Optimization of Thermal Conductivity vs. Bulk Density of Steam-Exploded Loose-Fill Annual Lignocellulosics

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Lignocellulosics

2.2. SE Treatment

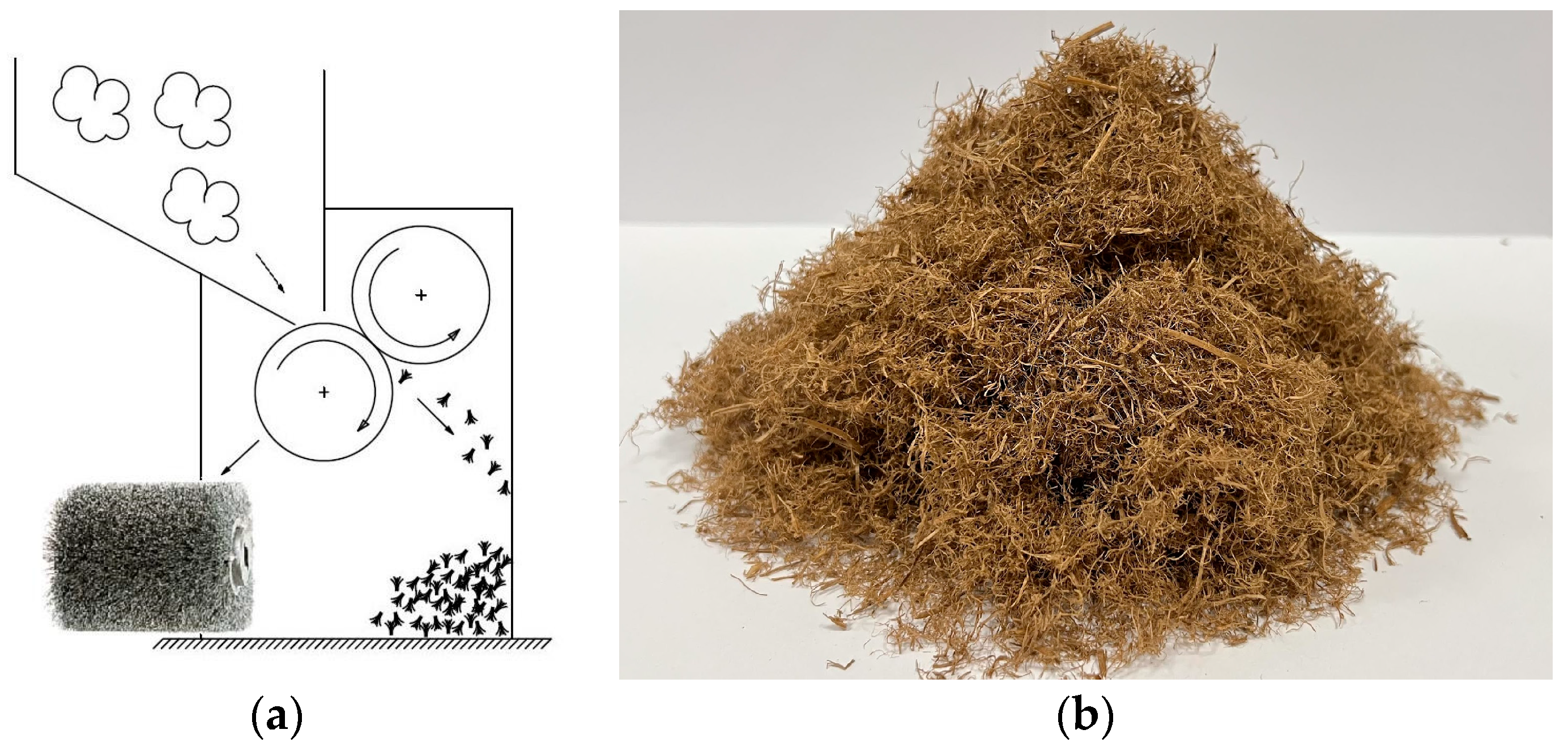

2.3. Mechanical Foaming of SE-LCB

2.4. Characterization of Raw and SE-LCB

2.4.1. Determination of Chemical Composition

2.4.2. Determination of Fourier Transform Infrared Spectra

2.4.3. Determination of Particle Size Distribution

2.4.4. Application of Light Microscopy

2.4.5. Determination of Water Retention Value

2.4.6. Determination of Bulk Density

2.4.7. Determination of Thermal Conductivity

2.5. Statistical Analysis

3. Results

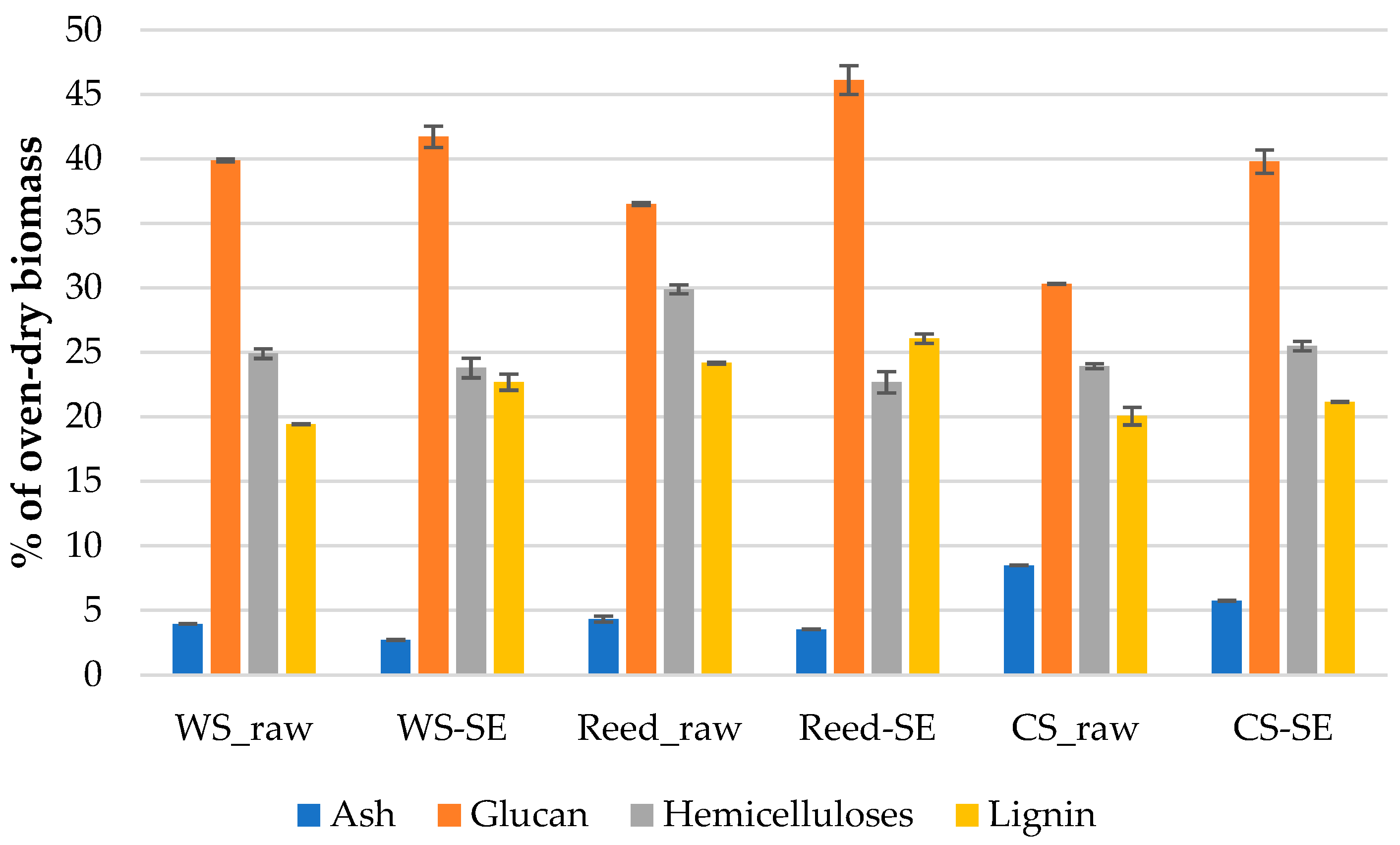

3.1. Chemical Composition and FTIR Analysis of Used LCB

3.2. Bulk Density and Particle Size Distribution

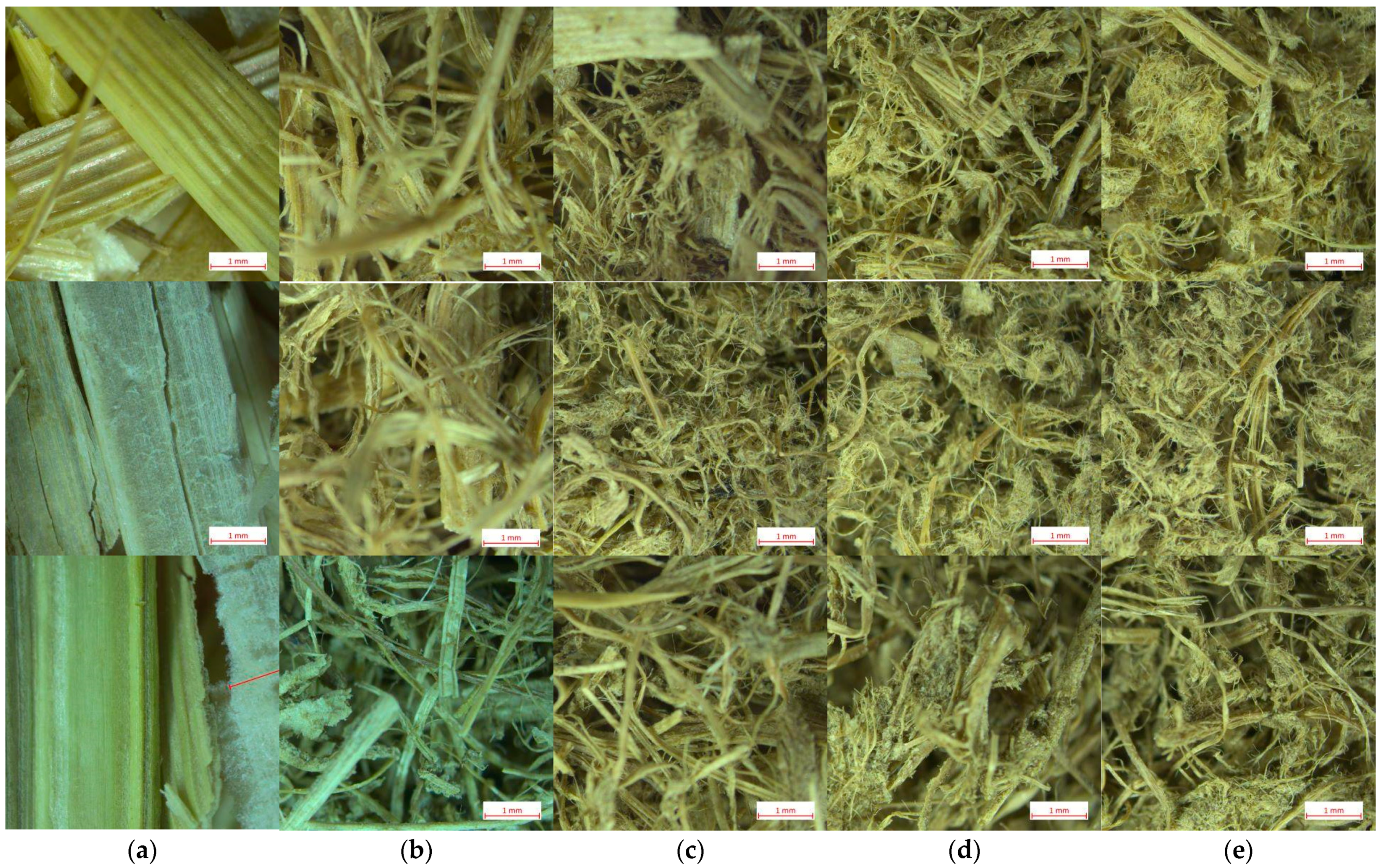

3.3. Analysis of Light Microscopy

3.4. Analysis of Water Retention Values

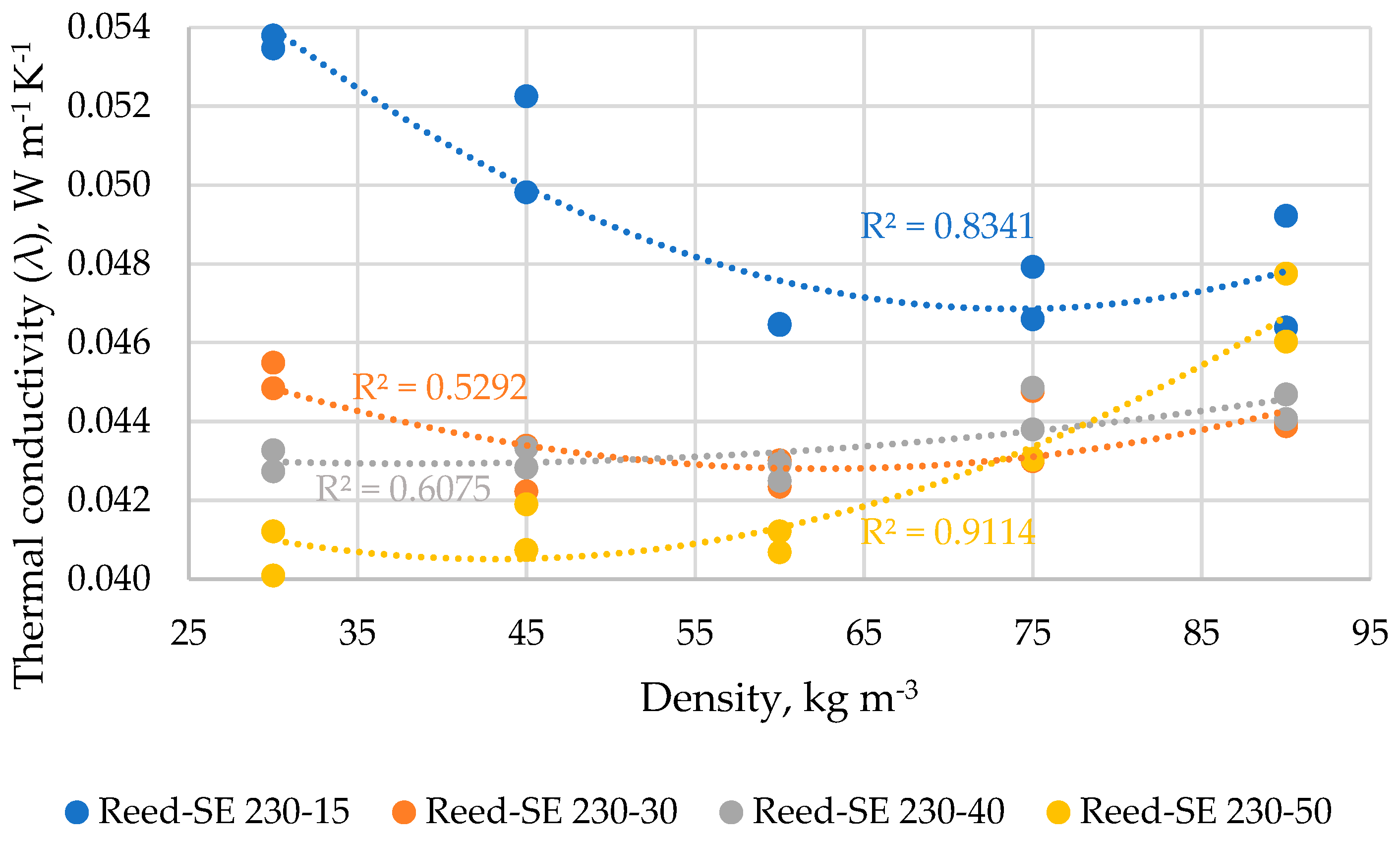

3.5. Analysis of Thermal Conductivity vs. Bulk Density

4. Discussion

5. Conclusions

- Lignocellulosic biomass of wheat straw, water reed and corn stalk treated by steam explosion under the conditions of 230 °C for 30 s and mechanically foamed by rotating wires system achieves significantly decreased bulk density (17–28 kg m−3) and contains mainly of cellulose (40–46%) that makes it suitable for thermal insulation applications.

- The lowest bulk density was attributed to the highly curled particle dimensions comprising the main fraction over 10 mm between 30% (corn) and 69% (reed).

- Water retention values of the treated biomass vary significantly (85–172%), with the lowest ones demonstrating reed samples, and have a tendency to decrease for all species with increasing SE severity that is attributed to the loss of hemicellulose.

- The relationship between detected thermal conductivity and bulk density of the samples in the range of 40–100 kg m−3 was described best (R2 53–94%) by the polynomial regression equations which approved the optimal thermal conductivity values (0.0409–0.0439 W K−1 m−1) achieved at the density between 45 kg m−3 and 60 kg m−3 for the samples treated for 50 s.

- This study suggests that the density level of investigated loose-fill lignocellulosic species not be higher than 60 kg m−3 in cases of application in the building cavities in a blow-in way.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Danish; Zhang, B.; Wang, Z.; Wang, B. Energy Production, Economic Growth and CO2 Emission: Evidence from Pakistan. Nat. Hazards 2018, 90, 27–50. [Google Scholar] [CrossRef]

- Asdrubali, F.; D’Alessandro, F.; Schiavoni, S. A Review of Unconventional Sustainable Building Insulation Materials. Sustain. Mater. Technol. 2015, 4, 1–17. [Google Scholar] [CrossRef]

- European Comission. A European Green Deal. Available online: https://ec.europa.eu/info/strategy/priorities-2019-2024/european-green-deal_en (accessed on 30 March 2023).

- Cintura, E.; Nunes, L.; Esteves, B.; Faria, P. Agro-Industrial Wastes as Building Insulation Materials: A Review and Challenges for Euro-Mediterranean Countries. Ind. Crops Prod. 2021, 171, 113833. [Google Scholar] [CrossRef]

- Zach, J.; Hroudová, J.; Brožovský, J.; Krejza, Z.; Gailius, A. Development of Thermal Insulating Materials on Natural Base for Thermal Insulation Systems. Procedia Eng. 2013, 57, 1288–1294. [Google Scholar] [CrossRef]

- Palumbo, M.; Avellaneda, J.; Lacasta, A.M. Availability of Crop By-Products in Spain: New Raw Materials for Natural Thermal Insulation. Resour. Conserv. Recycl. 2015, 99, 1–6. [Google Scholar] [CrossRef]

- Dikmen, N.; Ozkan, S.T.E. Unconventional Insulation Materials. In Insulation Materilas in Context of Sustainability; BoD–Books on Demand: Norderstedt, Germany, 2016; pp. 3–23. [Google Scholar]

- Stapulionienė, R.; Vaitkus, S.; Vėjelis, S.; Sankauskaitė, A. Investigation of Thermal Conductivity of Natural Fibres Processed by Different Mechanical Methods. Int. J. Precis. Eng. Manuf. 2016, 17, 1371–1381. [Google Scholar] [CrossRef]

- Lubke, H.; Ihnat, V.; Boruvka, V. Straw Pulp as a Secondary Lignocellulosic Raw Material and Its Impact on Properties of Insulating Fiberboards Part I. Characteristic of Straw Fibre from the Perspective of the Mass Creation. Wood Res. 2014, 59, 747–756. [Google Scholar]

- Theng, D.; El Mansouri, N.E.; Arbat, G.; Ngo, B.; Delgado-Aguilar, M.; Pèlach, M.; Fullana-i-Palmer, P.; Mutjé, P. Fiberboards Made from Corn Stalk Thermomechanical Pulp and Kraft Lignin as a Green Adhesive. BioResources 2017, 12, 2379–2393. [Google Scholar] [CrossRef]

- Köbbing, J.F.; Thevs, N.; Zerbe, S. The Utilisation of Reed (Phragmites Australis): A Review. Mires Peat 2013, 13, 1–14. [Google Scholar]

- Kokta, B.V.; Ahmed, A. Steam Explosion Pulping. In Environmentally Friendly Technologies for the Pulp and Paper Industry; Young, R.A., Akhtar, M., Eds.; John Wiley & Sons: Hoboken, NJ, USA, 1998; pp. 191–214. ISBN 0471157708. [Google Scholar]

- Asada, C.; Sholahuddin; Nakamura, Y. Biorefinery System of Lignocellulosic Biomass Using Steam Explosion. In Cellulose Science and Derivatives; IntechOpen: London, UK, 2021. [Google Scholar]

- Zhang, B.; Li, H.; Chen, L.; Fu, T.; Tang, B.; Hao, Y.; Li, J.; Li, Z.; Zhang, B.; Chen, Q.; et al. Recent Advances in the Bioconversion of Waste Straw Biomass with Steam Explosion Technique: A Comprehensive Review. Processes 2022, 10, 1959. [Google Scholar] [CrossRef]

- Kang, C.; Kolya, H.; Jang, E.; Zhu, S.; Choi, B. Steam Exploded Wood Cell Walls Reveals Improved Gas Permeability and Sound Absorption Capability. Appl. Acoust. 2021, 179, 108049. [Google Scholar] [CrossRef]

- Han, G.; Deng, J.; Zhang, S.; Bicho, P.; Wu, Q. Effect of Steam Explosion Treatment on Characteristics of Wheat Straw. Ind. Crop. Prod. 2010, 31, 28–33. [Google Scholar] [CrossRef]

- Schnabel, T.; Huber, H.; Petutschnigg, A.; Jäger, A. Analysis of Plant Materials Pre-Treated by Steam Explosion Technology for Their Usability as Insulating Materials. Agron. Res. 2019, 17, 1191–1198. [Google Scholar] [CrossRef]

- Andzs, M.; Tupciauskas, R.; Veveris, A.; Andze, L.; Abolins, J. Biomass Conversion into Blow-in Heat Insulation Materials by Steam Explosion. Holzforschung 2017, 71, 641–644. [Google Scholar] [CrossRef]

- Schritt, H.; Pleissner, D. Recycling of Organic Residues to Produce Insulation Composites: A Review. Clean. Waste Syst. 2022, 3, 100023. [Google Scholar] [CrossRef]

- Berzins, A.; Tupciauskas, R.; Andzs, M.; Pavlovichs, G. Development of Thermal Insulation Materials from Plant Fibres by Steam Explosion Pre-Treatment. In Proceedings of the 18th Annual Meeting of the Northern European Network for Wood Science and Engineering, Goettingen, Germany, 21–22 September 2022; Brischke, C., Buschalsky, A., Eds.; University of Göttingen: Göttingen, Germany, 2022; pp. 177–180. [Google Scholar]

- Berzins, A.; Tupciauskas, R.; Andzs, M.; Pavlovichs, G. Potential of Some Latvian Industrial Crops Residuals for Conversion to Bio-Based Thermal Insulation Material. Mater. Sci. Forum 2022, 1071, 139–146. [Google Scholar] [CrossRef]

- EN 14774-3; Solid Biofuels—Determination of Moisture Content—Oven Dry Method—Part 3: Moisture in General Analysis Sample. CSN Stand. European Committee: Brussels, Belgium, 2009.

- Overend, R.P.; Chornet, E.; Gascoigne, J.A. Fractionation of Lignocellulosics by Steam-Aqueous Pretreatments. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 1987, 321, 523–536. [Google Scholar] [CrossRef]

- Sluiter, A.; Hames, B.; Ruiz, R.; Scarlata, C.; Sluiter, J.; Templeton, D.; Crocker, D. Determination of Structural Carbohydrates and Lignin in Biomass; Laboratory Analytical Procedure NREL/TP-510-42618; National Renewable Energy Laboratory: Golden, CO, USA, 2012. [Google Scholar]

- Sluiter, A.; Hames, B.; Ruiz, R.; Scarlata, C.; Sluiter, J.; Templeton, D. Determination of Ash in Biomass; Laboratory Analytical Procedure NREL/TP-510-42622; National Renewable Energy Laboratory: Golden, CO, USA, 2008. [Google Scholar]

- EN 15149-1; Solid Biofuels—Determination of Particle Size Distribution—Part 1: Oscillating Screen Method Using Sieve Apertures of 1 Mm and Above. European Committee: Brussels, Belgium, 2010; pp. 1–13.

- SCAN-C 62:00; Water Retention Value. Secretariat, Scandinavian Pulp, Paper and Board Testing Committee: Stockholm, Sweden, 2000; pp. 1–5.

- EN 15103; Solid Biofuels—Determination of Bulk Density. European Committee: Brussels, Belgium, 2009; pp. 1–12.

- ISO-8301; Thermal Insulation—Determination of Steady-State Thermal Resistance and Related Properties—Heat Flow Meter Apparatus. ISO: Geneva, Switzerland, 2010.

- Rasmussen, T.V. Density of Loose-Fill Insulation Material Exposed to Cyclic Humidity Conditions; Danish Building Research Institute: Hørsholm, Denmark, 2005; p. 38. [Google Scholar]

- Montgomery, D.C. Design and Analysis of Experiments, 9th ed.; John Wiley & Sons: Hoboken, NJ, USA, 2017; ISBN 9781119113478. [Google Scholar]

- Lizasoain, J.; Rincón, M.; Theuretzbacher, F.; Enguídanos, R.; Nielsen, P.J.; Potthast, A.; Zweckmair, T.; Gronauer, A.; Bauer, A. Biogas Production from Reed Biomass: Effect of Pretreatment Using Different Steam Explosion Conditions. Biomass Bioenergy 2016, 95, 84–91. [Google Scholar] [CrossRef]

- Bellamy, L.J. The Infrared Spectra of Complex Molecules, Volume 2: Advances in Infrared Group Frequencies, 2nd ed.; Chapman and Hall: London, UK, 1980; ISBN 978-94-011-6520-4. [Google Scholar]

- Faix, O. Fourier Transform Infrared Spectroscopy. In Springer Series in Wood Science. Methods in Lignin Chemistry; Lin, S.Y., Dence, C.W., Eds.; Springer: Berlin/Heidelberg, Germany, 1992; pp. 233–241. [Google Scholar]

- Jakobsons, J.; Hortling, B.; Erins, P.; Sundquist, J. Characterization of Alkali Soluble Fraction of Steam Exploded Birch Wood. Holzforschung 1995, 49, 51–59. [Google Scholar] [CrossRef]

- Cui, L.; Liu, Z.; Si, C.; Hui, L.; Kang, N.; Zhao, T. Influence of Steam Explosion Pretreatment on the Composition and Structure of Wheat Straw. BioResources 2012, 7, 4202–4213. [Google Scholar] [CrossRef]

- Vitrone, F.; Ramos, D.; Vitagliano, V.; Ferrando, F.; Salvad, J. All-Lignocellulosic Fiberboards from Giant Reed (Arundo donax L.): Effect of Steam Explosion Pre-Treatment on Physical and Mechanical Properties. Constr. Build. Mater. 2022, 319, 126064. [Google Scholar] [CrossRef]

- Vitrone, F.; Ramos, D.; Ferrando, F.; Salvad, J. Binderless Fiberboards for Sustainable Construction. Materials, Production Methods and Applications. J. Build. Eng. 2021, 44, 102625. [Google Scholar] [CrossRef]

- Tupciauskas, R.; Rizhikovs, J.; Brazdausks, P.; Fridrihsone, V.; Andzs, M. Influence of Steam Explosion Pre-Treatment Conditions on Binder-Less Boards from Hemp Shives and Wheat Straw. Ind. Crop. Prod. 2021, 170, 8. [Google Scholar] [CrossRef]

- Robertson, G.; Olson, J.; Allen, P.; Chan, B.E.N.; Seth, R. Measurement of Fiber Length, Coarseness, and Shape with the Fiber Quality Analyzer. Tappi J. 1999, 82, 93–98. [Google Scholar]

- Cheng, Q.; Wang, J.; McNeel, J.F.; Jacobson, P.M. Water Retention Value Measurements of Cellulosic Materials Using a Centrifuge Technique. Bioresourses 2010, 5, 1945–1954. [Google Scholar]

| Sample | Time, s | logR0 |

|---|---|---|

| LCB 1-SE-230 2/15 | 15 | 3.23 |

| LCB-SE-230/30 | 30 | 3.53 |

| LCB-SE-230/40 | 40 | 3.65 |

| LCB-SE-230/50 | 50 | 3.75 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tupciauskas, R.; Berzins, A.; Pavlovics, G.; Bikovens, O.; Filipova, I.; Andze, L.; Andzs, M. Optimization of Thermal Conductivity vs. Bulk Density of Steam-Exploded Loose-Fill Annual Lignocellulosics. Materials 2023, 16, 3654. https://doi.org/10.3390/ma16103654

Tupciauskas R, Berzins A, Pavlovics G, Bikovens O, Filipova I, Andze L, Andzs M. Optimization of Thermal Conductivity vs. Bulk Density of Steam-Exploded Loose-Fill Annual Lignocellulosics. Materials. 2023; 16(10):3654. https://doi.org/10.3390/ma16103654

Chicago/Turabian StyleTupciauskas, Ramunas, Andris Berzins, Gunars Pavlovics, Oskars Bikovens, Inese Filipova, Laura Andze, and Martins Andzs. 2023. "Optimization of Thermal Conductivity vs. Bulk Density of Steam-Exploded Loose-Fill Annual Lignocellulosics" Materials 16, no. 10: 3654. https://doi.org/10.3390/ma16103654

APA StyleTupciauskas, R., Berzins, A., Pavlovics, G., Bikovens, O., Filipova, I., Andze, L., & Andzs, M. (2023). Optimization of Thermal Conductivity vs. Bulk Density of Steam-Exploded Loose-Fill Annual Lignocellulosics. Materials, 16(10), 3654. https://doi.org/10.3390/ma16103654