Numerical Modeling of the Dynamic Elastic Modulus of Concrete

Abstract

1. Introduction

2. Numerical Simulations

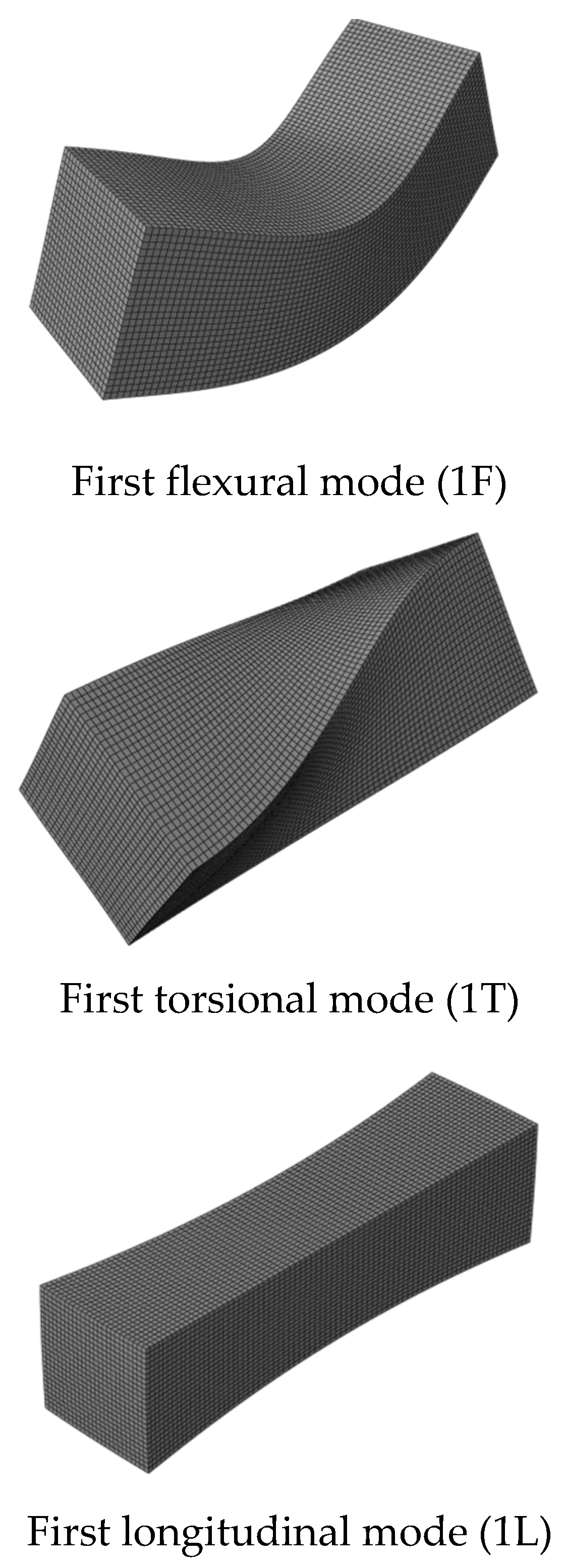

2.1. Frequency Equations of an Isotropic and Homogeneous Material

2.2. Effect of Porosity

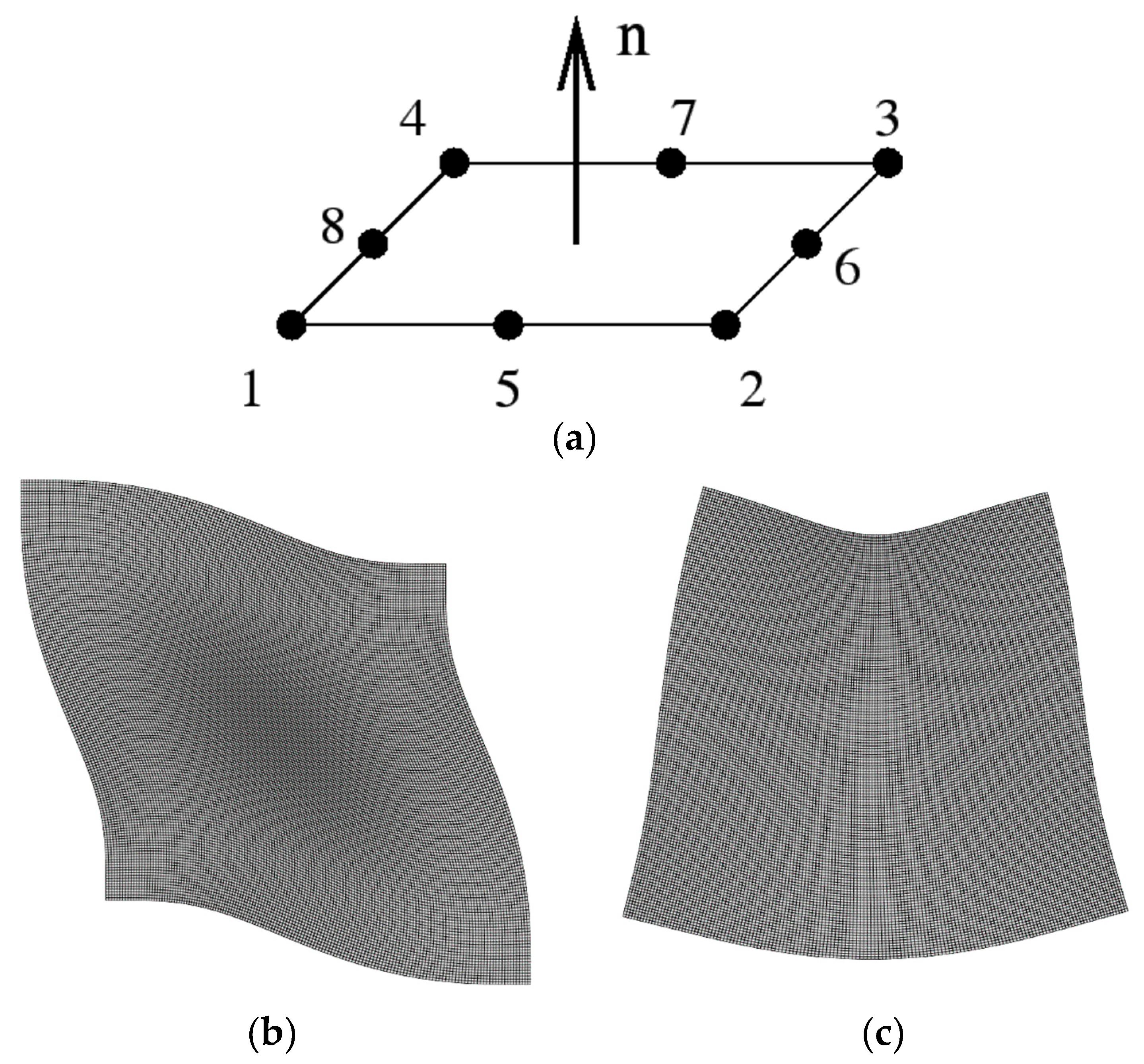

2.3. Biphasic Material

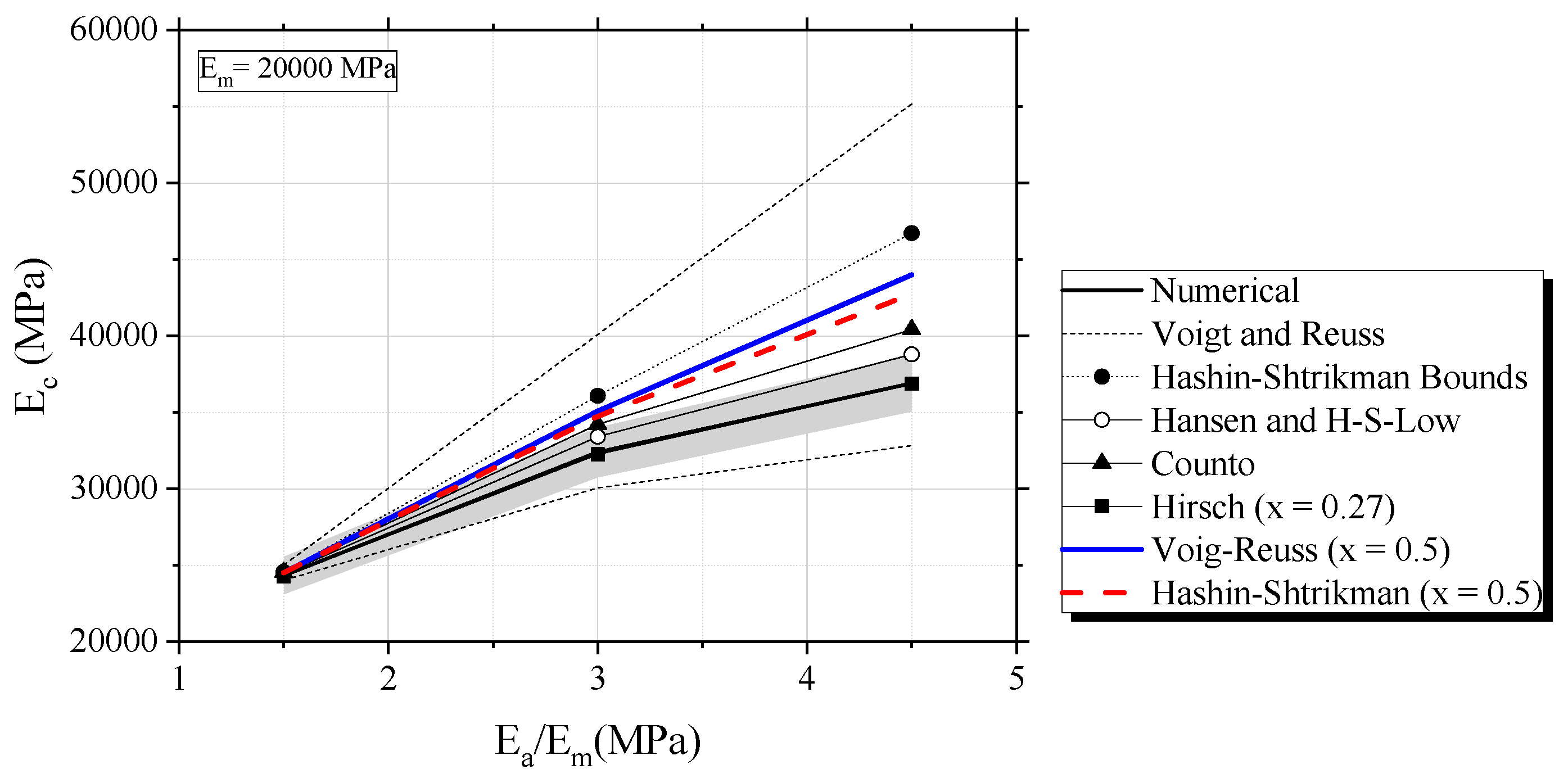

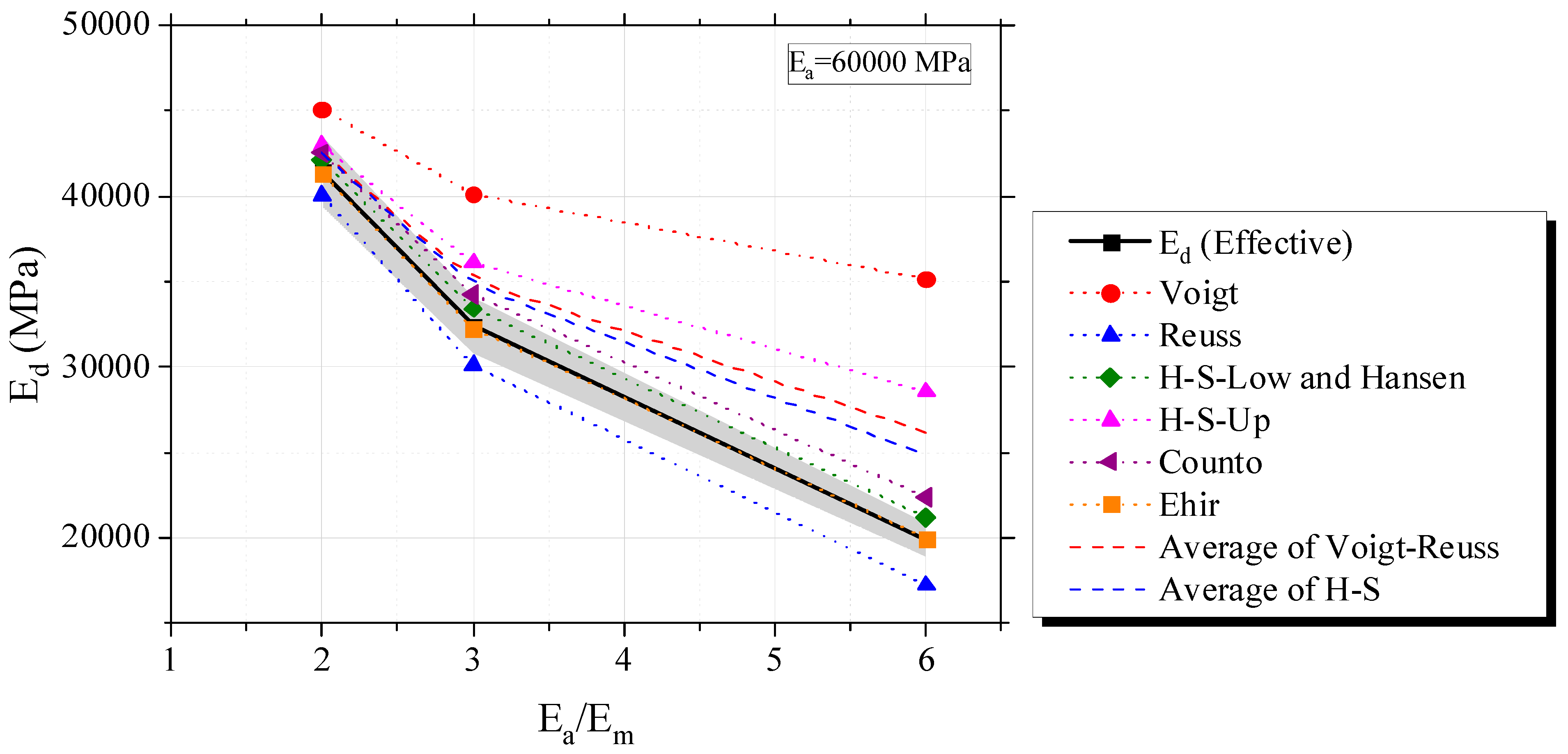

2.3.1. Influence of Individual Elastic Properties of Phases (Ea/Em)

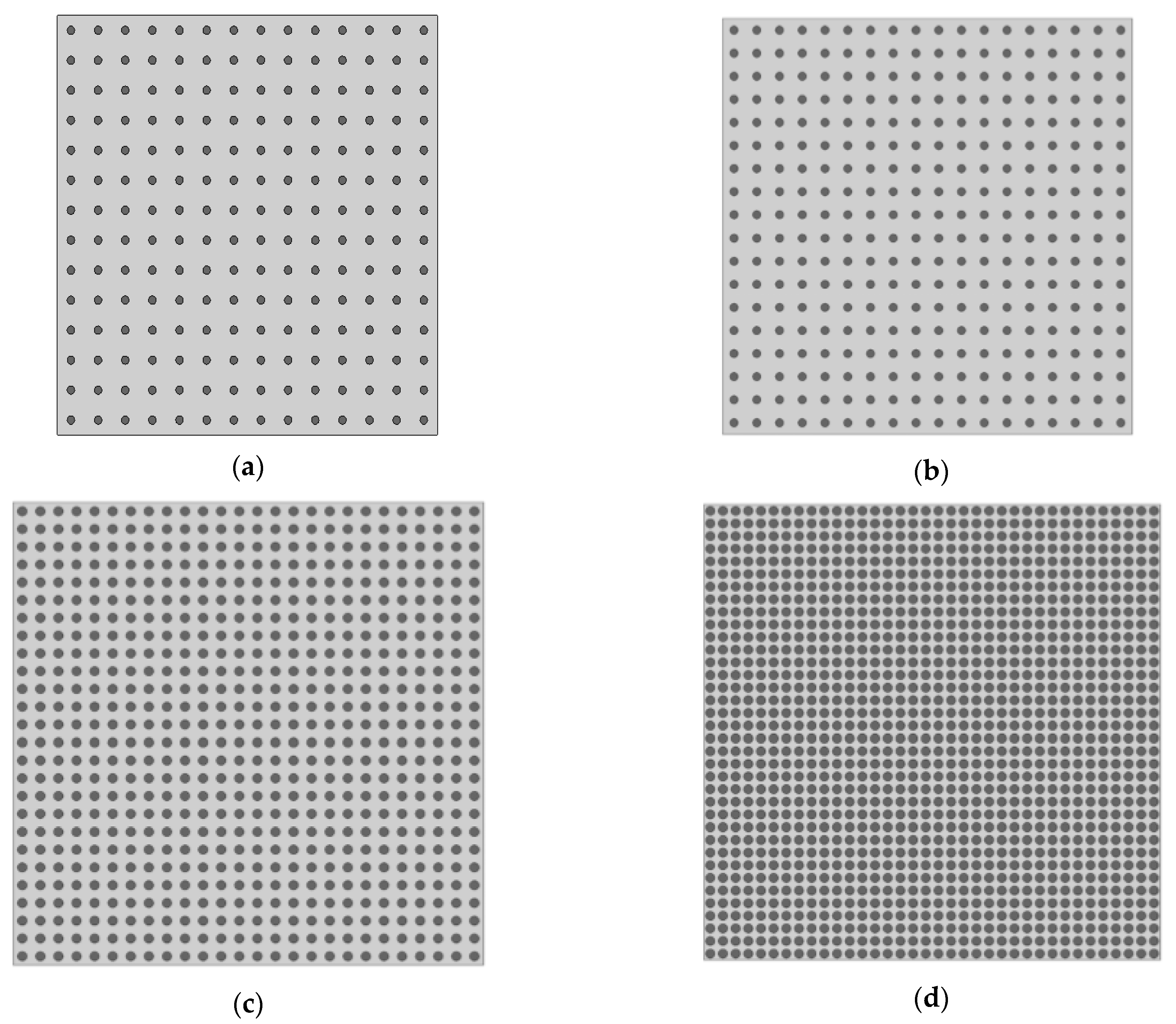

2.3.2. Effect of Volumetric Fraction

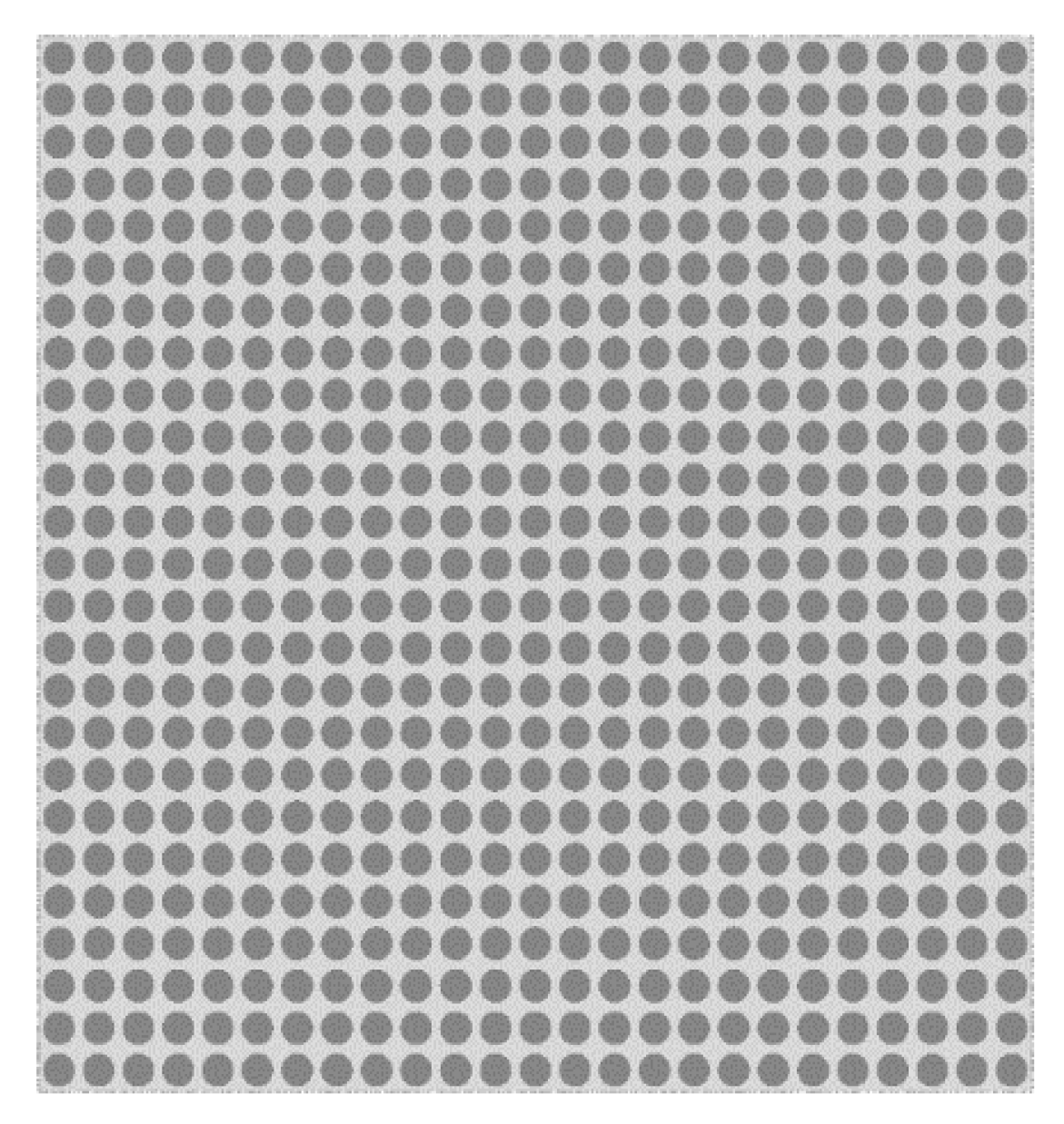

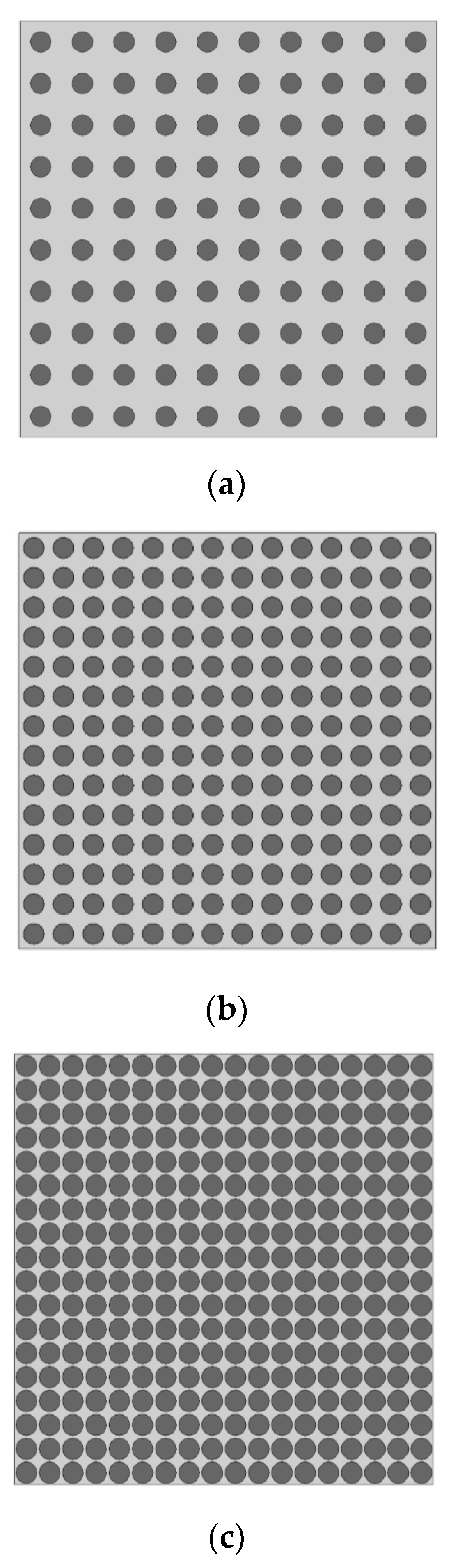

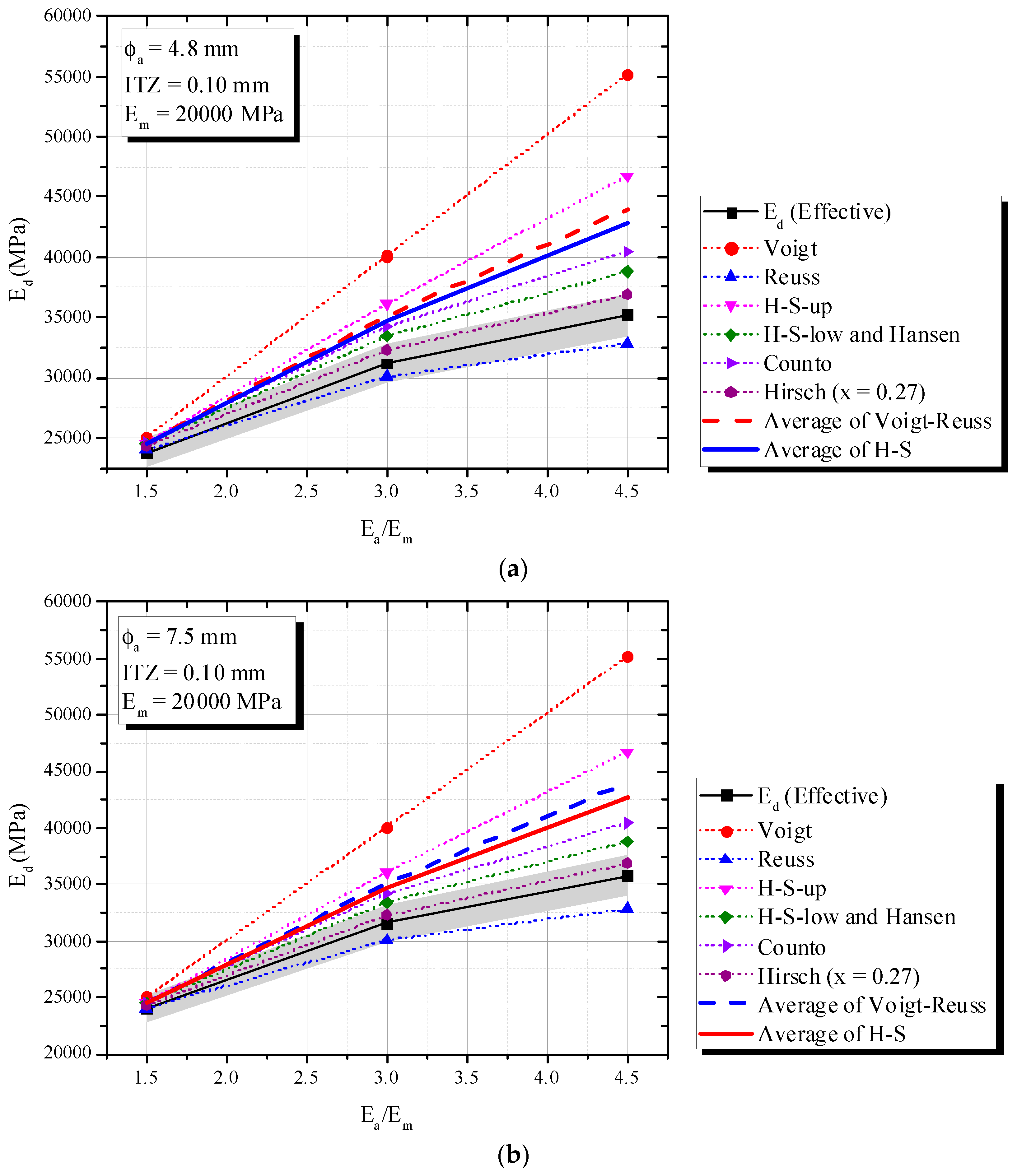

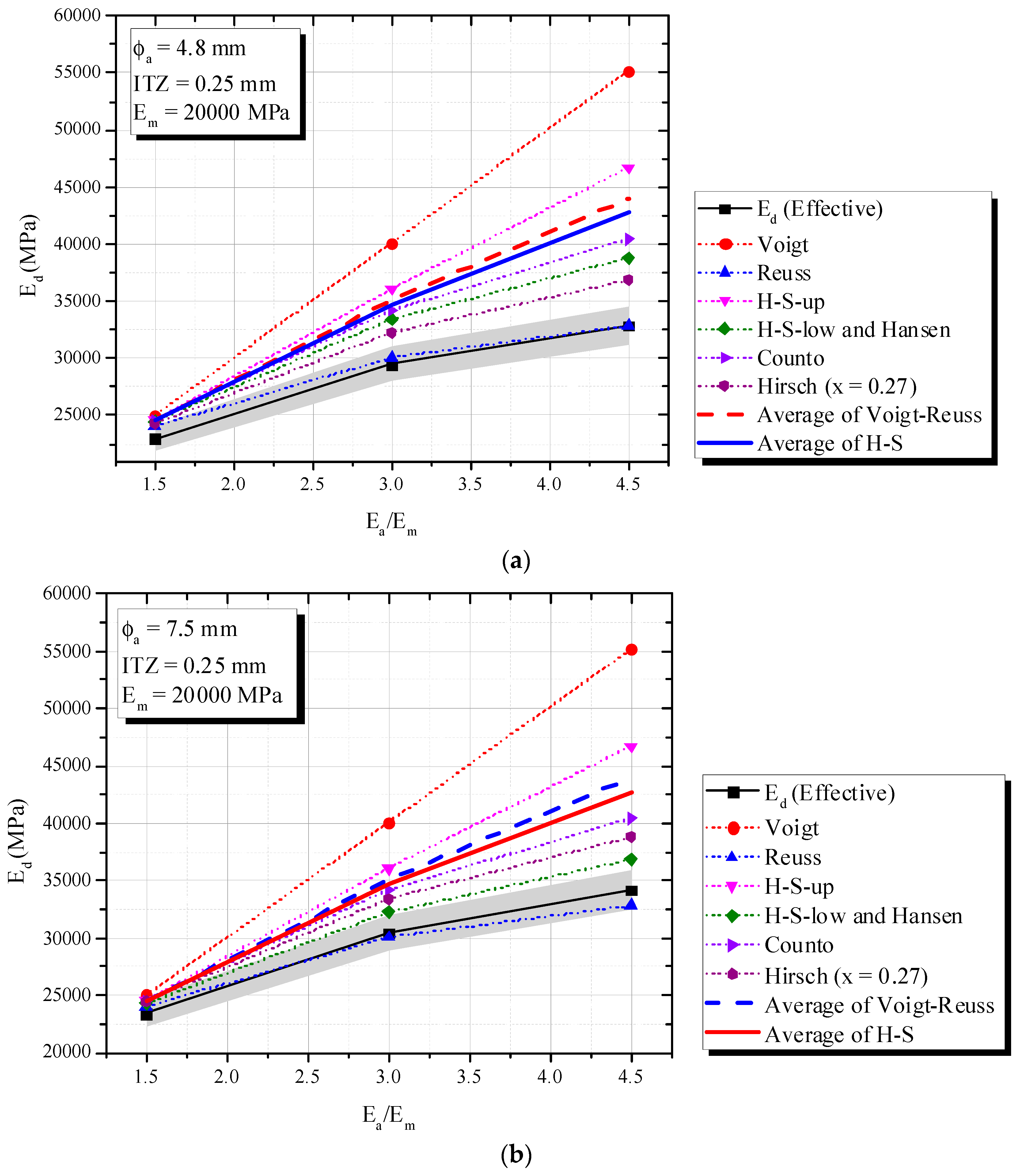

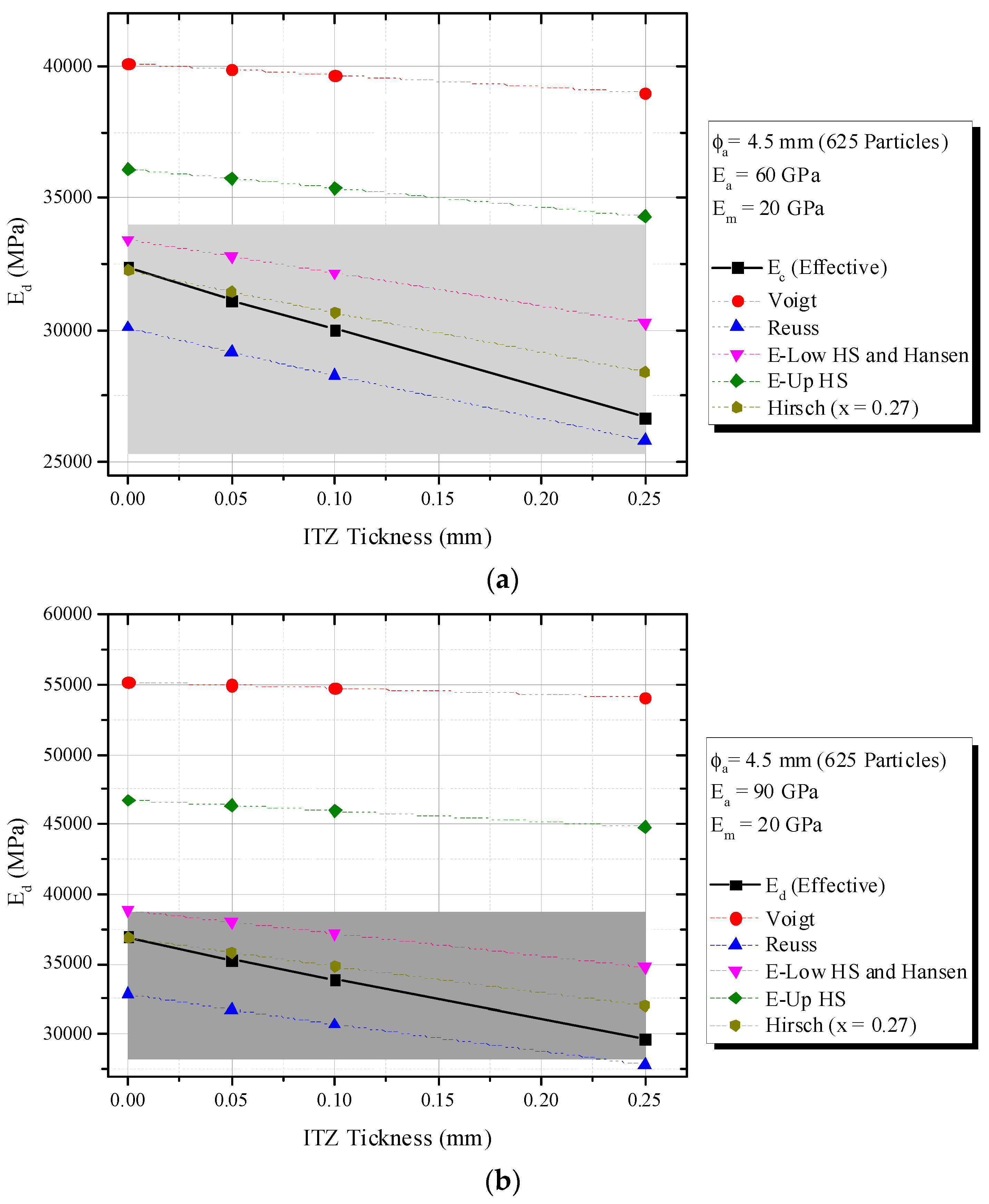

2.4. Triphasic Composite Material

3. Experimental Validation

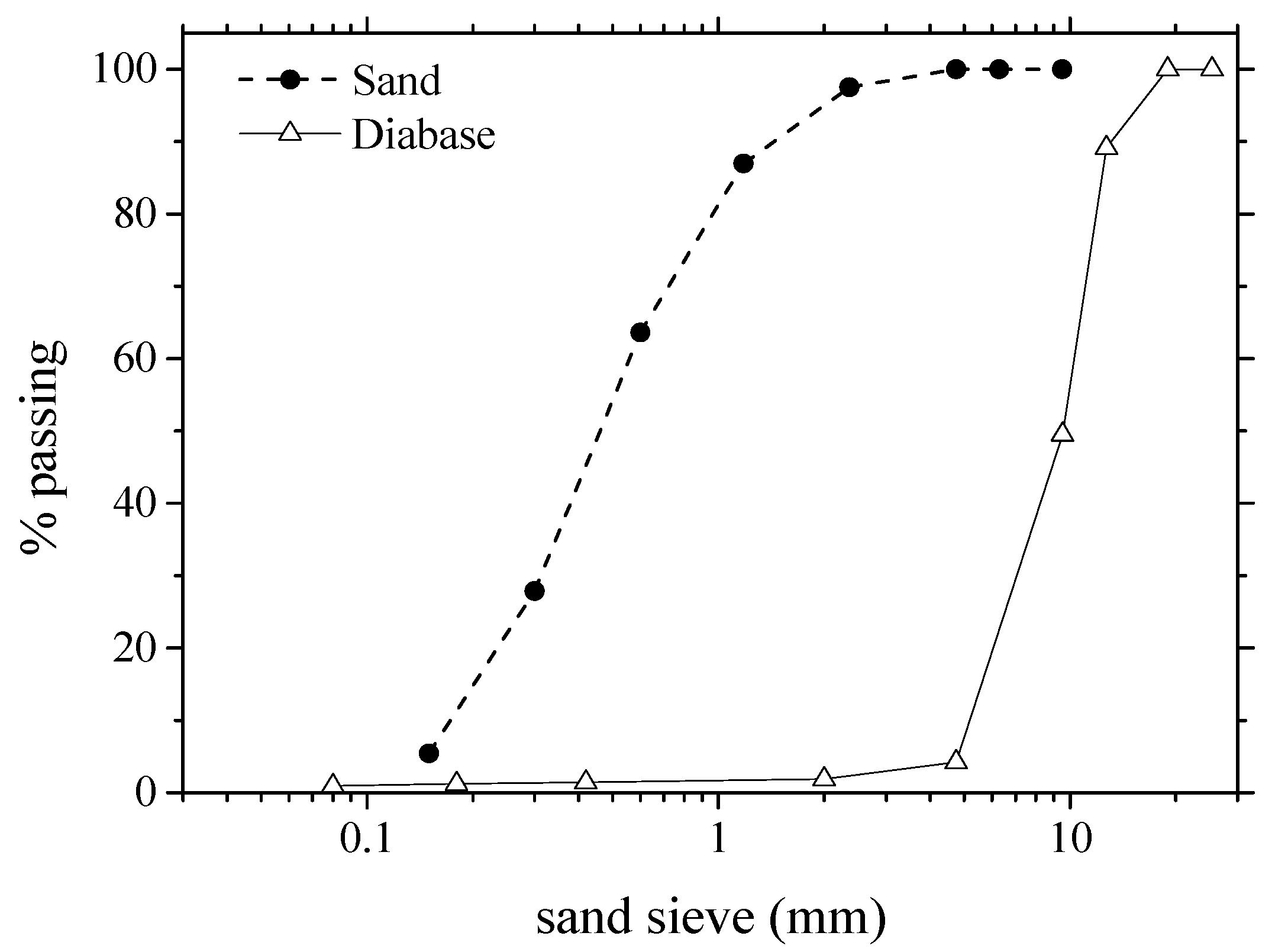

3.1. Materials and Mixes

3.2. Specimens

- (i)

- Mortars (1-M, 2-M and 3-M)—five prismatic specimens of 40 mm × 40 mm × 160 mm.

- (ii)

- Concretes (1-C, 2-C and 3-C)—five prismatic specimens of 150 mm × 150 mm × 500 mm.

- (iii)

- Rocks’ samples—five cylindrical samples of 55 mm × 125 mm created by core drills extracted from an intact diabase rock.

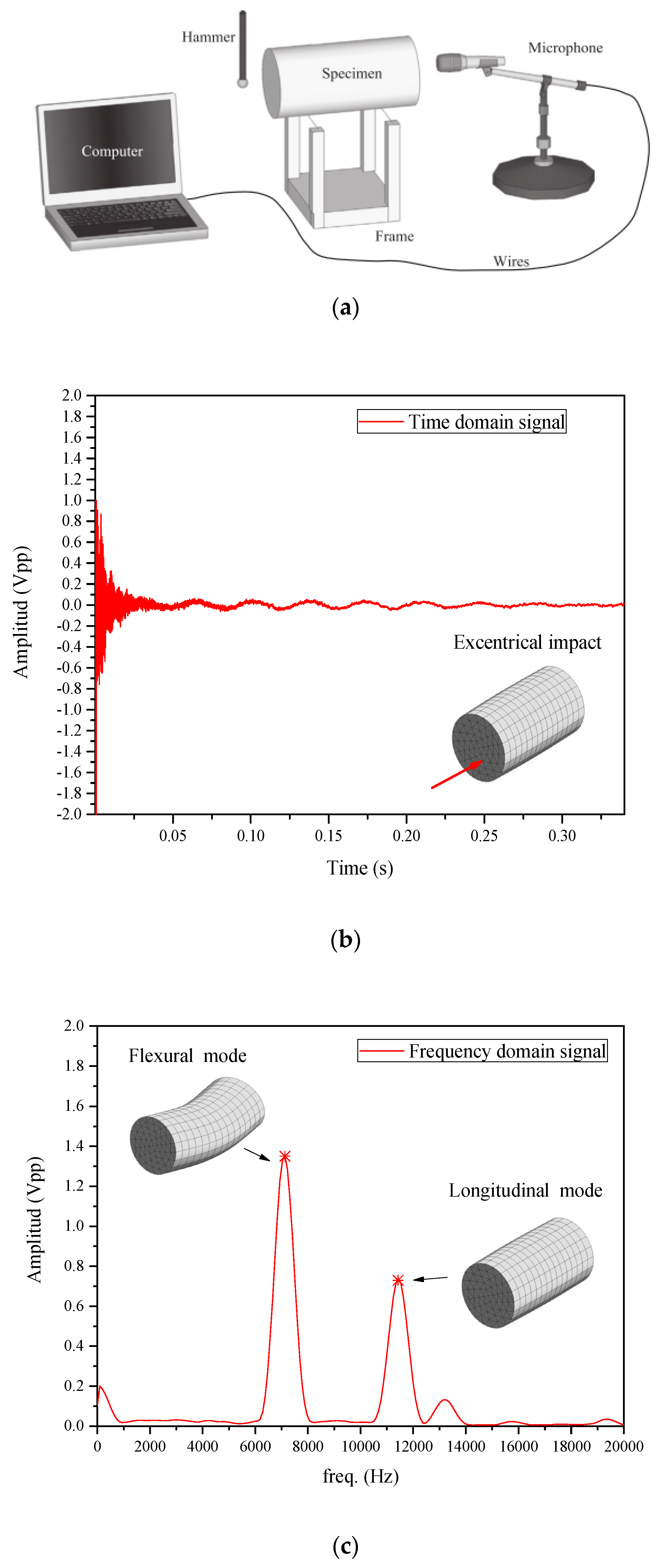

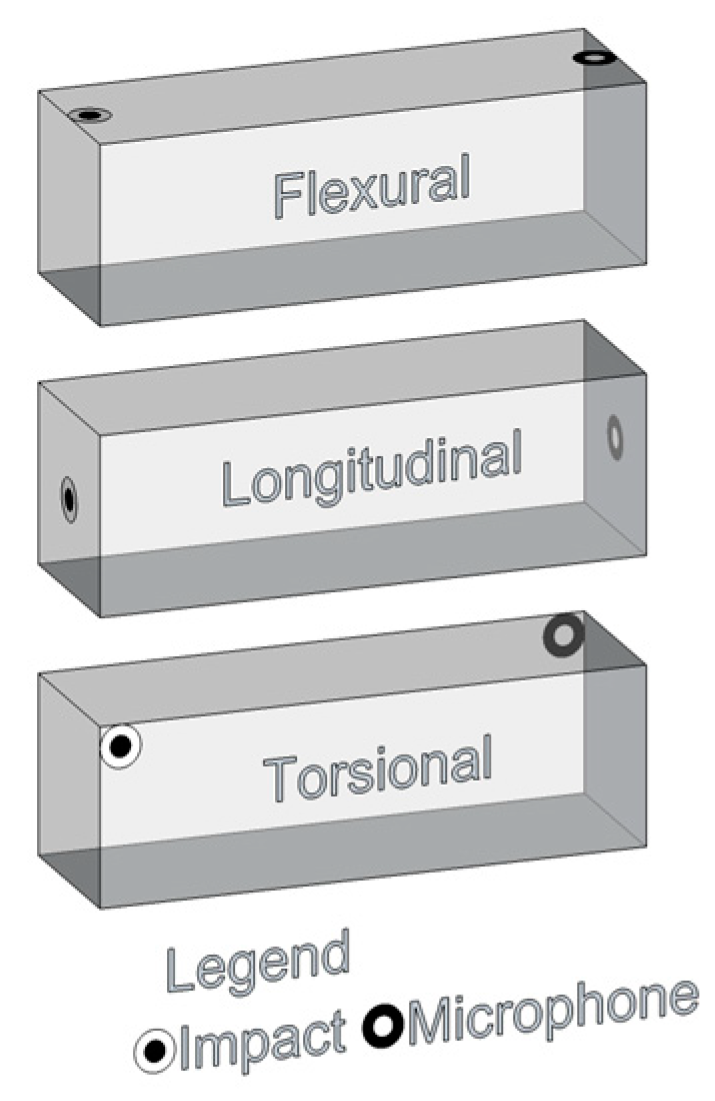

3.3. Acoustic Tests and Evaluation of Experimental Ed

3.4. Experimental Results and Discussion

4. Conclusions and Final Remarks

- (i)

- Homogenization composite models such as Reuss and Hirsch (i.e., x = 0 and x = 0.27) provide good accuracy to predict the dynamic elastic modulus, presenting a maximum error of 5%. Hirsch (x = 0.27) is the most reliable predictor of Ed for ITZ values of 0.05 mm and 0.10 mm, while the Reuss model is the best fit for ITZ = 0.25 mm. In experimental studies, a similar trend was observed, where Hirsch (x = 0.27) successfully predicted the Ed(t) phenomenon for concretes with low and moderate water–cement ratios (w/c = 0.3 and 0.5), while the Reuss was the only model to predict the mixture with w/c = 0.70 with an error consistently lower than 5%.

- (ii)

- In both numerical simulations and experimental validation, Voigt, H-S, and Hansen models consistently produce overestimated values for Ed.

- (iii)

- Hashin-Shtrikman limits do not contain biphasic theoretical models and cannot be applied to dynamic situations perfectly [18].

- (iv)

- The effective Poisson ratio determined by means of natural frequency measurements demonstrates a notable margin of error, owing to the anisotropy produced by the configuration and orientation of coarse aggregates within the mortar. Furthermore, the arrangement of these coarse aggregates may also affect the measurement, as varying arrangements with equivalent elastic properties and volumetric fractions can result in divergent Poisson ratio values.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mehta, P.J.M.; Monteiro, P.K. Concreto: Estrutura, Propriedades e Materiais, 3a; McGraw-Hil: New York, NY, USA, 2008. [Google Scholar]

- Malhotra, V.; Sivasundaram, V. Resonant Frequency Methods * 7.1 7.2. In Nondestructive Testing of Concrete, 1st ed.; CRC Press: New York, NY, USA, 1989. [Google Scholar]

- Neville, A.M. Propriedades do Concreto, 2a; PINI: São Paulo, Brazil, 1997. [Google Scholar]

- ASTM C215-02; Standard Test Method for Fundamental Transverse, Longitudinal, and Torsional Resonant Frequencies of Concrete Specimens. American Society for Testing and Materials: West Conshohocken, PA, USA, 2003; pp. 1–7.

- ASTM E1876-01; Standard Test Method for Dynamic Young’ s Modulus, Shear Modulus, and Poisson’ s Ratio by Impulse Excitation of Vibration. American Society for Testing and Materials: West Conshohocken, PA, USA, 2001.

- Swamy, N.; Rigby, G. Dynamic properties of hardened paste, mortar and concrete. Matériaux Constr. 1971, 4, 13–40. [Google Scholar] [CrossRef]

- Bawa, N.S.; Graft-Johnson, J.W.S. Effect of Mix Proportion, Water-Cement Ratio, Age and Curing Conditions on the Dynamic Modulus of Elasticity of Concrete. Build. Sci. 1969, 3, 171–177. [Google Scholar]

- Lydon, F.D.; Iacovou, M. Some factors affecting the dynamic modulus of elasticity of high strength concrete. Cem. Concr. Res. 1995, 25, 1246–1256. [Google Scholar] [CrossRef]

- Voigt, W. Űber die Beziehung zwischen den beiden Elastizi ä tskonstanten isotroper Körper. Wied. Ann. J. 1889, 38, 573–587. [Google Scholar] [CrossRef]

- Monteiro, P.J.M.; Chang, C.T. The elastic moduli of calcium hydroxide. Cem. Concr. Res. 1995, 25, 1605–1609. [Google Scholar] [CrossRef]

- Topçu, İ.B. Alternative estimation of the modulus of elasticity for dam concrete. Cem. Concr. Res. 2005, 35, 2199–2202. [Google Scholar] [CrossRef]

- Topçu, İ.; Bilir, T.; Boğa, A. Estimation of the modulus of elasticity of slag concrete by using composite material models. Constr. Build. Mater. 2010, 24, 741–748. [Google Scholar] [CrossRef]

- Reuss, A. Berchung der Fiessgrenze von Mischkristallen auf Grund der Plastizi ä tsbedingung für Einkristalle, Zeitschrift Für Angew. Math. Und Mech. 1929, 9, 49–58. [Google Scholar] [CrossRef]

- Hill, R. The Elastic Behaviour of a Crystalline Aggregate. Proc. Phys. Soc. 1952, 65, 349–354. [Google Scholar] [CrossRef]

- Hashin, Z.; Shtrikman, S. A variational approach to the theory of the elastic behaviour of multiphase materials. J. Mech. Phys. Solids. 1963, 11, 127–140. [Google Scholar] [CrossRef]

- Nilsen, U.; Monteiro, P.J.M. Concrete: A three phase material. Cem. Concr. Res. 1993, 23, 147–151. [Google Scholar] [CrossRef]

- Simeonov, P.; Ahmad, S. Effect of transition zone on the elastic behavior of cement-based composites. Cem. Concr. Res. 1995, 25, 165–176. [Google Scholar] [CrossRef]

- Nemat-nasser, S.; Srivastava, A. Bounds on effective dynamic properties of elastic composites. J. Mech. Phys. Solids. 2013, 61, 254–264. [Google Scholar] [CrossRef]

- Garboczi, E.J.; Berryman, J.G. Elastic moduli of a material containing composite inclusions: Effective medium theory and finite element computations. Mech. Mater. 2001, 33, 455–470. [Google Scholar] [CrossRef]

- Constantinides, G.; Ulm, F.J. The effect of two types of C-S-H on the elasticity of cement-based materials: Results from nanoindentation and micromechanical modeling. Cem. Concr. Res. 2004, 34, 67–80. [Google Scholar] [CrossRef]

- Chen, Q.; Nezhad, M.M.; Fisher, Q.; Zhu, H.H. Multi-scale approach for modeling the transversely isotropic elastic properties of shale considering multi-inclusions and interfacial transition zone. Int. J. Rock Mech. Min. Sci. 2016, 84, 95–104. [Google Scholar] [CrossRef]

- Zheng, J.; Zhou, X.; Sun, L. Analytical solution for Young’s modulus of concrete with aggregate aspect ratio effect. Mag. Concr. Res. 2015, 67, 963–971. [Google Scholar] [CrossRef]

- Zheng, J.-J.; Wu, Y.-F.; Zhou, X.-Z.; Wu, Z.-M.; Jin, X.-Y. Prediction of young’s modulus of concrete with two types of elliptical aggregate. ACI Mater. J. 2014, 111, 603–612. [Google Scholar] [CrossRef]

- Zheng, J.; Zhou, X.; Jin, X. An n-layered spherical inclusion model for predicting the elastic moduli of concrete with inhomogeneous ITZ. Cem. Concr. Compos. 2012, 34, 716–723. [Google Scholar] [CrossRef]

- Musiket, K.; Rosendahl, M.; Xi, Y. Fracture of Recycled Aggregate Concrete under High Loading Rates. J. Mater. Civ. Eng. 2016, 25, 864–870. [Google Scholar] [CrossRef]

- Pichler, B.; Hellmich, C.; Eberhardsteiner, J. Spherical and acicular representation of hydrates in a micromechanical model for cement paste: Prediction of early-age elasticity and strength. Acta Mech. 2009, 203, 137–162. [Google Scholar] [CrossRef]

- Qu, H.C.; Zhang, P. A Novel Approach to Determine the Elastic Properties of the Interphase between the Aggregate and the Cement Paste. Key Eng. Mater. 2011, 462, 680–685. [Google Scholar] [CrossRef]

- Duplan, F.; Abou-Chakra, A.; Turatsinze, A.; Escadeillas, G.; Brule, S.; Masse, F. Prediction of modulus of elasticity based on micromechanics theory and application to low-strength mortars. Constr. Build. Mater. 2014, 50, 437–447. [Google Scholar] [CrossRef]

- Pickett, G. Equations for Computing Elastic Constants from Flexural and Torsional Resonant Frequencies of Vibration of Prisms and Cylinders. Proc. Am. Soc. Test. Mater. 1945, 45, 846–866. [Google Scholar]

- Boccaccini, A.R.; Fan, Z. A new approach for the young’s modulus-porosity correlation of ceramic materials. Ceram. Int. 1997, 23, 239–245. [Google Scholar] [CrossRef]

- Hasselman, D.P.H. On the Porosity Dependence of the Elastic Moduli of Polycrystalline Refractory Materials. J. Am. Ceram. Soc. 1962, 45, 452–453. [Google Scholar] [CrossRef]

- Hashin, Z. The Elastic Moduli of Heterogeneous Materials. J. Appl. Mech. 1962, 29, 143. [Google Scholar] [CrossRef]

- Mackenzie, J.K. The elastic constants of a solid containing spherical holes. Proc. Phys. Soc. 1950, 63, 2–11. [Google Scholar] [CrossRef]

- Shehata. Deformações Instantâneas do Concreto. In Concreto, Ensino, Pesqui. e Realiz.; Isaia, G.C., Ed.; Ibracon: São Paulo, Brazil, 2005; pp. 631–685. [Google Scholar]

- Jia, Z.; Han, Y.; Zhang, Y.; Qiu, C.; Hu, C.; Li, Z. Quantitative characterization and elastic properties of interfacial transition zone around coarse aggregate in concrete. J. Wuhan Univ. Technol. Sci. Ed. 2017, 32, 838–844. [Google Scholar] [CrossRef]

- Li, G.; Zhao, Y.; Pang, S.-S.; Li, Y. Effective Young’s modulus estimation of concrete. Cem. Concr. Res. 1999, 29, 1455–1462. [Google Scholar] [CrossRef]

- C150/C150M-22; Standard Specification for Portland Cement. American Society for Testing and Materials: West Conshohocken, PA, USA, 2011.

- ABNT NBR 5733; Cimento Portland de Alta Resistência Inicial. Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brazil, 1991; pp. 1–5.

- ABNT NBR 7211; Agregados Para Concreto-Especificação. Associação Brasileira de Normas Técnicas (ABNT): Rio de Janeiro, Brazil, 2009.

- CEB FIB. Model Code 2010; CEB FIB—Comité Euro-Internationale du Béton: Lausanne, Switzerland, 2010. [Google Scholar]

| E (MPa) | ν | G (MPa) | fbend (Hz) | fshear (Hz) | ||

|---|---|---|---|---|---|---|

| 20,000 | 0.15 | 8696 | 141.4 | 8020 | 93.3 | 7881 |

| 20,000 | 0.2 | 8333 | 141.4 | 7994 | 91.3 | 7730 |

| 20,000 | 0.25 | 8000 | 141.4 | 7965 | 89.4 | 7587 |

| 30,000 | 0.15 | 13,043 | 173.2 | 9822 | 114.2 | 9652 |

| 30,000 | 0.2 | 12,500 | 173.2 | 9790 | 111.8 | 9467 |

| 30,000 | 0.25 | 12,000 | 173.2 | 9756 | 109.5 | 9292 |

| 40,000 | 0.15 | 17,391 | 200.0 | 11,341 | 131.9 | 11,145 |

| 40,000 | 0.2 | 16,667 | 200.0 | 11,305 | 129.1 | 10,931 |

| 40,000 | 0.25 | 16,000 | 200.0 | 11,265 | 126.5 | 10,729 |

| Model | Parameter | K or A | E0 or G0 (MPa) | R2 |

|---|---|---|---|---|

| Mackenzie | G | K = 2.896 | G0 = 12,340.899 | 0.99872 |

| Mackenzie | E | K = 2.370 | E0 = 29,593.245 | 0.99935 |

| Hanselmann-Hashin | G | A = −4.976 | G0 = 13,148.495 | 0.97948 |

| Hanselmann-Hashin | E | A = −3.314 | E0 = 30,590.435 | 0.99187 |

| ID | Cement (kg) | Sand (kg) | Water (kg) | Superplasticizer (kg) | |

|---|---|---|---|---|---|

| 1-M | 1.00 | 2.00 | 0.50 | 0.010 (1%) | |

| 2-M | 1.00 | 2.00 | 0.30 | 0.010 (1%) | |

| 3-M | 1.00 | 2.00 | 0.70 | 0 | |

| ID | Cement (kg) | Sand (kg) | Coarse Aggregate (kg) | Water (kg) | Superplasticizer (kg) |

| 1-C | 1.00 | 2.00 | 3.00 | 0.50 | 0.010 (1%) |

| 2-C | 1.00 | 2.00 | 3.00 | 0.30 | 0.010 (1%) |

| 3-C | 1.00 | 2.00 | 3.00 | 0.70 | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gidrão, G.d.M.S.; Carrazedo, R.; Bosse, R.M.; Silvestro, L.; Ribeiro, R.; de Souza, C.F.P. Numerical Modeling of the Dynamic Elastic Modulus of Concrete. Materials 2023, 16, 3955. https://doi.org/10.3390/ma16113955

Gidrão GdMS, Carrazedo R, Bosse RM, Silvestro L, Ribeiro R, de Souza CFP. Numerical Modeling of the Dynamic Elastic Modulus of Concrete. Materials. 2023; 16(11):3955. https://doi.org/10.3390/ma16113955

Chicago/Turabian StyleGidrão, Gustavo de Miranda Saleme, Ricardo Carrazedo, Rúbia Mara Bosse, Laura Silvestro, Rodrigo Ribeiro, and Carlos Francisco Pecapedra de Souza. 2023. "Numerical Modeling of the Dynamic Elastic Modulus of Concrete" Materials 16, no. 11: 3955. https://doi.org/10.3390/ma16113955

APA StyleGidrão, G. d. M. S., Carrazedo, R., Bosse, R. M., Silvestro, L., Ribeiro, R., & de Souza, C. F. P. (2023). Numerical Modeling of the Dynamic Elastic Modulus of Concrete. Materials, 16(11), 3955. https://doi.org/10.3390/ma16113955