Simulation of High-Performance Surface Plasmon Resonance Sensor Based on D-Shaped Dual Channel Photonic Crystal Fiber for Temperature Sensing

Abstract

1. Introduction

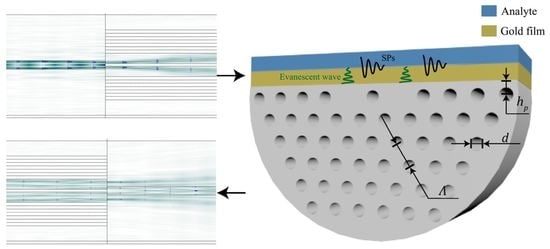

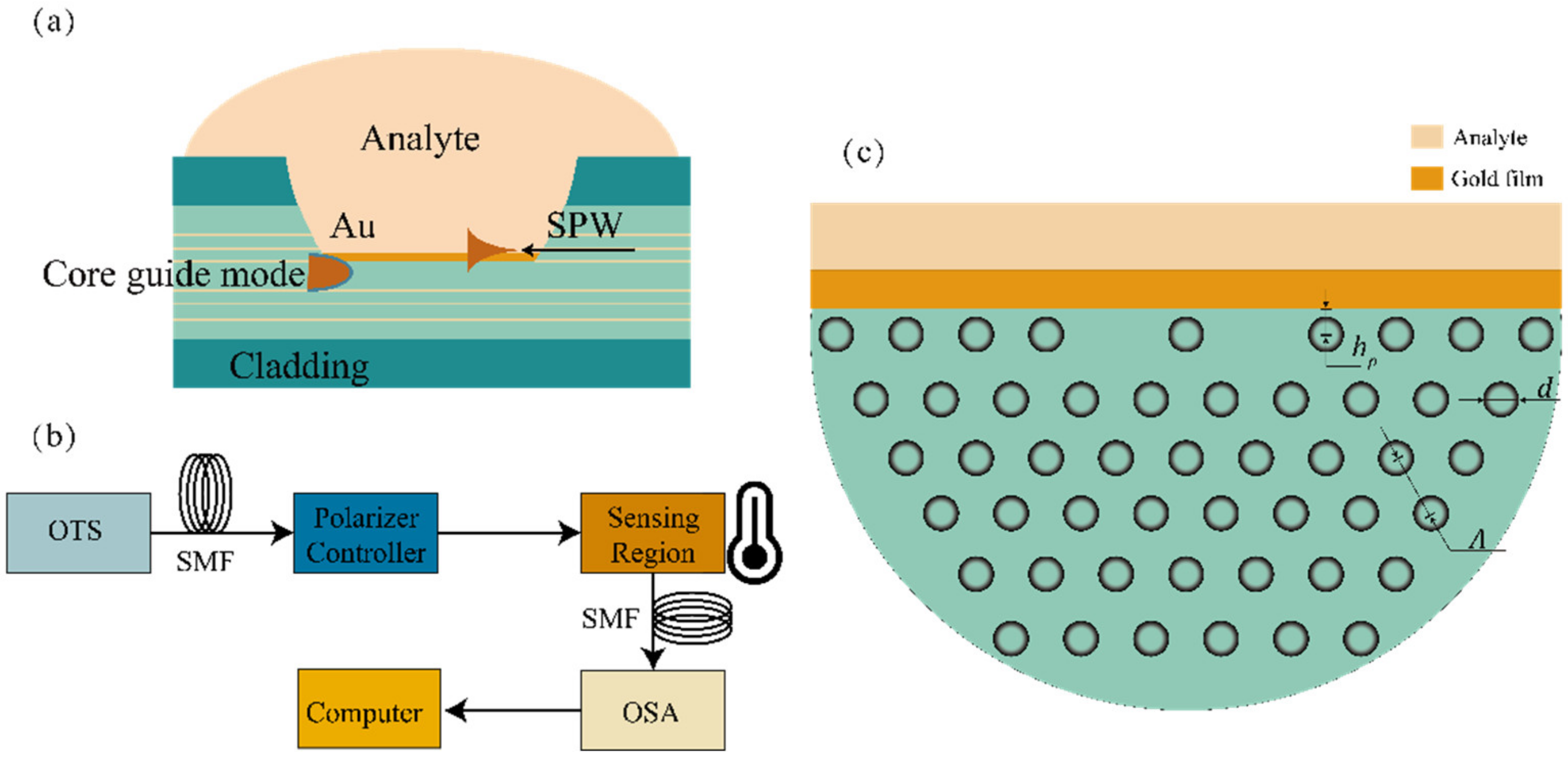

2. Device Design and Theoretical Foundation

3. Results and Discussion

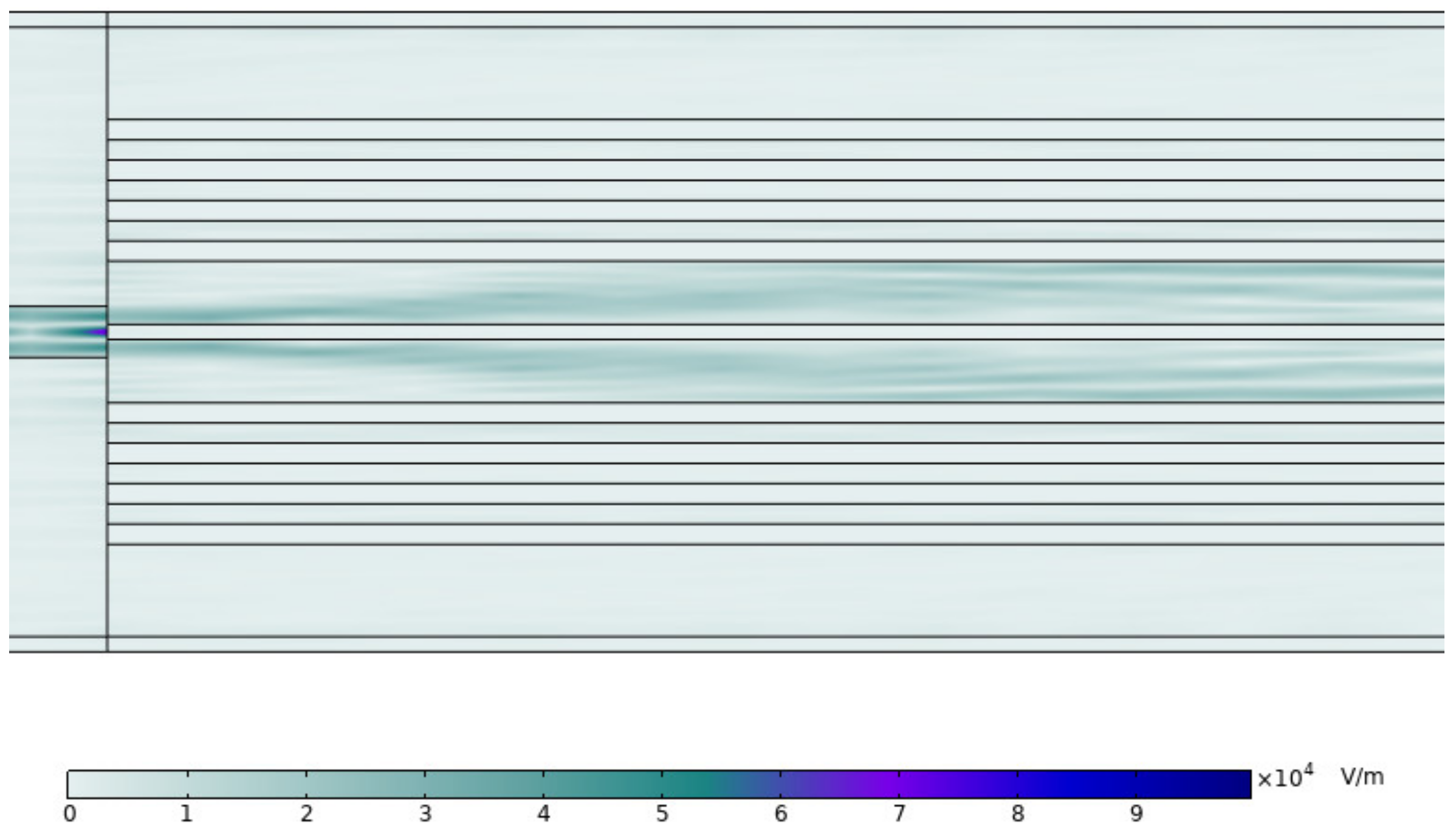

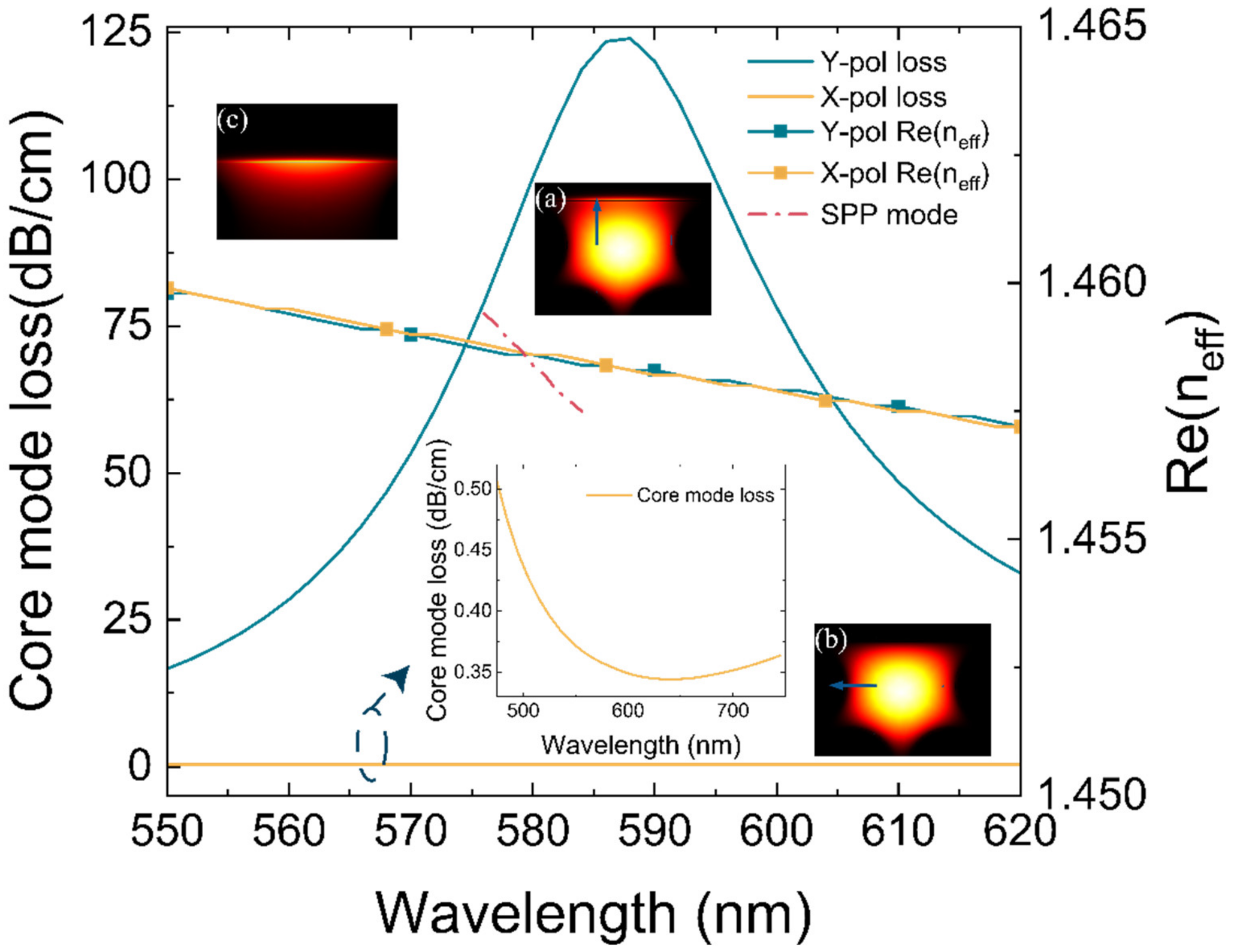

3.1. Excitation of Surface Plasmon Resonance

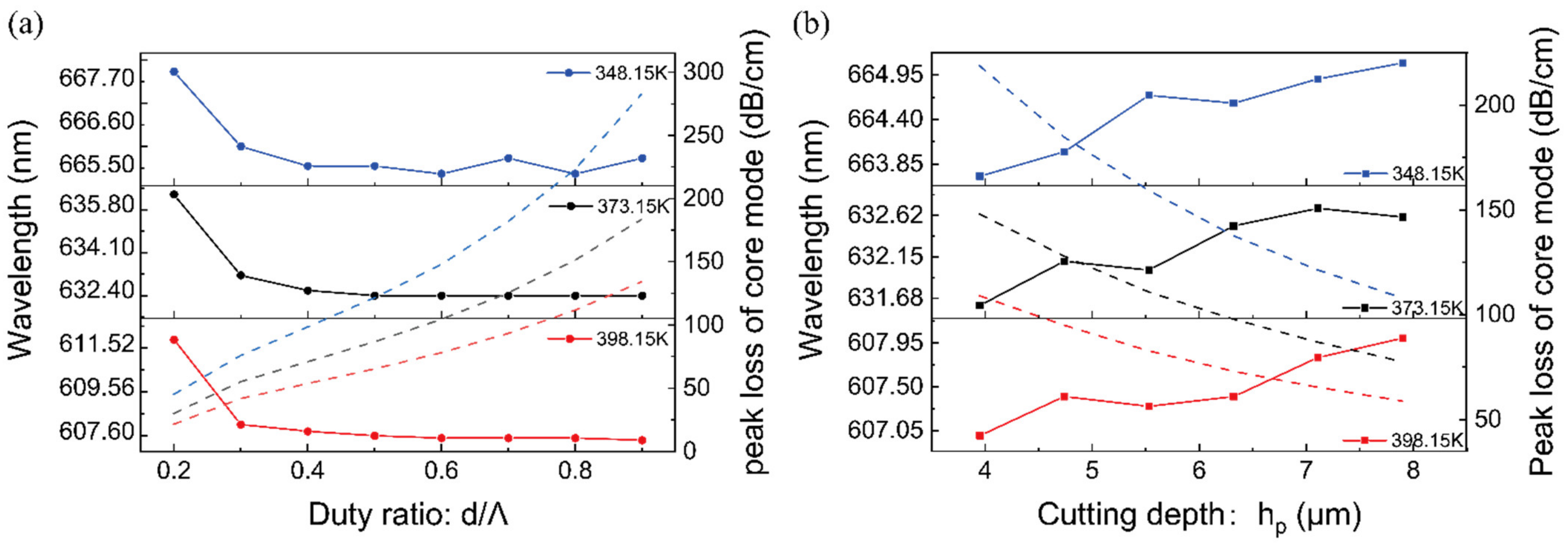

3.2. Duty Ratios and Polish Depth

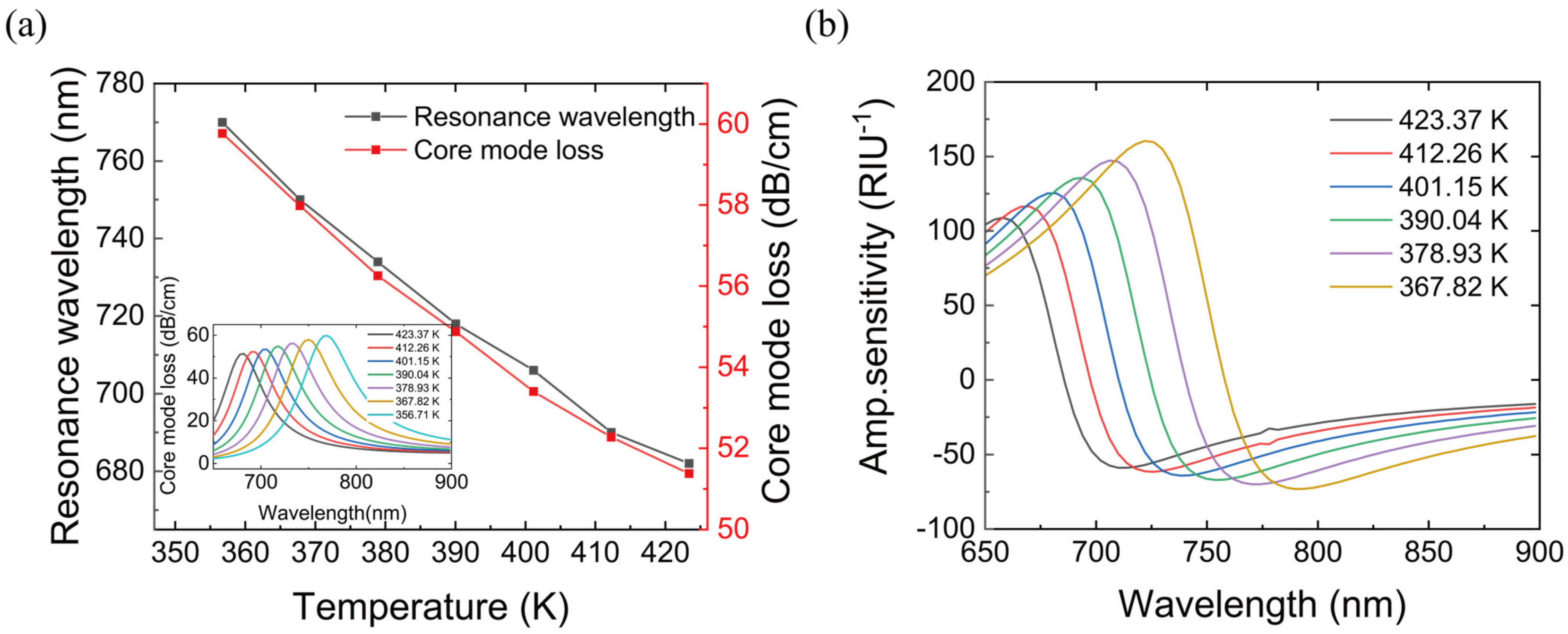

3.3. Wavelength Sensitivity, Amplitude Sensitivity, and Corresponding Resolution

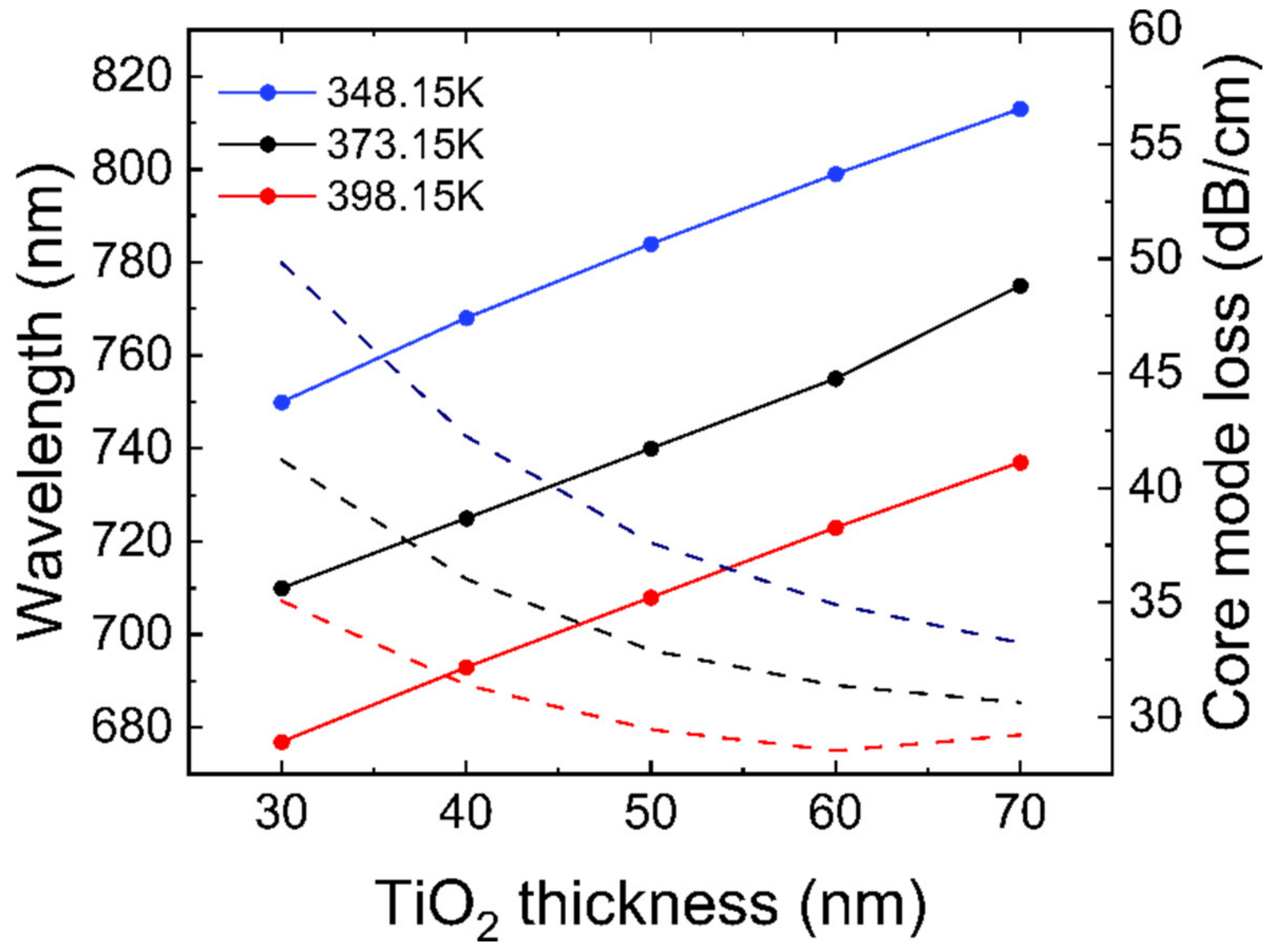

3.4. Nano-Titania Thin Film Sensitization

3.5. Mode Field Diameter

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Nath, P.; Singh, H.K.; Datta, P.; Sarma, K.C. All-Fiber Optic Sensor for Measurement of Liquid Refractive Index. Sens. Actuators A Phys. 2008, 148, 16–18. [Google Scholar] [CrossRef]

- Shi, Q.; Kuhlmey, B.T. Optimization of Photonic Bandgap Fiber Long Period Grating Refractive-Index Sensors. Opt. Commun. 2009, 282, 4723–4728. [Google Scholar] [CrossRef]

- Zhu, T.; Wu, D.; Liu, M.; Duan, D.-W. In-Line Fiber Optic Interferometric Sensors in Single-Mode Fibers. Sensors 2012, 12, 10430–10449. [Google Scholar] [CrossRef] [PubMed]

- Navarrete, M.-C.; Díaz-Herrera, N.; González-Cano, A.; Esteban, Ó. Surface Plasmon Resonance in the Visible Region in Sensors Based on Tapered Optical Fibers. Sens. Actuators B Chem. 2014, 190, 881–885. [Google Scholar] [CrossRef]

- Verma, R.K.; Gupta, B.D. Surface Plasmon Resonance Based Fiber Optic Sensor for the IR Region Using a Conducting Metal Oxide Film. J. Opt. Soc. Am. A 2010, 27, 846–851. [Google Scholar] [CrossRef]

- An, G.; Hao, X.; Li, S.; Yan, X.; Zhang, X. D-Shaped Photonic Crystal Fiber Refractive Index Sensor Based on Surface Plasmon Resonance. Appl. Opt. 2017, 56, 6988–6992. [Google Scholar] [CrossRef]

- Xu, H.; Song, Y.; Zhu, P.; Zhao, W.; Liu, T.; Wang, Q.; Zhao, T. Alcohol Sensor Based on Surface Plasmon Resonance of ZnO Nanoflowers/Au Structure. Materials 2022, 15, 189. [Google Scholar] [CrossRef]

- Jorgenson, R.C.; Yee, S.S. A Fiber-Optic Chemical Sensor Based on Surface Plasmon Resonance. Sens. Actuators B Chem. 1993, 12, 213–220. [Google Scholar] [CrossRef]

- Skorobogatiy, M.; Kabashin, A.V. Photon Crystal Waveguide-Based Surface Plasmon Resonance Biosensor. Appl. Phys. Lett. 2006, 89, 143518. [Google Scholar] [CrossRef]

- Yu, R.; Chen, Y.; Shui, L.; Xiao, L. Hollow-Core Photonic Crystal Fiber Gas Sensing. Sensors 2020, 20, 2996. [Google Scholar] [CrossRef]

- Qu, J.-H.; Leirs, K.; Maes, W.; Imbrechts, M.; Callewaert, N.; Lagrou, K.; Geukens, N.; Lammertyn, J.; Spasic, D. Innovative FO-SPR Label-Free Strategy for Detecting Anti-RBD Antibodies in COVID-19 Patient Serum and Whole Blood. ACS Sens. 2022, 7, 477–487. [Google Scholar] [CrossRef] [PubMed]

- Song, Y.; Sun, M.; Wu, H.; Zhao, W.; Wang, Q. Temperature Sensor Based on Surface Plasmon Resonance with TiO2-Au-TiO2 Triple Structure. Materials 2022, 15, 7766. [Google Scholar] [CrossRef] [PubMed]

- Situ, C.; Mooney, M.H.; Elliott, C.T.; Buijs, J. Advances in Surface Plasmon Resonance Biosensor Technology towards High-Throughput, Food-Safety Analysis. TrAC Trends Anal. Chem. 2010, 29, 1305–1315. [Google Scholar] [CrossRef]

- Zhao, Y.; Deng, Z.; Li, J. Photonic Crystal Fiber Based Surface Plasmon Resonance Chemical Sensors. Sens. Actuators B Chem. 2014, 202, 557–567. [Google Scholar] [CrossRef]

- Ge, D.; Shi, J.; Rezk, A.; Ma, C.; Zhang, L.; Yang, P.; Zhu, S. Two-Dimensional Hole-Array Grating-Coupling-Based Excitation of Bloch Surface Waves for Highly Sensitive Biosensing. Nanoscale Res. Lett. 2019, 14, 1–9. [Google Scholar] [CrossRef]

- Gonzalez-Valencia, E.; del Villar, I.; Torres, P. Novel Bloch Wave Excitation Platform Based on Few-Layer Photonic Crystal Deposited on D-Shaped Optical Fiber. Sci. Rep. 2021, 11, 11266. [Google Scholar] [CrossRef]

- Kaňok, R.; Kaňok, K.; Hlubina, P.; Gembalová, L.; Ciprian, D.; Zubiate, P.; De, N.; Morrás, A.; Lopez-Torres, D. Efficient Optical Sensing Based on Phase Shift of Waves Supported by a One-Dimensional Photonic Crystal. Sensors 2021, 21, 6535. [Google Scholar] [CrossRef]

- Guobin, R.; Zhi, W.; Shuqin, L.; Shuisheng, J. Mode Classification and Degeneracy in Photonic Crystal Fibers. Opt. Express 2003, 11, 1310–1321. [Google Scholar] [CrossRef]

- Ahmed, R.; Aoni, R.A.; Fabrizio, D.P. Design of Ultra-Flattened Zero Dispersion Shifted Photonic Crystal Fibers with Lower Confinement Loss for Telecommunication Applications. In Proceedings of the 2013 CIOMP-OSA Summer Session on Optical Engineering, Design and Manufacturing, Changchun, China, 4–9 August 2013; Optica Publishing Group: Washington, DC, USA, 2013; p. Tu6. [Google Scholar]

- McPeak, K.M.; Jayanti, S.V.; Kress, S.J.P.; Meyer, S.; Iotti, S.; Rossinelli, A.; Norris, D.J. Plasmonic Films Can Easily Be Better: Rules and Recipes. ACS Photonics 2015, 2, 326–333. [Google Scholar] [CrossRef]

- Naik, G.V.; Shalaev, V.M.; Boltasseva, A. Alternative Plasmonic Materials: Beyond Gold and Silver. Adv. Mater. 2013, 25, 3264–3294. [Google Scholar] [CrossRef]

- Ye, H.-Y.; Chen, C.-B.; Zhou, J.-Y.; Meng, Z.-M. Sodium-Based Surface Plasmon Resonances for High-Performance Optical Sensing in the Near Infrared. IEEE J. Sel. Top. Quantum Electron. 2021, 27, 1–8. [Google Scholar] [CrossRef]

- Zuhayer, A.; Abd-Elnaby, M.; Ahammad, S.H.; Eid, M.M.A.; Sorathiya, V.; Rashed, A.N.Z. A Gold-Plated Twin Core D-Formed Photonic Crystal Fiber (PCF) for Ultrahigh Sensitive Applications Based on Surface Plasmon Resonance (SPR) Approach. Plasmonics 2022, 17, 2089–2101. [Google Scholar] [CrossRef]

- Sakib, M.N.; Hossain, M.B.; Al-tabatabaie, K.F.; Mehedi, I.M.; Hasan, M.T.; Hossain, M.A.; Amiri, I.S. High Performance Dual Core D-Shape PCF-SPR Sensor Modeling Employing Gold Coat. Results Phys. 2019, 15, 102788. [Google Scholar] [CrossRef]

- Bing, P.; Liu, Q.; Wu, G.; Yuan, S.; Li, Z.; Du, H.; Yao, J. A Plasmonic Sensor Based on D-Shaped Dual-Core Microchannel Photonic Crystal Fiber. Plasmonics 2022, 17, 1471–1478. [Google Scholar] [CrossRef]

- Luan, N.; Hou, D.; Ji, X.; Zhang, W.; Qi, Y.; Song, L.; Liu, J. Orthogonal-Sided Polished Microstructured Optical Fiber-Based SPR Sensor for Simultaneous Measurement of Temperature and Refractive Index. IEEE Photonics J. 2022, 14. [Google Scholar] [CrossRef]

- Guo, X.; Han, L.; Liu, F.; Li, S. Refractive Index Sensing Characteristics of Dual-Core PCF Based on Surface Plasmon Resonance. Optik (Stuttg) 2020, 218, 164796. [Google Scholar] [CrossRef]

- Hossain, M.B.; Mahendiran, T.V.; Abdulrazak, L.F.; Mehedi, I.M.; Hossain, M.A.; Rana, M.M. Numerical Analysis of Gold Coating Based Quasi D-Shape Dual Core PCF SPR Sensor. Opt. Quantum Electron. 2020, 52, 446. [Google Scholar] [CrossRef]

- Ghosh, G.; Endo, M.; Iwasaki, T. Temperature-Dependent Sellmeier Coefficients and Chromatic Dispersions for Some Optical Fiber Glasses. J. Light. Technol. 1994, 12, 1338–1342. [Google Scholar] [CrossRef]

- Wei, Y.; Wu, P.; Zhu, Z.; Liu, L.; Liu, C.; Hu, J.; Wang, S.; Zhang, Y. Surface-Plasmon-Resonance-Based Optical-Fiber Micro-Displacement Sensor with Temperature Compensation. Sensors 2018, 18, 3210. [Google Scholar] [CrossRef]

- Vial, A.; Grimault, A.-S.; Macías, D.; Barchiesi, D.; de la Chapelle, M.L. Improved Analytical Fit of Gold Dispersion: Application to the Modeling of Extinction Spectra with a Finite-Difference Time-Domain Method. Phys. Rev. B 2005, 71, 85416. [Google Scholar] [CrossRef]

- Han, B.; Zhang, Y.; Siyu, E.; Wang, X.; Yang, D.; Wang, T.; Lu, K.; Wang, F. Simultaneous Measurement of Temperature and Strain Based on Dual SPR Effect in PCF. Opt. Laser Technol. 2019, 113, 46–51. [Google Scholar] [CrossRef]

- Lin, K.; Lu, Y.; Luo, Z.; Zheng, R.; Wang, P.; Ming, H. Numerical and Experimental Investigation of Temperature Effects on the Surface Plasmon Resonance Sensor. Chin. Opt. Lett. 2009, 7, 428–431. [Google Scholar]

- Beach, R.T.; Christy, R.W. Electron-Electron Scattering in the Intraband Optical Conductivity of Cu, Ag, and Au. Phys. Rev. B 1977, 16, 5277. [Google Scholar] [CrossRef]

- Lawrence, W.E. Electron-Electron Scattering in the Low-Temperature Resistivity of the Noble Metals. Phys. Rev. B 1976, 13, 5316. [Google Scholar] [CrossRef]

- Holstein, T. Optical and Infrared Volume Absorptivity of Metals. Phys. Rev. 1954, 96, 535. [Google Scholar] [CrossRef]

- Turhan-Sayan, G.; Ozdemir, S.K. Temperature Effects on Surface Plasmon Resonance: Design Considerations for an Optical Temperature Sensor. J. Light. Technol. 2003, 21, 805. [Google Scholar]

- Liu, C.; Wang, F.; Lv, J.; Sun, T.; Liu, Q.; Fu, C.; Mu, H.; Chu, P.K. A Highly Temperature-Sensitive Photonic Crystal Fiber Based on Surface Plasmon Resonance. Opt. Commun. 2016, 359, 378–382. [Google Scholar] [CrossRef]

- Peng, Y.; Hou, J.; Huang, Z.; Lu, Q. Temperature Sensor Based on Surface Plasmon Resonance within Selectively Coated Photonic Crystal Fiber. Appl. Opt. 2012, 51, 6361–6367. [Google Scholar] [CrossRef]

- Luo, W.; Meng, J.; Li, X.; Xie, Q.; Yi, D.; Wang, Y.; Hong, X. Temperature Effects on Surface Plasmon Resonance Sensor Based on Side-Polished D-Shaped Photonic Crystal Fiber. Measurement 2021, 181, 109504. [Google Scholar] [CrossRef]

- Hasan, M.R.; Akter, S.; Rifat, A.A.; Rana, S.; Ahmed, K.; Ahmed, R.; Subbaraman, H.; Abbott, D. Spiral Photonic Crystal Fiber-Based Dual-Polarized Surface Plasmon Resonance Biosensor. IEEE Sens. J. 2018, 18, 133–140. [Google Scholar] [CrossRef]

- Kaur, V.; Singh, S. Design of Titanium Nitride Coated PCF-SPR Sensor for Liquid Sensing Applications. Opt. Fiber Technol. 2019, 48, 159–164. [Google Scholar] [CrossRef]

- Young, M. Mode-Field Diameter of Single-Mode Optical Fiber by Far-Field Scanning. Appl. Opt. 1998, 37, 5605–5619. [Google Scholar] [CrossRef]

- Nivedha, S.; Babu, P.R.; Senthilnathan, K. D-Shaped Plasmonic Sensor Using a Molybdenum Disulfide Doped Photonic Crystal Fiber. IOP Conf. Ser. Mater. Sci. Eng. 2017, 263, 52031. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, H.; Dong, J.; Hu, S.; Zhu, W.; Qiu, W.; Lu, H.; Yu, J.; Guan, H.; Gao, S.; et al. Sensitivity-Enhanced Surface Plasmon Resonance Sensor Utilizing a Tungsten Disulfide (WS2) Nanosheets Overlayer. Photon. Res. 2018, 6, 485–491. [Google Scholar] [CrossRef]

- Luan, N.; Wang, R.; Lv, W.; Yao, J. Surface Plasmon Resonance Sensor Based on D-Shaped Microstructured Optical Fiber with Hollow Core. Opt. Express 2015, 23, 8576–8582. [Google Scholar] [CrossRef] [PubMed]

- Singh, S.; Mishra, S.K.; Gupta, B.D. Sensitivity Enhancement of a Surface Plasmon Resonance Based Fibre Optic Refractive Index Sensor Utilizing an Additional Layer of Oxides. Sens. Actuators A Phys. 2013, 193, 136–140. [Google Scholar] [CrossRef]

- Bhatia, P.; Gupta, B.D. Surface Plasmon Resonance Based Fiber Optic Refractive Index Sensor Utilizing Silicon Layer: Effect of Doping. Opt. Commun. 2013, 286, 171–175. [Google Scholar] [CrossRef]

| Parameters | Value | Parameters | Value |

|---|---|---|---|

| Δ | 0.77 | TD | 185 K |

| Γ | 0.55 | EF | 5.51 eV |

| γ | 1.42 × 10−5 K−1 | M | 0.44 |

| KB | 1.38 × 10−23 J/K |

| Ref. | Wavelength Sensitivity (nm/RIU) | Wavelength Resolution (RIU) | Amp. Sensitivity (RIU−1) |

|---|---|---|---|

| [44] | 2000 | 5 × 10−5 | 200 |

| [45] | 2459 | 4.17 × 10−5 | - |

| [46] | 2900 | 3.44 × 10−5 | 120 |

| [47] | ~3000 | 2.67 × 10−5 | - |

| [48] | 3385 | 3.13 × 10−5 | - |

| Proposed Sensor(Au) | 2164 | 3.58 × 10−5 | 376.76 |

| Proposed Sensor(with TiO2) | 3392.86 | 1.47 × 10−5 | 73.12 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, H.; Song, Y.; Sun, M.; Wang, Q. Simulation of High-Performance Surface Plasmon Resonance Sensor Based on D-Shaped Dual Channel Photonic Crystal Fiber for Temperature Sensing. Materials 2023, 16, 37. https://doi.org/10.3390/ma16010037

Wu H, Song Y, Sun M, Wang Q. Simulation of High-Performance Surface Plasmon Resonance Sensor Based on D-Shaped Dual Channel Photonic Crystal Fiber for Temperature Sensing. Materials. 2023; 16(1):37. https://doi.org/10.3390/ma16010037

Chicago/Turabian StyleWu, Haoyu, Yutong Song, Meng Sun, and Qi Wang. 2023. "Simulation of High-Performance Surface Plasmon Resonance Sensor Based on D-Shaped Dual Channel Photonic Crystal Fiber for Temperature Sensing" Materials 16, no. 1: 37. https://doi.org/10.3390/ma16010037

APA StyleWu, H., Song, Y., Sun, M., & Wang, Q. (2023). Simulation of High-Performance Surface Plasmon Resonance Sensor Based on D-Shaped Dual Channel Photonic Crystal Fiber for Temperature Sensing. Materials, 16(1), 37. https://doi.org/10.3390/ma16010037