Energy Harvesting of Deionized Water Droplet Flow over an Epitaxial Graphene Film on a SiC Substrate

Abstract

1. Introduction

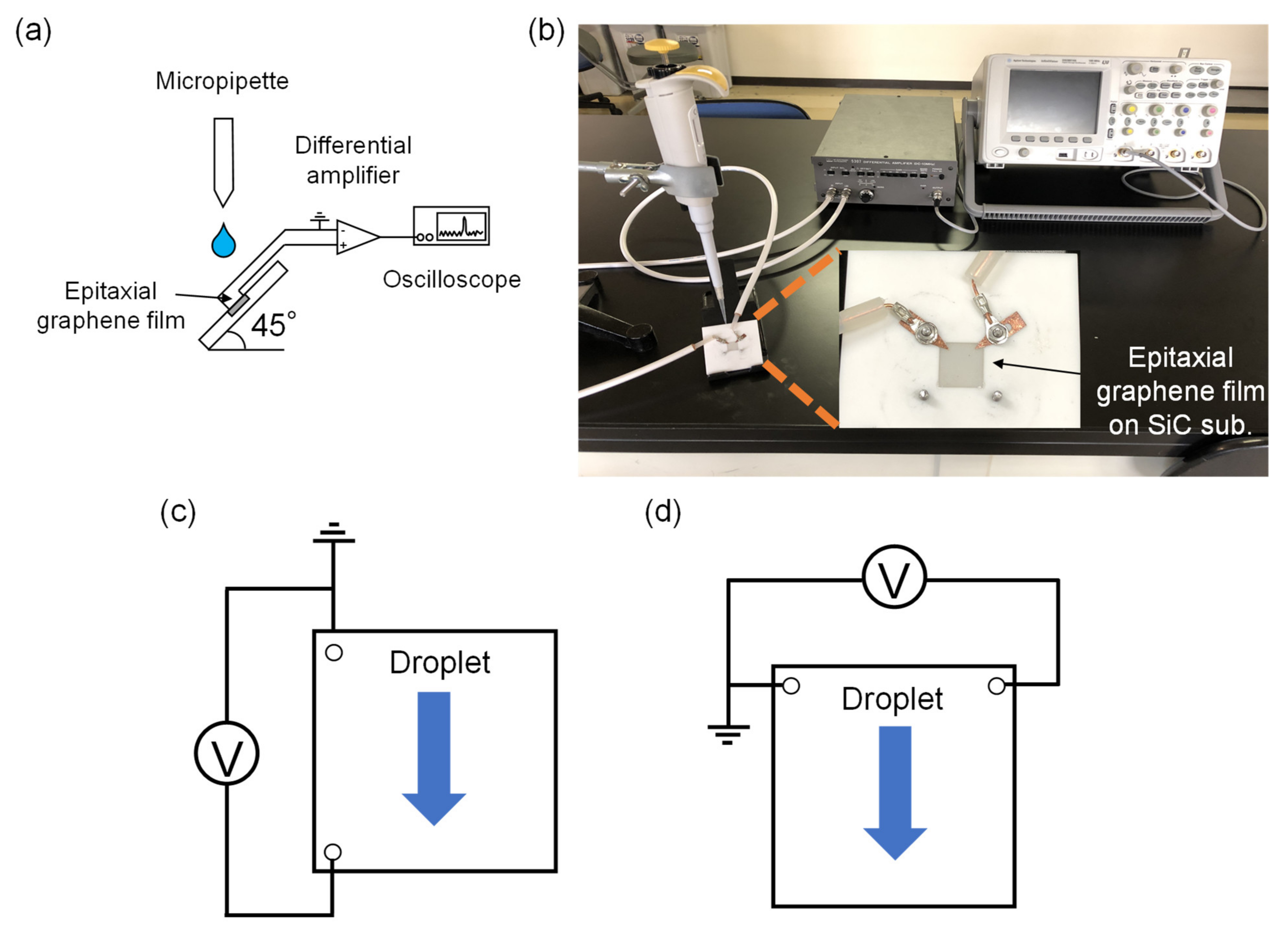

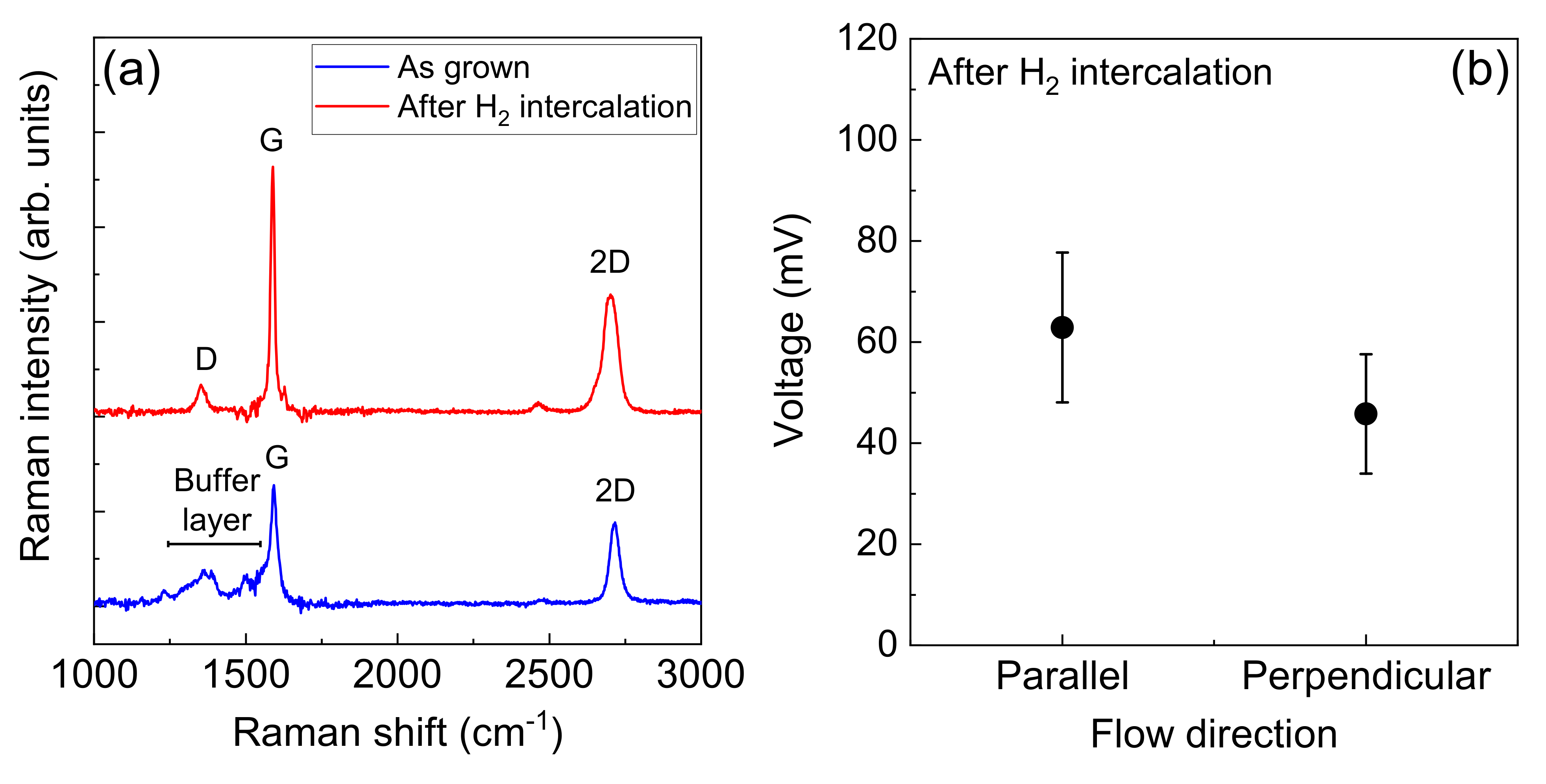

2. Materials and Methods

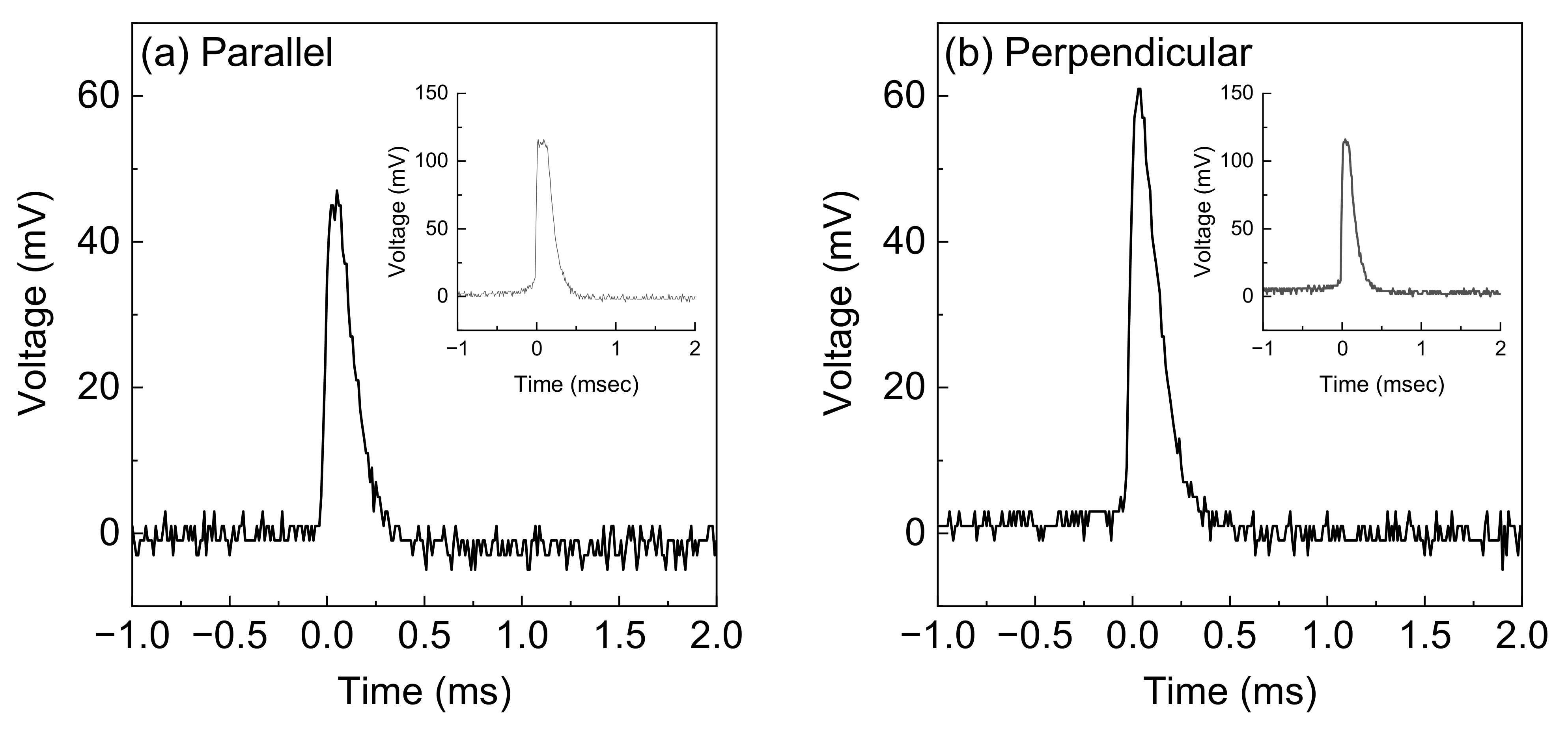

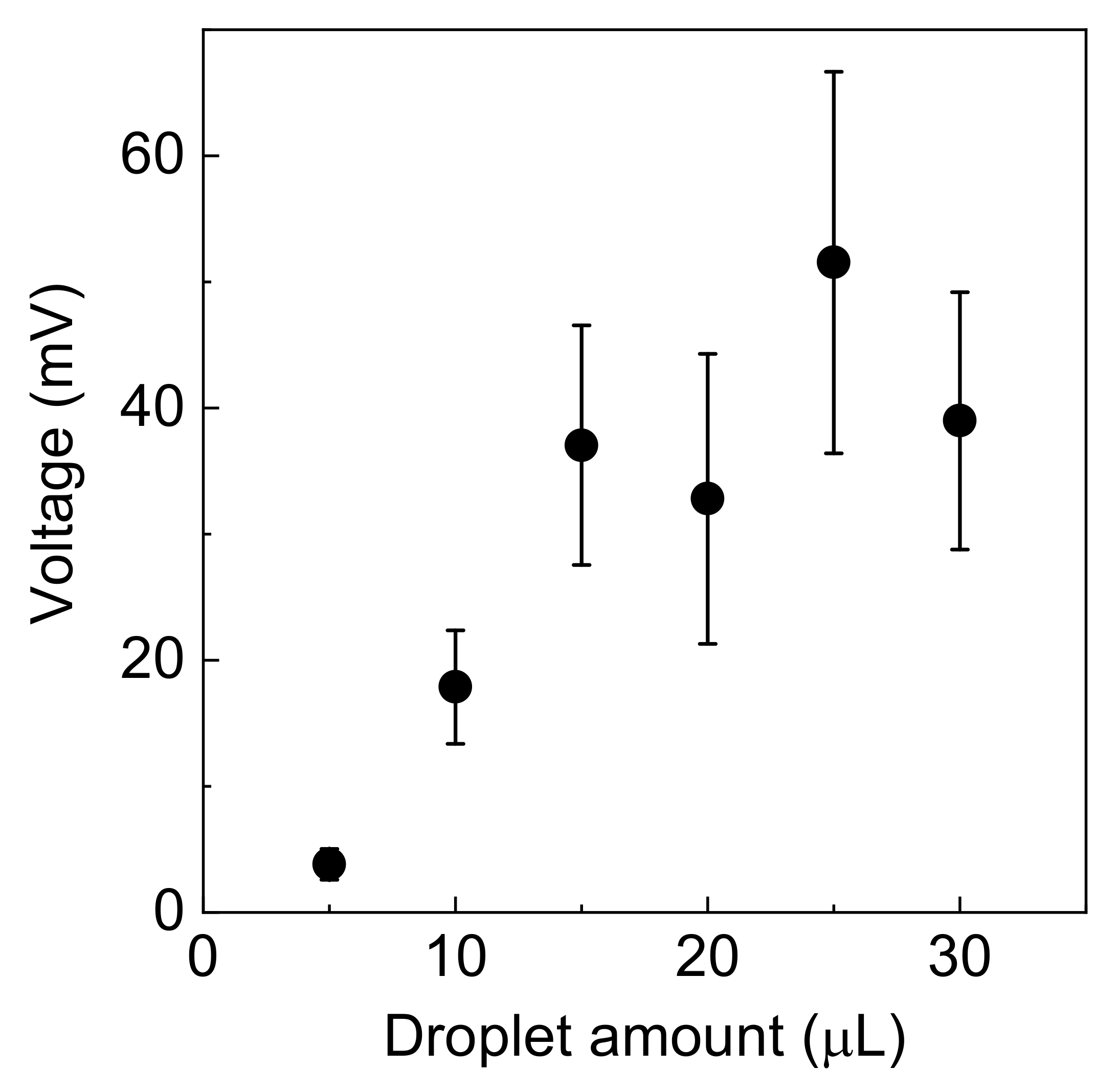

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Geim, A.K.; Novoselov, K.S. The rise of graphene. Nat. Mater. 2007, 6, 183–191. [Google Scholar] [CrossRef] [PubMed]

- Novoselov, K.S.; Minshchenko, A.; Carvalho, A.; Castro Neto, A.H. 2D materials and van der Waals heterostructures. Science 2016, 353, aac9439. [Google Scholar] [CrossRef]

- Kim, T.; Fan, S.; Lee, S.; Joo, M.K.; Lee, Y.H. High–mobility junction field–effect transistor via graphene/MoS2 heterointerface. Sci. Rep. 2020, 10, 13101. [Google Scholar] [CrossRef] [PubMed]

- Melnikova-Kominkova, Z.; Jurkova, K.; Vales, V.; Drogowska-Horná, K.; Frank, O.; Kalbac, M. Strong and efficient doping of monolayer MoS2 by a graphene electrode. Phys. Chem. Chem. Phys. 2019, 21, 25700–25706. [Google Scholar] [CrossRef]

- Schedin, F.; Geim, A.K.; Morozov, S.V.; Hill, E.W.; Blake, P.; Katsnelson, M.I.; Novoselov, K.S. Detection of individual gas molecules adsorbed on graphene. Nat. Mater. 2007, 6, 652–655. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.W.; Hung, S.C.; Yang, M.D.; Yeh, C.W.; Wu, C.H.; Chi, G.C.; Ren, F.; Pearton, S.J. Oxygen sensors made by monolayer graphene under room temperature. Appl. Phys. Lett. 2011, 99, 243502. [Google Scholar] [CrossRef]

- Chen, G.; Paronyan, T.M.; Harutyunyan, A.R. Sub-ppt gas detection with pristine graphene. Appl. Phys. Lett. 2012, 101, 053119. [Google Scholar] [CrossRef]

- Wu, H.; Li, Q.; Bu, X.; Liu, W.; Cao, G.; Li, X.; Wang, X. Gas sensing performance of graphene-metal contact after thermal annealing. Sens. Actuators B 2019, 282, 408–416. [Google Scholar] [CrossRef]

- Li, H.; Han, X.; Childress, A.S.; Rao, A.M.; Koley, G. Investigation of carrier density and mobility variations in graphene caused by surface adsorbates. Physica E 2019, 107, 96–100. [Google Scholar] [CrossRef]

- Ohno, Y.; Maehashi, K.; Yamashiro, Y.; Matsumoto, K. Electrolyte-gated graphene field-effect transistors for detecting pH and protein adsorption. Nano Lett. 2009, 9, 3318–3322. [Google Scholar] [CrossRef]

- Ohno, Y.; Maehashi, K.; Matsumoto, K. Label–free biosensors based on aptamer–modified graphene field–effect transistors. J. Am. Chem. Soc. 2010, 132, 18012–18013. [Google Scholar] [CrossRef]

- Wang, L.; Wang, X.; Wu, Y.; Guo, M.; Gu, C.; Dai, C.; Kong, D.; Wang, Y.; Zhang, C.; Qu, D.; et al. Rapid and ultrasensitive electromechanical detection of ions, biomolecules and SARS-CoV-2 RNA in unamplified samples. Nat. Biomed. Eng. 2022, 6, 276–285. [Google Scholar] [CrossRef]

- Rodrigues, T.; Mishyn, V.; Leroux, Y.R.; Butruille, L.; Woitrain, E.; Barras, A.; Aspermair, P.; Happy, H.; Kleber, C.; Boukherroub, R.; et al. Highly performing graphene-based field effect transistor for the differentiation between mild-moderate-severe myocardial injury. Nano Today 2022, 43, 101391. [Google Scholar] [CrossRef]

- Zaccariotto, G.C.; Silva, M.K.L.; Rocha, G.S.; Cesarino, I. A novel method for the detection of SARS-CoV-2 based on graphene-impedimetric immunosensor. Materials 2021, 14, 4230. [Google Scholar] [CrossRef]

- Leve, Z.D.; Iwuoha, E.I.; Ross, N. Thesynergistic properties and gas sensing performance of functionalized graphene-based sensors. Materials 2022, 15, 1326. [Google Scholar] [CrossRef]

- Yang, W.; Cai, X.; Guo, S.; Wen, L.; Sun, Z.; Shang, R.; Shi, X.; Wang, J.; Chen, H.; Li, Z. A high performance triboelectric nanogenerator based on MXene/graphene oxide electrode for glucose detection. Materials 2022, 16, 841. [Google Scholar] [CrossRef]

- Wong, L.J.; Kaminer, I.; Ilic, O.; Joannopoulos, J.D.; Soljačić, M. Towards graphene plasmon-based free-electron infrared to X-ray sources. Nat. Photonics 2016, 10, 46–52. [Google Scholar] [CrossRef]

- Kaminer, I.; Katan, Y.T.; Buljan, H.; Shen, Y.; Ilic, O.; López, J.J.; Wong, L.J.; Joannopoulos, J.D.; Soljačić, M. Efficient plasmonic emission by the quantum Čerenkov effect from hot carriers in graphene. Nat. Commun. 2016, 7, ncomms11880. [Google Scholar] [CrossRef]

- Beltaos, A.; Bergren, A.J.; Bosnick, K.; Pekas, N.; Lane, S.; Cui, K.; Matković, A.; Meldrum, A. Visible light emission in graphene field effect transistors. Nano Futures 2017, 1, 025004. [Google Scholar] [CrossRef]

- Kataoka, T.; Fukunaga, F.; Murakami, N.; Sugiyama, Y.; Ohno, Y.; Nagase, M. Far-infrared emission from graphene on SiC by current injection. Jpn. J. Appl. Phys. 2022, 61, SD1019. [Google Scholar] [CrossRef]

- Mattern, F.; Flörkemeier, C. Vom Internet der Computer zum Internet der Dinge. Informatik-Spektrum 2010, 33, 107–121. [Google Scholar] [CrossRef]

- Alam, T. A reliable communication framework and its use in Internet of things (IoT). Int. J. Sci. Res. Com. Sci. Eng. Infor. Technol. 2018, 3, 450–456. [Google Scholar]

- Liu, J.; Dai, L.; Baur, J.W. Multiwalled carbon nanotubes for flow-induced voltage generation. J. Appl. Phys. 2007, 101, 064312. [Google Scholar] [CrossRef]

- Yuan, Q.; Zhao, Y.P. Hydroelectric voltage generation based on water-filled single-walled carbon nanotubes. J. Am. Chem. Soc. 2009, 131, 6374–6376. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.H.; Kim, D.; Kim, S.; Han, C.S. Flow-induced voltage generation in high-purity metallic and semiconducting carbon nanotubes. Appl. Phys. Lett. 2011, 99, 104103. [Google Scholar] [CrossRef]

- Zhong, H.; Wu, Z.; Li, X.; Xu, W.; Xu, S.; Zhang, S.; Xu, Z.; Chen, H.; Lin, S. Graphene based two dimensional hybrid nanogenerator for concurrently harvesting energy from sunlight and water flow. Carbon 2016, 105, 199–204. [Google Scholar] [CrossRef]

- Kwak, S.S.; Lin, S.; Lee, J.H.; Ryu, H.; Kim, T.Y.; Zhong, H.; Chen, H.; Kim, S.W. Triboelectrification-induced large electric power generation from a single moving droplet on graphene/polytetrafluoroethylene. ACS Nano 2016, 10, 7297–7302. [Google Scholar] [CrossRef]

- Zhong, H.; Xia, J.; Wang, F.; Chen, H.; Wu, H.; Lin, S. Graphene-piezoelectric material heterostructure for harvesting energy from water flow. Adv. Funct. Mater. 2017, 27, 1604226. [Google Scholar] [CrossRef]

- Okada, T.; Kalita, G.; Tanemura, M.; Yamashita, I.; Meyyappan, M.; Samukawa, S. Role of doped nitrogen in graphene for flow-induced power generation. Adv. Eng. Mater. 2018, 20, 1800387. [Google Scholar] [CrossRef]

- Park, D.; Won, S.; Kim, K.S.; Jung, J.Y.; Choi, J.Y.; Nah, J. The influence of substrate-dependent triboelectric charging of graphene on the electric potential generation by the flow of electrolyte droplets. Nano Energy 2018, 54, 66–72. [Google Scholar] [CrossRef]

- Okada, T.; Kalita, G.; Tanemura, M.; Yamashita, I.; Meyyappan, M.; Samukawa, S. Nitrogen doping effect on flow-induced voltage generation from graphene-water interface. Appl. Phys. Lett. 2018, 112, 023902. [Google Scholar] [CrossRef]

- Fei, W.; Shen, C.; Zhang, S.; Chen, H.; Li, L.; Guo, G. Waving potential at volt level by a pair of graphene sheets. Nano Energy 2019, 60, 656–660. [Google Scholar] [CrossRef]

- Li, C.; Tian, Z.; Liang, L.; Yin, S.; Shen, P.K. Electricity Generation from Capillary-Driven Ionic Solution Flow in a Three-Dimensional Graphene Membrane. ACS Appl. Mater. Interfaces 2019, 11, 4922–4929. [Google Scholar] [CrossRef]

- Zhen, Z.; Li, Z.; Zhao, X.; Zhong, Y.; Huang, M.; Zhu, H. A non-covalent cation-π interaction-based humidity-driven electric nanogenerator prepared with salt decorated wrinkled graphene. Nano Energy 2019, 62, 189–196. [Google Scholar] [CrossRef]

- Kang, J.; Chae, J.; Shu, C.; Jung, W. A study on the effects of the number of layers of graphene for flow-induced power generation on graphene/polytetrafluoroethylene membranes. Mater. Lett. 2019, 255, 126530. [Google Scholar] [CrossRef]

- Zhen, Z.; Li, Z.; Zhao, X.; He, Y.; Zhong, Y.; Huang, M.; Wang, M.; Zhu, H. A wrinkled graphene and ionic liquid based electric generator for the sea energy harvesting. 2D Materials 2019, 6, 045040. [Google Scholar] [CrossRef]

- Sun, Y.Y.; Mai, V.P.; Yang, R.J. Effects of electrode placement position and tilt angles of a platform on voltage induced by NaCl electrolyte flowing over graphene wafer. Appl. Energy 2020, 261, 114435. [Google Scholar] [CrossRef]

- Kuriya, K.; Ochiai, K.; Kalita, G.; Tanemura, M.; Komiya, A.; Kikugawa, G.; Ohara, T.; Yamashita, I.; Ohuchi, F.S.; Meyyappan, M.; et al. Output density quantification of electricity generation by flowing deionized water on graphene. Appl. Phys. Lett. 2020, 117, 123905. [Google Scholar] [CrossRef]

- Cai, H.; Guo, Y.; Guo, W. Synergistic effect of substrate and ion-containing water in graphene based hydrovoltaic generators. Nano Energy 2021, 84, 105939. [Google Scholar] [CrossRef]

- Li, C.; Yang, D.; Hasan, S.W.; Zhang, X.; Tian, Z.Q.; Shen, P.K. Electricity generation from ionic solution flowing through packed three-dimensional graphene powders. Nanotechnology 2021, 32, 355401. [Google Scholar] [CrossRef]

- Kong, H.; Si, P.; Li, M.; Qiu, X.; Liu, J.; Wang, X.; Wang, Q.; Li, L.; Wang, Y. Enhanced electricity generation from graphene microfluidic channels for self-powered flexible sensors. Nano Lett. 2022, 22, 3266–3274. [Google Scholar] [CrossRef] [PubMed]

- Zhai, Z.; Shen, H.; Chen, J.; Li, X.; Li, Y. Metal-free synthesis of boron-doped graphene glass by hot-filament chemical vapor deposition for wave energy harvesting. ACS Appl. Mater. Interfaces 2020, 12, 2805–2815. [Google Scholar] [CrossRef]

- Král, P.; Shapiro, M. Nanotube electron drag in flowing liquids. Phys. Rev. Lett. 2001, 86, 131–134. [Google Scholar] [CrossRef] [PubMed]

- Ghosh, S.; Sood, A.K.; Kumar, N. Carbon Nanotube Flow Sensors. Science 2003, 299, 1042–1044. [Google Scholar] [CrossRef] [PubMed]

- Yin, J.; Li, X.; Yu, J.; Zhang, Z.; Zhou, J.; Guo, W. Generating electricity by moving a droplet of ionic liquid along graphene. Nat. Nanotechnol. 2014, 9, 378–383. [Google Scholar] [CrossRef] [PubMed]

- Mitsuno, T.; Taniguchi, Y.; Ohno, Y.; Nagase, M. Ion sensitivity of large-area epitaxial graphene film on SiC substrate. Appl. Phys. Lett. 2017, 111, 213103. [Google Scholar] [CrossRef]

- Nakai, H.; Akiyama, D.; Taniguchi, Y.; Kishinobu, I.; Wariishi, H.; Ohno, Y.; Nagase, M.; Ikeda, T.; Tabata, A.; Nagamune, H. Charge-independent protein adsorption characteristics of epitaxial graphene field-effect transistor on SiC substrate. J. Appl. Phys. 2021, 130, 074502. [Google Scholar] [CrossRef]

- Yamasaki, S.; Nakai, H.; Murayama, K.; Ohno, Y.; Nagase, M. Electron transfer characteristics of amino adsorption on epitaxial graphene FETs on SiC substrates. AIP Adv. 2022, 12, 105310. [Google Scholar] [CrossRef]

- Riedl, C.; Coletti, C.; Iwasaki, T.; Zakharov, A.A.; Starke, U. Quasi-free-standing epitaxial graphene on SiC obtained by hydrogen. Phys. Rev. Lett. 2009, 103, 246804. [Google Scholar] [CrossRef]

- Aritsuki, T.; Nakashima, T.; Kobayashi, K.; Ohno, Y.; Nagase, M. Epitaxial graphene on SiC formed by the surface structure control technique. Jpn. J. Appl. Phys. 2016, 55, 06GF03. [Google Scholar] [CrossRef]

- Li, H.-J.; Zhang, D.; Wang, H.; Chen, Z.; Ou, N.; Wang, P.; Wang, D.; Wang, X.; Yang, J. Molecule-driven nanoenergy generator. Small 2019, 15, 1804146. [Google Scholar] [CrossRef]

- Nagase, M.; Hibino, H.; Kageshima, H.; Yamaguchi, H. Contact conductance measurement of locally suspended graphene on SiC. Appl. Phys. Express 2010, 3, 045101. [Google Scholar] [CrossRef]

- Kobayashi, K.; Tanabe, S.; Tao, T.; Okumura, T.; Nakashima, T.; Aritsuki, T.; O, R.S.; Nagase, M. Resistivity anisotropy measured using four probes in epitaxial graphene on silicon carbide. Appl. Phys. Express 2015, 8, 036602. [Google Scholar] [CrossRef]

- Fromm, F.; Oliveira Jr, M.H.; Molina-Sanchez, A.; Hundhausen, M.; Lopes, J.M.J.; Riechert, H.; Wirtz, L.; Seyller, T. Contribution of the buffer layer to the Raman spectrum of epitaxial graphene on SiC(0001). New J. Phys. 2013, 15, 043031. [Google Scholar] [CrossRef]

- Musumeci, F.; Pollack, G.H. High electrical permittivity of ultrapure water at the water–platinum interface. Chem. Phys. Lett. 2014, 613, 19–23. [Google Scholar] [CrossRef]

- Yatsuzuka, K.; Higashiyama, Y.; Asano, K. Electrification of polymer surface caused by sliding ultrapure water. IEEE Trans. Ind. Appl. 2019, 32, 825–831. [Google Scholar] [CrossRef]

- Armitage, J.L.; Ghanbarzadeh, A.; Bryant, M.G.; Neville, A. Investigating the influence of friction and material wear on triboelectric charge transfer in metal–polymer contacts. Tribol. Lett. 2022, 70, 46. [Google Scholar] [CrossRef]

- Tan, J.; Guo, Y.; Guo, W. Ultralow friction of ion-containing water nanodroplets. Nano Res. 2023, 16, 1792–1797. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ohno, Y.; Shimmen, A.; Kinoshita, T.; Nagase, M. Energy Harvesting of Deionized Water Droplet Flow over an Epitaxial Graphene Film on a SiC Substrate. Materials 2023, 16, 4336. https://doi.org/10.3390/ma16124336

Ohno Y, Shimmen A, Kinoshita T, Nagase M. Energy Harvesting of Deionized Water Droplet Flow over an Epitaxial Graphene Film on a SiC Substrate. Materials. 2023; 16(12):4336. https://doi.org/10.3390/ma16124336

Chicago/Turabian StyleOhno, Yasuhide, Ayumi Shimmen, Tomohiro Kinoshita, and Masao Nagase. 2023. "Energy Harvesting of Deionized Water Droplet Flow over an Epitaxial Graphene Film on a SiC Substrate" Materials 16, no. 12: 4336. https://doi.org/10.3390/ma16124336

APA StyleOhno, Y., Shimmen, A., Kinoshita, T., & Nagase, M. (2023). Energy Harvesting of Deionized Water Droplet Flow over an Epitaxial Graphene Film on a SiC Substrate. Materials, 16(12), 4336. https://doi.org/10.3390/ma16124336