Mechanical and Thermoanalytical Study of Polypropylene Geomats Exposed in the Field and the Laboratory

Abstract

:1. Introduction

2. Materials and Methods

2.1. Geomat Characteristics

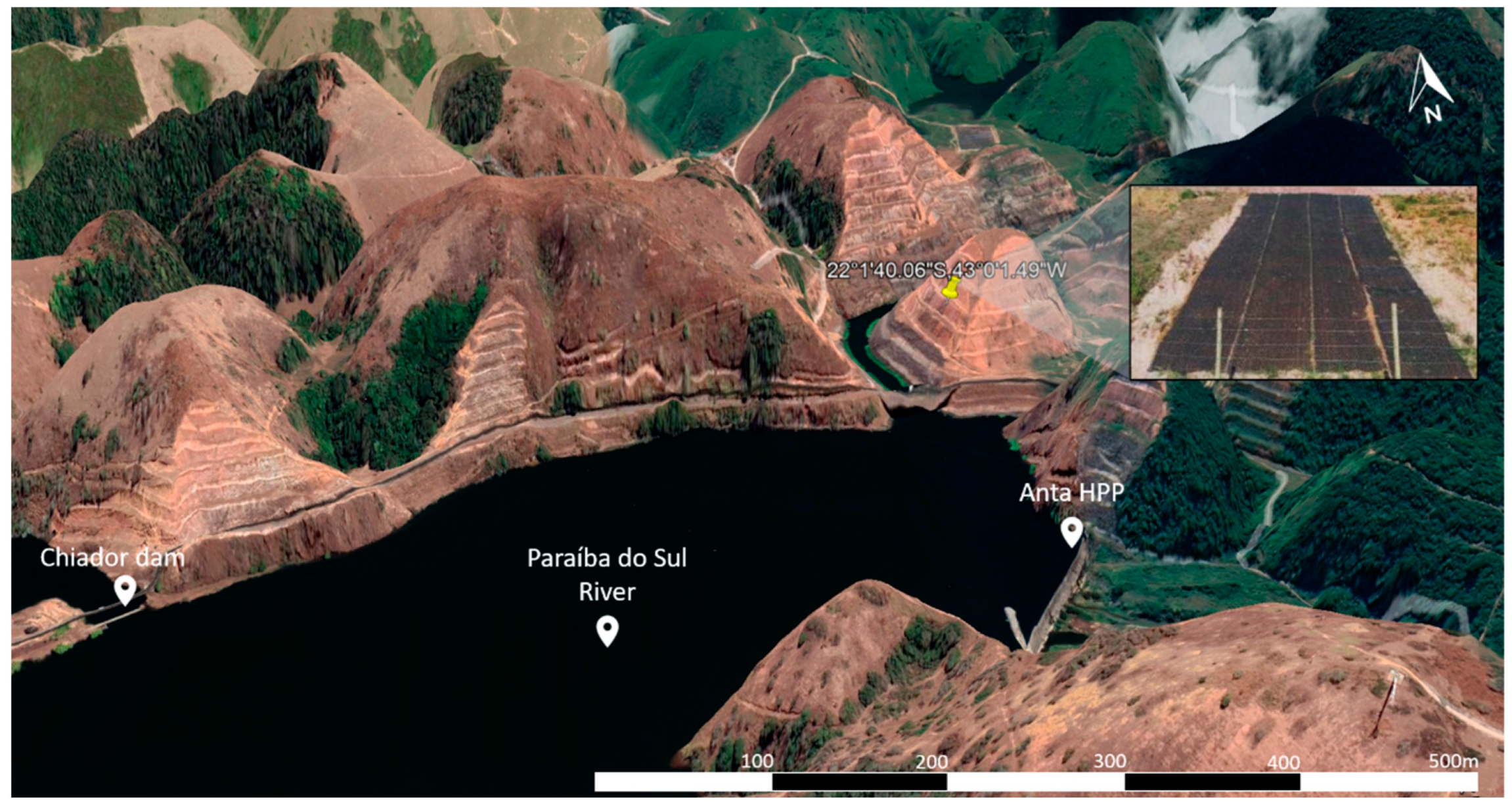

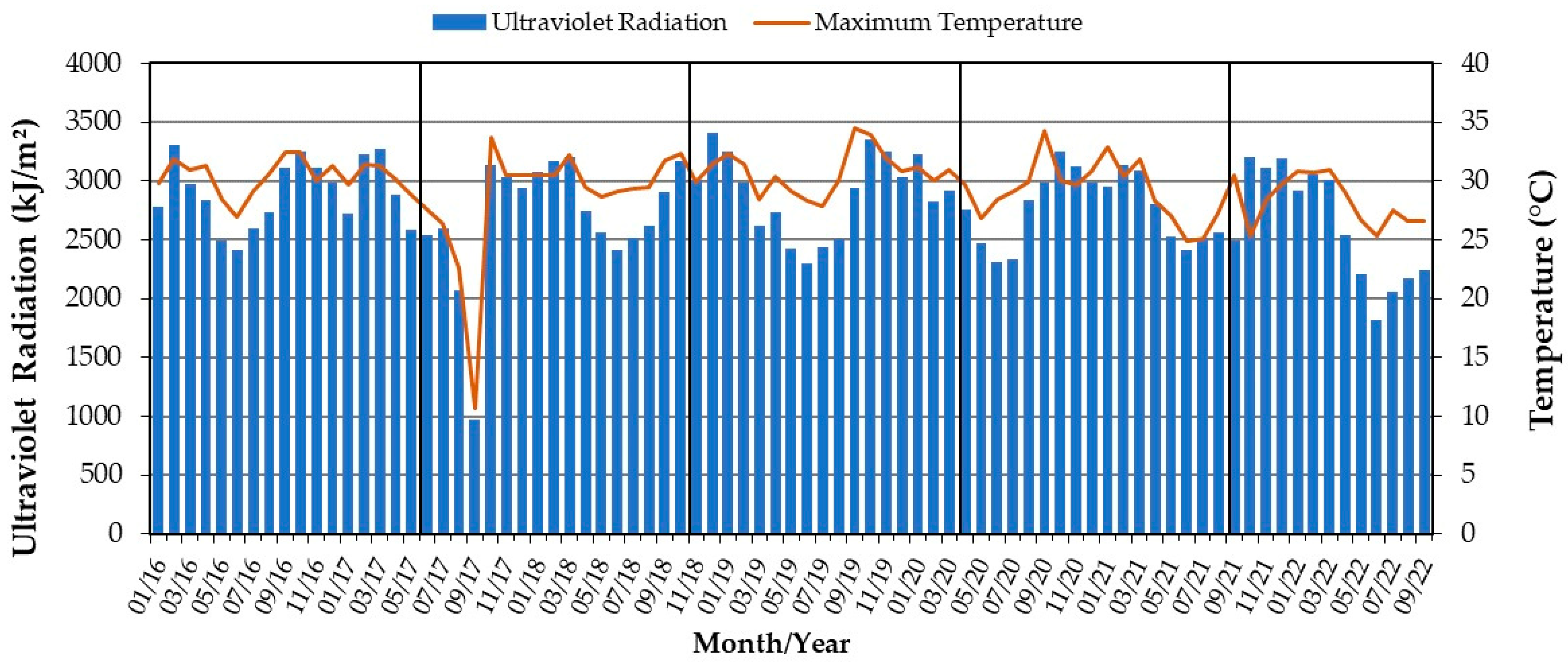

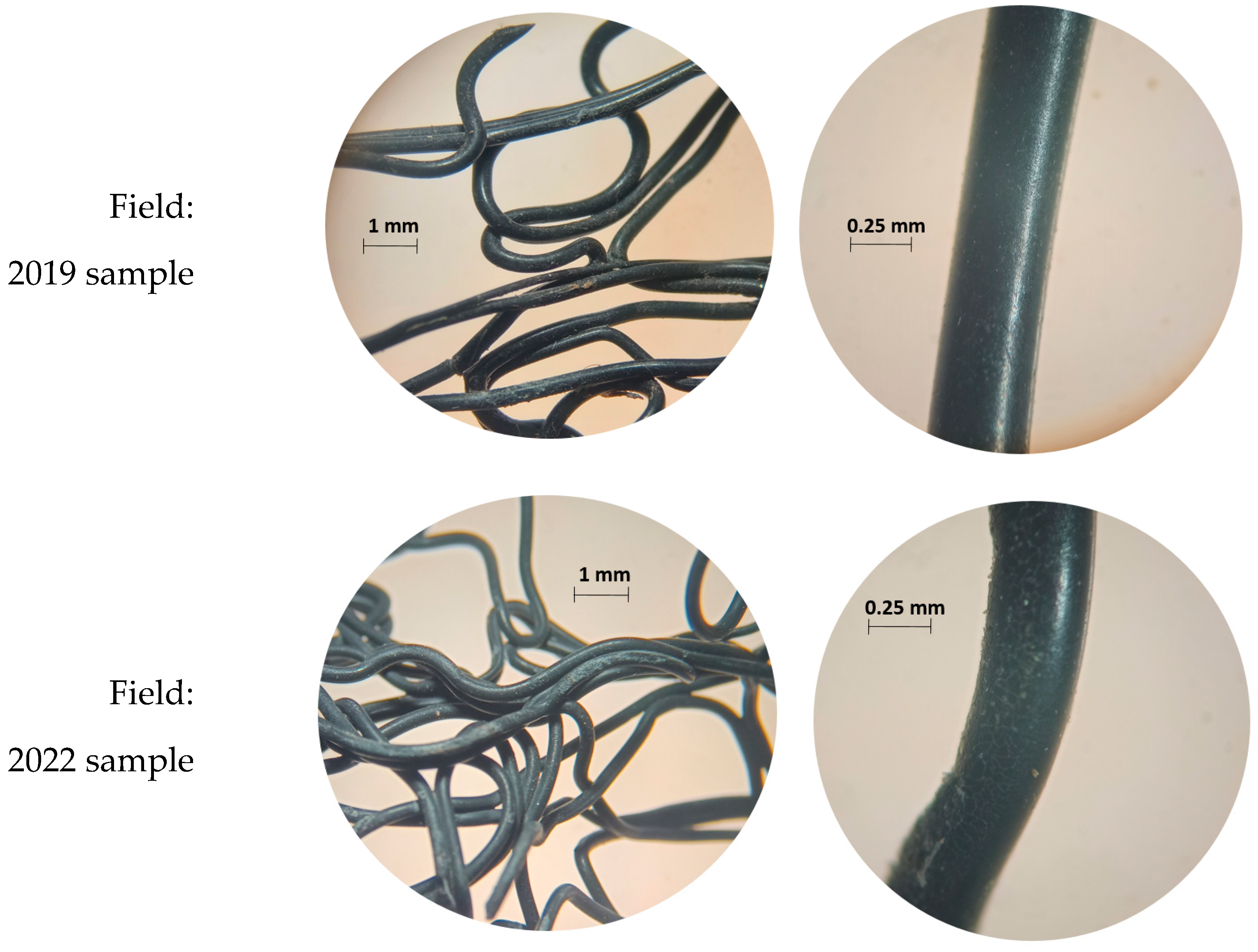

2.2. Exposure in the Field

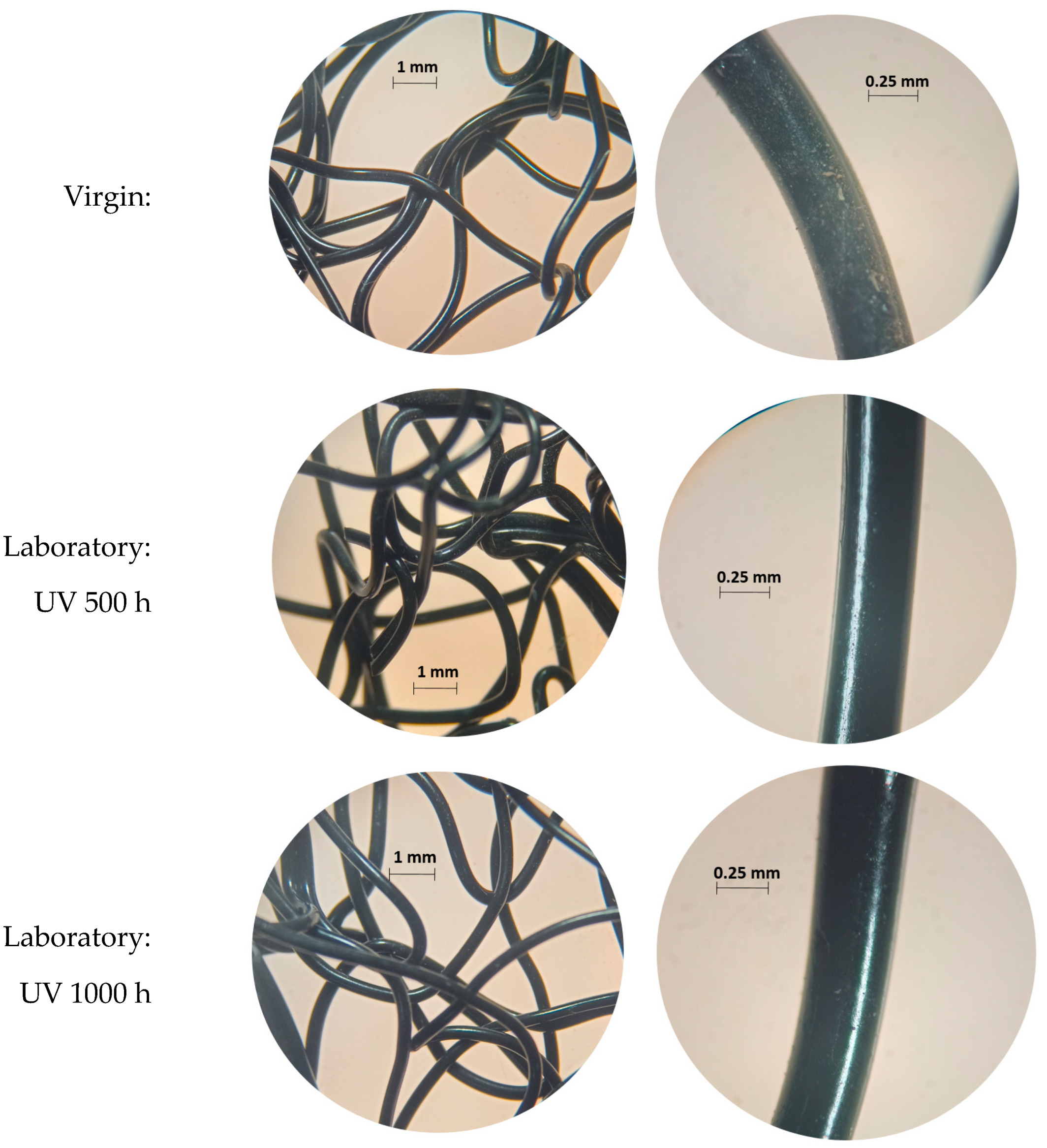

2.3. Exposure in the Laboratory

2.4. Mechanical Method

2.5. Thermoanalytical Methods

3. Results and Discussion

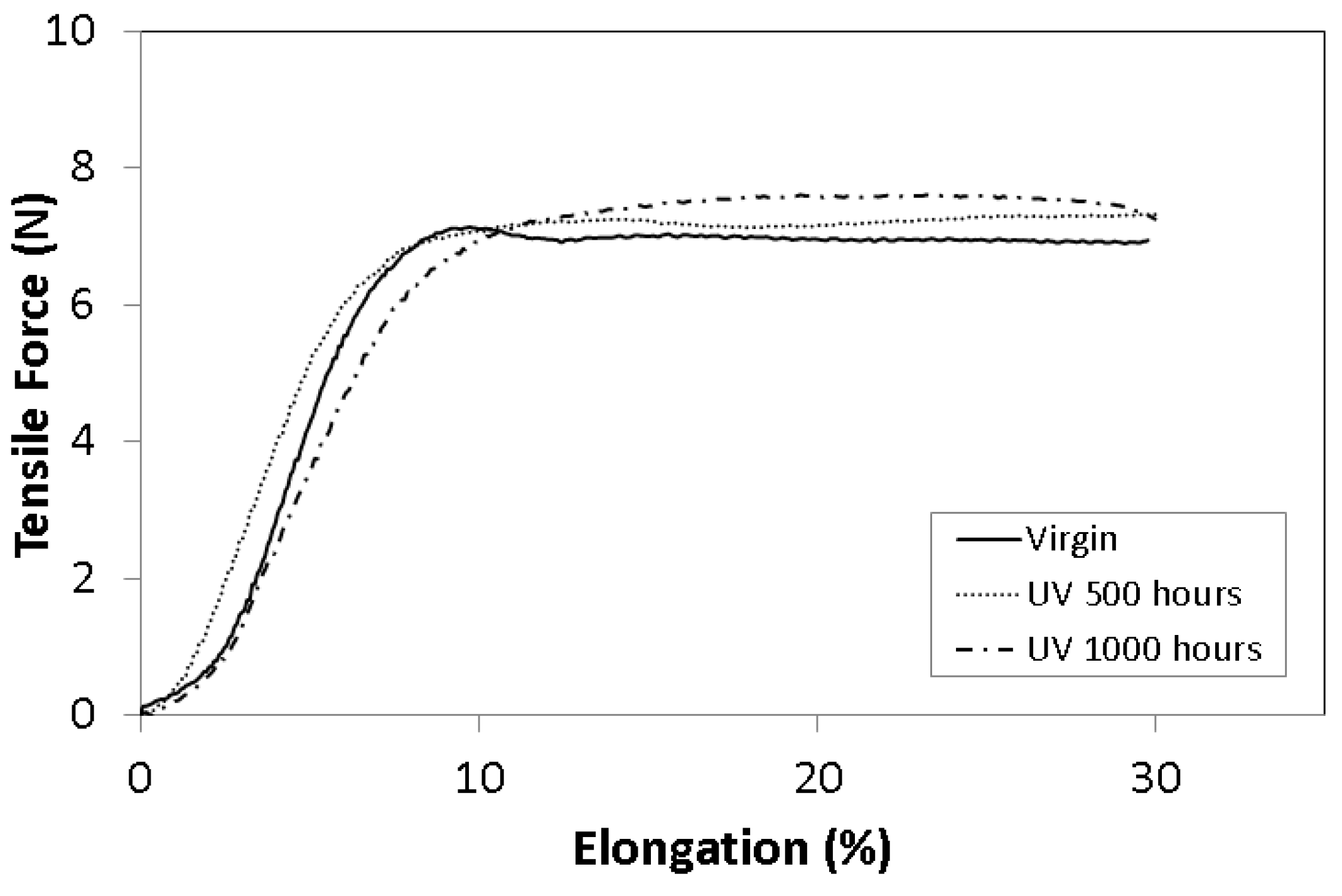

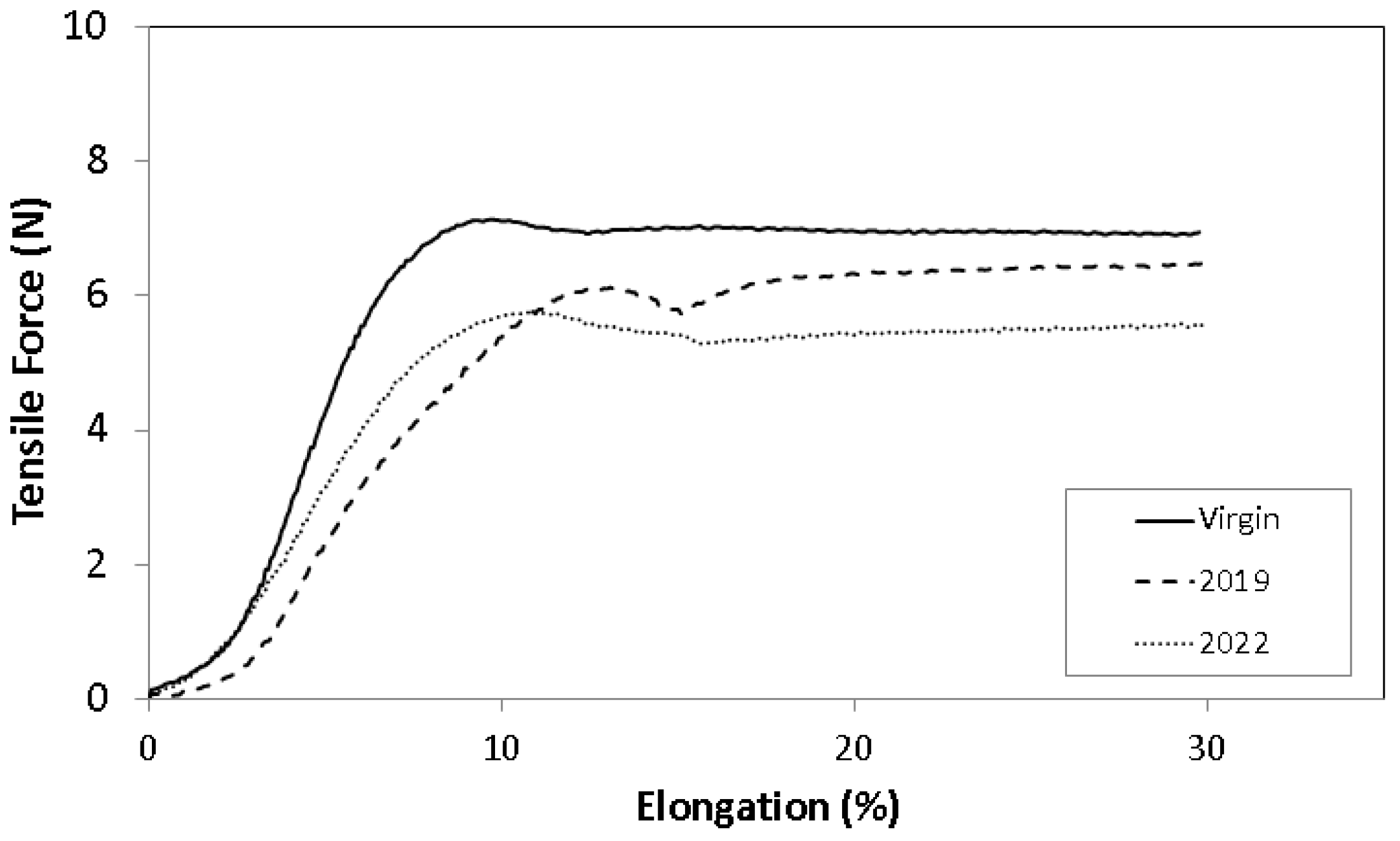

3.1. Degradation and Resistance of Polymer Wire

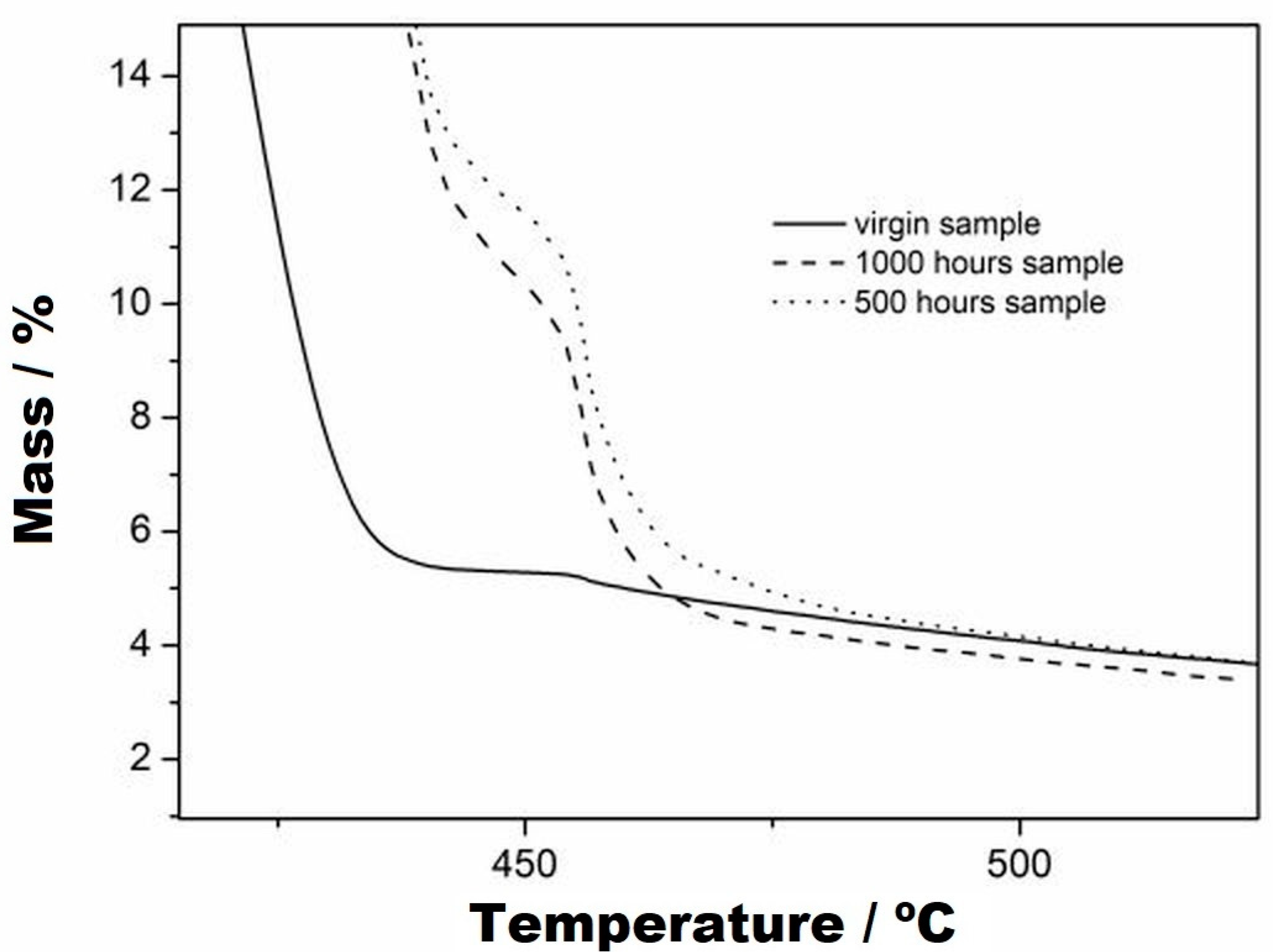

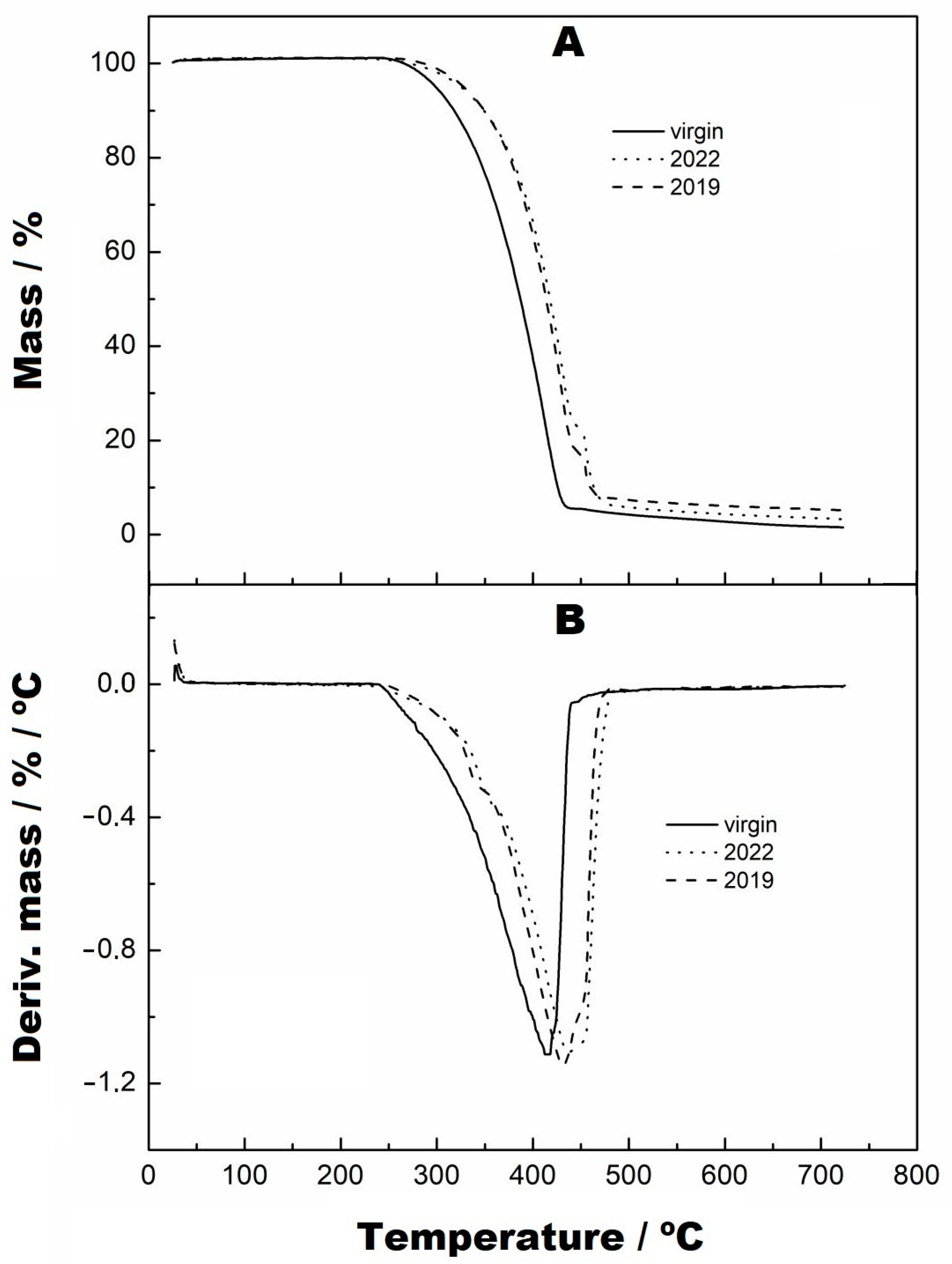

3.2. Thermal Analyses

4. Conclusions

- The geomat wires exposed in the field showed a more significant decrease in resistance when compared to the results of the samples exposed in the laboratory. This indicates that exposure in the field is more aggressive than exposure to UV radiation in a laboratory.

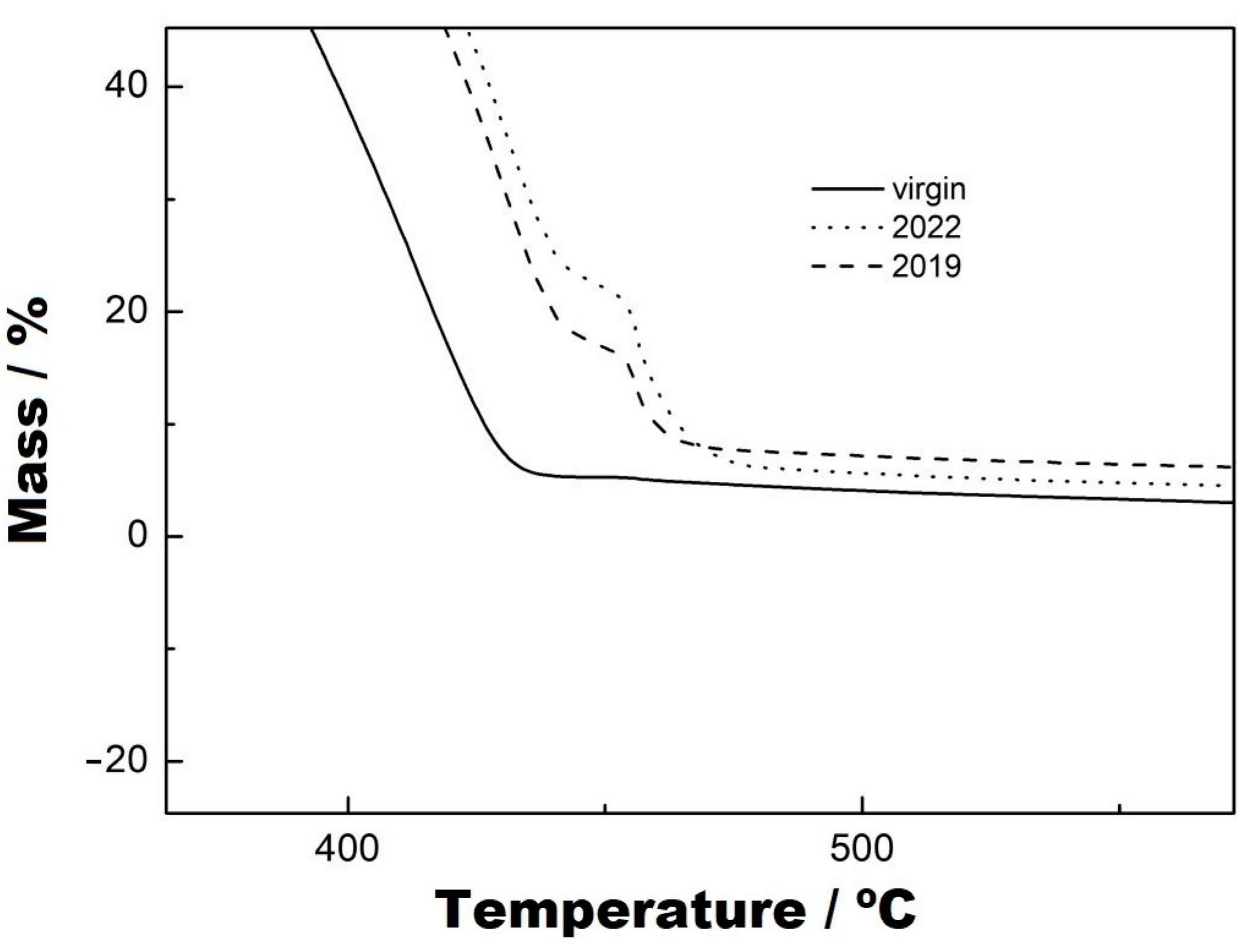

- In the samples collected in the field, it was observed that the TG curves showed thermal decomposition of the virgin sample before the collected samples, as seen in the TG and DTG curves. Contrary to what was observed in the samples exposed in the laboratory, where the virgin sample showed a lower thermal decomposition stage (as seen in the TG curves) than the samples submitted to UV radiation, the samples exposed to UV radiation (500 h and 1000 h) presented the same decomposition characteristics.

- The exposure times in the laboratory and the field increased the thermal decomposition temperatures of the samples. This indicates that degradation caused by UV radiation (in the field and the laboratory) alters the structure of molecules, generating disruption of intermolecular or intramolecular bonds and consequently changing decomposition behaviour. Thus, during thermal decomposition, a material goes through other, more stable stages (which undergo other stages of decomposition). This was verified with the formation of carbonaceous material impregnated in the crucibles during the TG tests.

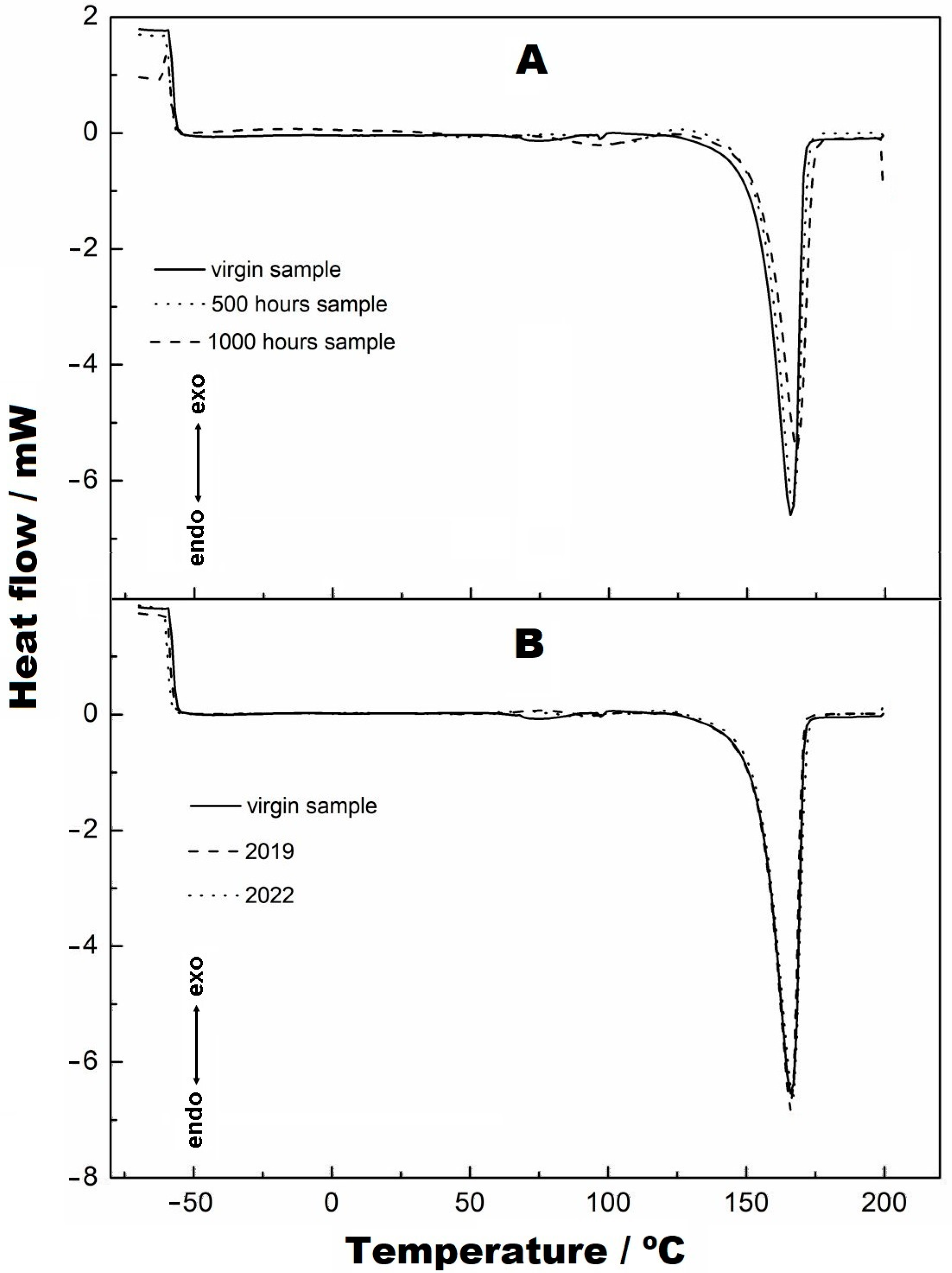

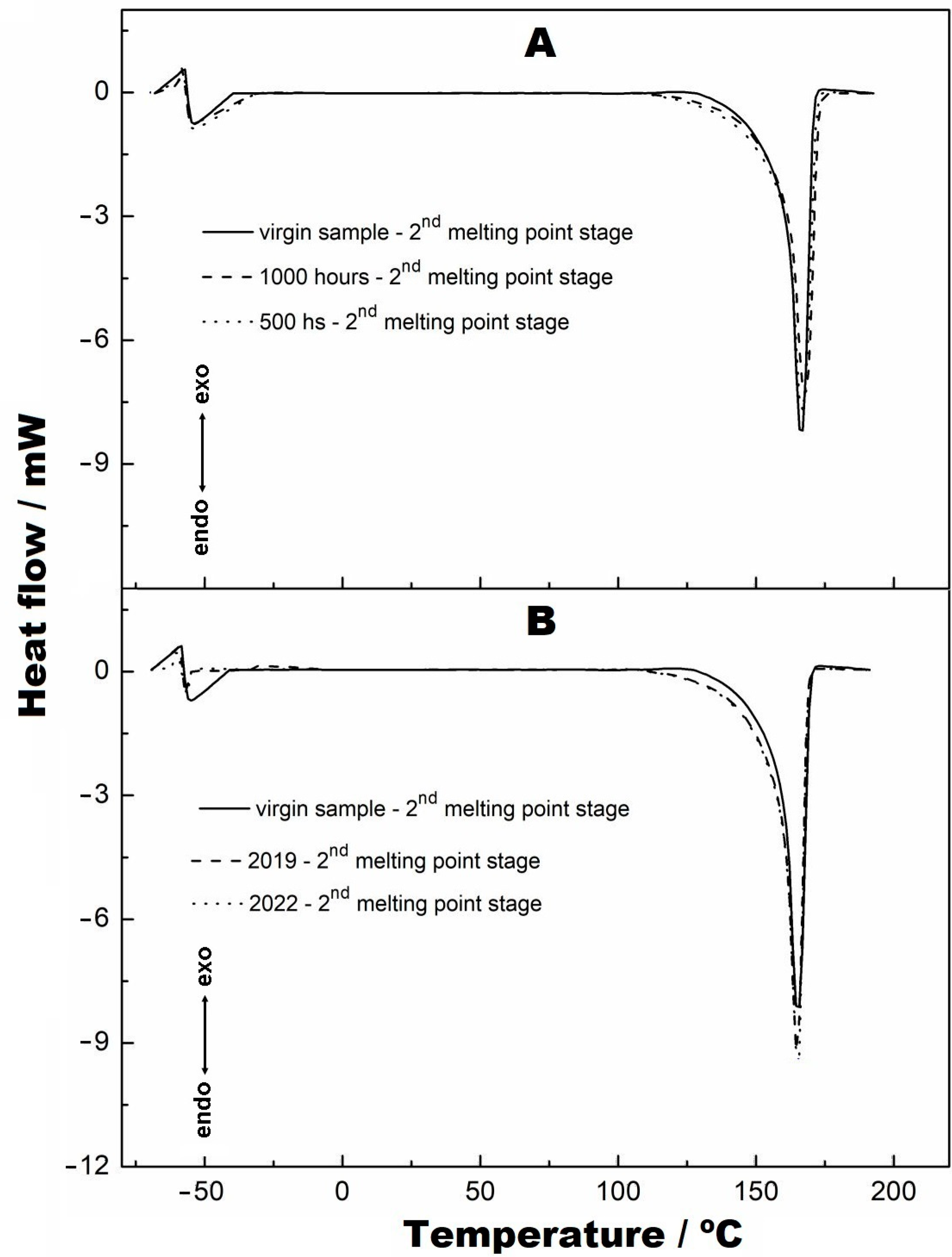

- From the DSC analyses, the samples showed similar behaviours for the melting peaks.

- Evaluation of the wires of the geomats was presented as an alternative to analysing the tensile strengths of discontinuous geosynthetic materials such as the geomats.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Morgan, R.P.C. Soil Erosion and Conservation; Blackwell Science: Oxford, UK, 2005; p. 11. [Google Scholar]

- Toy, T.J.; Foster, G.R.; Renard, K.G. Soil Erosion: Processes, Prediction, Measurement, and Control; John Wiley and Sons: New York, NY, USA, 2002; pp. 10–20. [Google Scholar]

- Allen, S. Evaluation and Standardization of Rolled Erosion Control Products. Geotext. Geomembr. 1996, 14, 207–221. [Google Scholar] [CrossRef]

- Carroll, R.G.; Rodencal, J.; Collin, J.G. Geosynthetics in Erosion Control-The Principles. Geotext. Geomembr. 1992, 12, 523–534. [Google Scholar] [CrossRef]

- Midha, V.K.; Suresh Kumar, S. Influence of Woven Structure on Coir Rolled Erosion-Control Products. Geosynth. Int. 2013, 20, 396–407. [Google Scholar] [CrossRef]

- Theisen, M.S. The role of geosynthetics in erosion and sediment control: An overview. Geotext. Geomembr. 1992, 11, 535–550. [Google Scholar] [CrossRef]

- Zheng, X.; Lu, X.; Zhou, M.; Huang, W.; Zhong, Z.; Wu, X.; Zhao, B. Experimental Study on Mechanical Properties of Root–Soil Composite Reinforced by MICP. Materials 2022, 15, 3586. [Google Scholar] [CrossRef] [PubMed]

- Lekha, K.R. Field Instrumentation and Monitoring of Soil Erosion in Coir Geotextile Stabilised Slopes—A Case Study. Geotext. Geomembr. 2004, 22, 399–413. [Google Scholar] [CrossRef]

- Da Luz, M.; Aparicio Ardila, M.; dos Santos Junior, R.; Valentin, C.; Schliewe, M.; Coelho, A.; Lins da Silva, J. Geomats Used to Control Erosion on Reservoir Margins in Brazilian Hydroelectric Power Plants. Water 2021, 13, 1444. [Google Scholar] [CrossRef]

- Melo, M.T.S.; Palmeira, E.M.; Santos, E.C.G.; da Luz, M.P. Geosynthetic Performance against Slope Erosion Caused by High Intensity Rainfall. Geosynth. Int. 2021, 28, 421–434. [Google Scholar] [CrossRef]

- Chen, S.-C.; Chang, K.-T.; Wang, S.-H.; Lin, J.-Y. The efficiency of artificial materials used for erosion control on steep slopes. Environ. Earth Sci. 2010, 62, 197–206. [Google Scholar] [CrossRef]

- Marques, A.R.; Santiago de Oliveira Patrício, P.; Soares dos Santos, F.; Monteiro, M.L.; de Carvalho Urashima, D.; de Souza Rodrigues, C. Effects of the Climatic Conditions of the Southeastern Brazil on Degradation the Fibers of Coir-Geotextile: Evaluation of Mechanical and Structural Properties. Geotext. Geomembr. 2014, 42, 76–82. [Google Scholar] [CrossRef]

- Aparicio Ardila, M.A.; dos Santos Junior, R.D.; Kobelnik, M.; Valentin, C.A.; Silva Schliewe, M.; Teixeira Coelho, A.; Lins da Silva, J.; Pereira da Luz, M. Semi-Rigid Erosion Control Techniques with Geotextiles Applied to Reservoir Margins in Hydroelectric Power Plants, Brazil. Water 2021, 13, 500. [Google Scholar] [CrossRef]

- Xu, Y.; Su, C.; Huang, Z.; Yang, C.; Yang, Y. Research on the Protection of Expansive Soil Slopes under Heavy Rainfall by Anchor-Reinforced Vegetation Systems. Geotext. Geomembr. 2022, 50, 1147–1158. [Google Scholar] [CrossRef]

- Tan, H.; Chen, F.; Chen, J.; Gao, Y. Direct shear tests of shear strength of soils reinforced by geomats and plant roots. Geotext. Geomembr. 2019, 47, 780–791. [Google Scholar] [CrossRef]

- Li, M.-H.; Khanna, S. Aging of Rolled Erosion Control Products for Channel Erosion Control. Geosynth. Int. 2008, 15, 224–231. [Google Scholar] [CrossRef]

- Suits, L.D.; Hsuan, Y.G. Assessing the photo-degradation of geosynthetics by outdoor exposure and laboratory weatherometer. Geotext. Geomembr. 2003, 21, 111–122. [Google Scholar] [CrossRef]

- Carneiro, J.R.; Lopes, M.L. Natural weathering of polypropylene geotextiles treated with different chemical stabilisers. Geosynth. Int. 2017, 24, 544–553. [Google Scholar] [CrossRef]

- Guimarães, M.G.A.; de Mattos Vidal, D.; de Carvalho Urashima, D.; Castro, C.A.C. Degradation of polypropylene woven geotextile: Tensile creep and weathering. Geosynth. Int. 2017, 24, 213–223. [Google Scholar] [CrossRef]

- Franco, Y.B.; Valentin, C.A.; Kobelnik, M.; Lins da Silva, J.; Ribeiro, C.A.; da Luz, M.P. Accelerated Aging Ultraviolet of a PET Nonwoven Geotextile and Thermoanalytical Evaluation. Materials 2022, 15, 4157. [Google Scholar] [CrossRef]

- Aparicio-Ardila, M.A.; Pedroso, G.O.M.; Kobelnik, M.; Valentin, C.A.; da Luz, M.P.; Lins da Silva, J. Evaluating the Degradation of a Nonwoven Polypropylene Geotextile Exposed to Natural Weathering for 3 Years. Int. J. Geosynth. Ground Eng. 2021, 7, 69. [Google Scholar] [CrossRef]

- Valentin, C.A.; Kobelnik, M.; Franco, Y.B.; Lavoie, F.L.; Silva, J.L.d.; Luz, M.P.d. Study of the ultraviolet effect and thermal analysis on polypropylene nonwoven geotextile. Materials 2021, 14, 1080. [Google Scholar] [CrossRef]

- Vianna, V.F.; Fleury, M.P.; Menezes, G.B.; Coelho, A.T.; Bueno, C.; Lins da Silva, J.; Luz, M.P. Bioengineering Techniques Adopted for Controlling Riverbanks’ Superficial Erosion of the Simplício Hydroelectric Power Plant, Brazil. Sustainability 2020, 12, 7886. [Google Scholar] [CrossRef]

- ABNT NBR ISO 9864; Geosynthetics—Test Method for the Determination of Mass per Unit Area of Geotextiles and Geotextile-Related Products. Brazilian Association of Technical Standards: Rio de Janeiro, Brazil, 2013.

- ABNT NBR ISO 9863–1; Geosynthetics—Determination of Thickness at Specified Pressures Part 1: Single Layers. Brazilian Association of Technical Standards: Rio de Janeiro, Brazil, 2013.

- ABNT NBR ISO 10319; Geosynthetics—Wide-Width Tensile Test. Brazilian Association of Technical Standards: Rio de Janeiro, Brazil, 2013.

- Alvares, C.A.; Stape, J.L.; Sentelhas, P.C.; Gonçalves, J.D.M.; Sparovek, G. Köppen’s climate classification map for Brazil. Meteorol. Z. 2013, 22, 711–728. [Google Scholar] [CrossRef] [PubMed]

- Scheirs, J. A Guide to Polymeric Geomembranes: A Practical Approach; Wiley: Hoboken, NJ, USA, 2009; 598p. [Google Scholar]

- Lavoie, F.L.; Kobelnik, M.; Valentin, C.A.; Tirelli, É.F.d.S.; Lopes, M.d.L.; Silva, J.L.d. Laboratory Study of the Ultraviolet Radiation Effect on an HDPE Geomembrane. Membranes 2021, 11, 390. [Google Scholar] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lins da Silva, J.; Valentin, C.A.; Kobelnik, M.; Pedroso, G.O.M.; Aparício-Ardila, M.A.; Araújo Júnior, L.P.V.d.; Luz, M.P.d. Mechanical and Thermoanalytical Study of Polypropylene Geomats Exposed in the Field and the Laboratory. Materials 2023, 16, 4148. https://doi.org/10.3390/ma16114148

Lins da Silva J, Valentin CA, Kobelnik M, Pedroso GOM, Aparício-Ardila MA, Araújo Júnior LPVd, Luz MPd. Mechanical and Thermoanalytical Study of Polypropylene Geomats Exposed in the Field and the Laboratory. Materials. 2023; 16(11):4148. https://doi.org/10.3390/ma16114148

Chicago/Turabian StyleLins da Silva, Jefferson, Clever Aparecido Valentin, Marcelo Kobelnik, Gabriel Orquizas Mattielo Pedroso, Maria Alejandra Aparício-Ardila, Luiz Paulo Vieira de Araújo Júnior, and Marta Pereira da Luz. 2023. "Mechanical and Thermoanalytical Study of Polypropylene Geomats Exposed in the Field and the Laboratory" Materials 16, no. 11: 4148. https://doi.org/10.3390/ma16114148

APA StyleLins da Silva, J., Valentin, C. A., Kobelnik, M., Pedroso, G. O. M., Aparício-Ardila, M. A., Araújo Júnior, L. P. V. d., & Luz, M. P. d. (2023). Mechanical and Thermoanalytical Study of Polypropylene Geomats Exposed in the Field and the Laboratory. Materials, 16(11), 4148. https://doi.org/10.3390/ma16114148