Influences of Cold Rolling and Aging on Microstructure and Property of CuCrSn Alloy

Abstract

:1. Introduction

2. Materials and Methods

2.1. Specimen Preparation

2.2. Microstructure Characterization

2.3. Microhardness and Conductivity Tests

2.4. Tensile Test and Fracture Surface Observation

3. Results and Discussion

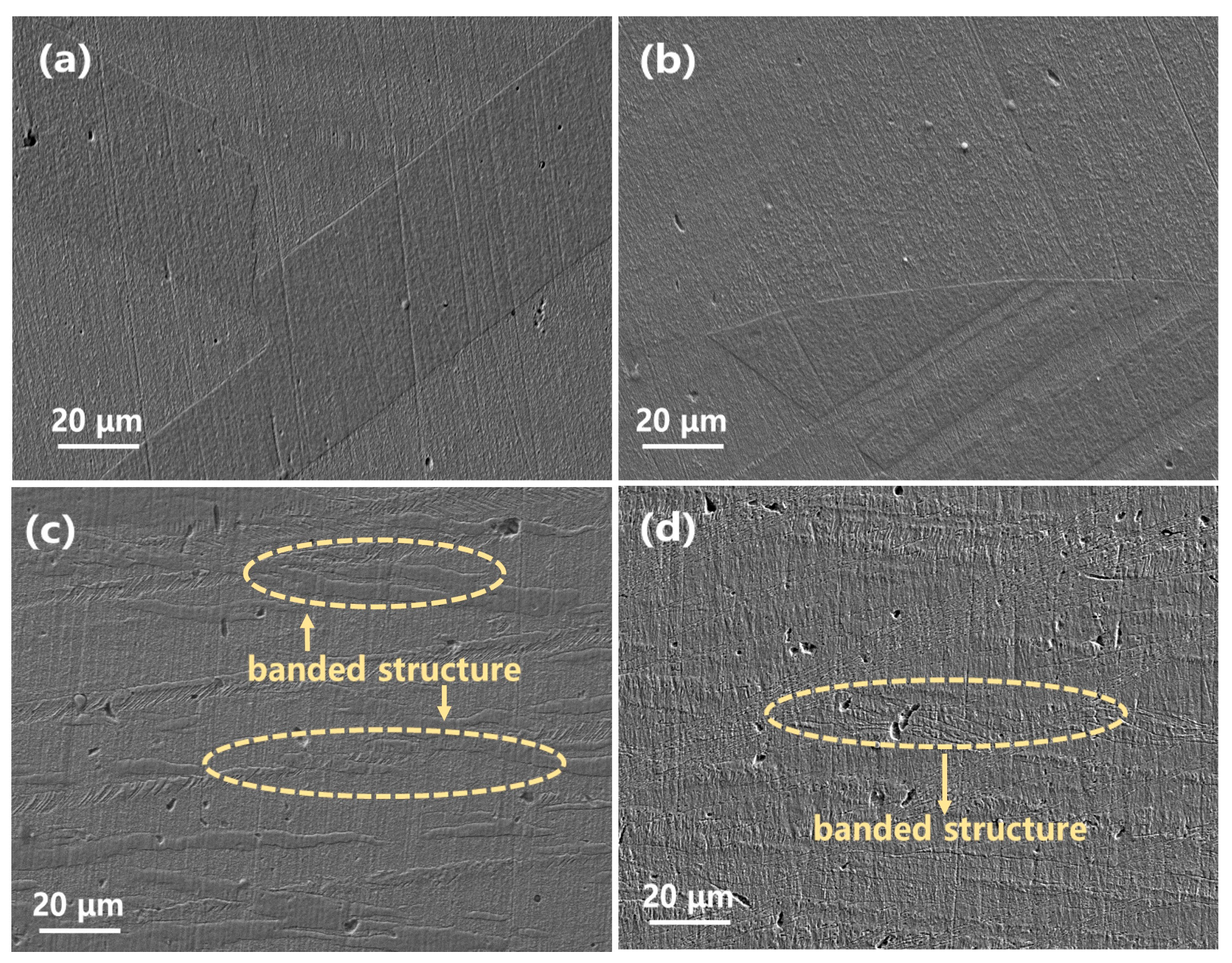

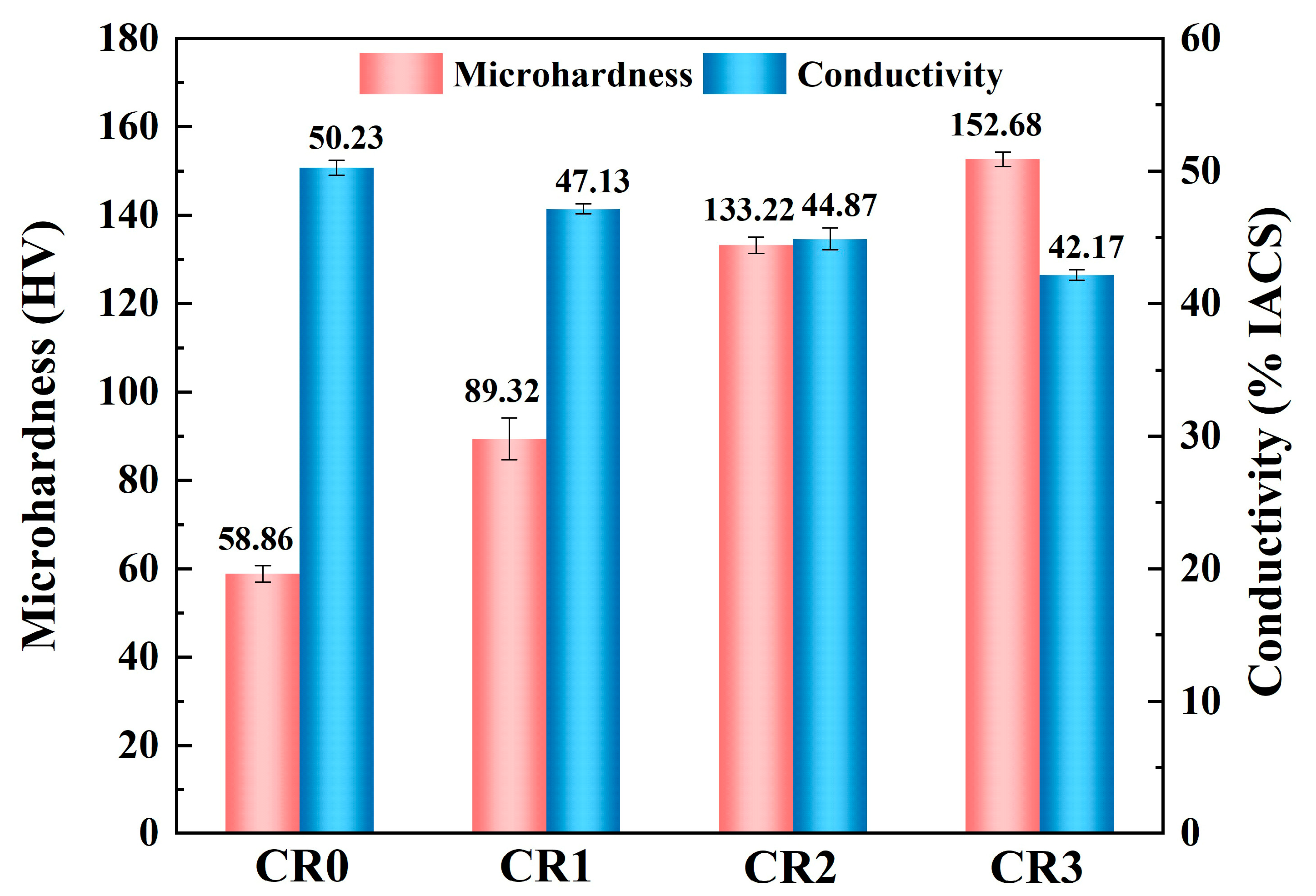

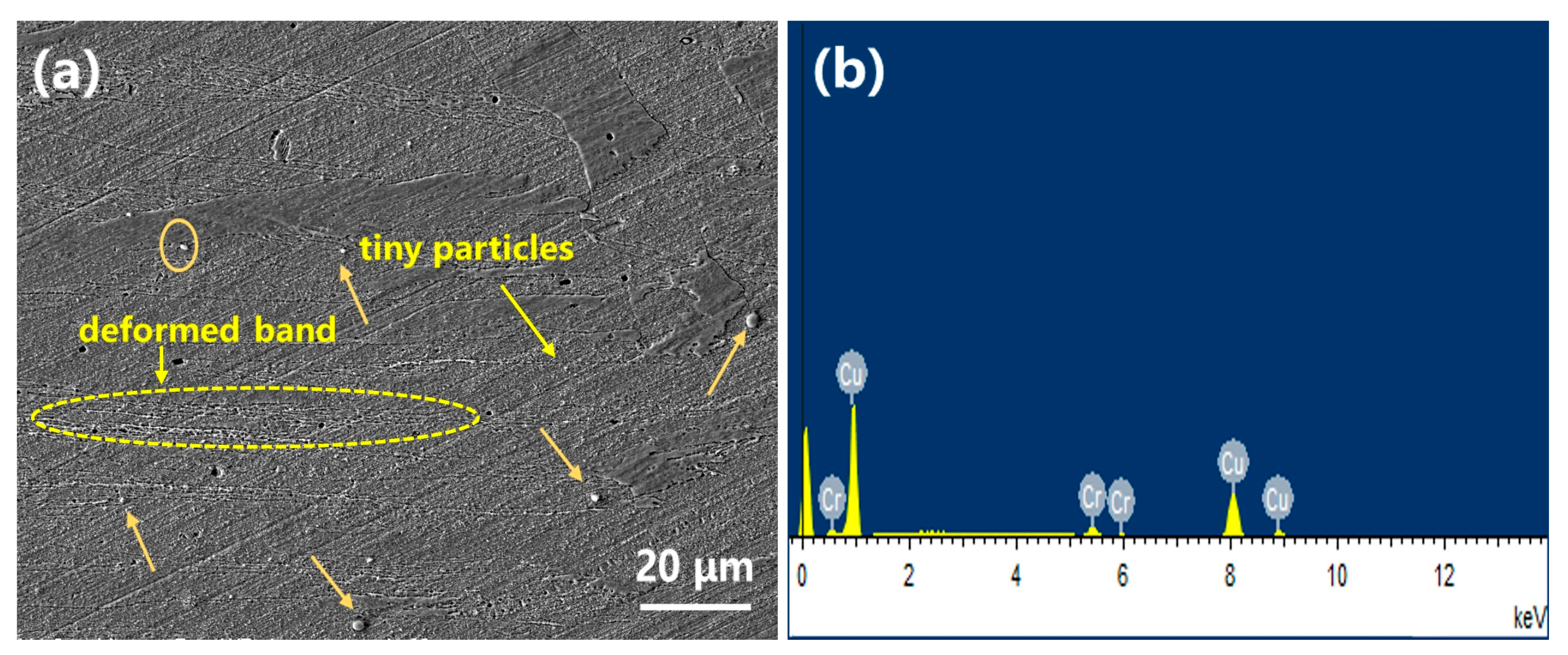

3.1. Microstructure and Properties of the Cold-Rolled CuCrSn Alloy

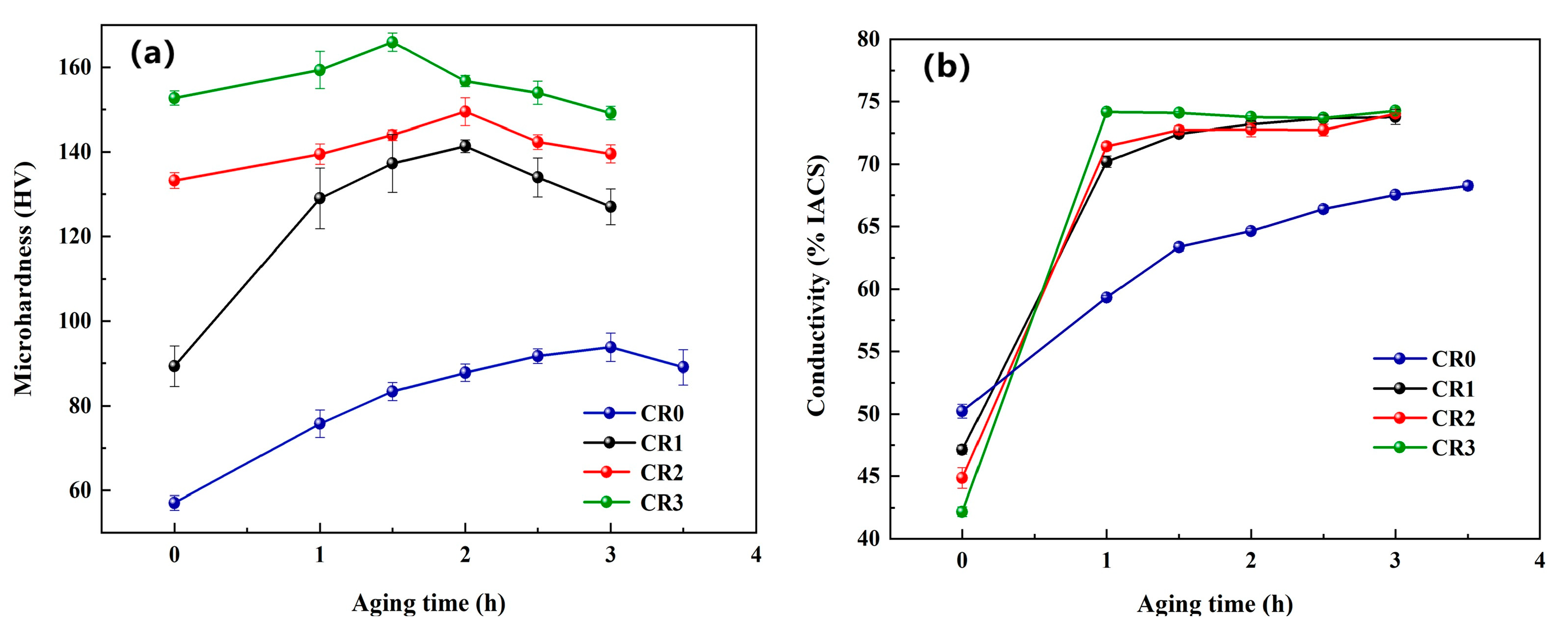

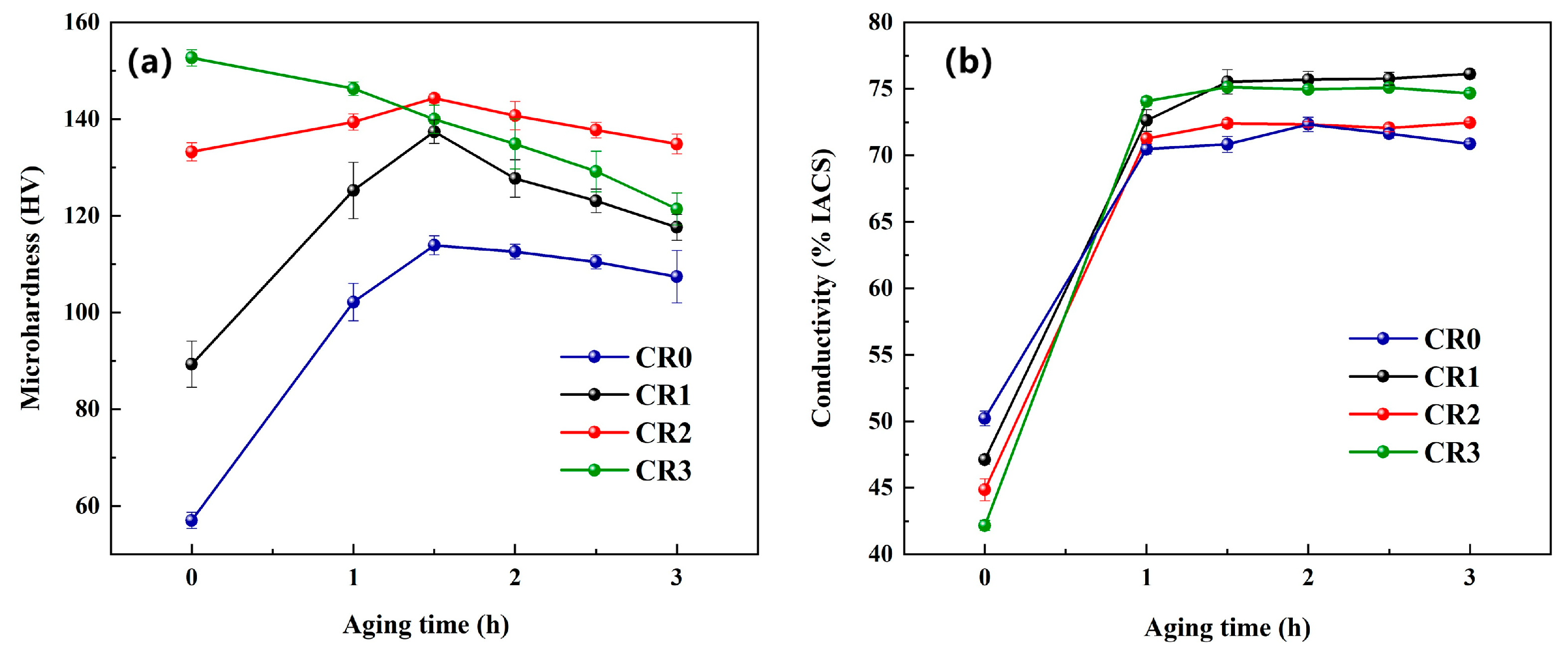

3.2. Properties of the Cold-Rolled CuCrSn Alloy after Different Aging Conditions

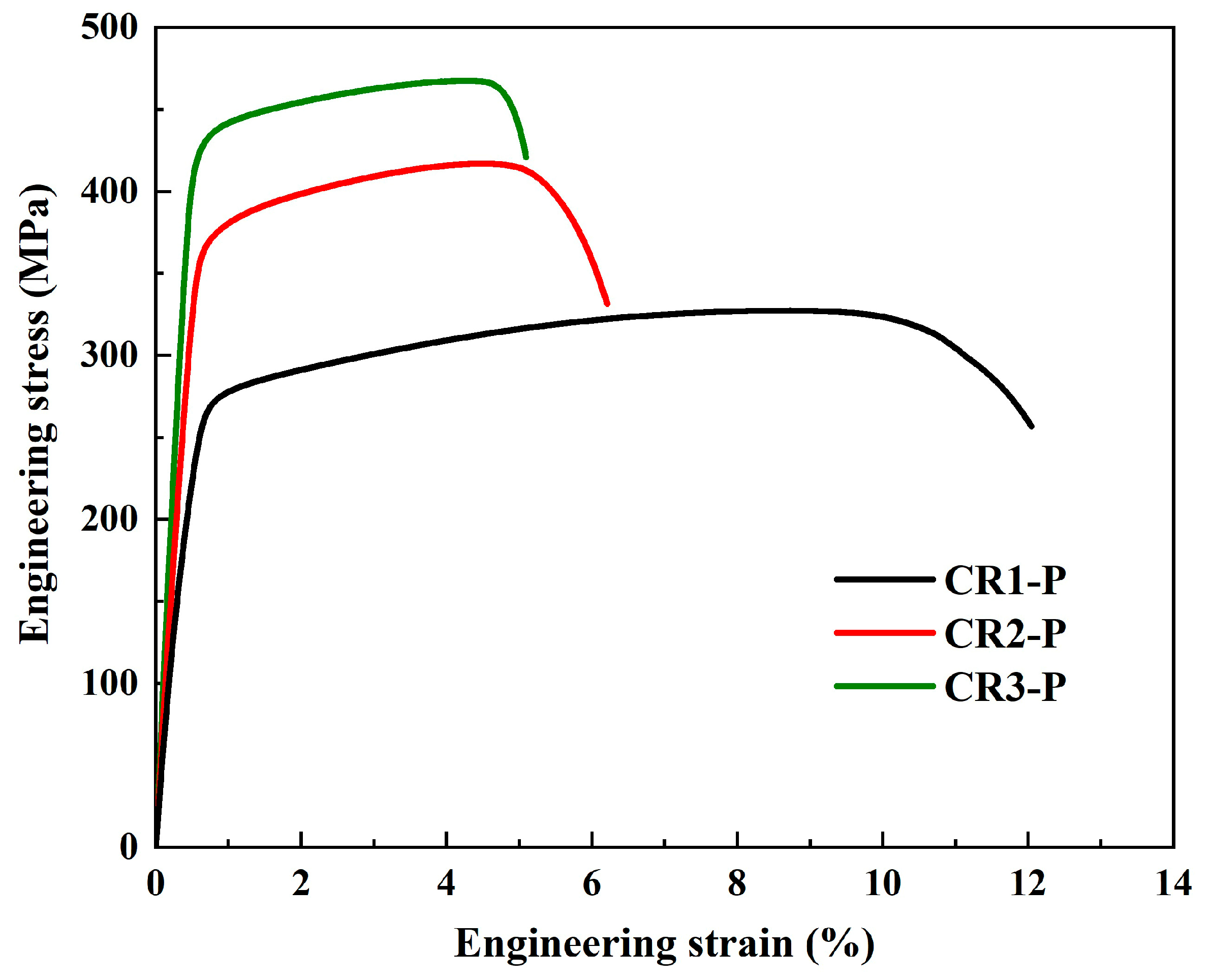

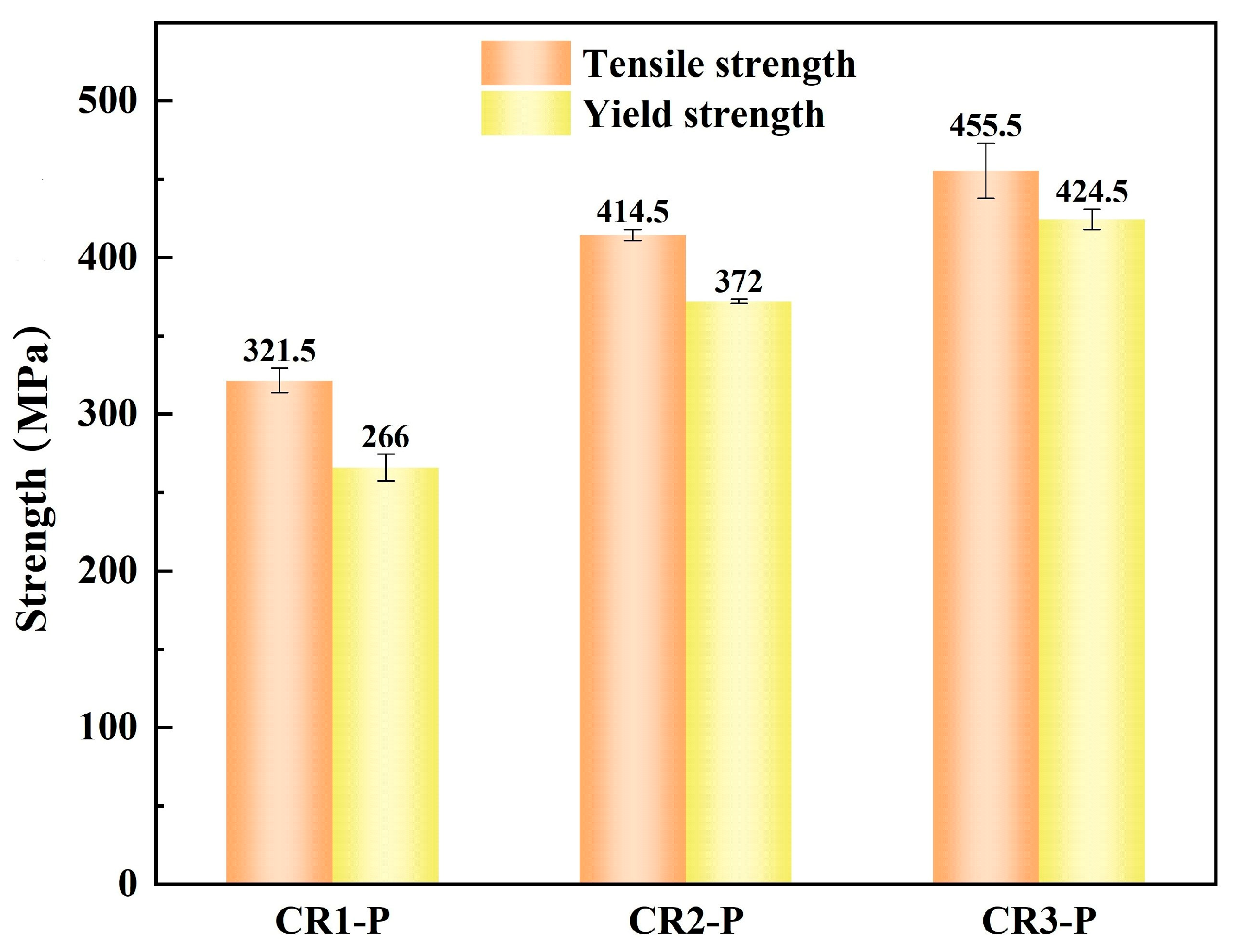

3.3. Tensile Behavior of the Peak-Aged CuCrSn Alloy

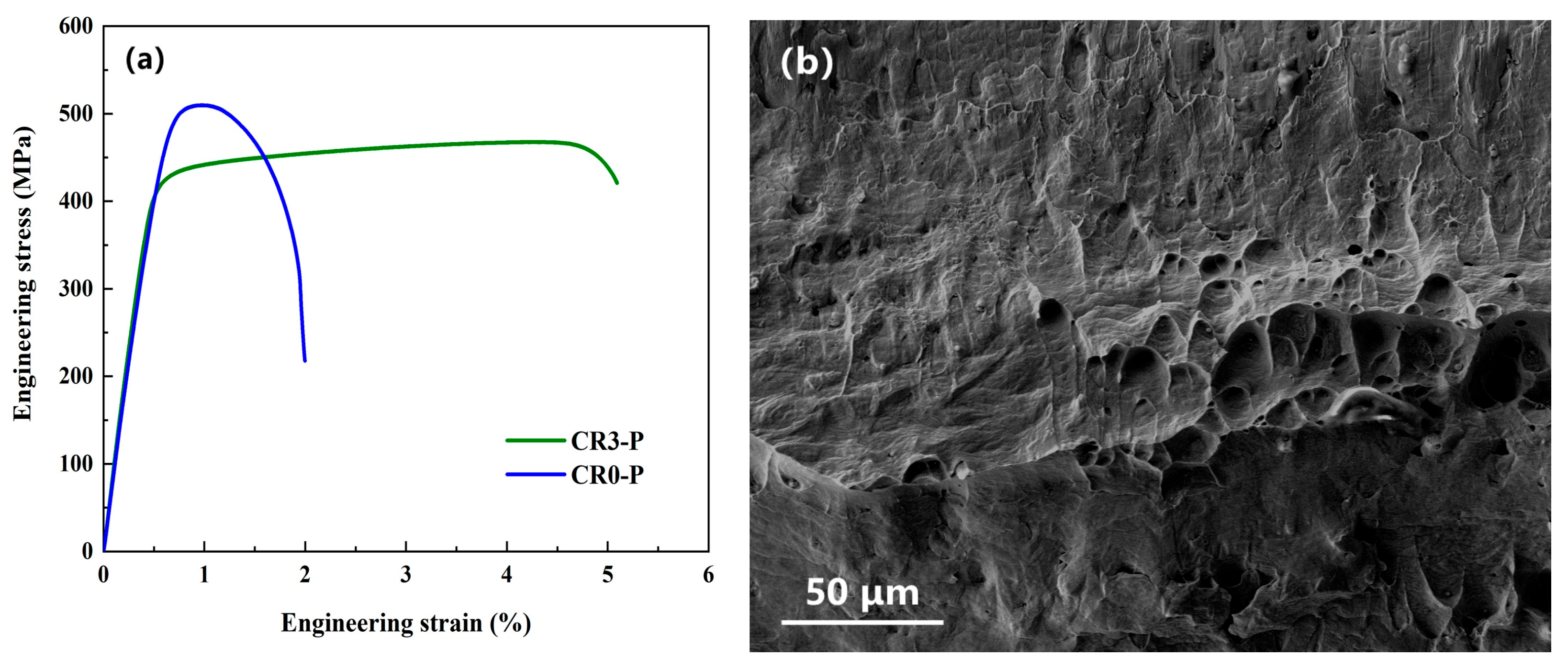

3.4. Properties of the CuCrSn Alloy Cold-Rolled after Aging

4. Conclusions

- (1)

- Cold rolling can change the coarse recrystallization structure of the alloy, and forms a deformation texture and bands with severe plastic deformation. A high density of dislocations were introduced during the cold rolling process, which significantly increased the microhardness but decreased the conductivity by a little.

- (2)

- The microhardness increases firstly and then decreases during the aging process, while the conductivity increases rapidly at the early aging stage and then becomes stable. Cold rolling before aging can accelerate the precipitation process, and the peak microhardness is also higher for the specimen with a higher cold-rolling ratio before aging. The most suitable aging temperature is related to the cold-rolling ratio before aging. Improving the aging temperature shortens the peak aging time.

- (3)

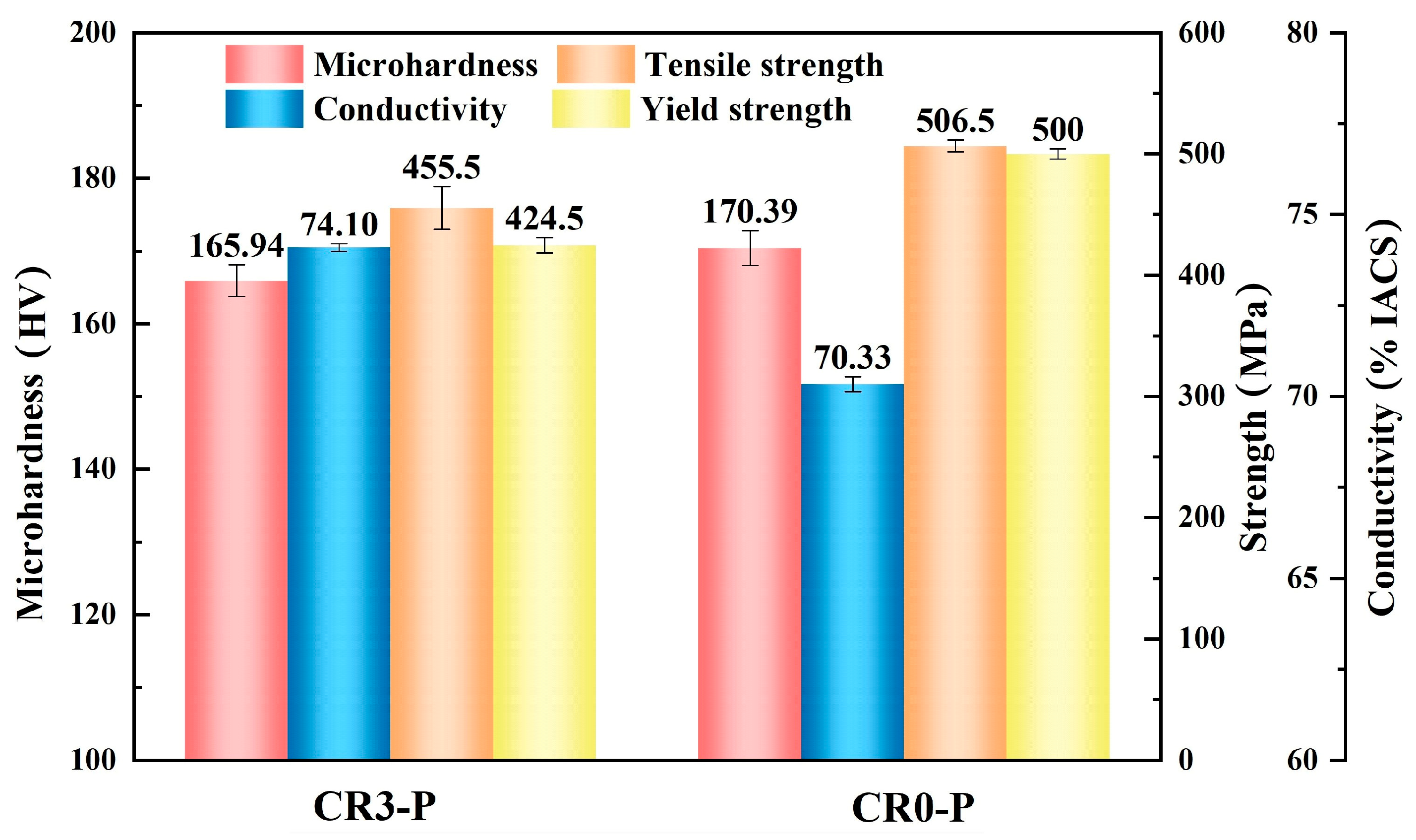

- Through aging firstly and then conducting cold rolling, the strength of the Cu-0.2Cr-0.25Sn alloy can be further improved, because the precipitation strengthening and deformation strengthening are both significant in this condition, and the conductivity can still maintain a relatively high level. A tensile strength of 506.5 MPa and a conductivity of 70.33% IACS were obtained for the specimen with the processes of annealing at 960 °C for 1 h, aging at 450 °C for 2 h and then 80% cold rolling.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cheng, J.Y.; Shen, B.; Yu, F.X. Precipitation in a Cu-Cr-Zr-Mg alloy during aging. Mater. Charact. 2013, 81, 68–75. [Google Scholar] [CrossRef]

- Fu, H.D.; Xu, S.; Li, W.; Xie, J.X.; Zhao, H.B.; Pan, Z.J. Effect of rolling and aging processes on microstructure and properties of Cu-Cr-Zr alloy. Mater. Sci. Eng. A 2017, 700, 107–115. [Google Scholar] [CrossRef]

- Fu, S.L.; Liu, P.; Chen, X.H.; Zhou, H.L.; Ma, F.C.; Li, W.; Zhang, K. Effect of aging process on the microstructure and properties of Cu-Cr-Ti alloy. Mater. Sci. Eng. A 2021, 802, 140598. [Google Scholar] [CrossRef]

- Luo, Z.Y.; Luo, F.X.; Xie, W.B.; Chen, H.M.; Wang, H.; Yang, B. The Effect of Precipitation Characteristics on Hardening Behavior in Cu-Cr-Sn Alloy with Sn Variation. Powder Metall. Met. Ceram. 2020, 58, 657–666. [Google Scholar] [CrossRef]

- Peng, H.C.; Xie, W.B.; Chen, H.M.; Wang, H.; Yang, B. Effect of micro-alloying element Ti on mechanical properties of Cu-Cr alloy. J. Alloy. Compd. 2021, 852, 157004. [Google Scholar] [CrossRef]

- Chen, J.S.; Wang, J.F.; Xiao, X.P.; Wang, H.; Chen, H.M.; Yang, B. Contribution of Zr to strength and grain refinement in Cu-Cr-Zr alloy. Mater. Sci. Eng. A 2019, 756, 464–473. [Google Scholar] [CrossRef]

- Ma, M.Z.; Li, Z.; Xiao, Z.; Zhu, H.R.; Zhang, X.; Zhao, F.Y. Microstructure and properties of a novel Cu-Cr-Yb alloy with high strength, high electrical conductivity and good softening resistance. Mater. Sci. Eng. A 2020, 795, 140001. [Google Scholar] [CrossRef]

- Xu, S.; Fu, H.D.; Wang, Y.T.; Xie, J.X. Effect of Ag addition on the microstructure and mechanical properties of Cu-Cr alloy. Mater. Sci. Eng. A 2018, 726, 208–214. [Google Scholar] [CrossRef]

- Yang, J.Z.; Bu, K.; Song, K.X.; Zhou, Y.J.; Huang, T.; Niu, L.Y.; Guo, H.W.; Du, Y.B.; Kang, J.W. Influence of low-temperature annealing temperature on the evolution of the microstructure and mechanical properties of Cu-Cr-Ti-Si alloy strips. Mater. Sci. Eng. A 2020, 798, 140120. [Google Scholar] [CrossRef]

- Sun, Y.Q.; Peng, L.J.; Huang, G.J.; Xie, H.F.; Mi, X.J.; Liu, X.H. Effects of Mg addition on the microstructure and softening resistance of Cu-Cr alloys. Mater. Sci. Eng. A 2020, 776, 139009. [Google Scholar] [CrossRef]

- Zhou, J.M.; Zhu, D.G.; Tang, L.T.; Jiang, X.S.; Chen, S.; Peng, X.; Hu, C.F. Microstructure and properties of powder metallurgy Cu-1%Cr-0.65%Zr alloy prepared by hot pressing. Vacuum 2016, 131, 156–163. [Google Scholar] [CrossRef]

- Hu, H.Q.; Xu, C.; Yang, L.J.; Zhang, H.H.; Song, Z.L. Recent Advances in the Research of High-Strength and High-Conductivity CuCrZr alloy. Mater. Rep. 2018, 32, 453–460. (In Chinese) [Google Scholar]

- Chen, T.T.; Hu, M.J.; Liu, W.Y.; Zhang, J.B. Study on Aging Kinetics of Cu-0.37Cr-0.046Sn Alloy Prepared by Antivacuum Melting. Hot Work. Technol. 2016, 45, 189–192. [Google Scholar]

- Li, J.Z.; Ding, H.; Li, B.M.; Gao, W.L.; Bai, J.; Sha, G. Effect of Cr and Sn additions on microstructure, mechanical-electrical properties and softening resistance of Cu-Cr-Sn alloy. Mater. Sci. Eng. 2021, 802, 140628. [Google Scholar] [CrossRef]

- Li, J.Z.; Ding, H.; Li, B.M. Study on the variation of properties of Cu-Cr-Zr alloy by different rolling and aging sequence. Mater. Sci. Eng. A 2021, 802, 140413. [Google Scholar] [CrossRef]

- Liao, W.N.; Zhang, C.X.; Qiang, H.; Song, W.F.; Hu, Y.Y. The comprehensive performance and strengthening mechanism of the columnar crystal Cu-Ni-Si alloy after two large deformation rates of cryogenic rolling-aging. J. Alloy. Compd. 2023, 936, 168281. [Google Scholar] [CrossRef]

- Wang, Y.D.; Wu, L.H.; Xue, P.; Zhang, H.; Ni, D.R.; Ma, Z.Y. Improved strength with good conductivity in Cu-Cr-Zr alloys: Determinant effect of under-aging treatment before rolling and aging. Mater. Sci. Eng. A 2022, 848, 143395. [Google Scholar] [CrossRef]

- Duan, S.W.; Guo, F.Q.; Wu, D.T.; Wang, T.; Tsuchiya, T.; Matsuda, K.; Zou, Y. Influences of pre-rolling deformation on aging precipitates and mechanical properties for a novel Al-Cu-Li alloy. J. Mater. Res. Technol. 2021, 15, 2379–2392. [Google Scholar] [CrossRef]

- Lai, Z.M.; Peng, K.Z.; Gao, B.B.; Mai, Y.J.; Jie, X.H. Achieving high strength and high electrical conductivity in Cu-Cr-Zr alloy by modifying shear banding during rolling. J. Alloy. Compd. 2023, 958, 170402. [Google Scholar] [CrossRef]

- Sprouster, D.J.; Cunningham, W.S.; Halada, G.P.; Yan, H.F.; Pattammattel, A.; Huang, X.L.; Olds, D.; Tilton, M.; Chu, Y.S.; Dooryhee, E.; et al. Dislocation microstructure and its influence on corrosion behavior in laser additively manufactured 316L stainless steel. Addit. Manuf. 2021, 47, 102263. [Google Scholar] [CrossRef]

- Yi, X.N.; Ma, A.L.; Zhang, L.M.; Zheng, Y.G. Crystallographic anisotropy of corrosion rate and surface faceting of polycrystalline 90Cu-10Ni in acidic NaCl solution. Mater. Des. 2022, 215, 110429. [Google Scholar] [CrossRef]

- Liu, H.; Gao, B.; Yang, Y.; Xu, M.N.; Li, X.F.; Li, C.; Pan, H.J.; Yang, J.R.; Zhou, H.; Zhu, X.K.; et al. Strain hardening behavior and microstructure evolution of gradient-structured Cu-Al alloys with low stack fault energy. J. Mater. Res. Technol. 2022, 19, 220–229. [Google Scholar] [CrossRef]

- Milligan, B.; Ma, D.; Allard, L.; Clarke, A.; Shyam, A. Crystallographic orientation-dependent strain hardening in a precipitation-strengthened Al-Cu alloy. Acta Mater. 2021, 205, 116577. [Google Scholar] [CrossRef]

- Gong, Q.H.; Liu, J.; Wu, F.; Chen, H.M.; Xie, W.B.; Wang, H.; Yang, B. Precipitation behavior and strengthening effects of the Cu-0.42Cr-0.16Co alloy during aging treatment. J. Alloy. Compd. 2023, 936, 168269. [Google Scholar] [CrossRef]

- Zhong, J.; Yang, S.F.; Zhao, P.; Xie, G.L.; Wang, A.R.; Li, J.S.; Liu, W. Solidification characteristics and precipitation behavior of the Cu-Cr-Nb alloys. J. Mater. Res. Technol. 2023, 23, 882–893. [Google Scholar] [CrossRef]

- Huang, L.; Peng, L.J.; Mi, X.J.; Zhao, G.; Huang, G.J.; Xie, H.F.; Zhang, W.J. Relationship between microstructure and properties of high-strength Cu-Ti-Cr alloys during aging. J. Alloy. Compd. 2023, 942, 168865. [Google Scholar] [CrossRef]

- Jia, Y.L.; Pang, Y.; Yi, J.; Lei, Q.; Li, Z.; Xiao, Z. Effects of pre-aging on microstructure and properties of Cu-Ni-Si alloys. J. Alloy. Compd. 2023, 942, 169033. [Google Scholar] [CrossRef]

- Wu, Z.X.; Hu, J.H.; Xin, Z.; Qin, L.X.; Jia, Y.L.; Jiang, Y.B. Microstructure and properties of Cu-Zn-Cr-Zr alloy treated by multistage thermo-mechanical treatment. Mater. Sci. Eng. A 2023, 870, 144679. [Google Scholar] [CrossRef]

| Serial Number | Pre Rolling | Annealing | First Rolling | Aging | Further Rolling |

|---|---|---|---|---|---|

| CR0 | 10 mm to 2 mm | 960 °C, 1 h | / | 400 °C and 450 °C for different time | / |

| CR0-P | / | 450 °C, 2 h | 2 mm to 0.4 mm | ||

| CR1 | 2 mm to 1.6 mm | 400 °C and 450 °C for different time | / | ||

| CR1-P | 2 mm to 1.6 mm | 400 °C, 2 h | / | ||

| CR2 | 2 mm to 1.0 mm | 400 °C and 450 °C for different time | / | ||

| CR2-P | 2 mm to 1.0 mm | 400 °C, 2 h | / | ||

| CR3 | 2 mm to 0.4 mm | 400 °C and 450 °C for different time | / | ||

| CR3-P | 2 mm to 0.4 mm | 400 °C, 1.5 h | / |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, T.; Zhang, Q.; Liu, F.; Feng, X.; Xu, C.; Song, Z. Influences of Cold Rolling and Aging on Microstructure and Property of CuCrSn Alloy. Materials 2023, 16, 3780. https://doi.org/10.3390/ma16103780

Chen T, Zhang Q, Liu F, Feng X, Xu C, Song Z. Influences of Cold Rolling and Aging on Microstructure and Property of CuCrSn Alloy. Materials. 2023; 16(10):3780. https://doi.org/10.3390/ma16103780

Chicago/Turabian StyleChen, Tao, Qingke Zhang, Feng Liu, Xiaolong Feng, Cheng Xu, and Zhenlun Song. 2023. "Influences of Cold Rolling and Aging on Microstructure and Property of CuCrSn Alloy" Materials 16, no. 10: 3780. https://doi.org/10.3390/ma16103780

APA StyleChen, T., Zhang, Q., Liu, F., Feng, X., Xu, C., & Song, Z. (2023). Influences of Cold Rolling and Aging on Microstructure and Property of CuCrSn Alloy. Materials, 16(10), 3780. https://doi.org/10.3390/ma16103780