Penetration Fracture Mechanism of Tungsten-Fiber-Reinforced Zr-Based Bulk Metallic Glasses Matrix Composite under High-Velocity Impact

Abstract

1. Introduction

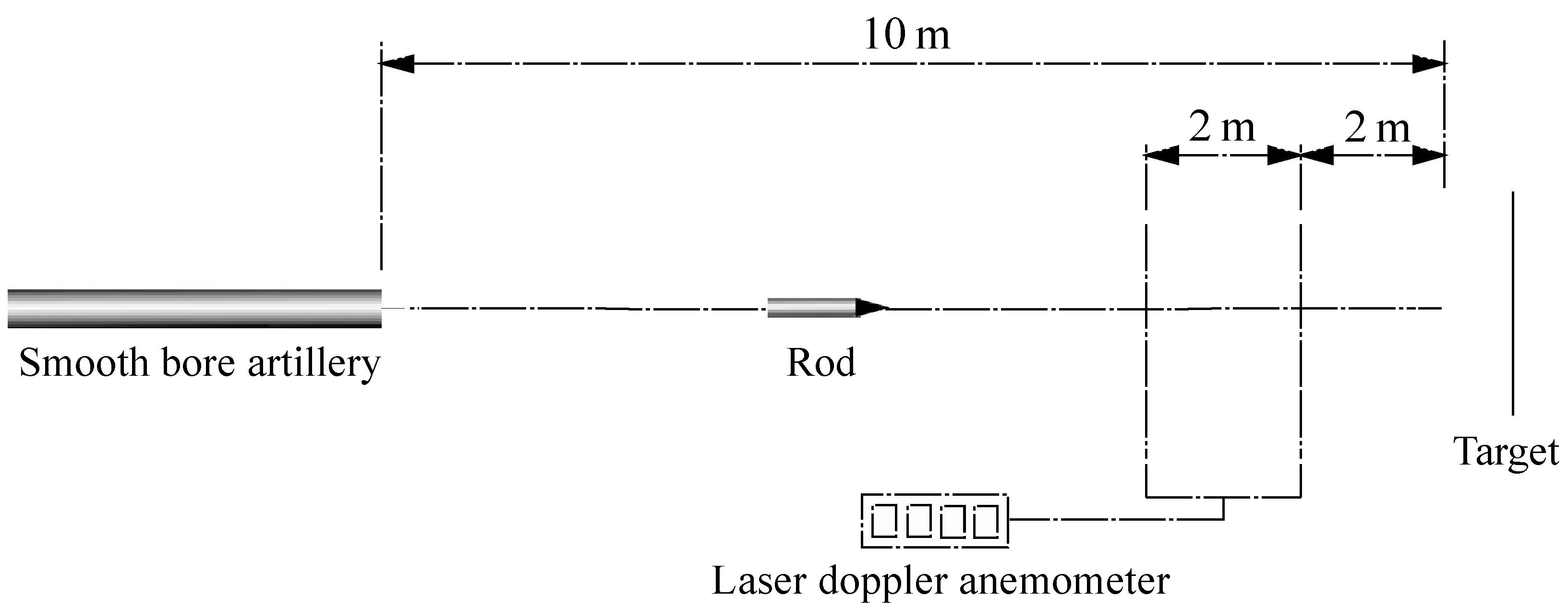

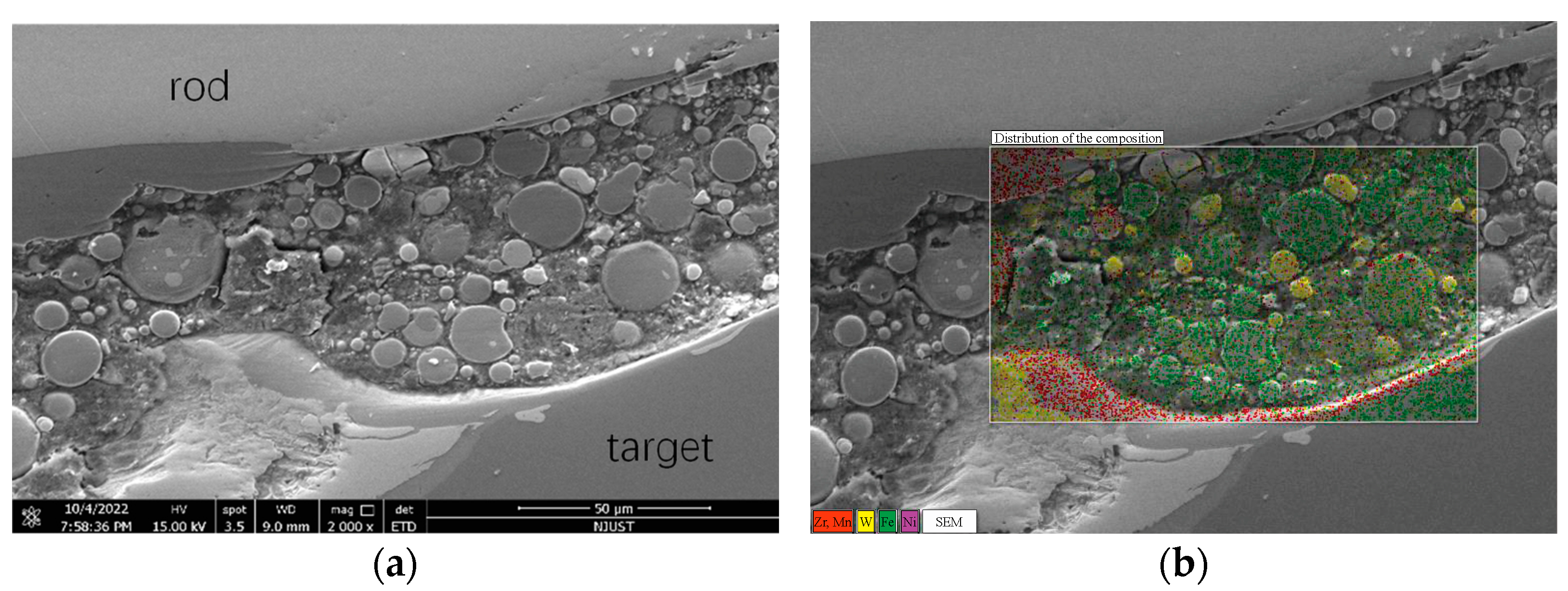

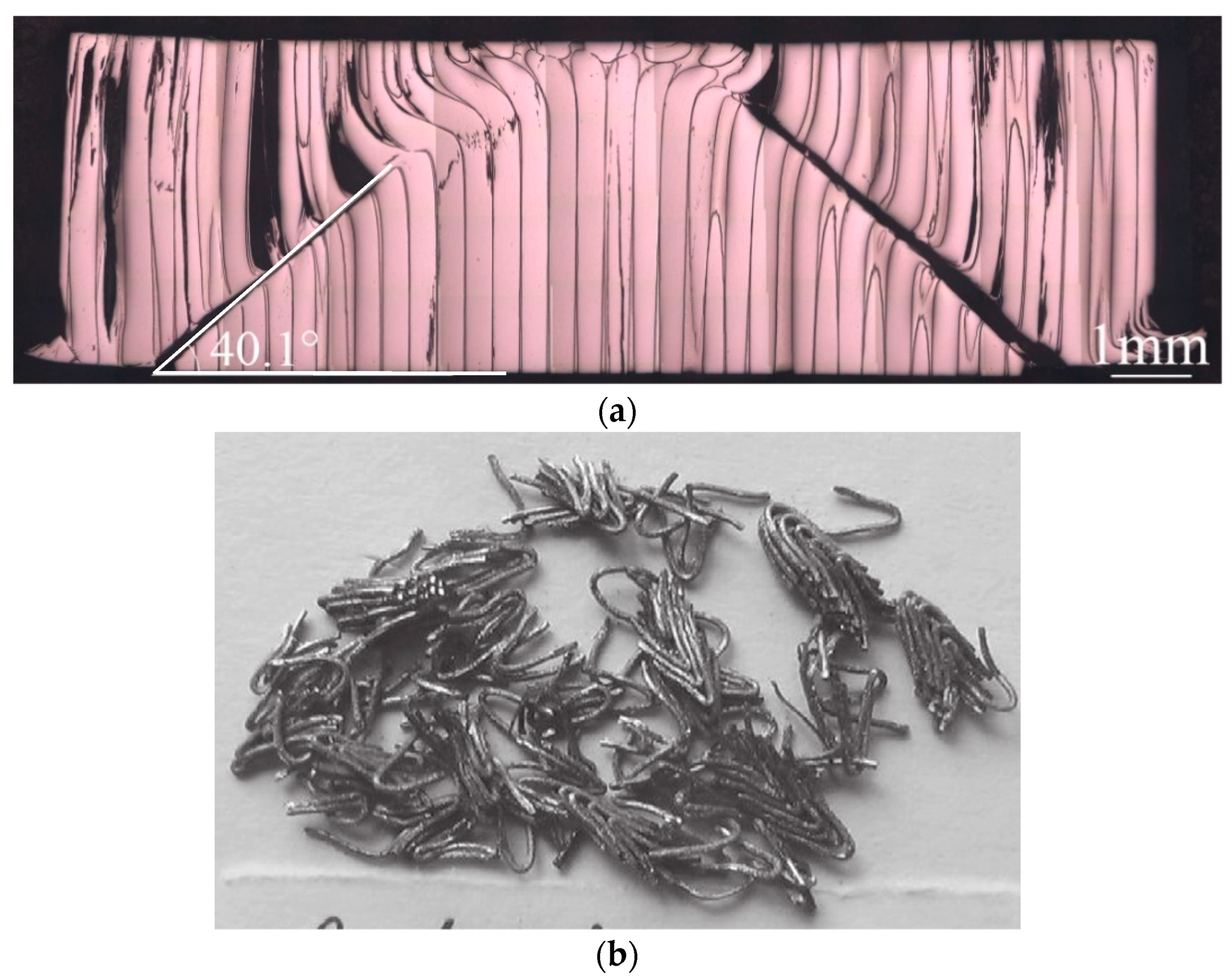

2. Experiment on WF/Zr-MG Rod

2.1. Setup of Experiment

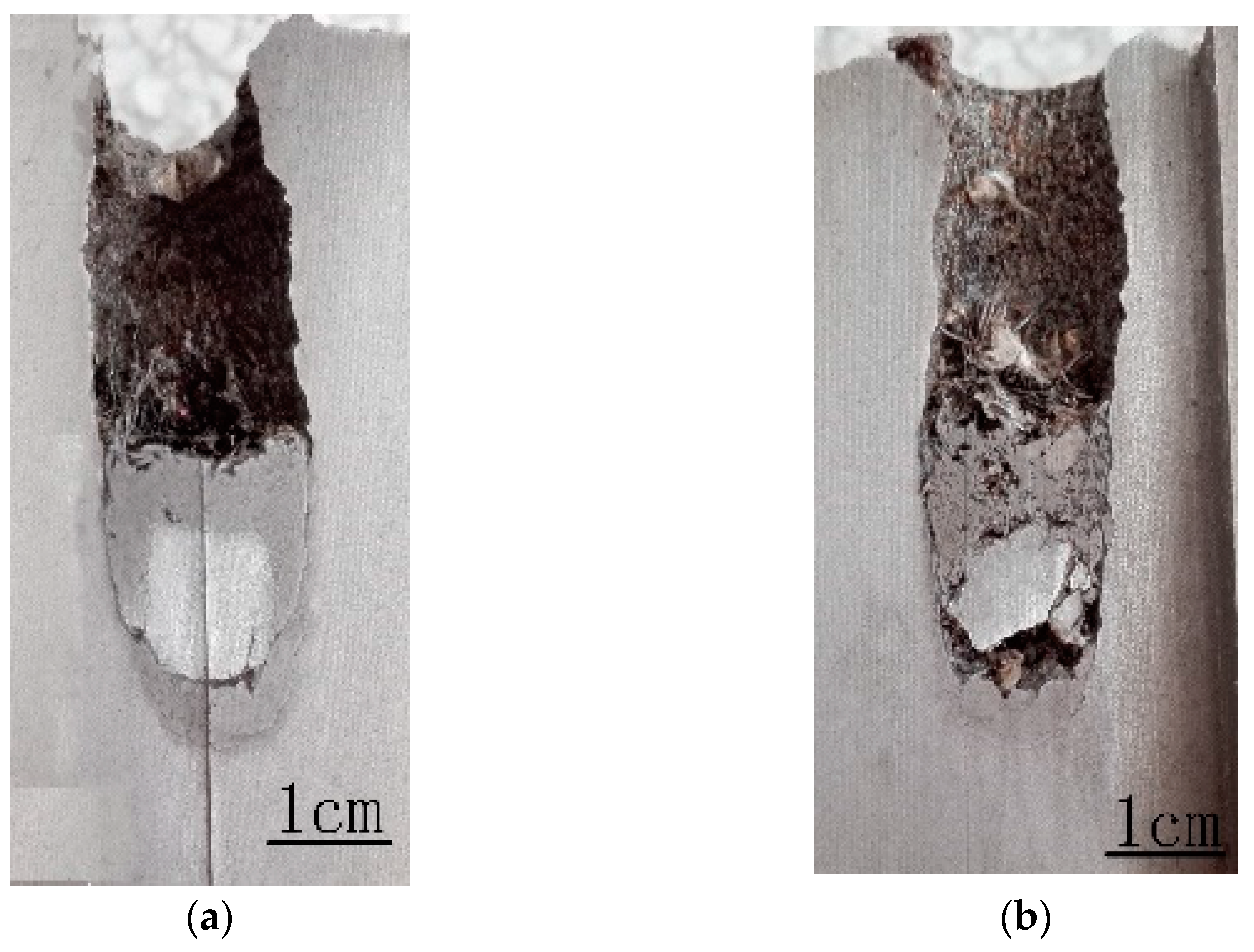

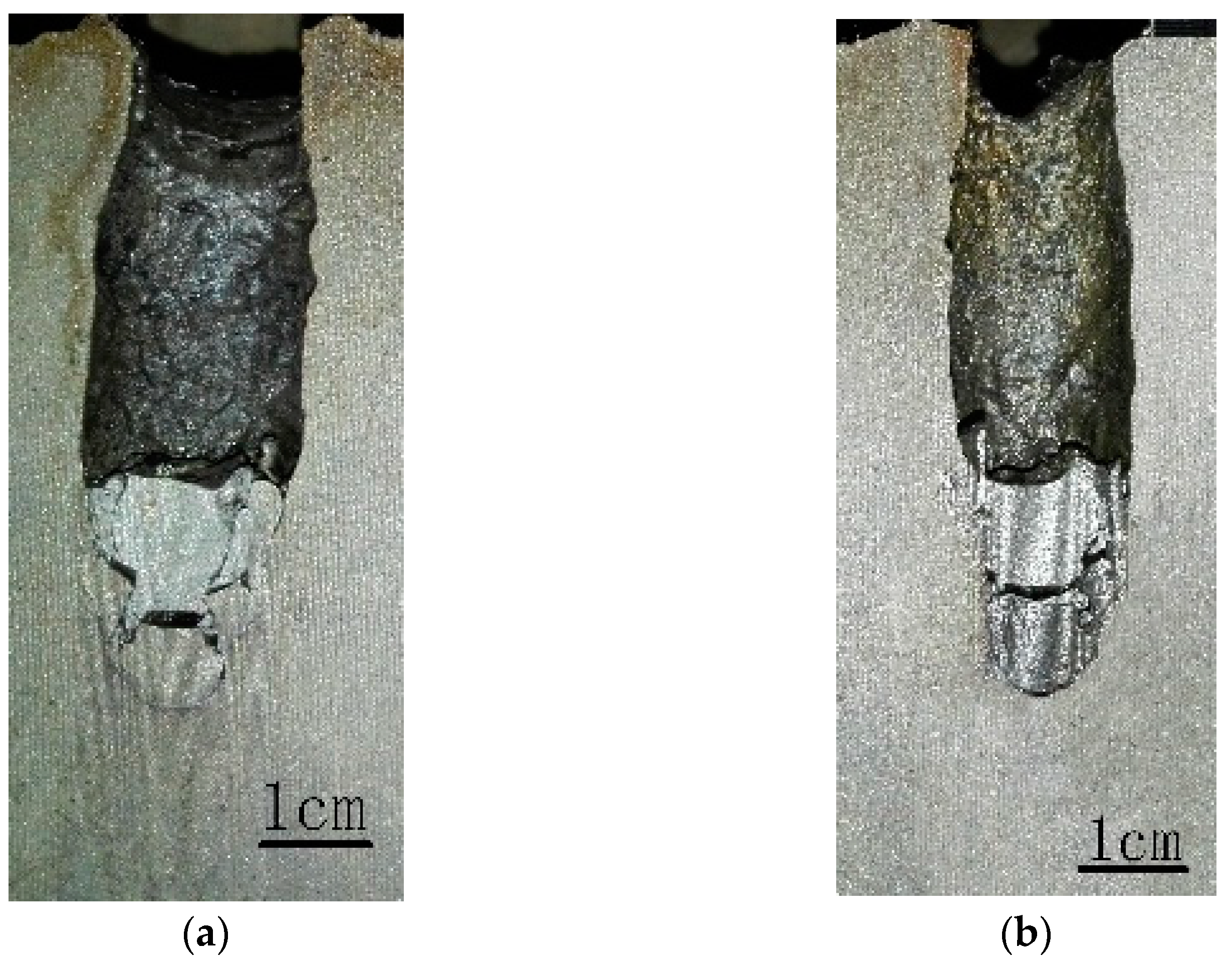

2.2. Experimental Results and Analysis

3. Penetration Fracture Mode of WF/Zr-MG Rod

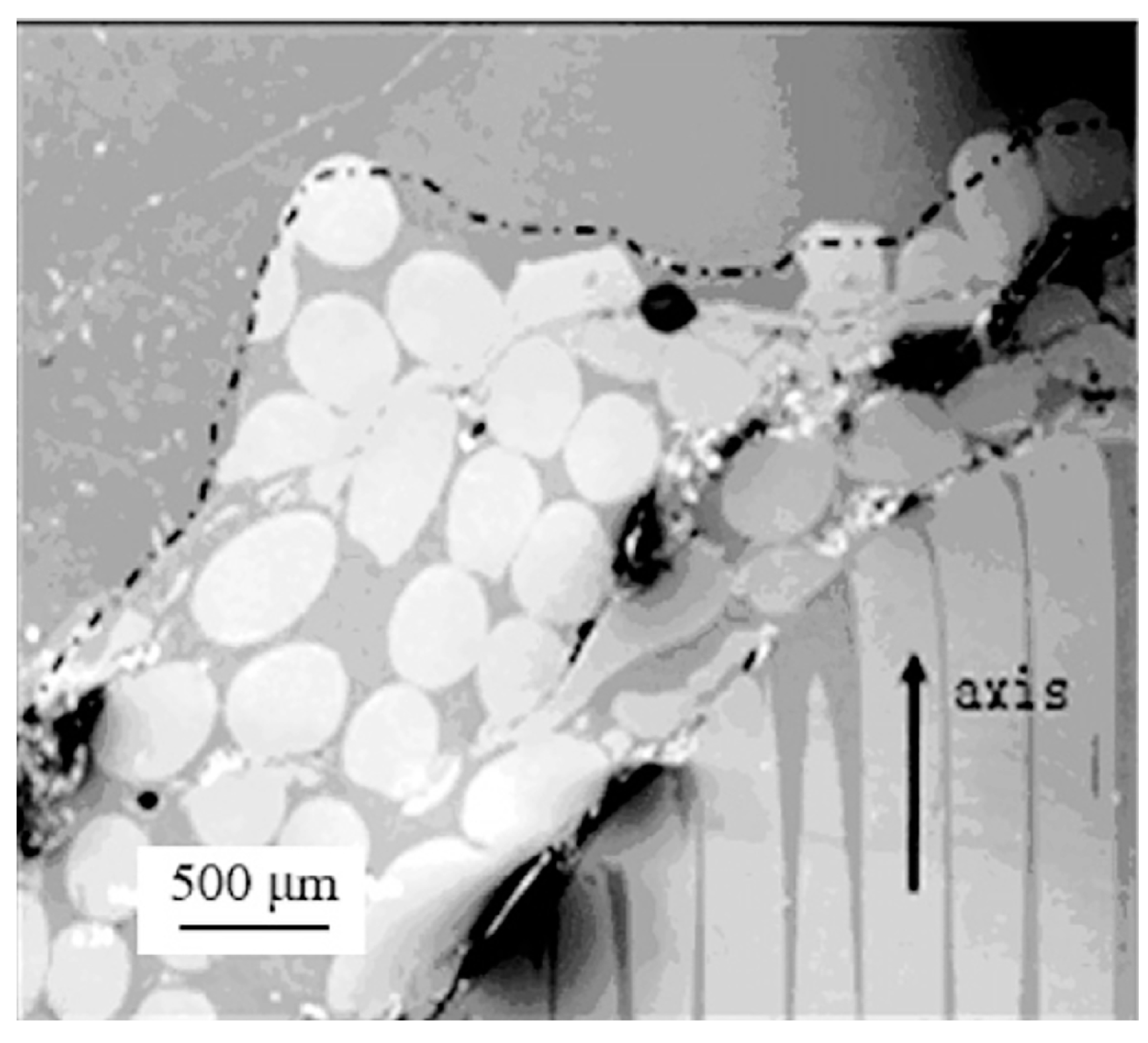

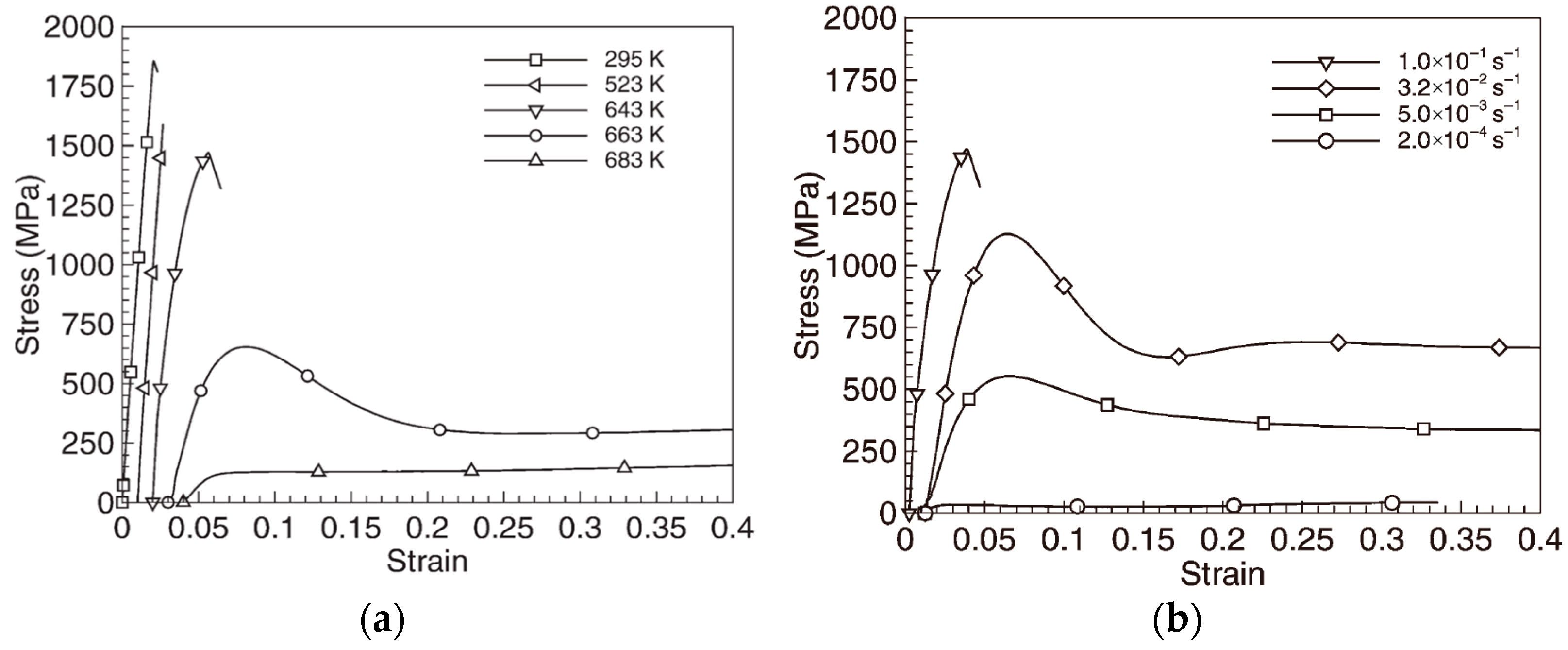

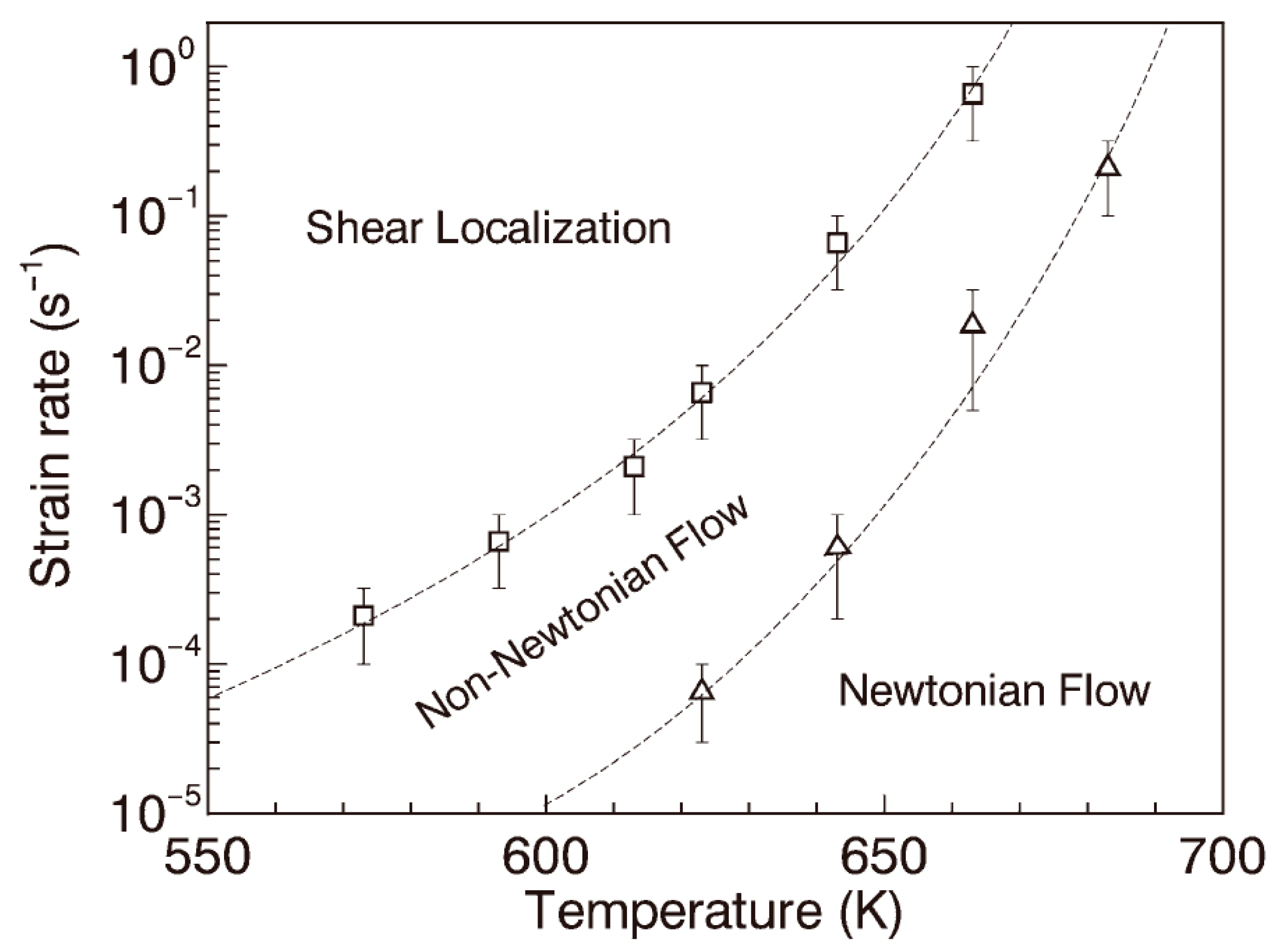

4. Discussion

4.1. Influence Factors of the Fracture Mode of WF/Zr-MG

4.2. Influence Mechanism of the Matrix of Zr-MG on Penetration Fracture Mode of WF/Zr-MG

5. Conclusions

- (1)

- When the impact velocity increases from 1000 m/s to 1500 m/s, the penetration fracture mode of WF/Zr-MG rods changes from shear fracture to the bending and backflow of tungsten fibers. The penetration fracture mode of WF/Zr-MG rods is mainly affected by the deformation mode of Zr-MG. At 1000 m/s, the fracture mode of Zr-MG is shear localization, and Zr-MG and tungsten fibers deform together, which leads to the penetration fracture mode of WF/Zr-MG rods being shear fracture. At 1500 m/s, the deformation mode of Zr-MG changes to non-Newtonian flow, and Zr-MG loses the constraint on the tungsten fibers, which causes the penetration fracture to change to the bending and backflow of tungsten fibers.

- (2)

- Under the same penetration conditions, the length of the quasi-steady penetration phase of WF/Zr-MG rods is longer than that of WHA rods, and the average crater diameter in the quasi-steady penetration phase is smaller, which results in the higher penetration ability of WF/Zr-MG rods.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Conner, R.; Dandliker, R.; Johnson, W. Mechanical properties of tungsten and steel fiber reinforced Zr41.25Ti13.75Cu12.5Ni10Be22.5 metallic glass matrix composites. Acta Mater. 1998, 46, 6089–6102. [Google Scholar] [CrossRef]

- Conner, R.; Dandliker, R.; Scruggs, V.; Johnson, W. Dynamic deformation behavior of tungsten-fiber/metallic–glass matrix composites. Int. J. Impact Eng. 2000, 24, 435–444. [Google Scholar] [CrossRef]

- Dandliker, R.B.; Conner, R.D.; Johnson, W.L. Melt infiltration casting of bulk metallic-glass matrix composites. J. Mater. Res. 1998, 13, 2896–2901. [Google Scholar] [CrossRef]

- Chen, G.; Hao, Y.; Chen, X.; Hao, H. Compressive behaviour of tungsten fibre reinforced Zr-based metallic glass at different strain rates and temperatures. Int. J. Impact Eng. 2017, 106, 110–119. [Google Scholar] [CrossRef]

- Du, C.; Du, Z.; Wang, K.; Dai, W.; Gao, G.; Zhu, Z.; Xu, L.; Chen, X. Effect of tungsten fiber diameter on the dynamic compression properties of tungsten fiber/Zr-based bulk metallic glasses matrix composite. Int. J. Impact Eng. 2022, 164, 104185. [Google Scholar] [CrossRef]

- Ma, W.; Kou, H.; Chen, C.; Li, J.; Chang, H.; Zhou, L.; Fu, H. Compressive deformation behaviors of tungsten fiber reinforced Zr-based metallic glass composites. Mater. Sci. Eng. A 2008, 486, 308–312. [Google Scholar] [CrossRef]

- Chen, S.; Li, W.; Zhang, L.; Fu, H.; Li, Z.; Zhu, Z.; Li, H.; Zhang, H.; Wang, A.; Wang, Y. Dynamic compressive mechanical properties of the spiral tungsten wire reinforced Zr-based bulk metallic glass composites. Compos. Part B Eng. 2020, 199, 108219. [Google Scholar] [CrossRef]

- Chen, S.; Zhang, L.; Fu, H.; Li, Z.; Zhu, Z.; Li, H.; Zhang, H.; Wang, A.; Wang, Y. Compressive mechanical properties and failure modes of Zr-based bulk metallic glass composites containing tungsten springs. Mater. Des. 2018, 160, 652–660. [Google Scholar] [CrossRef]

- Zhu, F.-L.; Chen, Y.; Zhu, G.-L. Numerical simulation study on penetration performance of depleted Uranium (DU) alloy fragments. Def. Technol. 2020, 17, 50–55. [Google Scholar] [CrossRef]

- Li, J.; Chen, X.; Huang, F. FEM analysis on the deformation and failure of fiber reinforced metallic glass matrix composite. Mater. Sci. Eng. A 2016, 652, 145–166. [Google Scholar] [CrossRef]

- Li, J.; Chen, X.; Huang, F. FEM analysis on the “self-sharpening” behavior of tungsten fiber/metallic glass matrix composite long rod. Int. J. Impact Eng. 2015, 86, 67–83. [Google Scholar] [CrossRef]

- Chen, X.; Wei, L.; Li, J. Experimental research on the long rod penetration of tungsten-fiber/Zr-based metallic glass matrix composite into Q235 steel target. Int. J. Impact Eng. 2015, 79, 102–116. [Google Scholar] [CrossRef]

- Du, C.; Shu, D.; Du, Z.; Gao, G.; Wang, M.; Zhu, Z.; Xu, L. Effect of L/D on penetration performance of tungsten fibre/Zr-based bulk metallic glass matrix composite rod. Int. J. Refract. Met. Hard Mater. 2019, 85, 105042. [Google Scholar] [CrossRef]

- Guo, W.; Jiang, H.; Wang, S.; Wan, M.; Fang, X.; Tian, S. Self-sharpening ability enhanced by torque gradient in twisted tungsten-fiber-reinforced Cu-Zn matrix composite. J. Alloys Compd. 2019, 794, 396–401. [Google Scholar] [CrossRef]

- Chen, X.; Chen, G. Experimental research on the penetration of tungsten-fiber/metallic-glass matrix composite material bullet into steel target. EPJ Web Conf. 2012, 26, 01049. [Google Scholar] [CrossRef]

- Rong, G.; Huang, D.; Yang, M. Penetrating behaviors of Zr-based metallic glass composite rods reinforced by tungsten fibers. Theor. Appl. Fract. Mech. 2012, 58, 21–27. [Google Scholar] [CrossRef]

- Liu, X.-F.; Tian, Z.-L.; Zhang, X.-F.; Chen, H.-H.; Liu, T.-W.; Chen, Y.; Wang, Y.-J.; Dai, L.-H. “Self-sharpening” tungsten high-entropy alloy. Acta Mater. 2020, 186, 257–266. [Google Scholar] [CrossRef]

- Chen, H.-H.; Zhang, X.-F.; Dai, L.-H.; Liu, C.; Xiong, W.; Tan, M.-T. Experimental study on WFeNiMo high-entropy alloy projectile penetrating semi-infinite steel target. Def. Technol. 2022, 18, 1470–1482. [Google Scholar] [CrossRef]

- Magness, L. Advanced Penetrator Materials. In Proceedings of the Armaments for the Army Transformation Conference, Parsippany, NJ, USA, 18–20 June 2001. [Google Scholar] [CrossRef]

- Du, C.; Fu, H.; Zhu, Z.; Wang, K.; Gao, G.; Zhou, F.; Xu, L.; Du, Z. Penetration Failure Mechanism of Multi-Diameter Tungsten Fiber Reinforced Zr-Based Bulk Metallic Glasses Matrix Composite Rod. Crystals 2022, 12, 124. [Google Scholar] [CrossRef]

- Lu, J.; Ravichandran, G.; Johnson, W. Deformation behavior of the Zr41.2Ti13.8Cu12.5Ni10Be22.5 bulk metallic glass over a wide range of strain-rates and temperatures. Acta Mater. 2003, 51, 3429–3443. [Google Scholar] [CrossRef]

- Masuhr, A.; Busch, R.; Johnson, W. Thermodynamics and kinetics of the Zr41.2Ti13.8Cu10.0Ni12.5Be22.5 bulk metallic glass forming liquid: Glass formation from a strong liquid. J. Non-Cryst. Solids 1999, 250-252, 566–571. [Google Scholar] [CrossRef]

- Grest, G.S.; Cohen, M.H.; Prigogine, I.; Rice, S.A. Liquids, glasses and the glass transition: A free volume approach. SA Rice I. Prigogine, Editeur. Adv. Chem. Phys. 1981, 48, 455–525. [Google Scholar]

- Rao, C.L.; Narayanamurthy, V.; Simha, K.R.Y. Applied Impact Mechanics; John Wiley & Sons: New York, NY, USA, 2016. [Google Scholar] [CrossRef]

- Meyers, M.A. Dynamic Behavior of Materials; Wiley: New York, NY, USA, 1994. [Google Scholar]

- Marsh, S.P. LASL Shock Hugoniot Data: LASL Shock Hugoniot Data; University of California Press: Berkeley, CA, USA, 1980. [Google Scholar]

- Anderson, C.E., Jr.; Littlefield, D.L.; Walker, J.D. Long-rod penetration, target resistance, and hypervelocity impact. Int. J. Impact Eng. 1993, 14, 1–12. [Google Scholar] [CrossRef]

- Anderson, C.E.; Walker, J.D. An examination of long-rod penetration. Int. J. Impact Eng. 1991, 11, 481–501. [Google Scholar] [CrossRef]

| No. | Material | Mass of Projectile (g) | Mass of Rod (g) |

|---|---|---|---|

| C1 | WF/Zr-MG | 112 | 62 |

| C2 | 113 | 62 | |

| W1 | WHA | 114 | 63 |

| W2 | 115 | 63 |

| No. | Material | Impact Velocity (m/s) | DOP (mm) | Length of TEP (mm) | Length of QSPP (mm) | Length of SPP (mm) | Diameter of QSPP (mm) |

|---|---|---|---|---|---|---|---|

| C1 | WF/Zr-MG | 1560 | 60 | 12.0 | 37.3 | 10.6 | 16.8 |

| C2 | 1523 | 63 | 10.1 | 43.3 | 9.6 | 16.3 | |

| W1 | WHA | 1447 | 56 | 13.6 | 22.6 | 19.8 | 19.6 |

| W2 | 1604 | 58 | 14.5 | 23.6 | 20.0 | 18.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, C.; Zhou, F.; Gao, G.; Du, Z.; Fu, H.; Zhu, Z.; Cheng, C. Penetration Fracture Mechanism of Tungsten-Fiber-Reinforced Zr-Based Bulk Metallic Glasses Matrix Composite under High-Velocity Impact. Materials 2023, 16, 40. https://doi.org/10.3390/ma16010040

Du C, Zhou F, Gao G, Du Z, Fu H, Zhu Z, Cheng C. Penetration Fracture Mechanism of Tungsten-Fiber-Reinforced Zr-Based Bulk Metallic Glasses Matrix Composite under High-Velocity Impact. Materials. 2023; 16(1):40. https://doi.org/10.3390/ma16010040

Chicago/Turabian StyleDu, Chengxin, Feng Zhou, Guangfa Gao, Zhonghua Du, Huameng Fu, Zhengwang Zhu, and Chun Cheng. 2023. "Penetration Fracture Mechanism of Tungsten-Fiber-Reinforced Zr-Based Bulk Metallic Glasses Matrix Composite under High-Velocity Impact" Materials 16, no. 1: 40. https://doi.org/10.3390/ma16010040

APA StyleDu, C., Zhou, F., Gao, G., Du, Z., Fu, H., Zhu, Z., & Cheng, C. (2023). Penetration Fracture Mechanism of Tungsten-Fiber-Reinforced Zr-Based Bulk Metallic Glasses Matrix Composite under High-Velocity Impact. Materials, 16(1), 40. https://doi.org/10.3390/ma16010040