Fabricated High-Strength, Low-Elastic Modulus Biomedical Ti-24Nb-4Zr-8Sn Alloy via Powder Metallurgy

Abstract

1. Introduction

2. Methods and Materials

2.1. Materials and Processing

2.2. Microstructure Characterization

2.3. Mechanical Testing

3. Results and Discussion

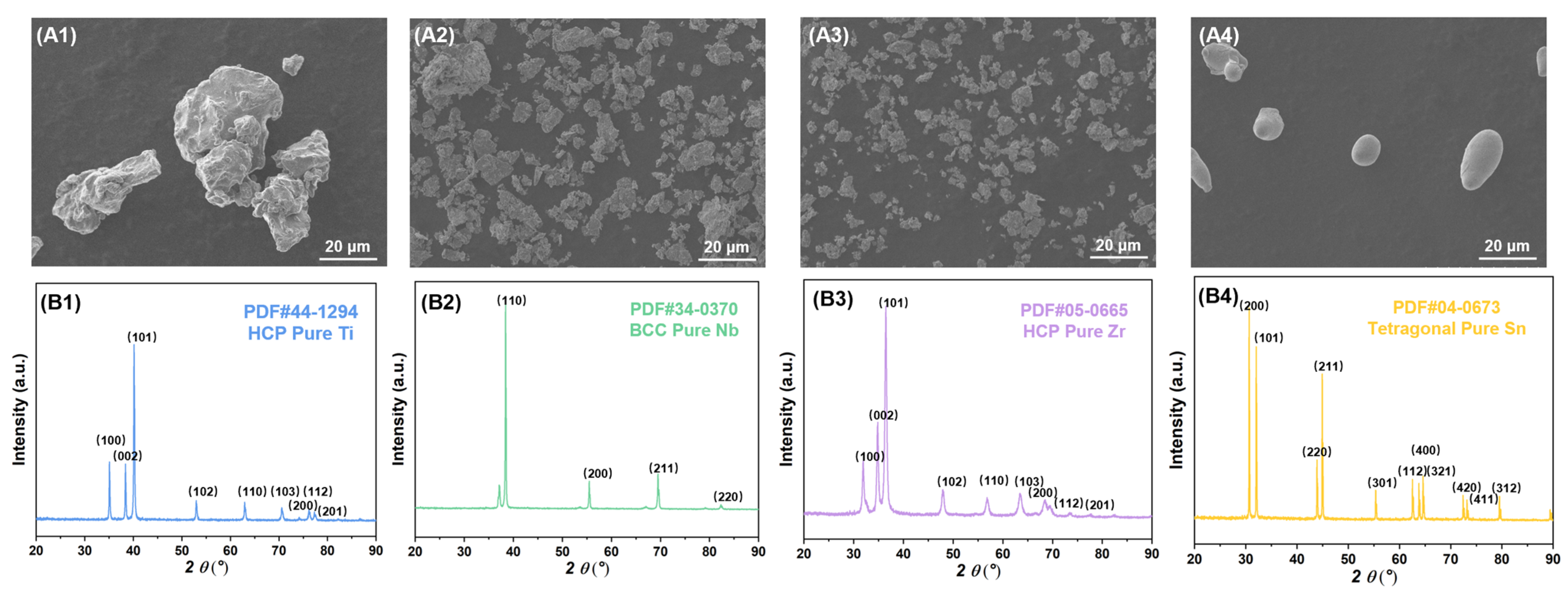

3.1. Powder Size and Microstructure Characterization

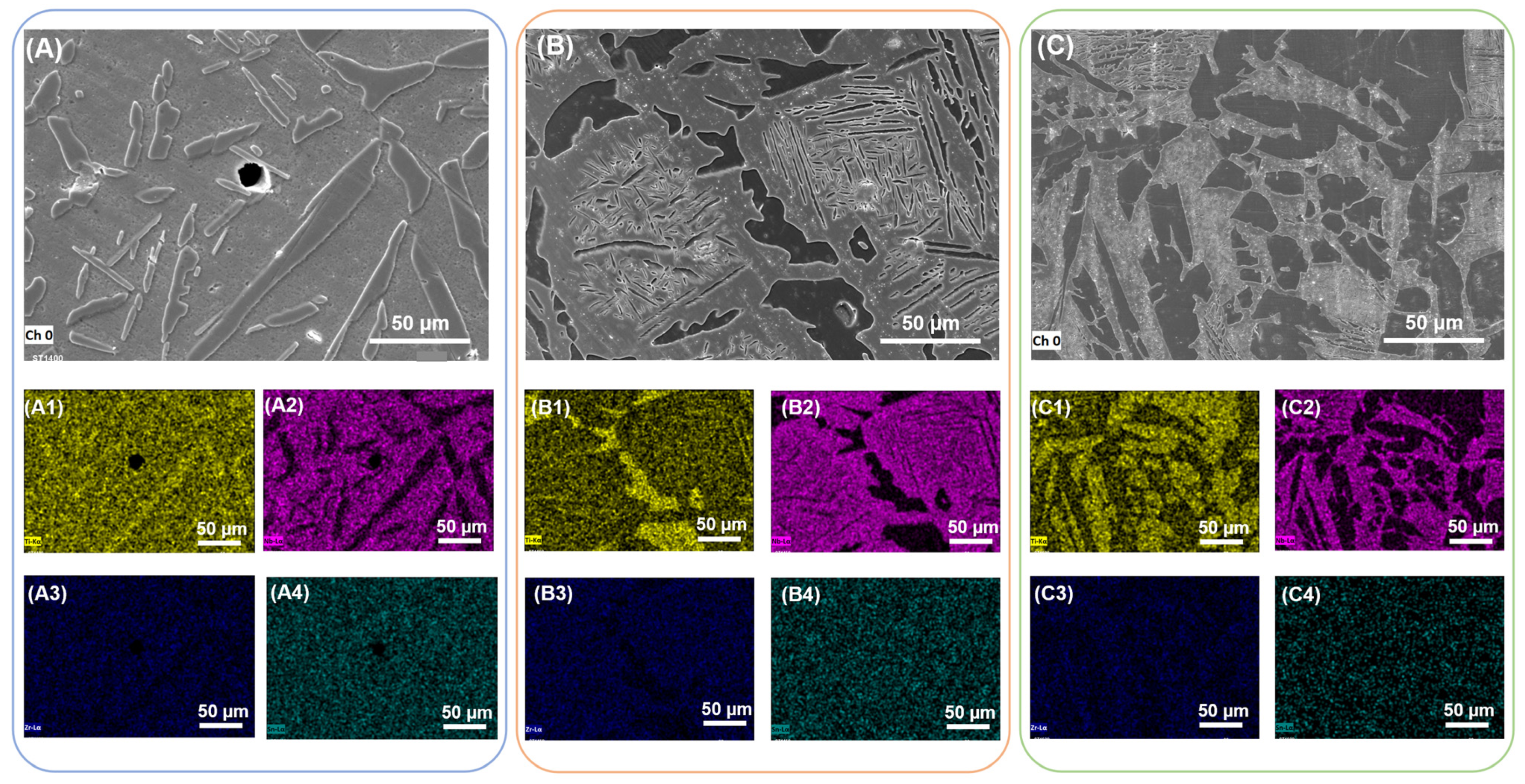

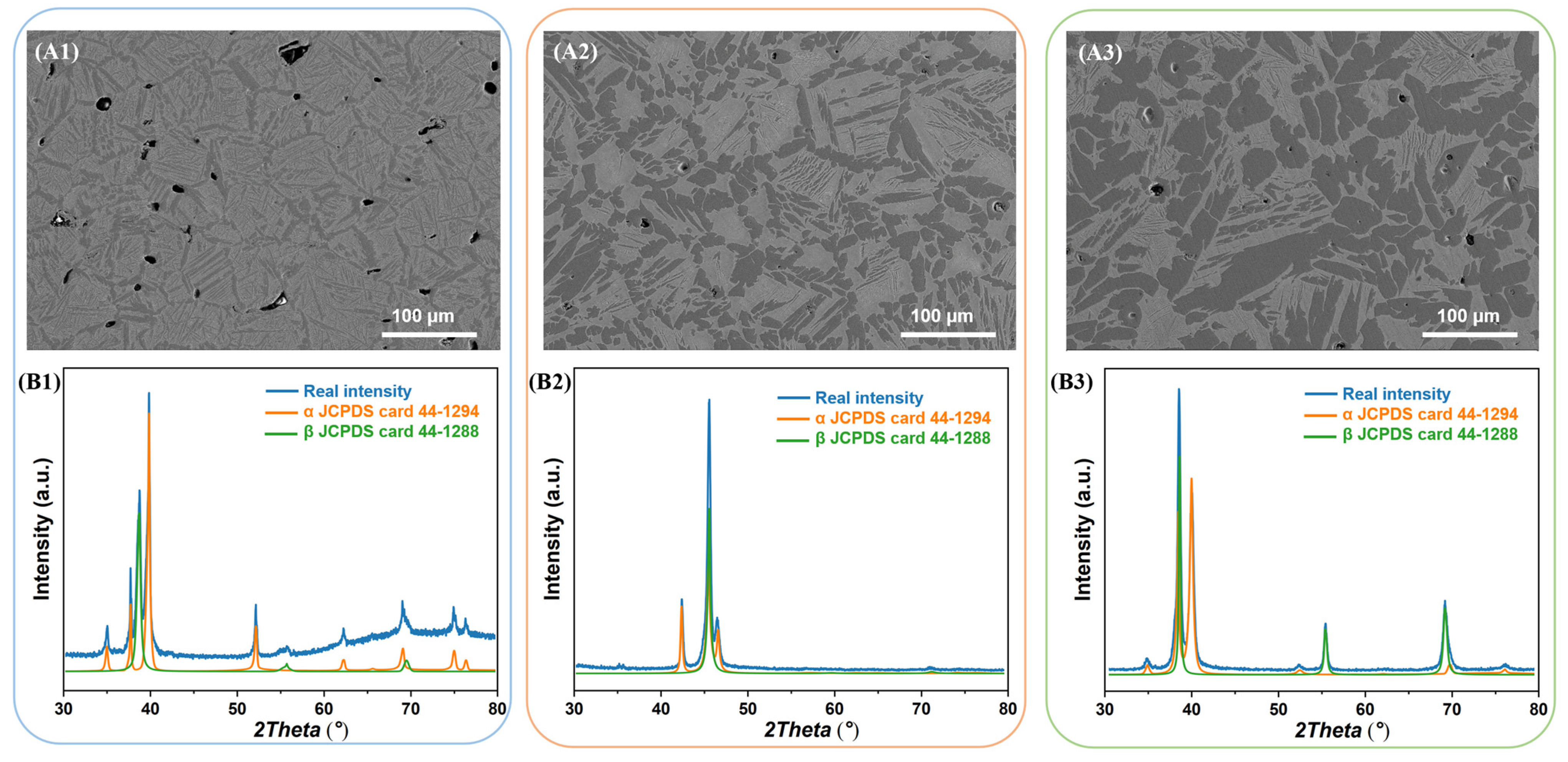

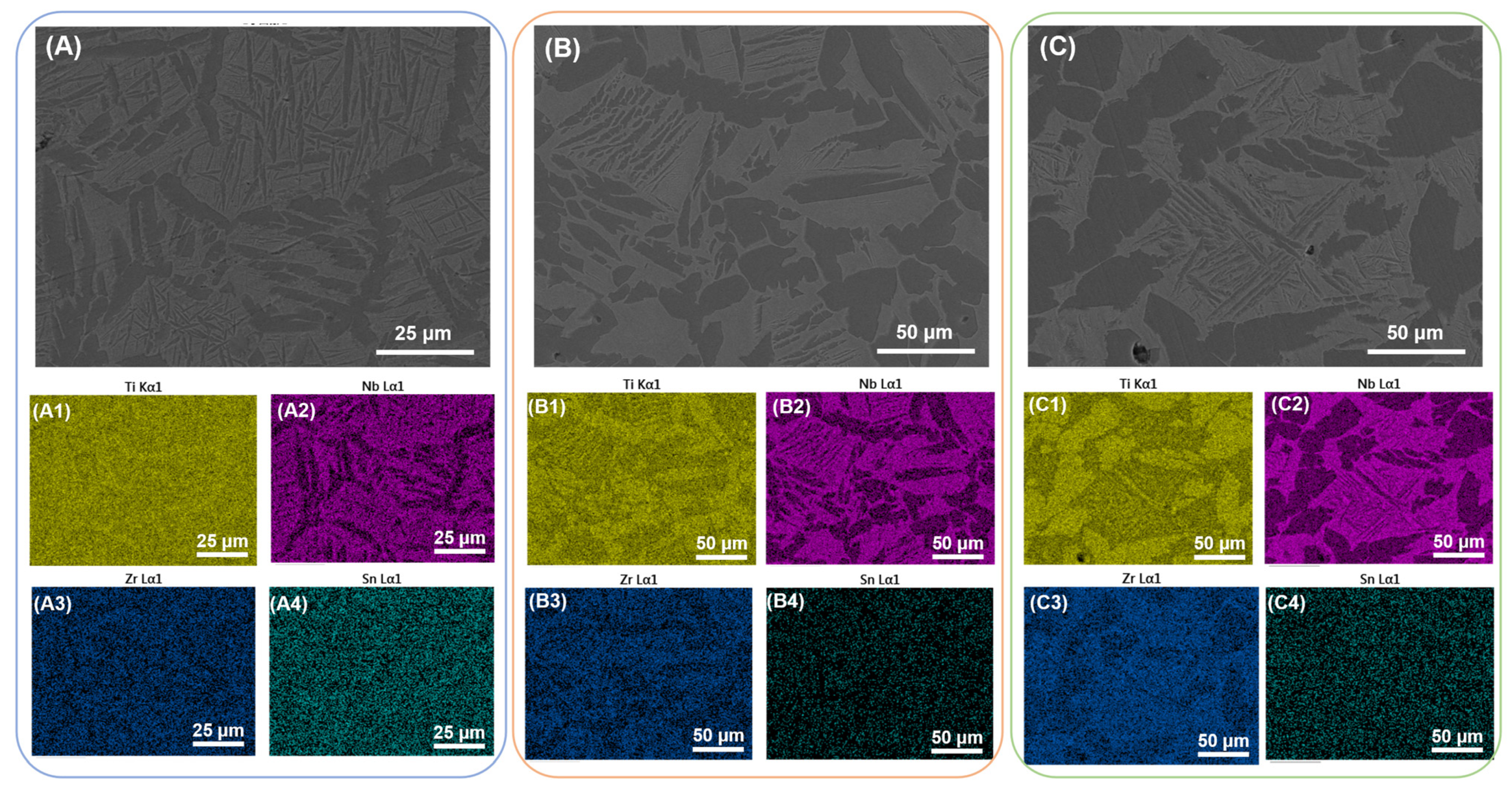

3.2. Microstructure Characterization of As-Sintered Samples

3.3. Microstructure Characterization of Solution Treated Samples

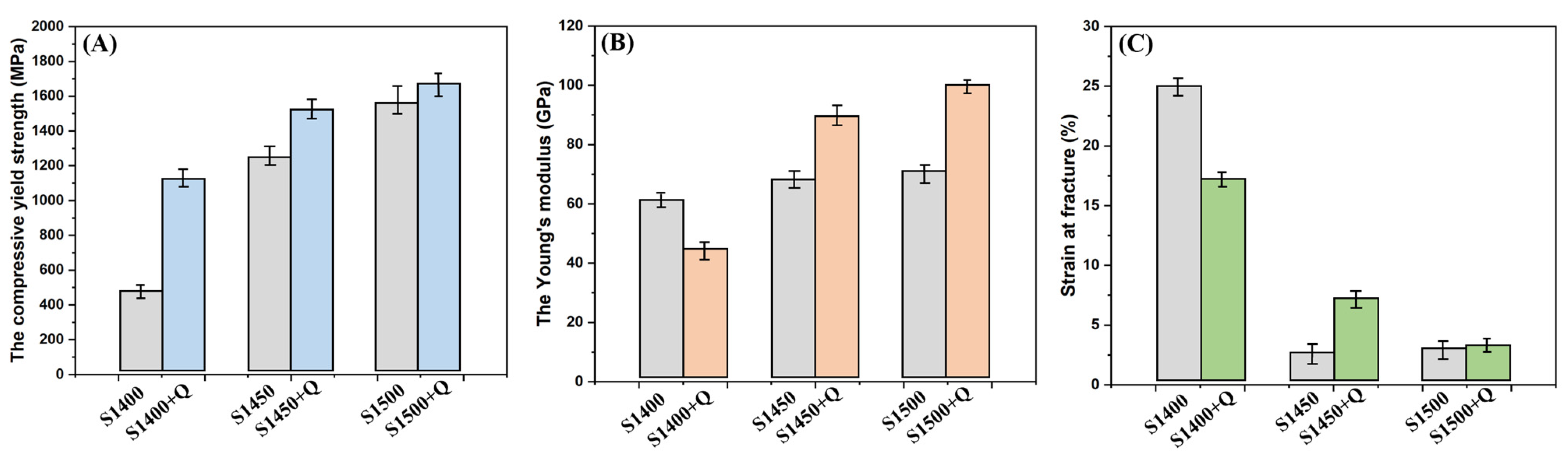

3.4. Mechanical Characterization and Fracture Analysis

4. Conclusions

- (1)

- The as-sintered samples have a two-phase microstructure where the secondary α phase were inside the grains, while the primary α phase precipitated along the grain boundaries of the matrix β phase. Beyond elements partitioning during the sintering process, Nb is enriched in the β matrix and absent in the α phase.

- (2)

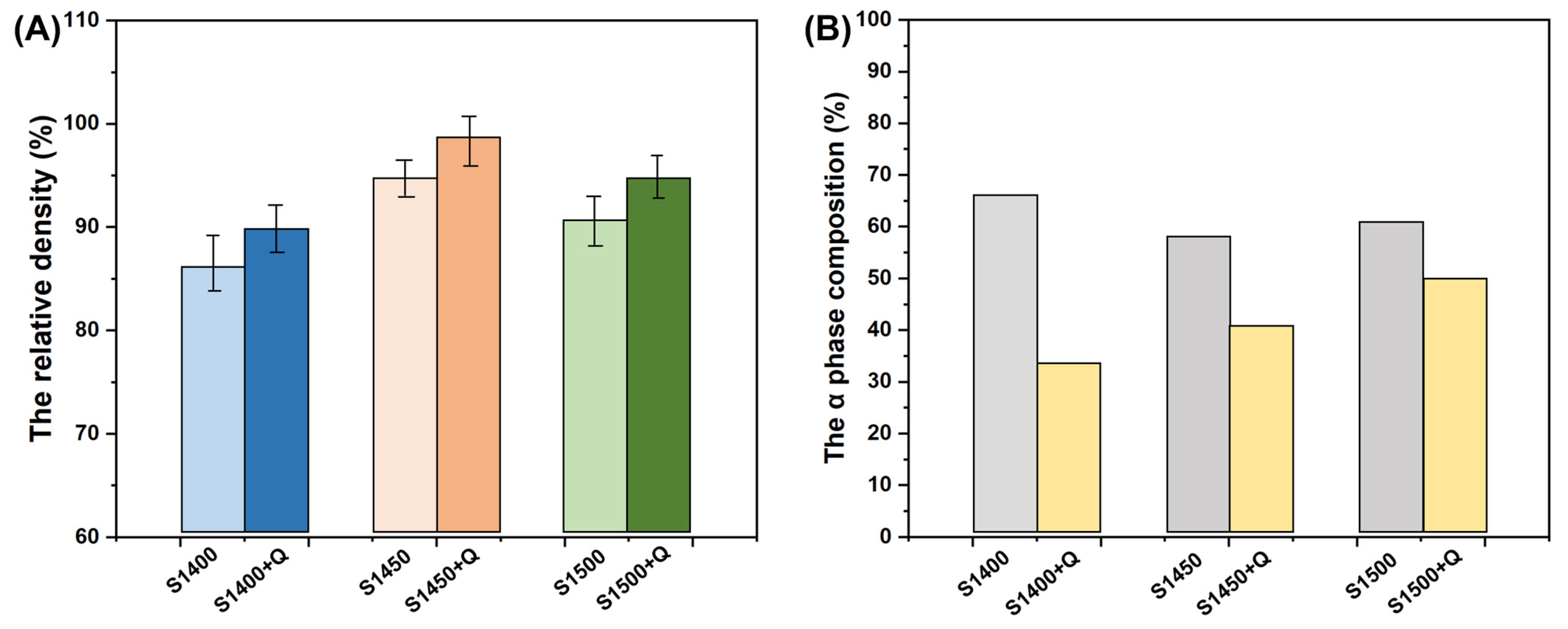

- The proportions of the α-precipitated phases of the samples sintered at 1400 °C, 1450 °C, and 1500 °C were 66.7%, 58.5% and 60.7%, respectively, and the density was 87%, 95% and 92%, respectively.

- (3)

- The microstructure of S1400 + Q sample changed significantly, the acicular α phase inside the grain disappeared, and the volume fraction of β phase was as high as 67.5%, while the morphology of S1450 + Q and S1500 + Q was similar to that before solution treatment, except that the porosity and the volume fraction of α phase reduced slightly.

- (4)

- Solution treatment can effectively suppress the precipitation of α phase in Ti2448 alloy, yielding samples with a bulk β phase. Therefore, the water-quenched sample exhibits good mechanical properties due to the absence of continuous GB-α phase. The S1400 + Q sample benefits from high porosity and a finer microstructure, and it has excellent comprehensive mechanical properties (the compressive yield stress is 1100 MPa, the strain at fracture is 17.5% and the Young’s modulus is 44 GPa), which are more applicable to orthopedic implants.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dai, N.; Zhang, L.-C.; Zhang, J.; Chen, Q.; Wu, M. Corrosion behavior of selective laser melted Ti-6Al-4 V alloy in NaCl solution. Corros. Sci. 2016, 102, 484–489. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, H.; Li, S.; Wang, S.; Wang, W.; Hou, W.; Hao, Y.; Yang, R.; Zhang, L. Compressive and fatigue behavior of beta-type titanium porous structures fabricated by electron beam melting. Acta Mater. 2017, 126, 58–66. [Google Scholar] [CrossRef]

- Li, J.; Bai, Y.; Fan, Z.; Li, S.; Hao, Y.; Yang, R.; Gao, Y. Effect of fluoride on the corrosion behavior of nanostructured Ti-24Nb-4Zr-8Sn alloy in acidulated artificial saliva. J. Mater. Sci. Technol. 2018, 34, 1660–1670. [Google Scholar] [CrossRef]

- Li, H.F.; Qiu, K.J.; Zhou, F.Y.; Li, L.; Zheng, Y.F. Design and development of novel antibacterial Ti-Ni-Cu shape memory alloys for biomedical application. Sci. Rep. 2016, 6, 37475. [Google Scholar] [CrossRef] [PubMed]

- Abd-elrhman, Y.; Gepreel, M.A.H.; Abdel-Moniem, A.; Kobayashi, S. Compatibility assessment of new V-free low-cost Ti–4.7Mo–4.5Fe alloy for some biomedical applications. Mater. Des. 2016, 97, 445–453. [Google Scholar] [CrossRef]

- Mahlobo, M.G.R.; Chikosha, L.; Olubambi, P.A. Study of the corrosion properties of powder rolled Ti–6Al–4V alloy ap-plied in the biomedical implants. J. Mater. Res. Technol. 2022, 18, 3631–3639. [Google Scholar] [CrossRef]

- Buciumeanu, M.; Bagheri, A.; Shamsaei, N.; Thompson, S.; Silva, F.; Henriques, B. Tribocorrosion behavior of additive manufactured Ti-6Al-4V biomedical alloy. Tribol. Int. 2018, 119, 381–388. [Google Scholar] [CrossRef]

- Hamidi, M.F.F.A.; Harun, W.S.W.; Samykano, M.; Ghani, S.A.C.; Ghazalli, Z.; Ahmad, F.; Sulong, A.B. A review of bio-compatible metal injection moulding process parameters for biomedical applications. Mater. Sci. Eng. C 2017, 78, 1263–1276. [Google Scholar] [CrossRef]

- Li, S.; Xu, Q.; Wang, Z.; Hou, W.; Hao, Y.; Yang, R.; Murr, L. Influence of cell shape on mechanical properties of Ti–6Al–4V meshes fabricated by electron beam melting method. Acta Biomater. 2014, 10, 4537–4547. [Google Scholar] [CrossRef]

- Heinl, P.; Müller, L.; Körner, C.; Singer, R.F.; Müller, F.A. Cellular Ti–6Al–4V structures with interconnected macro porosity for bone implants fabricated by selective electron beam melting. Acta Biomater. 2008, 4, 1536–1544. [Google Scholar] [CrossRef]

- Aufa, A.; Hassan, M.Z.; Ismail, Z. Recent advances in Ti-6Al-4V additively manufactured by selective laser melting for biomedical implants: Prospect development. J. Alloys Compd. 2022, 896, 163072. [Google Scholar] [CrossRef]

- Niinomi, M. Mechanical properties of biomedical titanium alloys. Mater. Sci. Eng. A 1998, 243, 231–236. [Google Scholar] [CrossRef]

- Wang, J.; Liu, L.; Yang, M.; Wu, X.; Li, S.; Zhang, W.; Zhang, H. Modification effect of graphene oxide on oxidation coating of Ti-3Zr-2Sn-3Mo-25 Nb near-β titanium alloy. J. Alloys Compd. 2022, 901, 163561. [Google Scholar] [CrossRef]

- Weng, F.; Chen, C.; Yu, H. Research status of laser cladding on titanium and its alloys: A review. Mater. Des. 2014, 58, 412–425. [Google Scholar] [CrossRef]

- Li, G.; Zhong, X.; Wang, X.; Gong, F.; Lei, H.; Zhou, Y.; Li, C.; Xiao, Z.; Ren, G.; Zhang, L.; et al. Titanium carbide nanosheets with defect structure for photothermal-enhanced sonodynamic therapy. Bioact. Mater. 2022, 8, 409–419. [Google Scholar] [CrossRef]

- Bordbar-Khiabani, A.; Gasik, M. Electrochemical and biological characterization of Ti–Nb–Zr–Si alloy for orthopedic applications. Sci. Rep. 2023, 13, 2312. [Google Scholar] [CrossRef] [PubMed]

- Hao, Y.L.; Zhang, Z.B.; Li, S.J.; Yang, R. Microstructure and mechanical behavior of a Ti–24Nb–4Zr–8Sn alloy processed by warm swaging and warm rolling. Acta Mater. 2012, 60, 2169–2177. [Google Scholar] [CrossRef]

- Fer, B.; Tingaud, D.; Hocini, A.; Hao, Y.; Leroy, E.; Prima, F.; Dirras, G. Powder Metallurgy Processing and Mechanical Properties of Controlled Ti-24Nb-4Zr-8Sn Heterogeneous Microstructures. Metals 2020, 10, 1626. [Google Scholar] [CrossRef]

- Zhang, Y.W.; Li, S.J.; Obbard, E.G.; Wang, H.; Wang, S.C.; Hao, Y.L.; Yang, R. Elastic properties of Ti–24Nb–4Zr–8Sn single crystals with bcc crystal structure. Acta Mater. 2011, 59, 3081–3090. [Google Scholar] [CrossRef]

- Nune, K.C.; Misra, R.D.K.; Li, S.J.; Hao, Y.L.; Yang, R. Osteoblast cellular activity on low elastic modulus Ti–24Nb–4Zr–8Sn alloy. Dent. Mater. 2017, 33, 152–165. [Google Scholar] [CrossRef]

- Li, X.; Wang, J.; Ye, S.; Zhou, Y.; Yu, P. An investigation of the tensile deformation mechanism of a high-oxygen Ti2448 alloy fabricated by powder metallurgy by use of the in-situ EBSD method. Mater. Sci. Eng. A 2021, 828, 141981. [Google Scholar] [CrossRef]

- Tang, Z.; Wei, X.; Li, T.; Wu, H.; Xiao, X.; Hao, Y.; Li, S.; Hou, W.; Shi, L.; Li, X.; et al. Three-Dimensionally Printed Ti2448 with Low Stiffness Enhanced Angiogenesis and Osteogenesis by Regulating Macrophage Polarization via Piezo1/YAP Signaling Axis. Front. Cell Dev. Biol. 2021, 9, 750948. [Google Scholar] [CrossRef] [PubMed]

- Madonsela, J.; Matizamhuka, W.; Machaka, R.; Shongwe, B.; Yamamoto, A. Sintering Performance and Corrosion behavior of biomedical Ti-24Nb-4Zr-8Sn alloy produced using SPS in various simulated body solutions. IOP Conf. Ser. Mater. Sci. Eng. 2018, 430, 012037. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, J.; Wang, P.; Fan, X.; Li, X.; Fu, J.; Li, S.; Fan, H.; Guo, Z. Low elastic modulus contributes to the osteointe-gration of titanium alloy plug. J. Biomed. Mater. Res. Part A 2013, 101B, 584–590. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.-F.; Li, S.-J.; Hou, W.-T.; Hao, Y.-L.; Huang, H.-H. Enhancing corrosion resistance and biocompatibility of interconnected porous β-type Ti-24Nb-4Zr-8Sn alloy scaffold through alkaline treatment and type I collagen immobilization. Appl. Surf. Sci. 2019, 476, 325–334. [Google Scholar] [CrossRef]

- Xu, R.; Tan, Z.; Xiong, D.; Fan, G.; Guo, Q.; Zhang, J.; Su, Y.; Li, Z.; Zhang, D. Balanced strength and ductility in CNT/Al composites achieved by flake powder metallurgy via shift-speed ball milling. Compos. Part A Appl. Sci. Manuf. 2017, 96, 57–66. [Google Scholar] [CrossRef]

- Chiba, A.; Daino, Y.; Aoyagi, K.; Yamanaka, K. Smoke Suppression in Electron Beam Melting of Inconel 718 Alloy Powder Based on Insulator–Metal Transition of Surface Oxide Film by Mechanical Stimulation. Materials 2021, 14, 4662. [Google Scholar] [CrossRef]

- Yim, S.; Aoyagi, K.; Yanagihara, K.; Bian, H.; Chiba, A. Effect of mechanical ball milling on the electrical and powder bed properties of gas-atomized Ti–48Al–2Cr–2Nb and elucidation of the smoke mechanism in the powder bed fusion electron beam melting process. J. Mater. Sci. Technol. 2023, 137, 36–55. [Google Scholar] [CrossRef]

- Salur, E.; Aslan, A.; Kuntoğlu, M.; Acarer, M. Effect of ball milling time on the structural characteristics and mechanical properties of nano-sized Y2O3 particle reinforced aluminum matrix composites produced by powder metallurgy route. Adv. Powder Technol. 2021, 32, 3826–3844. [Google Scholar] [CrossRef]

- Pradeep, N.B.; Hegde, M.M.R.; Patel, G.C.M.; Giasin, K.; Pimenov, D.Y.; Wojciechowski, S. Synthesis and charac-terization of mechanically alloyed nanostructured ternary titanium based alloy for biomedical applications. J. Mater. Res. Technol. 2022, 16, 88–101. [Google Scholar] [CrossRef]

- Li, X.; Ye, S.; Yuan, X.; Yu, P. Fabrication of biomedical Ti-24Nb-4Zr-8Sn alloy with high strength and low elastic modulus by powder metallurgy. J. Alloy. Compd. 2019, 772, 968–977. [Google Scholar] [CrossRef]

- Yang, C.L.; Zhang, Z.J.; Li, S.J.; Liu, Y.J.; Sercombe, T.B.; Hou, W.T.; Zhang, P.; Zhu, Y.K.; Hao, Y.L.; Zhang, Z.F.; et al. Simultaneous improvement in strength and plasticity of Ti-24Nb-4Zr-8Sn manufactured by selective laser melting. Mater. Des. 2018, 157, 52–59. [Google Scholar] [CrossRef]

- Sames, W.J.; List, F.A.; Pannala, S.; Dehoff, R.R.; Babu, S.S. The metallurgy and processing science of metal additive manu-facturing. Int. Mater. Rev. 2016, 61, 315–360. [Google Scholar] [CrossRef]

- Sun, F.J.; Qu, S.G.; Deng, Z.H.; Su, F.; Li, X.Q. Shear band formation and wear mechanism of titanium alloy powder metallurgy material prepared by HIP using Ti-6Al-4V pre-alloy powder. Int. J. Adv. Manuf. Technol. 2017, 93, 4439–4445. [Google Scholar] [CrossRef]

- Jiang, X.; Bai, J.; Yang, N.; Ran, Q.; Wang, S. Effect of deformation on α-β phase transformation temperature of a metestable TiZr based alloy. Mater. Lett. 2021, 285, 129003. [Google Scholar] [CrossRef]

- Kumar, K.N.; Muneshwar, P.; Singh, S.K.; Jha, A.K.; Pant, B.; George, K.M. Effect of Grain Boundary Alpha on Mechanical Properties of Ti5.4Al3Mo1V Alloy. JOM 2015, 67, 1265–1272. [Google Scholar] [CrossRef]

- Banerjee, R.; Bhattacharyya, D.; Collins, P.C.; Viswanathan, G.B.; Fraser, H.L. Precipitation of grain boundary α in a laser deposited compositionally graded Ti–8Al–xV alloy—An orientation microscopy study. Acta Mater. 2004, 52, 377–385. [Google Scholar] [CrossRef]

- Sen, I.; Tamirisakandala, S.; Miracle, D.B.; Ramamurty, U. Microstructural effects on the mechanical behavior of B-modified Ti–6Al–4V alloys. Acta Mater. 2007, 55, 4983–4993. [Google Scholar] [CrossRef]

- Shi, R.; Dixit, V.; Viswanathan, G.B.; Fraser, H.L.; Wang, Y. Experimental assessment of variant selection rules for grain boundary α in titanium alloys. Acta Mater. 2016, 102, 197–211. [Google Scholar] [CrossRef]

- Hariharan, A.; Goldberg, P.; Gustmann, T.; Maawad, E.; Pilz, S.; Schell, F.; Kunze, T.; Zwahr, C.; Gebert, A. Designing the microstructural constituents of an additively manufactured near β Ti alloy for an enhanced mechanical and corrosion response. Mater. Des. 2022, 217, 110618. [Google Scholar] [CrossRef]

- Yang, J.; Yu, H.; Yin, J.; Gao, M.; Wang, Z.; Zeng, X. Formation and control of martensite in Ti-6Al-4V alloy produced by selective laser melting. Mater. Des. 2016, 108, 308–318. [Google Scholar] [CrossRef]

- Kumar, P.; Ramamurty, U. Microstructural optimization through heat treatment for enhancing the fracture toughness and fatigue crack growth resistance of selective laser melted Ti 6Al 4V alloy. Acta Mater. 2019, 169, 45–59. [Google Scholar] [CrossRef]

- Xue, A.; Lin, X.; Wang, L.; Wang, J.; Huang, W. Influence of trace boron addition on microstructure, tensile properties and their anisotropy of Ti6Al4V fabricated by laser directed energy deposition. Mater. Des. 2019, 181, 107943. [Google Scholar] [CrossRef]

- Foltz, J.W.; Welk, B.; Collins, P.; Fraser, H.L.; Williams, J.C. Formation of Grain Boundary α in β Ti Alloys: Its Role in Deformation and Fracture Behavior of These Alloys. Met. Mater. Trans. A 2011, 42, 645–650. [Google Scholar] [CrossRef]

- Bermingham, M.; McDonald, S.; Dargusch, M. Effect of trace lanthanum hexaboride and boron additions on microstructure, tensile properties and anisotropy of Ti-6Al-4V produced by additive manufacturing. Mater. Sci. Eng. A 2018, 719, 1–11. [Google Scholar] [CrossRef]

- Zhang, K.; Tian, X.; Bermingham, M.; Rao, J.; Jia, Q.; Zhu, Y.; Wu, X.; Cao, S.; Huang, A. Effects of boron addition on micro-structures and mechanical properties of Ti-6Al-4V manufactured by direct laser deposition. Mater. Des. 2019, 184, 108191. [Google Scholar] [CrossRef]

- Liu, C.M.; Wang, H.M.; Tian, X.J.; Liu, D. Development of a pre-heat treatment for obtaining discontinuous grain bound-ary α in laser melting deposited Ti–5Al–5Mo–5V–1Cr–1Fe alloy. Mater. Sci. Eng. A 2014, 604, 176–182. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, A.X.Y.; Cao, B.; Wang, Z.; Ma, X.; Cao, S.C. Fabricated High-Strength, Low-Elastic Modulus Biomedical Ti-24Nb-4Zr-8Sn Alloy via Powder Metallurgy. Materials 2023, 16, 3845. https://doi.org/10.3390/ma16103845

Guo AXY, Cao B, Wang Z, Ma X, Cao SC. Fabricated High-Strength, Low-Elastic Modulus Biomedical Ti-24Nb-4Zr-8Sn Alloy via Powder Metallurgy. Materials. 2023; 16(10):3845. https://doi.org/10.3390/ma16103845

Chicago/Turabian StyleGuo, Amy X. Y., Bin Cao, Zihan Wang, Xiao Ma, and Shan Cecilia Cao. 2023. "Fabricated High-Strength, Low-Elastic Modulus Biomedical Ti-24Nb-4Zr-8Sn Alloy via Powder Metallurgy" Materials 16, no. 10: 3845. https://doi.org/10.3390/ma16103845

APA StyleGuo, A. X. Y., Cao, B., Wang, Z., Ma, X., & Cao, S. C. (2023). Fabricated High-Strength, Low-Elastic Modulus Biomedical Ti-24Nb-4Zr-8Sn Alloy via Powder Metallurgy. Materials, 16(10), 3845. https://doi.org/10.3390/ma16103845