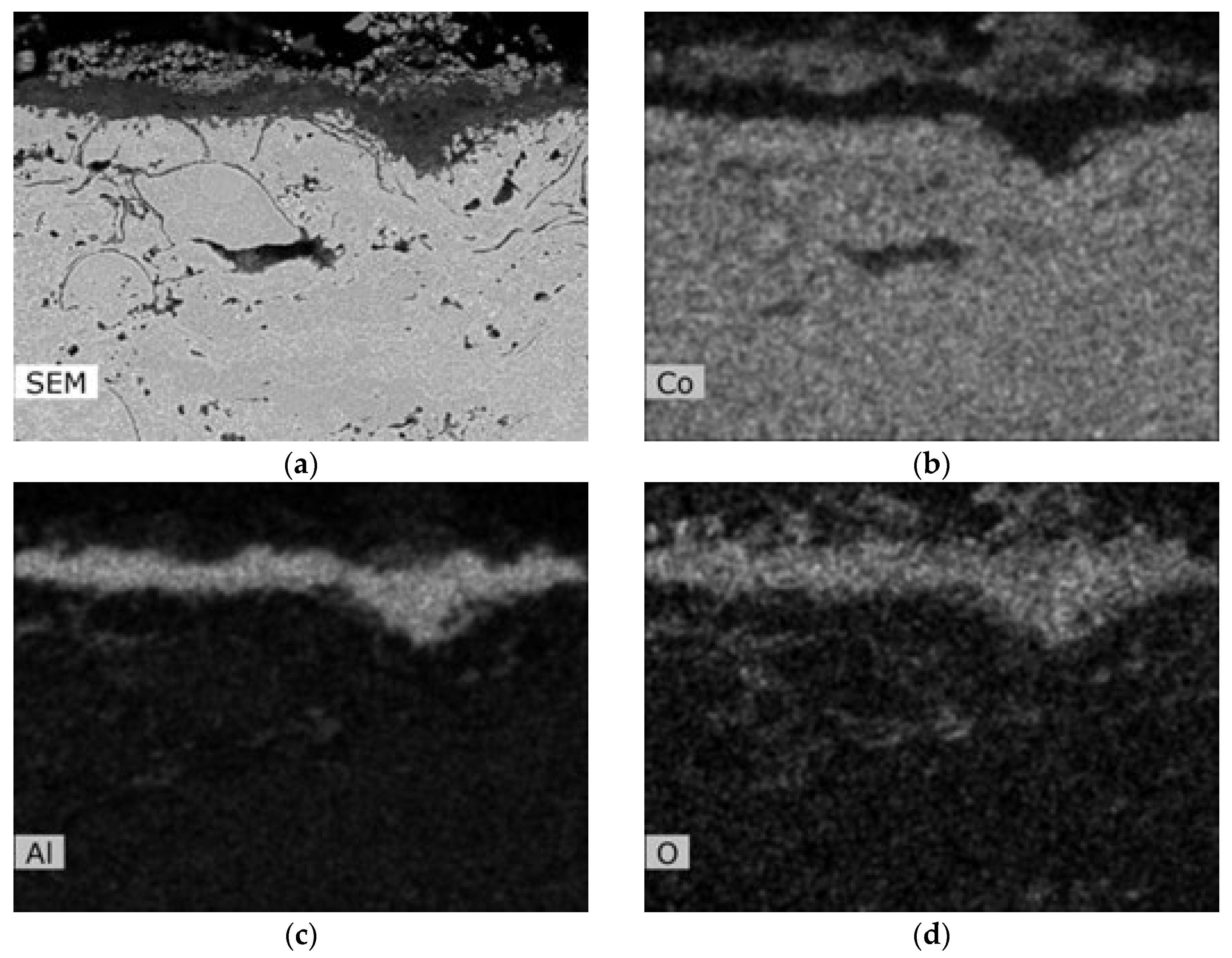

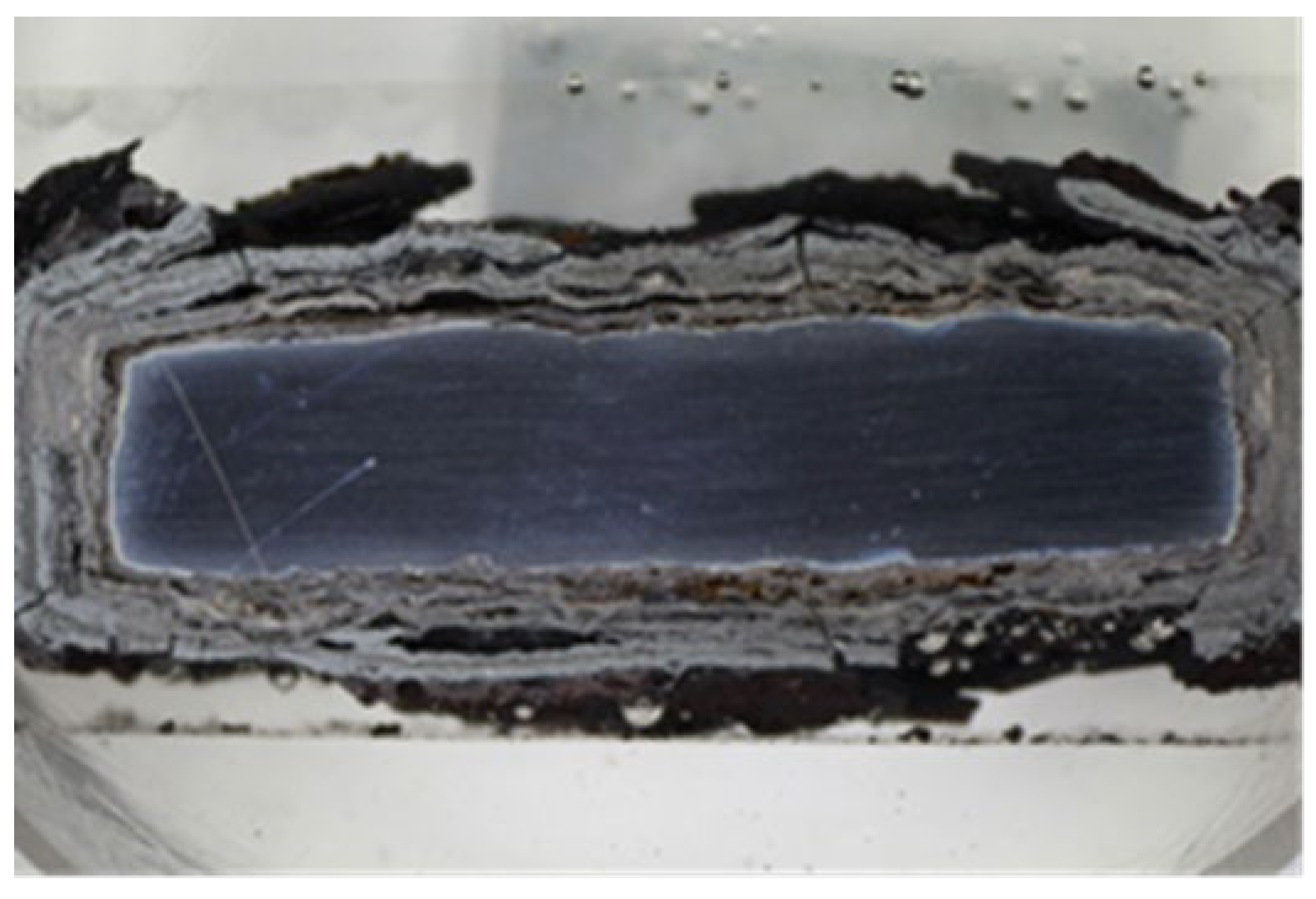

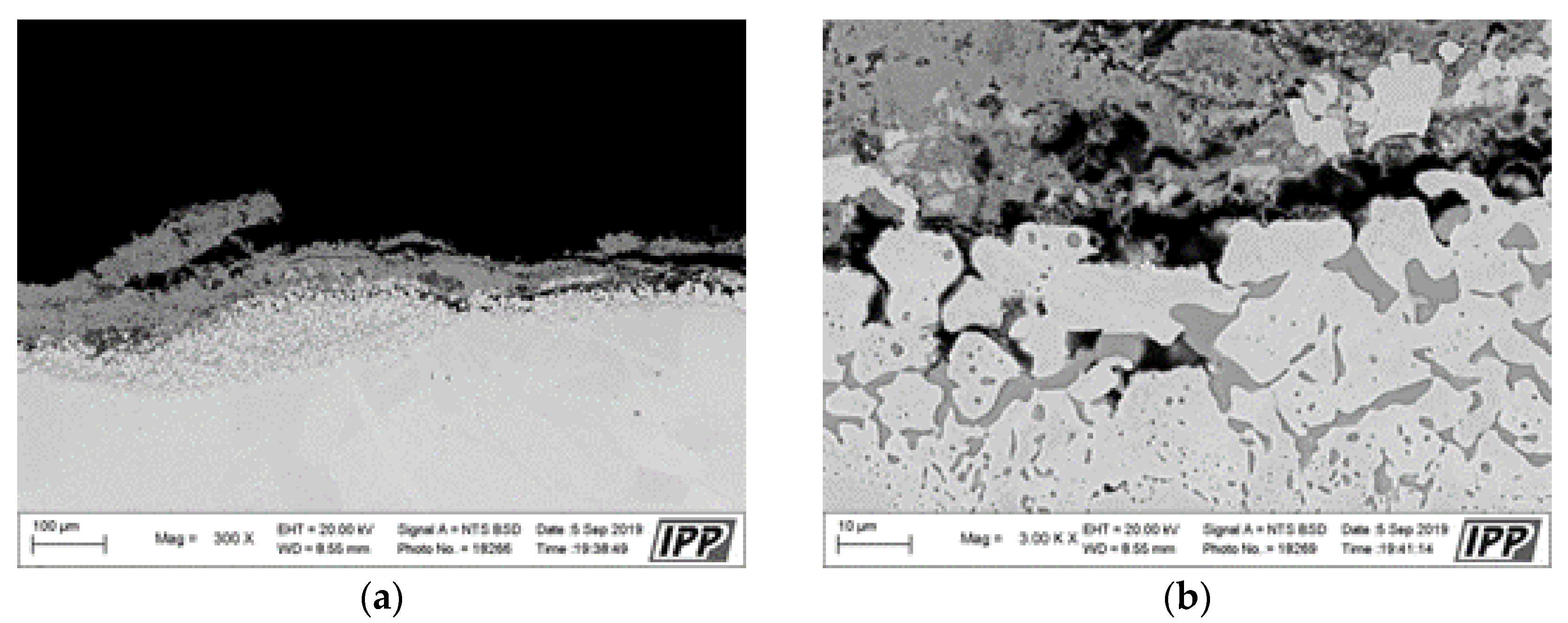

3.2. SEM/EDS Cross-Section Analysis

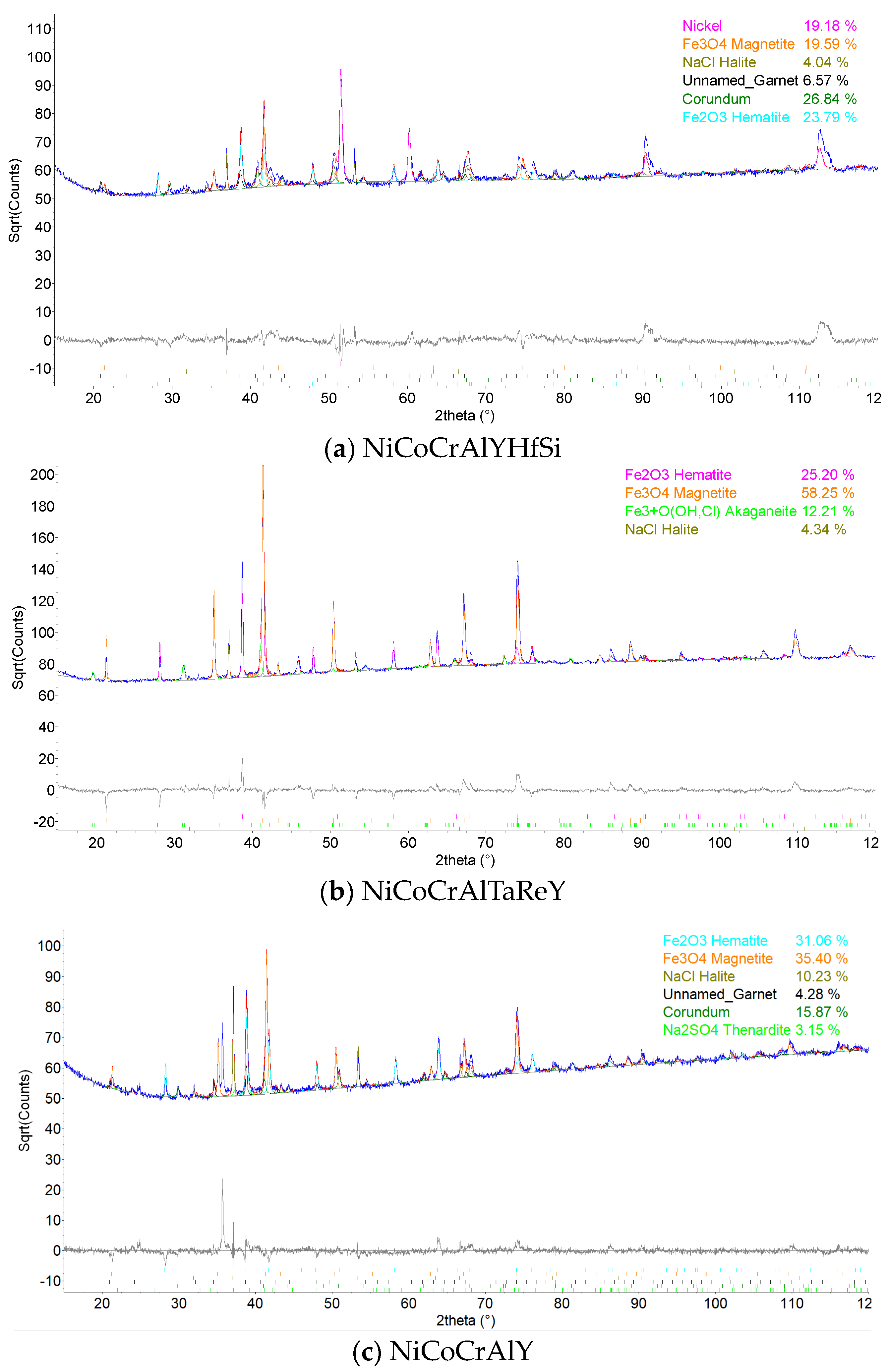

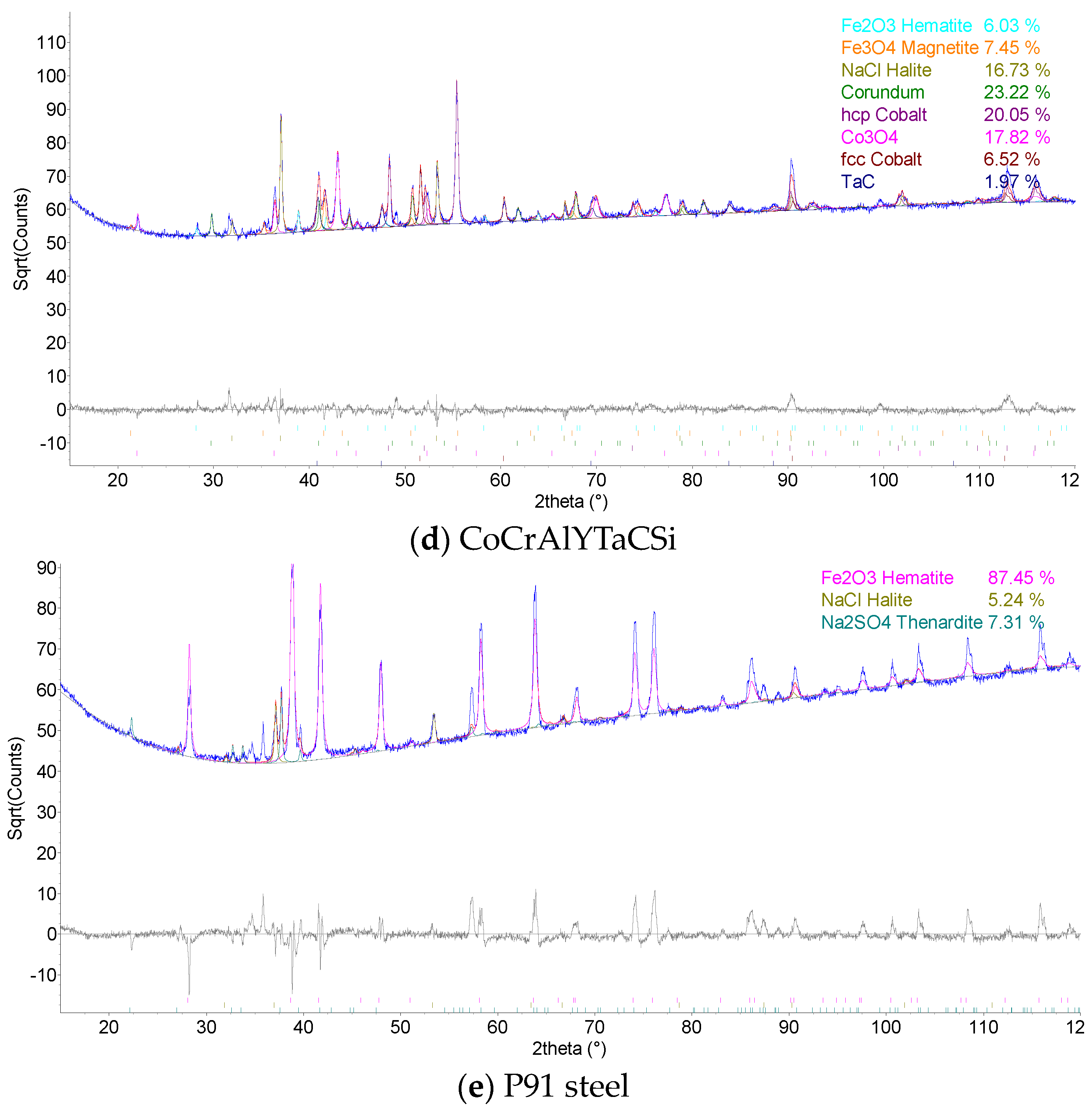

3.3. XRD Analysis

3.4. Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- He, J.; Xiong, W.; Zhang, W.; Li, W.; Long, K. Study on the high-temperature corrosion behavior of superheater steels of biomass-fired boiler in molten alkali salts’ mixtures. Adv. Mech. Eng. 2016, 18, 1687814016678163. [Google Scholar] [CrossRef]

- Sidhu, T.S.; Malik, A.; Prakash, S.; Agrawal, R.D. Oxidation and Hot Corrosion Resistance of HVOF WC-NiCrFeSiB Coating on Ni- and Fe-based Superalloys at 800 °C. J. Therm. Spray Technol. 2007, 16, 844–849. [Google Scholar] [CrossRef]

- Sidhu, T.S.; Malik, A.; Prakash, S.; Agrawal, R.D. Cyclic oxidation behavior of Ni and Fe-based superalloys in air and Na2SO4-25%NaCl molten salt environment at 800 °C. Int. J. Phys. Sci. 2006, 1, 27–33. [Google Scholar]

- Deb, D.; Ramakarishna, I.; Radhakrishnan, V.M. A comparative study of oxidation and hot corrosion of cast nickel base superalloy in different corrosive environments. Mater. Lett. 1996, 29, 19–23. [Google Scholar] [CrossRef]

- Badaruddin, M.; Risano AY, E.; Wardono, H.; Dwi, A. Hot-Corrosion of AISI 1020 Steel in a Molten NaCl/Na2SO4 Eutectic at 700 °C. Adv. Mech. Eng. AIP Conf. Proc. 2017, 1788, 030066. [Google Scholar]

- Gurrappa, I. Hot Corrosion Behavior of CM 247 LC Alloy in Na2SO4 and NaCl Environments. Adv. Mech. Eng. 1999, 51, 353–382. [Google Scholar]

- Hu, S.; Finklea, H.; Liu, X. A review on molten sulfate salts induced hot corrosion. J. Mater. Sci. Technol. 2021, 90, 243–254. [Google Scholar] [CrossRef]

- Santosh, K.; Manoj, K.; Amit, H. Combating hot corrosion of boiler tubes—A study. Eng. Fail. Anal. 2018, 94, 379–395. [Google Scholar]

- Jiang, Y.; Sun, Y.; Jacob, R.D.; Bruno, F.; Li, S. Novel Na2SO4-NaCl-ceramic composites as high temperature phase change materials for solar thermal power plants (Part I). Sol. Energy Mater. Sol. Cells 2018, 178, 74–83. [Google Scholar] [CrossRef]

- Lencová, K.; Frank Netrvalová, M.; Vostřák, M.; Lukáč, F.; Mušálek, R.; Česánek, Z.; Houdková, Š. Hot Corrosion Behavior of TWAS and HVOF NiCr-Based Coatings in Molten Salt. Materials 2023, 16, 1712. [Google Scholar] [CrossRef]

- Hruska, J.; Mlnarik, J.; Cizner, J. High-Temperature Corrosion of Nickel-Based Coatings for Biomass Boilers in Chlorine-Containing Atmosphere. Coatings 2022, 12, 116. [Google Scholar] [CrossRef]

- Alnaser, I.A.; Yunus, M.; Alfattani, R.; Alamro, T. High-Temperature Corrosion of APS- and HVOF-Coated Nickel-Based Super Alloy under Air Oxidation and Melted Salt Domains. Materials 2021, 14, 5119. [Google Scholar] [CrossRef]

- Ksiazek, M.; Nejman, I.; Boron, L. Investigation on Microstructure, Mechanical and Wear Properties of HVOF Sprayed Composite Coatings (WC–Co + CR) On Ductile Cast Iron. Materials 2021, 14, 3282. [Google Scholar] [CrossRef]

- Singh, S.; Goyal, K.; Bhatia, R. A review on protection of boiler tube steels with thermal spray coatings from hot corrosion. Mater. Today Proc. 2022, 56, 379–383. [Google Scholar] [CrossRef]

- Salehnasab, B.; Poursaeidi, E.; Mortazavi, S.; Farokhian, G. Hot corrosion failure in the first stage nozzle of a gas turbine engine. Eng. Fail. Anal. 2016, 60, 316–325. [Google Scholar] [CrossRef]

- Eliaz, N.; Shemesh, G.; Latanision, R.M. Hot corrosion in gas turbine components. Eng. Fail. Anal. 2002, 9, 31–43. [Google Scholar] [CrossRef]

- Karlsson, S.; Åmand, L.-E.; Liske, J. Reducing high-temperature corrosion on high-alloyed stainless steel superheaters by co-combustion of municipal sewage sludge in a fluidised bed boiler. Fuel 2015, 139, 482–493. [Google Scholar] [CrossRef]

- Lee, S.-H.; Themelis, N.J.; Castaldi, M.J. High-temperature corrosion in waste-to-energy boilers. J. Therm. Spray Technol. 2007, 16, 104–110. [Google Scholar] [CrossRef]

- Kawahara, K. Application of high temperature corrosion-resistant materials and coatings under severe corrosive environment in waste-to-energy boilers. J. Therm. Spray Technol. 2007, 16, 202–213. [Google Scholar] [CrossRef]

- Niu, K.; Tan, H.; Hui, S. Ash-related issues during biomass combustion: Alkali-induced slagging, silicate melt-induced slagging (ash fusion), agglomeration, corrosion, ash utilization, and related countermeasures. Prog. Energy Combust. Sci. 2016, 52, 1–61. [Google Scholar] [CrossRef]

- Yuan, K.; Peng, R.L.; Li, X.-H.; Talus, A.; Johansson, S.; Wang, Y.-D. Hot corrosion of MCrAlY coatings in sulphate and SO2 environment at 900° C: Is SO2 necessarily bad? Surf. Coat. Technol. 2015, 261, 41–53. [Google Scholar] [CrossRef]

- Paz, M.D.; Phother-Simon, J.; Andersson, S.; Jonsson, T. High temperature corrosion memory in a waste fired boiler–Influence of sulfur. Waste Manag. 2021, 130, 30–37. [Google Scholar] [CrossRef] [PubMed]

- Yuan, K.; Peng, R.L.; Li, X.-H.; Johansson, S. Hot corrosion behavior of HVOF-sprayed CoNiCrAlYSi coatings in a sulphate environment. Vacuum 2015, 122, 47–53. [Google Scholar] [CrossRef]

- Wang, Q.; Zhou, D.; Yu, M.; Shi, L.; Li, X.; Sun, Q. Oxidation and hot corrosion behaviors of Mo-doped NiMoAlY alloys at 750° C. Corros. Sci. 2022, 201, 110262. [Google Scholar] [CrossRef]

- Mobarra, R.; Jafari, A.H.; Karaminezhaad, M. Hot corrosion behavior of MCrAlY coatings on IN738LC. Surf. Coat. Technol. 2006, 201, 2202–2207. [Google Scholar] [CrossRef]

- Sidhu, T.S.; Prakash, S.; Agrawal, R.D. Hot corrosion and performance of nickel-based coatings. Curr. Sci. 2006, 90, 41–47. [Google Scholar]

| Coating/Specimen | Major Phases | Minor Phases |

|---|---|---|

| NiCoCrAlYHfSi | Al2O3, Fe2O3, Fe3O4, Ni | Garnet, NaCl |

| NiCoCrAlTaReY | Fe3O4, Fe2O3, Fe3 + O (OH, Cl) | NaCl |

| NiCoCrAlY | Fe3O4, Fe2O3, Al2O3, NaCl | Garnet, Na2SO4 |

| CoCrAlYTaCSi | Al2O3, hcp Co, Co3O4, NaCl | Fe3O4, fcc Co, Fe2O3 |

| P91 steel | Fe2O3 | Na2SO4, NaCl |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Česánek, Z.; Lencová, K.; Schubert, J.; Antoš, J.; Mušálek, R.; Lukáč, F.; Palán, M.; Vostřák, M.; Houdková, Š. High-Temperature Corrosion Behavior of Selected HVOF-Sprayed Super-Alloy Based Coatings in Aggressive Environment at 800 °C. Materials 2023, 16, 4492. https://doi.org/10.3390/ma16124492

Česánek Z, Lencová K, Schubert J, Antoš J, Mušálek R, Lukáč F, Palán M, Vostřák M, Houdková Š. High-Temperature Corrosion Behavior of Selected HVOF-Sprayed Super-Alloy Based Coatings in Aggressive Environment at 800 °C. Materials. 2023; 16(12):4492. https://doi.org/10.3390/ma16124492

Chicago/Turabian StyleČesánek, Zdeněk, Kateřina Lencová, Jan Schubert, Jakub Antoš, Radek Mušálek, František Lukáč, Marek Palán, Marek Vostřák, and Šárka Houdková. 2023. "High-Temperature Corrosion Behavior of Selected HVOF-Sprayed Super-Alloy Based Coatings in Aggressive Environment at 800 °C" Materials 16, no. 12: 4492. https://doi.org/10.3390/ma16124492

APA StyleČesánek, Z., Lencová, K., Schubert, J., Antoš, J., Mušálek, R., Lukáč, F., Palán, M., Vostřák, M., & Houdková, Š. (2023). High-Temperature Corrosion Behavior of Selected HVOF-Sprayed Super-Alloy Based Coatings in Aggressive Environment at 800 °C. Materials, 16(12), 4492. https://doi.org/10.3390/ma16124492