Test and Analysis of High-Permeability Material’s Microstructure in Magnetic Shielding Device

Abstract

1. Introduction

2. Theory of Microstructure’s Magnetic Properties

3. Test and Results

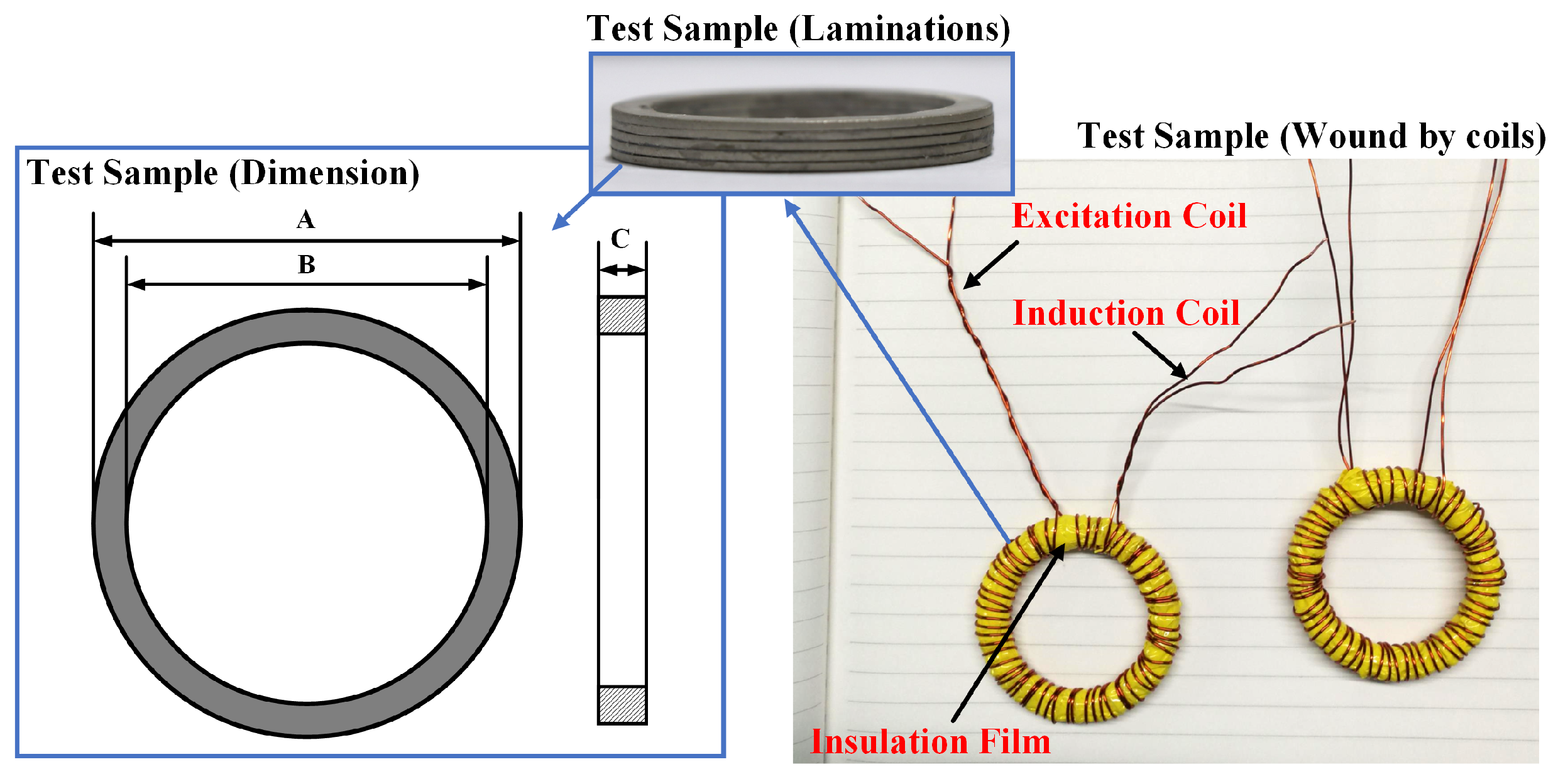

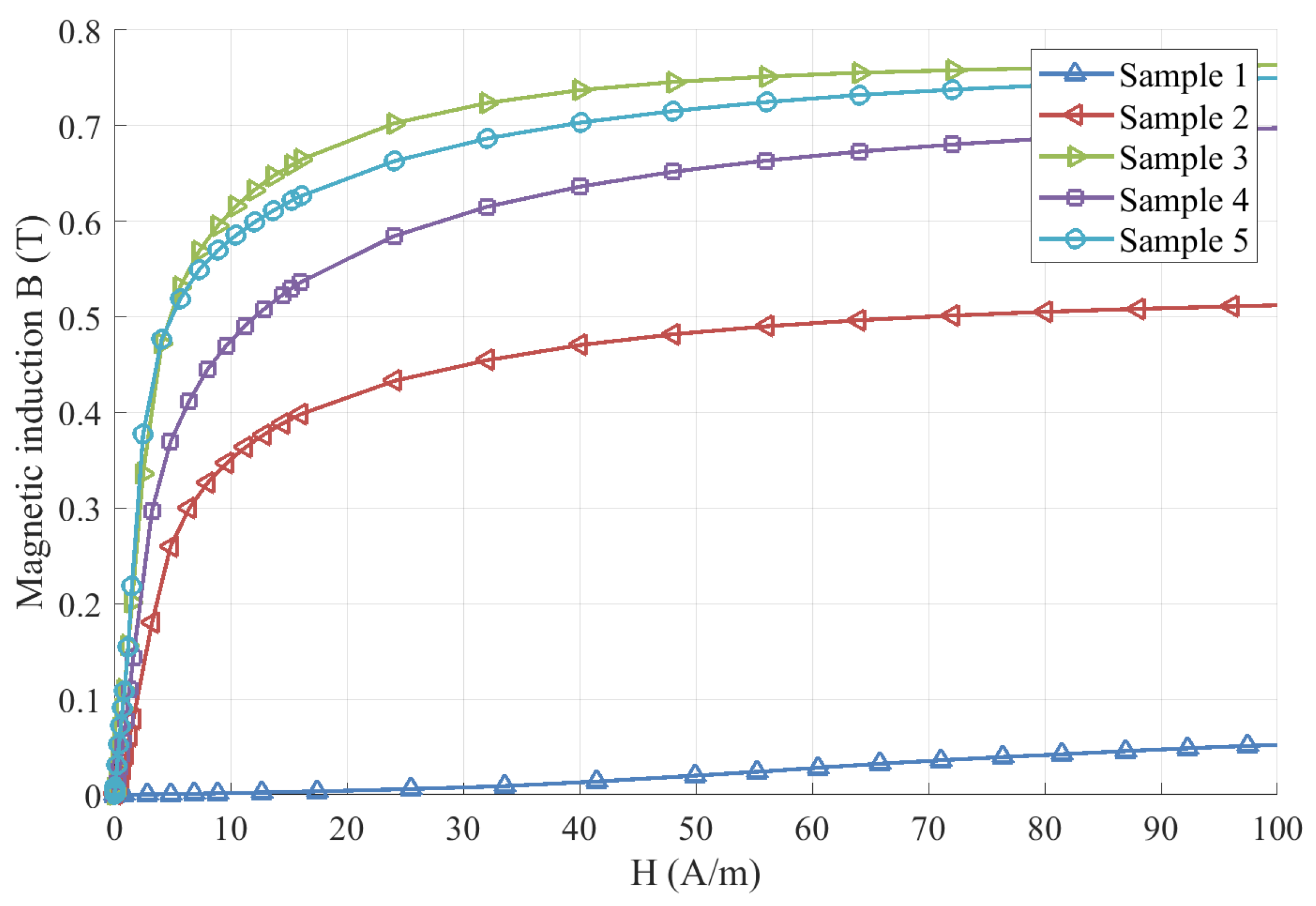

3.1. Magnetic Properties Test

3.2. Microstructure Test

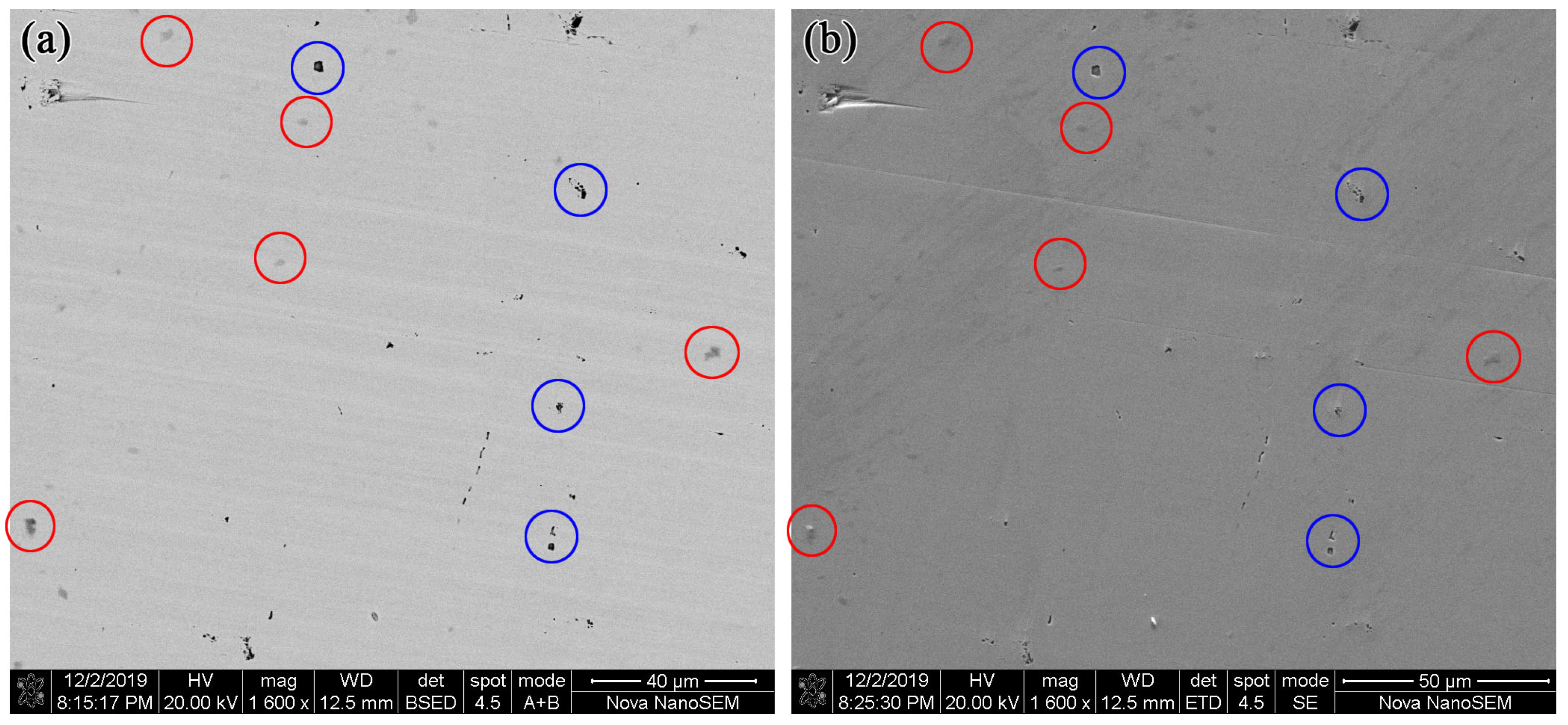

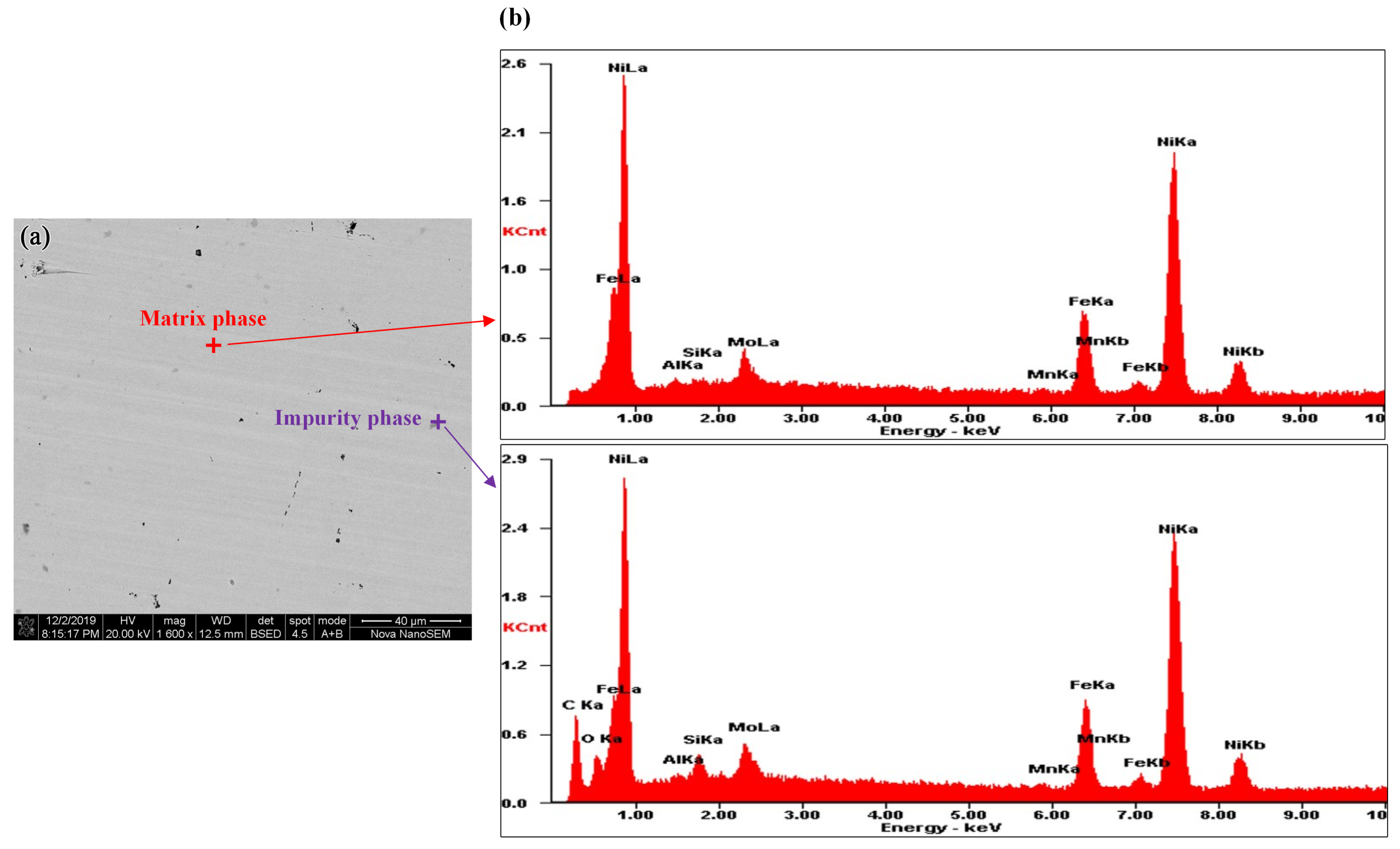

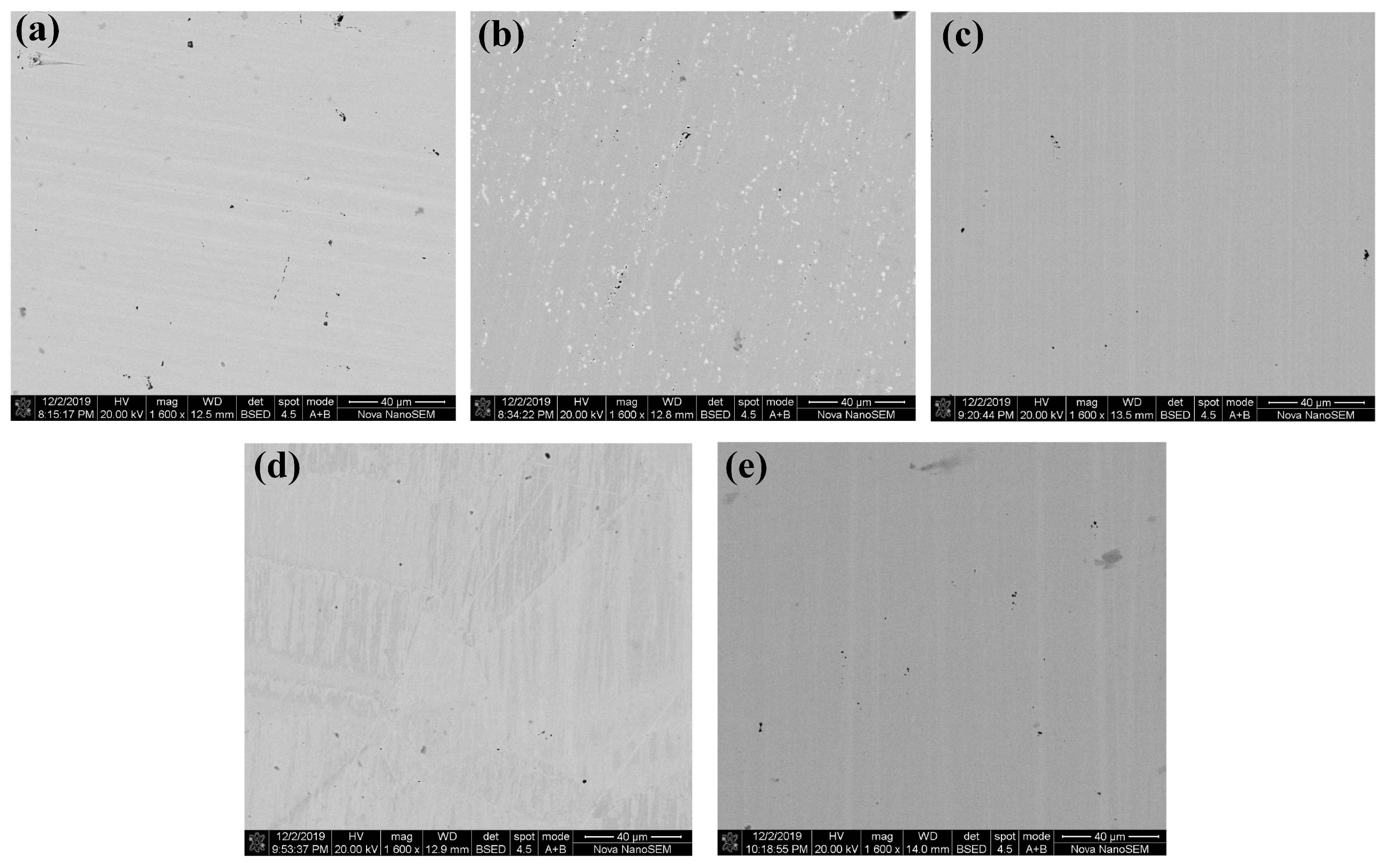

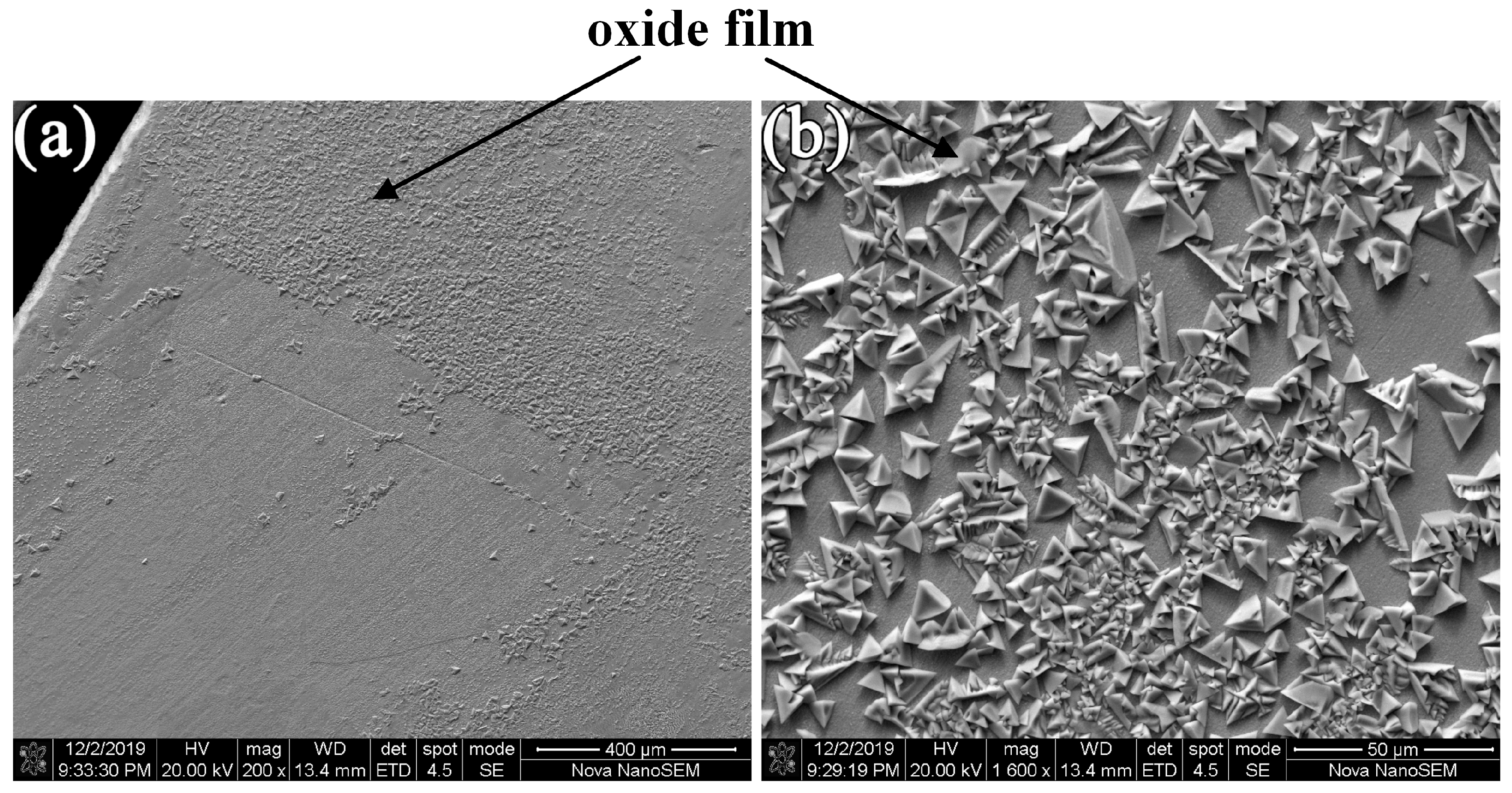

3.2.1. Material Composition Test

- Cut the test samples into appropriately sized pieces, then wash and dry the pieces for later use;

- Polish the surface of the sample pieces until they are smooth as a mirror;

- Place the test pieces in the SEM and observe them at magnification of 200 and 1600, respectively;

- Take photos in back scattered electron (BSE) mode and secondary electron detect (SED) mode in the typical area;

- Obtain the main constituent elements and their proportion using energy dispersive spectroscopy (EDS) at the detection location.

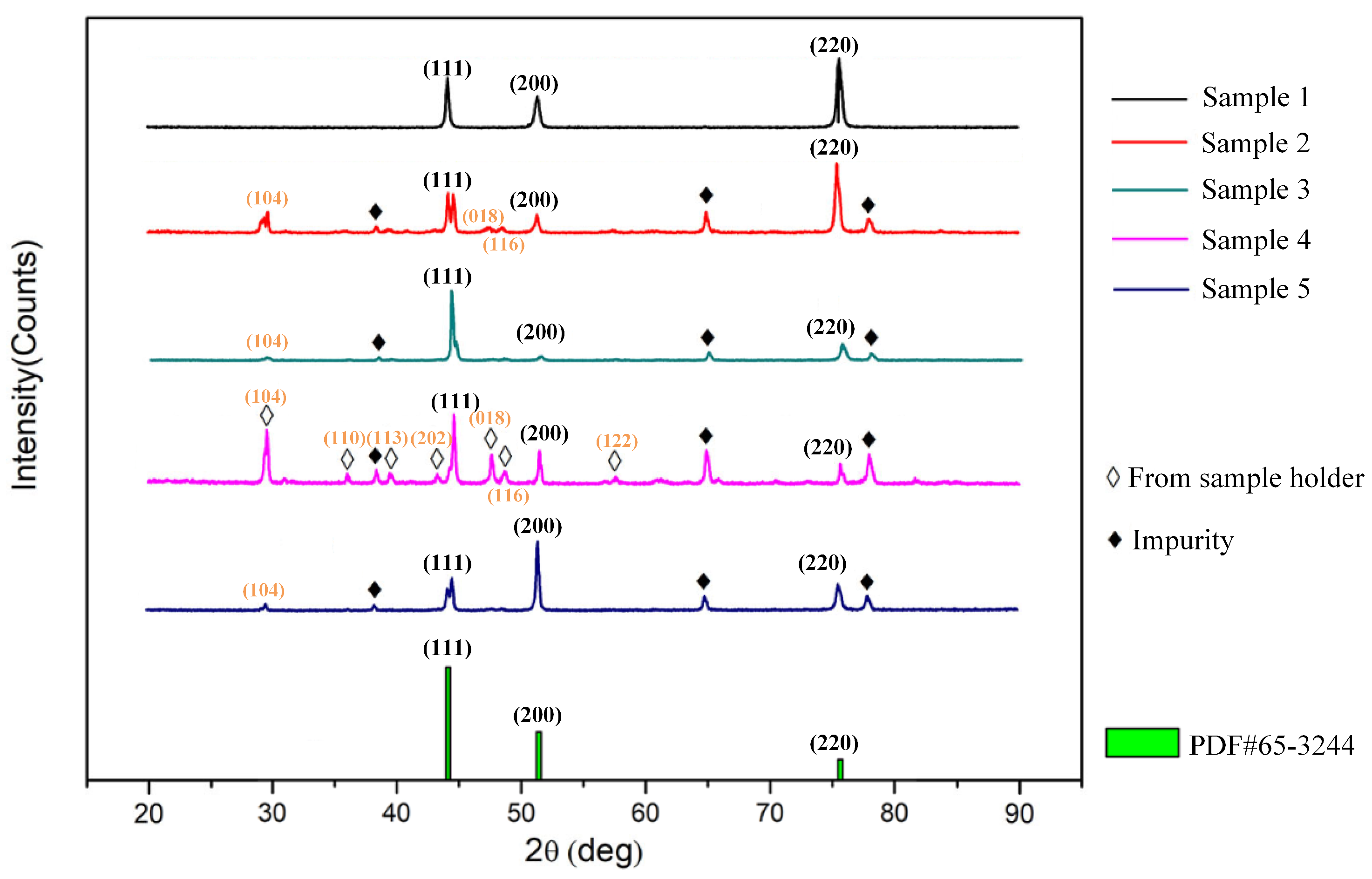

3.2.2. Texture Test

- Cut the test samples into appropriately sized pieces;

- Remove surface impurities of the sample pieces through polishing until the surface appears to be metallic luster;

- Fix the sample pieces using rubber putty as the sample holder and place the samples in XRD for detection;

- Analyze the XRD data and obtain the textures of the samples.

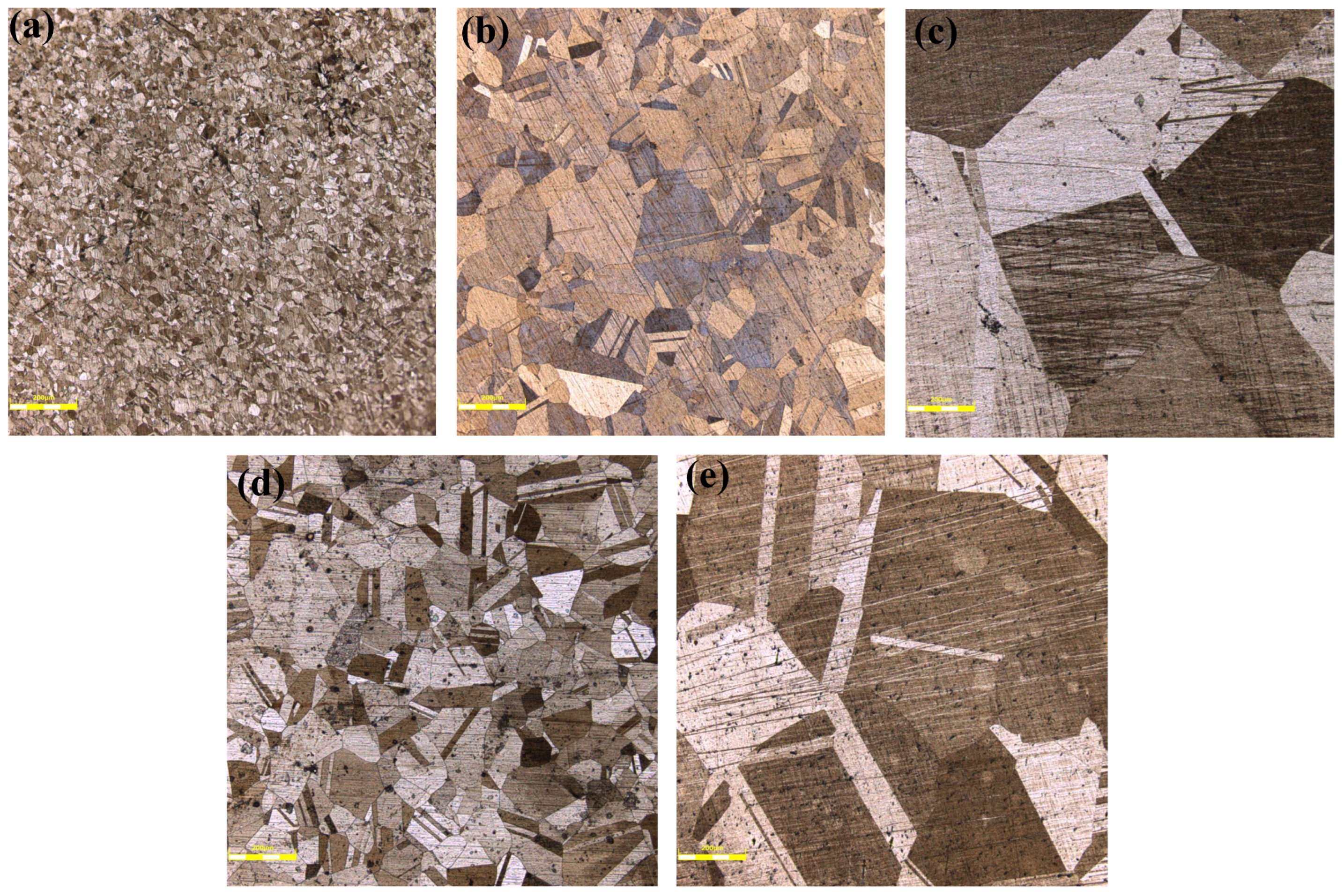

3.2.3. Grain Structure Test

- Cut the test samples into appropriately sized pieces;

- Polish the surface of the sample pieces;

- Make chemical corrosion on samples’ surface to present grain morphology;

- Observe the grain morphology of each sample and calculate the size of grain.

- Prepare the representative picture taken by CLSM for grain size calculation;

- Draw three circles with Radius , , and on the picture (the biggest circle should be as large as possible within the scope of the picture);

- Calculate the intersection points’ number of the grains and the circles ;

- Obtain the average grain size according to the equation below:where L is the sum of circumference of the three circles and M is the magnification.

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pan, D.; Li, J.; Jin, C.; Liu, T.; Lin, S.; Li, L. A New Calibration Method for Triaxial Fluxgate Magnetometer Based on Magnetic Shielding Room. IEEE Trans. Ind. Electron. 2020, 67, 4183–4192. [Google Scholar] [CrossRef]

- Sun, Z.; Fierlinger, P.; Han, J.; Li, L.; Liu, T.; Schnabel, A.; Stuiber, S.; Voigt, J. Limits of Low Magnetic Field Environments in Magnetic Shields. IEEE Trans. Ind. Electron. 2021, 68, 5385–5395. [Google Scholar] [CrossRef]

- Liu, Y.; Gao, H.; Ma, L.; Quan, J.; Fan, W.; Xu, X.; Fu, Y.; Duan, L.; Quan, W. Study on the Magnetic Noise Characteristics of Amorphous and Nanocrystalline Inner Magnetic Shield Layers of SERF Co-Magnetometer. Materials 2022, 15, 8267. [Google Scholar] [CrossRef] [PubMed]

- Sakamoto, Y.; Bidinosti, C.P.; Ichikawa, Y.; Sato, T.; Ohtomo, Y.; Kojima, S.; Funayama, C.; Suzuki, T.; Tsuchiya, M.; Furukawa, T.; et al. Development of high-homogeneity magnetic field coil for Xe-129 EDM experiment. Hyperfine Interact. 2015, 231, 141–146. [Google Scholar] [CrossRef]

- Moric, I.; Laurent, P.; Chatard, P.; de Graeve, C.M.; Thomin, S.; Christophe, V.; Grosjean, O. Magnetic shielding of the cold atom space clock PHARAO. Acta Astronaut. 2014, 102, 287–294. [Google Scholar] [CrossRef]

- He, K.; Wan, S.; Sheng, J.; Liu, D.; Wang, C.; Li, D.; Qin, L.; Luo, S.; Qin, J.; Gao, J.H. A high-performance compact magnetic shield for optically pumped magnetometer-based magnetoencephalography. Rev. Sci. Instrum. 2019, 90, 064102. [Google Scholar] [CrossRef]

- Baillet, S. Magnetoencephalography for brain electrophysiology and imaging. Nat. Neurosci. 2017, 20, 327–339. [Google Scholar] [CrossRef]

- Walker, T.G.; Larsen, M.S. Spin-Exchange-Pumped NMR Gyros. In Advances in Atomic, Molecular, and Optical Physics; Arimondo, E., Lin, C., Yelin, S., Eds.; Elsevier: Amsterdam, The Netherlands, 2016; Volume 65, pp. 373–401. [Google Scholar] [CrossRef]

- Nikolopoulos, C.D. Electromagnetic Compatibility for Space Systems Design; IGI Global: Hershey, PA, USA, 2018. [Google Scholar] [CrossRef]

- Cheng, Y.; Luo, Y.; Shen, R.; Kong, D.; Zhou, W. Testing and Analysis Method of Low Remanence Materials for Magnetic Shielding Device. Materials 2023, 16, 681. [Google Scholar] [CrossRef]

- Fang, X.; Ma, D.; Sun, B.; Xu, X.; Quan, W.; Xiao, Z.; Zhai, Y. A High-Performance Magnetic Shield with MnZn Ferrite and Mu-Metal Film Combination for Atomic Sensors. Materials 2022, 15, 6680. [Google Scholar] [CrossRef]

- Ma, D.; Fang, X.; Lu, J.; Wang, K.; Sun, B.; Gao, Y.; Xu, X.; Han, B. Analysis and Measurement of Differential-Mode Magnetic Noise in Mn-Zn Soft Ferrite Shield for Ultra-Sensitive Sensors. Materials 2022, 15, 8704. [Google Scholar] [CrossRef]

- Pizzo, F.; Roehri, N.; Villalon, S.M.; Trebuchon, A.; Chen, S.; Lagarde, S.; Carron, R.; Gavaret, M.; Giusiano, B.; McGonigal, A.; et al. Deep brain activities can be detected with magnetoencephalography. Nat. Commun. 2019, 10, 971, Erratum in Nat. Commun. 2021, 12, 2566. [Google Scholar] [CrossRef]

- Kvitkovic, J.; Patel, S.; Pamidi, S. Magnetic Shielding Characteristics of Hybrid High-Temperature Superconductor/Ferromagnetic Material Multilayer Shields. IEEE Trans. Appl. Supercond. 2017, 27, 4700705. [Google Scholar] [CrossRef]

- Ates, K.; Carlak, H.F.; Ozen, S. Dosimetry analysis of the magnetic field of underground power cables and magnetic field mitigation using an electromagnetic shielding technique. Int. J. Occup. Saf. Ergon. 2022, 28, 1672–1682. [Google Scholar] [CrossRef]

- Satpute, N.; Dhoka, P.; Iwaniec, M.; Jabade, S.; Karande, P. Manufacturing of Pure Iron by Cold Rolling and Investigation for Application in Magnetic Flux Shielding. Materials 2022, 15, 2630. [Google Scholar] [CrossRef]

- Shi, M.; Zhang, X.; Yang, J.; Yuan, S.; Wang, L. An Optimized Measurement Method for Magnetic Properties of Permalloy Sheet Under Demagnetization. IEEE Trans. Instrum. Meas. 2022, 71, 6003509. [Google Scholar] [CrossRef]

- Ghosh, N.C.; Das, H.N.; Gafur, M.A.; Hossain, A.K.M.A. Formation and magnetic properties of nanocrystalline 78.5-permalloy by mechanical alloying. Procedia Eng. 2014, 90, 136–139. [Google Scholar] [CrossRef]

- Sakakibara, M.; Uehara, G.; Adachi, Y. Prediction of Cylindrical Magnetic Shielding Performance by Considering the Magnetic Field Strength Inside the Material. IEEE Trans. Magn. 2022, 58, 6500404. [Google Scholar] [CrossRef]

- Fathabad, S.M.; Shahri, F. BH hysteresis measurement system for thin soft magnetic materials. Measurement 2021, 172, 108896. [Google Scholar] [CrossRef]

- De La Barriere, O.; Ragusa, C.; Khan, M.; Appino, C.; Fiorillo, F.; Mazaleyrat, F. A Simple Compensation Method for the Accurate Measurement of Magnetic Losses With a Single Strip Tester. IEEE Trans. Magn. 2016, 52, 2001204. [Google Scholar] [CrossRef]

- Cheng, R.; Rosenberg, A.; McIlroy, D.N.; Holman, Z.; Zhang, D.; Kranov, Y. The domain formation in Fe/Ni/Fe nanoscale magnetic antidot arrays. J. Appl. Phys. 2012, 111, 063902. [Google Scholar] [CrossRef]

- Zhang, Y.; Ren, Z.; Fu, Y.; Yuan, X.; Zhai, Y.; Huang, H.; Zhai, H. An investigation on the behavior of fine-grained magnetite particles as a function of size and surface modification. J. Phys. Chem. Solids 2009, 70, 505–509. [Google Scholar] [CrossRef]

- Herzer, G. Grain size dependence of coercivity and permeability in nanocrystalline ferromagnets. IEEE Trans. Magn. 1990, 26, 1397–1402. [Google Scholar] [CrossRef]

- Herzer, G. Soft magnetic nanocrystalline materials. Scr. Metall. Et Mater. 1995, 33, 1741–1756. [Google Scholar] [CrossRef]

- Schryer, N.L.; Walker, L.R. The motion of 180° domain walls in uniform dc magnetic fields. J. Appl. Phys. 1974, 45, 5406–5421. [Google Scholar] [CrossRef]

- Sablik, M.J.; Burkhardt, G.L.; Kwun, H.; Jiles, D.C. A model for the effect of stress on the low-frequency harmonic content of the magnetic induction in ferromagnetic materials. J. Appl. Phys. 1988, 63, 3930–3932. [Google Scholar] [CrossRef]

- Perkins, R.S.; Bernasconi, J.; Wiesmann, H.J. Magnetic properties of Sm(Co,Cu) alloys. II. Coercivity mechanism. J. Appl. Phys. 1976, 47, 2679–2687. [Google Scholar] [CrossRef]

- Tebble, R.S.; Craik, D.J. Magnetic Materials; Wiley-Interscience: Hoboken, NJ, USA, 1969. [Google Scholar]

- Li, Y.; Shang, X.; Zhai, M.; Yu, L.; Wang, L.; Zhao, S. Surface characteristics and microstructure evolution of a nickel-base single crystal superalloy treated by ultrasonic shot peening. J. Alloys Compd. 2022, 919, 165761. [Google Scholar] [CrossRef]

- Wu, J.; Jiang, X.; Wang, Y.; Dong, J.; Lou, L. Effects of Ta on microstructural stability and mechanical properties of hot corrosion resistant Ni-based single crystal superalloys during long-term thermal exposure. Mater. Sci. Eng. A 2021, 806, 140829. [Google Scholar] [CrossRef]

- GBT 6394-2017; Determination of Estimating the Average Grain Size of Metal. National Standard of the People’s Republic of China: Beijing, China, 2017.

| Sample No. | Sample Brand | Sample State | Manufacturer |

|---|---|---|---|

| Sample 1 | 1J85 | unannealed | Shanghai (DaiXin) |

| Sample 2 | 1J85 | annealed * | Shanghai (DaiXin) |

| Sample 3 | 1J85 | annealed * | Beijing (BeiYe) |

| Sample 4 | 1J85 | annealed * | Beijing (BeiYe) |

| Sample 5 | Mumetal | annealed * | Germany (VAC) |

| Sample No. | Thickness—One Piece (mm) | Thickness—Laminations C (mm) | Outer Diameter A (mm) | Inner Diameter B (mm) | Weight (g) |

|---|---|---|---|---|---|

| Sample 1 | 2.5 | 5.07 | 39.98 | 31.90 | 19.6 |

| Sample 2 | 1 | 2.83 | 40.00 | 32.05 | 10.4 |

| Sample 3 | 1 | 2.90 | 39.95 | 31.57 | 11.8 |

| Sample 4 | 2 | 6.24 | 40.04 | 31.98 | 23.8 |

| Sample 5 | 0.75 | 6.11 | 28.50 | 19.96 | 16.7 |

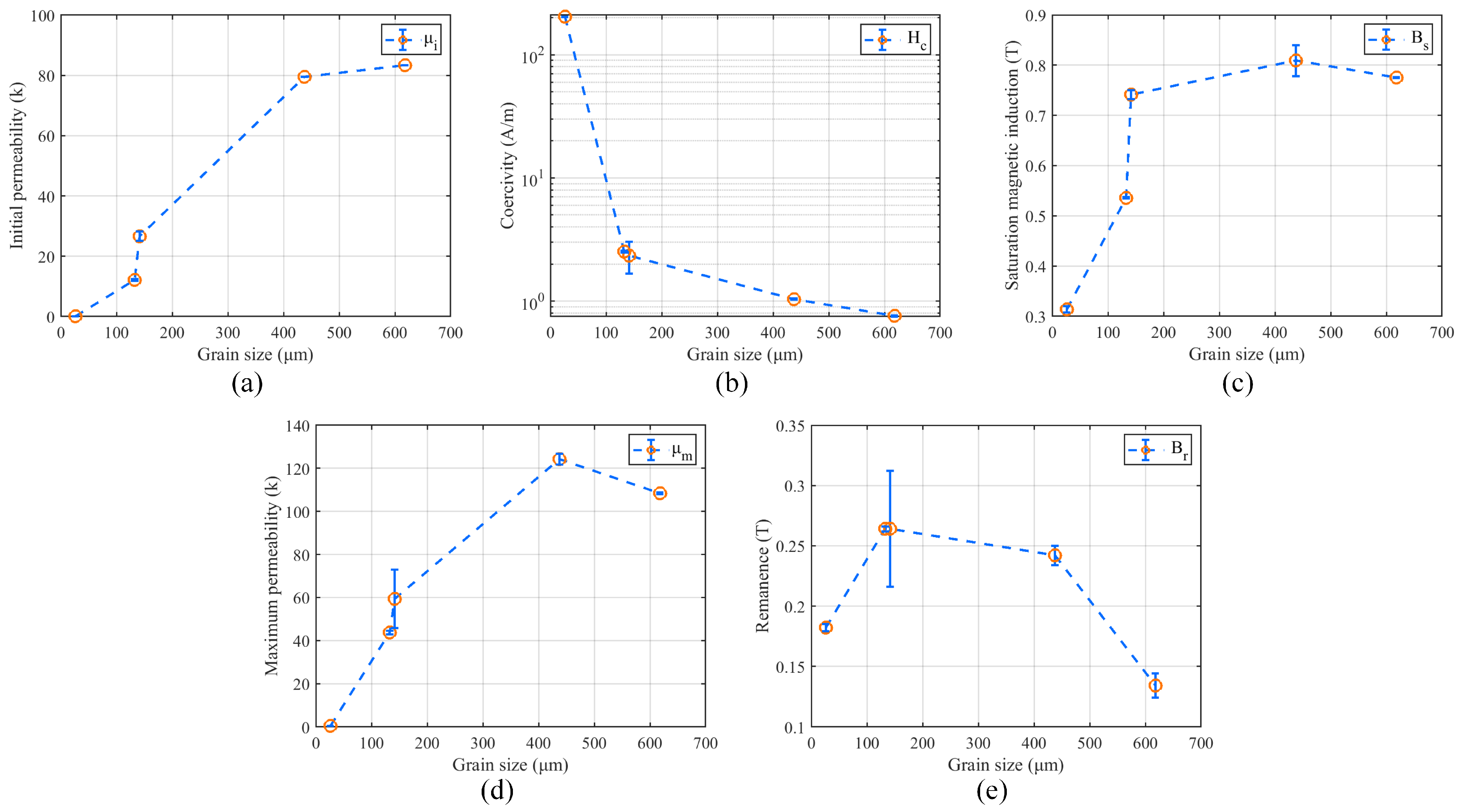

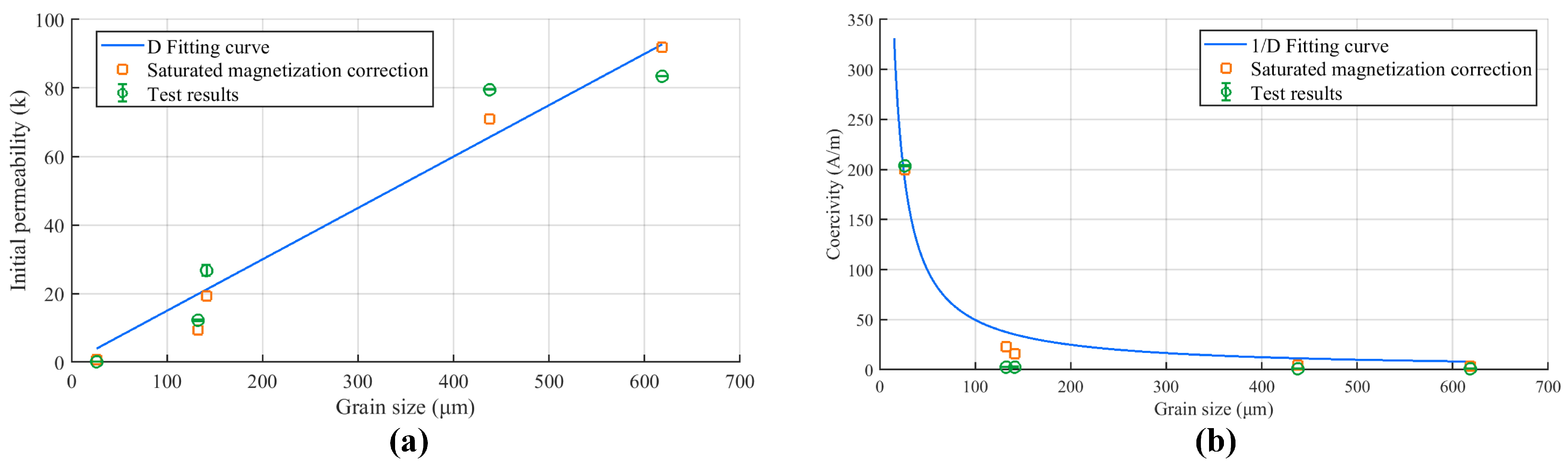

| Sample No. | Initial Permeability (k) | Maximum Permeability (k) | Saturation Magnetic Induction (T) | Remanence (T) | Coercivity (A/m) |

|---|---|---|---|---|---|

| Sample 1 | 0.134 ± 0.011 | 0.430 ± 0.008 | 0.314 ± 0.006 | 0.182 ± 0.003 | 203.550 ± 0.531 |

| Sample 2 | 12.130 ± 0.269 | 43.745 ± 0.829 | 0.536 ± 0.001 | 0.264 ±0.002 | 2.516 ±0.047 |

| Sample 3 | 83.395 ± 0.045 | 108.350 ± 0.367 | 0.775 ± 0.001 | 0.134 ± 0.010 | 0.757 ± 0.008 |

| Sample 4 | 26.675 ± 1.571 | 59.395 ± 13.615 | 0.741 ± 0.009 | 0.264 ± 0.048 | 2.347 ± 0.683 |

| Sample 5 | 79.505 ± 0.037 | 124.250 ± 2.572 | 0.809 ± 0.031 | 0.242 ± 0.008 | 1.038 ± 0.013 |

| Phase | Ni (wt%) | Fe (wt%) | Mo (wt%) | Mn (wt%) | Al (wt%) | Si (wt%) | C (wt%) | O (wt%) |

|---|---|---|---|---|---|---|---|---|

| Matrix phase | 78.21 | 14.73 | 5.70 | 0.50 | 0.58 | 0.27 | 0 | 0 |

| Impurity phase | 53.56 | 10.43 | 3.54 | 0.50 | 0.19 | 1.16 | 26.81 | 3.81 |

| Samp No. | Ni (wt%) | Fe (wt%) | Mo (wt%) | Mn (wt%) | Al (wt%) | Si (wt%) | Nb (wt%) |

|---|---|---|---|---|---|---|---|

| Sample 1 | 78.21 | 14.73 | 5.70 | 0.50 | 0.58 | 0.27 | 0 |

| Sample 2 | 78.14 | 11.02 | 2.82 | 0.69 | 0.69 | 0.52 | 6.12 |

| Sample 3 | 78.89 | 14.58 | 5.60 | 0.46 | 0.23 | 0.24 | 0 |

| Sample 4 | 78.39 | 14.34 | 5.67 | 0.53 | 0.61 | 0.46 | 0 |

| Sample 5 | 78.34 | 15.91 | 4.16 | 0.64 | 0.46 | 0.48 | 0 |

| Sample No. | Grain Size (m) |

|---|---|

| Sample 1 | 26.2 |

| Sample 2 | 132.4 |

| Sample 3 | 618.4 |

| Sample 4 | 141.6 |

| Sample 5 | 437.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, W.; Sun, J.; Han, B.; Ren, J.; Li, Y. Test and Analysis of High-Permeability Material’s Microstructure in Magnetic Shielding Device. Materials 2023, 16, 3956. https://doi.org/10.3390/ma16113956

Zhou W, Sun J, Han B, Ren J, Li Y. Test and Analysis of High-Permeability Material’s Microstructure in Magnetic Shielding Device. Materials. 2023; 16(11):3956. https://doi.org/10.3390/ma16113956

Chicago/Turabian StyleZhou, Weiyong, Jinji Sun, Bangcheng Han, Jianyi Ren, and Yifei Li. 2023. "Test and Analysis of High-Permeability Material’s Microstructure in Magnetic Shielding Device" Materials 16, no. 11: 3956. https://doi.org/10.3390/ma16113956

APA StyleZhou, W., Sun, J., Han, B., Ren, J., & Li, Y. (2023). Test and Analysis of High-Permeability Material’s Microstructure in Magnetic Shielding Device. Materials, 16(11), 3956. https://doi.org/10.3390/ma16113956