Optimizing Parameters with FEM Model for 20CrMnTi Laser Shocking

Abstract

1. Introduction

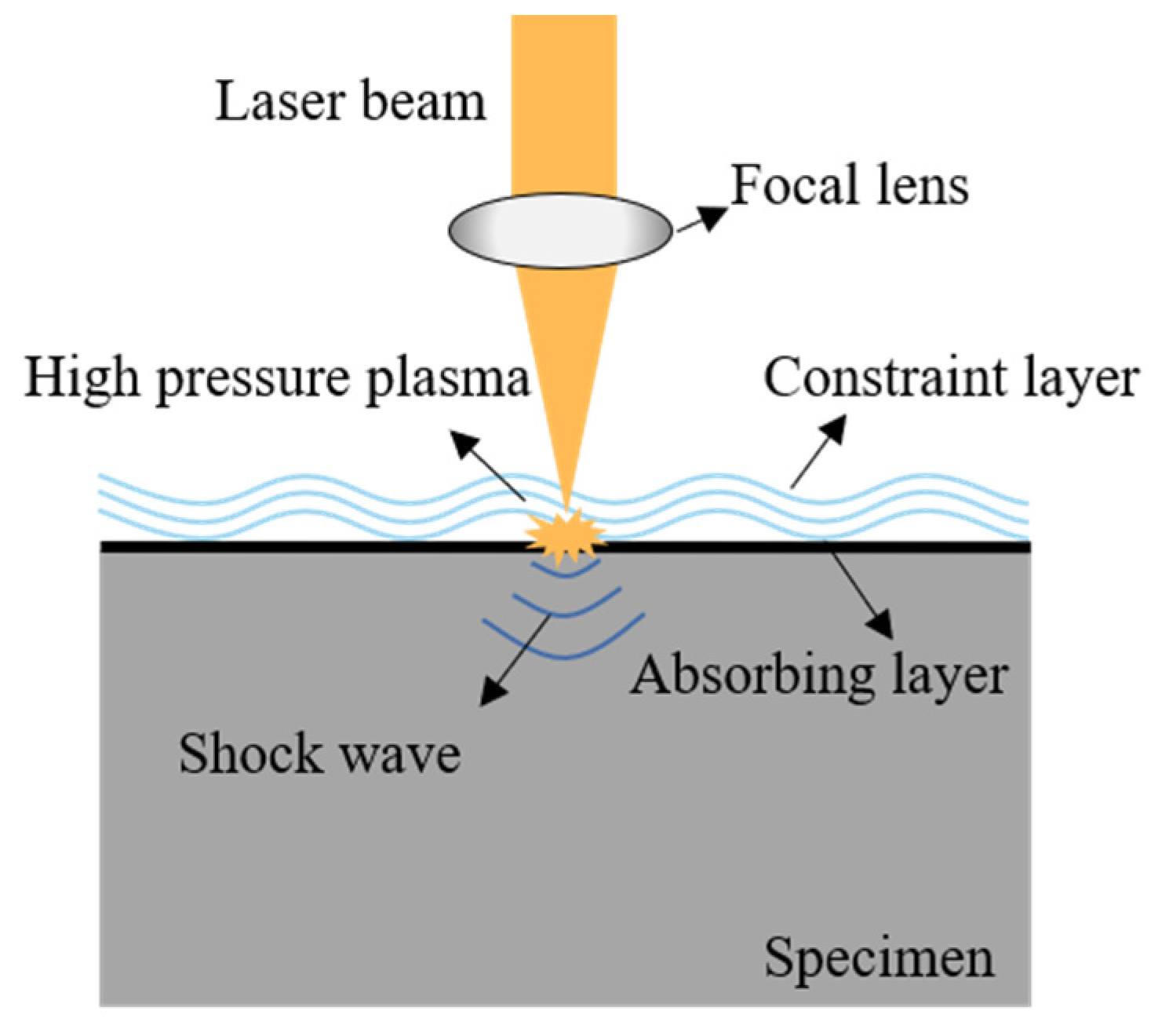

2. LSP Process and Model of Single-Point Laser Shocking

2.1. LSP Process

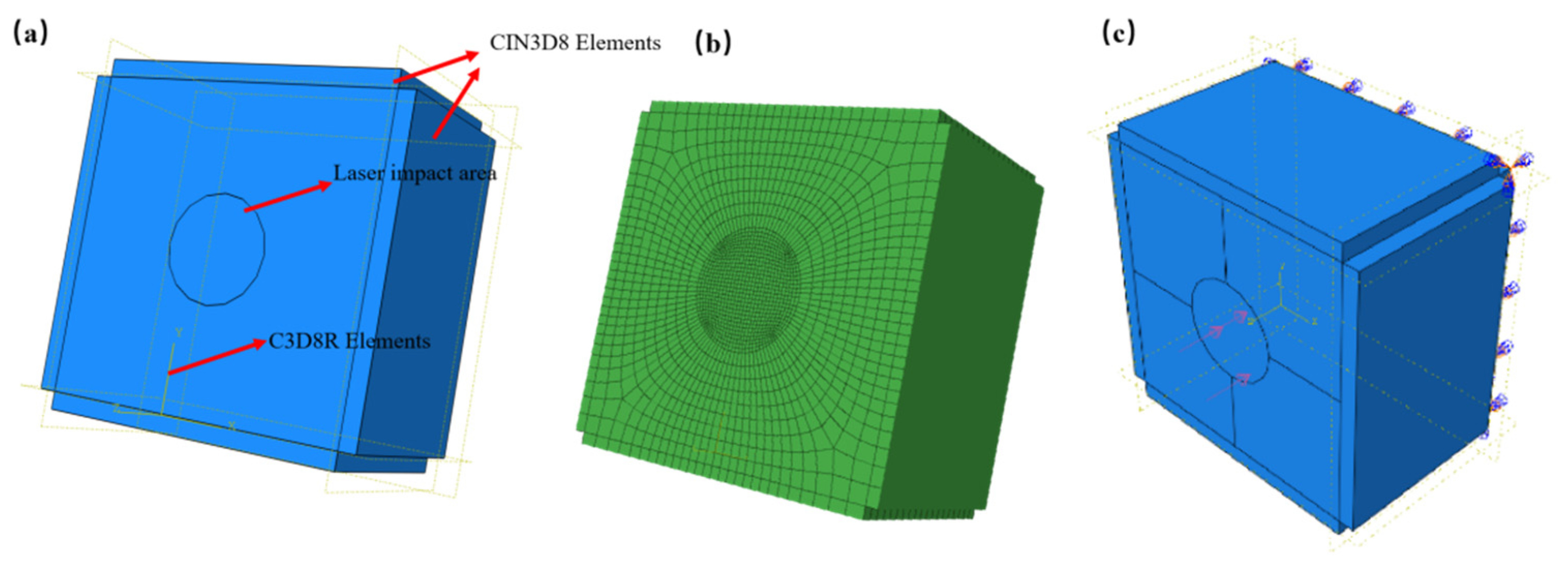

2.2. Model Construction and Computational Solution

3. Single-Point Laser Shock Experiments

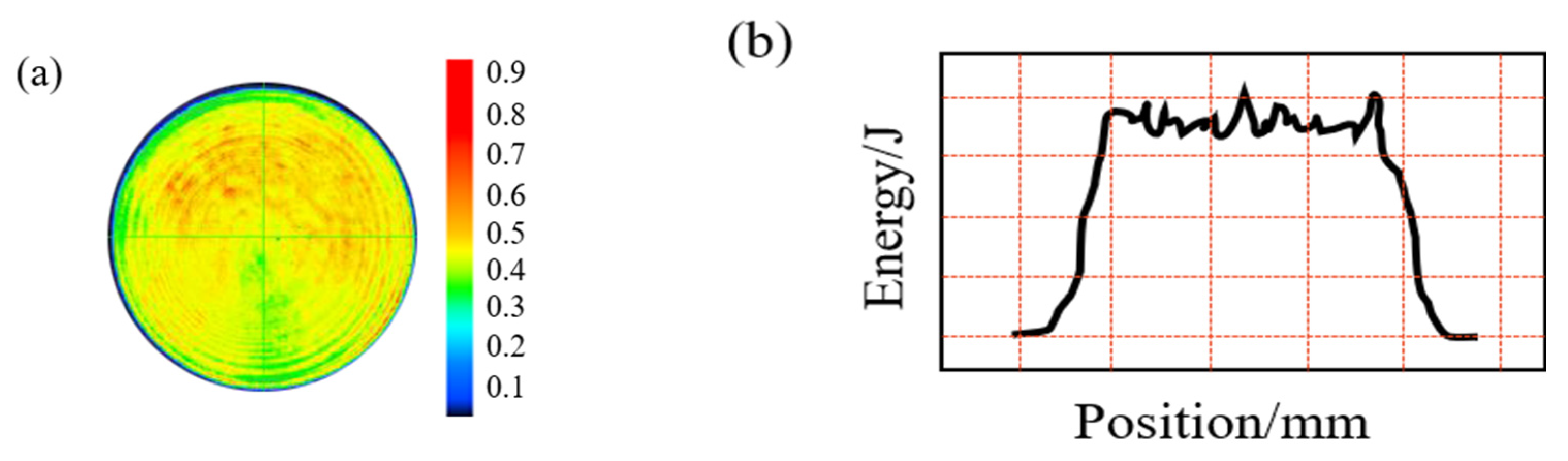

3.1. Experimental Conditions

3.2. Detection Methods

3.3. Experimental Results and Analysis

4. Results and Discussion

4.1. Mechanical Response of Materials to Different Laser Pulse Energies

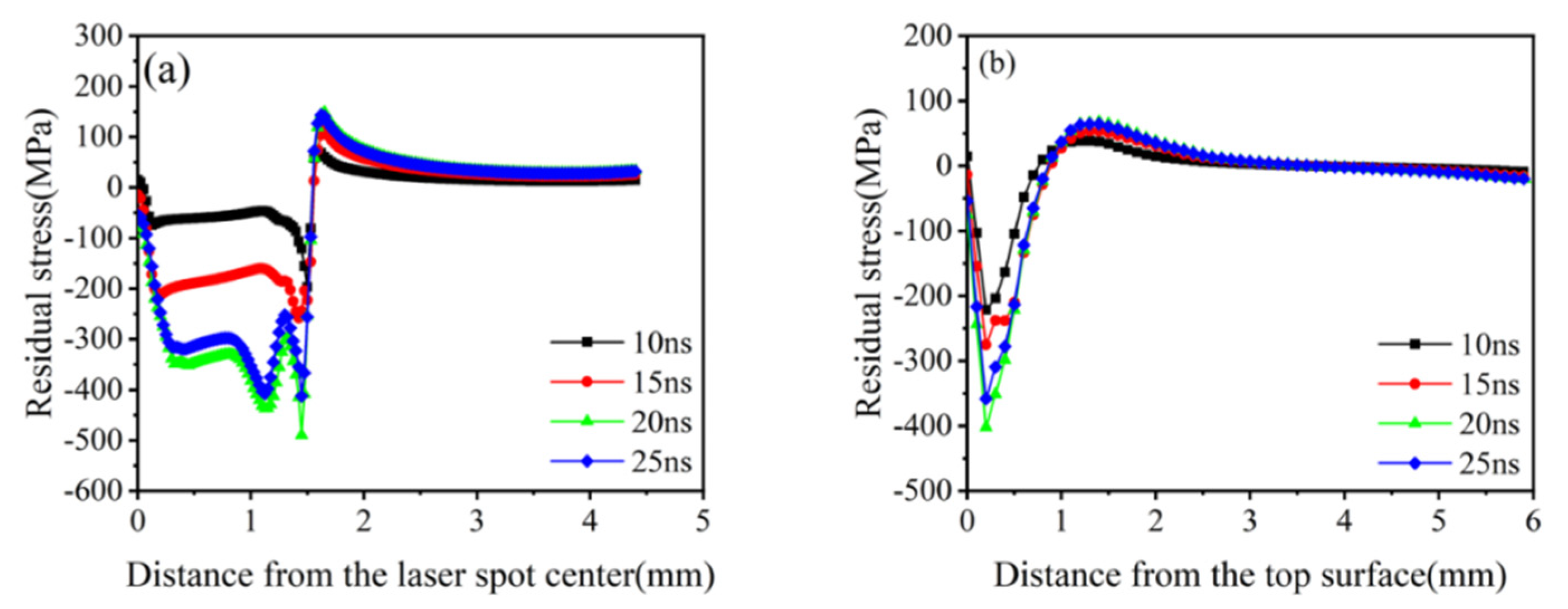

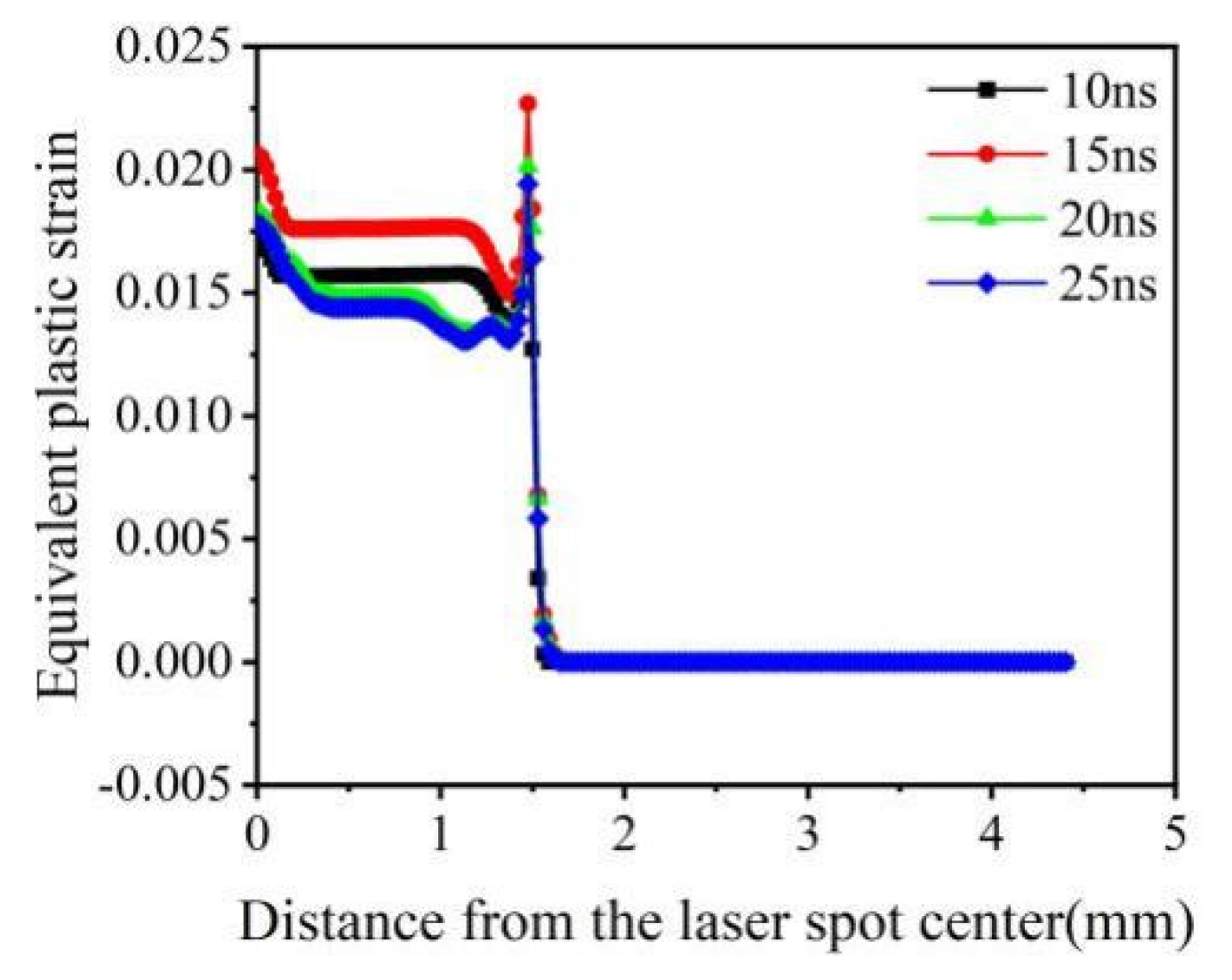

4.2. Mechanical Response of Materials at Different Pulse Widths

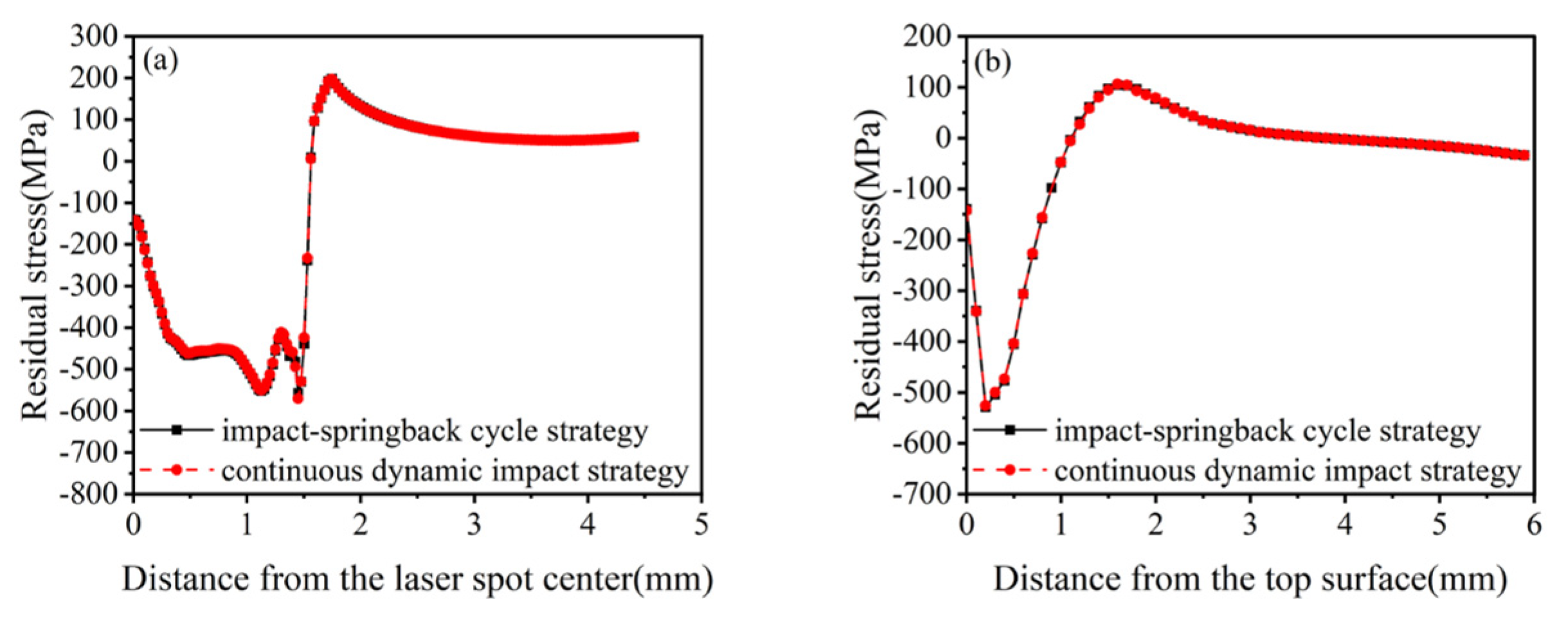

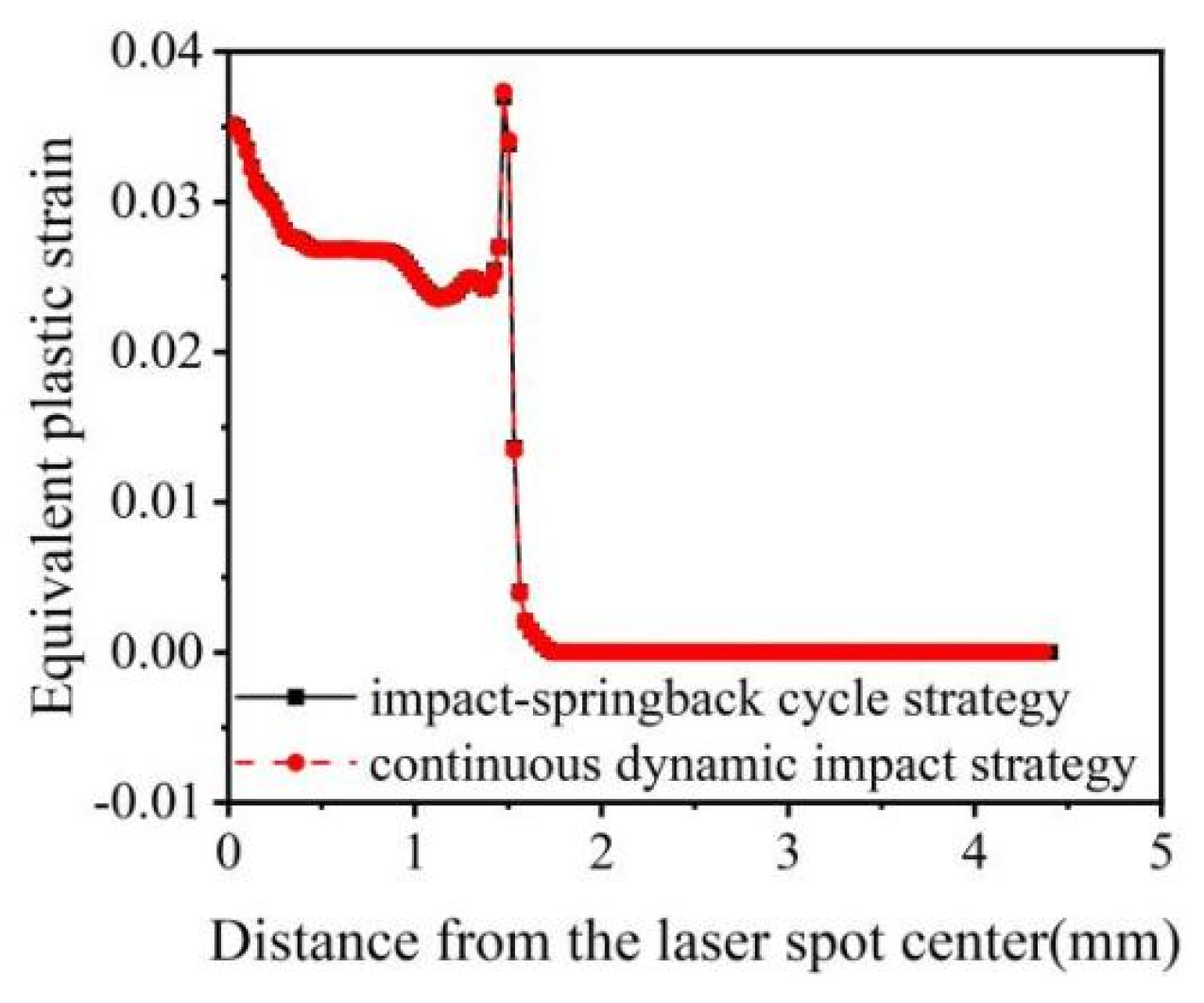

4.3. Mechanical Responses of Materials to Different Impact Numbers

4.4. Results of Multiple-Point Laser Shock

5. Conclusions

- Using the model to calculate and analyze the effects of the laser impact energy, the laser pulse width, and the number of impacts on the mechanical response of 20CrMnTi, the residual compressive stress on the surface after impact strengthening increases and then decreases as the laser impact energy increases. Further, the maximum residual compressive stress on the surface layer increases and then remains unchanged, with 5 J being the cut-off point.

- With the increase in the laser pulse width, the surface and surface-layer residual compressive stresses after laser shock peening increase and decrease, reaching their maxima at 20 ns. With the increase in the number of laser shocks, the surface and surface-layer residual compressive stresses after laser shock peening increase and then decrease, reaching maxima at five impacts.

- A comprehensive analysis shows that the optimal parameters for 20CrMnTi are 5 J, 20 ns, and 5 (impact energy, laser pulse width, and impacts, respectively). In addition, comparing the stress and strain fields between the impact–rebound cycle strategy and ongoing dynamic impact strategy using the same impact parameters, the continuous dynamic impact strategy is selected, saving computing resources, and it was applied in the subsequent multiple-point impact simulations with the optimal parameters.

- As multi-point shocks are the accumulation of single-point shocks, the residual compressive stress values of multi-point impacts are close to those of single-point impacts under the same process conditions. The results provide a reference for the process selection for the laser shock peening of 20CrMnTi.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Wang, J.B.; Ding, J.; Song, K.; Zhang, X.D.; Wang, L.S. Dynamic Stress Response of 20CrMnTi Steel under Impact Load with Modified J-C Ontogenetic Model Considering Adiabatic Temperature Rise. Mech. Strength 2019, 41, 1066–1070. (In Chinese) [Google Scholar]

- Zhu, Y.; Lu, Y.M.; Huang, C.W.; Liang, Y.L. The effect of TiN inclusions on the fracture mechanism of 20CrMnTi steel with lath martensite. Mater. Res. Express 2020, 7, 036509. [Google Scholar] [CrossRef]

- Tang, P.; Wu, Z.; Guo, B.; Lai. Evolution of fretting wear behaviors and mechanisms of 20CrMnTi steel after carburizing. Metals 2020, 10, 179. [Google Scholar] [CrossRef]

- Wang, Y.; Pan, X.; Wang, X.; Liu, Z.; Liu, S.; Wan, W.; Wang, P. Influence of laser shock peening on surface integrity and tensile property of high strength low alloy steel. Chin. J. Aeronaut. 2021, 34, 199–208. [Google Scholar] [CrossRef]

- Smith, T.R.; Sugar, J.D.; Schoenung, J.M.; Marchi, C.S. Relationship between manufacturing defects and fatigue properties of additive manufactured austenitic stainless steel. Mater. Sci. Eng. A 2019, 765, 138268. [Google Scholar] [CrossRef]

- Zhao, Y.; Tong, X.; Wei, X.H.; Xu, S.S.; Lan, S.; Wang, X.-L.; Wang, Z.W. Effects of microstructure on crack resistance and low-temperature toughness of ultra-low carbon high strength steel. Int. J. Plast. 2019, 116, 203–215. [Google Scholar] [CrossRef]

- Zhao, H.; Liu, J.; Hua, F.; Ran, Y.; Zi, R.; Li, B. Multiaxial fatigue life prediction model considering stress gradient and size effect. Int. J. Press. Vessel. Pip. 2022, 199, 104703. [Google Scholar] [CrossRef]

- Zhang, X.W.; Wen, J.F.; Zhang, X.C.; Wang, X.G.; Tu, S.-T. Effects of the stress state on plastic deformation and ductile failure: Experiment and numerical simulation using a newly designed tension-shear specimen. Fatigue Fract. Eng. Mater. Struct. 2019, 42, 2079–2092. [Google Scholar] [CrossRef]

- Yang, K.; Huang, Q.; Zhong, B.; Wang, Q.; Chen, Q.; Chen, Y.; Su, N.; Liu, H. Enhanced extra-long life fatigue resistance of a bimodal titanium alloy by laser shock peening. Int. J. Fatigue 2020, 141, 105868. [Google Scholar] [CrossRef]

- Huang, J.; Zhang, J.; Feng, W.; Wang, D.; Mei, Y.; Wang, X.; Zhao, Y. Fracture Data Analysis and Calculation of Drilling Tools in Gravel Formation in Dabei/Bozi Block. In Proceedings of the 2022 IEEE International Conference on Electrical Engineering, Big Data and Algorithms (EEBDA), Changchun, China, 24–26 February 2022; pp. 463–467. [Google Scholar]

- Guo, P.C.; Qu, L.F. Research and development of modern anti-fatigue manufacturing application technology. J. Lanzhou Inst. Technol. 2011, 18, 58–62. (In Chinese) [Google Scholar]

- Bagherifard, S.; Beretta, N.; Monti, S.; Riccio, M. On the fatigue strength enhancement of additively manufactured AlSi10Mg parts by mechanical and thermal post-processing. Mater. Des. 2018, 145, 28–41. [Google Scholar] [CrossRef]

- Li, X.; Lu, L.; Li, J.; Zhang, X.; Gao, H. Mechanical properties and deformation mechanisms of gradient nanostructured metals and alloys. Nat. Rev. Mater. 2020, 5, 706–723. [Google Scholar] [CrossRef]

- Wei, W.; Li, Y.; Xue, T.; Tao, S.; Mei, C.; Zhou, W.; Wang, J.; Wang, T. The research progress of machining mechanisms in milling wood-based materials. BioResources 2018, 13, 2139–2149. [Google Scholar] [CrossRef]

- Liu, Z.; He, M.; Zhao, J. Mechanical Machining Strengthening Mechanism and Material Processing Technology-a Review. China Mech. Eng. 2015, 26, 403. [Google Scholar]

- Maleki, E.; Unal, O.; Guagliano, M.; Bagherifard, S. The effects of shot peening, laser shock peening, and ultrasonic nanocrystal surface modification on the fatigue strength of Inconel 718. Mater. Sci. Eng. A 2021, 810, 141029. [Google Scholar] [CrossRef]

- Gujba, A.K.; Medraj, M. Laser peening process and its impact on materials properties in comparison with shot peening and ultrasonic impact peening. Materials 2014, 7, 7925–7974. [Google Scholar] [CrossRef]

- Zhang, Q.B.; Zhao, J. A review of dynamic experimental techniques and mechanical behavior of rock materials. Rock Mech. Rock Eng. 2014, 47, 1411–1478. [Google Scholar] [CrossRef]

- Qin, Z.; Li, B.; Huang, X.; Zhang, H.; Chen, R.; Xue, H.Q. The effect of laser shock peening on surface integrity and high and very high cycle fatigue properties of 2024-T351 aluminum alloy. Opt. Laser Technol. 2022, 149, 107897. [Google Scholar] [CrossRef]

- Luong, H.; Hill, M.R. The effects of laser peening and shot peening on high cycle fatigue in 7050-T7451 aluminum alloy. Mater. Sci. Eng. A 2010, 527, 699–707. [Google Scholar] [CrossRef]

- Prabhakaran, S.; Kalainathan, S.; Shukla, P.; Vijay, K. Vasudevan, Residual stress, phase, microstructure and mechanical property studies of ultrafine bainitic steel through laser shock peening. Opt. Laser Technol. 2019, 115, 447–458. [Google Scholar] [CrossRef]

- Dai, F.Z.; Cheng, W.; Zheng, Y.Y.; Chen, X.Z. The effect of rolling contact fatigue properties on 316 stainless steel under laser shock peening. Opt. Laser Technol. 2021, 141, 107159. [Google Scholar] [CrossRef]

- Cao, Y.; Wang, Z.; Shi, W.; Hua, G.; Qiu, M. Formation Mechanism and Weights Analysis of Residual Stress Holes in E690 High-Strength Steel by Laser Shock Peening. Coatings 2022, 12, 285. [Google Scholar] [CrossRef]

- Fan, J.J. Study of Laser Impact Strengthening of Peri-Hole Surfaces; Nanjing University of Aeronautics and Astronautics: Nanjing, China, 2011. (In Chinese) [Google Scholar]

- Liu, S.H.; Ding, D.P.; Hong, L.U.; Zheng, M.J. Study of Laser Strengthening on Inner Surface of Concrete Duct. Hot Work. Technol. 2004, 7, 38–40. [Google Scholar]

- Jiang, Q.; Li, S.; Zhou, C.; Zhang, B.; Zhang, Y. Effects of laser shock peening on the ultra-high cycle fatigue performance of additively manufactured Ti6Al4V alloy. J. Opt. Laser Technol. 2021, 144, 107391. [Google Scholar] [CrossRef]

- Wang, C.; Luo, K.; Wang, J.; Lu, J. Carbide-facilitated nanocrystallization of martensitic laths and carbide deformation in AISI 420 stainless steel during laser shock peening. J. Int. J. Plast. 2022, 150, 103191. [Google Scholar] [CrossRef]

- Wang, L.; Zhou, L.; Liu, L.; He, W.; Pan, X.; Nie, X.; Luo, S. Fatigue strength improvement in Ti-6Al-4V subjected to foreign object damage by combined treatment of laser shock peening and shot peening. Int. J. Fatigue 2021, 155, 106581. [Google Scholar] [CrossRef]

- Yaghmaie, R.; Guo, S.; Ghosh, S. Wavelet transformation induced multi-time scaling (WATMUS) model for coupled transient electro-magnetic and structural dynamics finite element analysis. Comput. Methods Appl. Mech. Eng. 2016, 303, 341–373. [Google Scholar] [CrossRef]

- Jiang, Y.; Xu, F.; Xu, B. Acoustic emission tomography based on simultaneous algebraic reconstruction technique to visualize the damage source location in Q235B steel plate. Mech. Syst. Signal Process. 2015, 64, 452–464. [Google Scholar] [CrossRef]

- Langer, K.; Spradlin, T.J.; Fitzpatrick, M.E. Finite element analysis of laser peening of thin aluminum structures. Metals 2020, 10, 93. [Google Scholar] [CrossRef]

- Ranjith Kumar, G.; Rajyalakshmi, G. FE simulation for stress distribution and surface deformation in Ti-6Al-4V induced by interaction of multi scale laser shock peening parameters. Optik 2020, 206, 164280. [Google Scholar]

- Ouyang, P.; Luo, X.; Dong, Z.; Zhang, S. Numerical Prediction of the Effect of Laser Shock Peening on Residual Stress and Fatigue Life of Ti-6Al-4V Titanium Alloy. Materials 2022, 15, 5503. [Google Scholar] [CrossRef] [PubMed]

- Samuel, A.G.; Ren, X.D.; Asuako, L.E.; Ren, Y.; Tong, Z. The effects of laser shock peening scanning patterns on residual stress distribution and fatigue life of AA2024 aluminium alloy. Opt. Laser Technol. 2018, 108, 177–185. [Google Scholar]

- Abhishek; Panda, S.S.; Kumar, S. Numerical analysis on residual stress hole generation in laser shock peening. Eur. Phys. J. Plus 2022, 137, 461. [Google Scholar] [CrossRef]

- Hassas, B.V.; Kouachi, S.; Eskanlou, A.; Bouhenguel, M.; Çelik, M.S.; Miller, J.D. The significance of positive and negative inertial forces in Particle-Bubble interaction and their role in the general flotation kinetics model. Miner. Eng. 2021, 170, 107006. [Google Scholar] [CrossRef]

- Wang, C.; Wang, X.; Xu, Y.; Gao, Z. Numerical modeling of the confifined laser shock peening of the OFHC copper. Int. J. Mech. Sci. 2016, 108–109, 104–114. [Google Scholar] [CrossRef]

| A | B | n | c |

|---|---|---|---|

| 720 | 712 | 0.68 | 0.01 |

| Parameters | Values |

|---|---|

| Pulse energy/J | 4 J |

| Pulse width/ns | 20 ns |

| Spot diameter/mm | 3 mm |

| Wavelength/nm | 1064 nm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, J.; Li, J.; Chen, X.; Xu, Z.; Lin, Y.; Jiang, Q.; Chen, J.; Li, Y. Optimizing Parameters with FEM Model for 20CrMnTi Laser Shocking. Materials 2023, 16, 328. https://doi.org/10.3390/ma16010328

Sun J, Li J, Chen X, Xu Z, Lin Y, Jiang Q, Chen J, Li Y. Optimizing Parameters with FEM Model for 20CrMnTi Laser Shocking. Materials. 2023; 16(1):328. https://doi.org/10.3390/ma16010328

Chicago/Turabian StyleSun, Jie, Jiayuan Li, Xiuyu Chen, Zhilong Xu, Yuru Lin, Qingshan Jiang, Junying Chen, and Yi Li. 2023. "Optimizing Parameters with FEM Model for 20CrMnTi Laser Shocking" Materials 16, no. 1: 328. https://doi.org/10.3390/ma16010328

APA StyleSun, J., Li, J., Chen, X., Xu, Z., Lin, Y., Jiang, Q., Chen, J., & Li, Y. (2023). Optimizing Parameters with FEM Model for 20CrMnTi Laser Shocking. Materials, 16(1), 328. https://doi.org/10.3390/ma16010328