3D Surface Scanning—A Novel Protocol to Characterize Virtual Nickel–Titanium Endodontic Instruments

Abstract

1. Introduction

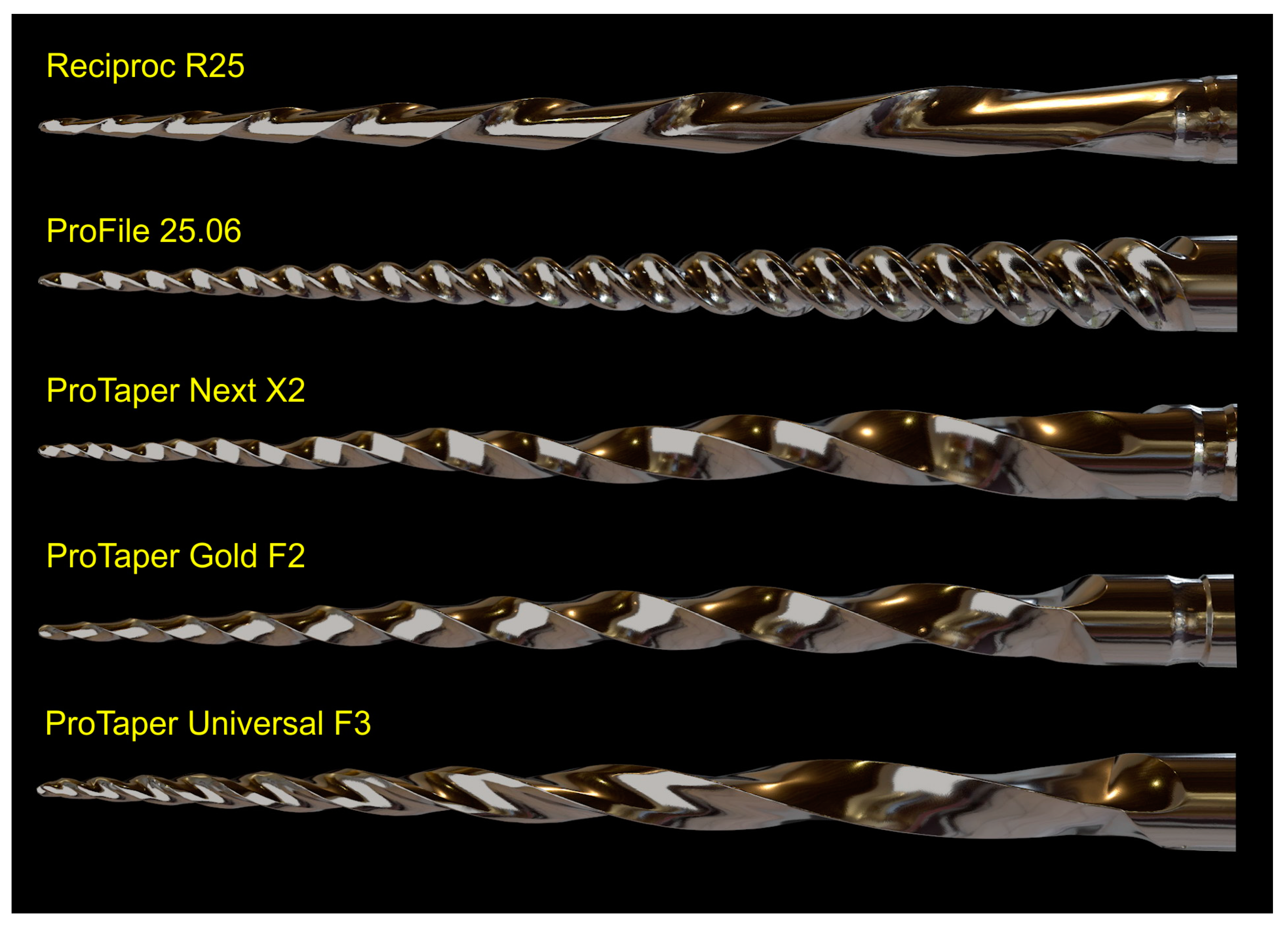

2. Materials and Methods

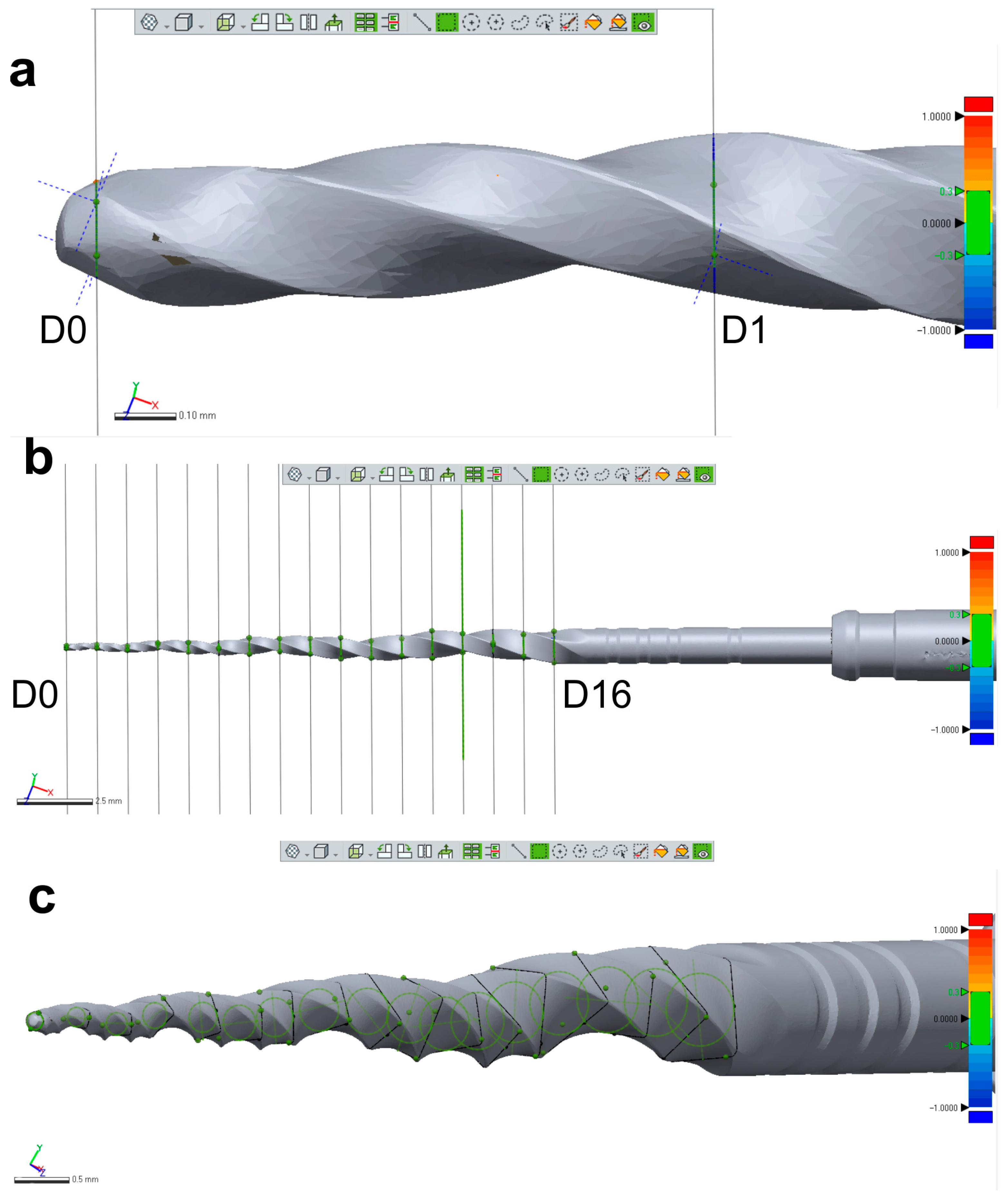

2.1. 3D Surface Scanning Procedure

2.2. Qualitative and Quantitative Validations

2.3. Reproducibility of Measurements

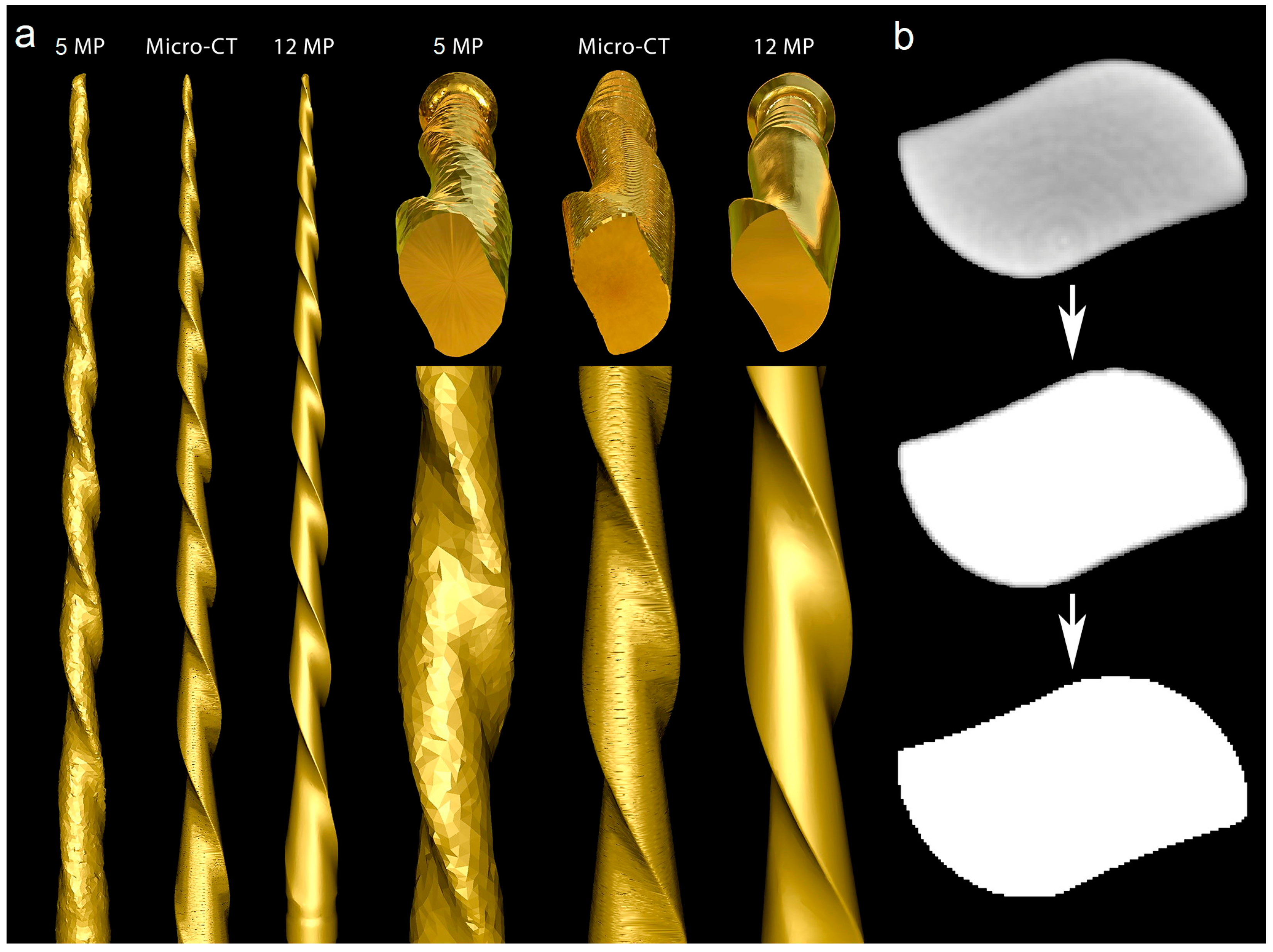

2.4. Optical Scanners vs. Micro-CT

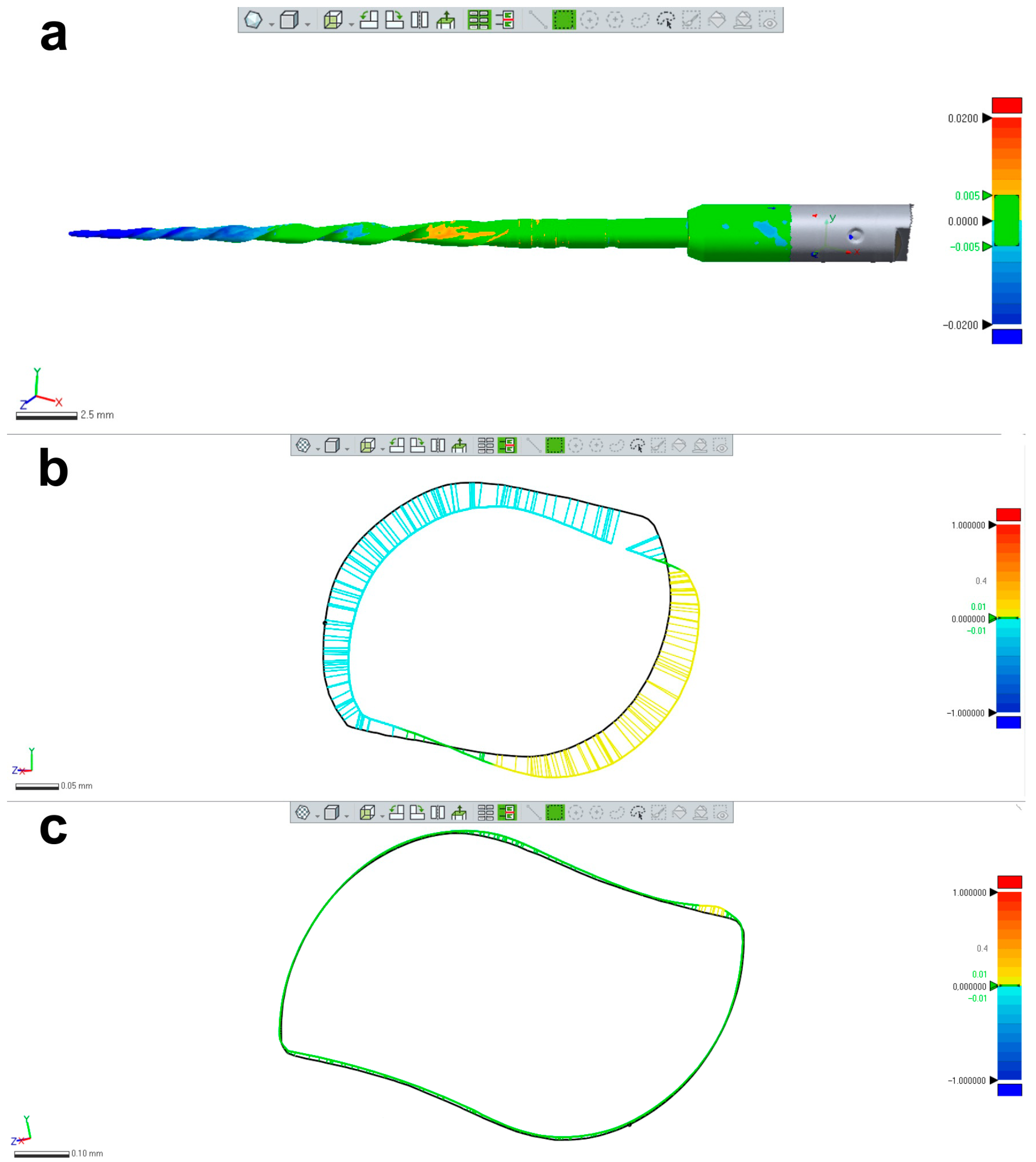

2.5. Research Application: Changes in the Instrument’s Morphology

2.6. Research Application: Finite Elements Analysis (FEA)

2.7. Other Applications: 3D Models for Commercial or Teaching Purposes

3. Results

3.1. Qualitative and Quantitative Validations

3.2. Reproducibility of Measurements

3.3. Optical Scanners vs. Micro-CT

3.4. Applications

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ordinola-Zapata, R.; Peters, O.A.; Nagendrababu, V.; Azevedo, B.; Dummer, P.M.H.; Neelakantan, P. What is of interest in Endodontology? A bibliometric review of research published in the International Endodontic Journal and the Journal of Endodontics from 1980 to 2019. Int. Endod. J. 2020, 53, 36–52. [Google Scholar] [CrossRef]

- Pedullà, E.; Grande, N.M.; Plotino, G.; Pappalardo, A.; Rapisarda, E. Cyclic fatigue resistance of three different nickel-titanium instruments after immersion in sodium hypochlorite. J. Endod. 2011, 37, 1139–1142. [Google Scholar] [CrossRef] [PubMed]

- Schäfer, E.; Bürklein, S.; Donnermeyer, D. A critical analysis of research methods and experimental models to study the physical properties of NiTi instruments and their fracture characteristics. Int. Endod. J. 2022, 55 (Suppl. 1), 72–94. [Google Scholar] [CrossRef] [PubMed]

- Hülsmann, M. A critical appraisal of research methods and experimental models for studies on root canal preparation. Int. Endod. J. 2022, 55 (Suppl. 1), 95–118. [Google Scholar] [CrossRef] [PubMed]

- Pedullà, E.; La Paglia, P.; La Rosa, G.R.M.; Gueli, A.M.; Pasquale, S.; Jaramillo, D.E.; Rapisarda, E. Cutting efficiency of heat-treated nickel-titanium single-file systems at different incidence angles. Aust. Endod. J. 2021, 47, 20–26. [Google Scholar] [CrossRef]

- Lopes, H.P.; Elias, C.N.; Vieira, M.V.; Vieira, V.T.; de Souza, L.C.; Dos Santos, A.L. Influence of surface roughness on the fatigue life of nickel-titanium rotary endodontic instruments. J. Endod. 2016, 42, 965–968. [Google Scholar] [CrossRef]

- Colaco, A.S.; Pai, V.A. Comparative evaluation of the efficiency of manual and rotary gutta-percha removal techniques. J. Endod. 2015, 41, 1871–1874. [Google Scholar] [CrossRef]

- Barbosa, F.O.; Gomes, J.A.; de Araujo, M.C. Fractographic analysis of K3 nickel-titanium rotary instruments submitted to different modes of mechanical loading. J. Endod. 2008, 34, 994–998. [Google Scholar] [CrossRef]

- Plotino, G.; Grande, N.M.; Porciani, P.F. Deformation and fracture incidence of Reciproc instruments: A clinical evaluation. Int. Endod. J. 2015, 48, 199–205. [Google Scholar] [CrossRef]

- McSpadden, J.T. Mastering instrument designs. In Mastering Endodontics Instrumentation; McSpadden, J.T., Ed.; Cloudland Institute: Chattanooga, TN, USA, 2007; pp. 37–97. [Google Scholar]

- Faus-Llacer, V.; Hamoud-Kharrat, N.; Marhuenda Ramos, M.T.; Faus-Matoses, I.; Zubizarreta-Macho, A.; Ruiz Sanchez, C.; Faus-Matoses, V. Influence of the geometrical cross-section design on the dynamic cyclic fatigue resistance of NiTi endodontic rotary files-an in vitro study. J. Clin. Med. 2021, 10, 4713. [Google Scholar] [CrossRef]

- Faus-Matoses, V.; Faus-Llacer, V.; Aldeguer Munoz, A.; Alonso Perez-Barquero, J.; Faus-Matoses, I.; Ruiz-Sanchez, C.; Zubizarreta-Macho, A. A novel digital technique to analyze the wear of CM-Wire NiTi alloy endodontic reciprocating files: An in vitro study. Int. J. Environ. Res. Public. Health 2022, 19, 3203. [Google Scholar] [CrossRef] [PubMed]

- Faus-Matoses, V.; Perez Garcia, R.; Faus-Llacer, V.; Faus-Matoses, I.; Alonso Ezpeleta, O.; Albaladejo Martinez, A.; Zubizarreta-Macho, A. Comparative study of the SEM evaluation, EDX assessment, morphometric analysis, and cyclic fatigue resistance of three novel brands of NiTi alloy endodontic files. Int. J. Environ. Res. Public. Health 2022, 19, 4414. [Google Scholar] [CrossRef] [PubMed]

- Beer, F.; Johnston, E.; DeWolf, J.; Mazurek, D. Torsion. In Mechanics of Materials, 8th ed.; Beer, F., Johnston, E., DeWolf, J., Mazurek, D., Eds.; McGraw-Hill Education: Singapore, 2020. [Google Scholar]

- Rekow, E.D. Digital dentistry: The new state of the art-Is it disruptive or destructive? Dent. Mater. 2020, 36, 9–24. [Google Scholar] [CrossRef] [PubMed]

- Gagliardi, J.; Versiani, M.A.; de Sousa-Neto, M.D.; Plazas-Garzon, A.; Basrani, B. Evaluation of the shaping characteristics of ProTaper Gold, ProTaper NEXT, and ProTaper Universal in curved canals. J. Endod. 2015, 41, 1718–1724. [Google Scholar] [CrossRef] [PubMed]

- Boutsioukis, C.; Kastrinakis, E.; Lambrianidis, T.; Verhaagen, B.; Versluis, M.; van der Sluis, L.W. Formation and removal of apical vapor lock during syringe irrigation: A combined experimental and Computational Fluid Dynamics approach. Int. Endod. J. 2014, 47, 191–201. [Google Scholar] [CrossRef]

- Bonessio, N.; Pereira, E.S.; Lomiento, G.; Arias, A.; Bahia, M.G.; Buono, V.T.; Peters, O.A. Validated finite element analyses of WaveOne Endodontic Instruments: A comparison between M-Wire and NiTi alloys. Int. Endod. J. 2015, 48, 441–450. [Google Scholar] [CrossRef]

- Farber, C.M.; Lemos, M.; Said Yekta-Michael, S. Effect of an endodontic e-learning application on students’ performance during their first root canal treatment on real patients: A pilot study. BMC Med. Educ. 2022, 22, 394. [Google Scholar] [CrossRef]

- Piedra-Cascon, W.; Methani, M.M.; Quesada-Olmo, N.; Jimenez-Martinez, M.J.; Revilla-Leon, M. Scanning accuracy of nondental structured light extraoral scanners compared with that of a dental-specific scanner. J. Prosthet. Dent. 2021, 126, 110–114. [Google Scholar] [CrossRef]

- Gom. ATOS Capsule: Optical Precision Measuring Machine; Gom GmbH: Braunschweig, Germany, 2017; pp. 1–16. [Google Scholar]

- McSpadden, J.T. Mastering the concepts. In Mastering Endodontics Instrumentation; McSpadden, J.T., Ed.; Cloudland Institute: Chattanooga, TN, USA, 2007; pp. 7–36. [Google Scholar]

- Sampaio-Fernandes, M.A.; Pinto, R.; Sampaio-Fernandes, M.M.; Sampaio-Fernandes, J.C.; Marques, D.; Figueiral, H. Accuracy of silicone impressions and stone models using two laboratory scanners: A 3D evaluation. Int. J. Prosthodont. 2022; online ahead of print. [Google Scholar] [CrossRef]

- Jeon, J.H.; Choi, B.Y.; Kim, C.M.; Kim, J.H.; Kim, H.Y.; Kim, W.C. Three-dimensional evaluation of the repeatability of scanned conventional impressions of prepared teeth generated with white- and blue-light scanners. J. Prosthet. Dent. 2015, 114, 549–553. [Google Scholar] [CrossRef]

- Orhan, K. Micro-Computed Tomography (Micro-CT) in Medicine and Engineering, 1st ed.; Springer Nature: Cham, Switzerland, 2020. [Google Scholar]

- Barrett, J.F.; Keat, N. Artifacts in CT: Recognition and avoidance. Radiographics 2004, 24, 1679–1691. [Google Scholar] [CrossRef]

- Necchi, S.; Petrini, L.; Taschieri, S.; Migliavacca, F. A comparative computational analysis of the mechanical behavior of two nickel-titanium rotary endodontic instruments. J. Endod. 2010, 36, 1380–1384. [Google Scholar] [CrossRef]

- Montalvao, D.; Alcada, F.S. Numeric comparison of the static mechanical behavior between ProFile GT and ProFile GT series X rotary nickel-titanium files. J. Endod. 2011, 37, 1158–1161. [Google Scholar] [CrossRef] [PubMed]

- Brotzu, A.; Felli, F.; Lupi, C.; Vendittozzi, C.; Fantini, E. Fatigue behaviour of lubricated NiTi endodontic rotary instruments. Frat. Integrità Strutt. 2014, 28, 19–31. [Google Scholar] [CrossRef]

- Chevalier, V.; Arbab-Chirani, R.; Arbab-Chirani, S.; Calloch, S. An improved model of 3-dimensional finite element analysis of mechanical behavior of endodontic instruments. Oral Surg. Oral Med. Oral Pathol. Oral Radiol. Endod. 2010, 109, e111–e121. [Google Scholar] [CrossRef] [PubMed]

- Versiani, M.A.; Leoni, G.B.; Steier, L.; De-Deus, G.; Tassani, S.; Pécora, J.D.; de Sousa-Neto, M.D. Micro-computed tomography study of oval-shaped canals prepared with the self-adjusting file, Reciproc, WaveOne, and ProTaper universal systems. J. Endod. 2013, 39, 1060. [Google Scholar] [CrossRef] [PubMed]

- Santos, A.; Resende, P.D.; Bahia, M.G.; Buono, V.T. Effects of R-phase on mechanical responses of a nickel-titanium endodontic instrument: Structural characterization and finite element analysis. Sci. World J. 2016, 2016, 7617493. [Google Scholar] [CrossRef] [PubMed]

| Levels | Reciproc R25 | ProFile Size 25, Taper 0.06 | ProTaper Next X2 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Perimeter | Area | Long Axis | Core | Perimeter | Area | Long Axis | Core | Perimeter | Area | Long Axis | Core | |

| Measurement assessment (average results after 2 evaluations) | ||||||||||||

| D0 | 0.6367 | 0.0306 | 0.2236 | 0.1706 | 0.6835 | 0.0294 | 0.2262 | 0.1548 | 0.5733 | 0.0254 | 0.2323 | 0.1633 |

| D1 | 0.9107 | 0.0621 | 0.3209 | 0.2350 | 0.8681 | 0.0475 | 0.2819 | 0.1922 | 0.7654 | 0.0388 | 0.2638 | 0.1766 |

| D2 | 1.1714 | 0.1031 | 0.4167 | 0.3087 | 1.0226 | 0.0658 | 0.3292 | 0.2259 | 0.9116 | 0.0564 | 0.2992 | 0.2047 |

| D3 | 1.3553 | 0.1328 | 0.4943 | 0.3282 | 1.2056 | 0.0901 | 0.3893 | 0.2635 | 1.0722 | 0.0757 | 0.3566 | 0.2350 |

| D4 | 1.4951 | 0.1625 | 0.5307 | 0.3612 | 1.3686 | 0.1133 | 0.4499 | 0.2894 | 1.2156 | 0.0987 | 0.4321 | 0.2727 |

| D5 | 1.6439 | 0.1955 | 0.5925 | 0.4041 | 1.5287 | 0.1402 | 0.5006 | 0.3228 | 1.4141 | 0.1321 | 0.4926 | 0.3154 |

| D6 | 1.7946 | 0.2292 | 0.6529 | 0.4197 | 1.6940 | 0.1710 | 0.5594 | 0.3562 | 1.5791 | 0.1631 | 0.5476 | 0.3522 |

| D7 | 1.9273 | 0.2593 | 0.7231 | 0.4443 | 1.8697 | 0.2028 | 0.6117 | 0.3848 | 1.7345 | 0.1959 | 0.6089 | 0.3807 |

| D8 | 2.0304 | 0.2878 | 0.7435 | 0.4638 | 2.0353 | 0.2407 | 0.6656 | 0.4177 | 1.8997 | 0.2335 | 0.6719 | 0.4158 |

| D9 | 2.1249 | 0.3088 | 0.8031 | 0.4689 | 2.2079 | 0.2784 | 0.7126 | 0.4461 | 2.0626 | 0.2736 | 0.7359 | 0.4485 |

| D10 | 2.2118 | 0.3304 | 0.8438 | 0.4775 | 2.3800 | 0.3208 | 0.7785 | 0.4764 | 2.2257 | 0.3174 | 0.7687 | 0.4809 |

| D11 | 2.2770 | 0.3450 | 0.8697 | 0.4814 | 2.5555 | 0.3694 | 0.8394 | 0.5088 | 2.3857 | 0.3650 | 0.8458 | 0.5164 |

| D12 | 2.3388 | 0.3584 | 0.9118 | 0.4815 | 2.7120 | 0.4158 | 0.8807 | 0.5381 | 2.5406 | 0.4124 | 0.9001 | 0.5483 |

| D13 | 2.3898 | 0.3701 | 0.9454 | 0.4824 | 2.8849 | 0.4699 | 0.9334 | 0.5690 | 2.6602 | 0.4509 | 0.9516 | 0.5713 |

| D14 | 2.4380 | 0.3811 | 0.9647 | 0.4836 | 3.0431 | 0.5201 | 0.9901 | 0.5971 | 2.7733 | 0.4870 | 0.9864 | 0.5932 |

| D15 | 2.4881 | 0.3916 | 0.9995 | 0.4838 | 3.1878 | 0.5775 | 1.0317 | 0.6362 | 2.8482 | 0.5142 | 1.0130 | 0.6156 |

| D16 | 2.7687 | 0.5421 | 1.0935 | 0.6669 | 3.3550 | 0.6341 | 1.0866 | 0.6382 | 3.0443 | 0.6013 | 1.0576 | 0.6714 |

| Standard deviation (after performing 10 measurements of each parameter) | ||||||||||||

| D1 | 0.0044 | 0.0019 | 0.0038 | 0.0003 | 0.0112 | 0.0006 | 0.0062 | 0.0004 | 0.0059 | 0.0028 | 0.0047 | 0.0007 |

| D8 | 0.0020 | 0.0187 | 0.0191 | 0.0003 | 0.0036 | 0.0015 | 0.0049 | 0.0007 | 0.0023 | 0.0006 | 0.0041 | 0.0002 |

| D16 | 0.0092 | 0.0044 | 0.0063 | 0.0021 | 0.0087 | 0.0007 | 0.0228 | 0.0013 | 0.0156 | 0.0078 | 0.0133 | 0.0029 |

| Interclass correlation coefficient (comparing results after 2 evaluations) | ||||||||||||

| 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 1.000 | 0.999 | 0.999 | 0.999 | |

| Levels | Reciproc R25 | ProFile Size 25, Taper 0.06 | ProTaper Next X2 | |||

|---|---|---|---|---|---|---|

| Volume | Surface Area | Volume | Surface Area | Volume | Surface Area | |

| Measurement assessment (average results after 2 evaluations) | ||||||

| D0 to D16 | 4.178 | 30.635 | 4.351 | 36.446 | 4.055 | 30.263 |

| Standard deviation (after performing 10 measurements of each parameter) | ||||||

| D0 to D16 | 0.0113 | 0.0576 | 0.0226 | 0.1446 | 0.0244 | 0.3098 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Martins, J.N.R.; Pinto, R.; Silva, E.J.N.L.; Simões-Carvalho, M.; Marques, D.; Martins, R.F.; Versiani, M.A. 3D Surface Scanning—A Novel Protocol to Characterize Virtual Nickel–Titanium Endodontic Instruments. Materials 2023, 16, 3636. https://doi.org/10.3390/ma16103636

Martins JNR, Pinto R, Silva EJNL, Simões-Carvalho M, Marques D, Martins RF, Versiani MA. 3D Surface Scanning—A Novel Protocol to Characterize Virtual Nickel–Titanium Endodontic Instruments. Materials. 2023; 16(10):3636. https://doi.org/10.3390/ma16103636

Chicago/Turabian StyleMartins, Jorge N. R., Ricardo Pinto, Emmanuel J. N. L. Silva, Marco Simões-Carvalho, Duarte Marques, Rui F. Martins, and Marco A. Versiani. 2023. "3D Surface Scanning—A Novel Protocol to Characterize Virtual Nickel–Titanium Endodontic Instruments" Materials 16, no. 10: 3636. https://doi.org/10.3390/ma16103636

APA StyleMartins, J. N. R., Pinto, R., Silva, E. J. N. L., Simões-Carvalho, M., Marques, D., Martins, R. F., & Versiani, M. A. (2023). 3D Surface Scanning—A Novel Protocol to Characterize Virtual Nickel–Titanium Endodontic Instruments. Materials, 16(10), 3636. https://doi.org/10.3390/ma16103636