Hybrid Plasmas for Materials Processing

Abstract

1. Introduction

- -

- Plasmas driven by multiple different electrical sources simultaneously;

- -

- Plasmas driven by multiple different electrical sources sequentially;

- -

- Plasmas having properties of thermal and nonthermal plasmas;

- -

- Plasmas enhanced by additional energy;

- -

- Plasmas operated in a unique medium.

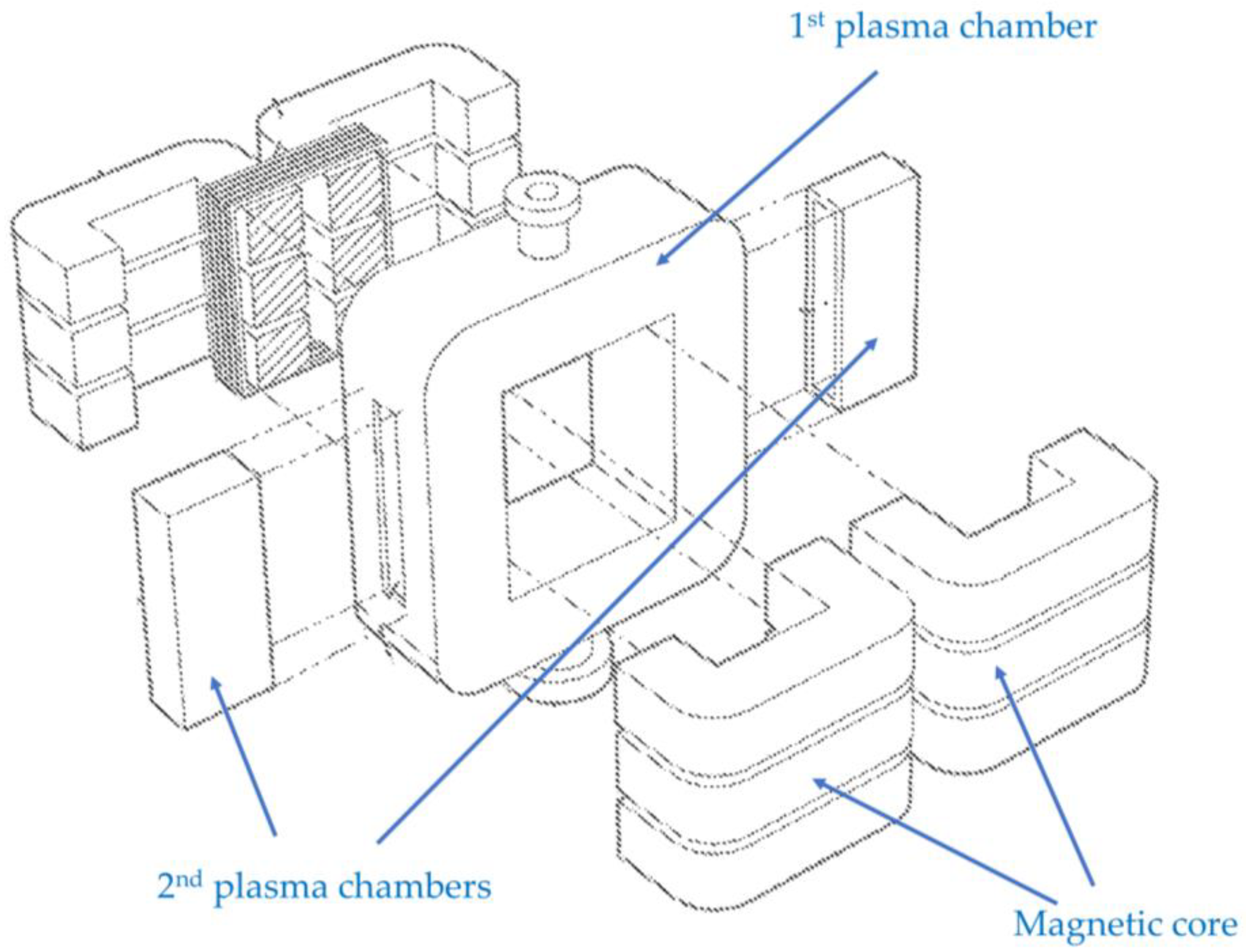

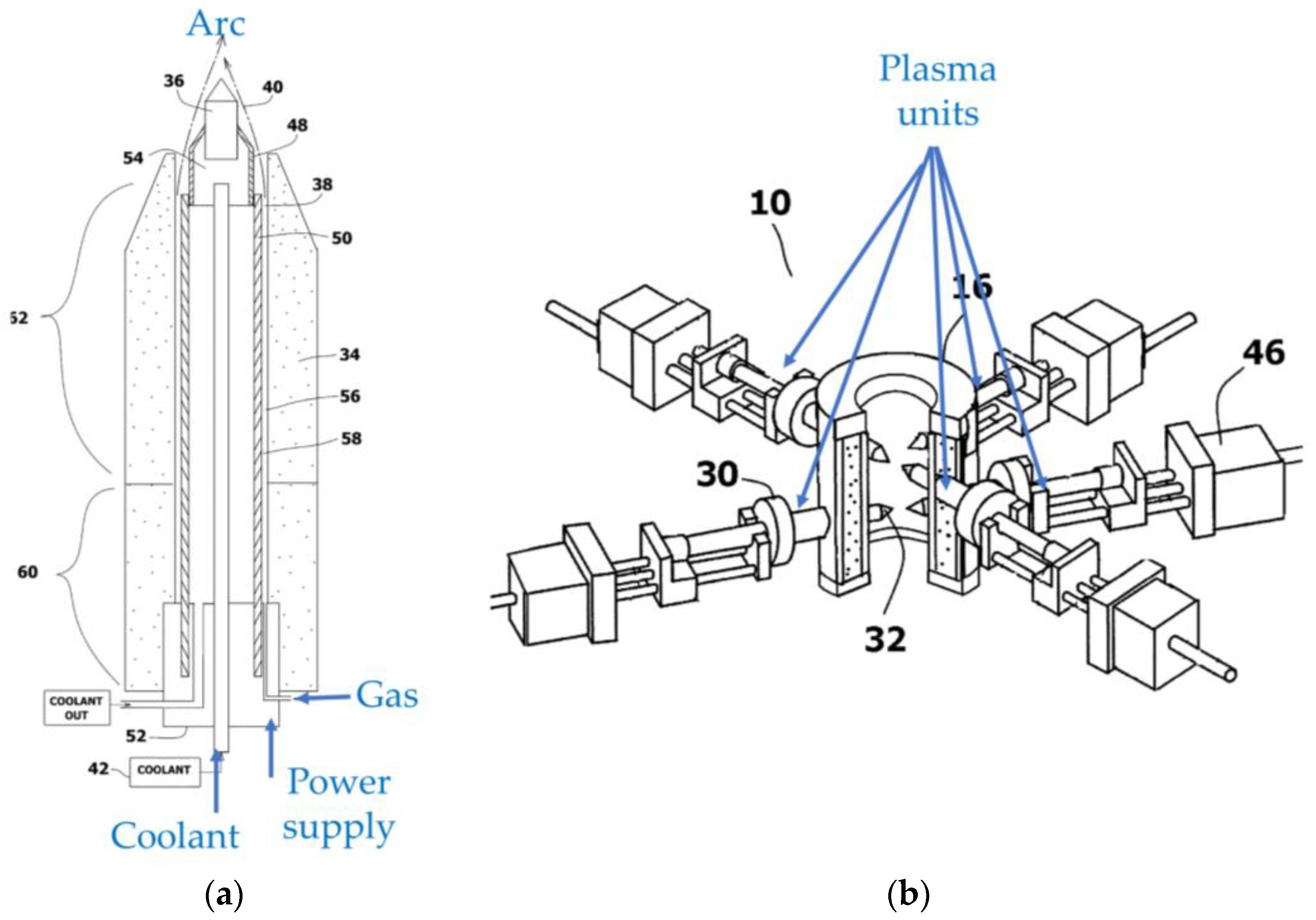

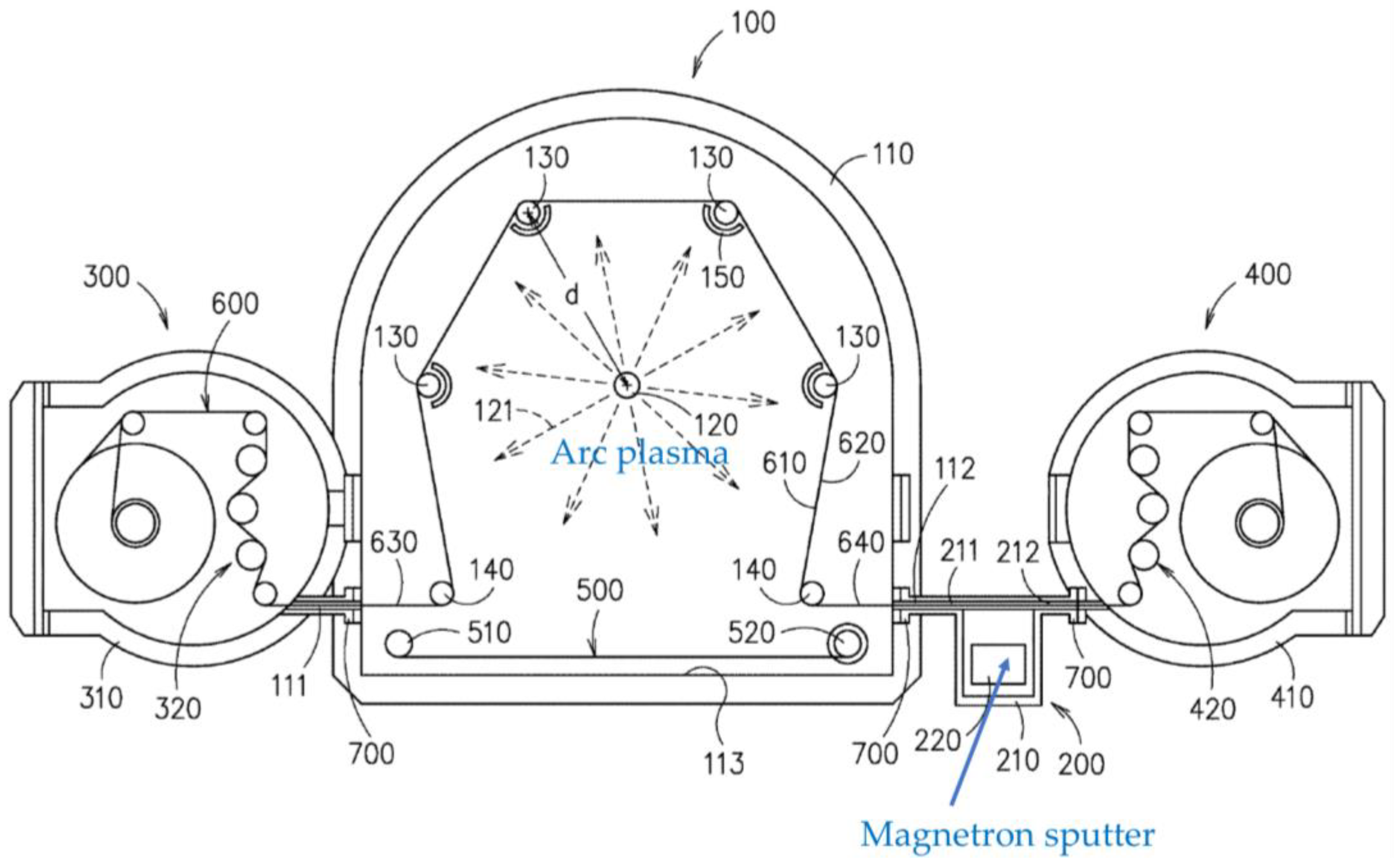

2. Plasmas Driven by Multiple Different Electrical Sources Simultaneously

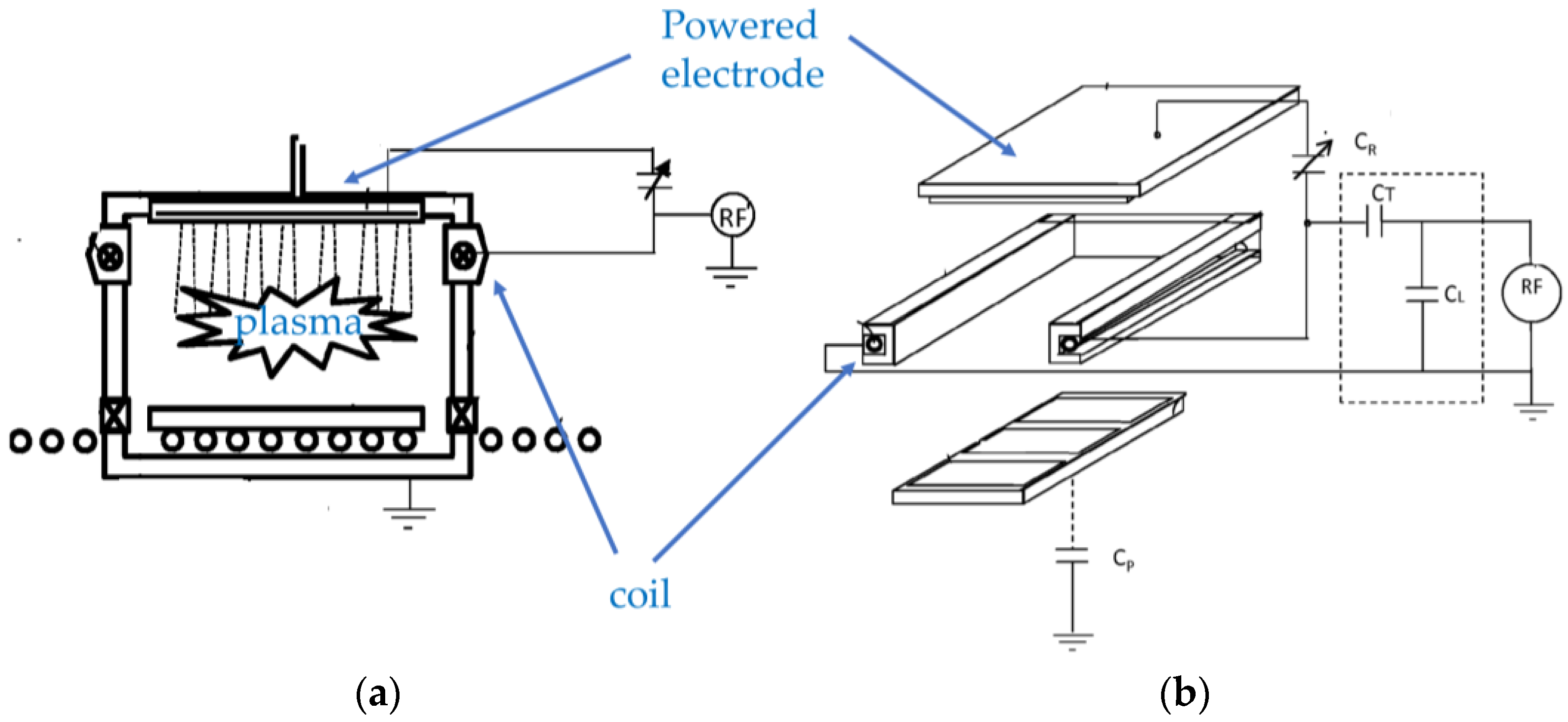

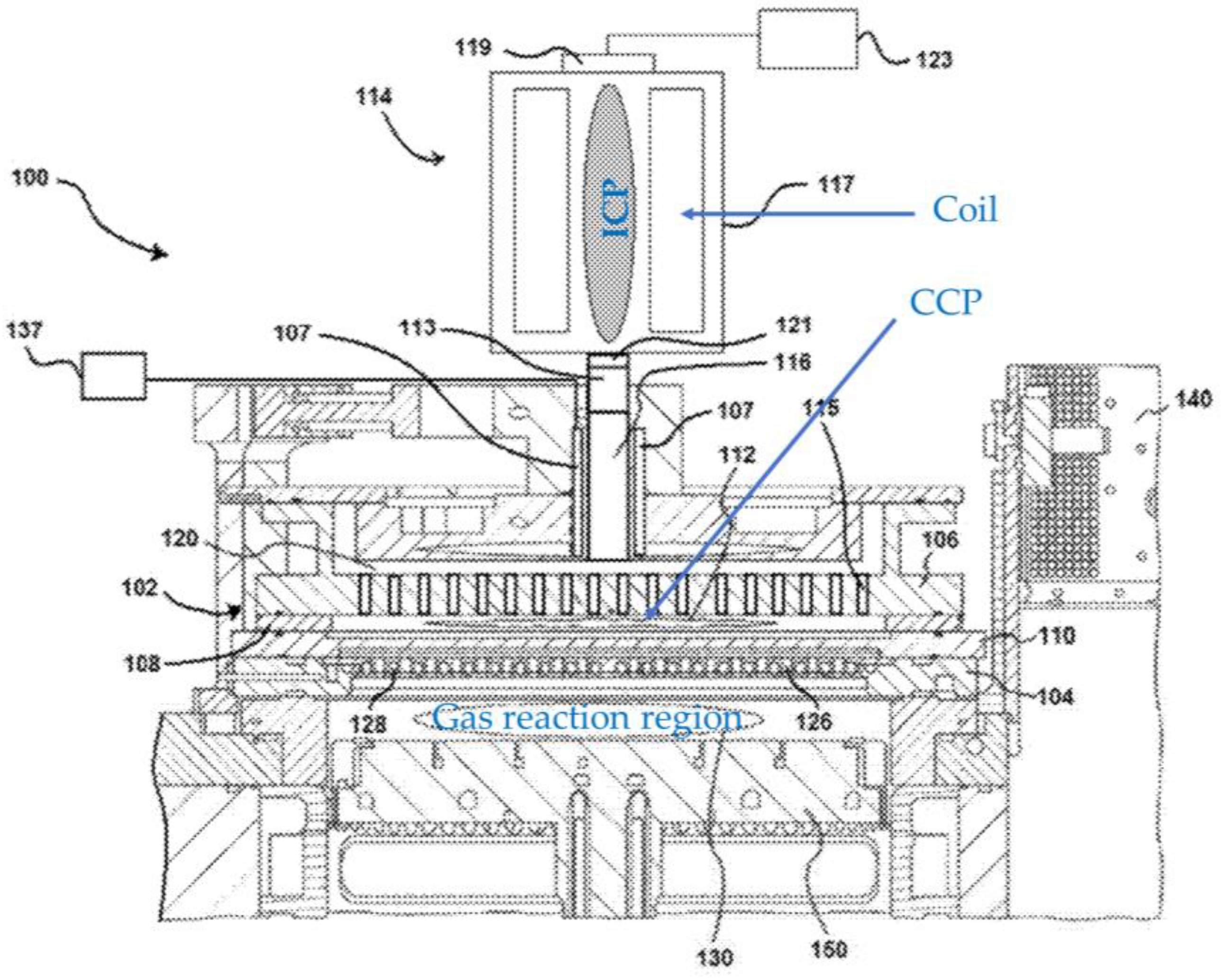

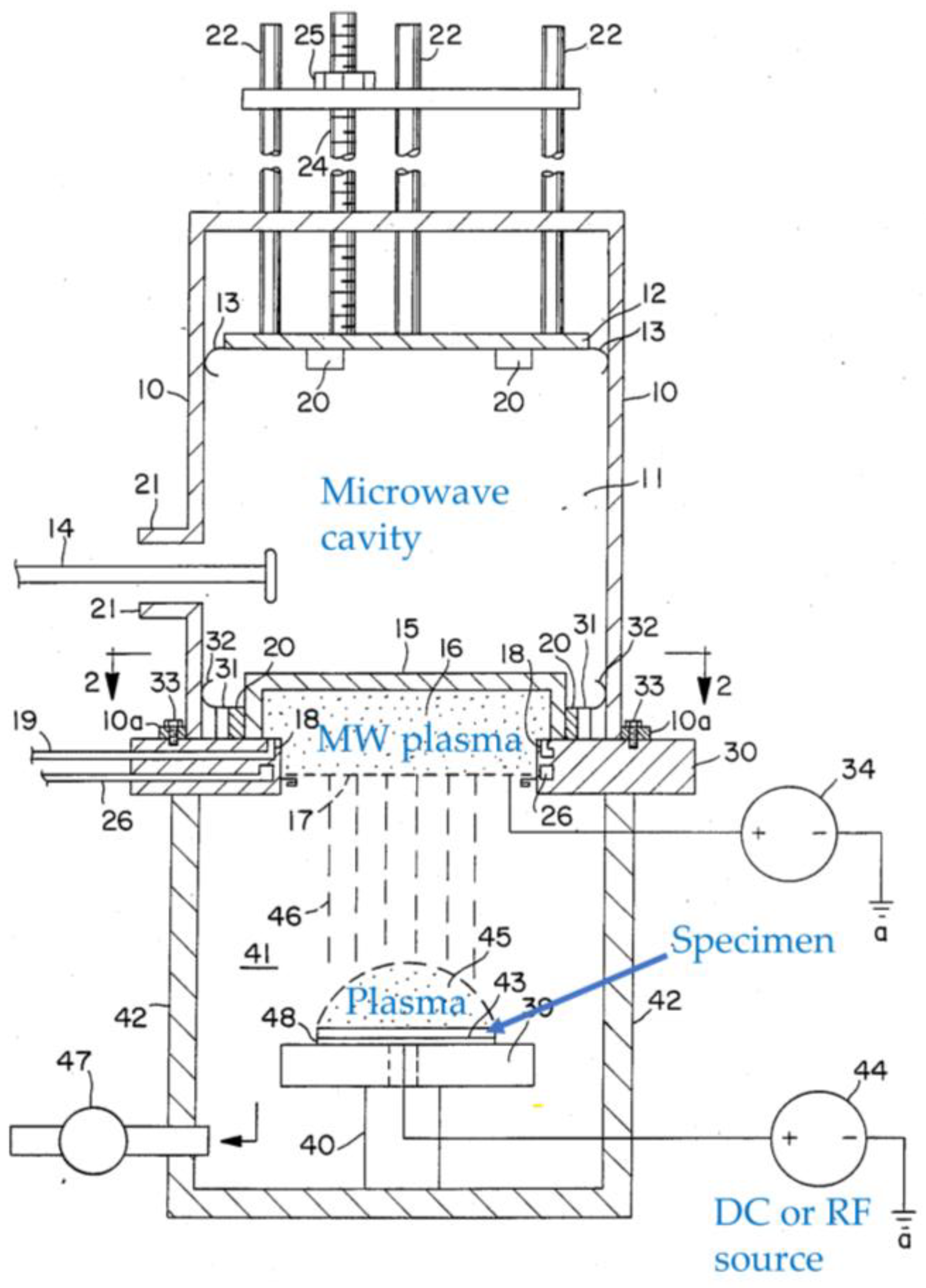

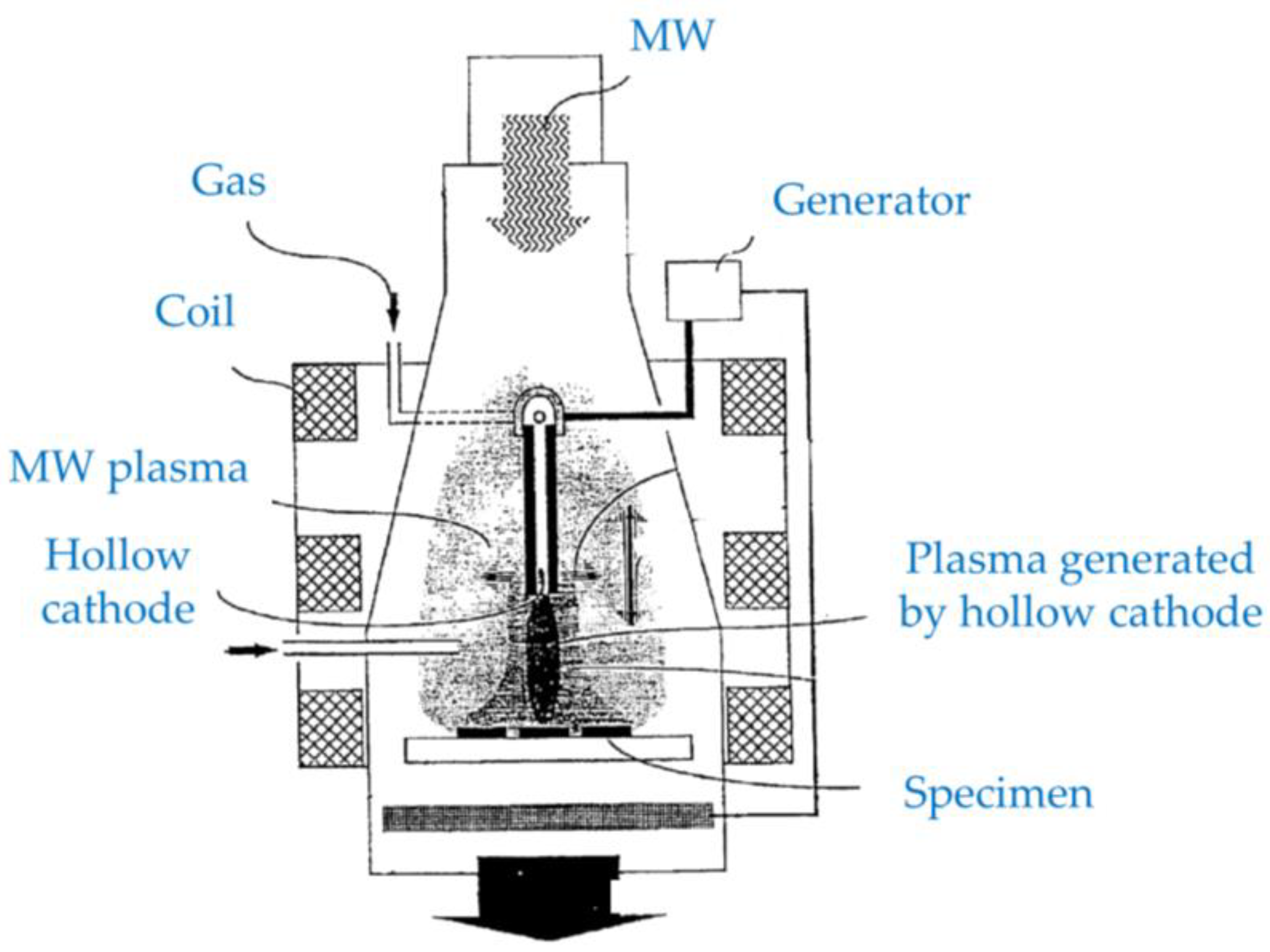

2.1. Combination of Two Plasmas

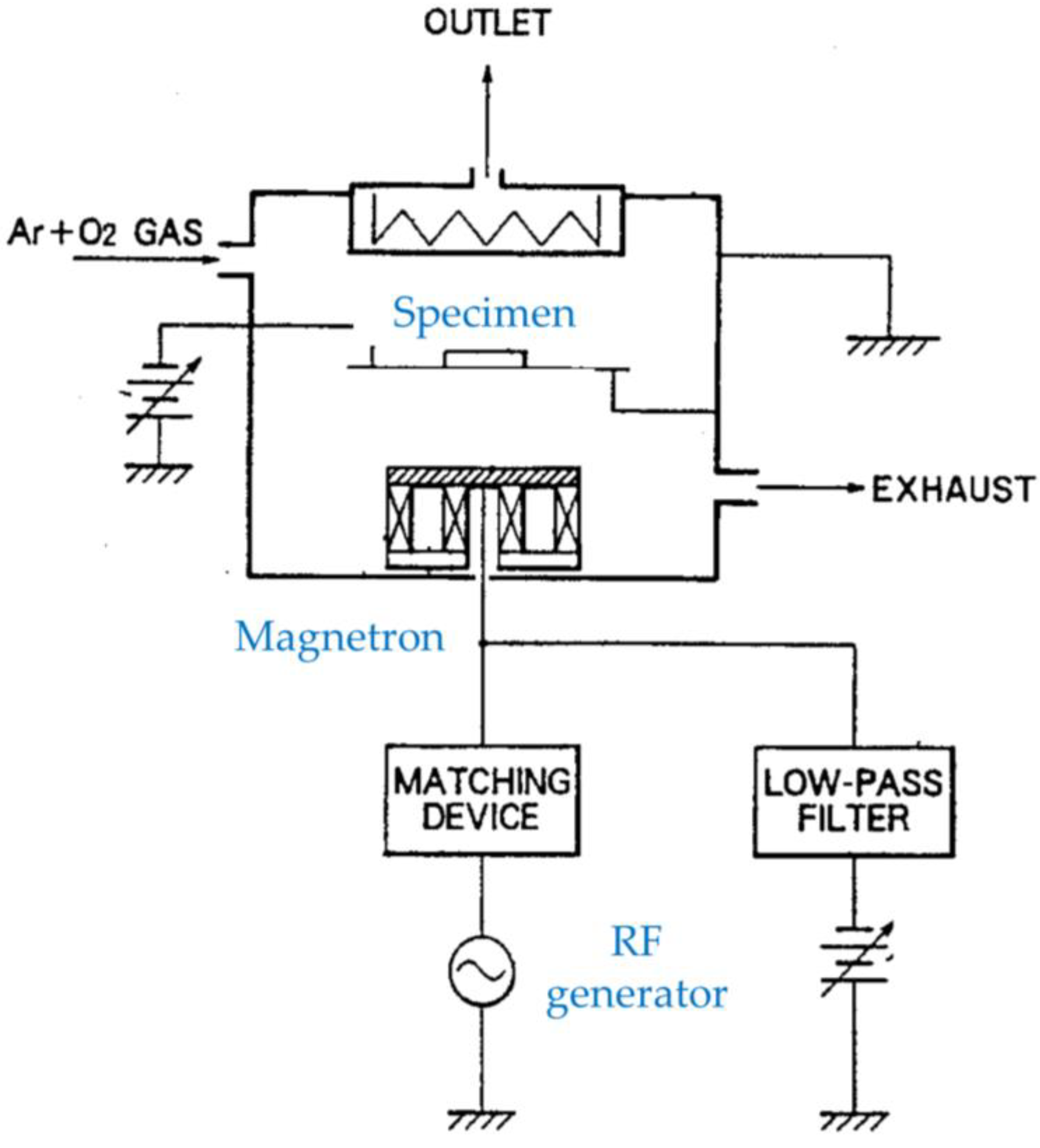

2.2. Ionized Magnetron Sputtering and Electron Cyclotron Resonance Magnetron Sputtering

2.3. Superposition

3. Plasmas Driven by Multiple Electrical Sources Sequentially

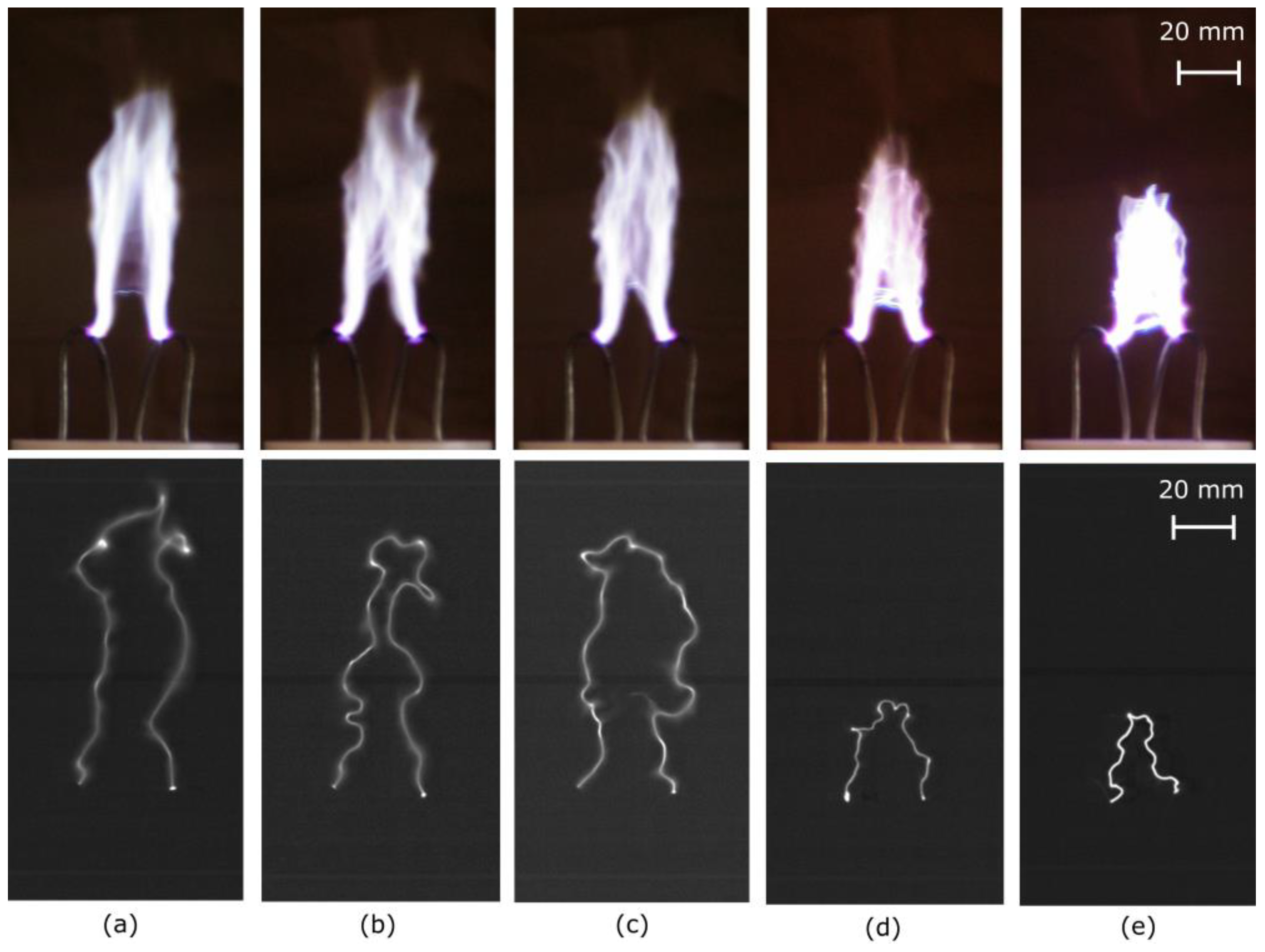

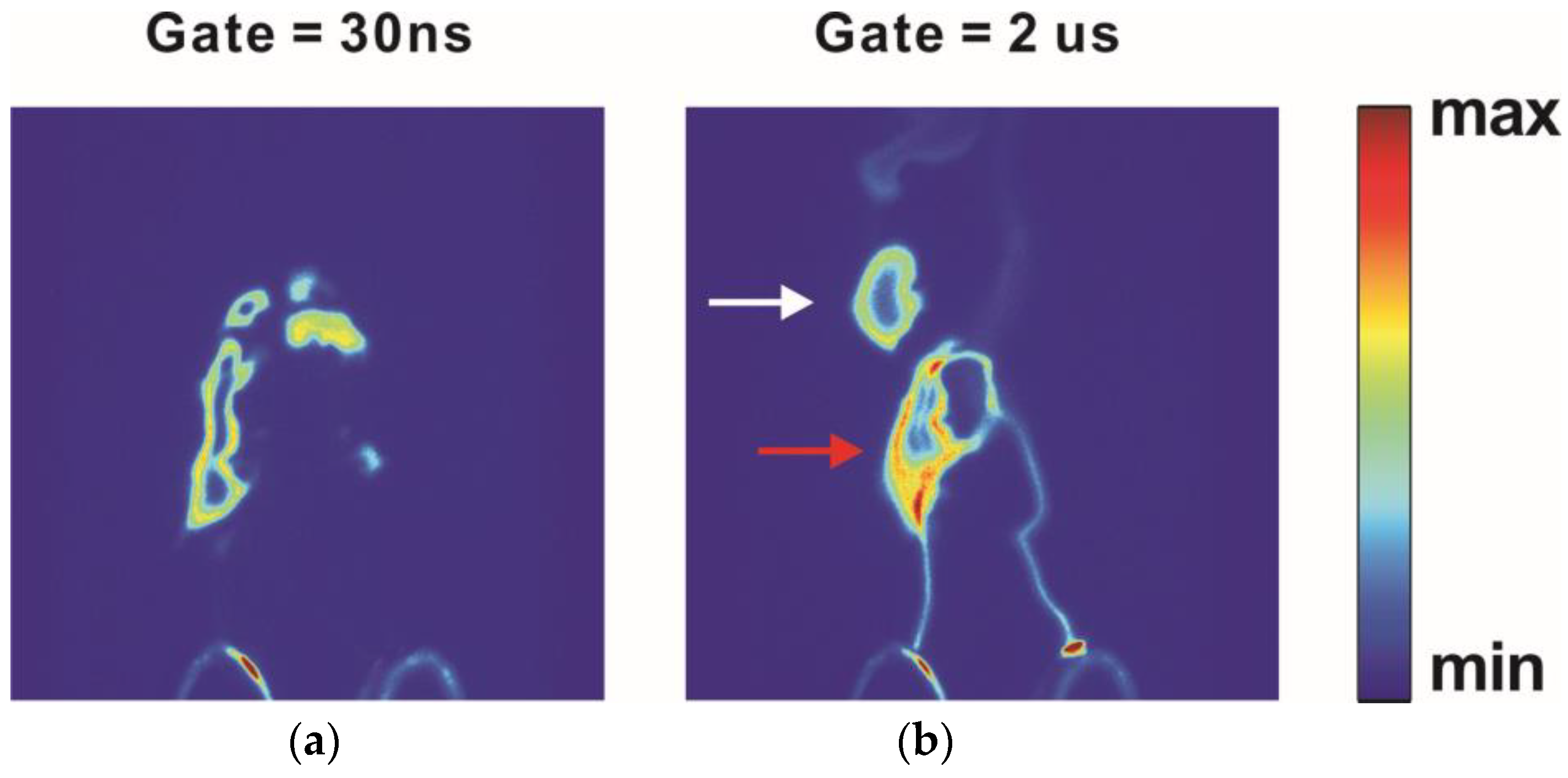

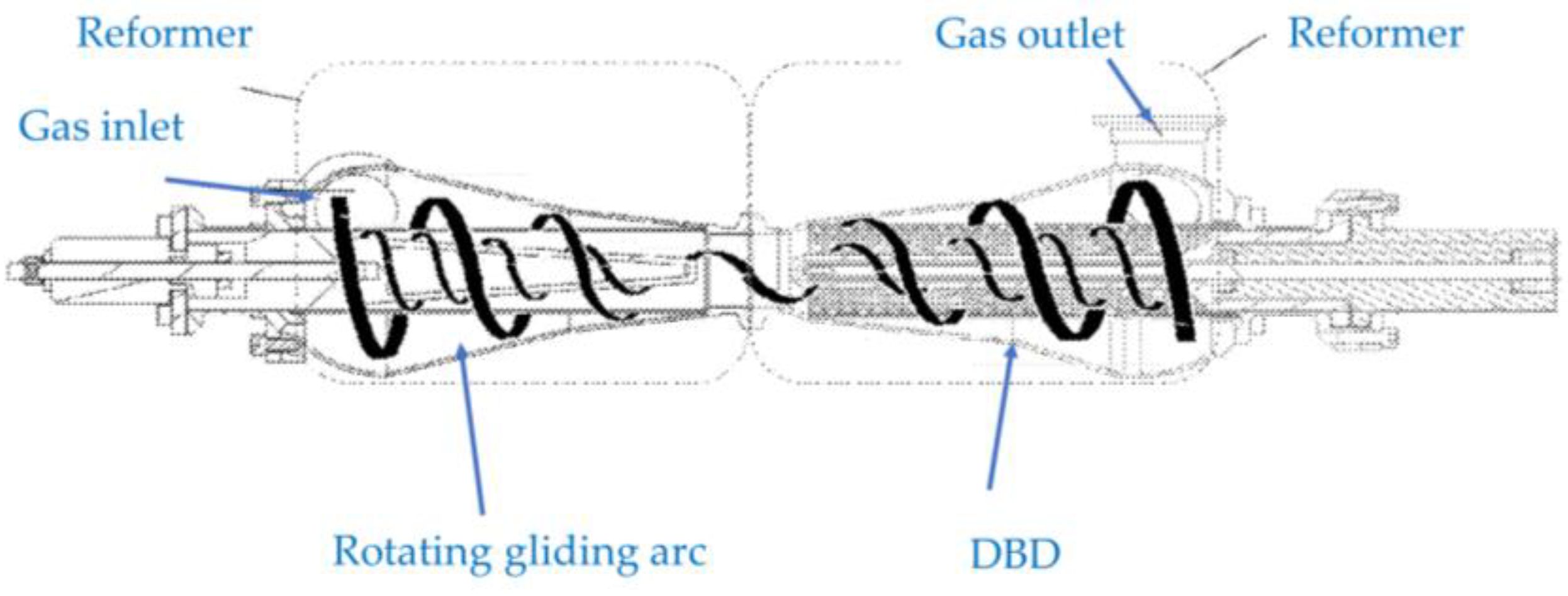

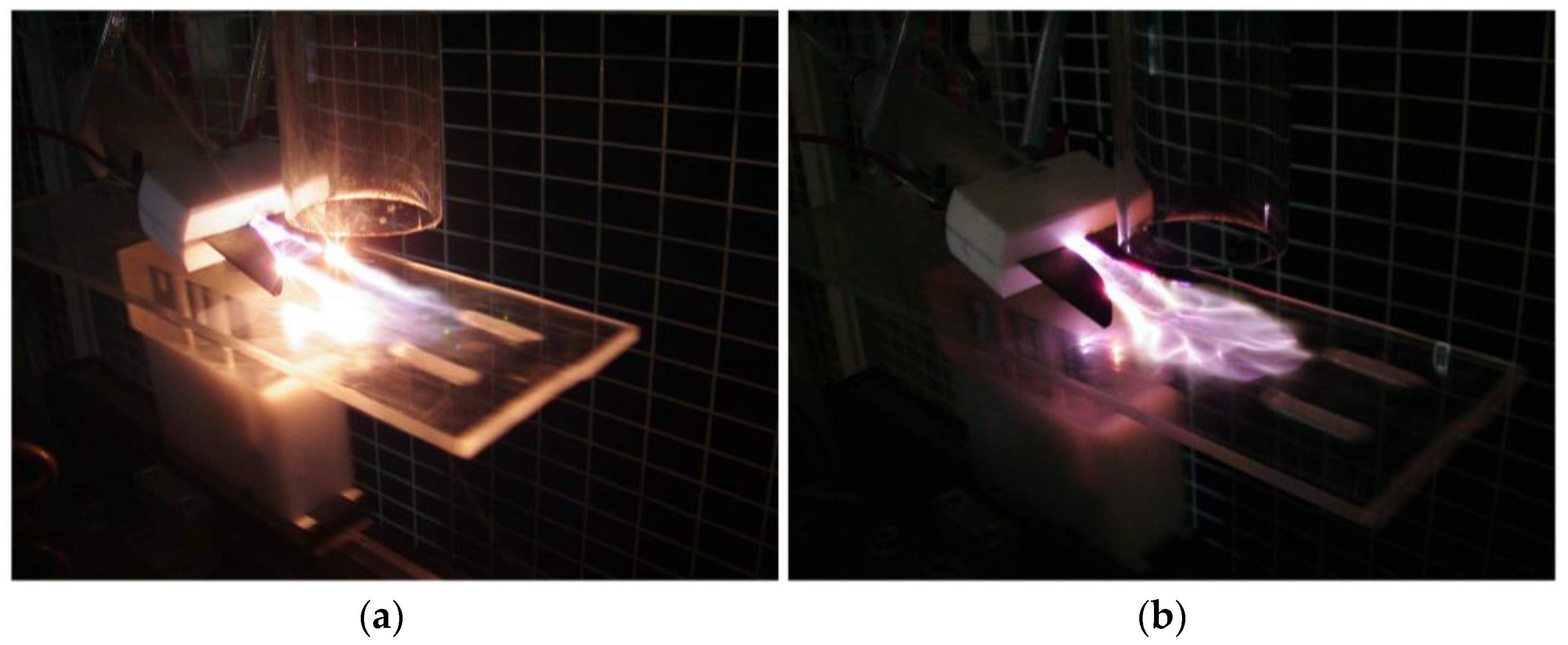

4. Plasmas Having Properties of Thermal and Nonthermal Plasmas

5. Plasmas Enhanced by Additional Energy

5.1. Combination with Thermal Energy

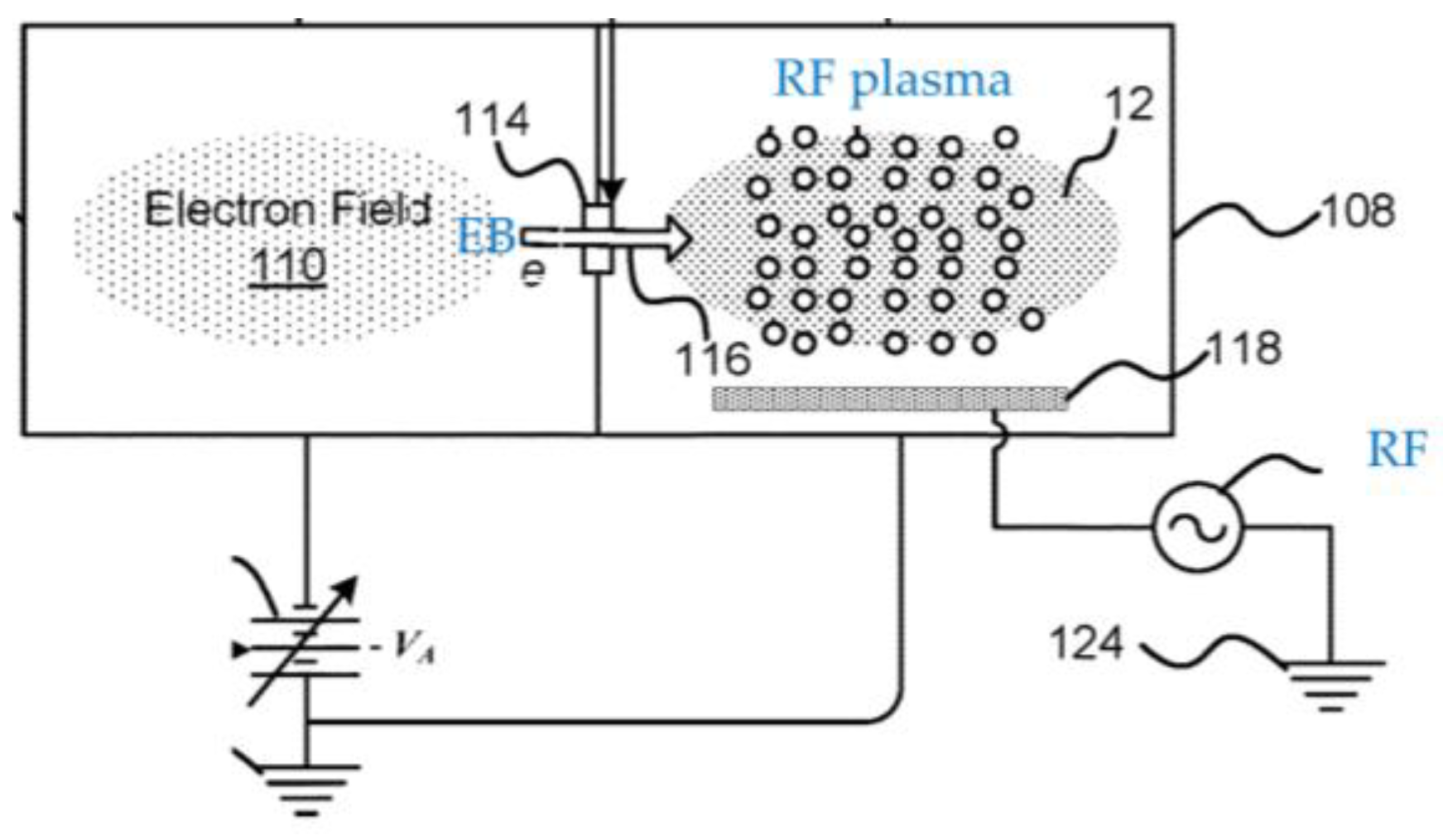

5.2. Combination with Electron Beam

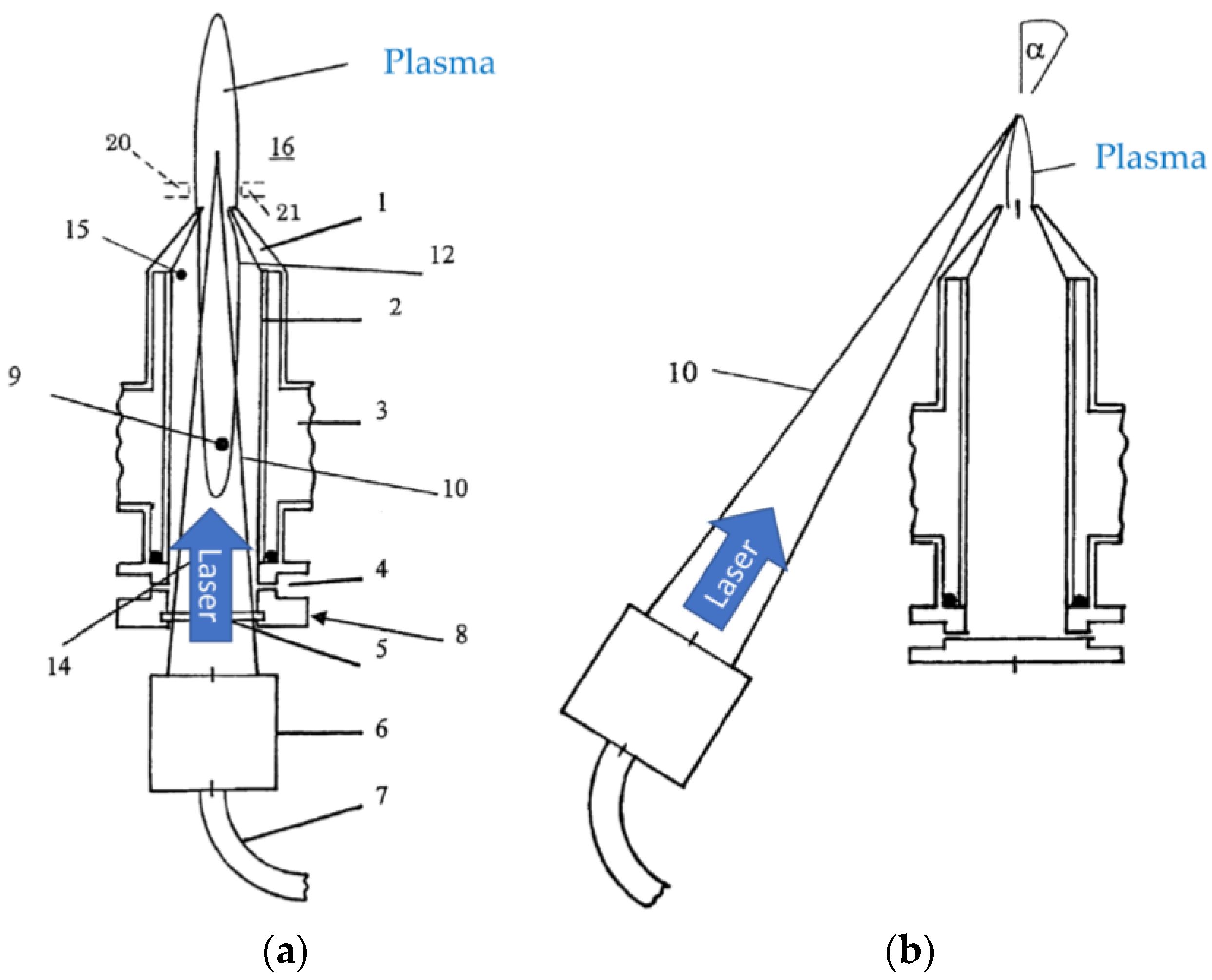

5.3. Combination with Photoexcitation

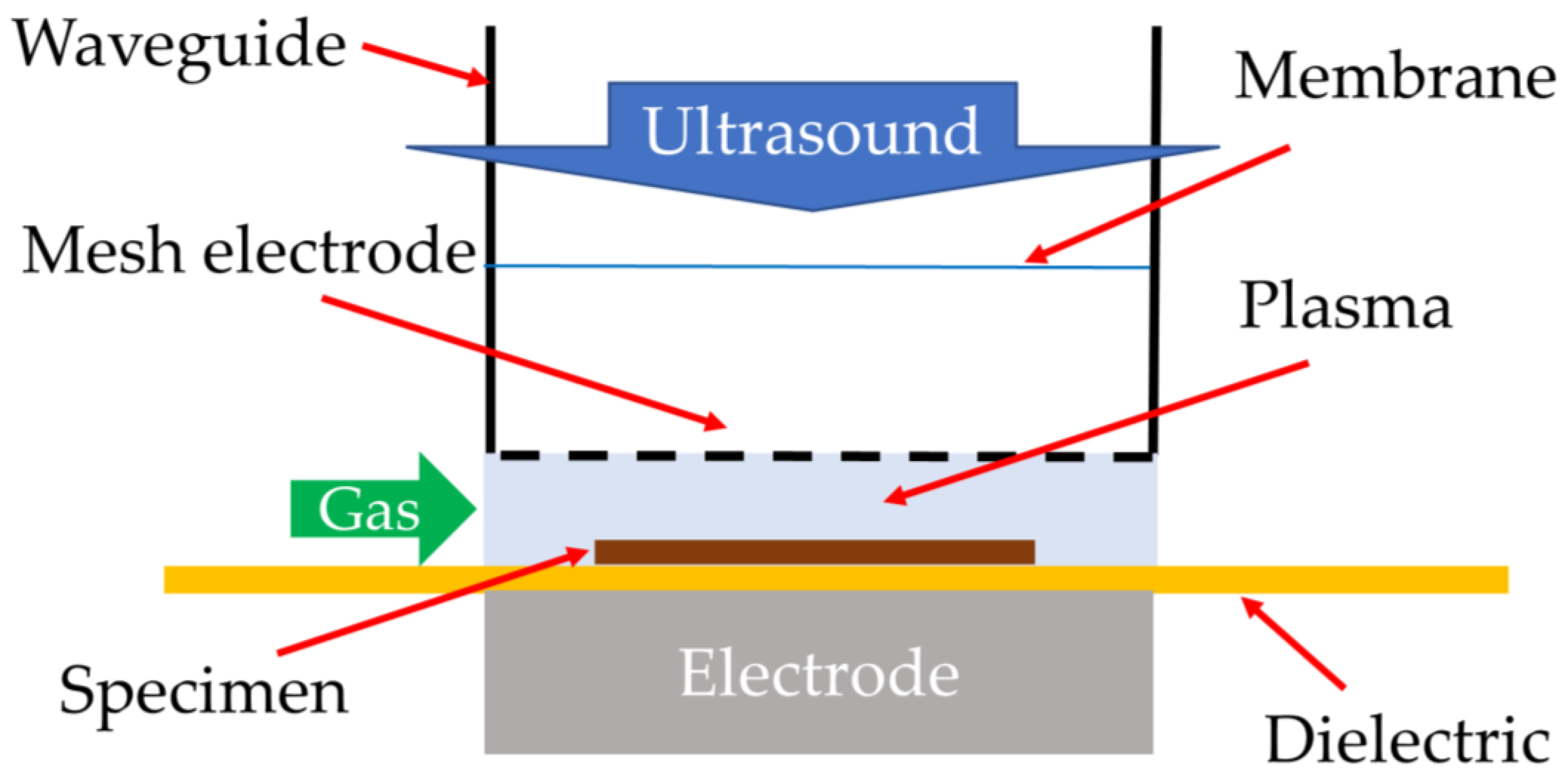

5.4. Combination with Acoustic Energy or Mechanical Vibration

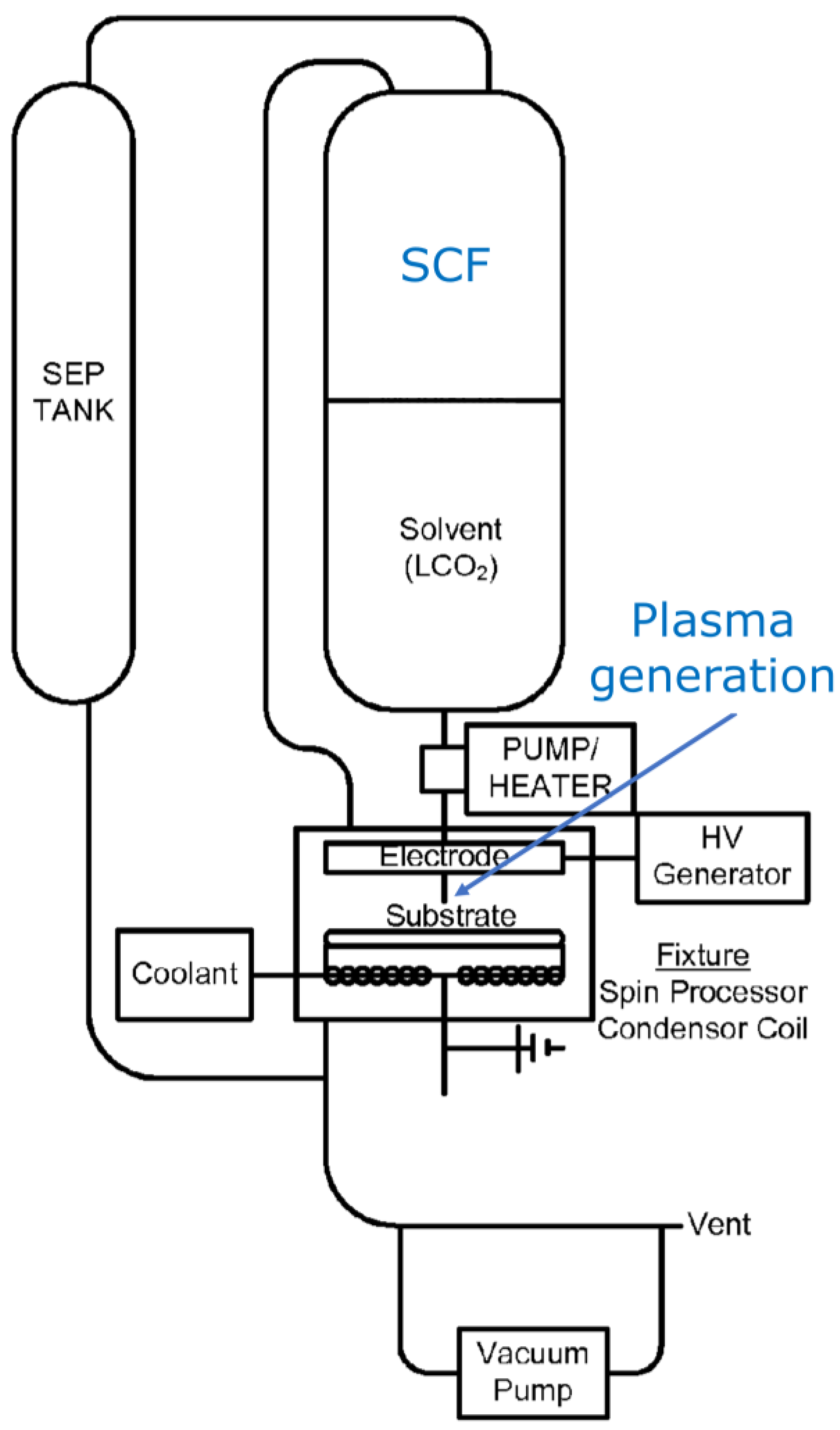

6. Plasmas Operated in a Unique Medium

7. Characterization Techniques

8. Discussion

9. Summary and Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fridman, A.; Kennedy, L.A. Plasma Physics and Engineering, 1st ed.; Taylor & Francis: New York, NY, USA, 2004. [Google Scholar] [CrossRef]

- Yoshida, T.; Tani, T.; Nishimura, H.; Akashi, K. Characterization of a hybrid plasma and its application to a chemical synthesis. J. Appl. Phys. 1983, 54, 640. [Google Scholar] [CrossRef]

- Kusano, Y. Plasma surface modification at atmospheric pressure. Surf. Eng. 2009, 25, 415–416. [Google Scholar] [CrossRef]

- Kusano, Y. Atmospheric pressure plasma processing for polymer adhesion—A review. J. Adhes. 2014, 90, 755–777. [Google Scholar] [CrossRef]

- McKelliget, J.W.; El-Kaddah, N. Modeling of materials synthesis in hybrid plasma reactors: Production of silicon by thermal decomposition of SiCI4. Metall. Trans. B 1990, 21, 589–598. [Google Scholar] [CrossRef]

- Saiki, G.; Kondo, J.; Takeda, K.; Mutsuo, M.; Tutomu, O. Process for Producing Ultrafine Particles of Metals, Metal Compounds and Ceramics and Apparatus Used Therefor. U.S. Patent 4,812,166 A, 14 March 1989. [Google Scholar]

- Cho, Y.K.; Tan, K.; Janakiraman, K.; Huang, J. Inductive/Capacitive Hybrid Plasma Source and System with Such Chamber. U.S. Patent 9,034,143 B2, 19 May 2015. [Google Scholar]

- Chen, X.; Garg, S.; Yang, J.G. RPS Assisted RF Plasma Source for Semiconductor Processing. U.S. Patent 9,741,545 B2, 22 August 2017. [Google Scholar]

- Chen, X.; Garg, S.; Yang, J.G. RPS Assisted RF Plasma Source for Semiconductor Processing. U.S. Patent 10,056,233 B2, 21 August 2018. [Google Scholar]

- Cui, Z.; Zhang, H.; Wang, A.; Chen, Z.; Ingle, N.K. 3D NAND High Aspect Ratio Structure Etch. U.S. Patent 10,692,880 B2, 23 June 2020. [Google Scholar]

- Roppel, T.A.; Asmussen, J.; Reinhard, D.K. Dual Plasma Microwave Apparatus and Method for Treating a Surface. U.S. Patent 4,691,662 A, 8 September 1987. [Google Scholar]

- Tonmitr, N.; Yonesu, A.; Hayashi, N. Surface sterilization using LF-microwave hybrid plasma. Jpn. J. Appl. Phys. 2021, 60, SAAE01. [Google Scholar] [CrossRef]

- Bárdoš, L.; Baránková, H. Device for Hybrid Plasma Processing. U.S. Patent 6,899,054 B1, 31 May 2005. [Google Scholar]

- Bárdoš, L.; Baránková, H.; Gustavsson, L.E.; Teer, D.G. New microwave and hollow cathode hybrid plasma sources. Surf. Coat. Technol. 2004, 177–178, 651–656. [Google Scholar] [CrossRef]

- Choi, D.K. Hybrid Plasma Reactor. U.S. Patent 8,866,390 B2, 21 October 2014. [Google Scholar]

- Choi, D.K. Hybrid Plasma Reactor. U.S. Patent 9,451,686 B2, 20 September 2016. [Google Scholar]

- Vaduganathan, L.; Poonamallie, B.A.; Nagalingam, M. Effects of Temperature and Flow Rates of Ozone Generator on the DBD by Varying Various Electrical Parameters. Am. J. Appl. Sci. 2012, 9, 1496–1502. [Google Scholar] [CrossRef]

- Kusano, Y.; Evetts, J.E.; Hutchings, I.M. Deposition of boron carbon nitride films by dual cathode magnetron sputtering. Thin Solid Films 1999, 343–344, 250–253. [Google Scholar] [CrossRef]

- Aijaz, A.; Lundin, D.; Larsson, P.; Helmersson, U. Dual-magnetron open field sputtering system for sideways deposition of thin films. Surf. Coat. Technol. 2010, 204, 2165–2169. [Google Scholar] [CrossRef]

- Kong, P.C.; Grandy, J.D. Methods of Chemically Converting First Materials to Second Materials Utilizing Hybrid-Plasma Systems. U.S. Patent 6,372,156 B1, 16 April 2002. [Google Scholar]

- Kong, P.C. Modular Hybrid Plasma Gasifier for Use in Converting Combustible Material to Synthesis Gas. U.S. Patent 10,208,263 B2, 19 February 2019. [Google Scholar]

- Smith, D.L. Thin-Film Deposition: Principles and Practice, 1st ed.; McGraw Hill, Inc.: New York, NY, USA, 1995; pp. 1–616. [Google Scholar]

- Chen, G.S.; Yang, L.C.; Tian, H.S.; Hsu, C.S. Evaluating substrate bias on the phase-forming behavior of tungsten thin films deposited by diode and ionized magnetron sputtering. Thin Solid Films 2005, 484, 83–89. [Google Scholar] [CrossRef]

- Chiu, K.F.; Barber, Z. Texture development in silver films deposited by ionised magnetron sputter deposition. Thin Solid Films 2000, 358, 264–269. [Google Scholar] [CrossRef]

- Chiu, K.P.; Barber, Z.H.; Somekh, R.E. The control of film stress using ionised magnetron sputter deposition. Thin Solid Films 1999, 343–344, 39–42. [Google Scholar] [CrossRef]

- Tranchant, J.; Angleraud, B.; Yessier, P.Y.; Besland, M.P.; Landesman, J.P.; Djouadi, M.A. Residual stress control in MoCr thin films deposited by ionized magnetron sputtering. Surf. Coat. Technol. 2006, 200, 6549–6553. [Google Scholar] [CrossRef]

- Tranchant, J.; Tessier, P.Y.; Landesman, J.P.; Djouadi, M.A.; Angleraud, B.; Renault, P.O.; Girault, B.; Goudeau, P. Relation between residual stresses and microstructure in Mo(Cr) thin films elaborated by ionized magnetron sputtering. Surf. Coat. Technol. 2008, 202, 2247–2251. [Google Scholar] [CrossRef]

- Christou, C.; Chiu, K.F.; Barber, Z.H. A spectroscopic study of DC magnetron and RF coil plasmas in ionised physical vapour deposition. Vacuum 2000, 58, 250–255. [Google Scholar] [CrossRef]

- Schneider, J.M.; Sproul, W.D. Crystalline alumina deposited at low temperatures by ionized magnetron sputtering. J. Vac. Sci. Technol. A 1997, 15, 1084–1088. [Google Scholar] [CrossRef]

- Schneider, J.M.; Sproul, W.D.; Matthews, A. Reactive ionized magnetron sputtering of crystalline alumina coatings. Surf. Coat. Technol. 1998, 98, 1473–1476. [Google Scholar] [CrossRef]

- Kusano, Y.; Christou, C.; Barber, Z.H.; Evetts, J.E.; Hutchings, I.M. Deposition of carbon nitride films by ionised magnetron sputtering. Thin Solid Films 1999, 355–356, 117–121. [Google Scholar] [CrossRef]

- Kusano, Y.; Barber, Z.H.; Evetts, J.E.; Hutchings, I.M. Tribological and mechanical properties of carbon nitride films deposited by ionised magnetron sputtering. Surf. Coat. Technol. 2000, 124, 104–109. [Google Scholar] [CrossRef]

- Kusano, Y.; Barber, Z.H.; Evetts, J.E.; Hutchings, I.M. Influence of inert gases on ionized magnetron plasma deposition of carbon nitride thin films. Surf. Coat. Technol. 2003, 174–175, 601–605. [Google Scholar] [CrossRef]

- Angleraud, B.; Mubumbila, N.; Tessier, P.Y. Effect of a r.f. antenna on carbon nitride films deposited by ionized r.f. magnetron sputtering. Diam. Relat. Mater. 2003, 12, 1093–1097. [Google Scholar] [CrossRef]

- Angleraud, B.; Tessier, P.Y. Improved film deposition of carbon and carbon nitride materials on patterned substrates by ionized magnetron sputtering. Surf. Coat. Technol. 2004, 180–181, 59–65. [Google Scholar] [CrossRef]

- Yoshida, T. Low-gas-pressure sputtering by means of microwave-enhanced magnetron plasma excited by electron cyclotron resonance. Appl. Phys. Lett. 1992, 61, 1733. [Google Scholar] [CrossRef]

- Xu, J.; Xinlu Deng, X.L.; Zhang, J.L.; Lu, W.G.; Ma, T.C. Characterization of CNx films prepared by twinned ECR plasma source enhanced DC magnetron sputtering. Thin Solid Films 2001, 390, 107–112. [Google Scholar] [CrossRef]

- Chatterjee, P.K.; Malhi, S.D.S.; deWit, M.; Hosack, H.; Harward, M.G.; Moslehi, M.M. Integrated Circuits. In Reference Data for Engineers: Radio, Electronics, Computer, and Communications, 9th ed.; Middleton, W.M., Valkenburg, M.E.V., Eds.; Newnes: Woburn, MA, USA, 2002; pp. 20-1–20-113. [Google Scholar] [CrossRef]

- Efthimion, P.C.; Gilson, E.; Grisham, L.; Kolchin, P.; Davidson, R.C.; YU, S.; Logan, B.G. ECR plasma source for heavy ion beam charge neutralization. Laser Part. Beams 2003, 21, 37–40. [Google Scholar] [CrossRef]

- Gudmundsson, J.T. Ionized physical vapor deposition (IPVD): Magnetron sputtering discharges. J. Phys. Conf. Ser. 2008, 100, 082002. [Google Scholar] [CrossRef]

- Helmersson, U.; Lattemann, M.; Bohlmark, J.; Ehiasarian, A.P.; Gudmundsson, J.T. Ionized physical vapor deposition (IPVD): A review of technology and applications. Thin Solid Films 2006, 513, 1–24. [Google Scholar] [CrossRef]

- Sarakinos, K.; Alami, J.; Konstantinidis, S. High power pulsed magnetron sputtering: A review on scientific and engineering state of the art. Surf. Coat. Technol. 2010, 204, 1661–1684. [Google Scholar] [CrossRef]

- Ito, W.; Oishi, A.; Okayama, S.; Yoshida, Y.; Homma, N.; Morishita, T.; Haga, T.; Yamaya, K. Highest crystallinity of a-axis YBCO films by DC-94.92 MHz hybrid plasma magnetron sputtering. Phys. C Supercond. 1993, 204, 295–298. [Google Scholar] [CrossRef]

- Yoshida, Y.; Ito, W.; Morishita, T. Method of Manufacturing Y-Ba-Cu-O Superconducting Thin Film. U.S. Patent 5,466,665 A, 14 November 1995. [Google Scholar]

- Ahn, H.S.; Hayashi, N.; Ihara, S.; Yamabe, C. Ozone Generation Characteristics by Superimposed Discharge in Oxygen-Fed Ozonizer. Jpn. J. Appl. Phys. 2003, 42, 6578–6583. [Google Scholar] [CrossRef]

- Leipold, F.; Schultz-Jensen, N.; Kusano, Y.; Bindslev, H.; Jacobsen, T. Decontamination of objects in a sealed container by means of atmospheric pressure plasmas. Food Control 2011, 22, 1296–1301. [Google Scholar] [CrossRef]

- Alim, M.M.; Oudini, N.; Tadjine, R. Experimental investigation of hybrid plasma reactor for duplex surface treatment. Eur. Phys. J. Appl. Phys. 2022, 97, 15. [Google Scholar] [CrossRef]

- Díaz-Guillén, J.C.; Alvarez-Vera, M.; Díaz-Guillén, J.A.; Acevedo-Davila, J.L.; Naeem, M.; Hdz-García, H.M.; Granda-Gutiérrez, E.E.; Muños-Arroyo, R. A Hybrid Plasma Treatment of H13 Tool Steel by Combining Plasma Nitriding and Post-Oxidation. J. Mater. Eng. Perform. 2018, 27, 6118–6126. [Google Scholar] [CrossRef]

- Díaz-Guillén, J.C.; Naeem, M.; Hdz-García, H.M.; Acevedo-Davila, J.L.; Díaz-Guillén, M.R.; Khan, M.A.; Iqbal, J.; Mtz-Enriquez, A.I. Duplex plasma treatment of AISI D2 tool steel by combining plasma nitriding (with and without white layer) and post-oxidation. Surf. Coat. Technol. 2020, 385, 125420. [Google Scholar] [CrossRef]

- Ueda, M.; Gomes, G.F.; Kostov, K.G.; Reuther, H.; Lepienski, C.M.; Soares, P.C., Jr.; Takai, O.; Silva, M.M. Results from Experiments on Hybrid Plasma Immersion Ion Implantation/Nitriding Processing of Materials. Braz. J. Phys. 2004, 34, 1632–1637. [Google Scholar] [CrossRef]

- Throwarh, K.; Hauert, R.; Thorwarth, G. Coating for a Titanium Alloy Substrate. EU Patent 2,996,732 B1, 1 January 2020. [Google Scholar]

- Hsieh, C.C.; Lin, D.L.; Tseng, C.P.; Tsai, W.F.; Chen, J.S.; Ai, C.F. Roll-to-Roll Hybrid Plasma Modular Coating System. U.S. Patent 9,892,889 B2, 13 February 2018. [Google Scholar]

- Fridman, A.; Nester, S.; Kennedy, L.A.; Saveliev, A.; Mutaf-Yardimci, O. Gliding arc gas discharge. Prog. Energy Combust. Sci. 1999, 25, 211–231. [Google Scholar] [CrossRef]

- Zhu, J.J.; Gao, J.L.; Ehn, A.; Aldén, M.; Li, Z.S.; Moseev, D.; Kusano, Y.; Salewski, M.; Alpers, A.; Gritzmann, P.; et al. Measurements of 3D slip velocities and plasma column lengths of a gliding arc discharge. Appl. Phys. Lett. 2015, 106, 044101. [Google Scholar] [CrossRef]

- Du, C.M.; Wang, J.; Zhang, L.; Li, H.X.; Liu, H.; Xiong, Y. The application of a non-thermal plasma generated by gas–liquid gliding arc discharge in sterilization. New J. Phys. 2012, 14, 013010. [Google Scholar] [CrossRef]

- Kusano, Y.; Sørensen, B.F.; Andersen, T.L.; Toftegaard, H.L.; Leipold, F.; Salewski, M.; Sun, Z.W.; Zhu, J.J.; Li, Z.S.; Aldén, M. Water-cooled non-thermal gliding arc for adhesion improvement of glass-fibre-reinforced polyester. J. Phys. D Appl. Phys. 2013, 46, 135203. [Google Scholar] [CrossRef]

- Kusano, Y.; Teodoru, S.; Leipold, F.; Andersen, T.L.; Sørensen, B.F.; Rozlosnik, N.; Michelsen, P.K. Gliding arc discharge—Application for adhesion improvement of fibre reinforced polyester composites. Surf. Coat. Technol. 2008, 202, 5579–5582. [Google Scholar] [CrossRef]

- Kusano, Y.; Sørensen, B.F.; Andersen, T.L.; Leipold, F. Adhesion improvement of glass-fibre reinforced polyester composites by gliding arc discharge treatment. J. Adhes. 2013, 89, 433–459. [Google Scholar] [CrossRef]

- Kusano, Y.; Bardenshtein, A.; Morgen, P. Fluoropolymer coated alanine films treated by atmospheric pressure plasmas—In comparison with gamma irradiation. Plasma Process. Polym. 2018, 15, 1700131. [Google Scholar] [CrossRef]

- Kusano, Y.; Berglund, L.; Aitomäki, Y.; Oksman, K.; Madsen, B. Gliding arc surface modification of carrot nanofibre coating—Perspective for composite processing. IOP Conf. Ser. Mater. Sci. Eng. 2016, 139, 012027. [Google Scholar] [CrossRef]

- Kusano, Y.; Andersen, T.L.; Toftegaard, H.L.; Leipold, F.; Bardenshtein, A.; Krebs, N. Plasma treatment of carbon fibres and glass-fibre-reinforced polyesters at atmospheric pressure for adhesion improvement. Int. J. Mater. Eng. Innov. 2014, 5, 122–137. [Google Scholar] [CrossRef]

- Kusano, Y.; Salewski, M.; Leipold, F.; Zhu, J.J.; Ehn, A.; Li, Z.S.; Aldén, M. Stability of alternating current gliding arcs. Eur. Phys. J. D 2014, 68, 319. [Google Scholar] [CrossRef]

- Lu, S.Y.; Sun, X.M.; Li, X.D.; Yan, J.H.; Du, C.M. Physical characteristics of gliding arc discharge plasma generated in a laval nozzle. Phys. Plasmas 2012, 19, 072122. [Google Scholar] [CrossRef]

- Mitsugi, F.; Furukawa, J.; Ohshima, T.; Kawasaki, H.; Kawasaki, T.; Aoqui, S.; Stryczewska, H.D. Observation of dynamic behavior of gliding arc discharge. Eur. Phys. J. Appl. Phys. 2013, 61, 24308. [Google Scholar] [CrossRef]

- Mutaf-Yardimci, O.; Saveliev, A.V.; Porshnev, P.I.; Fridman, A.A.; Kennedy, L.A. Non-equilibrium effects in gliding arc discharges. Ann. N. Y. Acad. Sci. 1999, 891, 304–308. [Google Scholar] [CrossRef]

- Šperka, J.; Souček, P.; Van Loon, J.J.W.A.; Dowson, A.; Schwarz, C.; Krause, J.; Kroesen, G.; Kudrle, V. Hypergravity effects on glide arc plasma. Eur. Phys. J. D 2013, 67, 1–9. [Google Scholar] [CrossRef]

- Sun, Z.W.; Zhu, J.J.; Li, Z.S.; Aldén, M.; Leipold, F.; Salewski, M.; Kusano, Y. Optical diagnostics of a gliding arc. Opt. Express 2013, 21, 6028–6044. [Google Scholar] [CrossRef]

- Tu, X.; Gallon, H.J.; Whitehead, J.C. Dynamic behavior of an atmospheric argon gliding arc plasma. IEEE Trans. Plasma Sci. 2011, 39, 2900–2901. [Google Scholar] [CrossRef]

- Zhao, T.L.; Liu, J.L.; Li, X.S.; Liu, J.B.; Song, Y.H.; Xu, Y.; Zhu, A.M. Temporal evolution characteristics of an annular-mode gliding arc discharge in a vortex flow. Phys. Plasmas 2014, 21, 053507. [Google Scholar] [CrossRef]

- Zhu, J.J.; Gao, J.L.; Li, Z.S.; Ehn, A.; Aldén, M.; Larsson, A.; Kusano, Y. Sustained diffusive alternating current gliding arc discharge in atmospheric pressure air. Appl. Phys. Lett. 2014, 105, 234102. [Google Scholar] [CrossRef]

- Zhu, J.J.; Sun, Z.W.; Li, Z.S.; Ehn, A.; Aldén, M.; Salewski, M.; Leipold, F.; Kusano, Y. Dynamics, OH distributions and UV emission of a gliding arc at various flow-rates investigated by optical measurements. J. Phys. D Appl. Phys. 2014, 47, 295303. [Google Scholar] [CrossRef]

- Zhu, J.J.; Gao, J.L.; Ehn, A.; Aldén, M.; Larsson, A.; Kusano, Y.; Li, Z.S. Spatiotemporally resolved characteristics of a gliding arc discharge in a turbulent air flow at atmospheric pressure. Phys. Plasmas 2017, 24, 013514. [Google Scholar] [CrossRef]

- Gangoli, S.P.; Gutsol, A.F.; Fridman, A.A. A non-equilibrium plasma source: Magnetically stabilized gliding arc discharge: I. Design and diagnostics. Plasma Sources Sci. Technol. 2010, 19, 065003. [Google Scholar] [CrossRef]

- Sagás, J.C.; Neto, A.H.; Filho, A.C.P.; Maciel, H.S.; Lacava, P.T. Basic characteristics of gliding-arc discharges in air and natural gas. IEEE Trans. Plasma Sci. 2011, 39, 775–780. [Google Scholar] [CrossRef]

- Xu, G.; Ding, X. Electrical characterization of a reverse vortex gliding arc reactor in atmosphere. IEEE Trans. Plasma Sci. 2012, 40, 3458–3464. [Google Scholar] [CrossRef]

- Kuznetsova, I.V.; Kalashnikov, N.Y.; Gutsol, A.F.; Fridman, A.A.; Kennedy, L.A. Effect of “overshooting” in the transitional regimes of the low-current gliding arc discharge. J. Appl. Phys. 2002, 92, 4231–4237. [Google Scholar] [CrossRef]

- Yu, L.; Yan, J.H.; Tu, X.; Li, X.D.; Lu, S.Y.; Cen, K.F. Effect of water on gliding arc discharge fluctuation. Europhys. Lett. 2008, 83, 45001. [Google Scholar] [CrossRef]

- Zhang, C.; Shao, T.; Xu, J.; Ma, H.; Duan, L.; Ren, C.; Yan, P. A gliding discharge in open air sustained by high-voltage resonant ac power supply. IEEE Trans. Plasma Sci. 2012, 40, 2843–2849. [Google Scholar] [CrossRef]

- Zhang, C.; Shao, T.; Yan, P.; Zhou, Y. Nanosecond-pulse gliding discharges between point-to-point electrodes in open air. Plasma Sources Sci. Technol. 2014, 23, 035004. [Google Scholar] [CrossRef]

- Korolev, Y.D.; Frants, O.B.; Geyman, V.G.; Landl, N.V.; Kasyanov, V.S. Low-current ‘gliding arc’ in air flow. IEEE Trans. Plasma Sci. 2011, 39, 3319–3325. [Google Scholar] [CrossRef]

- Benstaali, B.; Boubert, P.; Cheron, B.G.; Addou, A.; Brisset, J.L. Density and Rotational Temperature Measurements of the OH° and NO° Radicals Produced by a Gliding Arc in Humid Air. Plasma Chem. Plasma Process. 2002, 22, 553–571. [Google Scholar] [CrossRef]

- Chernyak, V.Y.; Prysiazhnevych, I.V.; Solomenko, O.V.; Olzewski, S.V.; Diatczyk, J.; Stryczewska, H.; Belenok, N.; Shyht, I. Determining of the electronic excitation temperature in atmospheric pressure plasmas by using emission spectra of metals with complex low-resolved multiplet structure. Ukr. J. Phys. 2010, 55, 1083–1089. [Google Scholar]

- Li, H.; Xie, M. Plasma parameters of a gliding arc jet at atmospheric pressure obtained by a line-ratio method. Plasma Sci. Technol. 2013, 15, 776. [Google Scholar] [CrossRef]

- Tu, X.; Yu, L.; Yan, J.H.; Cen, K.F.; Chéron, B.G. Dynamic and spectroscopic characteristics of atmospheric gliding arc in gas-liquid two-phase flow. Phys. Plasmas 2009, 16, 113506. [Google Scholar] [CrossRef]

- Zhu, J.J.; Ehn, A.; Gao, J.L.; Kong, C.D.; Aldén, M.; Larsson, A.; Salewski, M.; Leipold, F.; Kusano, Y.; Li, Z.S. Translational, rotational, vibrational and electron temperatures of a gliding arc discharge. Opt. Express 2017, 25, 20243–20257. [Google Scholar] [CrossRef]

- Dalaine, V.; Cormier, J.M.; Lefaucheux, P. A gliding discharge applied to H2S destruction. J. Appl. Phys. 1998, 83, 2435. [Google Scholar] [CrossRef]

- Dalaine, V.; Cormier, J.M.; Pellerin, S.; Lefaucheux, P. H2S destruction in 50 Hz and 25 kHz gliding arc reactors. J. Appl. Phys. 1998, 84, 1215. [Google Scholar] [CrossRef]

- Dalaine, V.; Cormier, J.M.; Pellerin, S.; Hnatiuc, E. Study and modelling of a 50 Hz gliding discharge. In Proceedings of the 6th International Conference on Optimization of Electrical and Electronic Equipments (OPTIM ’98), Brasov, Romania, 14–15 May 1998. [Google Scholar] [CrossRef]

- Richard, F.; Cormier, J.M.; Pellerin, S.; Chapelle, J. Physical study of a gliding arc discharge. J. Appl. Phys. 1996, 79, 2245. [Google Scholar] [CrossRef]

- Pellerin, S.; Richard, F.; Chapelle, J.; Cormier, J.M.; Musiol, K. Heat string model of bi-dimensional dc Glidarc. J. Phys. D Appl. Phys. 2000, 33, 2407–2419. [Google Scholar] [CrossRef]

- Pellerin, S.; Cormier, J.M.; Richard, F.; Musiol, K.; Chapelle, J. Determination of the electrical parameters of a bi-dimensional d.c. Glidarc. J. Phys. D Appl. Phys. 1999, 32, 891–897. [Google Scholar] [CrossRef]

- Fridman, A.; Gutsol, A.; Gangoli, S.; Ju, Y.; Ombrello, Y. Characteristics of Gliding Arc and Its Application in Combustion Enhancement. J. Propuls. Power 2008, 24, 1216–1228. [Google Scholar] [CrossRef]

- Ombrello, T.; Qin, X.; Ju, Y.; Gutsol, A.; Fridman, A.; Carter, C. Combustion Enhancement via Stabilized Piecewise Nonequilibrium Gliding Arc Plasma Discharge. AIAA J. 2006, 44, 142–150. [Google Scholar] [CrossRef]

- Skowrónska, B.; Chmielewski, T.; Golański, D.; Szulc, J. Weldability of S700MC steel welded with the hybrid plasma + MAG method. Manuf. Rev. 2020, 7, 4. [Google Scholar] [CrossRef]

- Korzhik, V.N.; Pashchin, N.A.; Mikhoduj, O.L.; Grinyuk, A.A.; Babich, A.A.; Khaskin, V.Y. Comparative evaluation of methods of arc and hybrid plasma-arc welding of aluminum alloy 1561 using consumable electrode. Paton Weld. J. 2017, 4, 30–34. [Google Scholar] [CrossRef]

- Chen, Q.; Wang, G.; Zhang, H.; Runsheng, L. Research on microstructure and mechanical properties of hybrid plasma arc and micro-rolling additive manufacturing of Inconel 718 superalloy. Rapid Prototyp. J. 2022, 28, 1509–1519. [Google Scholar] [CrossRef]

- Asai, S.; Ogawa, T.; Ishizaki, Y.; Minemura, T.; Minami, H.; Iyazaki, S.M. Application of Plasma MIG Hybrid Welding to Dissimilar Joints between Copper and Steel. Weld. World 2012, 56, 37–42. [Google Scholar] [CrossRef]

- Liu, R.; Hao, Y.; Wang, T.; Wang, L.; Bogaerts, A.; Guo, H.; Yi, Y. Hybrid plasma-thermal system for methane conversion to ethylene and hydrogen. Chem. Eng. J. 2023, 463, 142442. [Google Scholar] [CrossRef]

- Vasilieva, T.M.; Vasiliev, M.N.; Garaeva, V.V.; Zlobin, I.S.; Mint, Z.Y.; Htau, K.M.; Kyaw, H.W.Y.K.; Zaw, H.K.K. Hybrid plasma—Prospects for application in medicine and biology. Russ. Phys. J. 2020, 62, 2092–2100. [Google Scholar] [CrossRef]

- Chen, Z.; Ventzek, P.; Ranjan, A. Hybrid Electron Beam and RF Plasma System for Controlled Content of Radicals and Ions. U.S. Patent 11,205,562 B2, 21 December 2021. [Google Scholar]

- Kurz, T.; Heinemann, T.; Gilljohann, M.F.; Chang, Y.Y.; Couperus Cabadağ, J.P.; Debus, A.; Kononenko, O.; Pausch, R.; Schöbel, S.; Assmann, R.R.; et al. Demonstration of a compact plasma accelerator powered by laser-accelerated electron beams. Nat. Commun. 2021, 12, 2895. [Google Scholar] [CrossRef]

- Varghese, B.; Verhagen, R.; Jurna, M.; Palero, J.A.; Horton, M.R.; Bonito, V. Skin Treatment Device for Multiphoton Ionization-Based Skin Treatment. U.S. Patent 10,092,771 B2, 9 October 2018. [Google Scholar]

- Bayer, E.; Hoeschele, J.; Steinwandel, J.; Willneff, R. Laser-Plasma Hybrid Welding Method. U.S. Patent 6,940,036 B2, 6 September 2005. [Google Scholar]

- Fang, C.; Kusano, Y.; Bardenshtein, A. High-speed plasma treatment of polyethylene terephthalate films using ultrasound assisted dielectric barrier discharge. Packag. Technol. Sci. 2021, 35, 643–649. [Google Scholar] [CrossRef]

- Kusano, Y.; Madsen, B.; Berglund, L.; Aitomäki, Y.; Oksman, K. Dielectric barrier discharge plasma treatment of cellulose nanofibre surfaces. Surf. Eng. 2018, 34, 825–831. [Google Scholar] [CrossRef]

- Kusano, Y.; Madsen, B.; Berglund, L.; Oksman, K. Modification of cellulose nanofiber surfaces by He/NH3 plasma at atmospheric pressure. Cellulose 2019, 26, 7185–7194. [Google Scholar] [CrossRef]

- Kusano, Y.; Norrman, K.; Singh, S.V.; Leipold, F.; Morgen, P.; Bardenshtein, A.; Krebs, N. Ultrasound enhanced 50 Hz plasma treatment of glass-fiber-reinforced polyester at atmospheric pressure. J. Adhes. Sci. Technol. 2013, 27, 825–833. [Google Scholar] [CrossRef]

- Kusano, Y.; Singh, S.V.; Bardenshtein, A.; Krebs, N.; Rozlosnik, N. Plasma surface modification of glass fibre reinforced polyester enhanced by ultrasonic irradiation. J. Adhes. Sci. Technol. 2010, 24, 1831–1839. [Google Scholar] [CrossRef]

- Kusano, Y.; Singh, S.V.; Norrman, K.; Drews, J.; Leipold, F.; Rozlosnik, N.; Bardenshtein, A.; Krebs, N. Ultrasound enhanced plasma surface modification at atmospheric pressure. Surf. Eng. 2012, 28, 453–457. [Google Scholar] [CrossRef]

- Kusano, Y.; Singh, S.V.; Norrman, K.; Leipold, F.; Drews, J.; Morgen, P.; Bardenshtein, A.; Krebs, N. Ultrasound enhanced plasma treatment of glass-fibre-reinforced polyester in atmospheric pressure air for adhesion improvement. J. Adhes. 2011, 87, 720–731. [Google Scholar] [CrossRef]

- Kusano, Y.; Cederløf, D.J.H.; Fæster, S. Plasma surface modification of glass fibre sizing for manufacturing polymer composites. Key Eng. Mater. 2020, 843, 159–164. [Google Scholar] [CrossRef]

- Krebs, N.; Bardenshtein, A.; Kusano, Y.; Bindslev, H.; Mortensen, H.J. Enhancing Plasma Surface Modification Using High Intensity and High Power Ultrasonic Acoustic Waves. U.S. Patent 8,399,795 B2, 19 March 2013. [Google Scholar]

- Otsuka, T.; Teranishi, K.; Nakane, T. Effect of Ultrasound in High-Pressure Glow Discharge. Jpn. J. Appl. Phys. 2001, 40, 3797–3800. [Google Scholar] [CrossRef]

- Nakane, T.; Miyajima, T.; Otsuka, T. Current Waveforms of Electric Discharge in Air under High-Intensity Acoustic Standing. Jpn. J. Appl. Phys. 2004, 43, 2852–2856. [Google Scholar] [CrossRef]

- Bálek, R.; Pekárek, S.; Bartáková, Z. Power ultrasound interaction with DC atmospheric pressure electrical discharge. Ultrasonics 2006, 44, e549–e553. [Google Scholar] [CrossRef]

- Zhang, Q.H.; Du, R.; Zhang, J.H.; Zhang, Q.B. An investigation of ultrasonic-assisted electrical discharge machining in gas. Int. J. Mach. Tools Manuf. 2006, 46, 1582–1588. [Google Scholar] [CrossRef]

- Khatri, B.C.; Rathod, P.; Valaki, J.B. Ultrasonic vibration–assisted electric discharge machining: A research review. Proc. Inst. Mech. Eng. B J. Mech. Eng. Manuf. 2015, 230, 319–330. [Google Scholar] [CrossRef]

- Hatsuzawa, T.; Hayase, M.; Oguchi, T. Mechanical vibration assisted plasma etching for etch rate and anisotropy improvement. Precis. Eng. 2002, 26, 442–447. [Google Scholar] [CrossRef]

- Bálek, R.; Pekárek, S.; Bartáková, Z. Ultrasonic resonator with electrical discharge cell for ozone generation. Ultrasonics 2007, 46, 227–234. [Google Scholar] [CrossRef]

- Pekárek, S.; Bálek, R. Ozone generation by hollow-needle to plate electrical discharge in an ultrasound field. J. Phys. D Appl. Phys. 2004, 37, 1214. [Google Scholar] [CrossRef]

- Drews, J.; Kusano, Y.; Leipold, F.; Bardenshtein, A.; Krebs, N. Ozone production in a dielectric barrier discharge with ultrasonic irradiation. Ozone Sci. Eng. 2011, 33, 483–488. [Google Scholar] [CrossRef]

- Kusano, Y.; Drews, J.; Leipold, F.; Fateev, A.; Bardenshtein, A.; Krebs, N. Influence of ultrasonic irradiation on ozone generation in a dielectric barrier discharge. J. Phys. Conf. Ser. 2012, 406, 012006. [Google Scholar] [CrossRef]

- Pekárek, S.; Bálek, R.; Kuhn, J.; Pospíšil, M. Effect of ultrasound waves on a hollow needle to plate electrical discharge in air or mixture of air with VOCs. Czechoslov. J. Phys. 2006, 56, B982–B989. [Google Scholar] [CrossRef]

- Choi, K.S.; Nakamura, S.; Murata, Y. Improvement of Charging Performance of Corona Charger in Electrophotography by Irradiating Ultrasonic Wave to Surrounding Region of Corona Electrode. Jpn. J. Appl. Phys. 2005, 44, 3248–3252. [Google Scholar] [CrossRef]

- Li, J.; Ma, C.; Zhu, S.; Yu, F.; Dai, B.; Yang, D. A Review of Recent Advances of Dielectric Barrier Discharge Plasma in Catalysis. Nanomaterials 2019, 9, 1428. [Google Scholar] [CrossRef]

- Bogaerts, A.; Tu, X.; Whitehead, J.C.; Centi, G.; Lefferts, L.; Guaitella, O.; Azzolina-Jury, F.; Kim, H.H.; Murphy, A.B.; Schneider, W.F.; et al. The 2020 plasma catalysis roadmap. J. Phys. D Appl. Phys. 2020, 53, 443001. [Google Scholar] [CrossRef]

- Khoja, A.H.; Tahir, M.; Amin, N.A.S. Recent developments in non-thermal catalytic DBD plasma reactor for dry reforming of methane. Energy Convers. Manag. 2019, 183, 529–560. [Google Scholar] [CrossRef]

- García-Moncada, N.; van Rooij, G.; Cents, T.; Lefferts, L. Catalyst-assisted DBD plasma for coupling of methane: Minimizing carbon-deposits by structured reactors. Catal. Today 2021, 369, 210–220. [Google Scholar] [CrossRef]

- Bruggeman, P.J.; Bogaerts, A.; Pouvesle, J.M.; Robert, E.; Szili, E.J. Plasma-liquid interactions. J. Appl. Phys. 2021, 130, 200401. [Google Scholar] [CrossRef]

- Chung, K.H.; Lam, S.S.; Park, Y.K.; Kim, S.J.; Jung, S.C. Application of liquid-phase plasma for the production of hydrogen and carbon from the plasma-induced cracking of liquid hydrocarbons. Fuel 2022, 328, 125297. [Google Scholar] [CrossRef]

- Joshi, A.A.; Locke, B.R.; Arce, P.; Finney, W.C. Formation of hydroxyl radicals, hydrogen peroxide and aqueous electrons by pulsed streamer corona discharge in aqueous solution. J. Hazard. Mater. 1995, 41, 3–30. [Google Scholar] [CrossRef]

- Locke, B.R.; Sato, M.; Sunka, P.; Hoffmann, M.R.; Chang, J.S. Electrohydraulic Discharge and Nonthermal Plasma for Water Treatment. Ind. Eng. Chem. Res. 2006, 45, 882–905. [Google Scholar] [CrossRef]

- Goto, M.; Sasaki, M.; Kiyan, T.; Fang, T.; Roy, B.C.; Namihira, T.; Akiyama, H.; Hara, M. Reaction in Plasma Generated in Supercritical Carbon Dioxide. J. Phys. Conf. Ser. 2008, 121, 082009. [Google Scholar] [CrossRef]

- Stauss, S.; Muneoka, H.; Terashima, K. Review on plasmas in extraordinary media: Plasmas in cryogenic conditions and plasmas in supercritical fluids. Plasma Sources Sci. Technol. 2018, 27, 023003. [Google Scholar] [CrossRef]

- Kawashima, A.; Nomura, S.; Toyota, H.; Takemori, T.; Mukasa, S.; Maehara, T. A supercritical carbon diaoxide plasma process for preparing tungsten oxide nanowire. Nanotechnology 2007, 18, 495603. [Google Scholar] [CrossRef] [PubMed]

- Kiyan, T.; Uemura, A.; Tanaka, K.; Zhang, C.H.; Namihira, T.; Sakugawa, T.; Katsuki, S.; Akiyama, H.; Roy, B.C.; Sasaki, M.; et al. Pulsed discharge plasmas in supercritical carbon dioxide. In Proceedings of the IEEE Pulsed Power Conference, Monterey, CA, USA, 13–17 June 2005. [Google Scholar] [CrossRef]

- Kawashima, A.; Toyota, H.; Nomura, S.; Takemori, T.; Mukasa, S.; Maehara, T.; Yamashita, H. 27.12 MHz plasma generation in supercritical carbon dioxide. J. Appl. Phys. 2007, 101, 093303. [Google Scholar] [CrossRef]

- Kawashima, A.; Nomura, S.; Toyota, H. Carbon-Coated Metal Element-Containing Nanowire Manufacturing Method. JP Patent 4,958,085 B2, 20 June 2012. [Google Scholar]

- Jackson, D.P. Method and Apparatus for Treating a Substrate with Dense Fluid and Plasma. U.S. Patent 8,197,603 B2, 12 June 2012. [Google Scholar]

- Crintea, D.L.; Czarnetzki, U.; Iordanova, S.; Koleva, I.; Luggenhölscher, D. Plasma diagnostics by optical emission spectroscopy on argon and comparison with Thomson scattering. J. Phys. D Appl. Phys. 2009, 42, 045208. [Google Scholar] [CrossRef]

- Hest, M.F.A.v.; Graaf, A.d.; Sanden, M.C.M.v.d.; Hest, M.F.A.v.; Graaf, A.d.; Schram, D.C. Use of in situ FTIR spectroscopy and mass spectrometry in an expanding hydrocarbon plasma. Plasma Sources Sci. Technol. 2000, 9, 615. [Google Scholar] [CrossRef]

- Rowe, B. A mass spectrometer for plasma diagnostics. Measurements of ion translational temperature, polarization and velocity effects. Int. J. Mass Spectrom. Ion Phys. 1975, 16, 209–223. [Google Scholar] [CrossRef]

- Auciello, O.; Flamm, D.L. Plasma Diagnostics, Discharge Parameters and Chemistry, 1st ed.; Academic Press: Cambridge, MA, USA, 1989; pp. 1–470. [Google Scholar] [CrossRef]

- Ishikawa, K. Chapter 5—Plasma diagnostics. In Cold Plasma in Food and Agriculture: Fundamentals and Applications, 1st ed.; Misra, N.N., Schlüter, O., Cullen, P.J., Eds.; Academic Press: Cambridge, MA, USA, 2016; pp. 117–141. [Google Scholar] [CrossRef]

- Leng, Y. Materials Characterization: Introduction to Microscopic and Spectroscopic Methods, 2nd ed.; Wiley-VCH: Weinheim, Germany, 2013; pp. 1–383. [Google Scholar] [CrossRef]

- Drelich, J.W.; Boinovich, L.; Chibowski, E.; Volpe, C.D.; Hołysz, L.; Marmur, A.; Siboni, S. Contact Angles: History of over 200 Years of Open Questions. Surf. Innov. 2020, 8, 3–27. [Google Scholar] [CrossRef]

- Kusano, R.; Boulton, G.; Kusano, Y. Saltwater—Wettability on polymer surfaces and determination of surface tension. Int. J. Surf. Sci. Eng. 2021, 15, 281–293. [Google Scholar] [CrossRef]

- Kusano, R.; Kusano, Y. Symmetric expressions of surface tension components. J. Adhes. 2023. published online. [Google Scholar] [CrossRef]

- Hill, G. Modular Plasma Reformer Treatment System. U.S. Patent 10,293,303 B2, 21 May 2019. [Google Scholar]

- Kusano, Y.; Norrman, K.; Drews, J.; Leipold, F.; Singh, S.V.; Morgen, P.; Bardenshtein, A.; Krebs, N. Gliding arc surface treatment of glass fiber reinforced polyester enhanced by ultrasonic irradiation. Surf. Coat. Technol. 2011, 205, S490–S494. [Google Scholar] [CrossRef]

- Kusano, Y.; Zhu, J.J.; Ehn, A.; Li, Z.S.; Aldén, M.; Salewski, M.; Leipold, F.; Bardenshtein, A.; Krebs, N. Observation of gliding arc surface treatment. Surf. Eng. 2015, 31, 282–288. [Google Scholar] [CrossRef]

- King, B.; Patel, D.; Chen, J.Z.; Drapanauskaite, D.; Handler, R.; Nozaki, T.; Baltrusaitis, J. Comprehensive process and environmental impact analysis of integrated DBD plasma steam methane reforming. Fuel 2021, 304, 121328. [Google Scholar] [CrossRef]

- Kogelschatz, U. Dielectric-barrier Discharges: Their History, Discharge Physics, and Industrial Applications. Plasma Chem. Plasma Process. 2003, 23, 1–46. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kusano, R.; Kusano, Y. Hybrid Plasmas for Materials Processing. Materials 2023, 16, 4013. https://doi.org/10.3390/ma16114013

Kusano R, Kusano Y. Hybrid Plasmas for Materials Processing. Materials. 2023; 16(11):4013. https://doi.org/10.3390/ma16114013

Chicago/Turabian StyleKusano, Reinosuke, and Yukihiro Kusano. 2023. "Hybrid Plasmas for Materials Processing" Materials 16, no. 11: 4013. https://doi.org/10.3390/ma16114013

APA StyleKusano, R., & Kusano, Y. (2023). Hybrid Plasmas for Materials Processing. Materials, 16(11), 4013. https://doi.org/10.3390/ma16114013