Experimental Comparison of Laser Cladding and Powder Plasma Transferred Arc Welding Methods for Depositing Wear-Resistant NiSiB + 60% WC Composite on a Structural-Steel Substrate

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Surface Cladding

2.1.1. Laser Cladding (LC)

2.1.2. Powder Plasma Transferred Arc Welding (PPTAW)

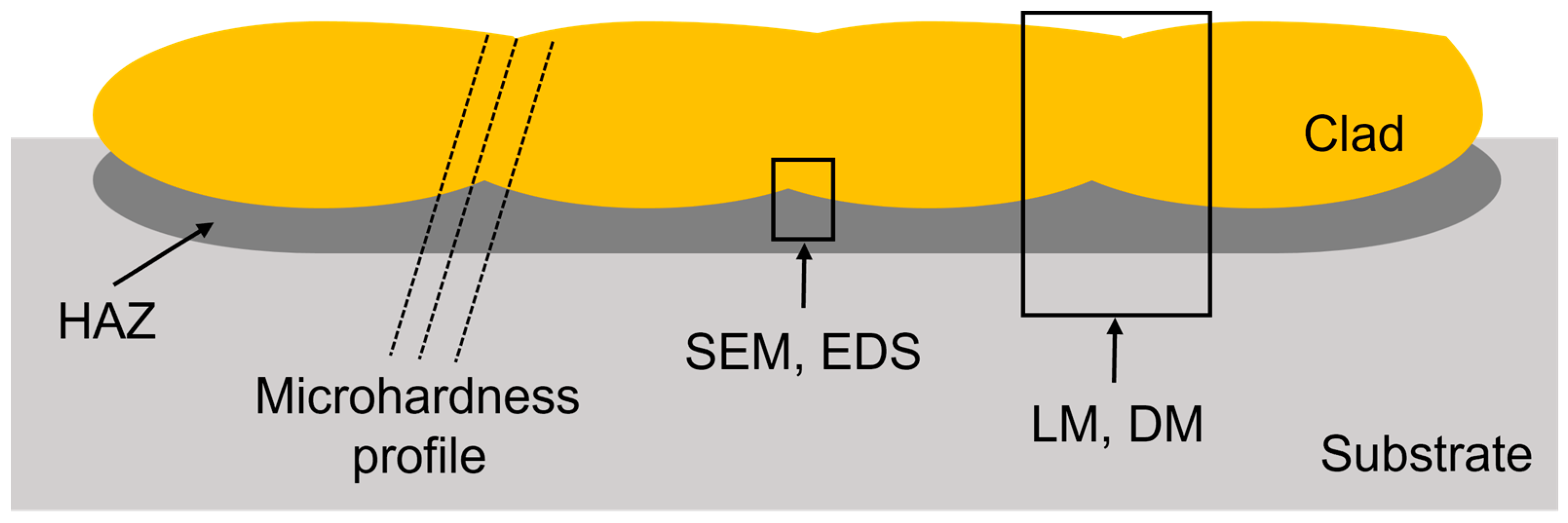

2.2. Characterization

3. Results and Discussion

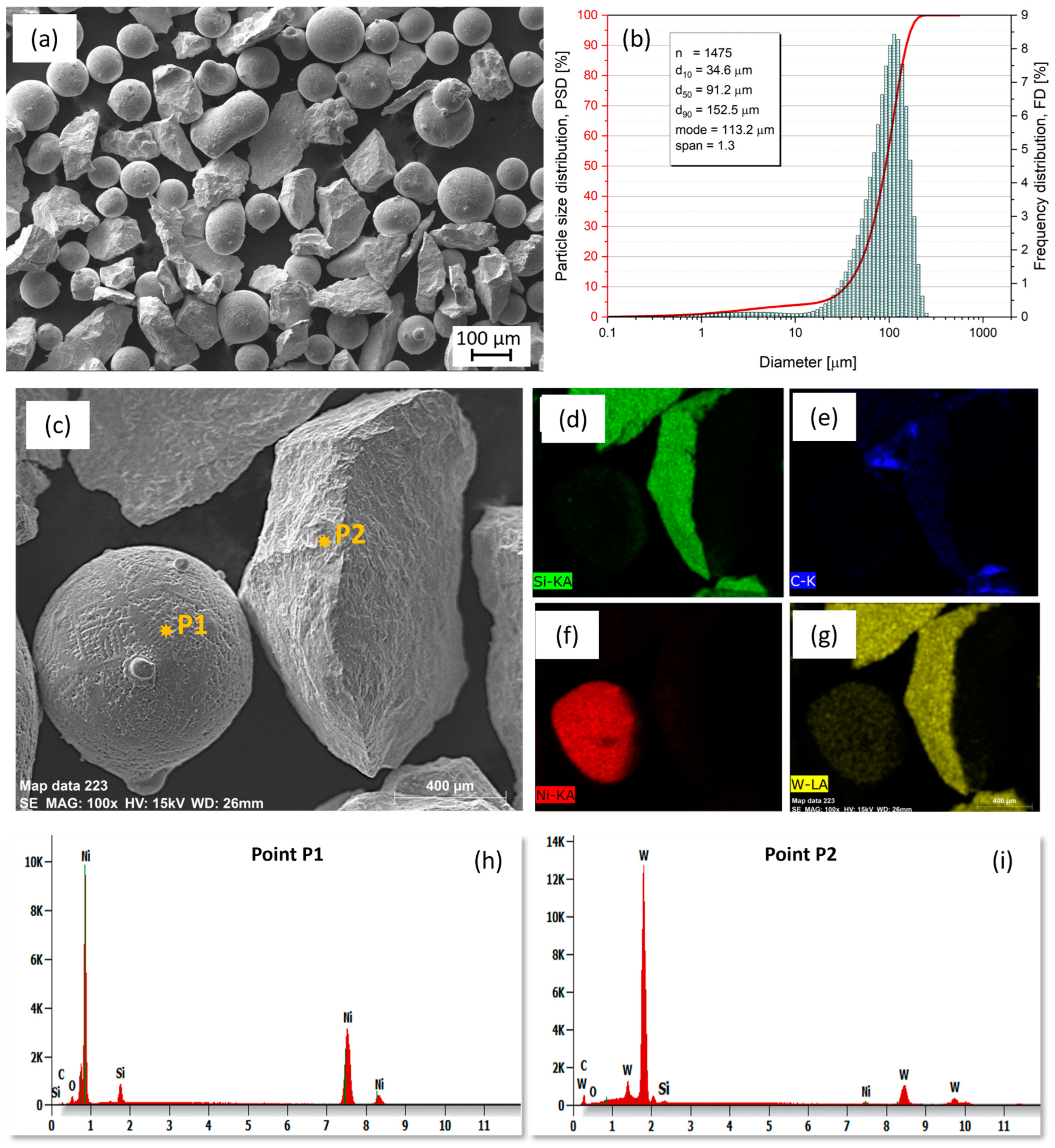

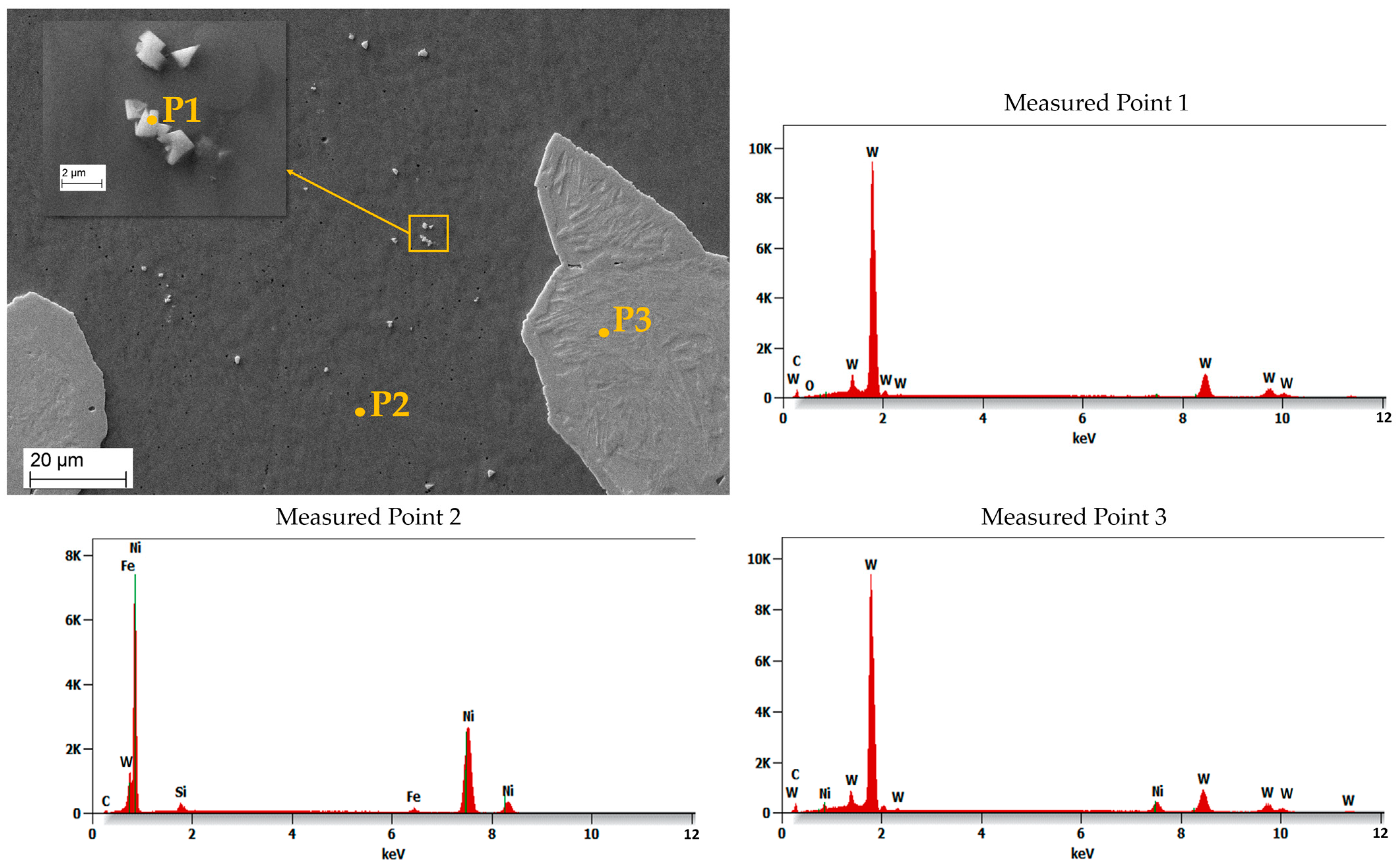

3.1. Powder Characterization

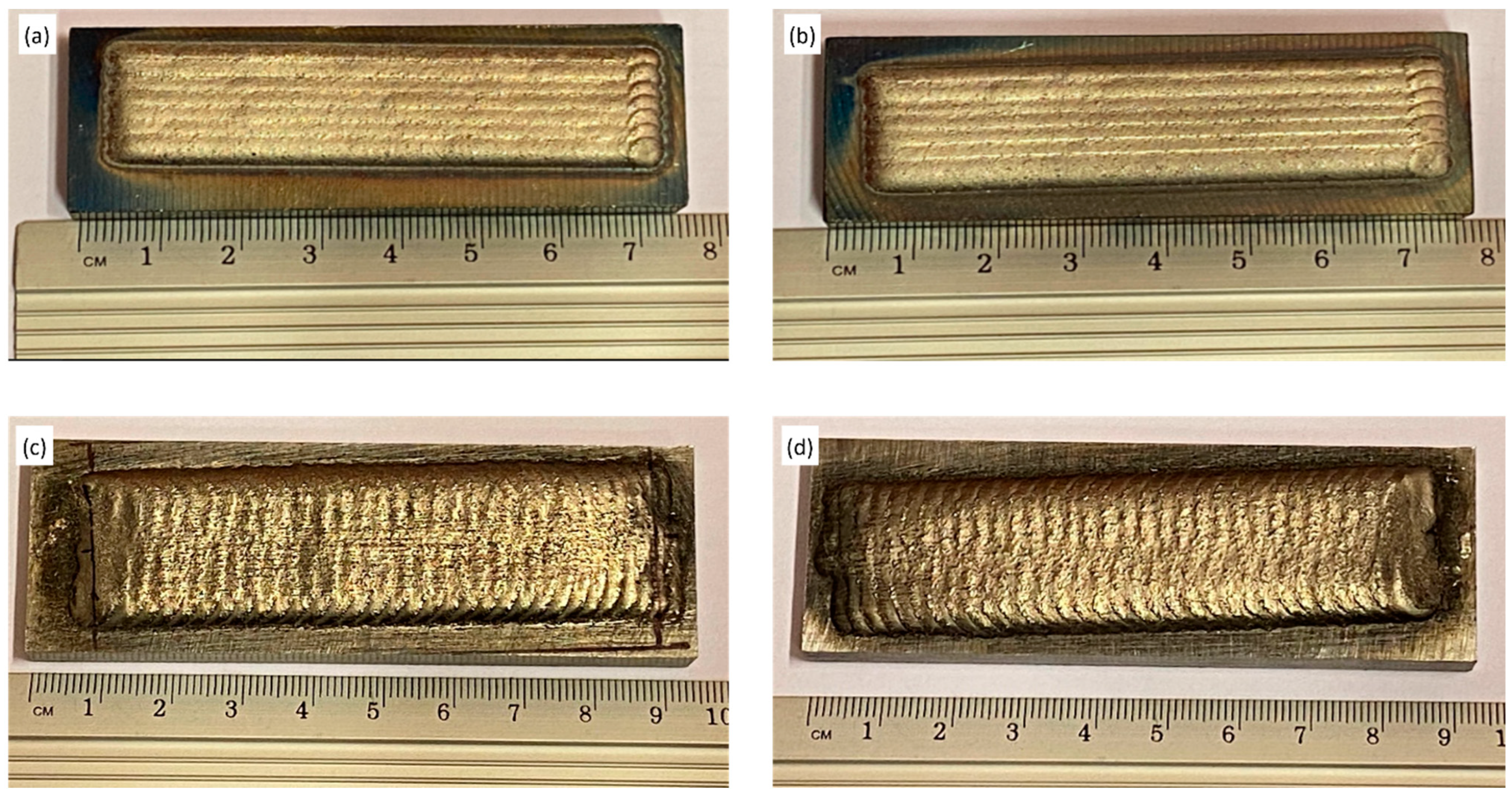

3.2. Cladding

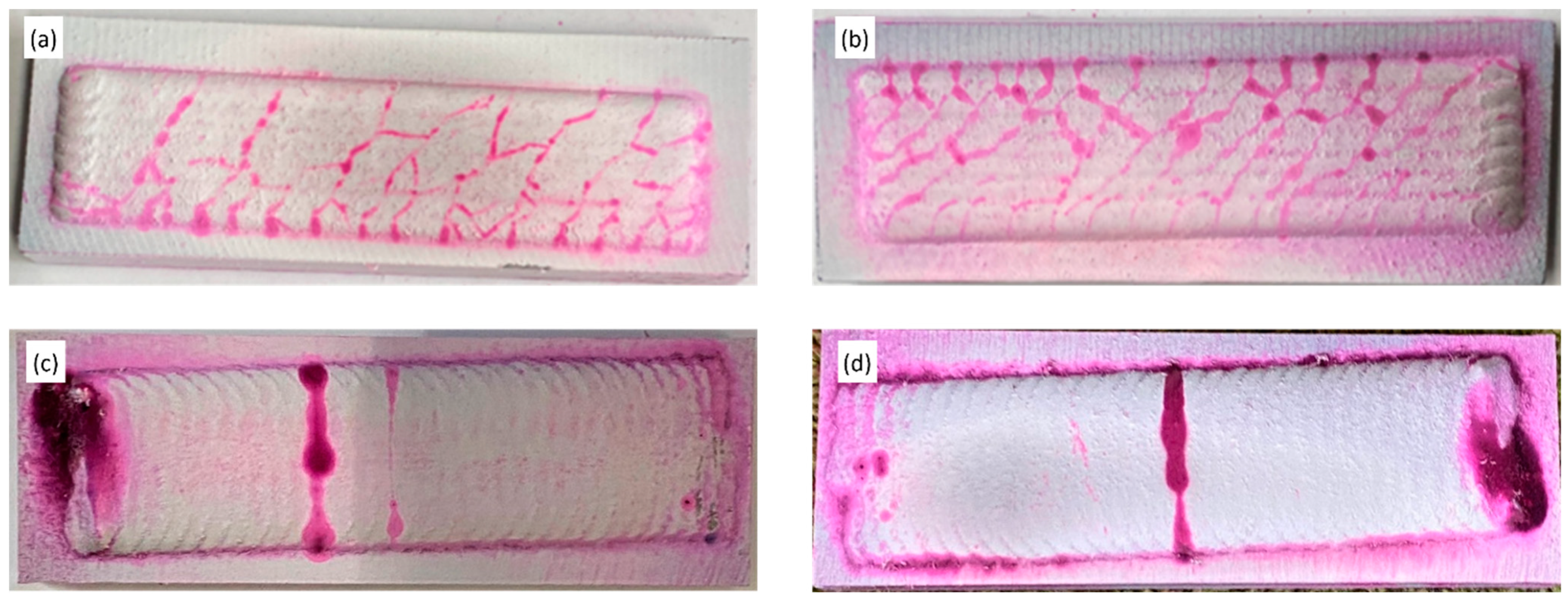

3.3. Surface Crack Investigation

3.4. Microhardness Tests

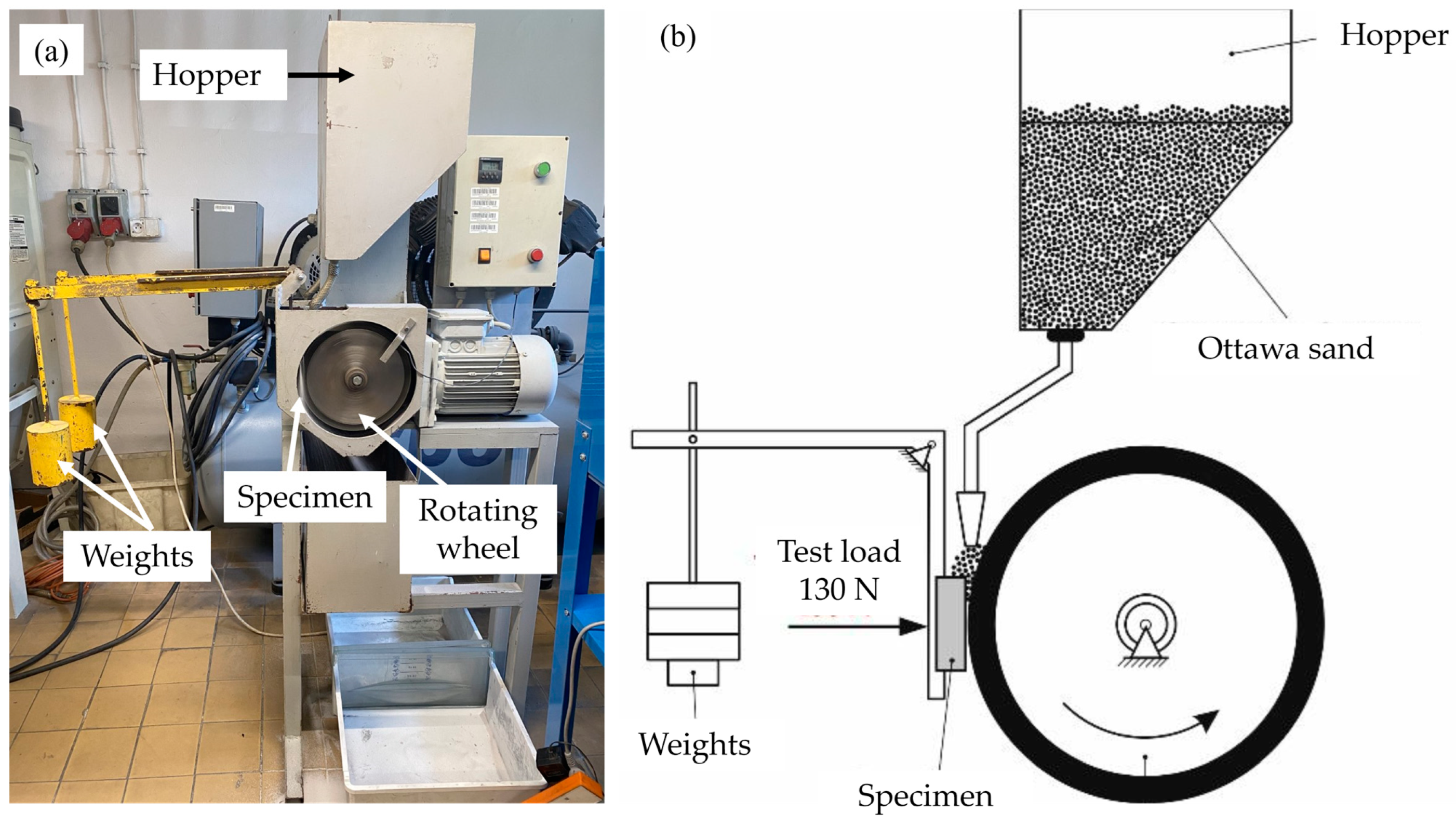

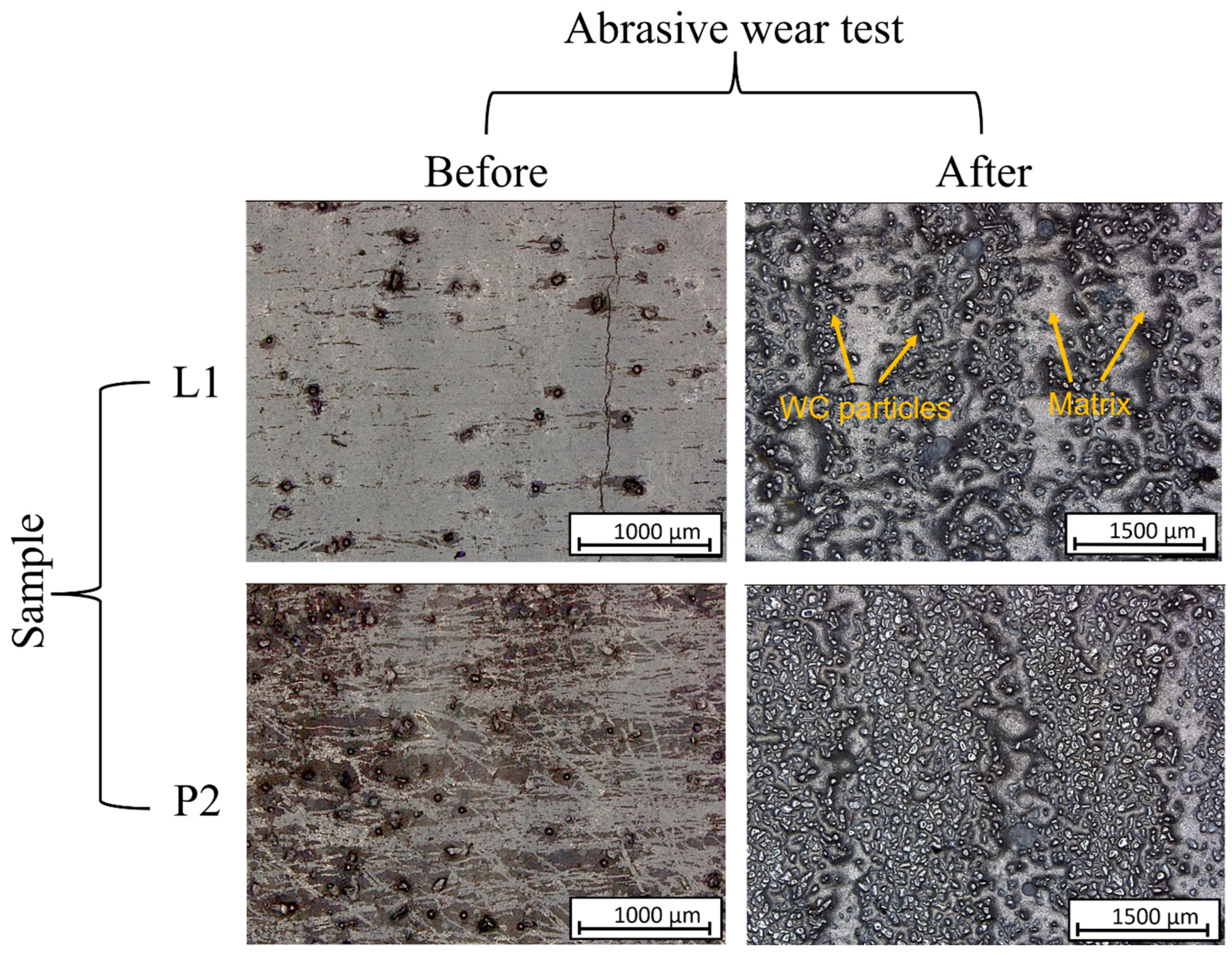

3.5. Abrasive-Wear Resistance Tests

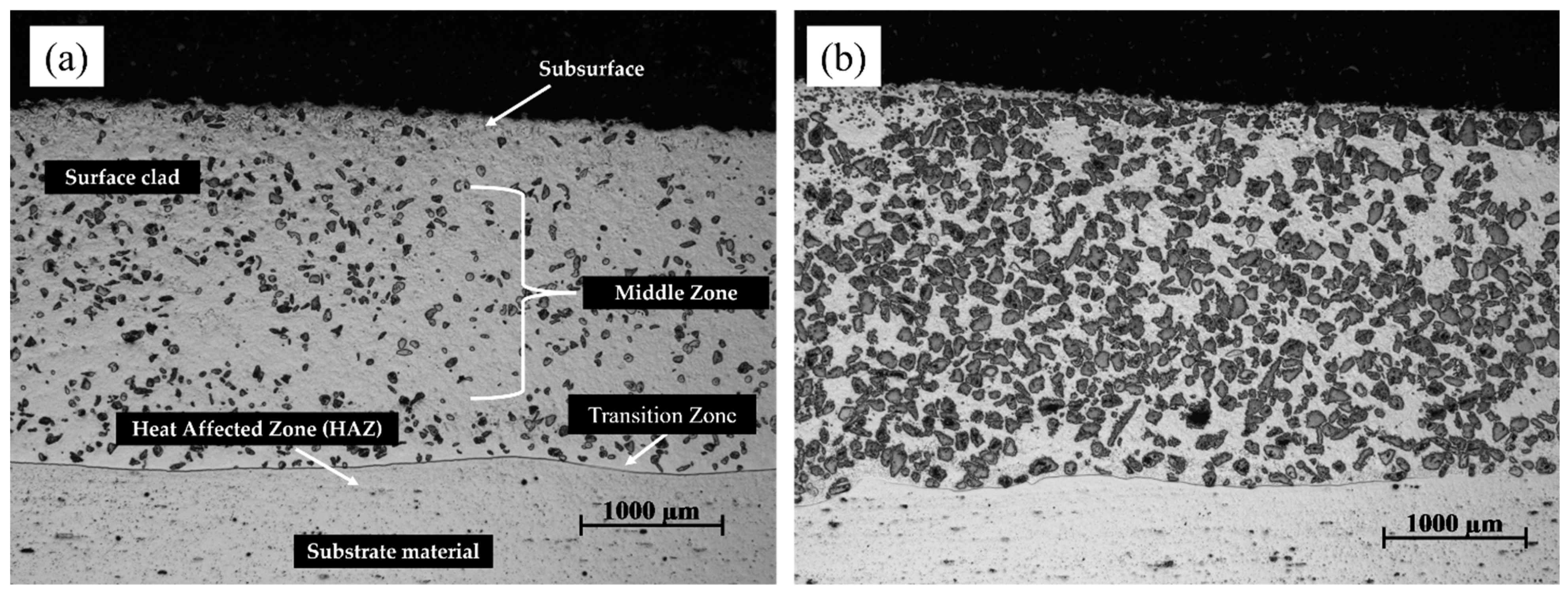

3.6. Microstructural Evolution

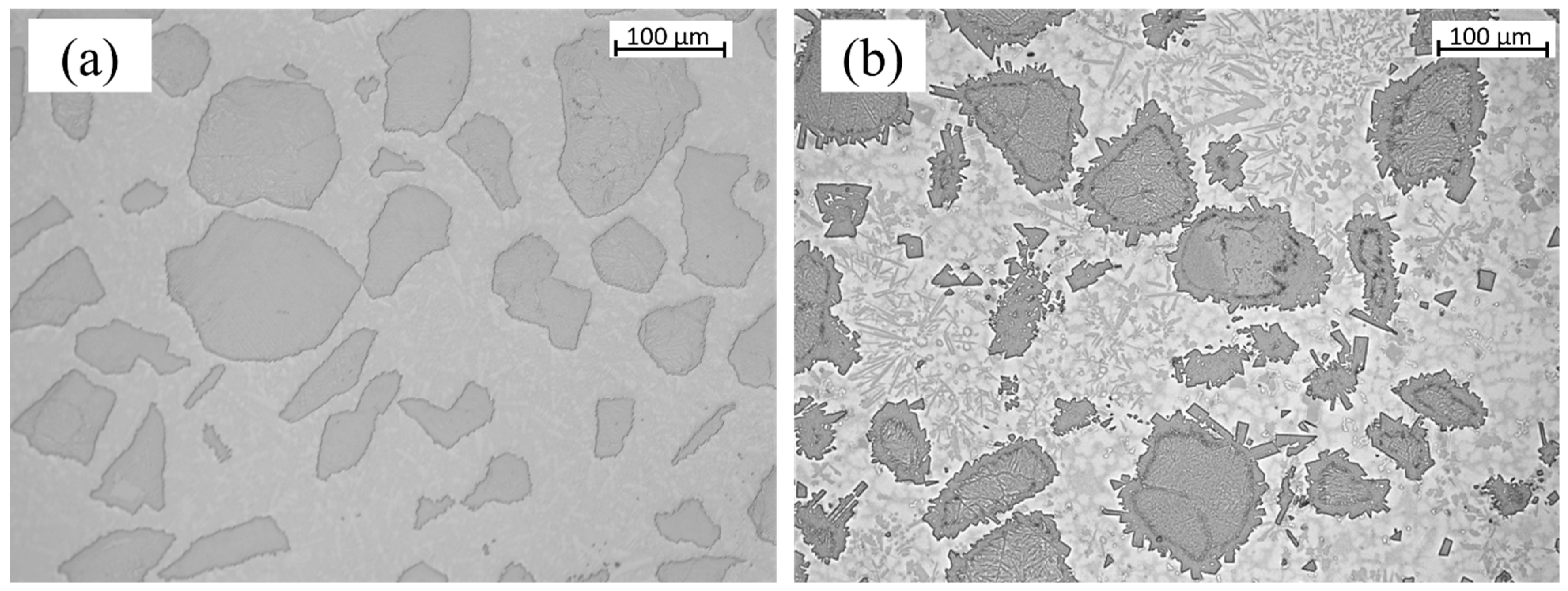

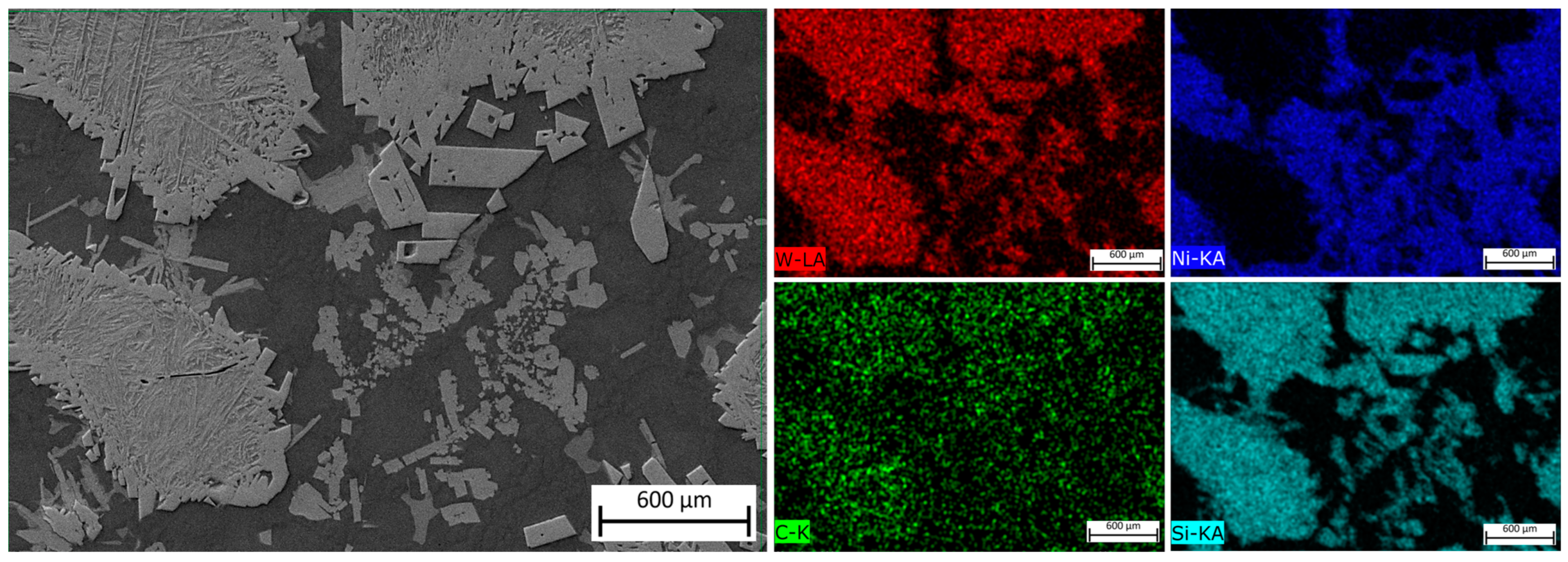

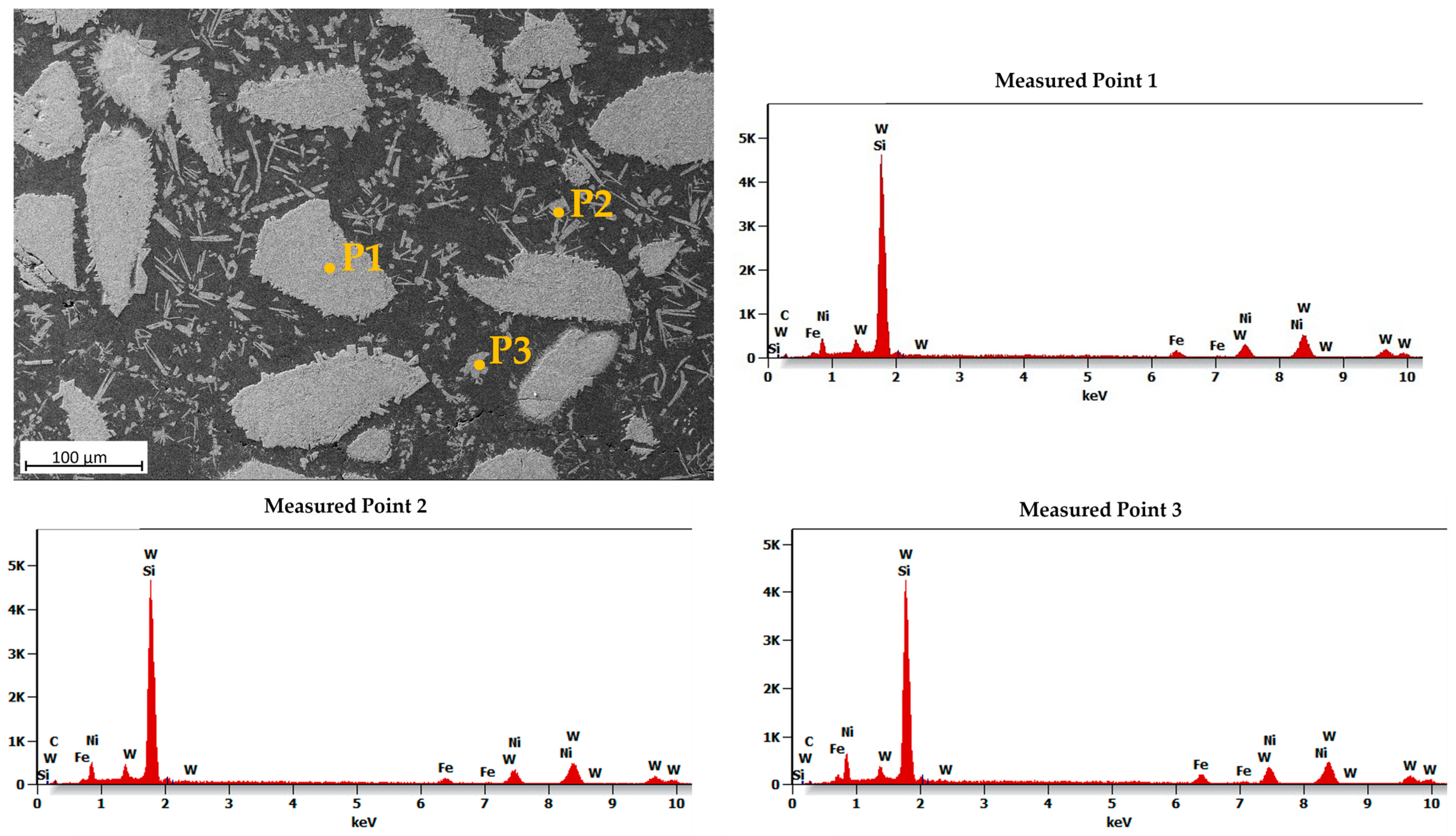

3.6.1. Middle Zone (MZ)

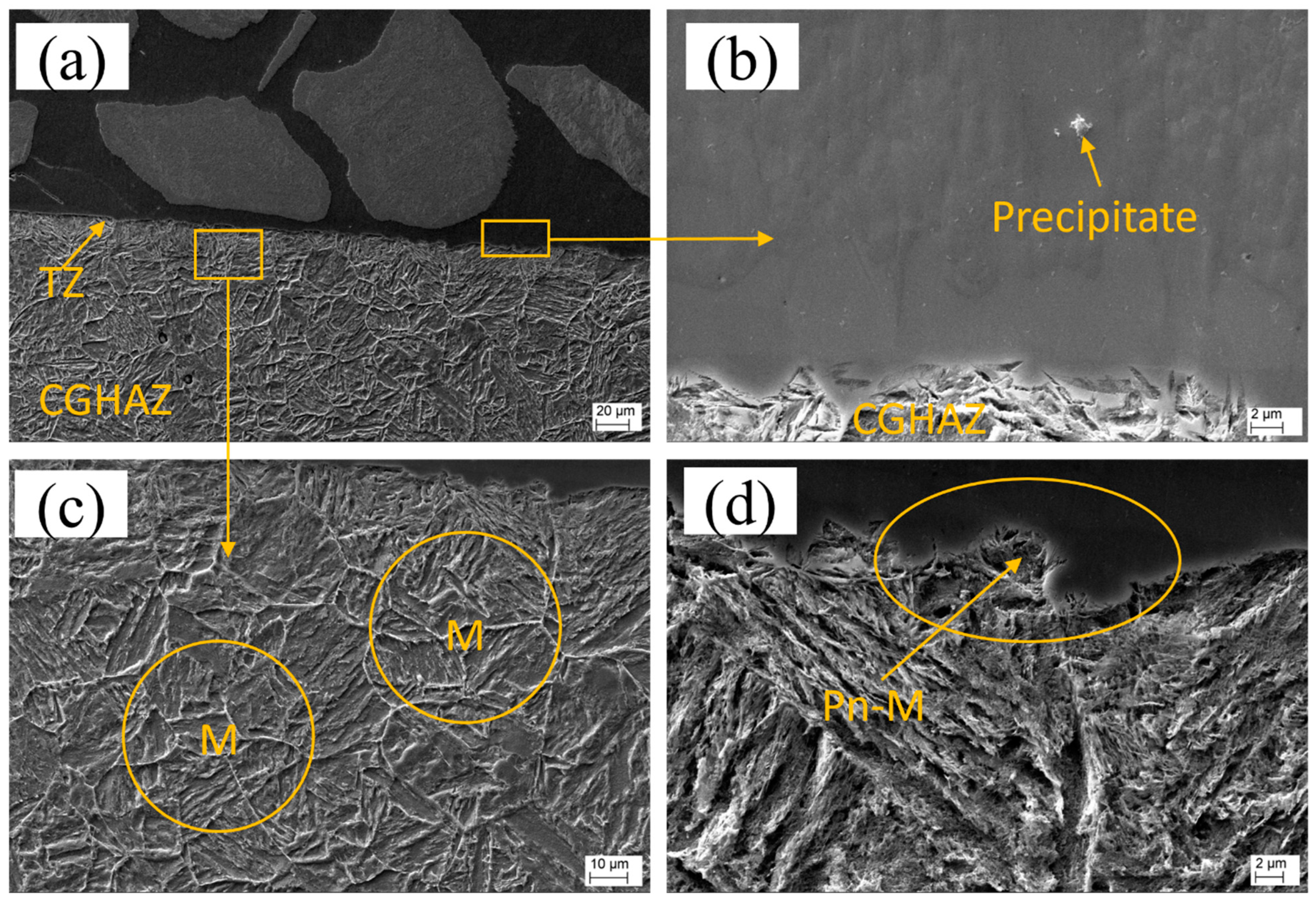

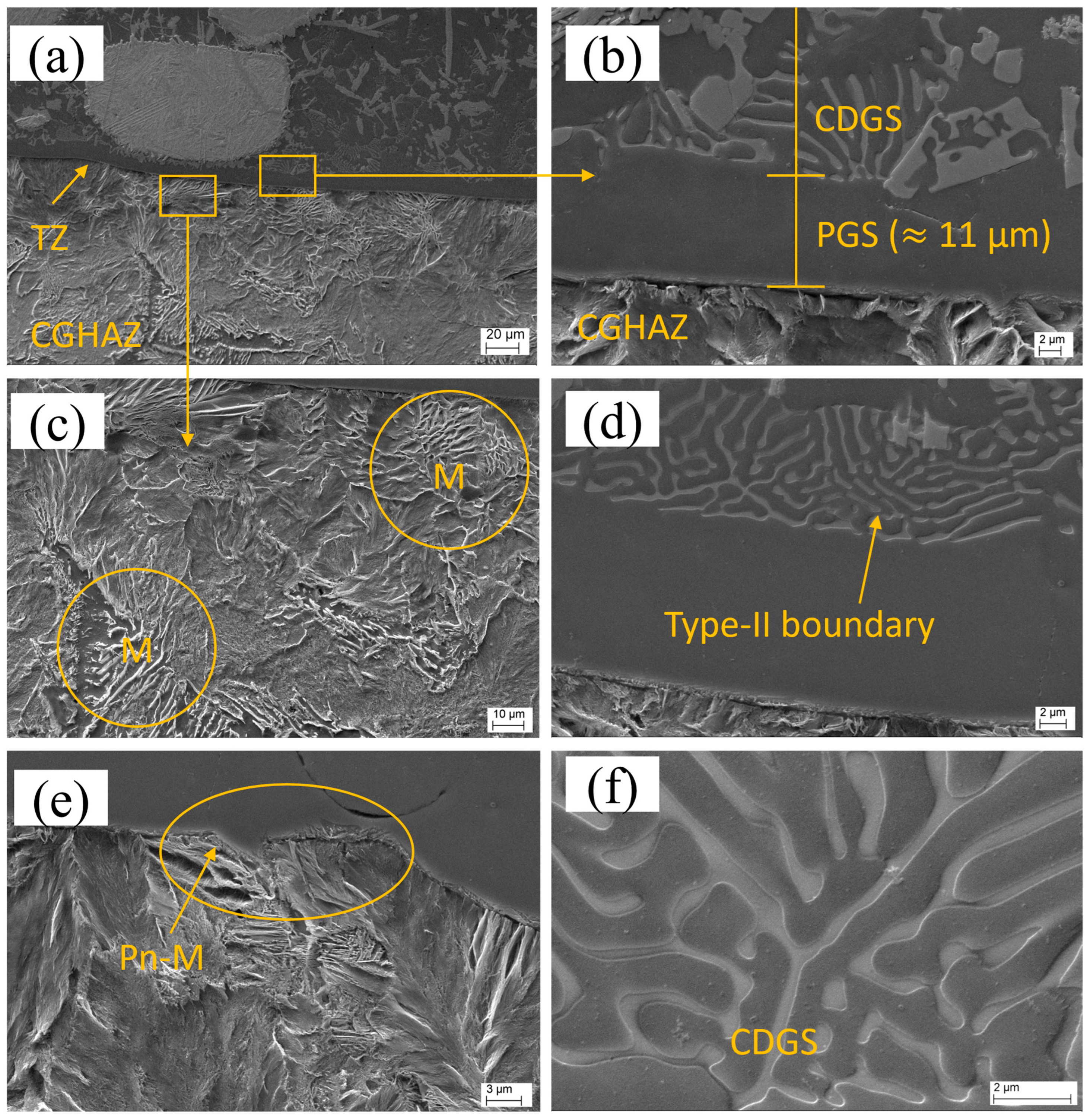

3.6.2. Transition Zone (TZ)

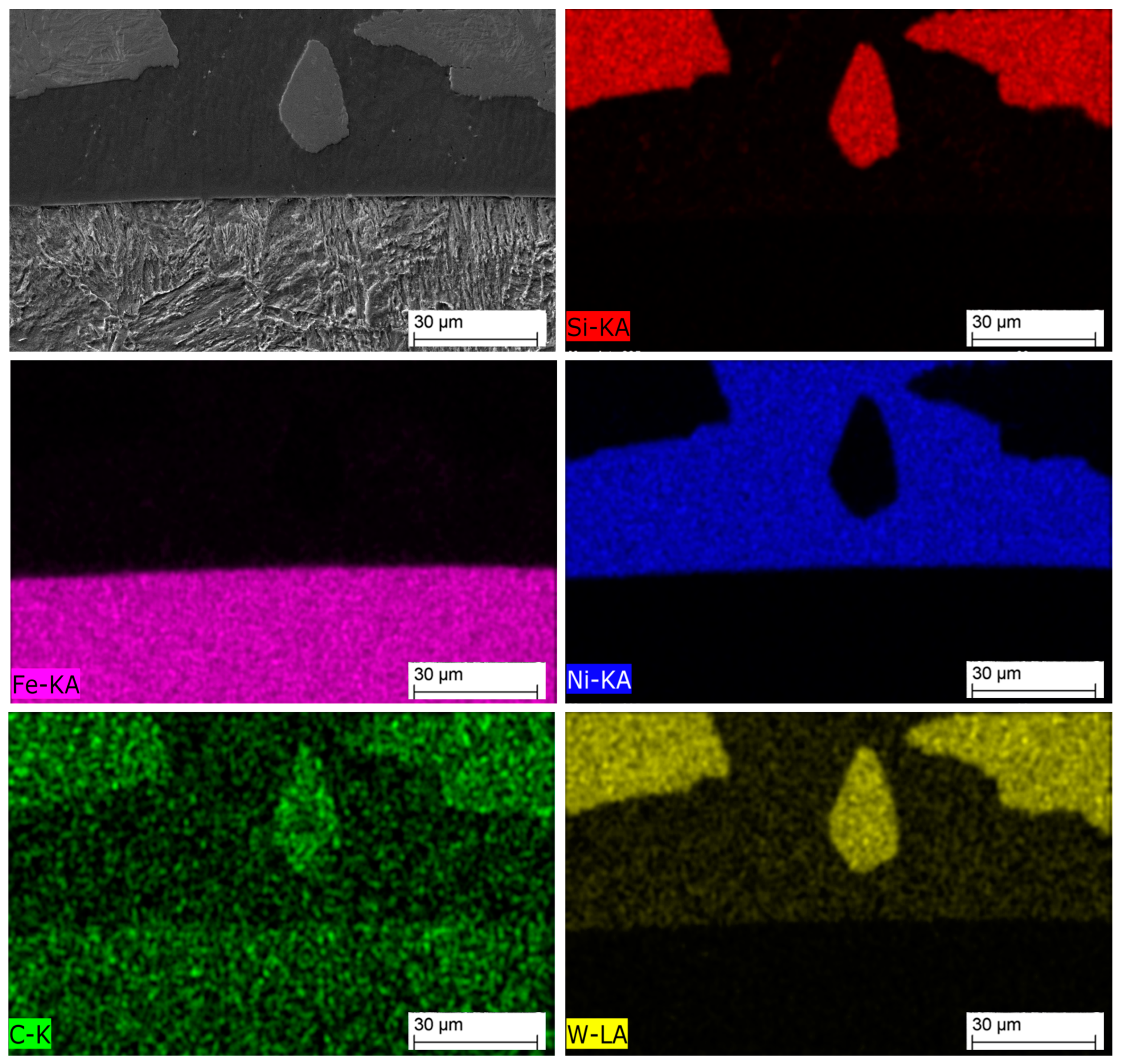

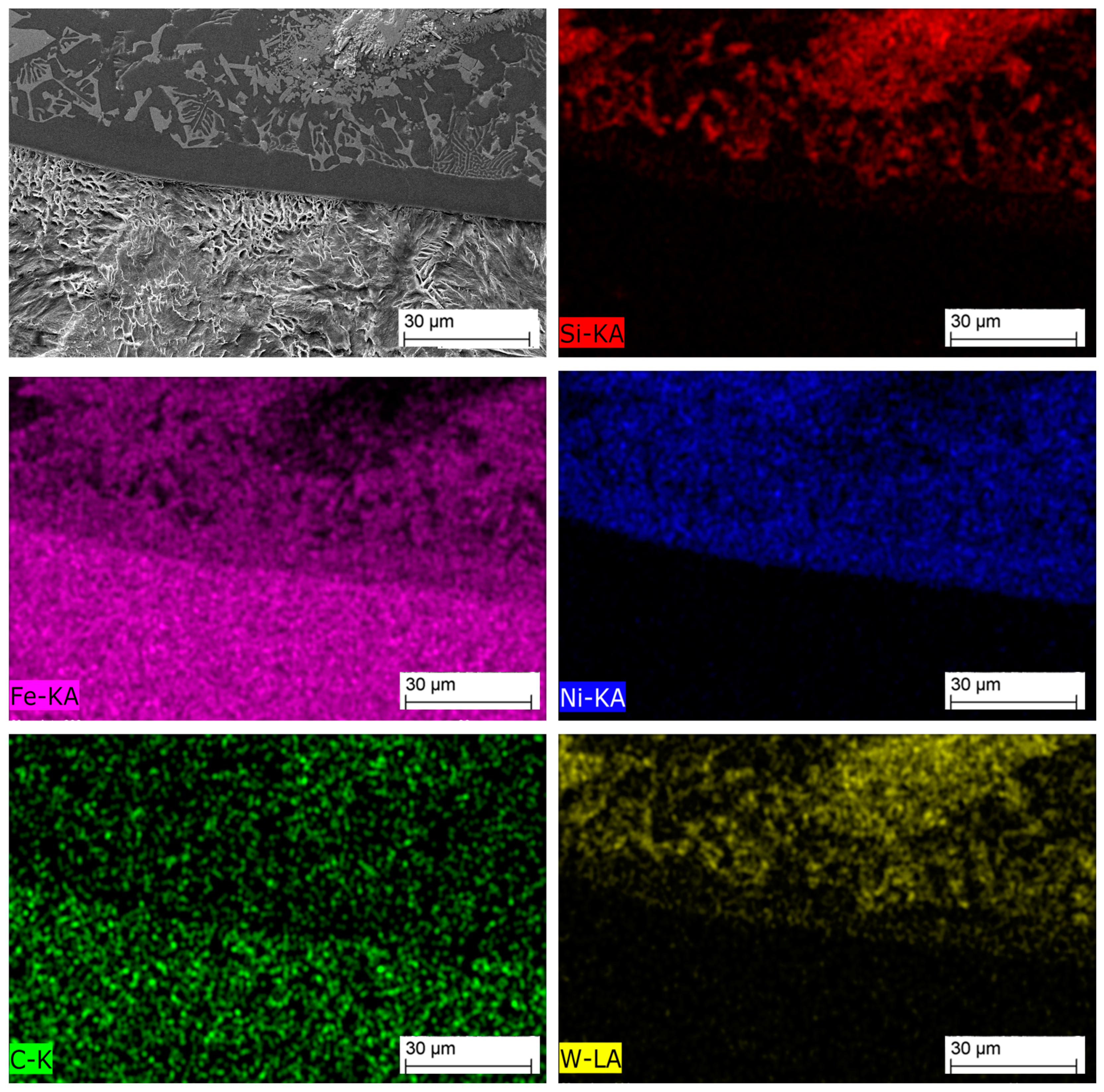

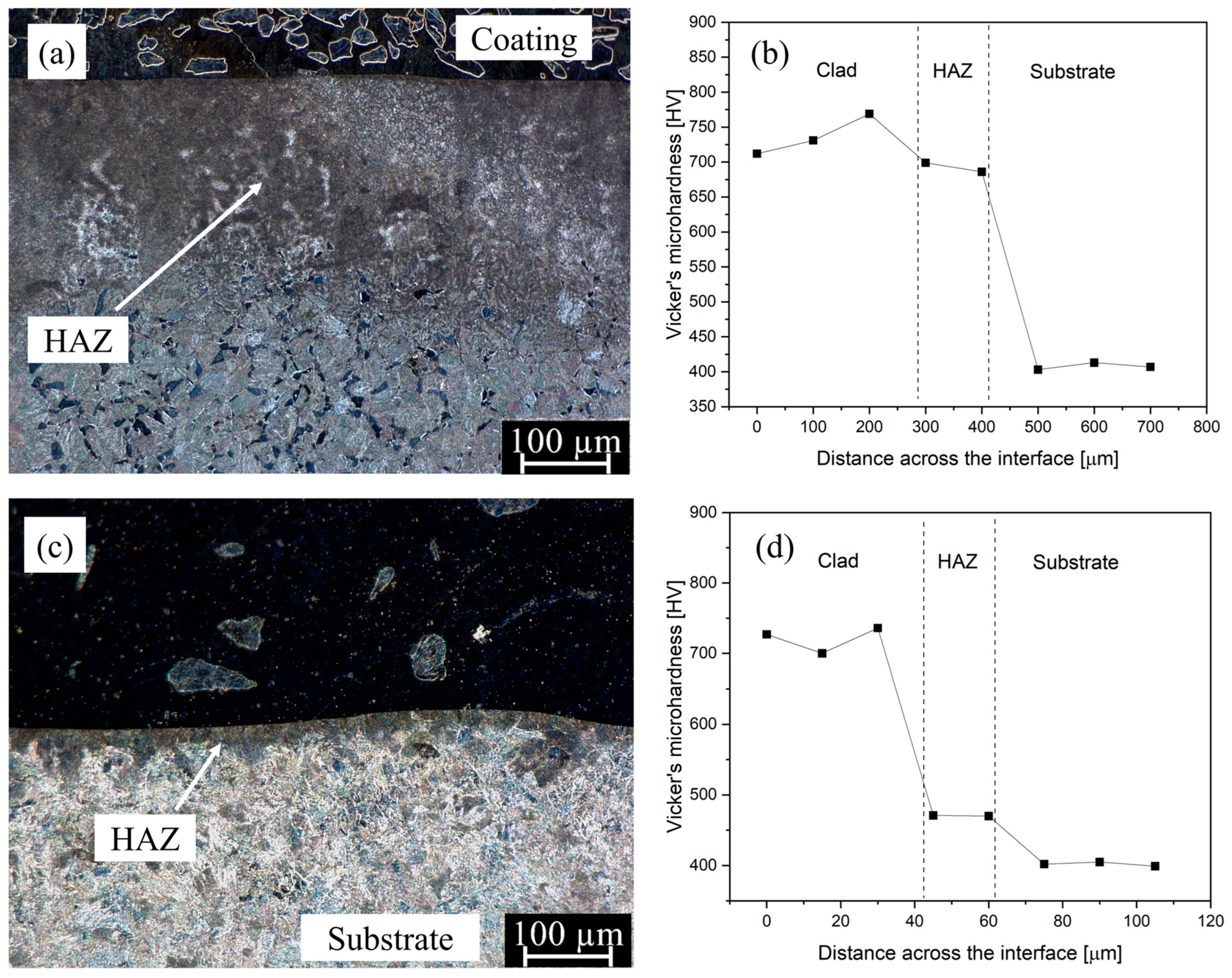

3.7. Dilution and Heat-Affected Zone (HAZ)

4. Conclusions

- A wear-resistant powder blend of composition NiSiB + 60% WC was successfully deposited on a structural-steel substrate using LC and PPTAW methods. There was precipitation of secondary WC phases in the matrix upon solidification for clads prepared by both methods. However, the clad from PPTAW had a dendritic microstructure, which is attributed to its relatively higher thermal cycles than those of the LC process.

- Penetrant test macroanalysis revealed that the clad prepared by the LC method had more surface cracks than the PPTAW counterpart, owing to the lower laser heat input. The microhardness of the matrix and reinforcing WC phases of the clads prepared by both methods were comparatively similar. However, when compared to a reference abrasive-wear-resistant material, AR400, the relative abrasive-wear resistance of the PPTAW clad was relatively higher, at 4.7, than the clad prepared by LC, at 4.5. The wear mechanism was found to be the same for clads prepared by both methods.

- The TZs for both clads were observed to be thin (approx. 9 µm for LC and approx. 11 µm for PPTAW), with a coarse-grain heat-affected zone (CGHAZ), made up of martensite laths, and a peninsula-like macrosegregation observed for clads from both methods. However, the PPTAW clad had a cellular–dendritic growth solidification (CDGS) and a type-II boundary at the TZ, which is explained as resulting from the thermal cycles of this method.

- The LC clad had a lower dilution coefficient, at 2.1%, than the PPTAW clad, with dilution coefficient of 4.5%. The higher heat retention of the LC method resulted in a larger HAZ (≈283 µm) with higher hardness (average of 680 HV) than the HAZ of the PPTAW clad, which was ≈35 µm and had an average hardness of 480 HV. EDS analysis showed elemental diffusion at the clad/substrate interface with a diffusion gradient, which shows that the bonding of the clad by both methods was metallurgical, making them more desirable for industrial antiwear applications.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fasihi, P.; Kendall, O.; Abrahams, R.; Mutton, P.; Qiu, C.; Schläfer, T.; Yan, W. Tribological Properties of Laser Cladded Alloys for Repair of Rail Components. Materials 2022, 15, 7466. [Google Scholar] [CrossRef] [PubMed]

- Zhong, W.; Hu, J.; Shen, P.; Wang, C.; Lius, Q. Experimental Investigation between Rolling Contact Fatigue and Wear of High-Speed and Heavy-Haul Railway and Selection of Rail Material. Wear 2011, 271, 2485–2493. [Google Scholar] [CrossRef]

- Mädler, K.; Zoll, A.; Heyder, R.; Brehmer, M. Rail Materials-Alternatives and Limits; Deutsche Bahn AG, DB Systemtechnik: Brandenburg-Kirchmöser, Germany, 2008; pp. 18–22. [Google Scholar]

- Fu, Z.; Ding, H.; Wang, W.; Liu, Q.; Guo, J.; Zhu, M. Investigation on Microstructure and Wear Characteristic of Laser Cladding Fe-Based Alloy on Wheel/Rail Materials. Wear 2015, 330, 592–599. [Google Scholar] [CrossRef]

- Lazorenko, G.; Kasprzhitskii, A.; Nazdracheva, T. Anti-Corrosion Coatings for Protection of Steel Railway Structures Exposed to Atmospheric Environments: A Review. Constr. Build. Mater. 2021, 288, 123115. [Google Scholar] [CrossRef]

- Wang, W.-J.; Fu, Z.-K.; Guo, J.; Zhang, Y.-Q.; Liu, Q.-Y.; Zhu, M.-H. Investigation on Wear Resistance and Fatigue Damage of Laser Cladding Coating on Wheel and Rail Materials under the Oil Lubrication Condition. Tribol. Trans. 2016, 59, 810–817. [Google Scholar] [CrossRef]

- Kim, J.-D.; Peng, Y. Plunging Method for Nd: YAG Laser Cladding with Wire Feeding. Opt. Lasers Eng. 2000, 33, 299–309. [Google Scholar] [CrossRef]

- Khamidullin, B.; Tsivilskiy, I.; Gorunov, A.; Gilmutdinov, A.K. Modeling of the Effect of Powder Parameters on Laser Cladding Using Coaxial Nozzle. Surf. Coat. Technol. 2019, 364, 430–443. [Google Scholar] [CrossRef]

- Cui, C.; Guo, Z.; Liu, Y.; Xie, Q.; Wang, Z.; Hu, J.; Yao, Y. Characteristics of Cobalt-Based Alloy Coating on Tool Steel Prepared by Powder Feeding Laser Cladding. Opt. Laser Technol. 2007, 39, 1544–1550. [Google Scholar] [CrossRef]

- Appiah, A.N.S.; Bialas, O.; Czupryński, A.; Adamiak, M. Powder Plasma Transferred Arc Welding of Ni-Si-B+ 60 Wt% WC and Ni-Cr-Si-B+ 45 Wt% WC for Surface Cladding of Structural Steel. Materials 2022, 15, 4956. [Google Scholar] [CrossRef]

- Czupryński, A. Microstructure and Abrasive Wear Resistance of Metal Matrix Composite Coatings Deposited on Steel Grade AISI 4715 by Powder Plasma Transferred Arc Welding Part 1. Mechanical and Structural Properties of a Cobalt-Based Alloy Surface Layer Reinforced with Particles of Titanium Carbide and Synthetic Metal–Diamond Composite. Materials 2021, 14, 2382. [Google Scholar] [CrossRef]

- Hou, Q.; He, Y.; Zhang, Q.; Gao, J. Influence of Molybdenum on the Microstructure and Wear Resistance of Nickel-Based Alloy Coating Obtained by Plasma Transferred Arc Process. Mater. Des. 2007, 28, 1982–1987. [Google Scholar] [CrossRef]

- Rokanopoulou, A.; Skarvelis, P.; Papadimitriou, G. Microstructure and Wear Properties of the Surface of 2205 Duplex Stainless Steel Reinforced with Al2O3 Particles by the Plasma Transferred Arc Technique. Surf. Coat. Technol. 2014, 254, 376–381. [Google Scholar] [CrossRef]

- Çelik, O.N. Microstructure and Wear Properties of WC Particle Reinforced Composite Coating on Ti6Al4V Alloy Produced by the Plasma Transferred Arc Method. Appl. Surf. Sci. 2013, 274, 334–340. [Google Scholar] [CrossRef]

- Takatani, Y.; Tomita, T.; Tani, K.; Harada, Y. Corrosion Behavior of Aluminum Weld Overlay Alloys with Dispersed Niobium Carbide Particles in Sodium Chloride Solution. J. Therm. Spray Technol. 1996, 5, 154–160. [Google Scholar] [CrossRef]

- Lai, C.-H.; Lin, S.-J.; Yeh, J.-W.; Chang, S.-Y. Preparation and Characterization of AlCrTaTiZr Multi-Element Nitride Coatings. Surf. Coat. Technol. 2006, 201, 3275–3280. [Google Scholar] [CrossRef]

- Wang, L.M.; Chen, C.C.; Yeh, J.W.; Ke, S.T. The Microstructure and Strengthening Mechanism of Thermal Spray Coating NixCo0.6Fe0.2CrySizAlTi0.2 High-Entropy Alloys. Mater. Chem. Phys. 2011, 126, 880–885. [Google Scholar] [CrossRef]

- Wadge, M.D.; Lowther, M.; Cooper, T.P.; Reynolds, W.J.; Speidel, A.; Carter, L.N.; Rabbitt, D.; Kudrynskyi, Z.R.; Felfel, R.M.; Ahmed, I.; et al. Tailoring Absorptivity of Highly Reflective Ag Powders by Pulsed-Direct Current Magnetron Sputtering for Additive Manufacturing Processes. J. Mater. Process. Technol. 2023, 317, 117985. [Google Scholar] [CrossRef]

- Yang, J.; Bai, B.; Ke, H.; Cui, Z.; Liu, Z.; Zhou, Z.; Xu, H.; Xiao, J.; Liu, Q.; Li, H. Effect of Metallurgical Behavior on Microstructure and Properties of FeCrMoMn Coatings Prepared by High-Speed Laser Cladding. Opt. Laser Technol. 2021, 144, 107431. [Google Scholar] [CrossRef]

- Sandhu, S.S.; Shahi, A.S. Metallurgical, Wear and Fatigue Performance of Inconel 625 Weld Claddings. J. Mater. Process. Technol. 2016, 233, 1–8. [Google Scholar] [CrossRef]

- Kumar, V.; Rakshit, R.; Das, A.K. Mechanical and Tribological Performance of Fiber Laser Cladded H-BN + SS316 Composite on SS316 Surface. J. Mater. Process. Technol. 2020, 278, 116509. [Google Scholar] [CrossRef]

- Ding, H.; Yang, T.; Wang, W.; Zhu, Y.; Lin, Q.; Guo, J.; Xiao, Q.; Gan, L.; Liu, Q. Optimization and Wear Behaviors of 316L Stainless Steel Laser Cladding on Rail Material. 24th Int. Conf. Wear Mater. 2023, 523, 204830. [Google Scholar] [CrossRef]

- Fu, K.; Zhong, C.; Zhang, L.; Wang, X.; Nie, B.; Xue, Y.; Gui, W.; Luan, B. Effect of Multiple Thermal Cycling on the Microstructure and Microhardness of Inconel 625 by High-Speed Laser Cladding. J. Mater. Res. Technol. 2023, 24, 1093–1107. [Google Scholar] [CrossRef]

- Fu, Y.; Li, L.; Guo, X.; Li, M.; Pan, Z.; Wang, H.; Liu, C.; Zhao, L. Fe-Co-Based Coating with High Hardness and High Saturation Magnetization Deposited by Co-Axial Powder Feeding Plasma Transferred Arc Welding. Mater. Lett. 2022, 315, 131928. [Google Scholar] [CrossRef]

- Farias, F.W.C.; da Cruz Payão Filho, J.; da Silva Júnior, D.A.; de Moura, R.N.; Rios, M.C.G. Microstructural Characterization of Ni-Based Superalloy 625 Clad Welded on a 9% Ni Steel Pipe by Plasma Powder Transferred Arc. Surf. Coat. Technol. 2019, 374, 1024–1037. [Google Scholar] [CrossRef]

- Ulutan, M.; Kiliçay, K.; Çelik, O.N.; Er, Ü. Microstructure and Wear Behaviour of Plasma Transferred Arc (PTA)-Deposited FeCrC Composite Coatings on AISI 5115 Steel. J. Mater. Process. Technol. 2016, 236, 26–34. [Google Scholar] [CrossRef]

- Wu, P.; Zhou, C.; Tang, X. Microstructural Characterization and Wear Behavior of Laser Cladded Nickel-Based and Tungsten Carbide Composite Coatings. Surf. Coat. Technol. 2003, 166, 84–88. [Google Scholar] [CrossRef]

- Wu, T.; Shi, W.; Xie, L.; Gong, M.; Huang, J.; Xie, Y.; He, K. Study on the Effect of Ni60 Transition Coating on Microstructure and Mechanical Properties of Fe/WC Composite Coating by Laser Cladding. Opt. Laser Technol. 2023, 163, 109387. [Google Scholar] [CrossRef]

- Yamaguchi, T.; Tanaka, K.; Hagino, H. Porosity Reduction in WC-12Co Laser Cladding by Aluminum Addition. Int. J. Refract. Met. Hard Mater. 2023, 110, 106020. [Google Scholar] [CrossRef]

- Appiah, A.N.S.; Bialas, O.; Żuk, M.; Czupryński, A.; Sasu, D.K.; Adamiak, M. Hardfacing of Mild Steel with Wear-Resistant Ni-Based Powders Containing Tungsten Carbide Particles Using Powder Plasma Transferred Arc Welding Technology. Mater. Sci.-Pol. 2022, 40, 42–63. [Google Scholar] [CrossRef]

- Czupryński, A.; Żuk, M. Matrix Composite Coatings Deposited on AISI 4715 Steel by Powder Plasma-Transferred Arc Welding. Part 3. Comparison of the Brittle Fracture Resistance of Wear-Resistant Composite Layers Surfaced Using the PPTAW Method. Materials 2021, 14, 6066. [Google Scholar] [CrossRef]

- Kim, J.-S.; Lee, H.-W. Effect of Welding Heat Input on Microstructure and Texture of Inconel 625 Weld Overlay Studied Using the Electron Backscatter Diffraction Method. Metall. Mater. Trans. A 2016, 47, 6109–6120. [Google Scholar] [CrossRef]

- Yoon, B.H.; Ahn, Y.S.; Lee, C.H. The Effect of Dilution on HAZ Liquation Cracking in PTAW Ni-Base Superalloys Overlay Deposit. ISIJ Int. 2002, 42, 178–183. [Google Scholar] [CrossRef]

- DuPont, J. Solidification of an Alloy 625 Weld Overlay. Metall. Mater. Trans. A 1996, 27, 3612–3620. [Google Scholar] [CrossRef]

- Gittos, M.; Gooch, T. Effect of Iron Dilution on Corrosion Resistance of Ni-Cr-Mo Alloy Cladding. Br. Corros. J. 1996, 31, 309–314. [Google Scholar] [CrossRef]

- Örnek, C.; Mansoor, M.; Larsson, A.; Zhang, F.; Harlow, G.S.; Kroll, R.; Carlà, F.; Hussain, H.; Derin, B.; Kivisäkk, U.; et al. The Causation of Hydrogen Embrittlement of Duplex Stainless Steel: Phase Instability of the Austenite Phase and Ductile-to-Brittle Transition of the Ferrite Phase–Synergy between Experiments and Modelling. Corros. Sci. 2023, 217, 111140. [Google Scholar] [CrossRef]

- Dong, L.; Peng, Q.; Xue, H.; Han, E.-H.; Ke, W.; Wang, L. Correlation of Microstructure and Stress Corrosion Cracking Initiation Behaviour of the Fusion Boundary Region in a SA508 Cl. 3-Alloy 52M Dissimilar Weld Joint in Primary Pressurized Water Reactor Environment. Corros. Sci. 2018, 132, 9–20. [Google Scholar] [CrossRef]

- Wu, Y.; Cai, Y.; Sun, D.; Zhu, J.; Wu, Y. Microstructure and Properties of High-Power Laser Welding of SUS304 to SA553 for Cryogenic Applications. J. Mater. Process. Technol. 2015, 225, 56–66. [Google Scholar] [CrossRef]

- Farias, F.W.C.; da Cruz Payão Filho, J.; de Azevedo, L.M.B. Microstructural and Mechanical Characterization of the Transition Zone of 9% Ni Steel Cladded with Ni-Based Superalloy 625 by GTAW-HW. Metals 2018, 8, 1007. [Google Scholar] [CrossRef]

- Pan, C.; Ma, K.; Chen, X.; Feng, S.; Fang, C.; Yang, H.; He, P. Corrosion Behavior of Ni-Based Coating with Ni-Coated TiC-Reinforced Particles by Induction Cladding in Molten Brass. Mater. Chem. Phys. 2023, 296, 127257. [Google Scholar] [CrossRef]

- Li, M.; Yang, J.; Han, B.; Song, L.; Li, P.; Dong, W.; Xue, X. Comparative Investigation on Microstructures and Properties of WC/Cr3C2 Reinforced Laser Cladding Ni-Based Composite Coatings Subjected to Ultrasonic Impact Treatment. Mater. Today Commun. 2023, 34, 105219. [Google Scholar] [CrossRef]

- Wu, W.; Zhang, C.; Wang, R.; Zhang, Y.; Lu, X. A High Temperature Wear-Resistant Ni-Based Alloy Coating for Coppery Blast Furnace Tuyere Application. Surf. Coat. Technol. 2023, 464, 129550. [Google Scholar] [CrossRef]

- ISO 14175; Welding Consumables—Gases and Gas Mixtures for Fusion Welding and Allied Processes. American Welding Society (ISO/TC 44/SC 3): Miami, FL, USA, 2008.

- PN-EN ISO 3452; Non-Destructive Testing—Penetrant Testing. South African Bureau of Standards (ISO/TC 135/SC 2): Pretoria, South Africa, 2021.

- ArunKumar, V.; Prakash, N.; Deenadayalan, K. Comparison between the Spherical and Angular Type WC Particles Reinforced in Nickel-Based Matrix Deposited Using Plasma Transferred Arc Welding Process. Mater. Today Proc. 2023, in press. [CrossRef]

- Li, W.; Di, R.; Yuan, R.; Song, H.; Lei, J. Microstructure, Wear Resistance and Electrochemical Properties of Spherical/Non-Spherical WC Reinforced Inconel 625 Superalloy by Laser Melting Deposition. J. Manuf. Process. 2022, 74, 413–422. [Google Scholar] [CrossRef]

- Phelan, D.; Dippenaar, R. Widmanstätten Ferrite Plate Formation in Low-Carbon Steels. Metall. Mater. Trans. A 2004, 35, 3701–3706. [Google Scholar] [CrossRef]

- Igwemezie, V.; Dirisu, P.; Mehmanparast, A. Critical Assessment of the Fatigue Crack Growth Rate Sensitivity to Material Microstructure in Ferrite-Pearlite Steels in Air and Marine Environment. Mater. Sci. Eng. A 2019, 754, 750–765. [Google Scholar] [CrossRef]

- Poloczek, T.; Lont, A.; Górka, J. The Structure and Properties of Laser-Cladded Inconel 625/TiC Composite Coatings. Materials 2023, 16, 1265. [Google Scholar] [CrossRef]

- Czupryński, A. Microstructure and Abrasive Wear Resistance of Metal Matrix Composite Coatings Deposited on Steel Grade AISI 4715 by Powder Plasma Transferred Arc Welding Part 2. Mechanical and Structural Properties of a Nickel-Based Alloy Surface Layer Reinforced with Particles of Tungsten Carbide and Synthetic Metal–Diamond Composite. Materials 2021, 14, 2805. [Google Scholar] [CrossRef]

- Shu, K.; Zhang, C.; Sun, D.; Wu, B.; Li, Z.; Wu, J.; Zheng, D.; Gu, L. Contact Cracking and Delamination of Thin Solid Lubricating Films on Deformable Substrates. Tribol. Int. 2021, 163, 107181. [Google Scholar] [CrossRef]

- Kotarska, A.; Poloczek, T.; Janicki, D. Characterization of the Structure, Mechanical Properties and Erosive Resistance of the Laser Cladded Inconel 625-Based Coatings Reinforced by TiC Particles. Materials 2021, 14, 2225. [Google Scholar] [CrossRef]

- Górka, J.; Czupryński, A.; Żuk, M.; Adamiak, M.; Kopyść, A. Properties and Structure of Deposited Nanocrystalline Coatings in Relation to Selected Construction Materials Resistant to Abrasive Wear. Materials 2018, 11, 1184. [Google Scholar] [CrossRef]

- Mondal, J.; Das, K.; Das, S. An Investigation of Mechanical Property and Sliding Wear Behaviour of 400Hv Grade Martensitic Steels. Wear 2020, 458, 203436. [Google Scholar] [CrossRef]

- Katinas, E.; Jankauskas, V.; Kazak, N.; Michailov, V. Improving Abrasive Wear Resistance for Steel Hardox 400 by Electro-Spark Deposition. J. Frict. Wear 2019, 40, 100–106. [Google Scholar] [CrossRef]

- Białobrzeska, B. Comparative Analysis of Abrasive-Wear Resistance of Brinar and Hardox Steels. Tribologia 2017, 272, 7–16. [Google Scholar] [CrossRef]

- Bansal, A.; Zafar, S.; Sharma, A.K. Microstructure and Abrasive Wear Performance of Ni-WC Composite Microwave Clad. J. Mater. Eng. Perform. 2015, 24, 3708–3716. [Google Scholar] [CrossRef]

- Döscher, M.; Pauli, M.; Müller, J. A Study on WSi2 Thin Films, Formed by the Reaction of Tungsten with Solid or Liquid Silicon, by Rapid Thermal Annealing. Thin Solid Films 1994, 239, 251–258. [Google Scholar] [CrossRef]

- Zygmuntowicz, J.; Miazga, A.; Konopka, K.; Edrysiak, K.J.; Kaszuwara, W. Alumina Matrix Ceramic-Nickel Composites Formed by Centrifugal Slip Casting. Process. Appl. Ceram. 2015, 9, 199–202. [Google Scholar] [CrossRef]

- Poloczek, T.; Czupryński, A.; Żuk, M.; Chruściel, M. Structure and Tribological Properties of Wear-Resistant Layers Produced in Process of Plasma Powder Surfacing. Weld. Technol. Rev. 2019, 91, 35–41. [Google Scholar] [CrossRef]

- Bianchi, L.; Leger, A.C.; Vardelle, M.; Vardelle, A.; Fauchais, P. Splat Formation and Cooling of Plasma-Sprayed Zirconia. Thin Solid Films 1997, 305, 35–47. [Google Scholar] [CrossRef]

- Bhowmik, A.; Yang, Y.; Zhou, W.; Chew, Y.; Bi, G. On the Heterogeneous Cooling Rates in Laser-Clad Al-50Si Alloy. Surf. Coat. Technol. 2021, 408, 126780. [Google Scholar] [CrossRef]

- Su, M.; Yuan, X.; Yue, C.; Zheng, W.; Kang, J. Effect of Liquid Film Constitutional Supercooling at the End of Solidification on the Hot Cracking Behavior of Al-4.0 Wt.%Cu Alloy. Mater. Lett. 2022, 328, 133116. [Google Scholar] [CrossRef]

- Xibao, W.; Hua, L. Metal Powder Thermal Behaviour during the Plasma Transferred-Arc Surfacing Process. Surf. Coat. Technol. 1998, 106, 156–161. [Google Scholar] [CrossRef]

- Nelson, T.W.; Lippold, J.; Mills, M. Investigation of Boundaries and Structures in Dissimilar Metal Welds. Sci. Technol. Weld. Join. 1998, 3, 249–255. [Google Scholar] [CrossRef]

- Yang, Y.; Kou, S. Macrosegregation Mechanisms in Arc Welds Made with Dissimilar Filler Metals. Sci. Technol. Weld. Join. 2010, 15, 15–30. [Google Scholar] [CrossRef]

- Soysal, T.; Kou, S.; Tat, D.; Pasang, T. Macrosegregation in Dissimilar-Metal Fusion Welding. Acta Mater. 2016, 110, 149–160. [Google Scholar] [CrossRef]

- Lou, L.-Y.; Liu, K.-C.; Jia, Y.-J.; Ji, G.; Wang, W.; Li, C.-J.; Li, C.-X. Microstructure and Properties of Lightweight Al0.2CrNbTiV Refractory High Entropy Alloy Coating with Different Dilutions Deposited by High Speed Laser Cladding. Surf. Coat. Technol. 2022, 447, 128873. [Google Scholar] [CrossRef]

- Rajeev, G.P.; Kamaraj, M.; Bakshi, S.R. Comparison of Microstructure, Dilution and Wear Behavior of Stellite 21 Hardfacing on H13 Steel Using Cold Metal Transfer and Plasma Transferred Arc Welding Processes. Surf. Coat. Technol. 2019, 375, 383–394. [Google Scholar] [CrossRef]

- Barrick, E.J.; Jain, D.; DuPont, J.N.; Seidman, D.N. Effects of Heating and Cooling Rates on Phase Transformations in 10 Wt Pct Ni Steel and Their Application to Gas Tungsten Arc Welding. Metall. Mater. Trans. A 2017, 48, 5890–5910. [Google Scholar] [CrossRef]

- Nippes, E.; Balaguer, J. A Study of the Weld Heat-Affected Zone Toughness of 9% Nickel Steel. Weld J 1986, 65, 237. [Google Scholar]

- Jang, J.-I.; Ju, J.-B.; Lee, B.-W.; Kwon, D.; Kim, W.-S. Micromechanism of Local Brittle Zone Phenomenon in Weld Heat-Affected Zones of Advanced 9% Ni Steel. J. Mater. Sci. Lett. 2001, 20, 2149–2152. [Google Scholar] [CrossRef]

| Sample ID | Cladding Method | Laser Power [kW] | PGFR * [L/min] |

|---|---|---|---|

| L1 | LC * | 1.5 | – |

| L2 | LC | 2.0 | – |

| P1 | PPTAW * | – | 1.0 |

| P2 | PPTAW | – | 1.2 |

| Parameter | Value | Unit |

|---|---|---|

| Abrasive particle grain size | 210–297 | µm |

| Feed rate | 335 | g/min |

| Pressure | 130 | Pa |

| Rubber wheel turns | 6000 | turns |

| Test time | 30 | min |

| C | O | Si | Ni | W | ||

|---|---|---|---|---|---|---|

| Point P1 | Atom % | 6.6 | 1.7 | 6.3 | 84.9 | – |

| Weigh t% | 1.5 | 0.5 | 3.4 | 94.4 | – | |

| Point P2 | Atom % | 54.4 | 3.1 | 0.3 | 0.3 | 41.8 |

| Weight % | 7.7 | 0.6 | 0.4 | 0.2 | 91.1 | |

| Sample | Mass before Test, [g] | Mass after Test, [g] | Mass Loss, [g] | Material Density, [g/cm3] | Volume Loss, [mm3] | Relative Abrasive-Wear Resistance |

|---|---|---|---|---|---|---|

| Surface clads | ||||||

| L1 | 159.5765 | 159.2499 | 0.3266 | 11.1935 | 29.1776 | 4.5 |

| L2 | 165.1587 | 164.6972 | 0.4615 | 11.1935 | 41.2292 | 3.2 |

| P1 | 196.0594 | 195.6905 | 0.3689 | 11.1935 | 32.9566 | 4.0 |

| P2 | 195.6418 | 195.3264 | 0.3154 | 11.1935 | 28.1771 | 4.7 |

| Reference Samples | ||||||

| H1 | 104.6219 | 103.4971 | 1.0318 | 7.7836 | 132.5607 | 1.0 |

| H2 | 111.7377 | 110.7989 | ||||

| Sample | Cladding Method | Layer Height, R (mm) | Penetration Depth, P (mm) | Layer Width, w (mm) | Dilution, D, % |

|---|---|---|---|---|---|

| L1 | LC | 1.8 | 0.2 | 16 | 2.1 |

| P2 | PPTAW | 2.7 | 0.5 | 24 | 4.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Adamiak, M.; Appiah, A.N.S.; Żelazny, R.; Batalha, G.F.; Czupryński, A. Experimental Comparison of Laser Cladding and Powder Plasma Transferred Arc Welding Methods for Depositing Wear-Resistant NiSiB + 60% WC Composite on a Structural-Steel Substrate. Materials 2023, 16, 3912. https://doi.org/10.3390/ma16113912

Adamiak M, Appiah ANS, Żelazny R, Batalha GF, Czupryński A. Experimental Comparison of Laser Cladding and Powder Plasma Transferred Arc Welding Methods for Depositing Wear-Resistant NiSiB + 60% WC Composite on a Structural-Steel Substrate. Materials. 2023; 16(11):3912. https://doi.org/10.3390/ma16113912

Chicago/Turabian StyleAdamiak, Marcin, Augustine Nana Sekyi Appiah, Radosław Żelazny, Gilmar Ferreira Batalha, and Artur Czupryński. 2023. "Experimental Comparison of Laser Cladding and Powder Plasma Transferred Arc Welding Methods for Depositing Wear-Resistant NiSiB + 60% WC Composite on a Structural-Steel Substrate" Materials 16, no. 11: 3912. https://doi.org/10.3390/ma16113912

APA StyleAdamiak, M., Appiah, A. N. S., Żelazny, R., Batalha, G. F., & Czupryński, A. (2023). Experimental Comparison of Laser Cladding and Powder Plasma Transferred Arc Welding Methods for Depositing Wear-Resistant NiSiB + 60% WC Composite on a Structural-Steel Substrate. Materials, 16(11), 3912. https://doi.org/10.3390/ma16113912