Mitigation of Thermal Instability for Electrical Properties in CaZrO3-Modified (Na, K, Li) NbO3 Lead-Free Piezoceramics

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

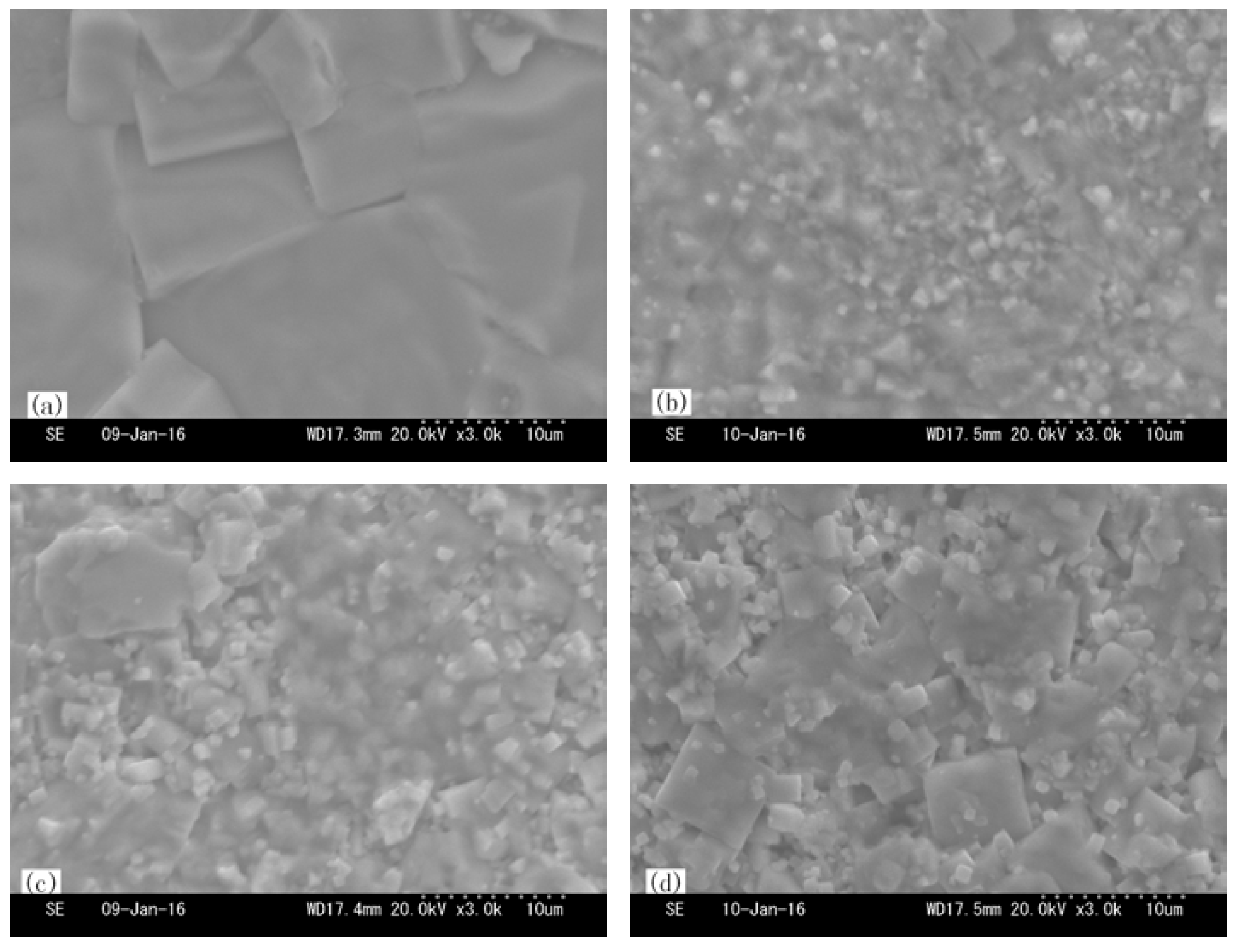

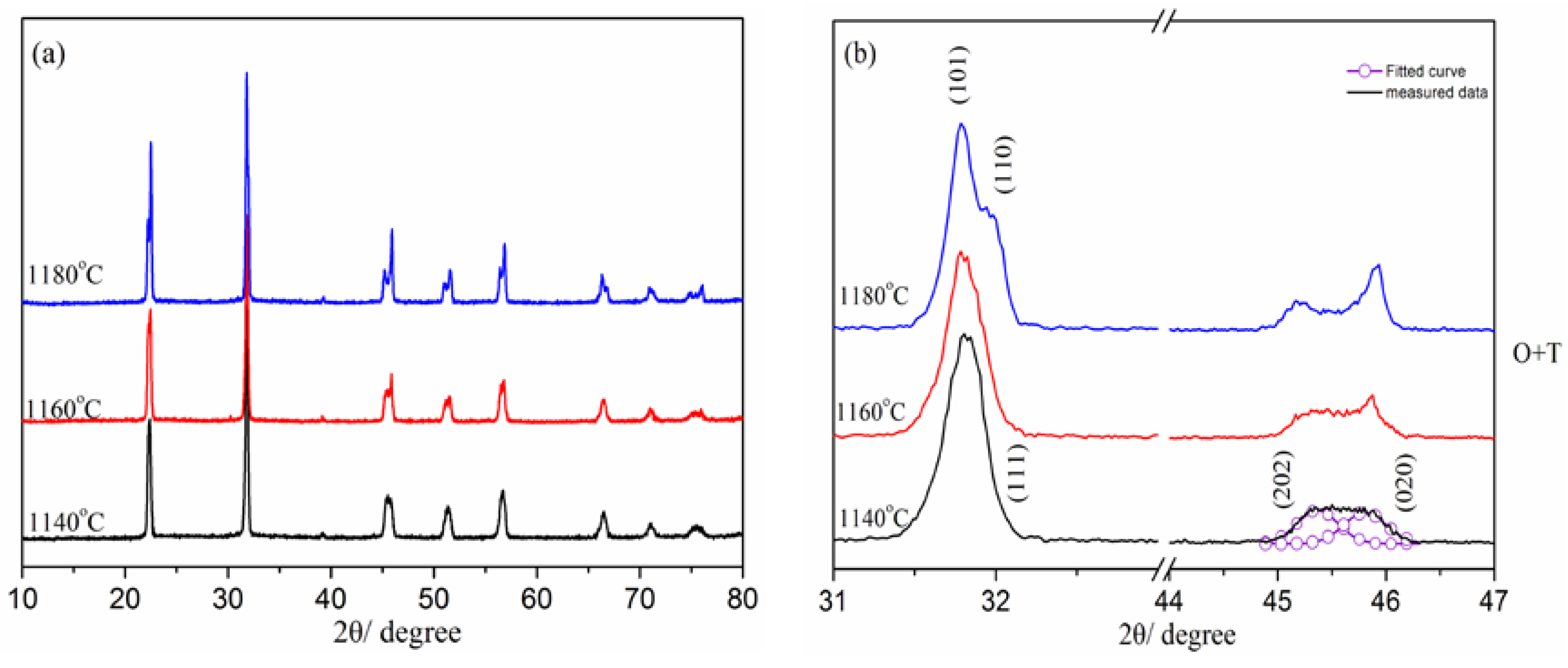

3.1. Structure

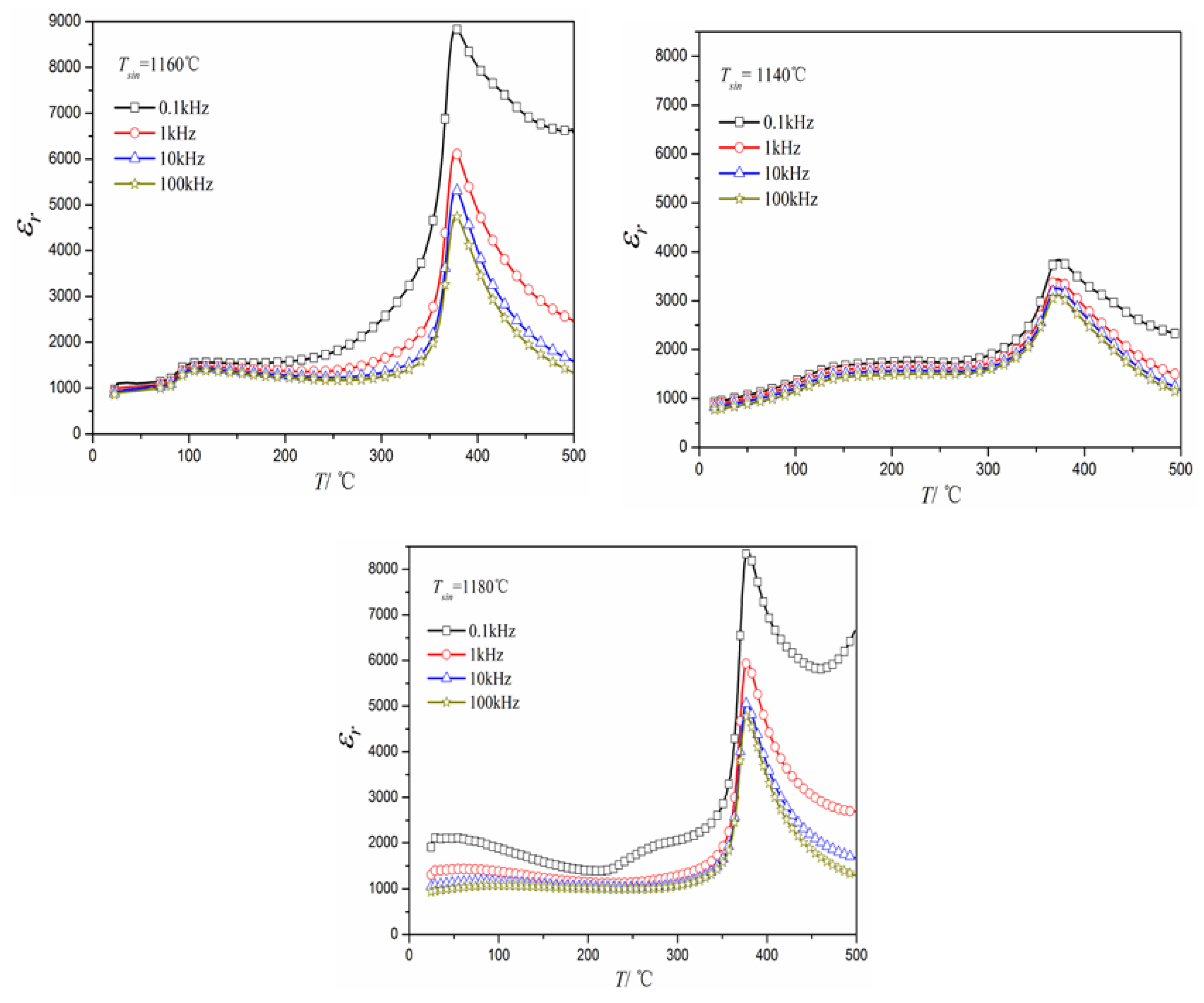

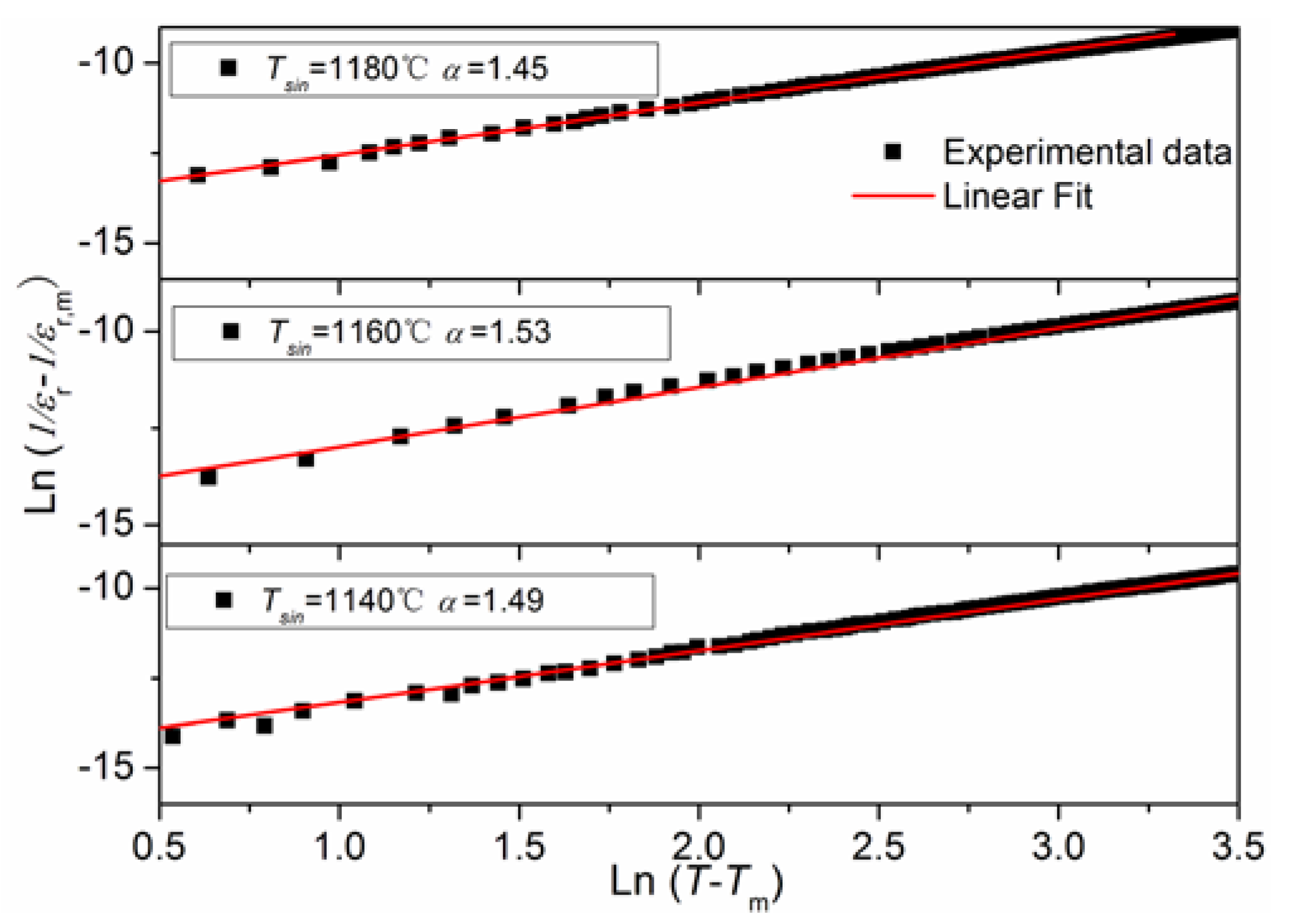

3.2. Dielectric Properties

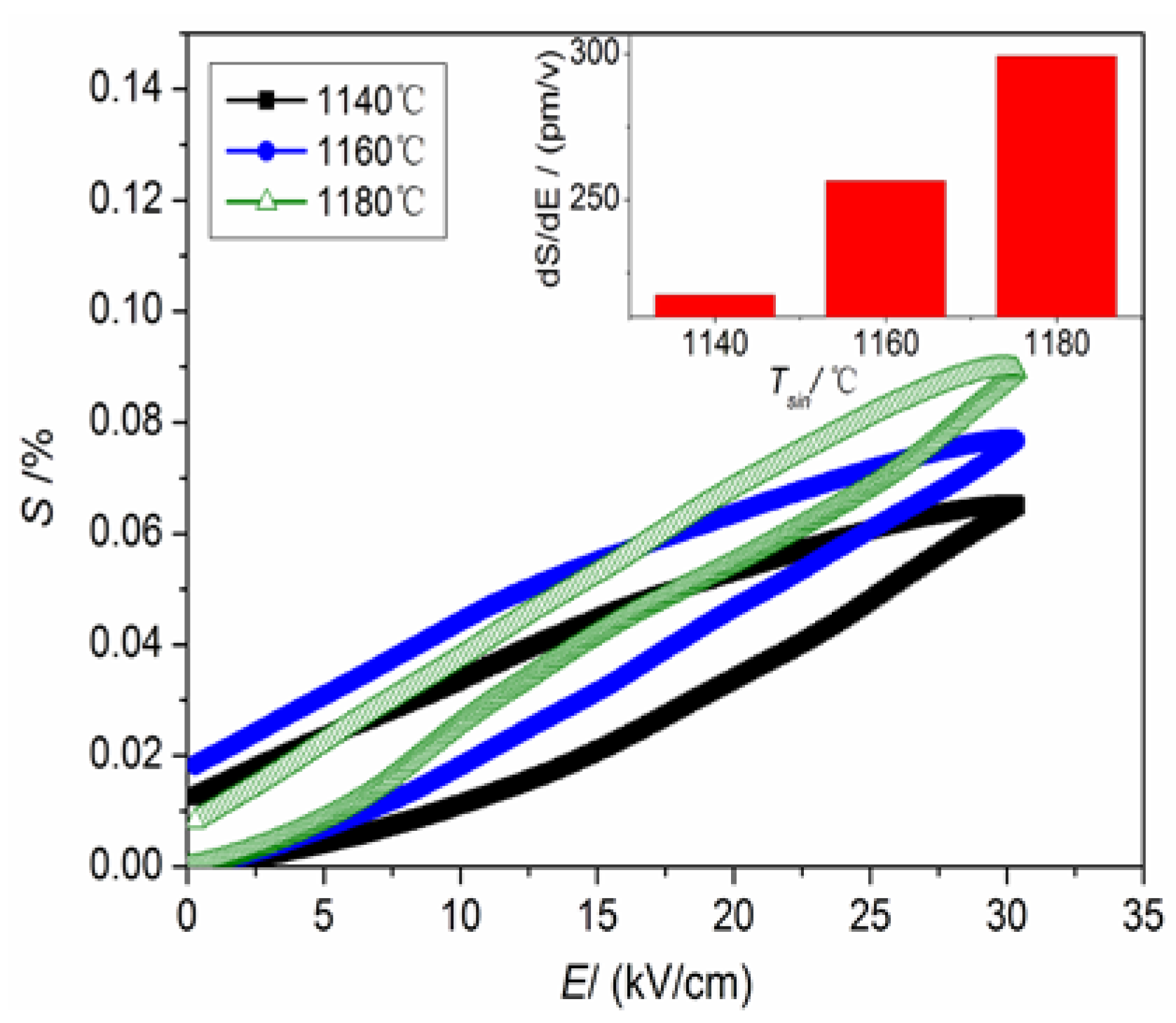

3.3. Ferroelectric Characteristics and Electromechanical Strain

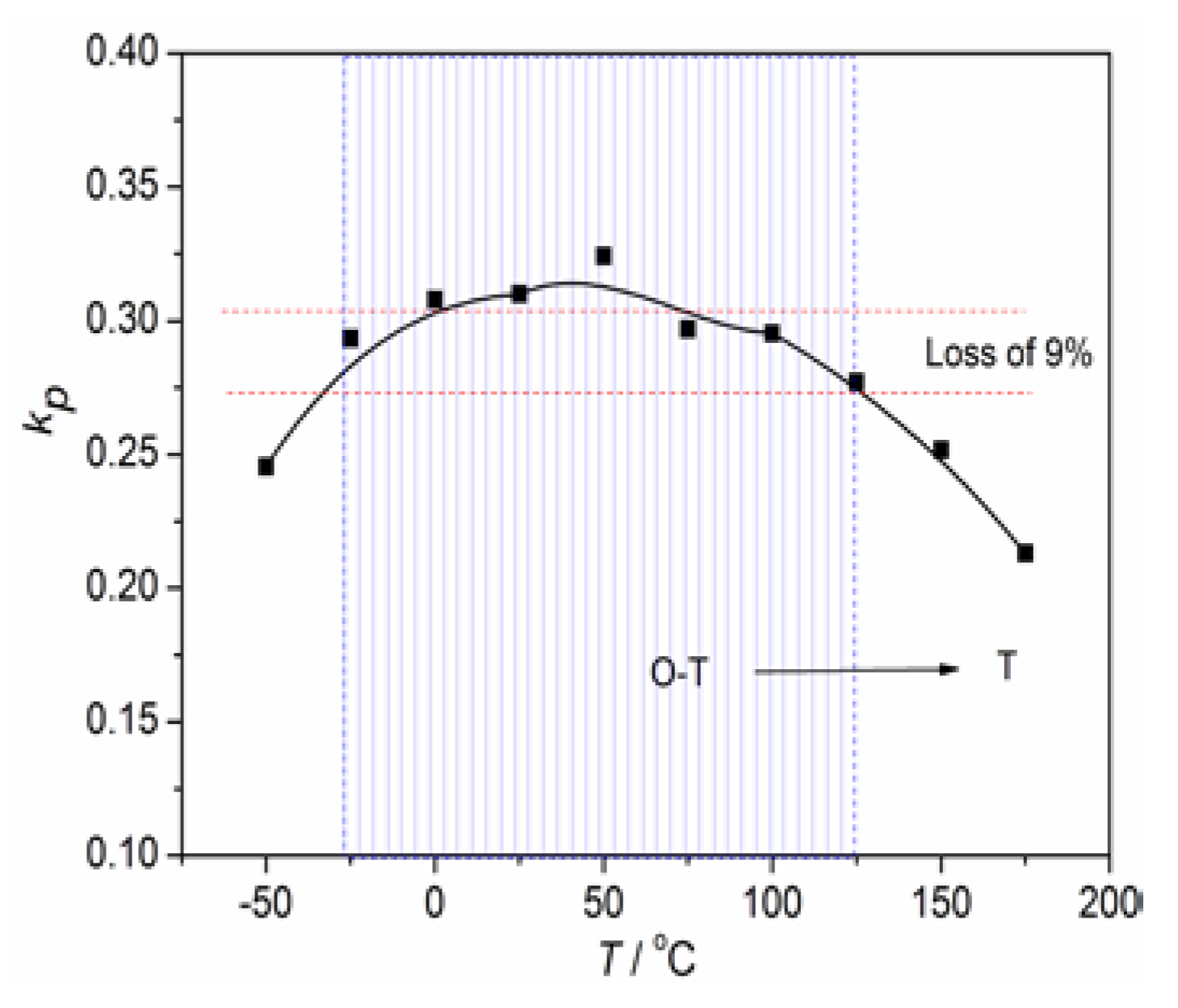

3.4. Electrical Properties and Thermal Instability

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, K.; Shen, Z.Y.; Zhang, B.P.; Li, J.F. (K,Na)NbO3-based lead-free piezoceramics: Status, prospects and challenges. J. Inorg. Mater 2014, 29, 13–22. [Google Scholar] [CrossRef]

- Guo, R.; Cross, L.E.; Park, S.E.; Noheda, B.; Cox, D.E.; Shirane, G. Origin of the high piezoelectric response in PbZr 1− x Ti x O 3. Phys. Rev. Lett. 2000, 84, 5423–5426. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Xia, R.; Shrout, T.R. Lead-free piezoelectric ceramics: Alternatives for PZT? J. Electroceram. 2007, 19, 251–257. [Google Scholar] [CrossRef]

- Rödel, J.; Jo, W.; Seifert, K.T.; Anton, E.M.; Granzow, T.; Damjanovic, D. Perspective on the development of lead-free piezoceramics. J. Am. Ceram. Soc. 2009, 92, 1153–1177. [Google Scholar] [CrossRef]

- Xiao, D.Q.; Wu, J.G.; Wu, L.; Zhu, J.G.; Yu, P.; Lin, D.M.; Liao, Y.W.; Sun, Y. Investigation on the composition design and properties study of perovskite lead-free piezoelectric ceramics. J. Mater. Sci. 2009, 44, 5408–5419. [Google Scholar] [CrossRef]

- Saito, Y.; Takao, H.; Tani, T.; Nonoyama, T.; Takatori, K.; Homma, T.; Nagaya, T.; Nakamura, M. Lead-free piezoceramics. Nature 2004, 432, 84–87. [Google Scholar] [CrossRef] [PubMed]

- Liang, W.; Wu, W.; Xiao, D.; Zhu, J. Effect of the Addition of CaZrO3 and LiNbO3 on the Phase Transitions and Piezoelectric Properties of K0.5Na0.5NbO3 Lead-Free Ceramics. J. Am. Ceram. Soc. 2011, 94, 4317–4322. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, L.Y.; Bai, W.F.; Shen, B.; Zhai, J.W.; Li, B. Effect of CaZrO3 on phase structure and electrical properties of KNN-based lead-free ceramics. Rsc. Adv. 2015, 5, 19647–19651. [Google Scholar] [CrossRef]

- Zheng, T.; Wu, J.; Xiao, D.; Zhu, J.; Wang, X.; Xin, L.; Lou, X. Strong Piezoelectricity in (1 – x)(K0.4Na0.6)(Nb0.96Sb0.04)O3-xBi0.5K0.5Zr1–ySnyO3 Lead-Free Binary System: Identification and Role of Multiphase Coexistence. ACS Appl. Mater. Interfaces 2015, 7, 5927–5937. [Google Scholar] [CrossRef]

- Zhang, Y.; Shen, B.; Zhai, J.W.; Zeng, H.R. New insight on sintering progress of KNN-based lead-free ceramics. J. Am. Ceram. Soc. 2016, 99, 752–755. [Google Scholar] [CrossRef]

- Zhang, S.J.; Xia, R.; Shrout, T.R. Piezoelectric properties in perovskite 0.948(K0.5Na0.5)NbO3–0.052LiSbO3 lead-free ceramics. Appl. Phys. Lett. 2007, 91, 132913. [Google Scholar] [CrossRef]

- Yao, F.-Z.; Wang, K.; Jo, W.; Webber, K.G.; Comyn, T.P.; Ding, J.-X.; Xu, B.; Cheng, L.-Q.; Zheng, M.-P.; Hou, Y.-D.; et al. Diffused phase transition boosts thermal stability of high-performance lead-free piezoelectrics. Adv. Funct. Mater. 2016, 26, 1217–1224. [Google Scholar] [CrossRef]

- Zhang, M.-H.; Wang, K.; Du, Y.-J.; Dai, G.; Sun, W.; Li, G.; Hu, D.; Thong, H.C.; Zhao, C.; Xi, X.-Q.; et al. High and temperature-insensitive piezoelectric strain in alkali niobate lead-free perovskite. J. Am. Chem. Soc. 2017, 139, 3889–3895. [Google Scholar] [CrossRef] [PubMed]

- Tao, H.; Wu, H.; Liu, Y.; Zhang, Y.; Wu, J.; Li, F.; Lyu, X.; Zhao, C.; Xiao, D.; Zhu, J.; et al. Ultrahigh performance in lead-free piezoceramics utilizing a relaxor slush polar state with multiphase coexistence. J. Am. Chem. Soc. 2019, 141, 13987–13994. [Google Scholar] [CrossRef]

- Jia, P.; Zheng, Z.; Li, Y.; Li, Z.; Liu, T.; Wang, Y. The achieving enhanced piezoelectric performance of KNN-based ceramics: Decisive role of multi-phase coexistence induced by lattice distortion. J. Alloys Compd. 2023, 930, 167416. [Google Scholar] [CrossRef]

- Zhao, Y.; Huang, R.; Liu, R.; Wang, X.; Zhou, H. Enhanced dielectric and piezoelectric properties in Li/Sb-modified (Na, K) NbO3 ceramics by optimizing sintering temperature. Ceram. Int. 2013, 39, 425–429. [Google Scholar] [CrossRef]

- Jiten, C.; Gaur, R.; Laishram, R.; Singh, K.C. Effect of sintering temperature on the microstructural, dielectric, ferroelectric and piezoelectric properties of (Na0.5K0.5)NbO3 ceramics prepared from nanoscale powders. Ceram. Int. 2016, 42, 14135–14140. [Google Scholar] [CrossRef]

- Chen, X.-M.; Wang, M.-Y.; Tomoaki, K.; Li, G.-R. N-ion-implanted ZnO microtubes for highly-efficient UV detection. Acta Phys. Sin-Ch. Ed. 2021, 70, 197701. [Google Scholar] [CrossRef]

- Rietveld, H.M. A profile refinement method for nuclear and magnetic structures. J. Appl. Crystallogr. 1969, 2, 65–71. [Google Scholar] [CrossRef]

- Onoe, M.; Jumonji, H. Useful formulas for piezoelectric ceramic resonators and their application to measurement of parameters. J. Acoust. Soc. Am. 1967, 41, 974–980. [Google Scholar] [CrossRef]

- Shen, Z.-Y.; Zhen, Y.; Wang, K.; Li, J.-F. Influence of Sintering Temperature on Grain Growth and Phase Structure of Compositionally Optimized High-Performance Li/Ta-Modified (Na,K)NbO3 Ceramics. J. Am. Ceram. Soc. 2009, 92, 1748–1752. [Google Scholar] [CrossRef]

- Park, C.W.; Yoon, D.Y. Abnormal grain growth in alumina with anorthite liquid and the effect of MgO addition. J. Am. Ceram. Soc. 2002, 85, 1585–1593. [Google Scholar] [CrossRef]

- Kumar, A.; Kumari, S.; Kumar, V.; Kumar, A.; Goyal, P.K.; Aggarwal, S.; Arya, A.; Sharma, A.L. Answer: Role of sintering temperature in tailoring the electrical properties of 0.98KNNS–0.02BNZSH piezoelectric ceramics. J. Mater. Sci.-Mater. Electron. 2023, 34, 4–6. [Google Scholar] [CrossRef]

- Shirane, G.; Newnham, R.E.; Pepinsky, R. Dielectric Properties and Phase Transitions of NaNbO3 and (Na,K)NbO3. Phys. Rev. 1954, 96, 581. [Google Scholar] [CrossRef]

- Chen, X.; Ruan, X.; Zhao, K.; He, X.; Zeng, J.; Li, Y.; Zheng, L.; Park, C.H.; Li, G. Low sintering temperature and high piezoelectric properties of Li-doped (Ba,Ca)(Ti,Zr)O3 lead-free ceramics. J. Alloys Compd. 2015, 632, 103–109. [Google Scholar] [CrossRef]

- Uchino, K.; Nomura, S. Critical exponents of the dielectric constants in diffused-phase-transition crystals. Ferroelectrics 1982, 44, 55–61. [Google Scholar] [CrossRef]

- Lide, D.R.E. Handbook of Chemistry and Physics, 90th ed.; CRC Press: Boca Raton, FL, USA, 2009. [Google Scholar]

- Chen, X.; Li, Y.; Zeng, J.; Zheng, L.; Park, C.H.; Li, G. Phase Transition and Large Electrostrain in Lead-Free Li-Doped (Ba, Ca)(Ti, Zr)O3 Ceramics. J. Am. Ceram. Soc. 2016, 99, 2170–2174. [Google Scholar] [CrossRef]

- Xing, J.; Tan, Z.; Zheng, T.; Wu, J.; Xiao, D.; Zhu, J. Research progress of high piezoelectric activity of potassium sodium niobate based lead-free ceramics. Acta Phys. Sin. 2020, 69, 127707. [Google Scholar] [CrossRef]

| Tsin (°C) | d33 (pC/CN) | kp | εr | tanδ | Relative Density (%) |

|---|---|---|---|---|---|

| 1140 | 96 | 0.28 | 987.85 | 0.0561 | 94.88 |

| 1160 | 159 | 0.34 | 873.43 | 0.0408 | 95.52 |

| 1180 | 180 | 0.31 | 920.03 | 0.0452 | 95.18 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, X.; Ai, C.; Yang, Z.; Ni, Y.; Yin, X.; You, J.; Li, G. Mitigation of Thermal Instability for Electrical Properties in CaZrO3-Modified (Na, K, Li) NbO3 Lead-Free Piezoceramics. Materials 2023, 16, 3720. https://doi.org/10.3390/ma16103720

Chen X, Ai C, Yang Z, Ni Y, Yin X, You J, Li G. Mitigation of Thermal Instability for Electrical Properties in CaZrO3-Modified (Na, K, Li) NbO3 Lead-Free Piezoceramics. Materials. 2023; 16(10):3720. https://doi.org/10.3390/ma16103720

Chicago/Turabian StyleChen, Xiaoming, Caoyuan Ai, Zhenghuai Yang, Yuanxian Ni, Xiaodong Yin, Jiankui You, and Guorong Li. 2023. "Mitigation of Thermal Instability for Electrical Properties in CaZrO3-Modified (Na, K, Li) NbO3 Lead-Free Piezoceramics" Materials 16, no. 10: 3720. https://doi.org/10.3390/ma16103720

APA StyleChen, X., Ai, C., Yang, Z., Ni, Y., Yin, X., You, J., & Li, G. (2023). Mitigation of Thermal Instability for Electrical Properties in CaZrO3-Modified (Na, K, Li) NbO3 Lead-Free Piezoceramics. Materials, 16(10), 3720. https://doi.org/10.3390/ma16103720