Mechanical Behavior of Titanium Alloys at Moderate Strain Rates Characterized by the Punch Test Technique

Abstract

1. Introduction

2. Materials and Method of Punching Test

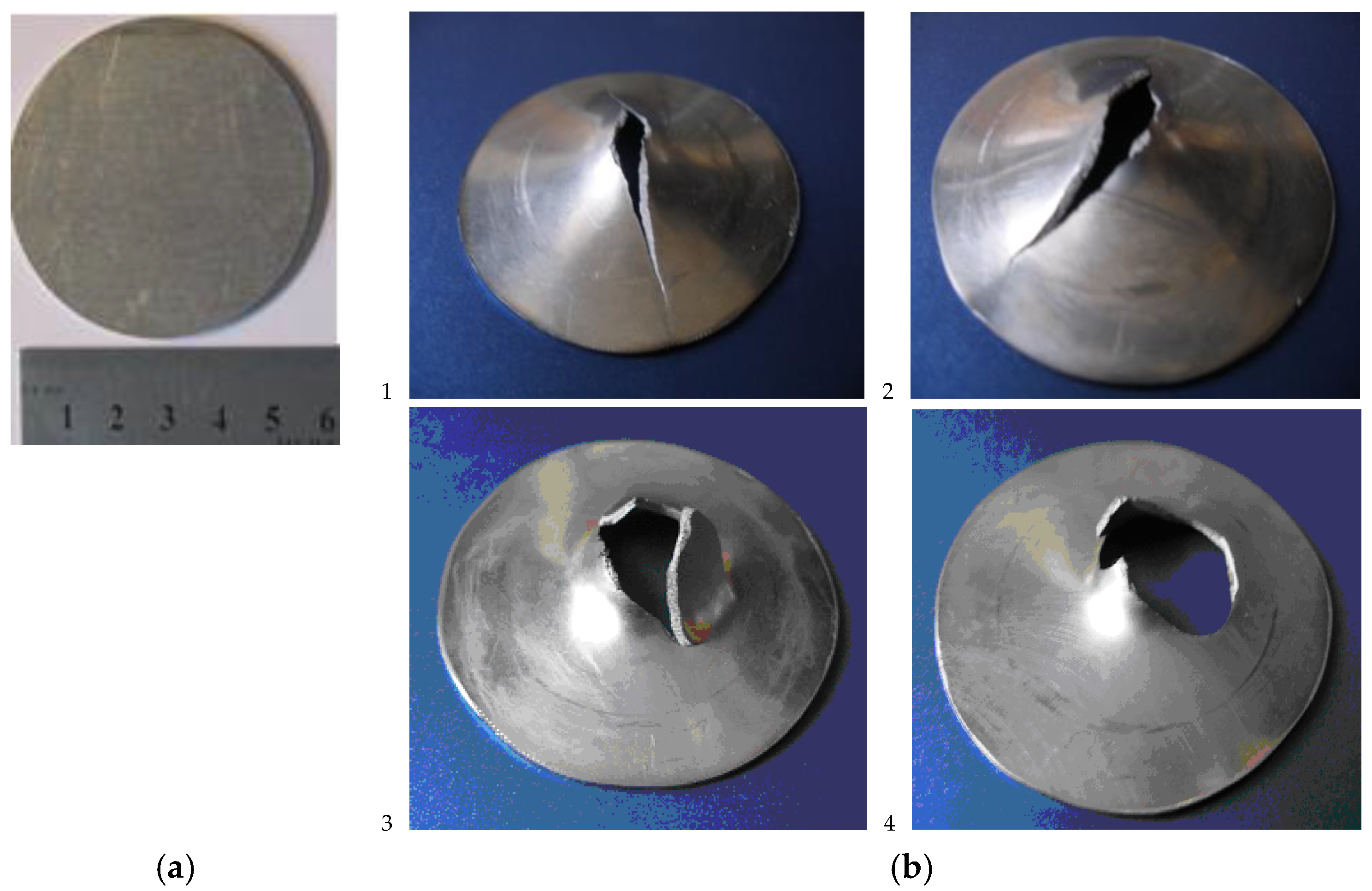

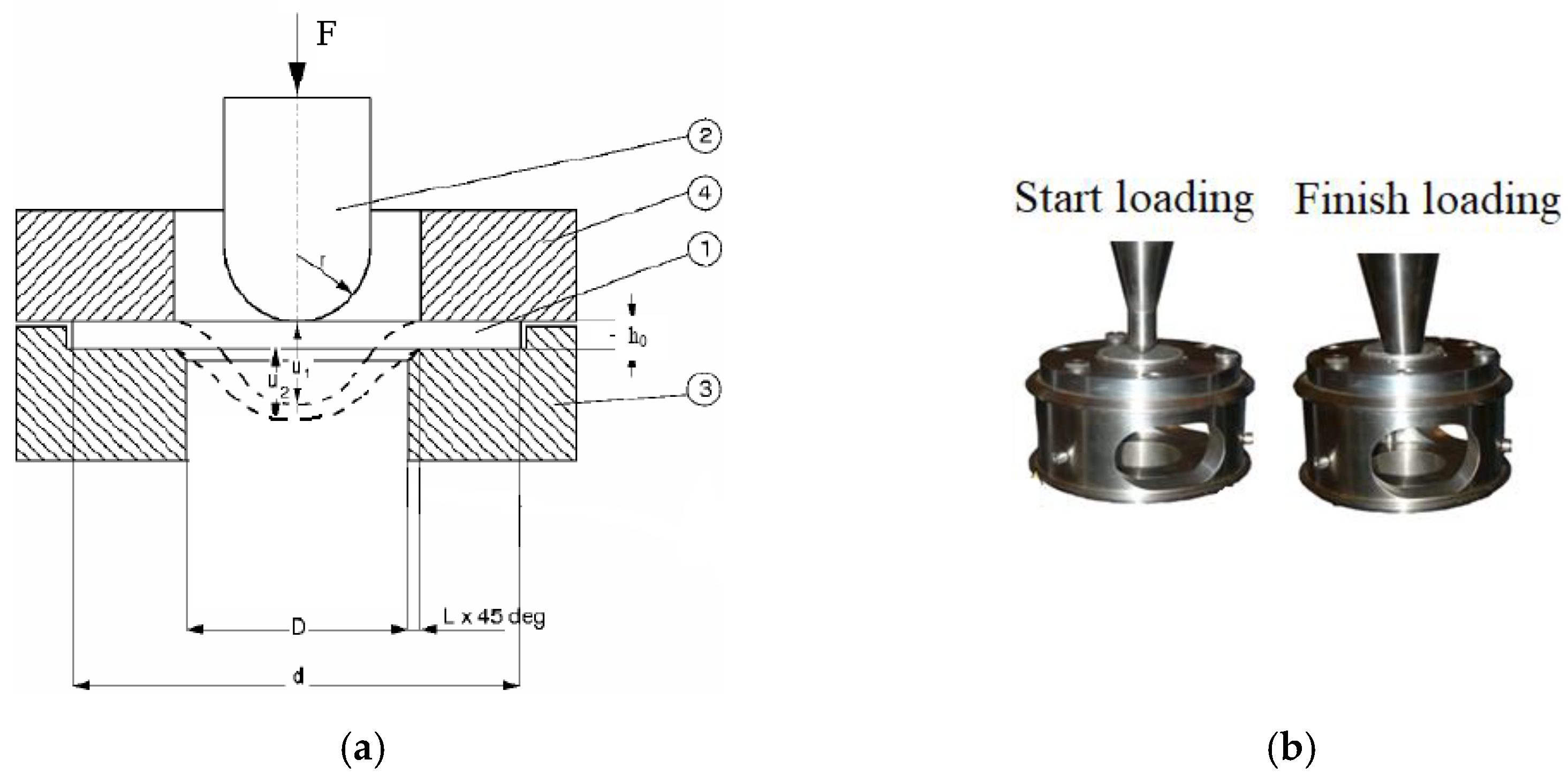

2.1. Material and Experimental Setup

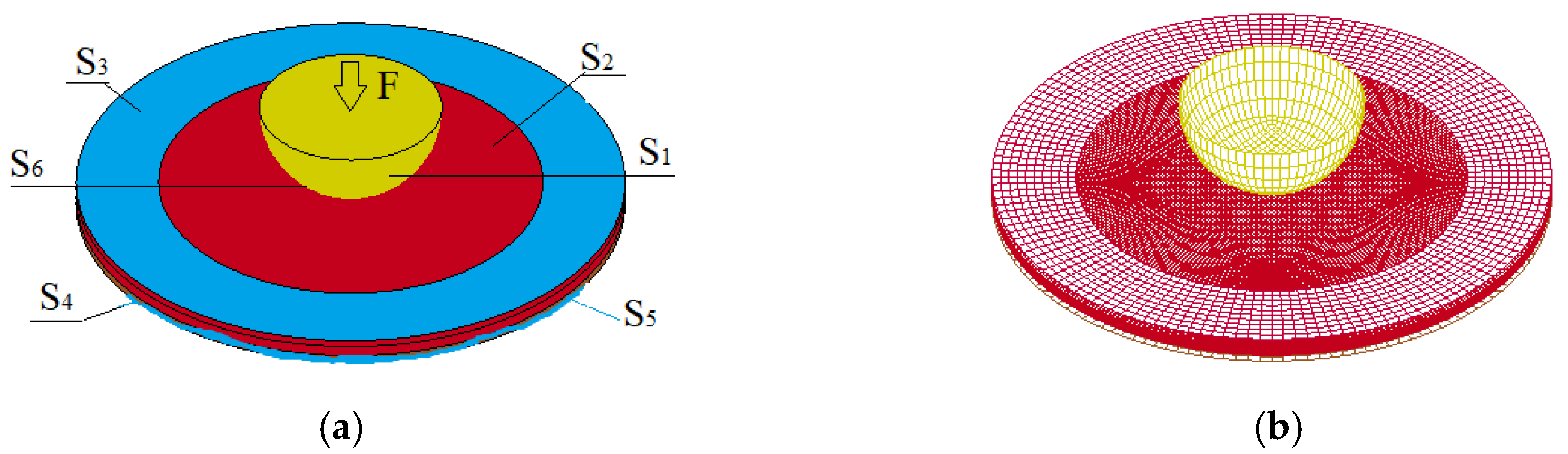

2.2. Numerical Simulation of Plastic Flow and Damage Evolution of Titanium Alloy during Dynamic Punching Test

3. Results

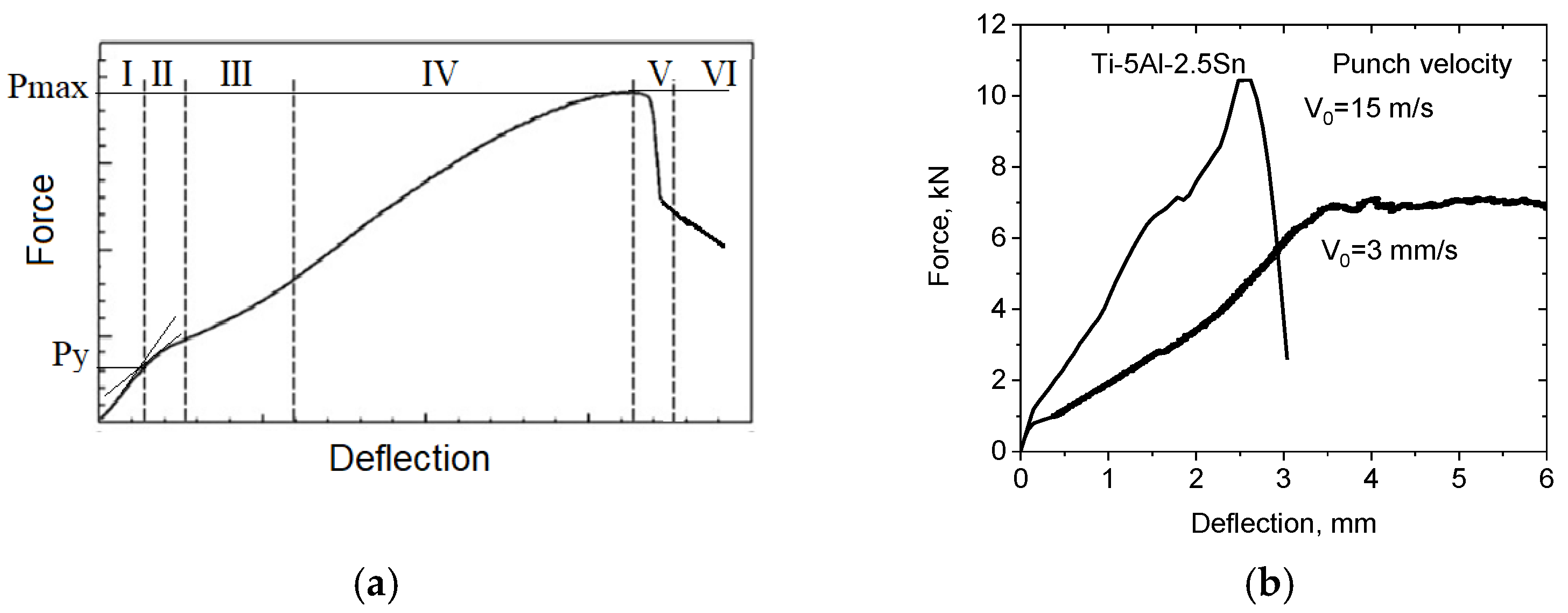

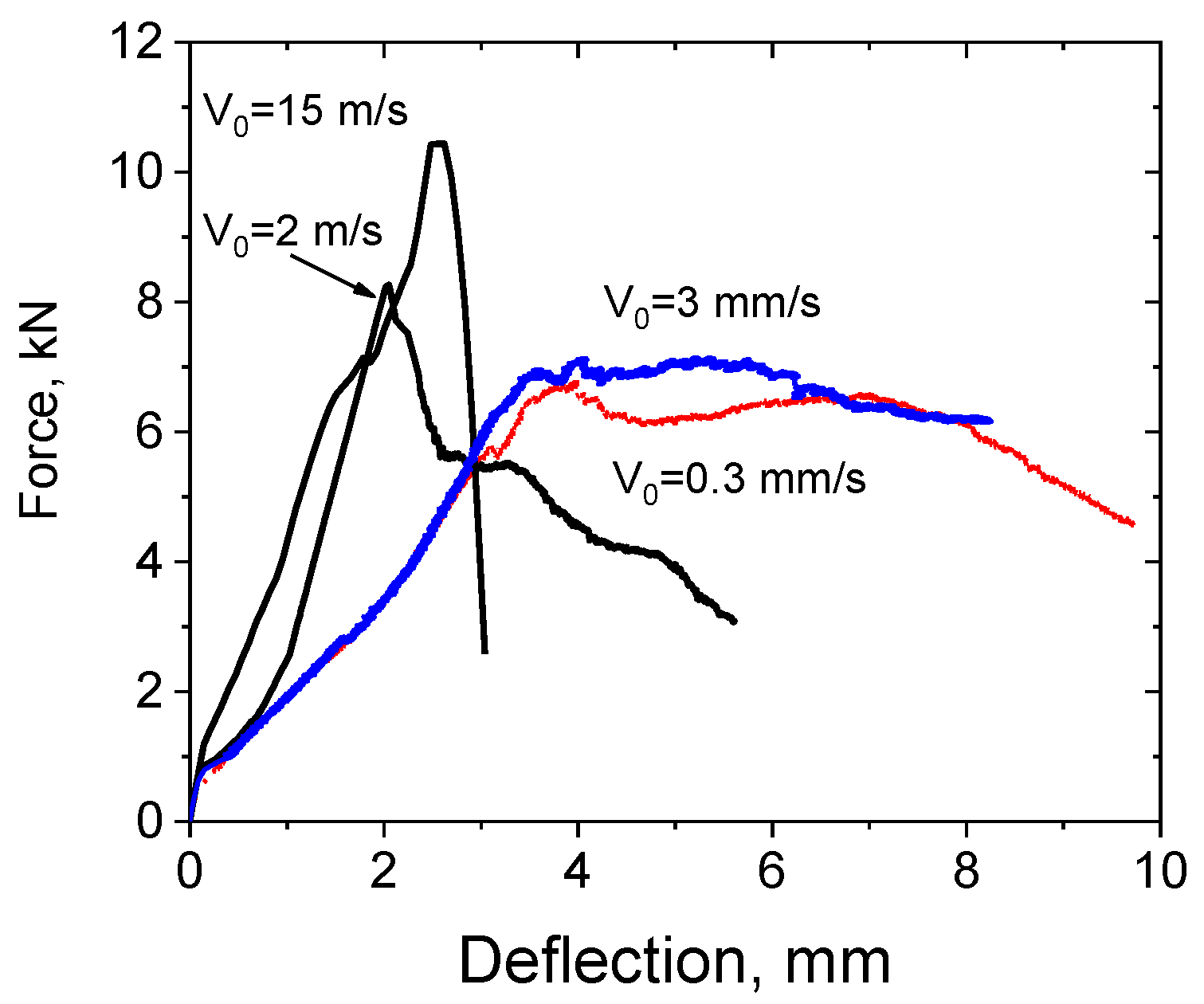

3.1. Experimantal Results

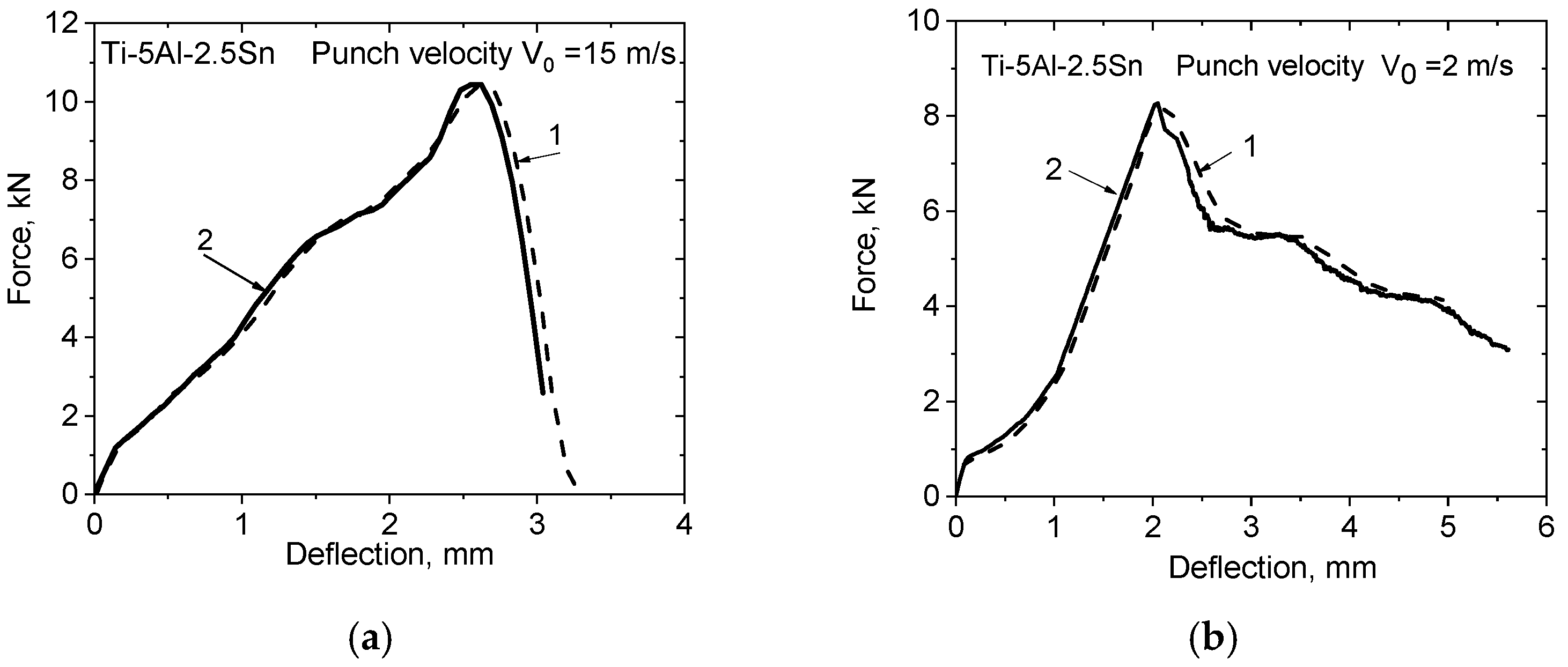

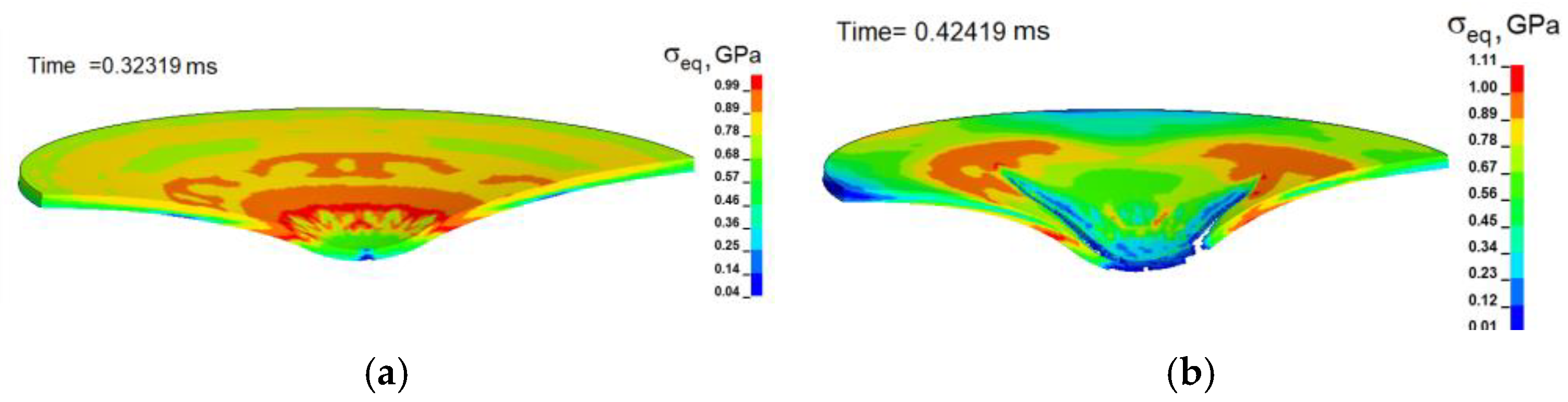

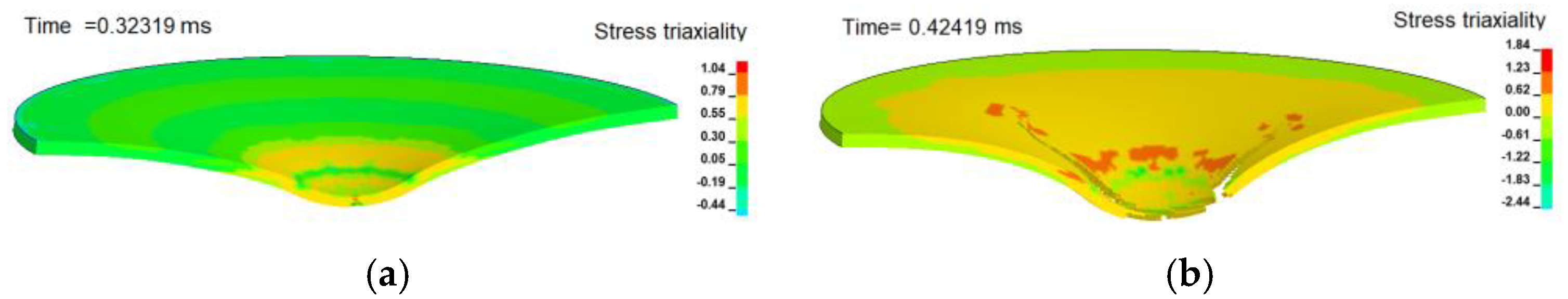

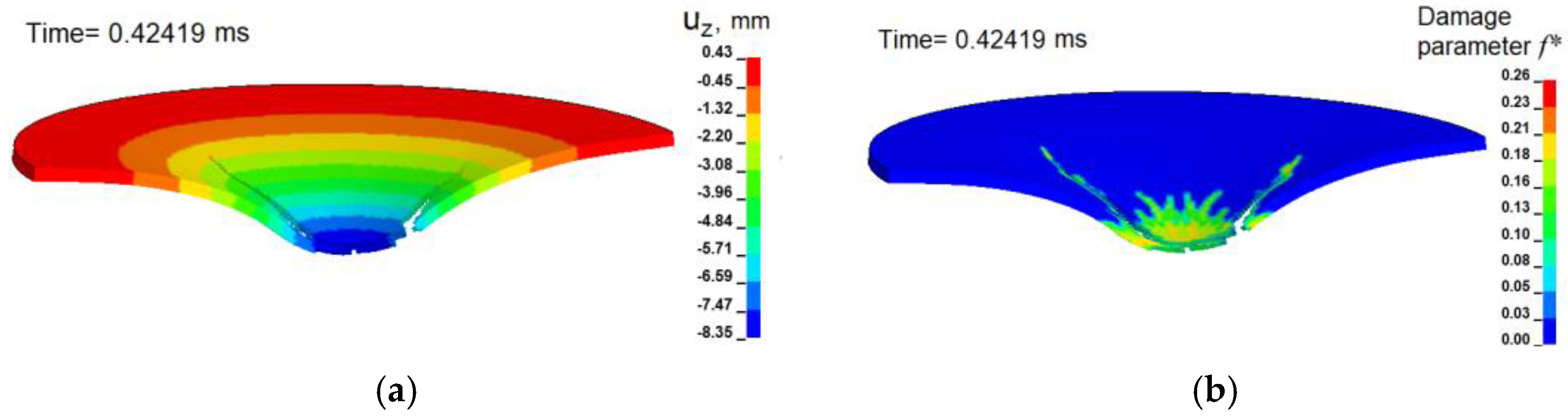

3.2. Simulation Results

4. Discussion

5. Conclusions

- The maximum values of plastic strain in the crack zone of fractured plates significantly exceeded the values of the macroscopic elongation δ of Ti-5Al-2.5Sn available in literature.

- The high local equivalent strains can realize in thin titanium plates at relatively small deflections during dynamic punching.

- The spatial distribution of damage and crack shape in a thin sheet of titanium alloy during stamping is significantly affected by the speed of the punch.

- An increase in the strain rate under conditions of a biaxial stress–strain state promotes the formation of localized shear bands and damage nucleation.

- The stress triaxiality parameter in the sheet of titanium alloy changes non-stationary and spatially inhomogeneous in the punching zone under deformation and damage development.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jayaprakash, M.; Ping, D.H.; Yamabe-Mitarai, Y. Enhanced yielding strength of near-α Ti–Al–Zr–Sn high temperature alloys. Mater. Sci. Eng. A 2015, 625, 131–139. [Google Scholar] [CrossRef]

- Lu, Z.; Zhang, X.; Ji, W.; Wei, W.; Yao, C.; Han, D. Investigation on the deformation mechanism of Ti–5Al-2.5Sn ELI titanium alloy at cryogenic and room temperatures. Mater. Sci. Eng. A 2021, 818, 141380. [Google Scholar] [CrossRef]

- Tan, M.J.; Chen, G.W.; Thiruvarudchelvan, S. High temperature deformation in Ti–5Al–2.5Sn alloy. J. Mater. Process. Technol. 2007, 192–193, 434–438. [Google Scholar] [CrossRef]

- Zhao, L.; Yasmeen, T.; Gao, P.; Wei, S.; Bai, Z.; Jiang, J.; Lin, J. Mechanism-based constitutive equations for superplastic forming of TA15 with equiaxed fine grain structure. Procedia Eng. 2017, 207, 1874–1879. [Google Scholar] [CrossRef]

- Ghosh, A.K.; Hamilton, C.H. Superplastic forming and diffusion bonding of titanium alloys. Def. Sci. J. 1986, 36, 153–177. [Google Scholar] [CrossRef]

- Tabie, V.M.; Li, C.; Saifu, W.; Li, J.; Xu, X. Mechanical properties of near alpha titanium alloys for high-temperature applications—A review. Aircr. Eng. Aerosp. Technol. 2020, 92, 521–540. [Google Scholar] [CrossRef]

- Luscher, D.J.; Buechler, M.A.; Walters, D.J.; Bolme, C.A.; Ramos, K.J. On computing the evolution of temperature for materials under dynamic loading. Int. J. Plast. 2018, 111, 188–210. [Google Scholar] [CrossRef]

- Skripnyak, V.V.; Skripnyak, V.A. Hexagonal close packed (hcp) alloys under dynamic impacts. J. Appl. Phys. 2022, 131, 16–19. [Google Scholar] [CrossRef]

- Çakan, B.G.; Soyarslan, C.; Bargmann, S.; Hähner, P. Experimental and computational study of ductile fracture in small punch tests. Materials 2017, 10, 1185. [Google Scholar] [CrossRef]

- Torres, J.; Gordon, A.P. Mechanics of the small punch test: A review and qualification of additive manufacturing materials. Int. J. Mater. Sci. 2021, 56, 10707–10744. [Google Scholar] [CrossRef]

- Bruchhausen, M.; Altstadt, E.; Austin TDymacek, P.; Holmström, S.; Jeffs, S.; Lacalle, R.; Lancaster, R.; Matocha, K.; Petzova, J. European standard on small punch testing of metallic materials. In Ubiquity Proceedings; Swansea University Bay Campus: Swansea, UK, 2018; Volume 1, (Suppl. S1), p. 11. [Google Scholar]

- Dabboussi, W.; Nemes, J.A. Modeling of ductile fracture using the dynamic punch test. Int. J. Mater. Sci. 2005, 47, 1282–1299. [Google Scholar] [CrossRef]

- Rubio-Gonzalez, C.; Mason, J.J. Experimental investigation of dynamic punch tests on isotropic and composite materials. Exp. Mech. 2001, 41, 129–139. [Google Scholar] [CrossRef]

- Mak, J.; Wuhrer, R.; Humphries, S.R.; Booth, N.; Heness, G.; Yeung, W.Y.; Wei, T.; Qin, J.N.; Ouyang, Q.B.; Zhang, D. Small punch test of LC4/SiC metal matrix composites. Adv. Mater. Res. 2010, 123–125, 439–442. [Google Scholar]

- Priel, E.; Mittelman, B.; Trabelsi, N.; Lulu-Bitton, N.; Haroush, S.; Kalabukhov, S.; Hayun, S.; Navi, N.U. Small punch testing of Al-TiB2 composites fabricated by spark plasma sintering: A computational and experimental study. J. Compos. Mater. 2022, 56, 3957–3969. [Google Scholar] [CrossRef]

- Skripnyak, N.V. The features of fracture behavior of an aluminum-magnesium alloy AMg6 under high-rate straining. Russ. Phys. J. 2015, 58, 691–697. [Google Scholar] [CrossRef]

- Li, X.; Guo, G.; Xiao, J.; Song, N.; Li, D. Constitutive modeling and the effects of strain-rate and temperature on the formability of Ti–6Al–4V alloy sheet. Mater. Des. 2014, 55, 325–334. [Google Scholar] [CrossRef]

- Li, H.; Chen, S.-F.; Zhang, S.-H.; Xu, Y.; Song, H.-W. Deformation characteristics, formability and springback control of Titanium alloy sheet at room temperature: A review. Materials 2022, 15, 5586. [Google Scholar] [CrossRef] [PubMed]

- Sirvin, Q.; Velay, V.; Bonnaire, R.; Penazzi, L. Mechanical behaviour modelling and finite element simulation of simple part of Ti-6Al-4V sheet under hot/warm stamping conditions. J. Manuf. Process. 2019, 38, 472–482. [Google Scholar] [CrossRef]

- Skripnyak, V.V.; Skripnyak, E.G.; Skripnyak, V.A. Fracture of titanium alloys at high strain rates and under stress triaxiality. Metals 2020, 10, 305. [Google Scholar] [CrossRef]

- Skripnyak, V.V.; Skripnyak, V.A. Localization of Plastic Deformation in Ti-6Al-4V Alloy. Metals 2021, 11, 1745. [Google Scholar] [CrossRef]

- Skripnyak, V.V.; Iohim, K.V.; Skripnyak, E.G.; Skripnyak, V.A. Plastic deformation of titanium alloy Ti-6Al-4V in a complex stressed state under tension at high-strain rates. Lett. Mater. 2021, 11, 267–272. [Google Scholar]

- Skripnyak, V.V.; Skripnyak, V.A. Mechanical behavior of alpha titanium alloys at high strain rates, elevated temperature, and under stress triaxiality. Metals 2022, 12, 1300. [Google Scholar] [CrossRef]

- García, T.E.; Rodríguez, C.; Belzunce, F.J.; Suárez, C. Estimation of the mechanical properties of metallic materials by means of the small punch test. J. Alloys Compd. 2014, 582, 708–717. [Google Scholar] [CrossRef]

- Vemula, A.M.; Reddy, G.C.M.; Hussain, M.M.; Kumar, A.; Kumar, N.; Allasi, H.L. Post-surface processing and virtual simulation analysis of ball-punch test on CP-Ti material. Adv. Mater. Sci. Eng. 2022, 2022, 5625427. [Google Scholar] [CrossRef]

- Lancaster, R.J.; Illsley, H.W.; Davies, G.R.; Jeffs, S.P.; Baxter, G.J. Modelling the small punch tensile behaviour of an aerospace alloy. Mater. Sci. Technol. 2016, 33, 1065–1973. [Google Scholar] [CrossRef]

- Hähner, P.; Soyarslan, C.; Gülçimen, B.Ç.; Bargmann, S. Determining tensile yield stresses from small punch tests: A numerical-based scheme. Mater. Des. 2019, 182, 107974. [Google Scholar] [CrossRef]

- Lancaster, R.J.; Jeffs, S.P.; Haigh, B.J.; Barnard, N.C. Derivation of material properties using small punch and shear punch test methods. Mater. Des. 2022, 215, 110473. [Google Scholar] [CrossRef]

- Abendroth, M.; Kuna, M. Determination of deformation and failure properties of ductile materials by means of the small punch test and neural networks. Comput. Mater. Sci. 2003, 28, 633–644. [Google Scholar] [CrossRef]

- Huang, T.; Zhan, M.; Wang, K.; Chen, F.; Guo, J.; Li, Y.; Song, Z.; Bai, L. Forming limit stress diagram prediction of pure titanium sheet based on GTN Model. Materials 2019, 12, 1783. [Google Scholar] [CrossRef]

- Safari, M.; Hosseinipour, S.J.; Azodi, H.D. Experimental and numerical analysis of forming limit diagram (FLD) and forming limit stress diagram (FLSD). Mater. Sci. Appl. 2011, 2, 497–503. [Google Scholar] [CrossRef]

- Bruchhausen, M.; Holmström, S.; Simonovski, I.; Austin, T.; Lapetite, J.-M.; Ripplinger, S.; de Haan, F. Recent developments in small punch testing: Tensile properties and DBTT. Theor. Appl. Fract. Mech. 2016, 86, 2–10. [Google Scholar] [CrossRef]

- Sun, Q.; Lu, Y.; Chen, J. Identification of material parameters of a shear modified GTN damage model by small punch test. Int. J. Fract. 2020, 222, 25–35. [Google Scholar] [CrossRef]

- Zhao, X.; Zhang, J. Small punch test of U-shaped notch of TC4 titanium alloy and its numerical simulation. J. Mater. Eng. Perform. 2013, 22, 3182–3191. [Google Scholar] [CrossRef]

- Lucon, E.; Benzing, J.; Hrabe, N. Development and validation of small punch testing at NIST National Institute of Standards and Technology Interagency or Internal Report 8303. Natl. Inst. Stand. Technol. Interag. Intern. 2020, 8303, 55. [Google Scholar]

- Lucon, E.; Benzing, J.T.; Derimow, N.; Hrabe, N. Small punch testing to estimate the tensile and fracture properties of additively manufactured Ti-6Al-4V. J. Mater. Eng. Perform. 2021, 30, 5039–5049. [Google Scholar] [CrossRef]

- Mao, X.; Takahashi, H. Development of a further-miniaturized specimen of 3 mm diameter for TJZM disk (0.3 mm) small punch tests. J. Nucl. Mater. 1987, 150, 42–52. [Google Scholar] [CrossRef]

- Contreras, M.A.; Rodríguez, C.; Belzunce, F.J.; Betegón, C. Use of the small punch test to determine the ductile-to-brittle transition temperature of structural steels. Fatigue Fract. Eng. Mater. Struct. 2008, 31, 727–737. [Google Scholar] [CrossRef]

- Bai, Y.; Wierzbicki, T. A new model of metal plasticity and fracture with pressure and Lode dependence. Int. J. Plast. 2008, 24, 1071–1096. [Google Scholar] [CrossRef]

- Zhang, J.; Zhao, Y.; Hixson, R.S.; Gray, G.T.; Wang, L.; Utsumi, W.; Takanori, H. Thermal equations of state for titanium obtained by high pressure—temperature diffraction studies. Phys. Rev. B 2008, 78, 054119. [Google Scholar] [CrossRef]

- Steinberg, D.J.; Cochran, S.G.; Guinan, M.W. A constitutive model for metals applicable at high-strain rate. J. Appl. Phys. 1980, 51, 1498–1504. [Google Scholar] [CrossRef]

- Springmann, M.; Kuna, M. Identification of material parameters of the Gurson–Tvergaard–Needleman model by combined experimental and numerical techniques. Comput. Mater. Sci. 2005, 32, 544–552. [Google Scholar] [CrossRef]

- Zhang, T.; Lu, K.; Mano, F.; Yamaguchi, Y.; Katsuyama, J.; Li, Y. A novel method to uniquely determine the parameters in Gurson–Tvergaard–Needleman model. Fatigue Fract. Eng. Mater. Struct. 2021, 44, 3399–3415. [Google Scholar] [CrossRef]

- Becker, R. Ring fragmentation predictions using the Gurson model with material stability conditions as failure criteria. Int. J. Solids Struct. 2002, 39, 3555–3580. [Google Scholar] [CrossRef]

- Meyer, L.W.; Pursche, F. Experimental Methods. In Adiabatic Shear Locatization; Dodd, B., Bai, Y., Eds.; Elsevier: Waltham, MA, USA, 2012; pp. 21–109. [Google Scholar]

- Sharkeev, Y.; Vavilov, V.; Skripnyak, V.A.; Belyavskaya, O.; Legostaeva, E.; Kozulin, A.; Chulkov, A.; Sorokoletov, A.; Skripnyak, V.V.; Eroshenko, A.; et al. Analyzing the deformation and fracture of bioinert titanium, zirconium and niobium alloys in different structural states by the use of infrared thermography. Metals 2018, 8, 703. [Google Scholar] [CrossRef]

- Roessig, K.M.; Mason, J.J. Adiabatic shear localization in the dynamic punch test, Part I: Experimental investigation. Int. J. Plast. 1999, 15, 241–262. [Google Scholar] [CrossRef]

- Bai, Y.; Dodd, B. Adiabatic Shear Localization: Occurrence, Theories and Applications, 1st ed.; Pergamon Press: Oxford, UK, 1992; p. 378. [Google Scholar]

- Martínez-Pañeda, E.; Cuesta, I.I.; Peñuelas, I.; Díaz, A.; Alegre, J.M. Damage modeling in small punch test specimens. Theor. Appl. Fract. Mech. 2016, 86, 51–60. [Google Scholar] [CrossRef]

| Material | Parameter | |||||

|---|---|---|---|---|---|---|

| Ti-5Al-2.5Sn | C0, GPa | , GPa μm1/2 | A0, K−1 | A1, K−1 | , s−1 | Tm, K |

| 0.665 | 0.628 | 0.0224 | 0.002 | 103 | 1875 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Skripnyak, V.V.; Iohim, K.V.; Skripnyak, V.A. Mechanical Behavior of Titanium Alloys at Moderate Strain Rates Characterized by the Punch Test Technique. Materials 2023, 16, 416. https://doi.org/10.3390/ma16010416

Skripnyak VV, Iohim KV, Skripnyak VA. Mechanical Behavior of Titanium Alloys at Moderate Strain Rates Characterized by the Punch Test Technique. Materials. 2023; 16(1):416. https://doi.org/10.3390/ma16010416

Chicago/Turabian StyleSkripnyak, Vladimir V., Kristina V. Iohim, and Vladimir A. Skripnyak. 2023. "Mechanical Behavior of Titanium Alloys at Moderate Strain Rates Characterized by the Punch Test Technique" Materials 16, no. 1: 416. https://doi.org/10.3390/ma16010416

APA StyleSkripnyak, V. V., Iohim, K. V., & Skripnyak, V. A. (2023). Mechanical Behavior of Titanium Alloys at Moderate Strain Rates Characterized by the Punch Test Technique. Materials, 16(1), 416. https://doi.org/10.3390/ma16010416