Thermal Behavior Changes of As-Received and Retrieved Bio-Active® (BA) and TriTanium® (TR) Multiforce Nickel–Titanium Orthodontic Archwires

Abstract

1. Introduction

2. Materials and Methods

2.1. Ethics Statement

2.2. Materials

Selection of the Investigated Archwires

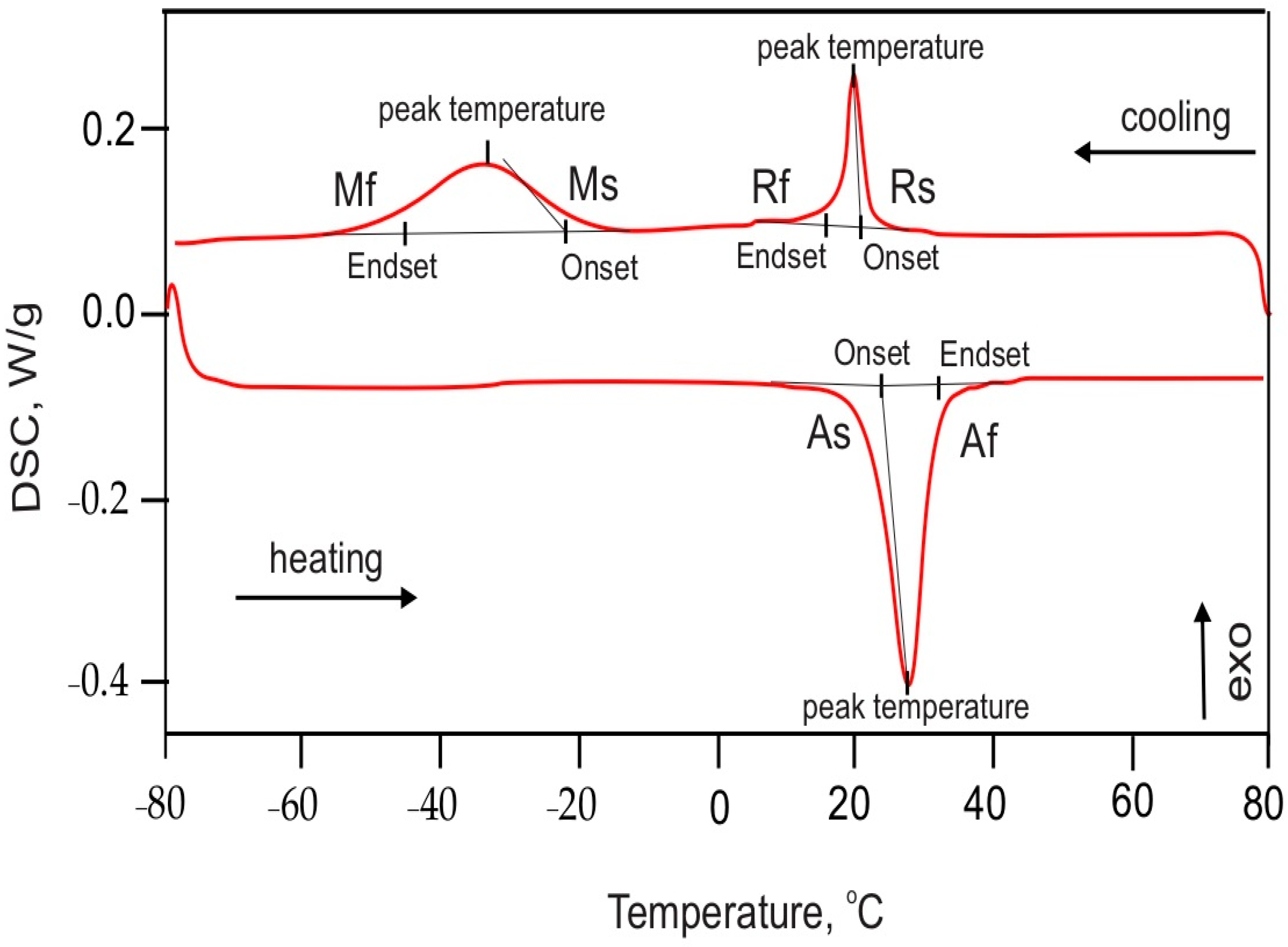

2.3. Methods

2.3.1. Disinfection Protocol

2.3.2. Differential Scanning Calorimetry

2.3.3. Statistical Analysis

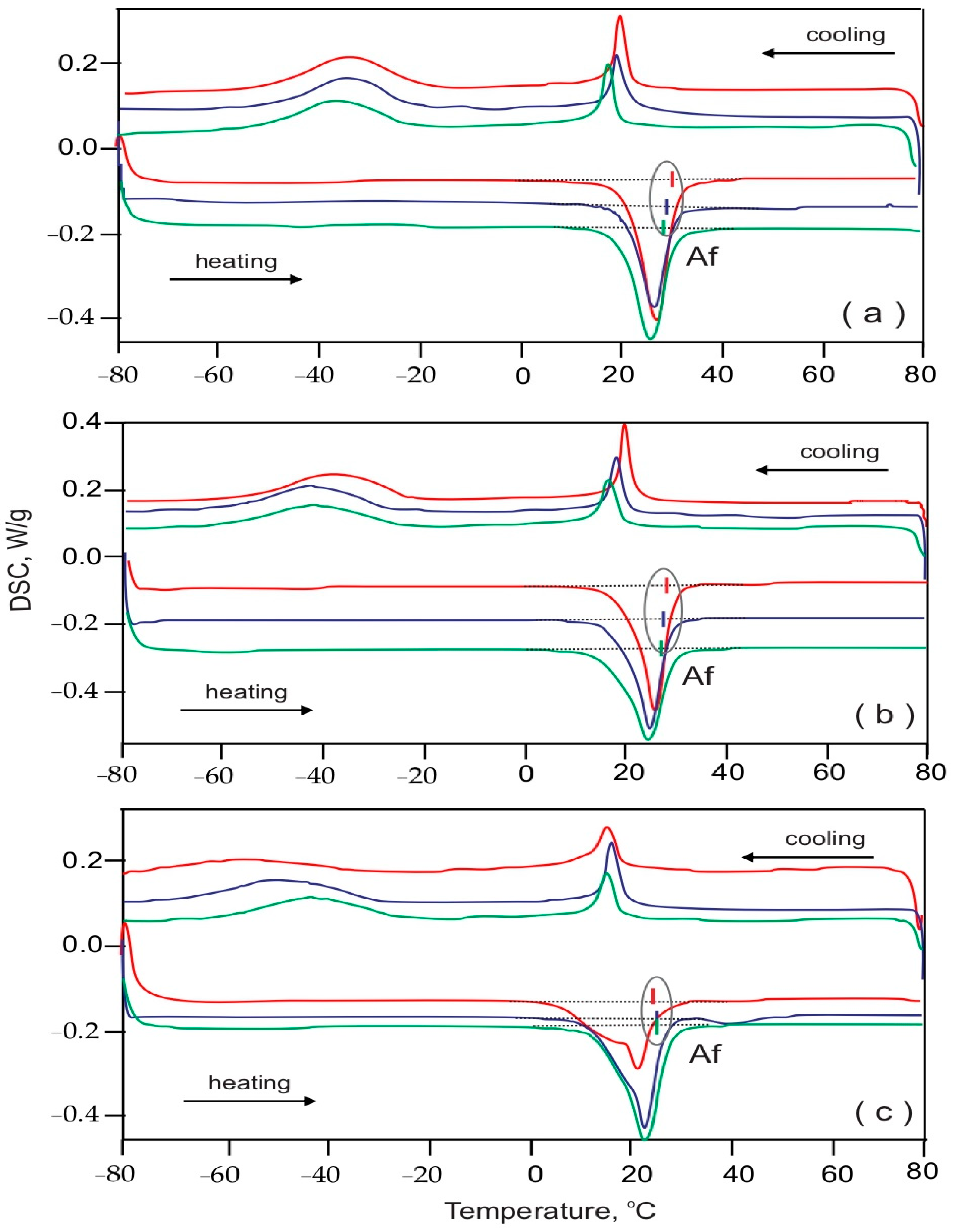

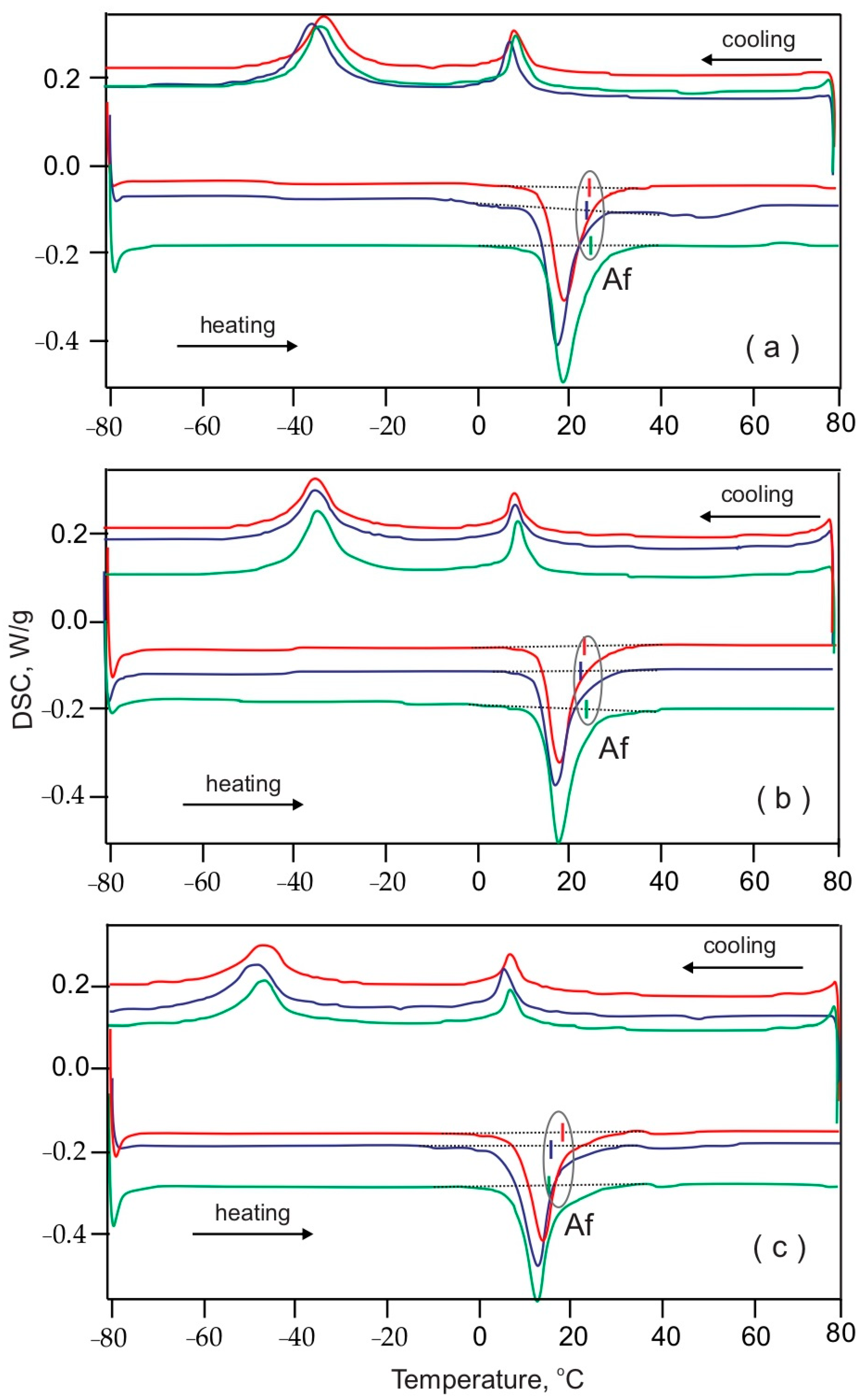

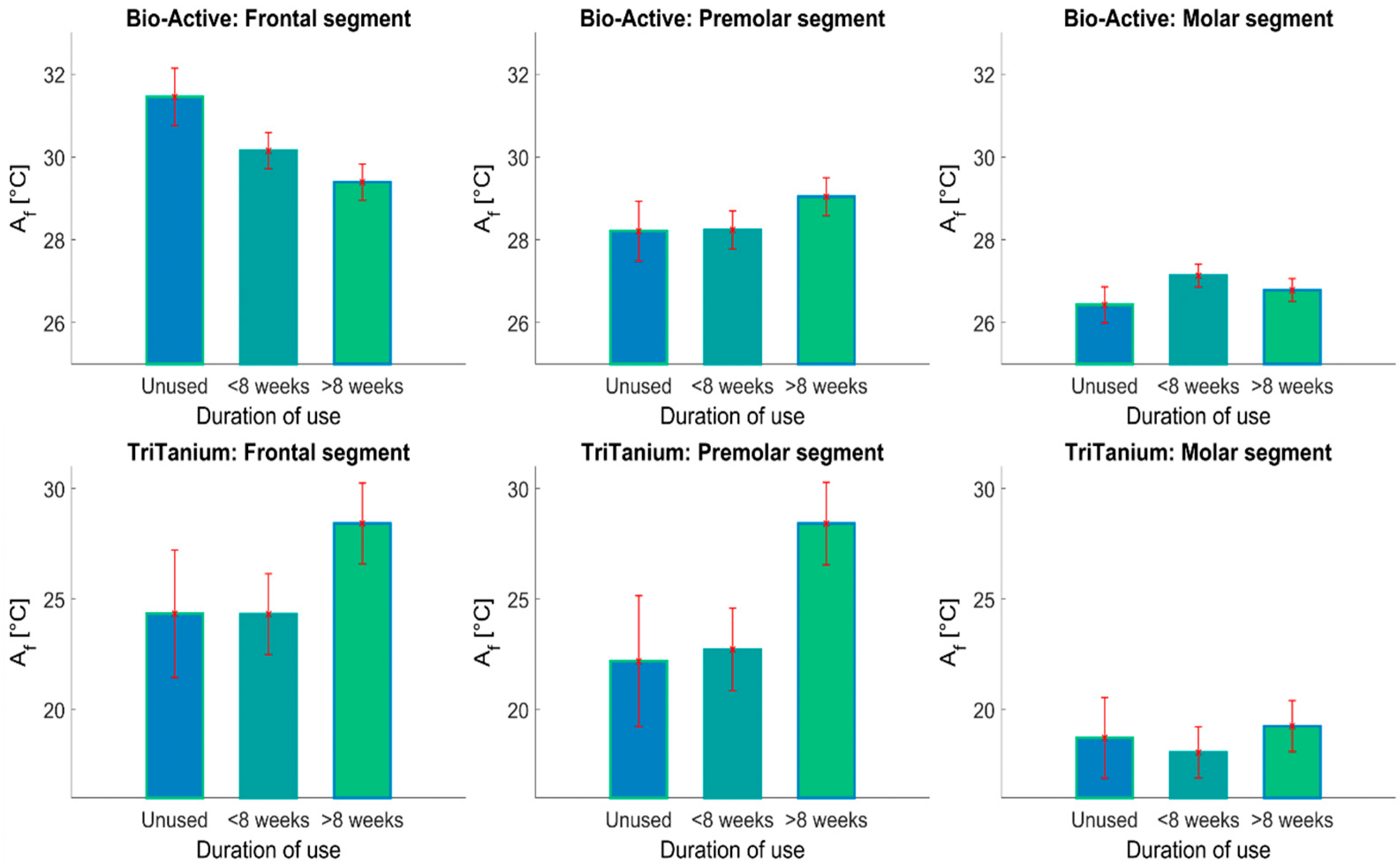

3. Results

4. Discussion

5. Conclusions

- -

- Bio-Active® archwires can be classified into the group of martensite-active wires (heat-activated) due to the fact that the manufacturers set the Af to be above room temperature and close to the temperature of the oral cavity.

- -

- The Af temperatures of TriTanium® archwires, classified as austenite-active (superelastic) archwires, are set quite below the temperature of the oral cavity. This means that at room temperature, before engaging the archwires into the bracket slot, they are already in the austenitic phase.

- -

- The investigated as-received Bio-Active® and TriTanium® orthodontic archwires had different Af temperatures in the three segments. The frontal segments possess the highest Af, followed by the premolar segments. The lowest Af temperatures were reported for the molar segments.

- -

- In general, the Af was lower in all the segments in the TriTanium® archwires when compared to the Bio-Active® archwires, both the unused ones as well as the ones used up to and over 8 weeks.

- -

- The thermal behavior does not change after clinical exposure.

- -

- Bio-Active® and TriTanium® archwires with dimensions of 0.016 × 0.022 inches can be used as first leveling archwires by additional cooling and are not recommended for use on patients with mouth breathing.

- -

- The thermal properties of the studied thermodynamic multiforce archwires depend on external factors, such as the environmental temperature, sleeping and/or staying with the mouth open and eating and/or drinking cold foods and beverages.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Meyers, M.A.; Chen, P.-Y.; Lopez, M.I.; Seki, Y.; Lin, A.Y. Biological materials: A materials science approach. J. Mech. Behav. Biomed. Mater. 2011, 4, 626–657. [Google Scholar] [CrossRef] [PubMed]

- Wever, D.; Veldhuizen, A.; De Vries, J.; Busscher, H.; Uges, D.; Van Horn, J. Electrochemical and surface characterization of a nickel–titanium alloy. Biomaterials 1998, 19, 761–769. [Google Scholar] [CrossRef] [PubMed]

- Trépanier, C.; Tabrizian, M.; Yahia, L.; Bilodeau, L.; Piron, D.L. Effect of modification of oxide layer on NiTi stent corrosion resistance. J. Biomed. Mater. Res. 1998, 43, 433–440. [Google Scholar] [CrossRef]

- Ren, Y.; Maltha, J.C.; Kuijpers-Jagtman, A.M. Optimum force magnitude for orthodontic tooth movement: A systematic liter-ature review. Angle Orthod. 2003, 73, 86–92. [Google Scholar] [PubMed]

- Wen, S.; Gan, J.; Li, F.; Zhou, Y.; Yan, C.; Shi, Y. Research status and prospect of additive manufactured nickel-titanium shape memory alloys. Materials 2021, 14, 4496. [Google Scholar] [CrossRef]

- Silva, E.J.; Giraldes, J.F.; de Lima, C.O.; Vieira, V.T.; Elias, C.N.; Antunes, H.S. Influence of Heat Treatment on Torsional Re-sistance and Surface Roughness of Nickel-Titanium Instruments. Int. Endod. J. 2019, 52, 1645–1651. [Google Scholar] [CrossRef]

- Silva, E.J.; Vieira, V.T.; Hecksher, F.; dos Santos Oliveira, M.R.; dos Santos Antunes, H.; Moreira, E.J. Cyclic Fatigue Using Severely Curved Canals and Torsional Resistance of Thermally Treated Reciprocating Instruments. Clin. Oral Investig. 2018, 22, 2633–2638. [Google Scholar] [CrossRef]

- Zhou, H.; Peng, B.; Zheng, Y.-F. An Overview of the Mechanical Properties of Nickel-Titanium Endodontic Instruments. Endod. Top. 2013, 29, 42–54. [Google Scholar] [CrossRef]

- Zupanc, J.; Vahdat-Pajouh, N.; Schäfer, E. New Thermomechanically Treated Niti Alloys—A Review. Int. Endod. J. 2018, 51, 1088–1103. [Google Scholar] [CrossRef]

- Hieawy, A.; Haapasalo, M.; Zhou, H.; Wang, Z.-J.; Shen, Y. Phase Transformation Behavior and Resistance to Bending and Cyclic Fatigue of Protaper Gold and PROTAPER Universal Instruments. J. Endod. 2015, 41, 1134–1138. [Google Scholar] [CrossRef]

- Martins, J.N.; Silva, E.J.; Marques, D.; Pereira, M.R.; Vieira, V.T.; Arantes-Oliveira, S.; Martins, R.F.; Braz Fernandes, F.; Versiani, M. Design, Metallurgical Features, and Mechanical Behaviour of NITI Endodontic Instruments from Five Different Heat-Treated Rotary Systems. Materials 2022, 15, 1009. [Google Scholar] [CrossRef] [PubMed]

- Burstone, C.J.; Choy, K. The Biomechanical Foundation of Clinical Orthodontics; Quintessence Publishing Co., Inc.: Chicago, IL, USA, 2015. [Google Scholar]

- Shaw, J.A.; Churchill, C.B.; Iadicola, M.A. Tips and Tricks for Characterizing Shape Memory Alloy Wire: Part 1-Differential Scanning Calorimetry and Basic Phenomena. Exp. Tech. 2008, 32, 55–62. [Google Scholar] [CrossRef]

- Miura, F.; Mogi, M.; Ohura, Y.; Hamanaka, H. The Super-Elastic Property of the Japanese Niti Alloy Wire for Use in Ortho-dontics. Am. J. Orthod. Dentofac. Orthop. 1986, 90, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Obaisi, N.A.; Galang-Boquiren, M.T.; Evans, C.A.; Tsay, T.G.; Viana, G.; Berzins, D.; Megremis, S. Comparison of the Trans-formation Temperatures of Heat-Activated Nickel-Titanium Orthodontic Archwires by Two Different Techniques. Dent. Ma-Terials 2016, 32, 879–888. [Google Scholar] [CrossRef] [PubMed]

- Spini, T.S.; Valarelli, F.P.; Cancado, R.H.; Freitas, K.M.S.D.; Villarinho, D.J. Transition temperature range of thermally activated nickel-titanium archwires. J. Appl. Oral Sci. 2014, 22, 109–117. [Google Scholar] [CrossRef] [PubMed]

- Berzins, D.W.; Roberts, H.W. Phase transformation changes in thermocycled nickel–titanium orthodontic wires. Dent. Mater. 2010, 26, 666–674. [Google Scholar] [CrossRef]

- Funakubo, H. Shape Memory Alloys; Gordon and Breach Science: New York, NY, USA, 1987. [Google Scholar]

- Brantley, W.A.; Eliades, T. Orthodontic Materials Scientific and Clinical Aspects; Thieme: Stuttgart, Garmany, 2001; Volume 29, pp. 77–103. [Google Scholar]

- Santoro, M.; Nicolay, O.F.; Cangialosi, T.J. Pseudoelasticity and Thermoelasticity of Nickel-Titanium Alloys: A Clinically Ori-ented Review. Part I: Temperature Transitional Ranges. Am. J. Orthod. Dentofac. Orthop. 2001, 119, 587–593. [Google Scholar] [CrossRef]

- Kusy, R.P.; Whitley, J.Q. Thermal and Mechanical Characteristics of Stainless Steel, Titanium-Molybdenum, and Nick-el-Titanium Archwires. Am. J. Orthod. Dentofac. Orthop. 2007, 131, 229–237. [Google Scholar] [CrossRef]

- Assawakawintip, T.; Santiwong, P.; Khantachawana, A.; Sipiyaruk, K.; Chintavalakorn, R. The Effects of Temperature and Time of Heat Treatment on Thermo-Mechanical Properties of Custom-Made Niti Orthodontic Closed Coil Springs. Materials 2022, 15, 3121. [Google Scholar] [CrossRef]

- Savi, M.A.; Paiva, A.; de Araujo, C.J.; de Paula, A.S. Shape Memory Alloys in Dynamics of Smart Systems and Structures; Lopes, V., Jr., Steffen, V., Jr., Savi, M., Eds.; Springer: Cham, Switzerland, 2016; pp. 155–188. [Google Scholar]

- Ohara, A.T. Clinical Importance of Austenitic Final Point in the Selection of Nickel-Titanium Alloys for Application in Ortho-dontic-Use Arches. Rev. Odontol. Mex. 2016, 20, 166–173. [Google Scholar] [CrossRef]

- Oguienko, O. Mechanical Properties of Graded Thermodynamic Nickel Titanium Archwires in Bending and Torsion. Master’s Thesis, University of Toronto, Toronto, ON, Canada, November 2017. [Google Scholar]

- Sakima, M.T. How Does Temperature Influence the Properties of Rectangular Nickel-Titanium Wires? Eur. J. Orthod. 2005, 28, 282–291. [Google Scholar] [CrossRef] [PubMed]

- Santoro, M.; Nicolay, O.F.; Cangialosi, T.J. Pseudoelasticity and Thermoelasticity of Nickel-Titanium Alloys: A Clinically Ori-ented Review. Part II: Deactivation Forces. Am. J. Orthod. Dentofac. Orthop. 2001, 119, 594–603. [Google Scholar] [CrossRef] [PubMed]

- Rodrigues, P.F.; Fernandes, F.M.B.; Magalhães, R.; Camacho, E.; Lopes, A.; Paula, A.S.; Basu, R.; Schell, N. Thermo-Mechanical Characterization of Niti Orthodontic Archwires with Graded Actuating Forces. J. Mech. Behav. Biomed. Mater. 2020, 107, 103747. [Google Scholar] [CrossRef] [PubMed]

- Roulias, P.; Mylonopoulou, I.-M.; Sifakakis, I.; Bourauel, C.; Eliades, T. Thermo-Mechanical Properties in Bending of a Multizone Nickel-Titanium Archwire: A Retrieval Analysis. Korean J. Orthod. 2023, 53, 89–98. [Google Scholar] [CrossRef]

- Kim, T.-K.; Kim, K.-D.; Baek, S.-H. Comparison of Frictional Forces during the Initial Leveling Stage in Various Combinations of Self-Ligating Brackets and Archwires with a Custom-Designed Typodont System. Am. J. Orthod. Dentofac. Orthop. 2008, 133, 187.e15–187.e24. [Google Scholar] [CrossRef] [PubMed]

- Razali, M.F.; Mahmud, A.S.; Mokhtar, N. Force Delivery of NITI Orthodontic Arch Wire at Different Magnitude of Deflections and Temperatures: A Finite Element Study. J. Mech. Behav. Biomed. Mater. 2018, 77, 234–241. [Google Scholar] [CrossRef]

- Olsen, M. SmartArch Multi-Force Superelastic Archwires: A New Paradigm in Orthodontic Treatment Efficiency. J. Clin. Orthod. 2020, 54, 70–81. [Google Scholar]

- Lombardo, L.; Ceci, M.; Mollica, F.; Mazzanti, V.; Palone, M.; Siciliani, G. Mechanical Properties of Multi-Force vs. Conventional Niti Archwires. J. Orofac. Orthop. Fortschr. Kieferorthopädie 2019, 80, 57–67. [Google Scholar] [CrossRef]

- Stoyanova-Ivanova, A.; Georgieva, M.; Petrov, V.; Andreeva, L.; Petkov, A.; Georgiev, V. Effects of Clinical Use on the Me-chanical Properties of Bio-Active® (BA) and Tritanium® (TR) Multiforce Nickel-Titanium Orthodontic Archwires. Materials 2023, 16, 483. [Google Scholar] [CrossRef]

- NT3® SE Niti Wire. Available online: https://www.americanortho.com/products/wire/niti-wire/ (accessed on 12 April 2023).

- Gc. Bio Active. Available online: https://www.gc.dental/ortho/en-US/products/bioactive (accessed on 12 April 2023).

- Lombardo, L.; Toni, G.; Stefanoni, F.; Mollica, F.; Guarneri, M.P.; Siciliani, G. The Effect of Temperature on the Mechanical Behavior of Nickel-Titanium Orthodontic Initial Archwires. Angle Orthod. 2012, 83, 298–305. [Google Scholar] [CrossRef]

- Modi, D.N.; Gupta, D.R.; Borah, D.M. Newer Orthodontic Archwires—A Review. Int. J. Appl. Dent. Sci. 2020, 6, 90–94. [Google Scholar] [CrossRef]

- Nakata, Y.; Tadaki, T.; Shimizu, K. Composition Dependence of the Atom Location of the Third Element in Ti-Ni-X Shape Memory Alloys. Mater. Trans. JIM 1991, 32, 1120–1127. [Google Scholar] [CrossRef]

- Moore, R. Intra-Oral Temperature Variation over 24 Hours. Eur. J. Orthod. 1999, 21, 249–261. [Google Scholar] [CrossRef] [PubMed]

- Airoldi, G.; Riva, G.; Vanelli, M.; Filippi, V.; Garattini, G. Oral Environment Temperature Changes Induced by Cold/Hot Liquid Intake. Am. J. Orthod. Dentofac. Orthop. 1997, 112, 58–63. [Google Scholar] [CrossRef]

- Meling, T.R.; Ødegaard, J. The Effect of Short-Term Temperature Changes on Superelastic Nickel-Titanium Archwires Activated in Orthodontic Bending. Am. J. Orthod. Dentofac. Orthop. 2001, 119, 263–273. [Google Scholar] [CrossRef] [PubMed]

- Pastor, F.; Rodríguez, J.C.; Barrera, J.M.; Delgado GarcíaMenocal, J.A.; Brizuela, A.; Puigdollers, A.; Espinar, E.; Gil, J. Effect of Fluoride Content of Mouthwashes on Superelastic Properties of NiTi Orthodontic Archwires. Materials 2022, 15, 6592. [Google Scholar] [CrossRef] [PubMed]

| Af Temperatures from Bio-Active® Archwires [°C] | ||||||||

|---|---|---|---|---|---|---|---|---|

| Before Clinical Use | Used up to 8 Weeks | Used over 8 Weeks | ||||||

| Frontal | Premolar | Molar | Frontal | Premolar | Molar | Frontal | Premolar | Molar |

| 31.45 | 28.21 | 26.17 | 30.39 | 28.10 | 27.36 | 30.23 | 28.79 | 27.45 |

| 31.45 | 28.21 | 26.69 | 30.32 | 28.48 | 27.42 | 26.90 | 27.48 | 26.46 |

| 29.99 | 28.84 | 27.69 | 30.36 | 30.28 | 27.70 | |||

| 29.99 | 26.39 | 26.50 | 29.28 | 29.15 | 26.37 | |||

| 30.06 | 29.38 | 26.70 | 30.18 | 29.49 | 25.95 | |||

| Af Temperatures from TriTanium® Archwires [°C] | ||||||||

|---|---|---|---|---|---|---|---|---|

| Before Clinical Use | Used up to 8 Weeks | Used over 8 Weeks | ||||||

| Frontal | Premolar | Molar | Frontal | Premolar | Molar | Frontal | Premolar | Molar |

| 23.65 | 21.85 | 19.02 | 23.35 | 20.45 | 15.87 | 30.36 | 26.88 | 22.26 |

| 25.03 | 22.53 | 18.42 | 22.45 | 21.39 | 16.76 | 25.09 | 23.84 | 16.69 |

| 25.17 | 24.90 | 17.45 | 24.63 | 23.97 | 17.67 | |||

| 25.50 | 24.53 | 22.15 | 38.06 | 37.36 | 22.79 | |||

| 25.11 | 22.33 | 18.03 | 23.95 | 24.99 | 16.85 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stoyanova-Ivanova, A.; Georgieva, M.; Petrov, V.; Martins, J.N.R.; Andreeva, L.; Petkov, A.; Petrova, N.; Georgiev, V. Thermal Behavior Changes of As-Received and Retrieved Bio-Active® (BA) and TriTanium® (TR) Multiforce Nickel–Titanium Orthodontic Archwires. Materials 2023, 16, 3776. https://doi.org/10.3390/ma16103776

Stoyanova-Ivanova A, Georgieva M, Petrov V, Martins JNR, Andreeva L, Petkov A, Petrova N, Georgiev V. Thermal Behavior Changes of As-Received and Retrieved Bio-Active® (BA) and TriTanium® (TR) Multiforce Nickel–Titanium Orthodontic Archwires. Materials. 2023; 16(10):3776. https://doi.org/10.3390/ma16103776

Chicago/Turabian StyleStoyanova-Ivanova, Angelina, Mirela Georgieva, Valeri Petrov, Jorge N. R. Martins, Laura Andreeva, Alexander Petkov, Nadia Petrova, and Velizar Georgiev. 2023. "Thermal Behavior Changes of As-Received and Retrieved Bio-Active® (BA) and TriTanium® (TR) Multiforce Nickel–Titanium Orthodontic Archwires" Materials 16, no. 10: 3776. https://doi.org/10.3390/ma16103776

APA StyleStoyanova-Ivanova, A., Georgieva, M., Petrov, V., Martins, J. N. R., Andreeva, L., Petkov, A., Petrova, N., & Georgiev, V. (2023). Thermal Behavior Changes of As-Received and Retrieved Bio-Active® (BA) and TriTanium® (TR) Multiforce Nickel–Titanium Orthodontic Archwires. Materials, 16(10), 3776. https://doi.org/10.3390/ma16103776