Research on Cutting Layer Characteristics of Superalloy under High-Pressure Cooling

Abstract

1. Introduction

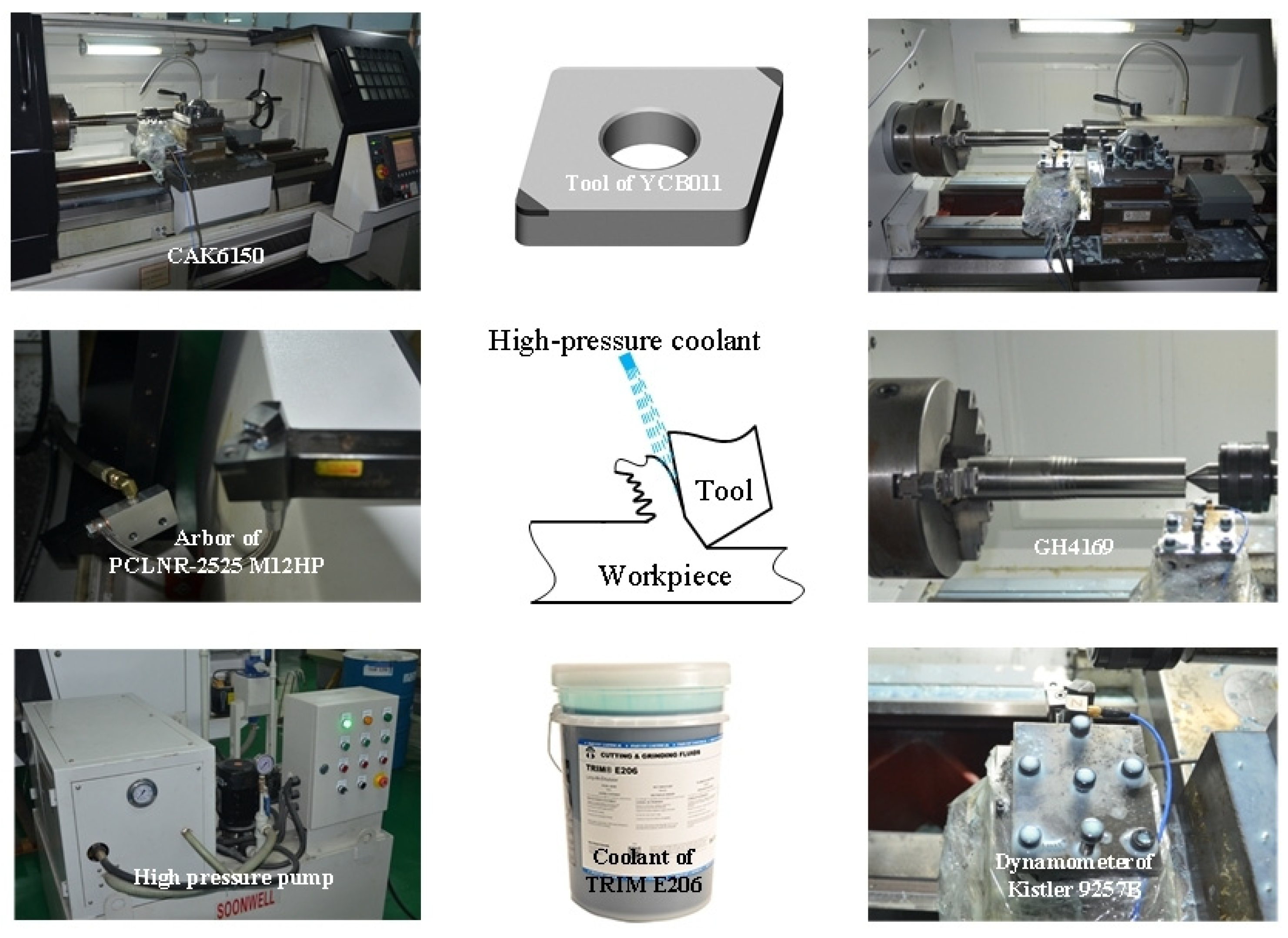

2. Experimental Design of a PCBN Tool Turning Superalloy under High-Pressure Cooling

2.1. Test Conditions

2.2. Test Scheme

3. Experimental Results and Discussion of PCBN Tool Turning Superalloy under High-Pressure Cooling

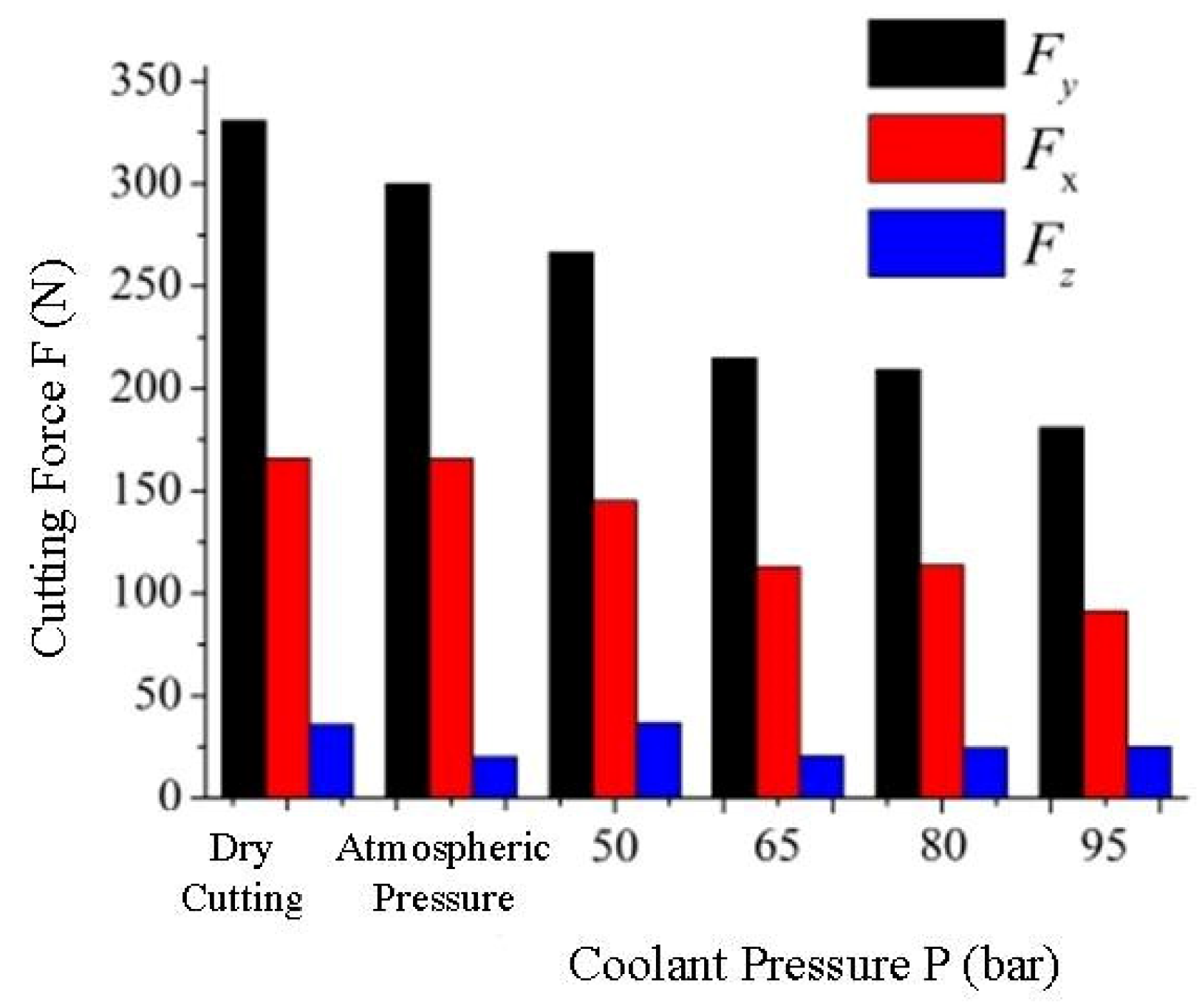

3.1. Research on the Cutting Force of Cutting GH4169 under High-Pressure Cooling

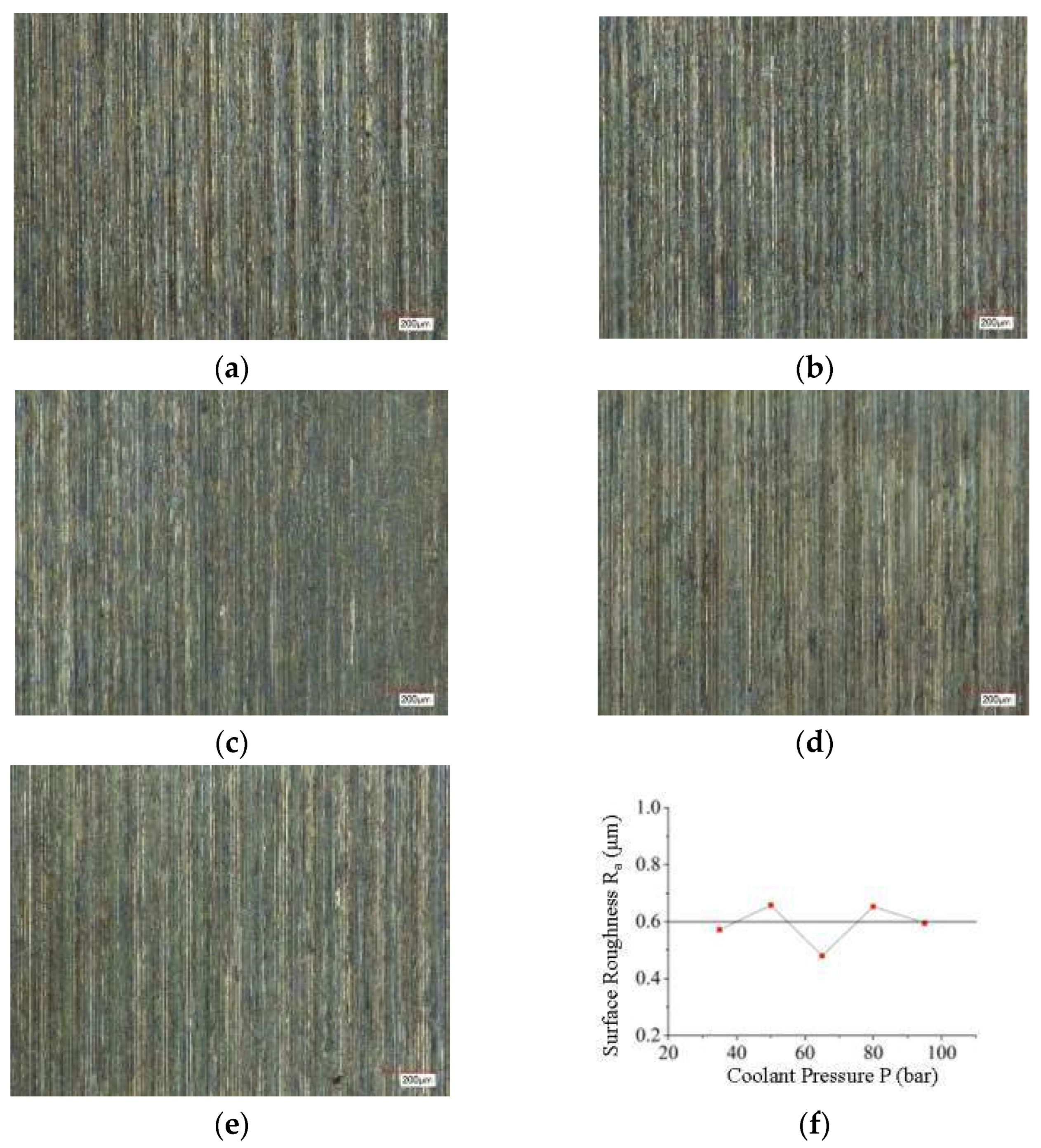

3.2. Research on the Machined Surface Roughness of Cutting GH4169 under High-Pressure Cooling

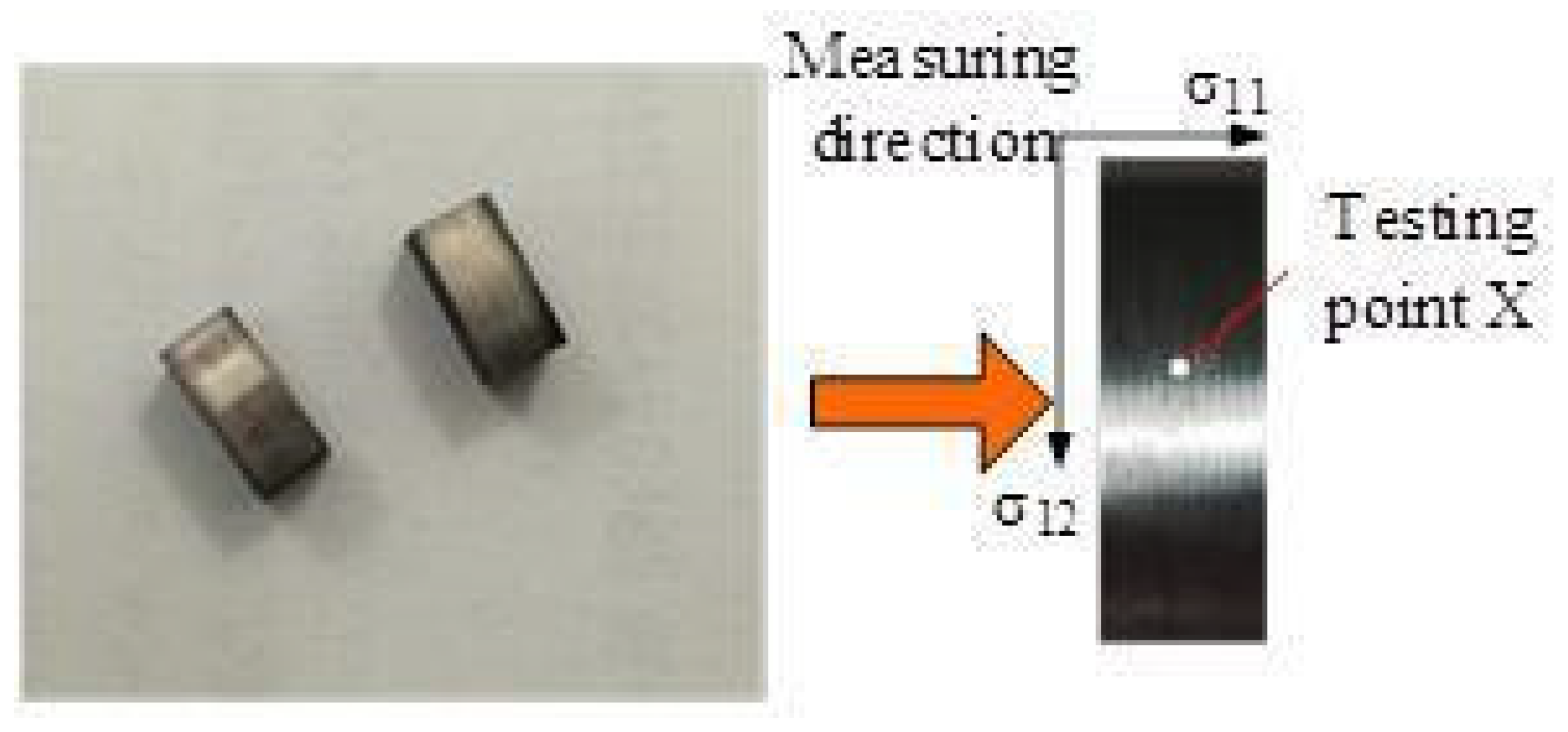

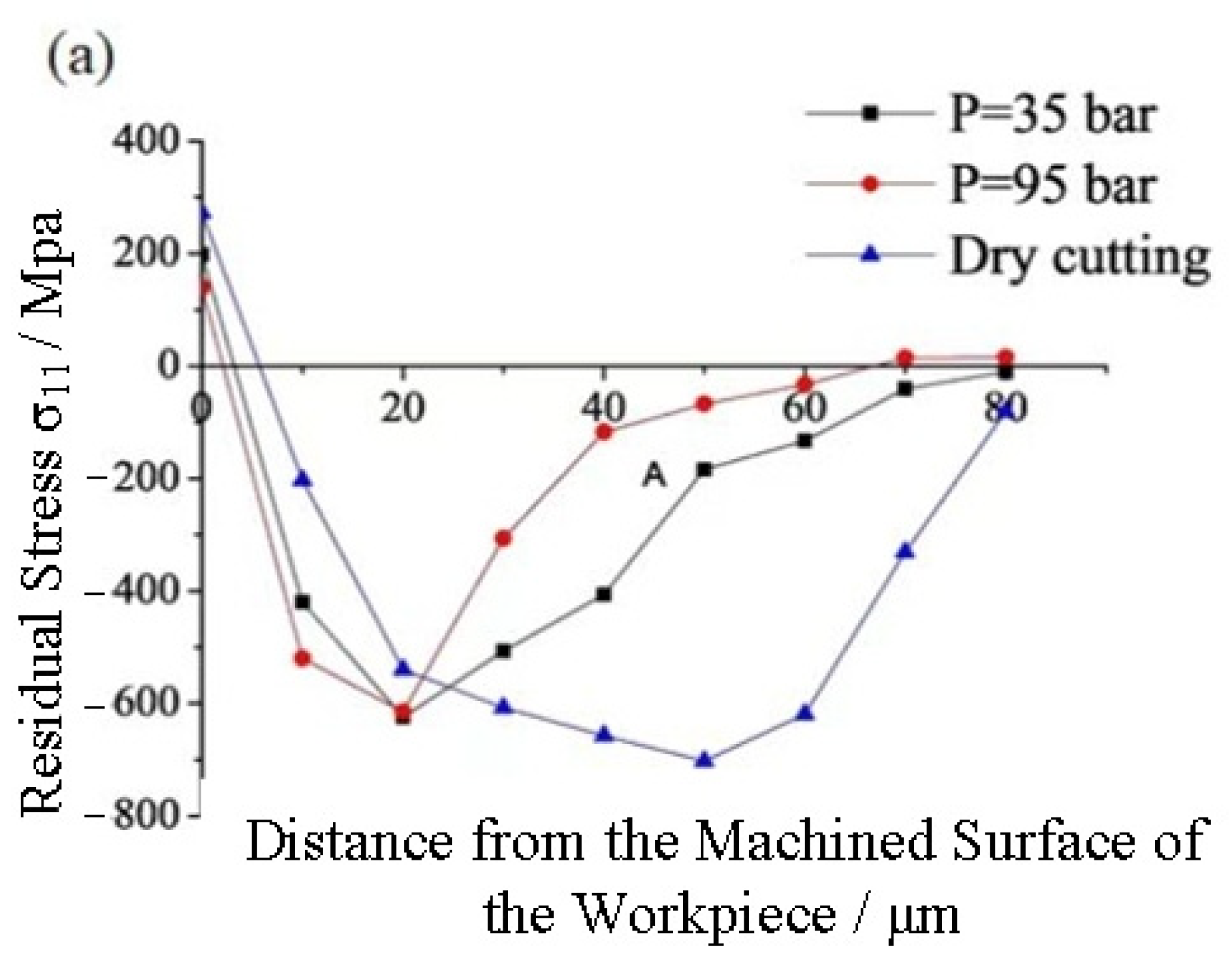

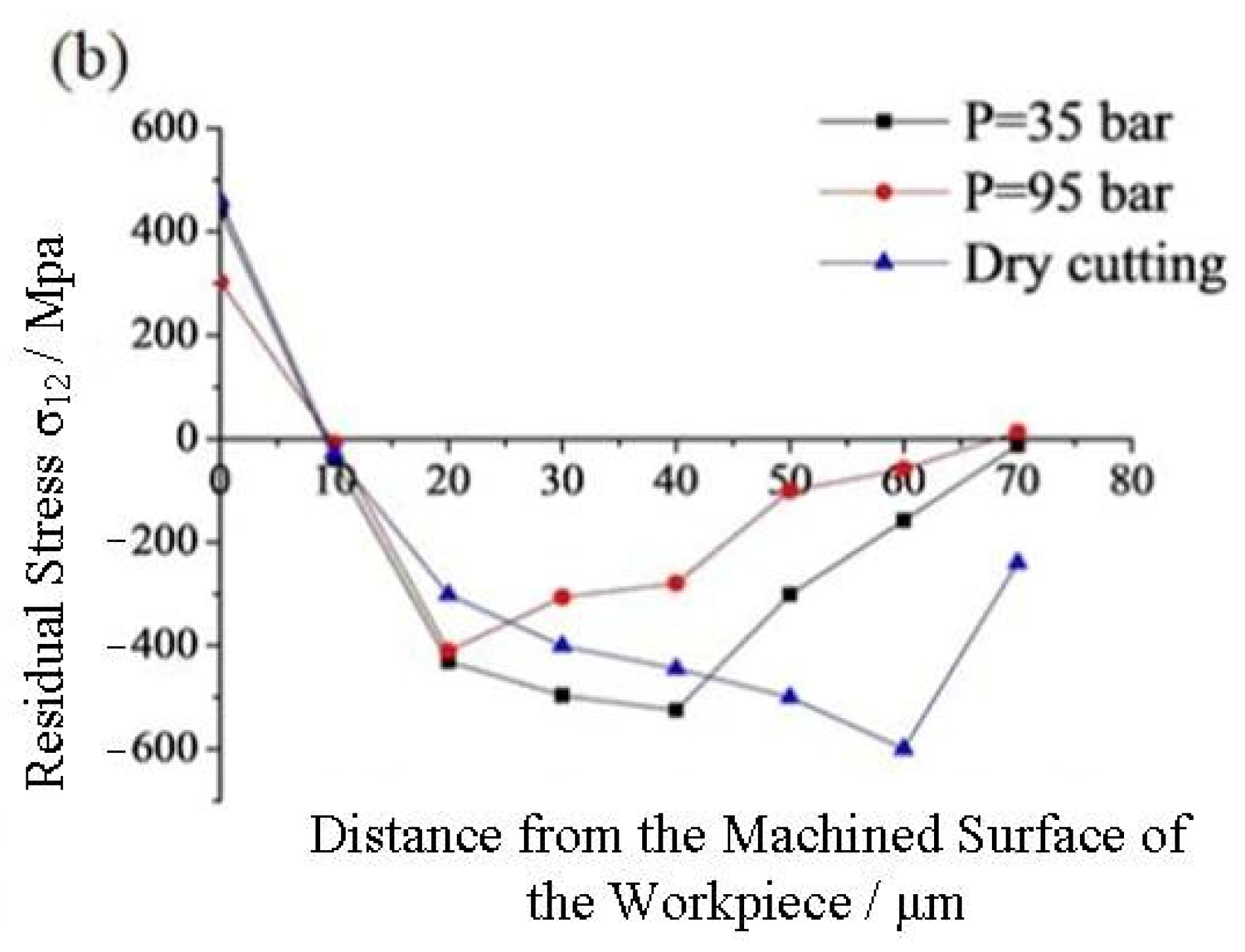

3.3. Research on Machined Surface Residual Stress While Cutting GH4169 in High-Pressure Cooling

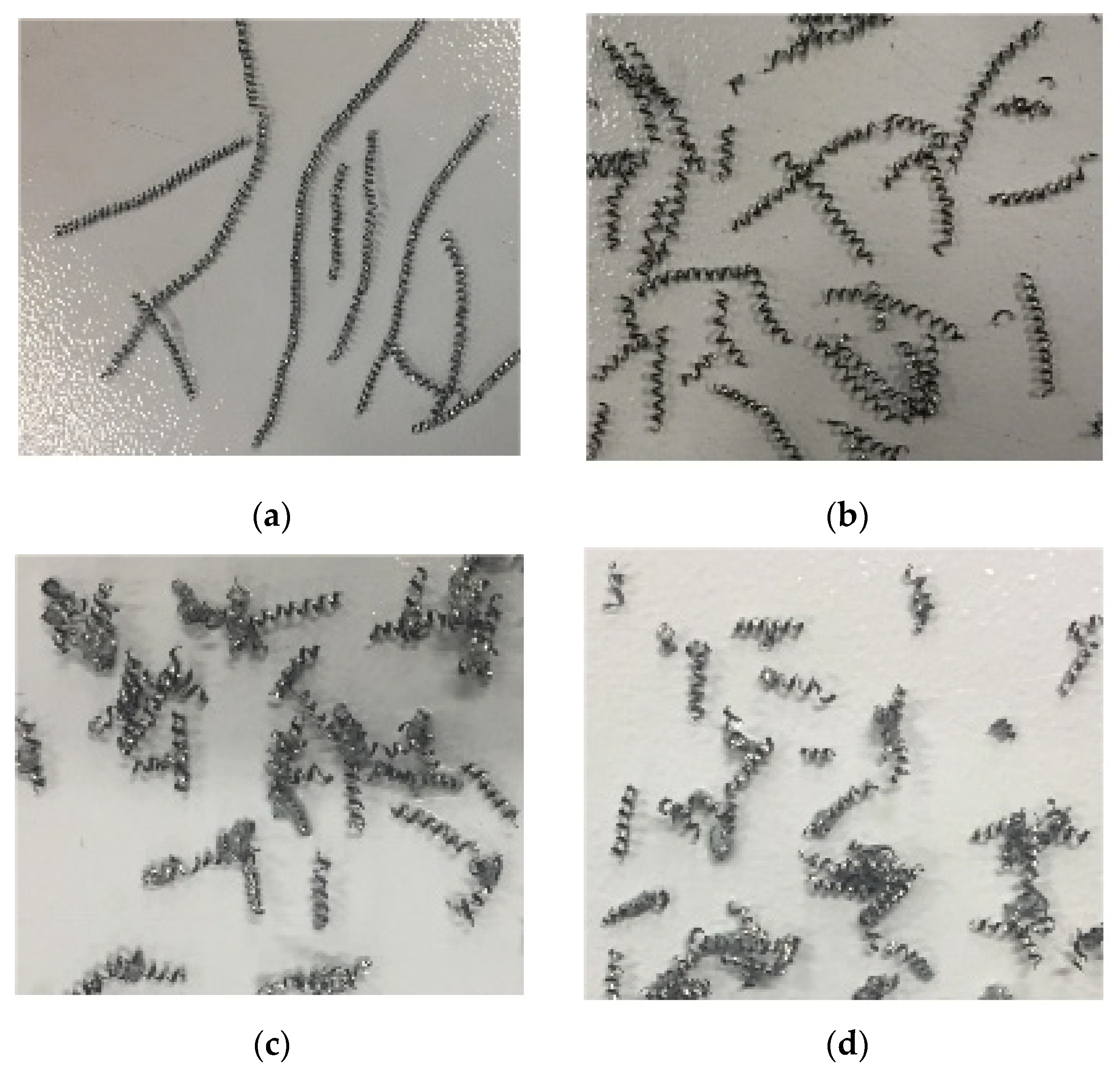

3.4. Research on the Chip Morphology of GH4169 Cutting under High-Pressure Cooling

3.4.1. Research on the Macroscopic Morphology of the GH4169 Chip

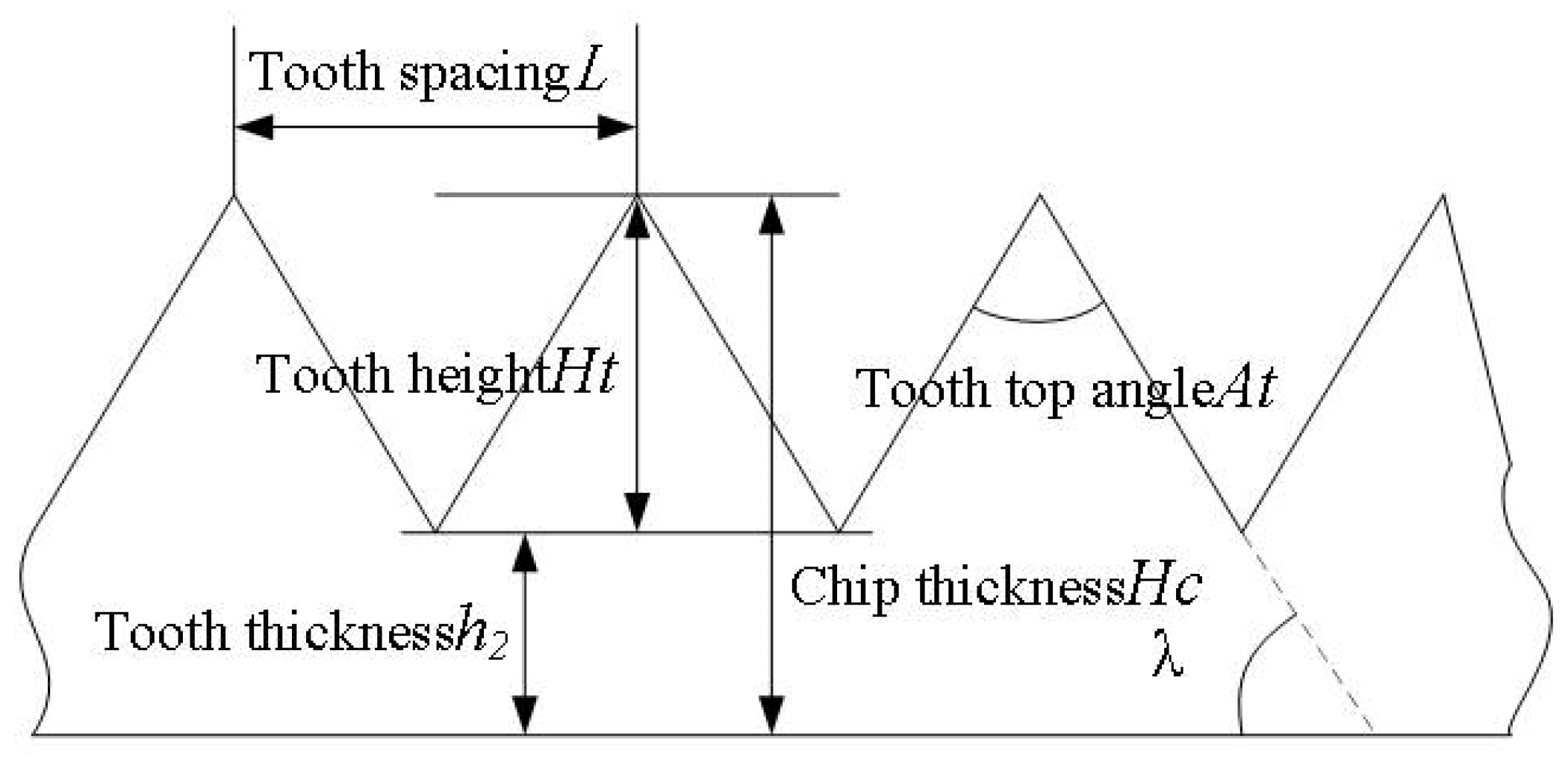

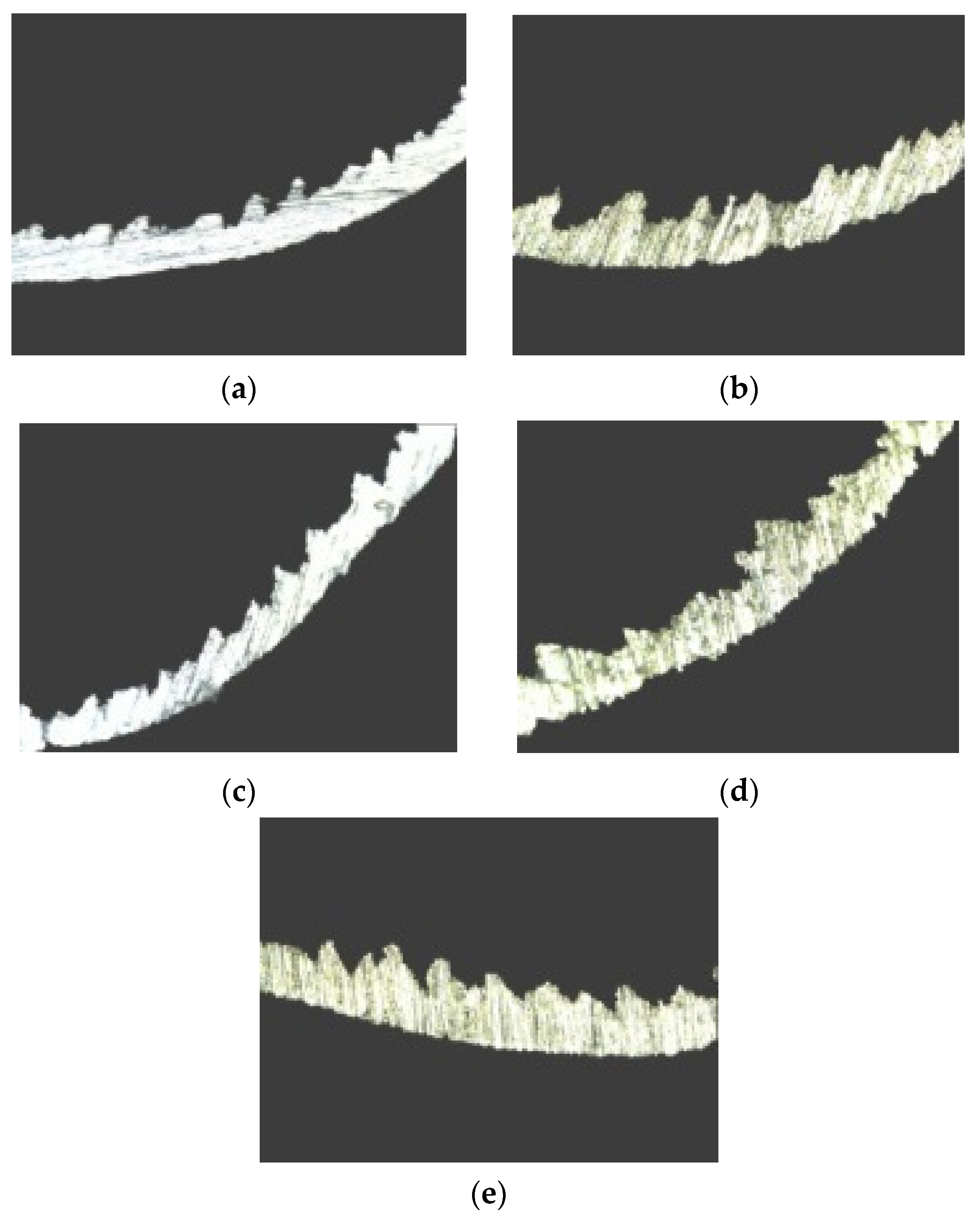

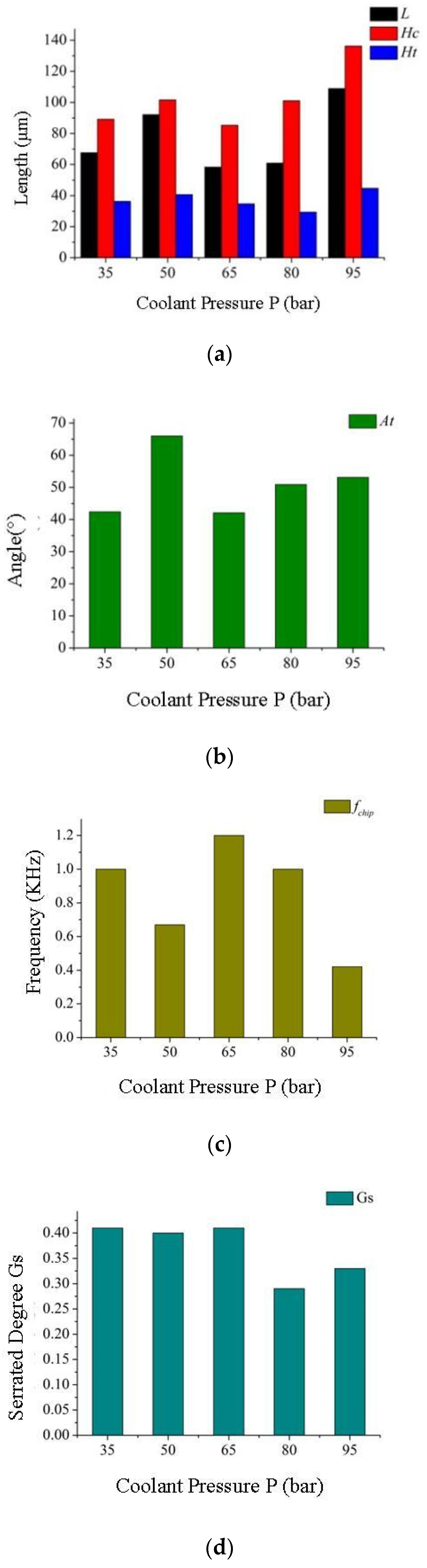

3.4.2. Research on the Micromorphology of the GH4169 Chip

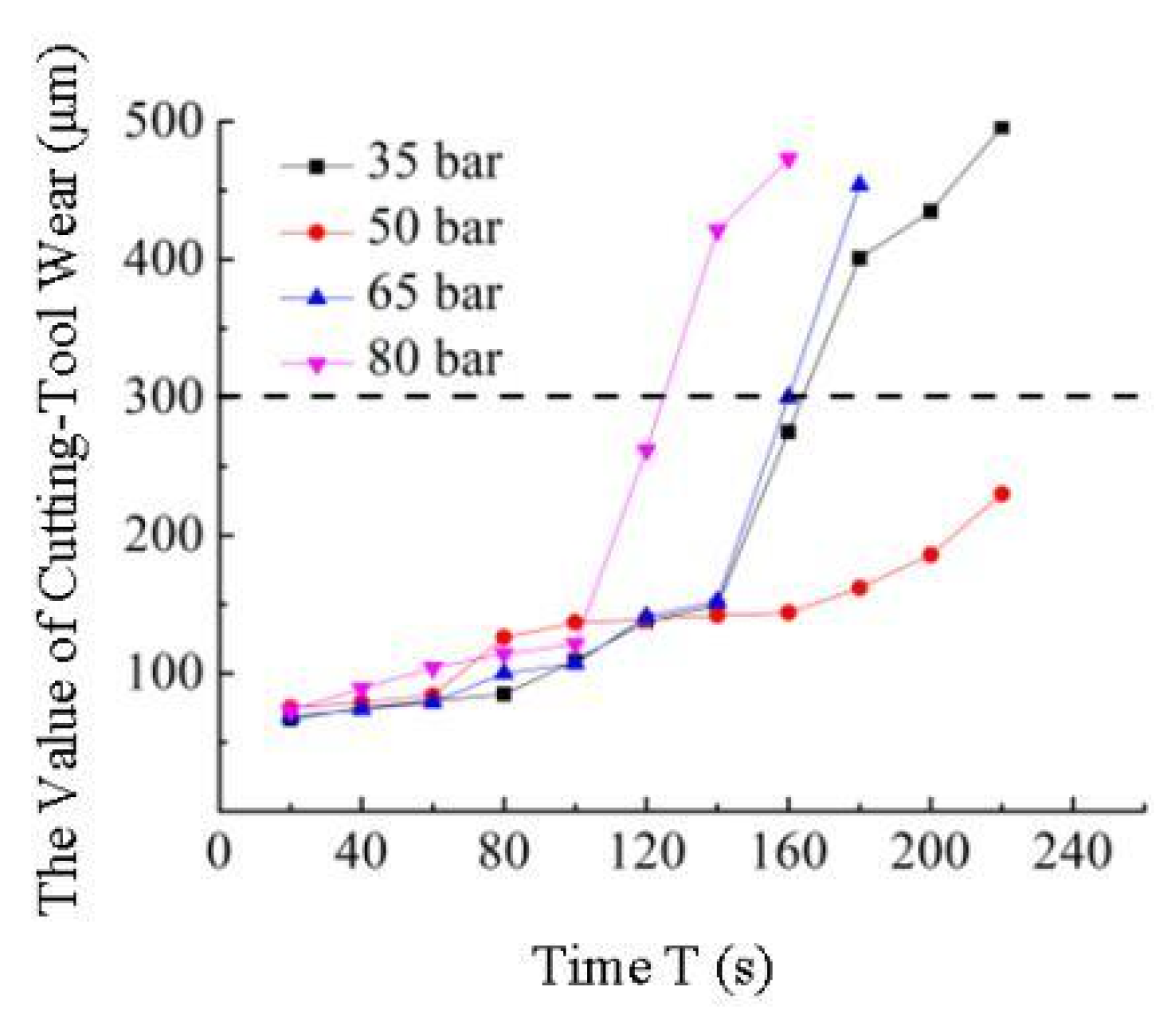

3.5. Research on PCBN Tool Life under High-Pressure Cooling

4. Conclusions

- (1)

- The axial force Fx and radial force Fy produced by PCBN tool cutting GH4169 under high-pressure cooling conditions are greatly influenced by coolant pressure, but the tangential force Fz is not significantly affected. Within the range of selected high-pressure cooling test parameters, the radial force can be reduced by 11~39% and 19~45%, respectively, compared to atmospheric cooling cutting and dry cutting.

- (2)

- When cutting GH4169 with the PCBN tool in the presence of high-pressure cooling, the high-pressure coolant has little effect on the roughness of the machined surface but has a great effect on the residual stress of the machined surface. The absolute value of the maximum residual stress on the machined surface of GH4169 under high-pressure cooling is lower than that under dry cutting conditions, and the maximum value is further reduced when the coolant pressure becomes larger.

- (3)

- According to the macroscopic morphology of chips, the high-pressure coolant has a significant effect on improving chip breaking ability. As the coolant pressure reaches 95 bar, the chip breaks quickly and presents C-type chips. According to the microscopic morphology of chips, the length between adjacent serrations, chip thickness, and addendum height tend to increase as the high-pressure coolant pressure increases.

- (4)

- To ensure the service life of the PCBN tool while cutting GH4169 under high-pressure cooling, the coolant pressure should not be too large, and 50 bar is more appropriate.

Author Contributions

Funding

Conflicts of Interest

References

- Jangali, S.G.; Gaitonde, V.N.; Kulkarni, V.N.; Madhusudhana, H.K. Analyzing the effect of cutting parameters on forces and tool-tip temperature in turning of nickel-based superalloy using FE simulation. Mater. Today Proc. 2021, 49, 1833–1843. [Google Scholar] [CrossRef]

- Li, J.M.; Wang, X.Y.; Qiao, Y.; Guo, P.Q. Research progress in superalloy machining. J. Univ. Jinan 2020, 34, 203–210. [Google Scholar]

- Ni, H.H.; Ji, F.F.; Chen, Y.G.; Nie, J.M. Experimental study on properties of PCBN tool material and cutting of 20CrMnTi alloy steel. Min. Metall. Eng. 2022, 42, 125–128. [Google Scholar]

- Li, X.; Zheng, G.; Yan, P.; Sun, Z.; Cheng, X.; Liu, H. Cutting performance of coated tools and machined surface integrity in superalloy clean cutting. China Mech. Eng. 2023, 34, 454–463. [Google Scholar]

- Wang, D.X.; Sun, S.F.; Tang, Y.Z.; Liu, X.F.; Jiang, J.L. Molecular dynamics simulation for grinding interface under minimum quantity lubrication. J. Xi’an Jiaotong Univ. 2020, 54, 168–175. [Google Scholar]

- Wang, K.; Xu, L.; Wang, X.Y.; Yan, W.R.; Wang, S.; Fang, J.M.; Jiao, X.J.; Li, J.P.; Zhao, G.L.; Zhang, J.Q. Wear mechanism of polycrystalline diamond tool in cryogenic cooling milling of Cf/ SiC composite. Sci. Technol. Eng. 2021, 21, 11125–11129. [Google Scholar]

- Iturbe, A.; Hormaetxe, E.; Garay, A.; Arrazola, P.J. Surface integrity analysis when machining Inconel 718 with conventional and cryogenic cooling. Procedia CIRP 2016, 45, 67–70. [Google Scholar] [CrossRef]

- Liu, E.; Wang, R.; Zhang, Y.; An, W. Tool wear analysis of cutting Ti-5553 with uncoated carbide tool under liquid nitrogen cooling condition using tool wear maps. J. Manuf. Process. 2021, 68, 877–887. [Google Scholar] [CrossRef]

- Shu, S.R.; Zhang, Y.; Xiao, C.; Qi, X. Numerical simulation of cooling performance of compound cooling turning tool with internal cooling and spray cooling. Modul. Mach. Tool Autom. Manuf. Tech. 2020, 155–159. [Google Scholar]

- Yang, F.; Yang, R.X. Experimental study on cutting high manganese steel using water vapor cooling and lubricating. Mod. Manuf. Eng. 2019, 81–85. [Google Scholar]

- Alagan, N.T.; Zeman, P.; Mara, V.; Beno, T.; Wretland, A. High-pressure flank cooling and chip morphology in turning Alloy 718. CIRP J. Manuf. Sci. Technol. 2021, 35, 659–674. [Google Scholar] [CrossRef]

- D’Addona, D.M.; Raykar, S.J. Thermal modeling of tool temperature distribution during high pressure coolant assisted turning of Inconel 718. Materials 2019, 12, 408. [Google Scholar] [CrossRef] [PubMed]

- Qi, Y.D.; Zhou, Y.S.; Cui, C.L. Research on high pressure cooling chip breaking technology for 304 stainless steel turning. Modul. Mach. Tool Autom. Manuf. Tech. 2022, 120, 112–114. [Google Scholar]

- Wu, M.; Li, L.; Liu, X.; Cheng, Y.; Yu, Y. Analysis and experimental study of the cutting mechanism in machined nickel-base superalloys GH4169 with PCBN tools under high pressure cooling. Integr. Ferroelectr. 2018, 189, 105–120. [Google Scholar] [CrossRef]

- Li, L.; Wu, M.; Liu, X.; Cheng, Y.; Yu, Y. Experimental study of the wear behavior of PCBN inserts during cutting of GH4169 superalloys under high-pressure cooling. Int. J. Adv. Manuf. Technol. 2018, 95, 1941–1951. [Google Scholar] [CrossRef]

- Alagan, N.T.; Zeman, P.; Hoier, P.; Beno, T.; Klement, U. Investigation of micro-textured cutting tools used for face turning of alloy 718 with high-pressure cooling. J. Manuf. Process. 2019, 37, 606–616. [Google Scholar] [CrossRef]

- Fang, Z.L.; Obikawa, T. Influence of cutting fluid flow on tool wear in high-pressure coolant turning using a novel internally cooled insert. J. Manuf. Process. 2020, 56, 1114–1125. [Google Scholar] [CrossRef]

- Liu, C.H.; Sugihara, T.; Enomoto, T. Interrupted cutting of Inconel 718 with AlTiSiN coated cemented carbide tool under high pressure coolant supply. Precis. Eng. 2022, 78, 124–133. [Google Scholar] [CrossRef]

- Mingyang, W.; Xu, Z.; Yong, C.; Ming, X.; Yaonan, C.; Lubin, L. Reaserch on mechanism and experimental of chip breaking during high pressure cooling turning of superalloys with PCBN tool. J. Mech. Eng. 2017, 53, 187–192. [Google Scholar]

- Alagan, N.T.; Hoier, P.; Zeman, P.; Klement, U.; Beno, T.; Wretland, A. Effects of high-pressure cooling in the flank and rake faces of WC tool on the tool wear mechanism and process conditions in turning of alloy 718. Wear 2019, 434, 102922. [Google Scholar] [CrossRef]

- Nasr, G.; Soltantarzeh, M.; Davoodi, B.; Hajaliakbari, A. Assessment of tool wear mechanisms in high-pressure jet-assisted turning process of a nickel-based superalloy. Wear 2020, 460, 203454. [Google Scholar] [CrossRef]

- Díaz-Álvarez, A.; Díaz-Álvarez, J.; Cantero, J.L.; Miguélez, M.H. High-pressure cooling in finishing turning of Haynes 282 using carbide tools: Haynes 282 and Inconel 718 comparison. Metals 2021, 11, 1916. [Google Scholar] [CrossRef]

- Wang, W.X.; Wu, M.Y.; Li, B.W.; Wang, X.Y.; Cheng, Y.N. Study on factors affecting chip formation during cutting GH4169 under high pressure cooling. Aeronaut. Manuf. Technol. 2020, 63, 93–102. [Google Scholar]

- Li, L.B.; Wu, M.Y.; Liu, L. The research on the cutting test of Ni–based superalloy GH4169 and optimization of process parameters under high pressure cooling. Integr. Ferroelectr. 2021, 218, 83–96. [Google Scholar] [CrossRef]

- Sørby, K.; Vagnorius, Z. High-pressure cooling in turning of Inconel 625 with ceramic cutting tools. Procedia CIRP 2018, 77, 74–77. [Google Scholar] [CrossRef]

- Wu, M.Y.; Wu, S.J.; Chu, W.X.; Liu, K.; Cheng, Y. Study on stress distribution of cutting tool for cutting superalloy under high-pressure cooling. Aeronaut. Manuf. Technol. 2019, 62, 26–34. [Google Scholar]

- Alagan, N.T.; Hoier, P.; Beno, T.; Klement, U.; Wretland, A. Coolant boiling and cavitation wear–a new tool wear mechanism on WC tools in machining Alloy 718 with high-pressure coolant. Wear 2020, 452, 203284. [Google Scholar] [CrossRef]

- Wu, M.; Yu, Y.; Cheng, Y.; Li, L.; Zhao, X. Experimental investigation of chip plastic side flow in machining of GH4169 superalloy under high-pressure cooling. Ferroelectrics 2018, 530, 82–96. [Google Scholar] [CrossRef]

- Wei, M.; Wu, M.Y.; Xu, J.M.; Cheng, J. Influence of flank wear on the microstructure characteristics of the GH4169 metamorphic layer under high-pressure cooling. Materials 2023, 16, 2944. [Google Scholar] [CrossRef]

- Zhang, Y.L.; Wu, M.Y.; Liu, K.K.; Zhang, J. Optimization research of machining parameters for cutting GH4169 based on tool vibration and surface roughness under high-pressure cooling. Materials 2021, 14, 7861. [Google Scholar] [CrossRef]

- Liu, L.; Wu, M.Y.; Li, L.B.; Cheng, Y. FEM simulation and experiment of high-pressure cooling effect on cutting force and machined surface quality during turning Inconel 718. Integr. Ferroelectr. 2020, 206, 160–172. [Google Scholar] [CrossRef]

- Wang, F.J.; Guo, W.L.; Liu, R.A.; Gong, X.Q. Simulation study on friction performance of tool under high pressure cooling. Mach. Des. Manuf. 2021, 369, 65–68+73. [Google Scholar]

- Wu, M.Y.; Chu, W.X.; Liu, K.K.; Wu, S.J.; Cheng, Y.N. Analysis of surface residual stress and formation mechanism of metamorphic layer in PCBN Tool cutting superalloy under high-pressure cooling. J. Mech. Eng. 2022, 58, 231–243. [Google Scholar]

- Wu, M.; Yu, Y.; Cheng, Y.; Li, L.; Zhao, X. Geometrical characterization test of serrated chips under high-pressure cooling. China Mech. Eng. 2019, 30, 38–45. [Google Scholar]

- Shaw, M.C.; Vyas, A. The mechanism of chip formation with hard turning steel. CIRP Ann. Manuf. Technol. 1998, 47, 77–82. [Google Scholar] [CrossRef]

| Ni | Cr | Mo | Nb | Ti | Al | C | Si | Mn | Fe |

|---|---|---|---|---|---|---|---|---|---|

| 53.38 | 18.40 | 3.0 | 5.13 | 1.1 | 0.38 | 0.017 | 0.062 | 0.05 | residual |

| Density ρ/(g/cm3) | Yield Strength δ0.2/MPa | Tensile Strength δb/MPa | Elongation δS/% | Shrinkage Ratio ψ/% | Impact Ductility ak/(MJ/m2) | Hardness HB |

|---|---|---|---|---|---|---|

| 8.28 | 1152 | 1376 | 19 | 45.5 | 348 | 410–420 |

| Coolant P/bar | Cutting Amount | Chamfer Angle | Chamfer Width |

|---|---|---|---|

| dry cutting, atmospheric pressure, 35, 50, 65, 80, 95 | vc = 125 m/min, 160 m/min, f = 0.05 mm/r, 0.1 mm/r, ap = 0.4 mm, 1 mm | 15° | 0.15 mm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, L.; Chen, S.; Li, T.; Wu, M. Research on Cutting Layer Characteristics of Superalloy under High-Pressure Cooling. Materials 2023, 16, 3931. https://doi.org/10.3390/ma16113931

Li L, Chen S, Li T, Wu M. Research on Cutting Layer Characteristics of Superalloy under High-Pressure Cooling. Materials. 2023; 16(11):3931. https://doi.org/10.3390/ma16113931

Chicago/Turabian StyleLi, Lubin, Shuning Chen, Tiankang Li, and Mingyang Wu. 2023. "Research on Cutting Layer Characteristics of Superalloy under High-Pressure Cooling" Materials 16, no. 11: 3931. https://doi.org/10.3390/ma16113931

APA StyleLi, L., Chen, S., Li, T., & Wu, M. (2023). Research on Cutting Layer Characteristics of Superalloy under High-Pressure Cooling. Materials, 16(11), 3931. https://doi.org/10.3390/ma16113931