Solid-State Dewetting as a Driving Force for Structural Transformation and Magnetization Reversal Mechanism in FePd Thin Films

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

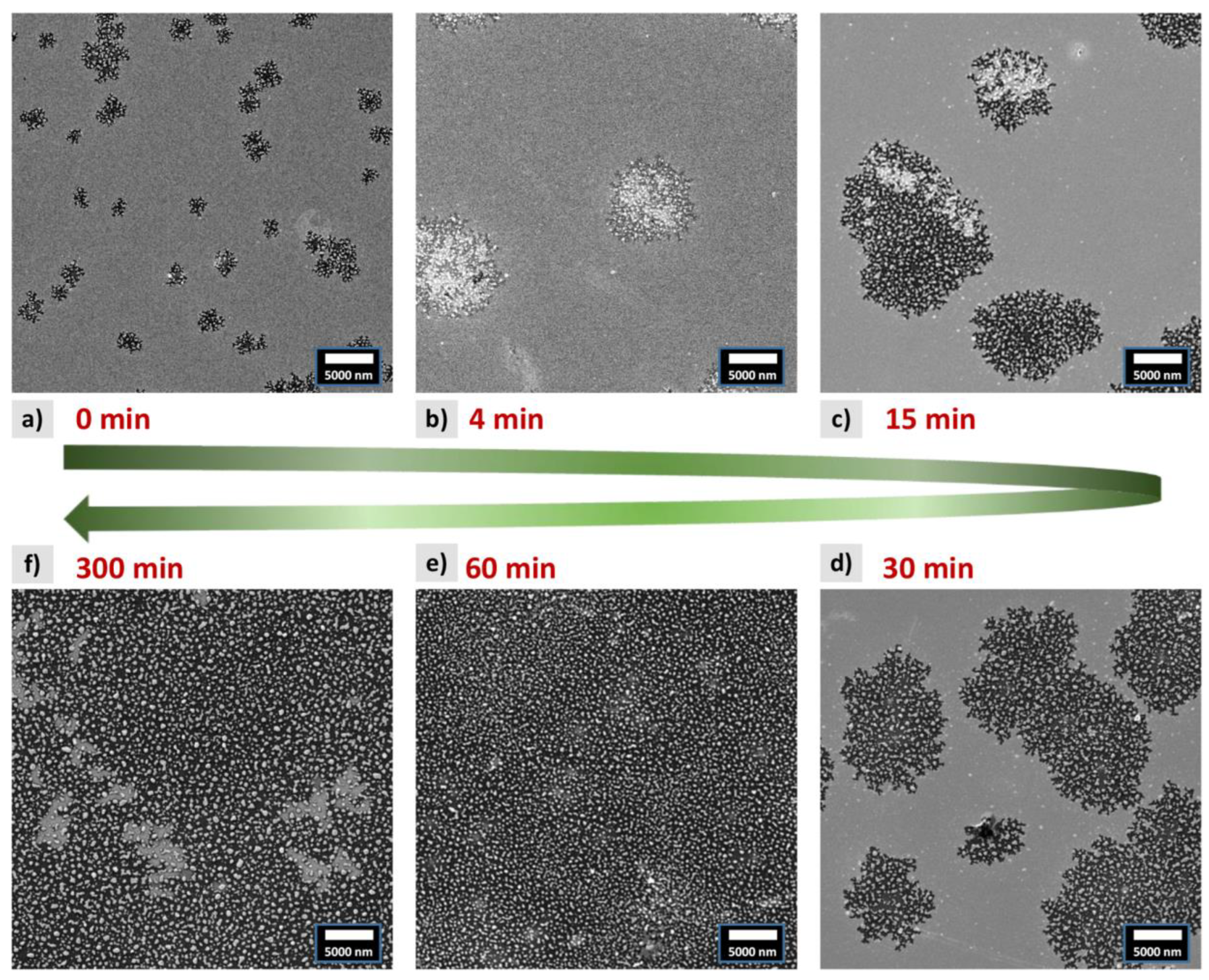

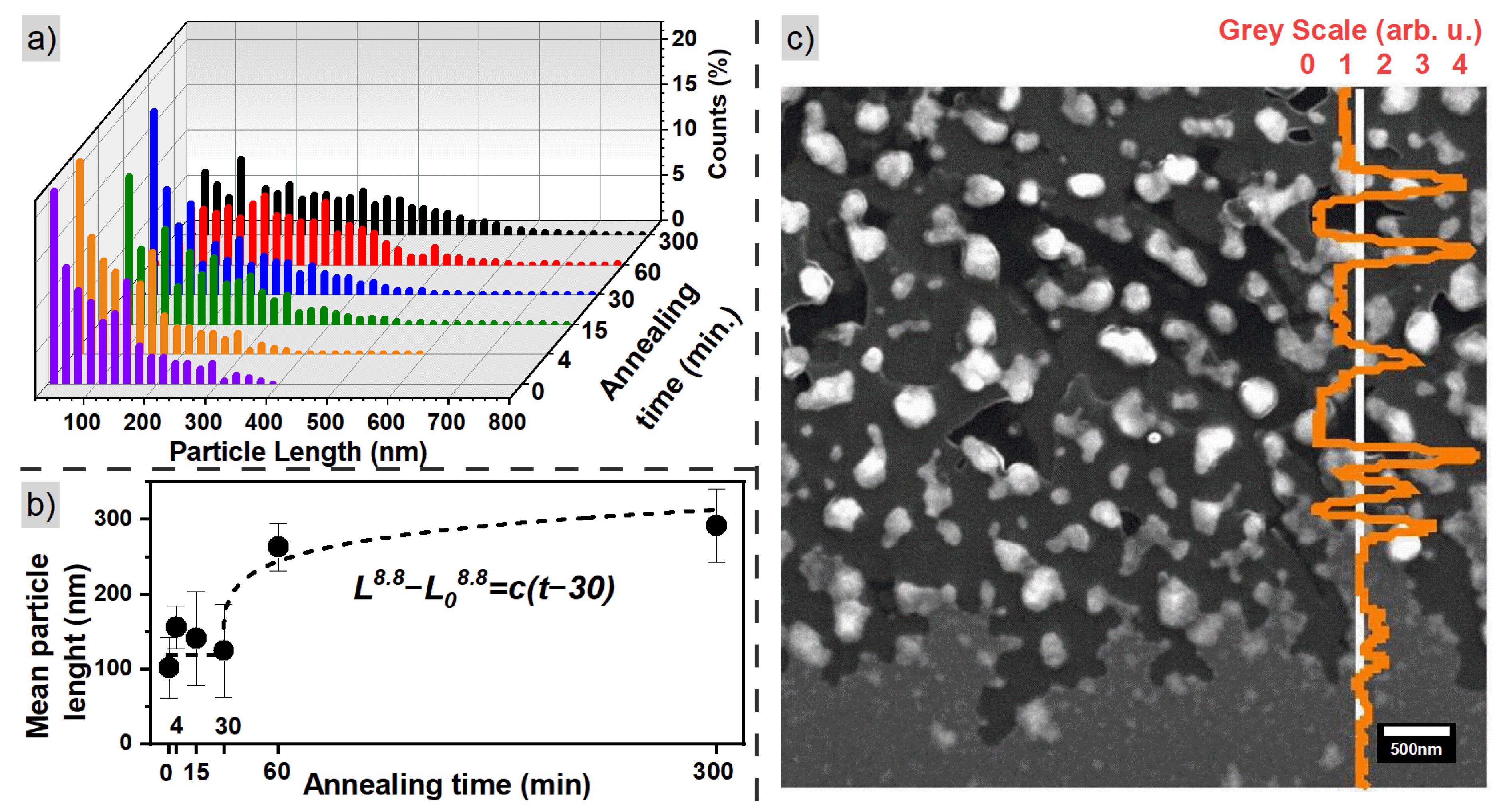

3.1. Crystallographic Structure and Morphology

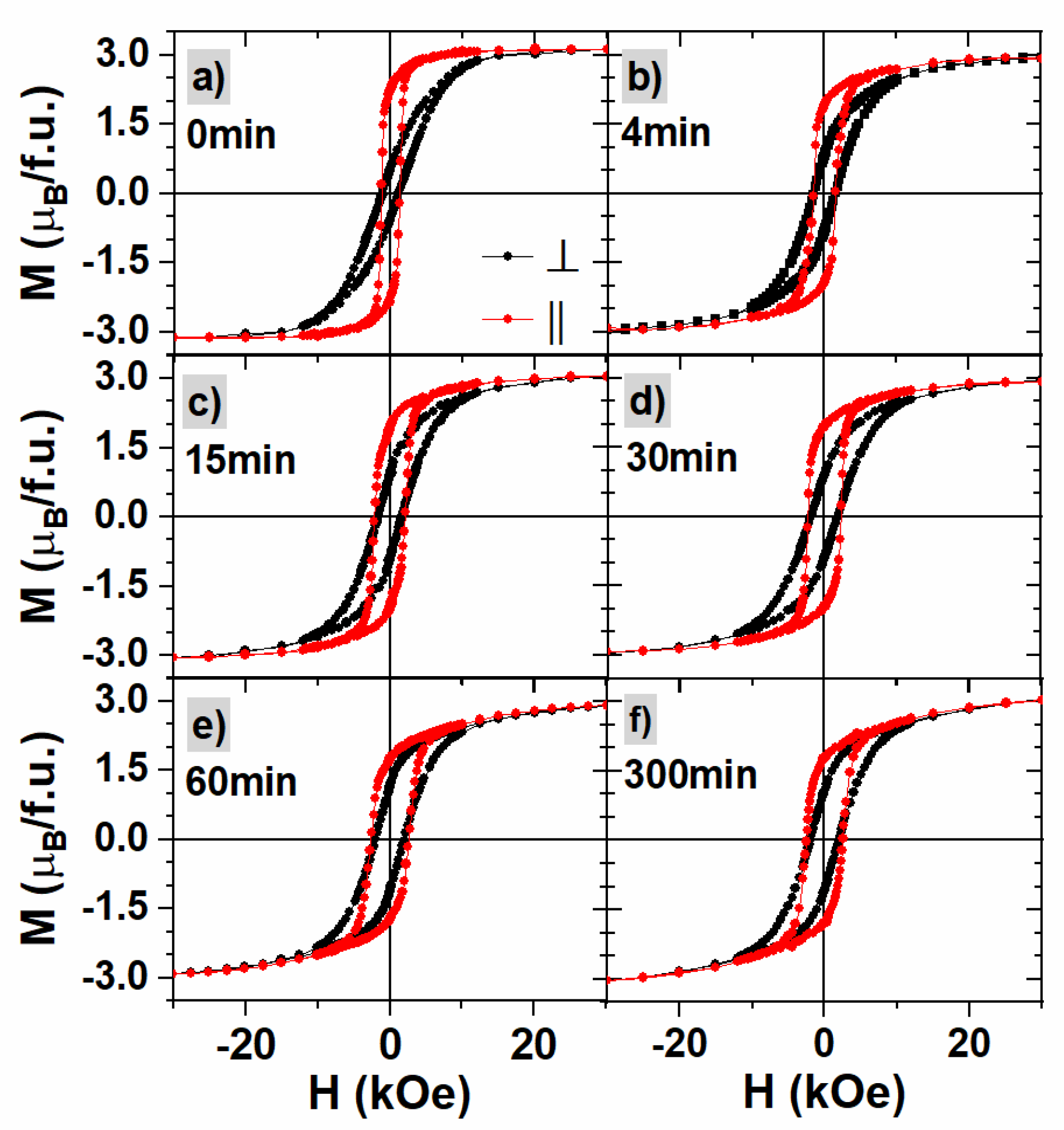

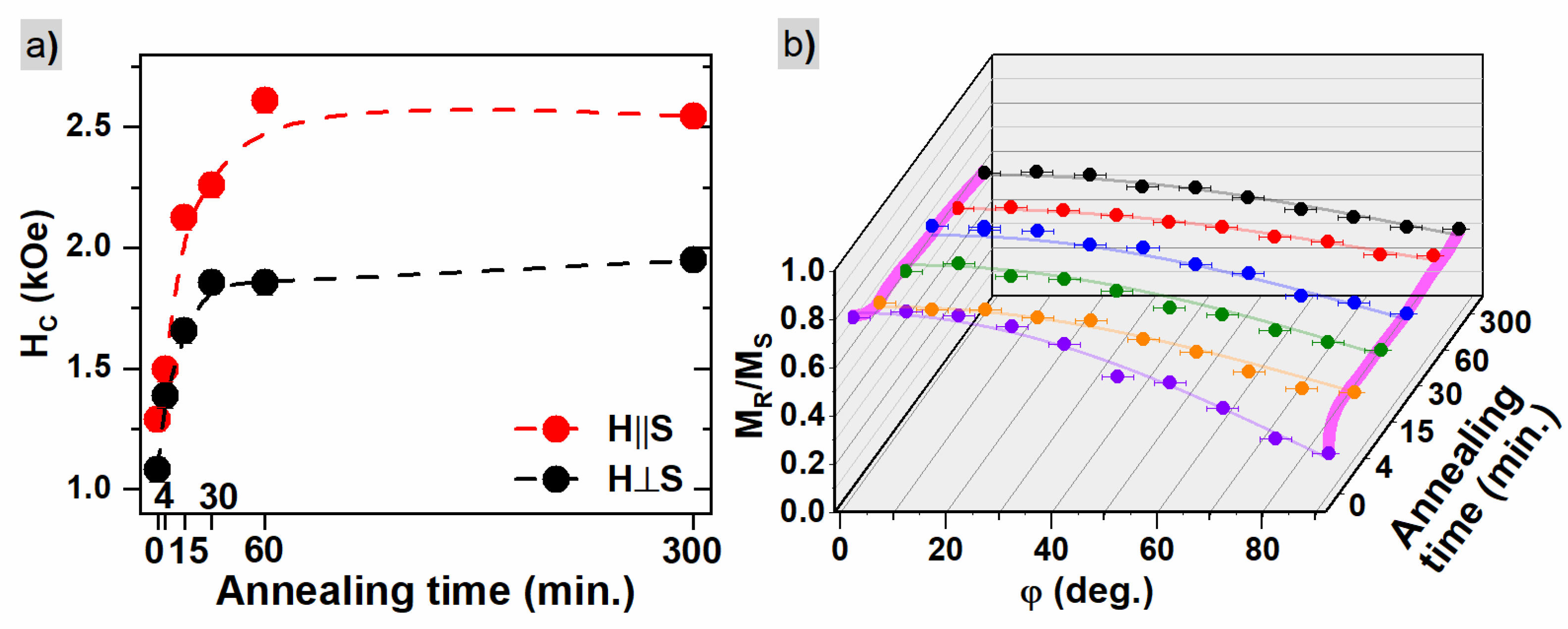

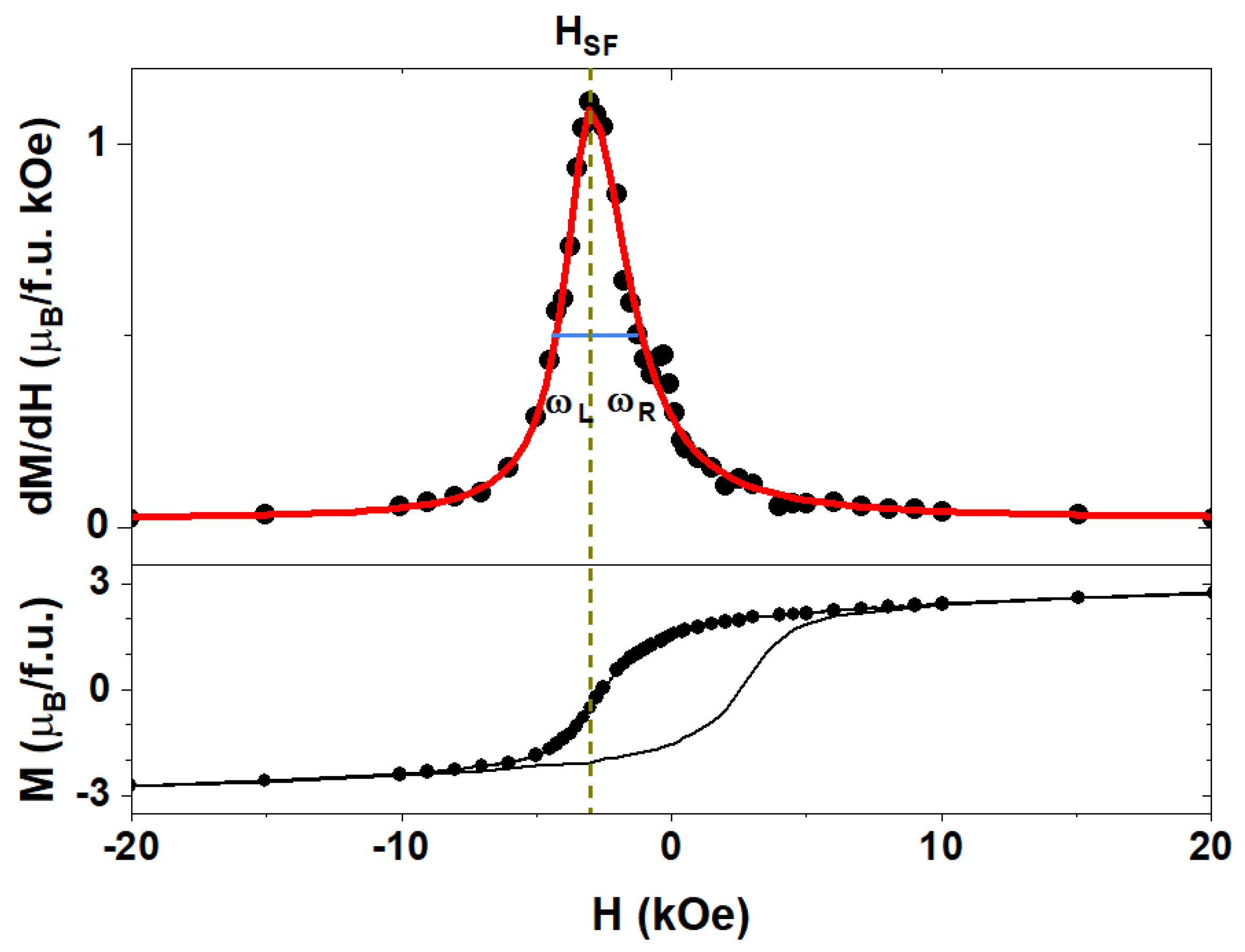

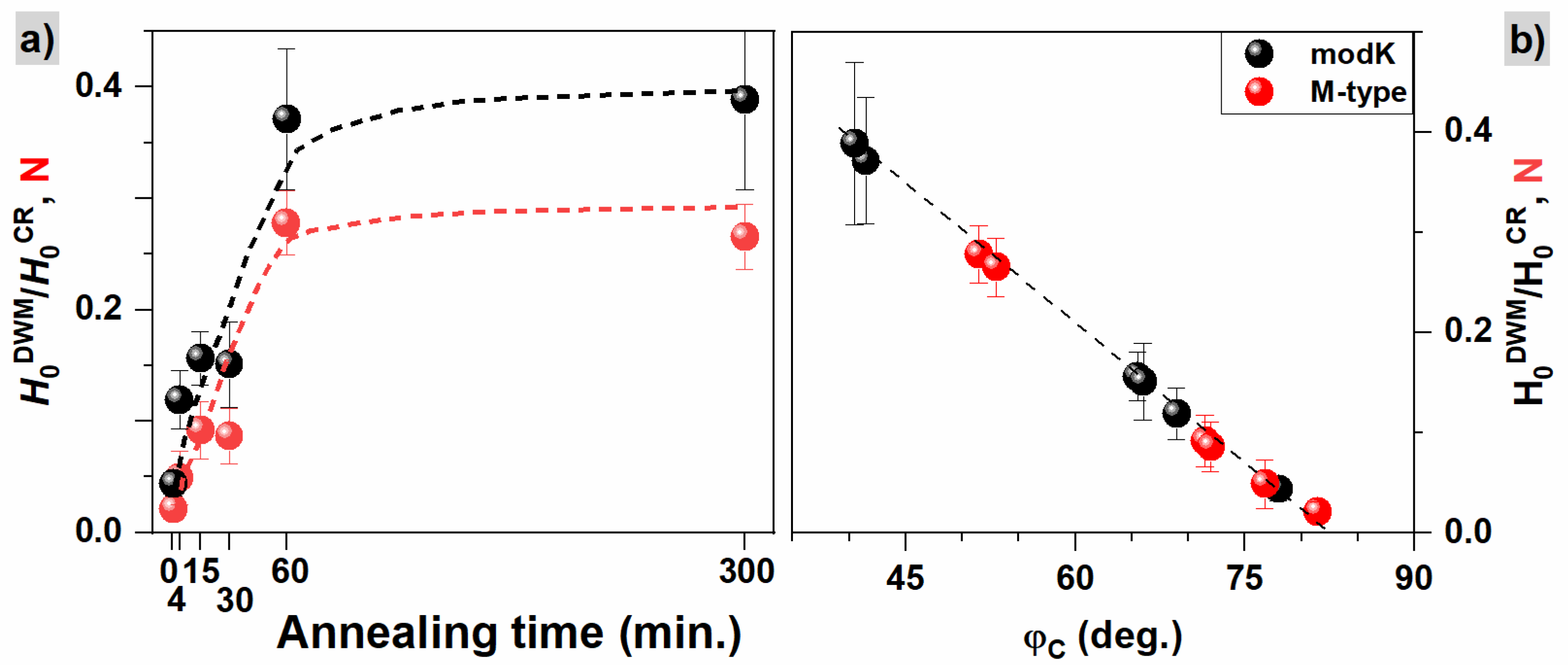

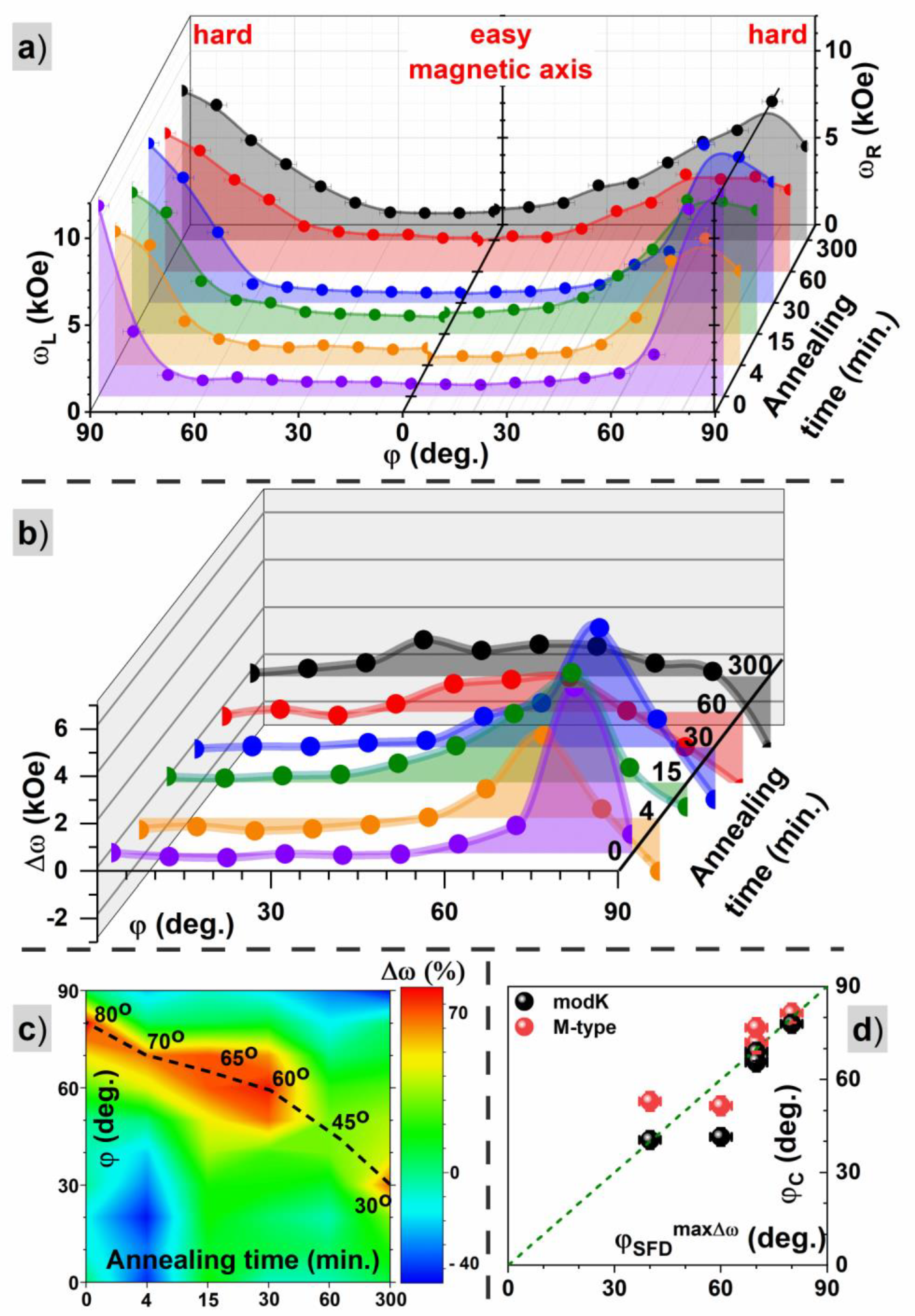

3.2. Macroscopic Magnetic Properties

- (the in-plane squareness value from Table 1);

- (the value of squareness for out-of-plane direction from Table 1).

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Nguyen, D.C.; Chu, C.C.; Lee, C.H.; Lai, W.C.; Chang, C.-S.S. Coercivity enhancement of FePd thin films prepared by the post-annealing of off-stoichiometric magnetron-sputtered multilayers. J. Appl. Phys. 2018, 123, 073901. [Google Scholar] [CrossRef]

- Yu, G.-L.; Cheng, T.-M.; Cheng, Z.-R.; Zhang, X.-X. Exploration of new phase structure of FePd crystalline alloy with a stoichiometric of 1:1. Comput. Mater. Sci. 2021, 188, 110168. [Google Scholar] [CrossRef]

- Seiner, H.; Stoklasová, P.; Sedlák, P.; Ševčík, M.; Janovská, M.; Landa, M.; Fukuda, T.; Yamaguchi, T.; Kakeshita, T. Evolution of soft-phonon modes in Fe-Pd shape memory alloy under large elastic-like strains. Acta Mater. 2016, 105, 182–188. [Google Scholar] [CrossRef]

- Qin, H.J.; Zakeri, K.; Ernst, A.; Sandratskii, L.M.; Buczek, P.; Marmodoro, A.; Chuang, T.H.; Zhang, Y.; Kirschner, J. Long-living terahertz magnons in ultrathin metallic ferromagnets. Nat. Commun. 2015, 6, 6126. [Google Scholar] [CrossRef]

- Kumar, A.; Behera, N.; Gupta, R.; Husain, S.; Stopfel, H.; Kapaklis, V.; Brucas, R.; Svedlindh, P. Impact of the crystal orientation on spin-orbit torques in fe/pd bilayers. J. Phys. D. Appl. Phys. 2020, 53, 355003. [Google Scholar] [CrossRef]

- Mayr, S.; Ye, J.; Stahn, J.; Knoblich, B.; Klein, O.; Gilbert, D.A.; Albrecht, M.; Paul, A.; Böni, P.; Kreuzpaintner, W. Indications for Dzyaloshinskii-Moriya interaction at the Pd/Fe interface studied by in situ polarized neutron reflectometry. Phys. Rev. B 2020, 101, 24404. [Google Scholar] [CrossRef]

- Miranda, I.P.; Klautau, A.B.; Bergman, A.; Petrilli, H.M. Band filling effects on the emergence of magnetic skyrmions: Pd/Fe and Pd/Co bilayers on Ir(111). Phys. Rev. B 2022, 105, 224413. [Google Scholar] [CrossRef]

- Dupé, B.; Bihlmayer, G.; Böttcher, M.; Blügel, S.; Heinze, S. Engineering skyrmions in transition-metal multilayers for spintronics. Nat. Commun. 2016, 7, 11779. [Google Scholar] [CrossRef]

- Wang, X.; Krylyuk, S.; Josell, D.; Zhang, D.; Wang, J.P.; Gopman, D.B. Effect of Oblique Versus Normal Deposition on the Properties of Perpendicularly Magnetized L10FePd Thin Films. IEEE Magn. Lett. 2020, 11, 2504105. [Google Scholar] [CrossRef]

- Iihama, S.; Sakuma, A.; Naganuma, H.; Oogane, M.; Mizukami, S.; Ando, Y. Influence of L10 order parameter on Gilbert damping constants for FePd thin films investigated by means of time-resolved magneto-optical Kerr effect. Phys. Rev. B 2016, 94, 174425. [Google Scholar] [CrossRef]

- Zhang, D.; Huang, D.; Wu, R.J.; Lattery, D.; Liu, J.; Wang, X.; Gopman, D.B.; Mkhoyan, K.A.; Wang, J.P.; Wang, X. Low Gilbert damping and high thermal stability of Ru-seeded L10-phase FePd perpendicular magnetic thin films at elevated temperatures. Appl. Phys. Lett. 2020, 117, 082405. [Google Scholar] [CrossRef] [PubMed]

- Zhang, D.L.; Sun, C.; Lv, Y.; Schliep, K.B.; Zhao, Z.; Chen, J.Y.; Voyles, P.M.; Wang, J.P. L10 Fe-Pd Synthetic Antiferromagnet through an fcc Ru Spacer Utilized for Perpendicular Magnetic Tunnel Junctions. Phys. Rev. Appl. 2018, 9, 44028. [Google Scholar] [CrossRef]

- Naganuma, H.; Kim, G.; Kawada, Y.; Inami, N.; Hatakeyama, K.; Iihama, S.; Nazrul Islam, K.M.; Oogane, M.; Mizukami, S.; Ando, Y. Electrical Detection of Millimeter-Waves by Magnetic Tunnel Junctions Using Perpendicular Magnetized L10 -FePd Free Layer. Nano Lett. 2015, 15, 623–628. [Google Scholar] [CrossRef]

- Zhang, D.-L.; Schliep, K.B.; Wu, R.J.; Quarterman, P.; Reifsnyder Hickey, D.; Lv, Y.; Chao, X.; Li, H.; Chen, J.-Y.; Zhao, Z.; et al. Enhancement of tunneling magnetoresistance by inserting a diffusion barrier in L1 0 -FePd perpendicular magnetic tunnel junctions. Appl. Phys. Lett. 2018, 112, 152401. [Google Scholar] [CrossRef]

- Bonell, F.; Murakami, S.; Shiota, Y.; Nozaki, T.; Shinjo, T.; Suzuki, Y. Large change in perpendicular magnetic anisotropy induced by an electric field in FePd ultrathin films. Appl. Phys. Lett. 2011, 98, 232510. [Google Scholar] [CrossRef]

- Seemann, K.M.; Hickey, M.C.; Baltz, V.; Hickey, B.J.; Marrows, C.H. Spin-dependent scattering and the spin polarization of a diffusive current in partly disordered L10 epitaxial FePd. New J. Phys. 2010, 12, 33033. [Google Scholar] [CrossRef]

- Wunderlich, W.; Takahashi, K.; Kubo, D.; Matsumura, Y.; Nishi, Y. Magnetostriction properties of FePd thin films: Dependence on microstructure. J. Alloys Compd. 2009, 475, 339–342. [Google Scholar] [CrossRef]

- Ma, Y.; Zink, M.; Mayr, S.G. Biocompatibility of single crystalline Fe70Pd30 ferromagnetic shape memory films. Appl. Phys. Lett. 2010, 96, 213703. [Google Scholar] [CrossRef]

- Rozman, K.Z.; Pecko, D.; Trafela, S.; Samardzija, Z.; Spreitzer, M.; Jaglicic, Z.; Nadrah, P.; Zorko, M.; Bele, M.; Tisler, T.; et al. Austenite-martensite transformation in electrodeposited Fe70Pd30 NWs: A step towards making bio-nano-actuators tested on in vivo systems. Smart Mater. Struct. 2018, 27, 35018. [Google Scholar] [CrossRef]

- Yang, Y.; Lyu, M.; Li, J.H.; Zhu, D.M.; Yuan, Y.F.; Liu, W. Ultra-small bimetallic iron-palladium (FePd) nanoparticle loaded macrophages for targeted tumor photothermal therapy in NIR-II biowindows and magnetic resonance imaging. RSC Adv. 2019, 9, 33378–33387. [Google Scholar] [CrossRef]

- Yang, Z.; Li, J.; Li, J.; Zhang, B.; Li, J.; Sheng, S.; Ding, P. Magnetic Properties and Biocompatibility of Different Thickness (Pd/Fe)n Coatings Deposited on Pure Ti Surface via Multi Arc Ion Plating. Materials 2022, 15, 1831. [Google Scholar] [CrossRef] [PubMed]

- Herrera, E.; Riva, J.; Aprea, S.; Silva, O.F.; Bercoff, P.G.; Granados, A.M. FePd nanowires modified with cyclodextrin as improved catalysts: Effect of the alloy composition on colloidal stability and catalytic capacity. Catal. Sci. Technol. 2022, 12, 2962–2971. [Google Scholar] [CrossRef]

- Zhang, N.; Qiu, Y.; Sun, H.; Hao, J.; Chen, J.; Xi, J.; Liu, J.; He, B.; Bai, Z.W. Substrate-Assisted Encapsulation of Pd-Fe Bimetal Nanoparticles on Functionalized Silica Nanotubes for Catalytic Hydrogenation of Nitroarenes and Azo Dyes. ACS Appl. Nano Mater. 2021, 4, 5854–5863. [Google Scholar] [CrossRef]

- Wang, J.; Wang, Z.; Zhao, D.; Xu, C. Facile fabrication of nanoporous PdFe alloy for nonenzymatic electrochemical sensing of hydrogen peroxide and glucose. Anal. Chim. Acta 2014, 832, 34–43. [Google Scholar] [CrossRef] [PubMed]

- Yang, C.; Feng, W.; Li, Y.; Tian, X.; Zhou, Z.; Lu, L.; Nie, Y. A promising method for diabetes early diagnosis via sensitive detection of urine glucose by Fe–Pd/rGO. Dye. Pigment. 2019, 164, 20–26. [Google Scholar] [CrossRef]

- Shao, Z.; An, L.; Li, Z.; Huang, Y.; Hu, Y.; Ren, S. Eutectic crystallized FePd nanoparticles for liquid metal magnet. Chem. Commun. 2020, 56, 6555–6558. [Google Scholar] [CrossRef] [PubMed]

- Chang, P.C.; Chuang, T.H.; Wei, D.H.; Lin, W.C. Thermally modulated hydrogenation in FexPd1-x alloy films: Temperature-driven peculiar variation of magnetism. Appl. Phys. Lett. 2020, 116, 102407. [Google Scholar] [CrossRef]

- Wang, W.H.; Cheng, Y.S.; Sheu, H.S.; Lin, W.C.; Jiang, P.H. Exchange-bias dependent diffusion rate of hydrogen discovered from evolution of hydrogen-induced noncollinear magnetic anisotropy in FePd thin films. Phys. Rev. B 2021, 104, 224420. [Google Scholar] [CrossRef]

- Vlasova, N.I.; Kandaurova, G.S.; Shchegoleva, N.N. Effect of the polytwinned microstructure parameters on magnetic domain structure and hysteresis properties of the CoPt-type alloys. J. Magn. Magn. Mater. 2000, 222, 138–158. [Google Scholar] [CrossRef]

- Steiner, M.A.; Comes, R.B.; Floro, J.A.; Soffa, W.A.; Fitz-Gerald, J.M. L1′ ordering: Evidence of L10–L12 hybridization in strained Fe38.5Pd61.5 epitaxial films. Acta Mater. 2015, 85, 261–269. [Google Scholar] [CrossRef]

- Vlasova, N.I.; Popov, A.G.; Shchegoleva, N.N.; Gaviko, V.S.; Stashkova, L.A.; Kandaurova, G.S.; Gunderov, D.V. Discovery of metastable tetragonal disordered phase upon phase transitions in the equiatomic nanostructured FePd alloy. Acta Mater. 2013, 61, 2560–2570. [Google Scholar] [CrossRef]

- Pathak, R.; Golovnia, O.A.; Gerasimov, E.G.; Popov, A.G.; Vlasova, N.I.; Skomski, R.; Kashyap, A. Ab initio study of the magnetic properties of possible phases in binary Fe-Pd alloys. J. Magn. Magn. Mater. 2020, 499, 166266. [Google Scholar] [CrossRef]

- Bahamida, S.; Fnidiki, A.; Coïsson, M.; Olivetti, E.S.; Barrera, G.; Celegato, F.; Tiberto, P.; Boudissa, M. Disordered to ordered phase transformation: Correlation between microstructure and magnetic properties in Fe-Pd thin films. J. Appl. Phys. 2022, 131, 123902. [Google Scholar] [CrossRef]

- Wang, X.; Krylyuk, S.; Josell, D.; Zhang, D.; Lyu, D.; Wang, J.P.; Gopman, D.B. Buffer layer engineering of L10FePd thin films with large perpendicular magnetic anisotropy. AIP Adv. 2021, 11, 25106. [Google Scholar] [CrossRef]

- Endo, Y.; Yamanaka, Y.; Kawamura, Y.; Yamamoto, M. Formation of L10-type ordered FePd phase in multilayers composed of Fe and Pd. Jpn. J. Appl. Phys. Part 1 Regul. Pap. Short Notes Rev. Pap. 2005, 44, 3009–3014. [Google Scholar] [CrossRef]

- Issro, C.; Püschl, W.; Pfeiler, W.; Rogl, P.F.; Soffa, W.A.; Acosta, M.; Schmerber, G.; Kozubski, R.; Pierron-Bohnes, V. Temperature-driven changes of order and magnetism in FePd thin films and thin foil. Scr. Mater. 2005, 53, 447–452. [Google Scholar] [CrossRef]

- Barrera, G.; Celegato, F.; Cialone, M.; Coïsson, M.; Rizzi, P.; Tiberto, P. Effect of the substrate crystallinity on morphological and magnetic properties of fe70pd30 nanoparticles obtained by the solid-state dewetting. Sensors 2021, 21, 7420. [Google Scholar] [CrossRef]

- Schuler, J.D.; Copeland, G.; Hattar, K.; Rupert, T.J.; Briggs, S.A. Solid-state dewetting instability in thermally-stable nanocrystalline binary alloys. Materialia 2020, 9, 100618. [Google Scholar] [CrossRef]

- Leroy, F.; Borowik, Ł.; Cheynis, F.; Almadori, Y.; Curiotto, S.; Trautmann, M.; Barbé, J.C.; Müller, P. How to control solid state dewetting: A short review. Surf. Sci. Rep. 2016, 71, 391–409. [Google Scholar] [CrossRef]

- Barrera, G.; Celegato, F.; Coïsson, M.; Cialone, M.; Rizzi, P.; Tiberto, P. Formation of free-standing magnetic particles by solid-state dewetting of Fe80Pd20 thin films. J. Alloys Compd. 2018, 742, 751–758. [Google Scholar] [CrossRef]

- Hsiao, S.N.; Liu, S.H.; Chen, C.C.; Chou, C.L.; Chen, S.K.; Su, S.H.; Chiu, K.F.; Sung, C.K. A comparison of rapid-annealed FePt and FePd thin films: Internal stress, L10 ordering, and texture. Vacuum 2016, 125, 1–5. [Google Scholar] [CrossRef]

- Perzanowski, M.; Zabila, Y.; Morgiel, J.; Polit, A.; Krupiński, M.; Dobrowolska, A.; Marszałek, M. AFM, XRD and HRTEM Studies οf Annealed FePd Thin Films. Acta Phys. Pol. A 2010, 117, 423–426. [Google Scholar] [CrossRef]

- Krupinski, M.; Perzanowski, M.; Zarzycki, A.; Zabila, Y.; Marszałek, M. Ordered FePdCu nanoisland arrays made by templated solid-state dewetting. Nanotechnology 2015, 26, 425301. [Google Scholar] [CrossRef] [PubMed]

- Massalski, T.B.; Okamoto, H.; Subramanian, P.R.; Kacprzak, L. Alloy Phase Diagrams, 2nd ed.; Okamoto, H., Schlesinger, M.E., Mueller, E.M., Eds.; ASM International: Novelty, OH, USA, 2016; ISBN 978-1-62708-163-4. [Google Scholar]

- Perzanowski, M.; Krupinski, M.; Zarzycki, A.; Zabila, Y.; Marszalek, M. Determination of grain shape of laser-irradiated FePdCu thin alloy films. Appl. Surf. Sci. 2014, 302, 129–133. [Google Scholar] [CrossRef]

- Rodríguez-Carvajal, J. Recent developments of the program FULLPROF. Newsl. Comm. Powder Diffr. 2001, 26, 12–19. [Google Scholar]

- Ohtake, M.; Itabashi, A.; Futamoto, M.; Kirino, F.; Inaba, N. Crystal Orientation, Order Degree, and Surface Roughness of FePd-Alloy Film Formed on MgO(001) Substrate. IEEE Trans. Magn. 2015, 51, 2100904. [Google Scholar] [CrossRef]

- Vlasova, N.I.; Kleinerman, N.M.; Serikov, V.V.; Popov, A.G. Mössbauer study of fine structure features of equiatomic FePd alloy after severe plastic deformation and ordering annealing. J. Alloys Compd. 2014, 583, 191–197. [Google Scholar] [CrossRef]

- Futamoto, M.; Nakamura, M.; Ohtake, M.; Inaba, N.; Shimotsu, T. Growth of L10-ordered crystal in FePt and FePd thin films on MgO(001) substrate. AIP Adv. 2016, 6, 85302. [Google Scholar] [CrossRef]

- Shima, H.; Oikawa, K.; Fujita, A.; Fukamichi, K.; Ishida, K.; Sakuma, A. Lattice axial ratio and large uniaxial magnetocrystalline anisotropy in L10-type FePd single crystals prepared under compressive stress. Phys. Rev. B 2004, 70, 224408. [Google Scholar] [CrossRef]

- Krupinski, M.; Perzanowski, M.; Polit, A.; Zabila, Y.; Zarzycki, A.; Dobrowolska, A.; Marszalek, M. X-ray absorption fine structure and x-ray diffraction studies of crystallographic grains in nanocrystalline FePd:Cu thin films. J. Appl. Phys. 2011, 109, 64306. [Google Scholar] [CrossRef]

- Thompson, C. V Grain Growth in Thin Films. Annu. Rev. Mater. Sci. 1990, 20, 245–268. [Google Scholar] [CrossRef]

- Zotov, N.; Hiergeist, R.; Savan, A.; Ludwig, A. Effects of annealing time on the structural and magnetic properties of L10 FePt thin films. Thin Solid Films 2010, 518, 4977–4985. [Google Scholar] [CrossRef]

- Zaninetti, L. Poissonian and non-Poissonian Voronoi diagrams with application to the aggregation of molecules. Phys. Lett. Sect. A Gen. At. Solid State Phys. 2009, 373, 3223–3229. [Google Scholar] [CrossRef]

- Teran, A.V.; Bill, A.; Bergmann, R.B. Time-evolution of grain size distributions in random nucleation and growth crystallization processes. Phys. Rev. B 2010, 81, 75319. [Google Scholar] [CrossRef]

- Jacquet, P.; Podor, R.; Ravaux, J.; Teisseire, J.; Gozhyk, I.; Jupille, J.; Lazzari, R. Grain growth: The key to understand solid-state dewetting of silver thin films. Scr. Mater. 2016, 115, 128–132. [Google Scholar] [CrossRef]

- Sudheer; Mondal, P.; Rai, V.N.; Srivastava, A.K. A study of growth and thermal dewetting behavior of ultra-thin gold films using transmission electron microscopy. AIP Adv. 2017, 7, 75303. [Google Scholar] [CrossRef]

- Thompson, C.V. Solid-State Dewetting of Thin Films. Annu. Rev. Mater. Res. 2012, 42, 399–434. [Google Scholar] [CrossRef]

- Vlasova, N.I.; Popov, A.G.; Shchegoleva, N.N. Effect of the structural state of the FePd equiatomic alloy on the temperature dependence of the initial magnetic susceptibility and the Curie temperature. Phys. Met. Metallogr. 2009, 107, 359–369. [Google Scholar] [CrossRef]

- Cable, J.W.; Wollan, E.O.; Koehler, W.C. Distribution of magnetic moments in Pd-3d and Ni-3d alloys. Phys. Rev. 1965, 138, A755. [Google Scholar] [CrossRef]

- Galanakis, I.; Ostanin, S.; Alouani, M.; Dreyssé, H.; Wills, J.M. Theoretical study of magnetic properties and x-ray magnetic circular dichroism of the ordered Fe0.5Pd0.5 alloy. Phys. Rev. B 2000, 61, 599–608. [Google Scholar] [CrossRef]

- Liu, T.; Ma, L.; Zhao, S.Q.; Ma, D.D.; Li, L.; Cheng, G.; Rao, G.H. Crystal structure and magnetic properties of FexPd1−x thin films annealed at 550 °C. J. Mater. Sci. Mater. Electron. 2017, 28, 3616–3620. [Google Scholar] [CrossRef]

- O’Handley, R.C. Modern Magnetic Materials: Principles and Applications; Wiley-lnterscience Publicatio: New York, NY, USA, 2000; ISBN 978-0-471-15566-9. [Google Scholar]

- Yiping, L.; Hadjipanayis, G.C.; Sorensen, C.M.; Klabunde, K.J. Structural and magnetic properties of ultrafine Fe-Pd particles. J. Appl. Phys. 1994, 75, 5885–5887. [Google Scholar] [CrossRef]

- Idigoras, O.; Suszka, A.K.K.; Vavassori, P.; Obry, B.; Hillebrands, B.; Landeros, P.; Berger, A.; Vavasspri, P.; Obry, B.; Hillevrands, B.; et al. Magnetization reversal of in-plane uniaxial Co films and its dependence on epitaxial alignment. J. Appl. Phys. 2014, 115, 83912. [Google Scholar] [CrossRef]

- Zhao, Z.; Ding, J.; Chen, J.; Wang, J. The effects of pinning layer on the magnetic properties of FePt perpendicular media. J. Magn. Magn. Mater. 2004, 272–276, 2186–2188. [Google Scholar] [CrossRef]

- Klemmer, T.; Hoydick, D.; Okumura, H.; Zhang, B.; Soffa, W.A. Magnetic hardening and coercivity mechanisms in L10ordered FePd ferromagnets. Scr. Metall. Mater. 1995, 33, 1793–1805. [Google Scholar] [CrossRef]

- Skomski, R.; Coey, J.M.D. Giant energy product in nanostructured two-phase magnets. Phys. Rev. B 1993, 48, 15812–15816. [Google Scholar] [CrossRef] [PubMed]

- Baker, S.H.; Lees, M.; Roy, M.; Binns, C. Structure and magnetism in Fe/FexPd1-x core/shell nanoparticles formed by alloying in Pd-embedded Fe nanoparticles. J. Phys. Condens. Matter 2013, 25, 386004. [Google Scholar] [CrossRef]

- Tiberto, P.; Celegato, F.; Barrera, G.; Coisson, M.; Vinai, F.; Rizzi, P. Magnetization reversal and microstructure in polycrystalline Fe50Pd50 dot arrays by self-assembling of polystyrene nanospheres. Sci. Technol. Adv. Mater. 2016, 17, 462–472. [Google Scholar] [CrossRef]

- Stoner, E.C.; Wohlfarth, E.P. A mechanism of magnetic hysteresis in heterogeneous alloys. Philos. Trans. R. Soc. London. Ser. A Math. Phys. Sci. 1948, 240, 599–642. [Google Scholar] [CrossRef]

- Aharoni, A. Angular dependence of nucleation by curling in a prolate spheroid. J. Appl. Phys. 1997, 82, 1281–1287. [Google Scholar] [CrossRef]

- Kondorsky, E. On hysteresis in ferromagnetics. J. Phys. 1940, 2, 161. [Google Scholar]

- Ratnam, D.V.; Buessem, W.R. Angular Variation of Coercive Force in Barium Ferrite. J. Appl. Phys. 1972, 43, 1291–1293. [Google Scholar] [CrossRef]

- Suponev, N.P.; Grechishkin, R.M.; Lyakhova, M.B.; Pushkar, Y.E. Angular dependence of coercive field in (Sm,Zr) (Co,Cu,Fe) alloys. J. Magn. Magn. Mater. 1996, 157-158, 376–377. [Google Scholar] [CrossRef]

- Mathews, M.; Houwman, E.P.; Boschker, H.; Rijnders, G.; Blank, D.H.A. Magnetization reversal mechanism in La0.67Sr0.33MnO3thin films on NdGaO3substrates. J. Appl. Phys. 2010, 107, 013904. [Google Scholar] [CrossRef]

- Han, X.M.; Ma, J.H.; Wang, Z.; Yao, Y.L.; Zuo, Y.L.; Xi, L.; Xue, D.S. Tunable in-plane uniaxial anisotropy and the magnetization reversal mechanism of patterned high-frequency soft magnetic FeTa strips. J. Phys. D. Appl. Phys. 2013, 46, 485004. [Google Scholar] [CrossRef]

- Kronmüller, H.; Durst, K.-D.; Sagawa, M. Analysis of the magnetic hardening mechanism in RE-FeB permanent magnets. J. Magn. Magn. Mater. 1988, 74, 291–302. [Google Scholar] [CrossRef]

- Givord, D.; Rossignol, M.F.; Taylor, D.W. Coercivity mechanisms in hard magnetic materials. J. Phys. IV 1992, 02, C3-95–C3-104. [Google Scholar] [CrossRef]

- Viqueira, M.S.; Bajales, N.; Urreta, S.E.; Bercoff, P.G. Magnetization mechanisms in ordered arrays of polycrystalline Fe 100−x Co x nanowires. J. Appl. Phys. 2015, 117, 204302. [Google Scholar] [CrossRef]

- Komogortsev, S.V.; Fel’k, V.A.; Li, O.A. The magnetic dipole-dipole interaction effect on the magnetic hysteresis at zero temperature in nanoparticles randomly dispersed within a plane. J. Magn. Magn. Mater. 2019, 473, 410–415. [Google Scholar] [CrossRef]

| Time of Annealing (min) | (kOe) ±0.05 | (f.u.) ±0.03 | (f.u.) ±0.03 | ±0.02 | (kOe) ±0.05 | (f.u.) ±0.03 | (f.u.) ±0.03 | ±0.01 | (MJ/m3) ±0.02 |

|---|---|---|---|---|---|---|---|---|---|

| 0 | 1.29 | 2.28 | 3.11 | 0.73 | 1.08 | 0.53 | 3.12 | 0.17 | 0.41 |

| 4 | 1.49 | 1.91 | 2.97 | 0.64 | 1.38 | 0.81 | 2.96 | 0.27 | 0.26 |

| 15 | 2.12 | 1.92 | 3.06 | 0.63 | 1.66 | 0.91 | 3.04 | 0.30 | 0.26 |

| 30 | 2.26 | 1.94 | 2.94 | 0.66 | 1.86 | 0.89 | 2.96 | 0.30 | 0.26 |

| 60 | 2.61 | 1.69 | 2.88 | 0.60 | 1.85 | 1.15 | 2.94 | 0.39 | 0.16 |

| 300 | 2.55 | 1.79 | 3.08 | 0.61 | 1.95 | 1.08 | 3.09 | 0.35 | 0.16 |

| Time of Annealing (min) | (deg.) | ||||

|---|---|---|---|---|---|

| 0 | 0.613(22) | 0.151(14) | 0.764(36) | 1.7 | 0.80(4) |

| 4 | 0.399(14) | 0.249(9) | 0.648(24) | 3.0 | 0.62(4) |

| 15 | 0.361(14) | 0.279(9) | 0.641(23) | 3.2 | 0.56(5) |

| 30 | 0.379(12) | 0.283(8) | 0.662(20) | 2.8 | 0.57(4) |

| 60 | 0.216(5) | 0.377(4) | 0.593(9) | 3.5 | 0.36(3) |

| 300 | 0.256(9) | 0.331(6) | 0.588(14) | 4.4 | 0.44(4) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zarzycki, A.; Perzanowski, M.; Krupinski, M.; Marszalek, M. Solid-State Dewetting as a Driving Force for Structural Transformation and Magnetization Reversal Mechanism in FePd Thin Films. Materials 2023, 16, 92. https://doi.org/10.3390/ma16010092

Zarzycki A, Perzanowski M, Krupinski M, Marszalek M. Solid-State Dewetting as a Driving Force for Structural Transformation and Magnetization Reversal Mechanism in FePd Thin Films. Materials. 2023; 16(1):92. https://doi.org/10.3390/ma16010092

Chicago/Turabian StyleZarzycki, Arkadiusz, Marcin Perzanowski, Michal Krupinski, and Marta Marszalek. 2023. "Solid-State Dewetting as a Driving Force for Structural Transformation and Magnetization Reversal Mechanism in FePd Thin Films" Materials 16, no. 1: 92. https://doi.org/10.3390/ma16010092

APA StyleZarzycki, A., Perzanowski, M., Krupinski, M., & Marszalek, M. (2023). Solid-State Dewetting as a Driving Force for Structural Transformation and Magnetization Reversal Mechanism in FePd Thin Films. Materials, 16(1), 92. https://doi.org/10.3390/ma16010092