Graphene-Iron Ore Tailings–Based Cementitious Composites with High Early Flexural Strength

Abstract

1. Introduction

2. Experimental Section

2.1. Raw Materials

2.2. Preparation of Graphene-Iron Ore Tailings–Based Cementitious Composites

2.3. Testing Methods

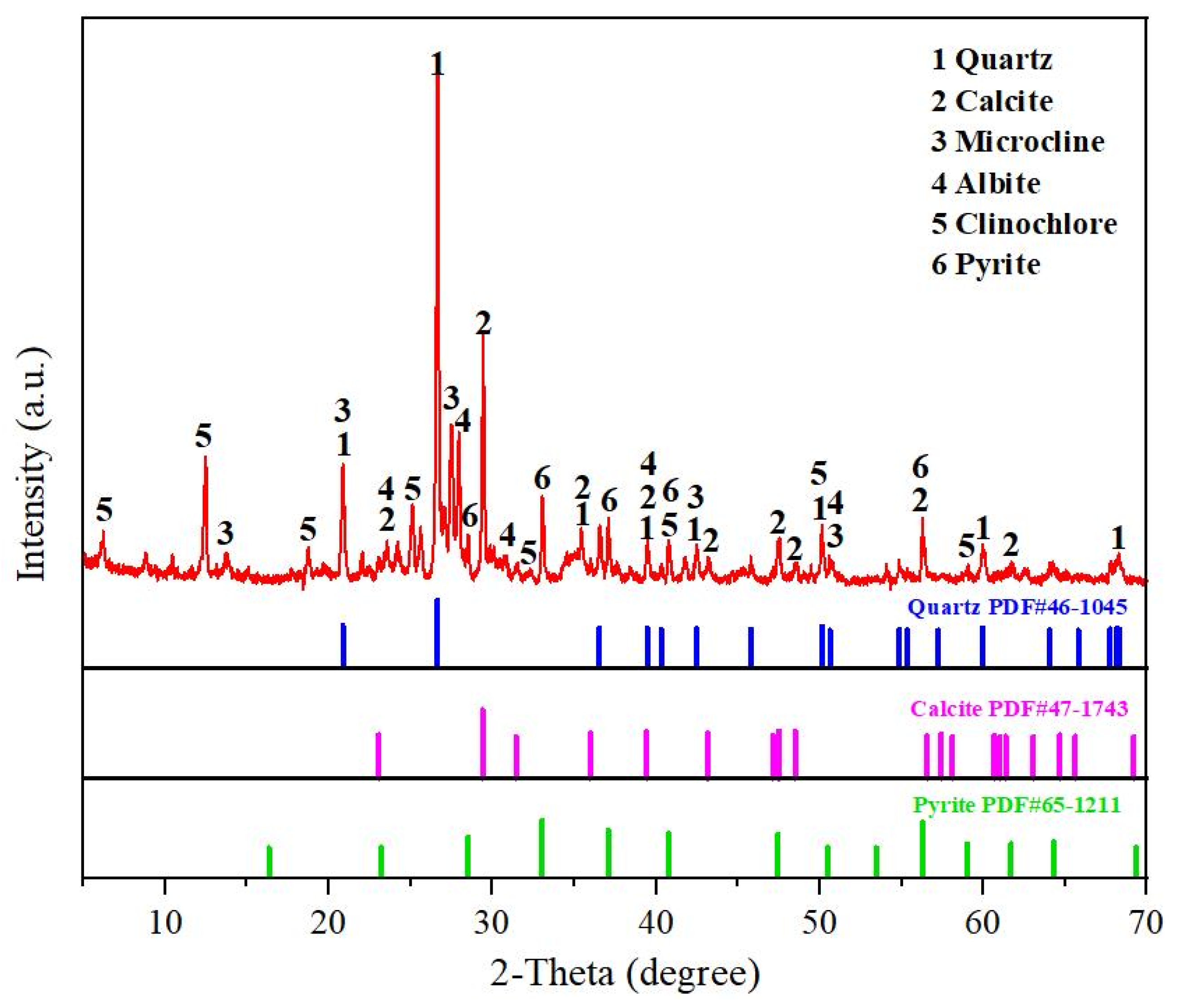

2.3.1. Phase Analysis of Iron Ore Tailings

2.3.2. Compressive and Flexural Strengths Test

2.3.3. Microstructure Test

3. Results and Discussion

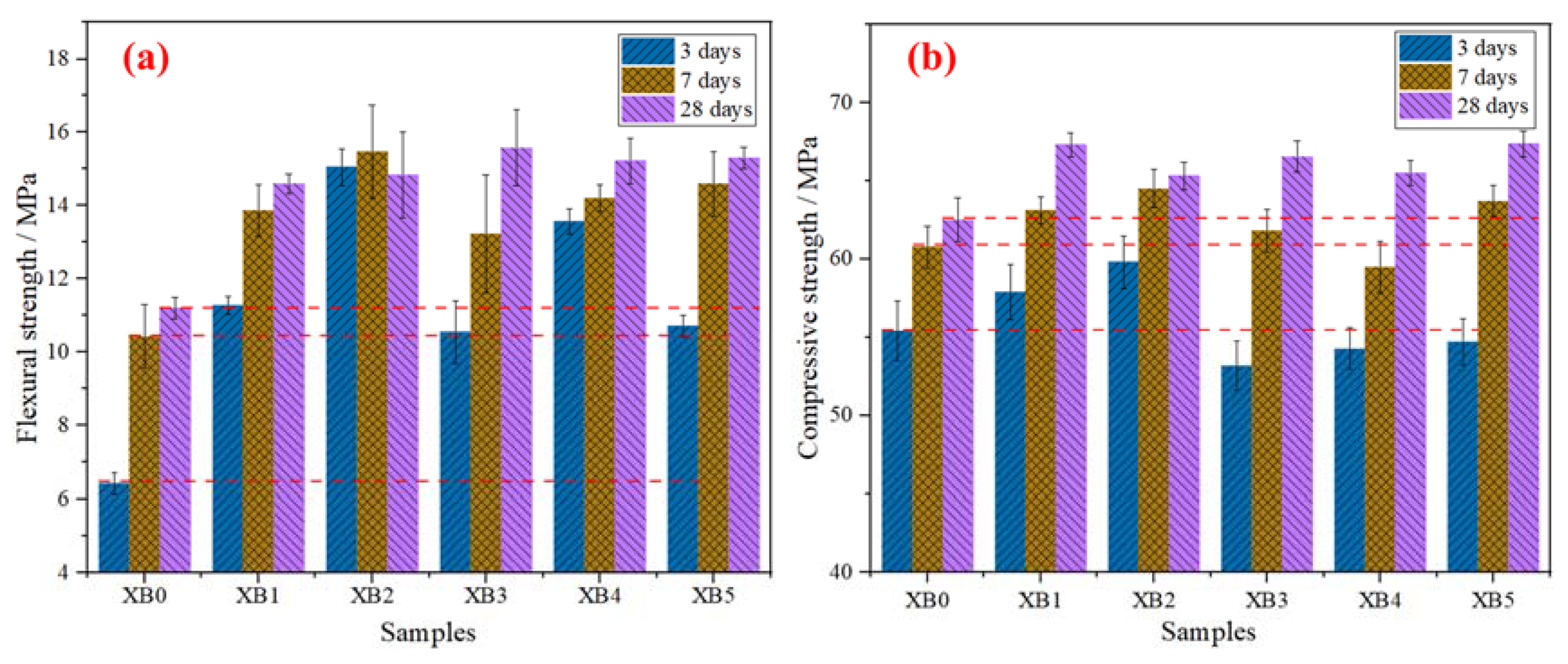

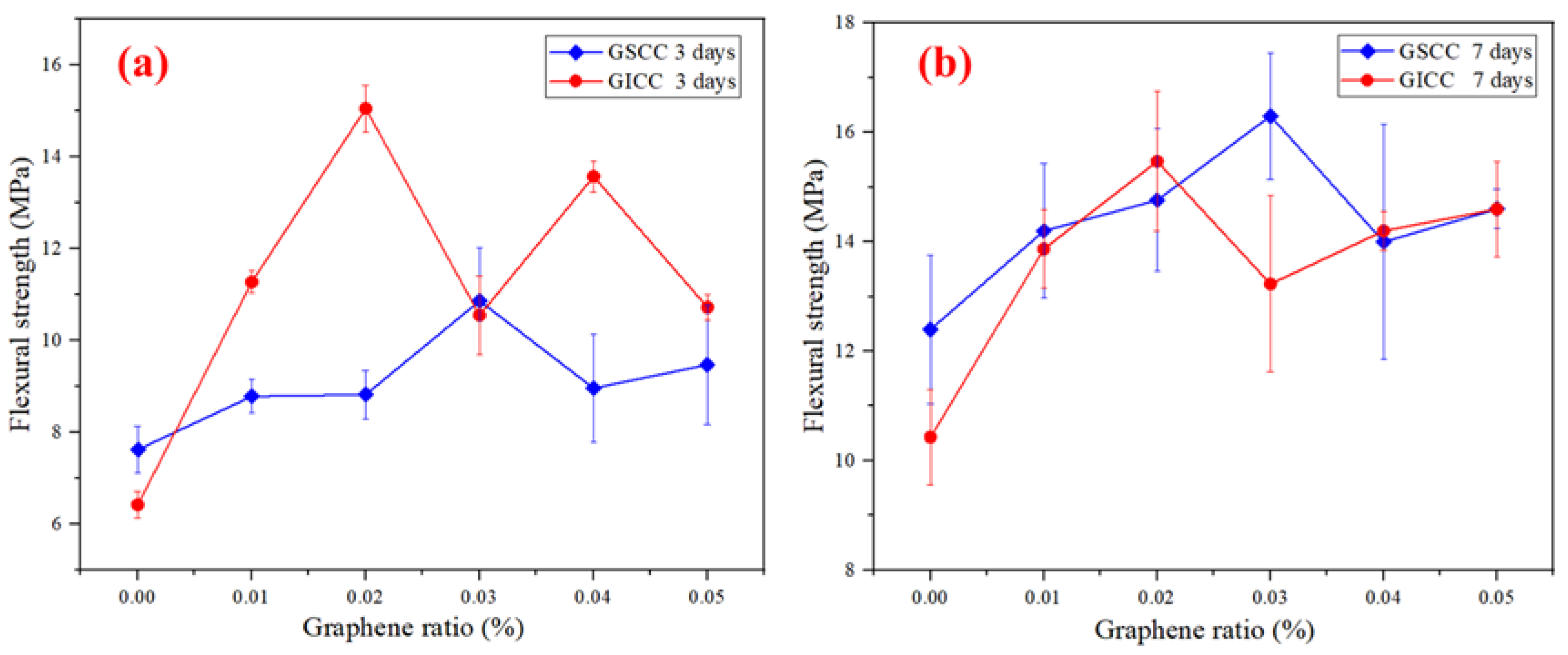

3.1. Flexural and Compressive Strengths

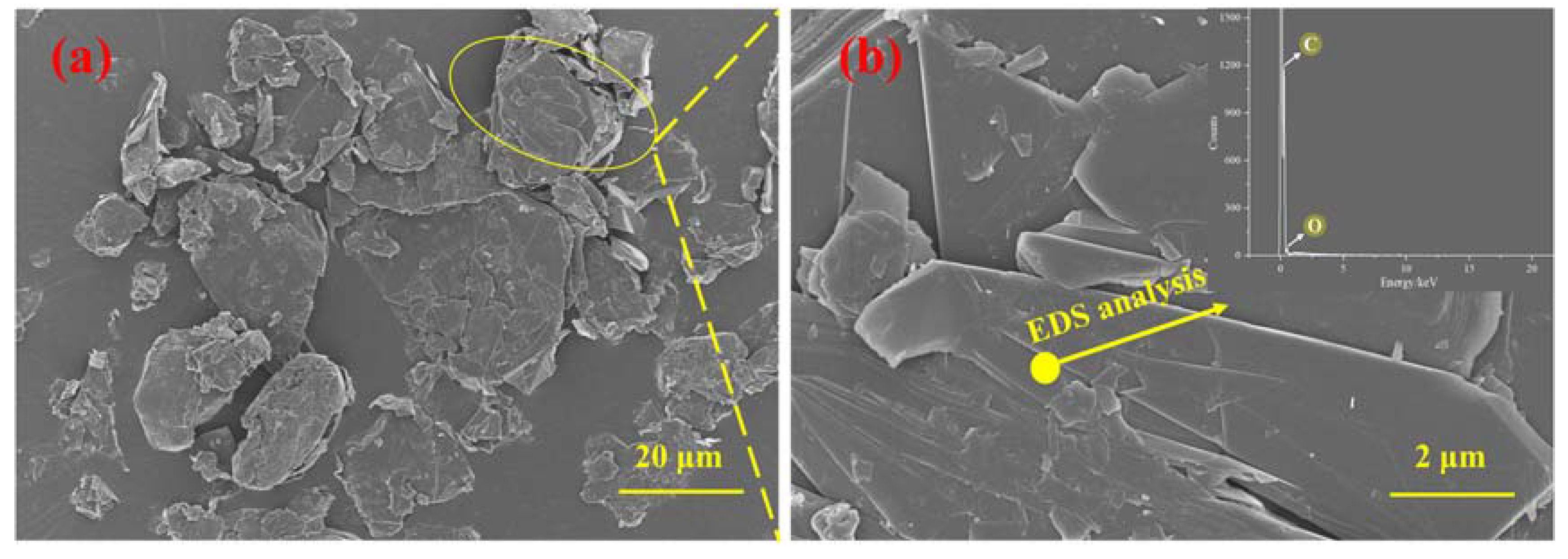

3.2. Microstructure Analysis

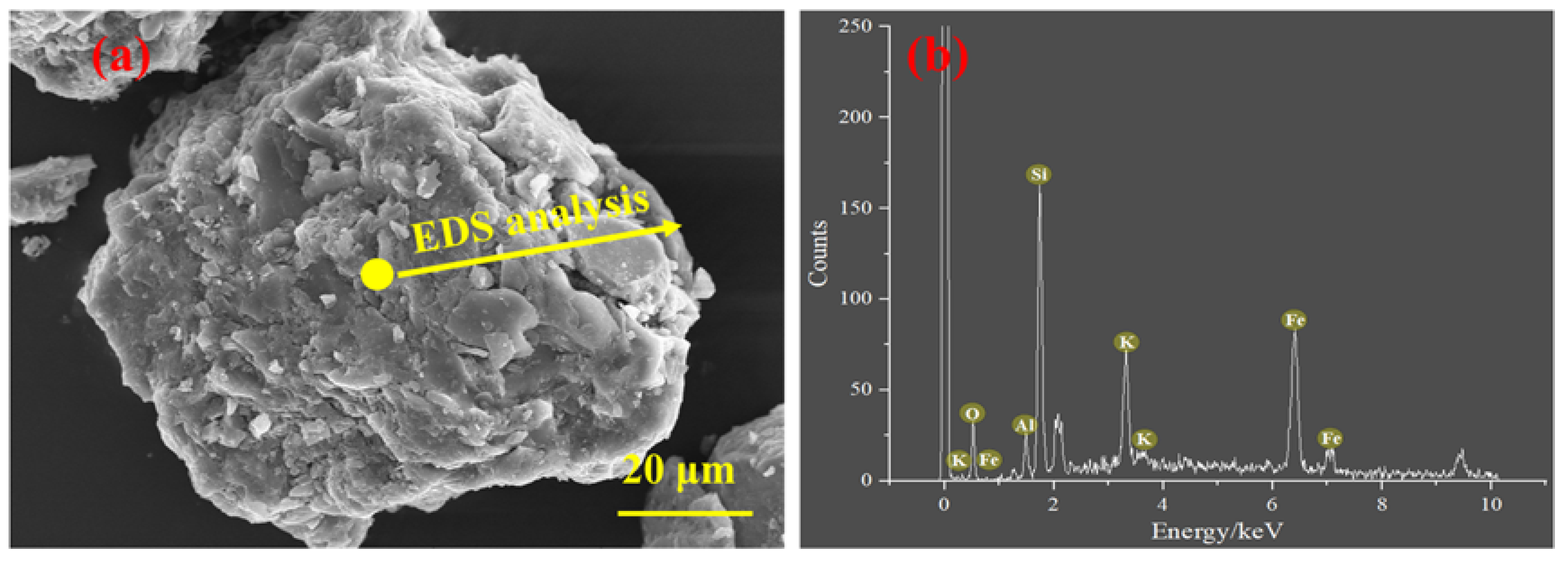

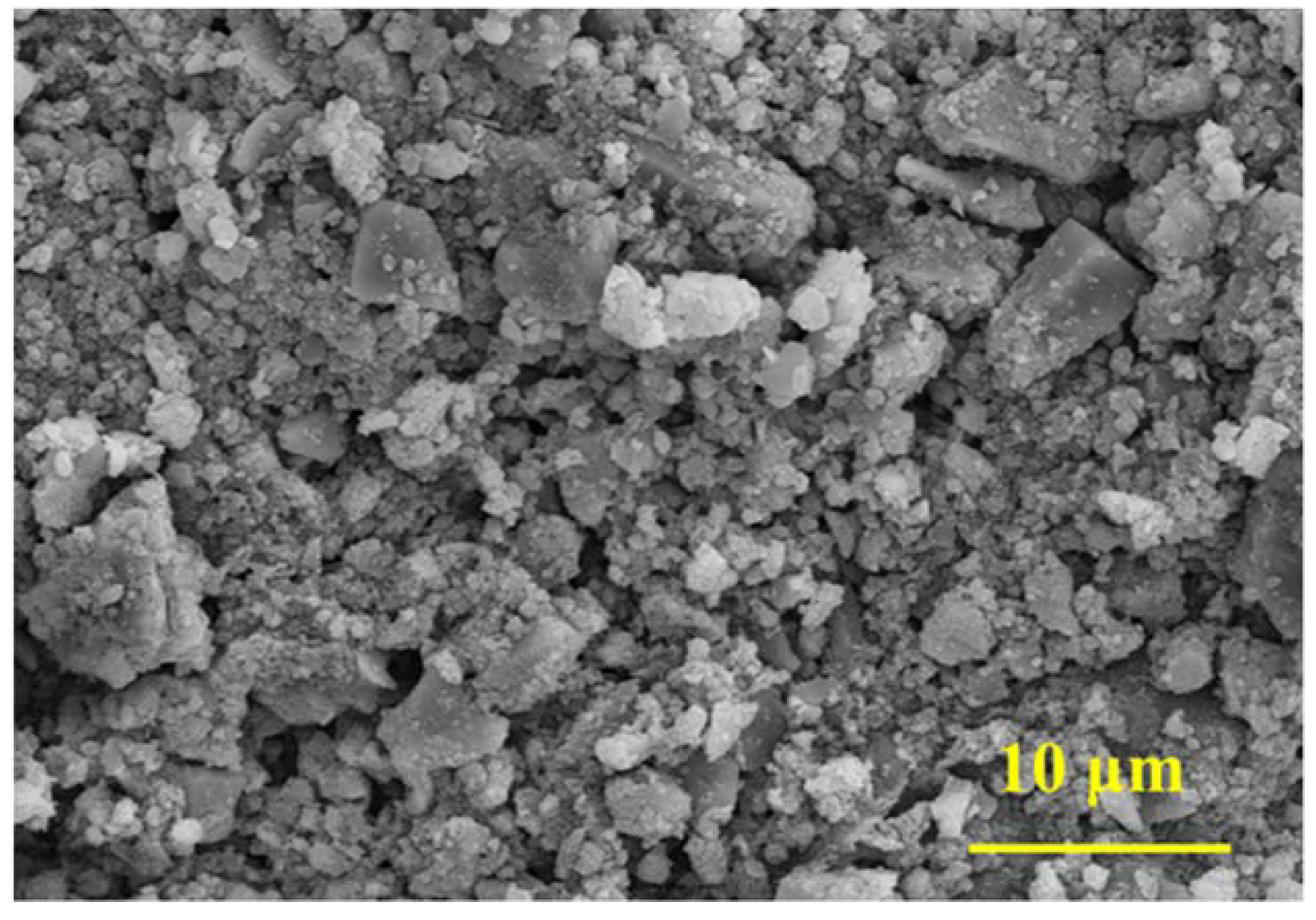

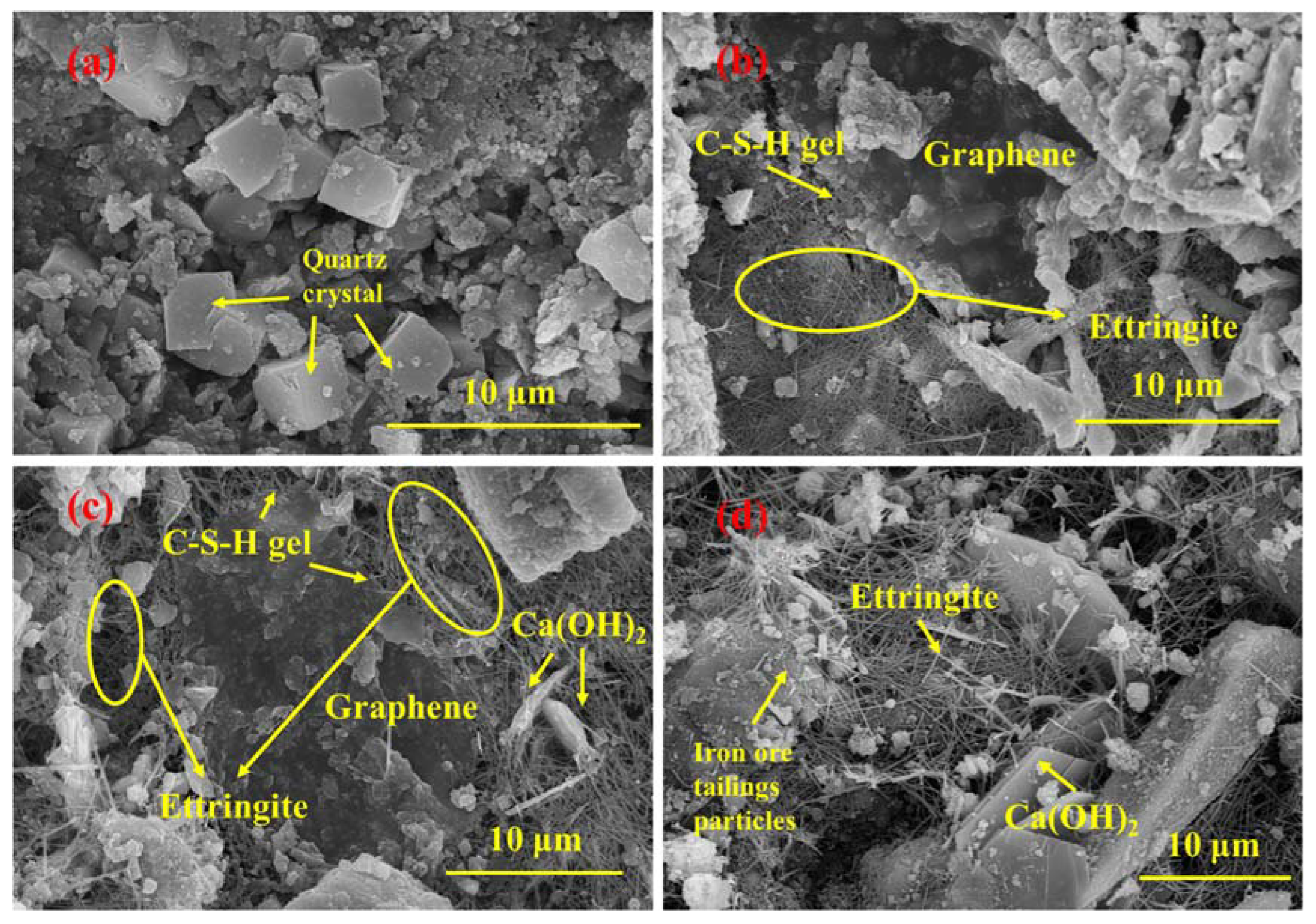

3.2.1. The Effect of Raw Materials

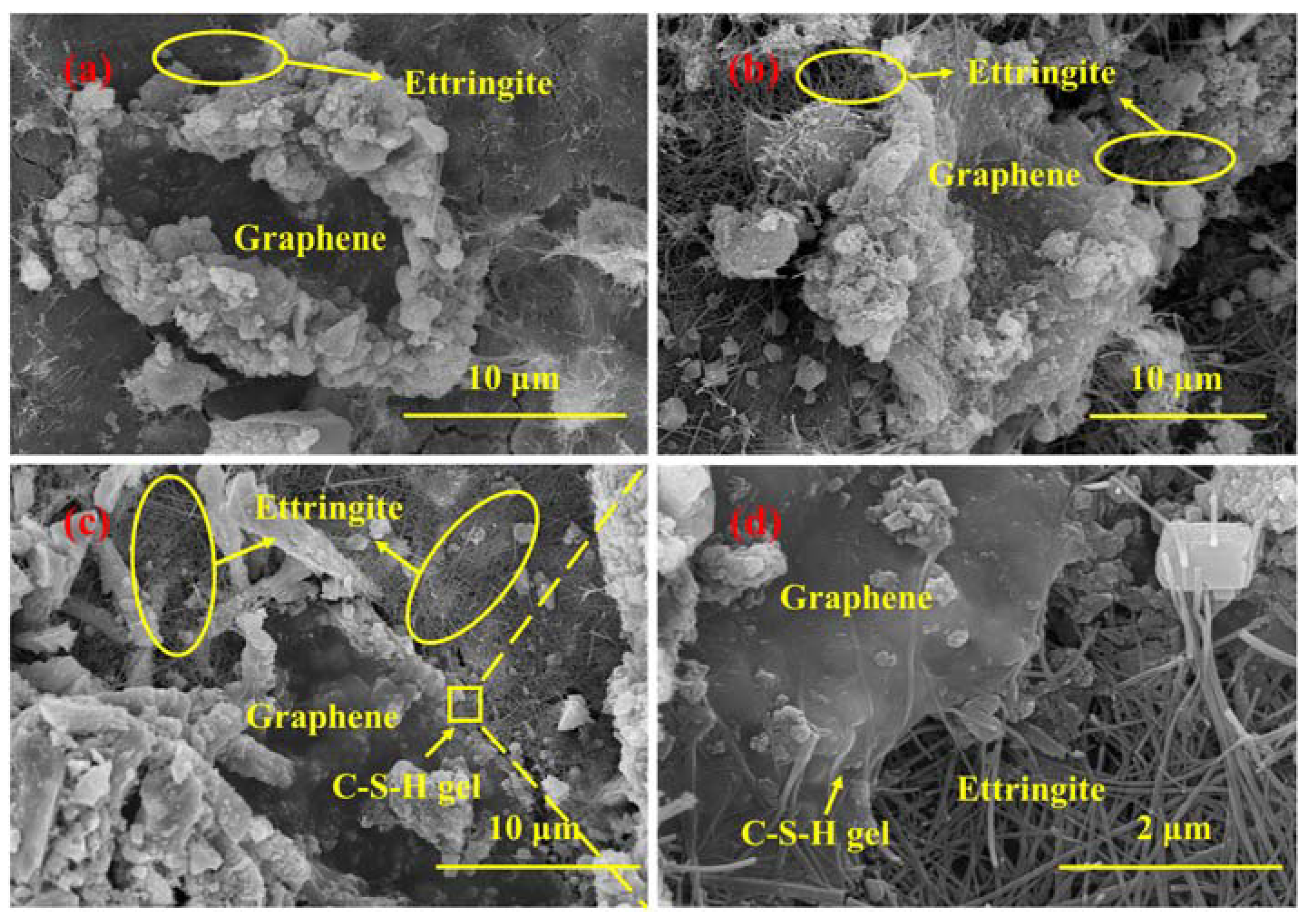

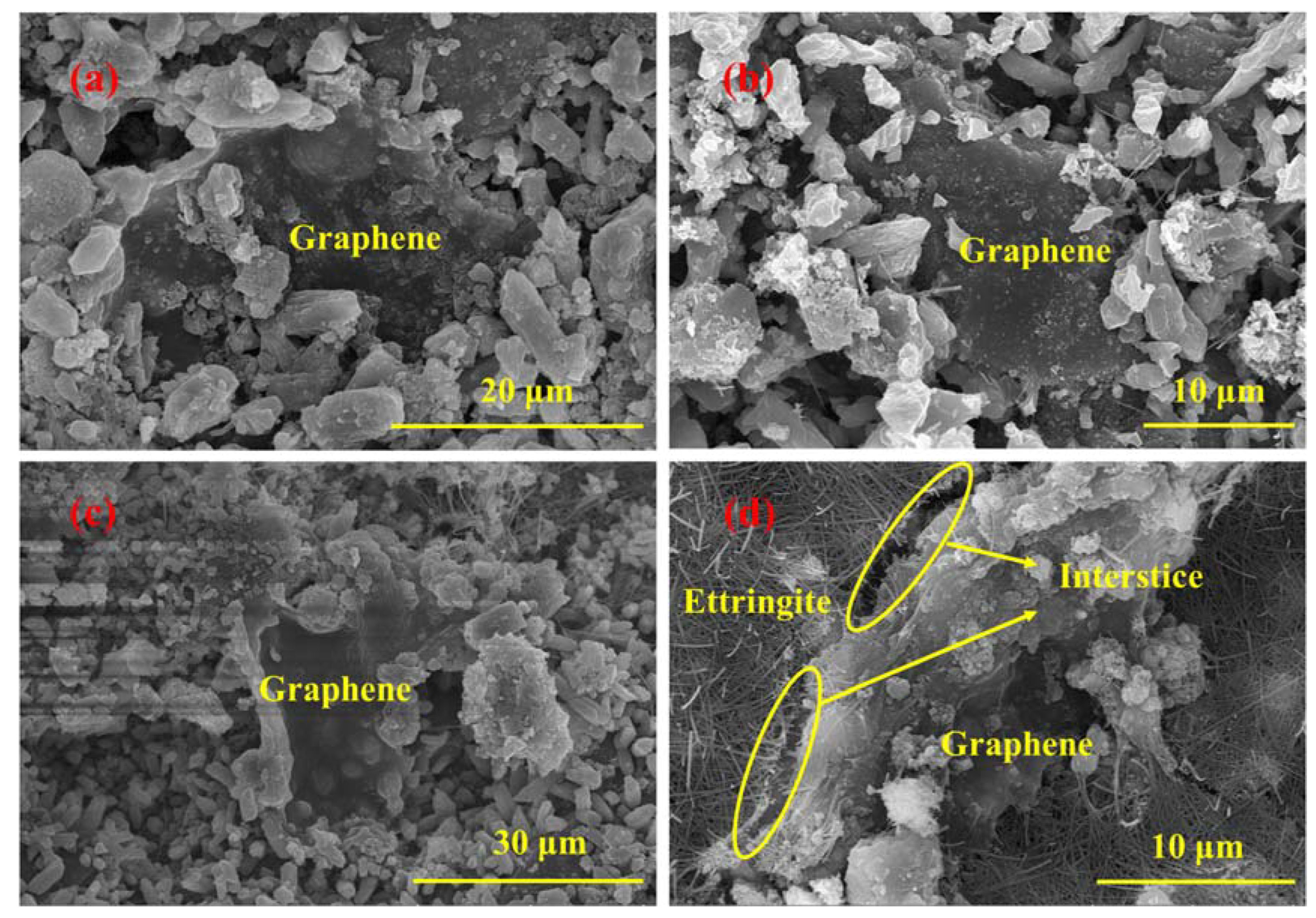

3.2.2. The Effect of Graphene Content

3.2.3. The Effect of Hydration Age

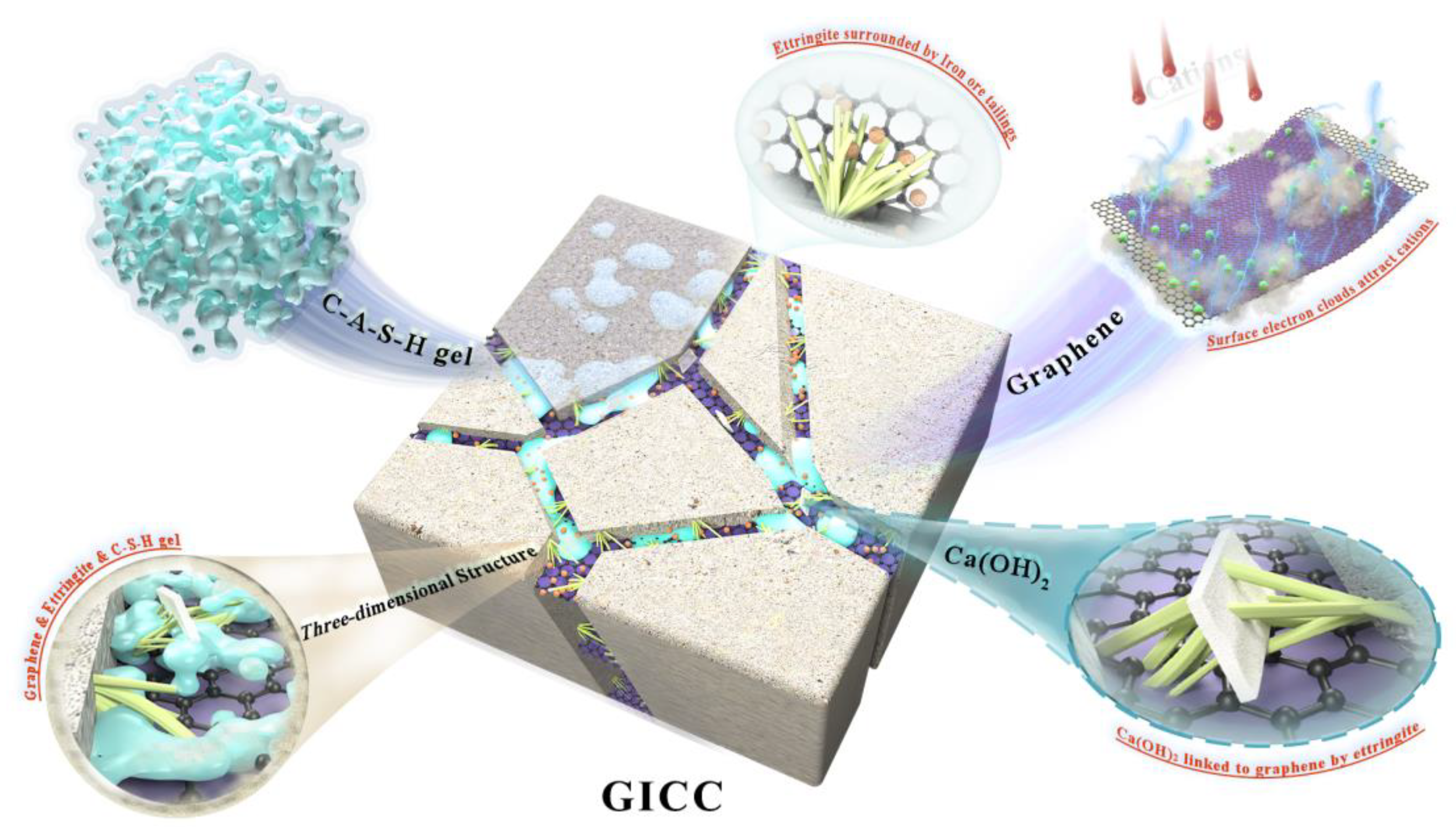

3.3. Flexural Strength Reinforcement Mechanism

4. Conclusions

- (1)

- The early mechanical properties of iron ore tailings–based cementitious composites were enhanced by using graphene. Graphene showed a great effect on the flexural strength development of iron ore tailings–based cementitious composites while keeping the compressive strength basically unchanged.

- (2)

- Graphene can significantly improve the flexural strength of iron ore tailings–based cementitious composites in a short hydration time. When adding a 0.02 wt.% dosage of graphene, the 3-day flexural strength of GICC attained 15.05 MPa. It was 134.4% higher than that of the iron ore tailings–based cementitious composite without graphene.

- (3)

- There was a three-dimensional structure of graphene-ettringite-C-(A)-S-H gel in the GICC system. This structure can effectively improve the flexural strength of iron ore tailings–based cementitious composites.

- (4)

- A proper amount of iron ore tailings deposited onto the graphene can solidify the three-dimensional structure. However, when the graphene content exceeded 0.02 wt.%, large amounts of iron ore tailings were likely to deposit onto the graphene surface. They separated the graphene from the cement matrix, thus reducing the flexural strength of GICC.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ravichandran, D.; Prem, P.R.; Kaliyavaradhan, S.K.; Ambily, P.S. Influence of fibers on fresh and hardened properties of Ultra High Performance Concrete (UHPC)—A review. J. Build. Eng. 2022, 57, 104922. [Google Scholar] [CrossRef]

- Sagar, R.V.; Prasad, B.R.; Kumar, S.S. An experimental study on cracking evolution in concrete and cement mortar by the b-value analysis of acoustic emission technique. Cem. Concr. Res. 2012, 42, 1094–1104. [Google Scholar] [CrossRef]

- Bendjillali, K.; Chemrouk, M.; Goual, M.S.; Boulekbache, B. Behaviour of polypropylene fibre mortars conserved in different environments. Eur. J. Environ. Civ. Eng. 2013, 17, 687–699. [Google Scholar] [CrossRef]

- Wydra, M.; Dolny, P.; Sadowski, G.; Fangrat, J. Flexural Behaviour of Cementitious Mortars with the Addition of Basalt Fibres. Materials 2021, 14, 1334. [Google Scholar] [CrossRef] [PubMed]

- Chen, H.; Xie, C.; Fu, C.; Liu, J.; Wei, X.; Wu, D. Orthogonal Analysis on Mechanical Properties of Basalt–Polypropylene Fiber Mortar. Materials 2020, 13, 2937. [Google Scholar] [CrossRef]

- Kumar, K.S.J.; Rao, M.V.S.; Reddy, V.S.; Shrihari, S. Performance evaluation of nano-silica concrete. In Proceedings of the 2nd International Conference on Design and Manufacturing Aspects for Sustainable Energy (ICMED 2020), Hyderabad, India, 10–12 July 2020; Volume 184, p. 01076. [Google Scholar] [CrossRef]

- Du, Y.B.; Gao, P.W.; Yang, J.M.; Shi, F.T.; Shabaz, M. Experimental Analysis of Mechanical Properties and Durability of Cement-Based Composite with Carbon Nanotube. Adv. Mater. Sci. Eng. 2021, 2021, 1–12. [Google Scholar] [CrossRef]

- Yang, H.B.; Cui, H.Z.; Tang, W.C.; Li, Z.J.; Han, N.X.; Xing, F. A critical review on research progress of graphene/cement based composites. Compos. Part A Appl. Sci. Manuf. 2017, 102, 273–296. [Google Scholar] [CrossRef]

- Wan, S.J.; Fang, S.L.; Jiang, L.; Cheng, Q.F.; Baughman, R.H. Graphene Sheets: Strong, Conductive, Foldable Graphene Sheets by Sequential Ionic and π Bridging. Adv. Mater. 2018, 30, 1870275. [Google Scholar] [CrossRef]

- Novoselov, K.S.; Geim, A.K.; Morozov, S.V.; Jiang, D.; Zhang, Y.; Dubonos, S.V.; Grigorieva, I.V.; Firsov, A.A. Electric field effect in atomically thin carbon films. Science 2004, 306, 666–669. [Google Scholar] [CrossRef]

- Liao, W.; Zhou, G.; Xi, F. Optical properties for armchair-edge graphene nanoribbons. J. Appl. Phys. 2008, 104, 126105. [Google Scholar] [CrossRef]

- Zheng, Q.F.; Han, B.G.; Cui, X.; Yu, X.; Ou, J.P. Graphene-engineered cementitious composites: Small makes a big impact. Nanomater. Nanotechnol. 2017, 7, 1847980417742304. [Google Scholar] [CrossRef]

- Cui, K.; Chang, J.; Sabri, M.M.S.; Huang, J.D. Influence of Graphene Nanoplates on Dispersion, Hydration Behavior of Sulfoaluminate Cement Composites. Materials 2022, 15, 5357. [Google Scholar] [CrossRef] [PubMed]

- Ling, X.Z.; Guo, X.Y.; Zhong, J.; Ma, J.J.; Tang, L.; Xing, D.L.; Su, J.G.; Cong, S.Y. Investigation of the Effect of Graphene Oxide on the Properties and Microstructure of Clay-Cement Composite Grouting Materials. Materials 2022, 15, 1623. [Google Scholar] [CrossRef]

- Aliyev, E.; Filiz, V.; Khan, M.M.; Lee, Y.J.; Abetz, C.; Abetz, V. Structural Characterization of Graphene Oxide: Surface Functional Groups and Fractionated Oxidative Debris. Nanomaterials 2019, 9, 1180. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.; Wang, J.; Lu, C.-X.; Liu, B.-W.; Zhang, K.; Li, C.-Z. Influence of graphene oxide additions on the microstructure and mechanical strength of cement. Carbon 2015, 95, 1083–1084. [Google Scholar] [CrossRef]

- Lv, S.H.; Ma, Y.J.; Qiu, C.C.; Zhou, Q.F. Regulation of GO on cement hydration crystals and its toughening effect. Mag. Concr. Res. 2013, 65, 1246–1254. [Google Scholar] [CrossRef]

- Shang, Y.; Zhang, D.; Yang, C.; Liu, Y.Y.; Liu, Y. Effect of graphene oxide on the rheological properties of cement pastes. Constr. Build. Mater. 2015, 96, 20–28. [Google Scholar] [CrossRef]

- Fakhim, B.; Hassani, A.; Rashidi, A.; Ghodousi, P. Preparation and mechanical properties of graphene oxide: Cement nanocomposites. Sci. World J. 2014, 2014, 276323. [Google Scholar]

- Indukuri, C.S.R.; Nerella, R.; Madduru, S.R.C. Effect of graphene oxide on microstructure and strengthened properties of fly ash and silica fume based cement composites. Constr. Build. Mater. 2019, 229, 116863. [Google Scholar] [CrossRef]

- Xu, G.; Du, S.; He, J.L.; Shi, X.M. The role of admixed graphene oxide in a cement hydration system. Carbon 2019, 148, 141–150. [Google Scholar] [CrossRef]

- Abdullah, A.; Taha, M.; Rashwan, M.; Fahmy, M. Efficient Use of Graphene Oxide and Silica Fume in Cement-Based Composites. Materials 2021, 14, 6541. [Google Scholar] [CrossRef] [PubMed]

- Gholampour, A.; Valizadeh Kiamahalleh, M.; Tran, D.N.H.; Ozbakkaloglu, T.; Losic, D. From Graphene Oxide to Reduced Graphene Oxide: Impact on the Physiochemical and Mechanical Properties of Graphene–Cement Composites. ACS Appl. Mater. Interfaces 2017, 9, 43275–43286. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.N.; Feng, D.C.; Zhong, J.; Shi, X.M. Reinforcement of cement paste by reduced graphene oxide: Effect of dispersion state. Mater. Struct. 2022, 55, 1–15. [Google Scholar] [CrossRef]

- Wei, J.; Jia, Z.Y.; Wang, Y.; Jiang, Y.C.; Miao, Z.; Zhou, Y.Q. Enhanced thermoelectric performance of low carbon cement-based composites by reduced graphene oxide. Energy Build. 2021, 250, 111279. [Google Scholar] [CrossRef]

- Chintalapudi, K.; Pannem, R.M.R. An intense review on the performance of Graphene Oxide and reduced Graphene Oxide in an admixed cement system. Constr. Build. Mater. 2020, 259, 120598. [Google Scholar] [CrossRef]

- Qi, X.Q.; Zhang, S.L.; Wang, T.T.; Guo, S.Y.; Ren, R. Effect of High-Dispersible Graphene on the Strength and Durability of Cement Mortars. Materials 2021, 14, 915. [Google Scholar] [CrossRef]

- Lv, S.H.; Liu, J.J.; Sun, T.; Ma, Y.J.; Zhou, Q.F. Effect of GO nanosheets on shapes of cement hydration crystals and their formation process. Constr. Build. Mater. 2014, 64, 231–239. [Google Scholar] [CrossRef]

- Lv, S.H.; Deng, L.J.; Yang, W.Q.; Zhou, Q.F.; Cui, Y.Y. Use of graphene oxide nanosheets to regulate the microstructure of hardened cement paste to increase its strength and toughness. Crystengcomm 2014, 16, 8508–8516. [Google Scholar] [CrossRef]

- Lv, S.; Deng, L.; Yang, W.; Zhou, Q.; Cui, Y. Fabrication of polycarboxylate/graphene oxide nanosheet composites by copolymerization for reinforcing and toughening cement composites. Cem. Concr. Compos. 2016, 66, 1–9. [Google Scholar] [CrossRef]

- Tong, T.; Fan, Z.; Liu, Q.; Wang, S.; Tan, S.S.; Yu, Q. Investigation of the effects of graphene and graphene oxide nanoplatelets on the micro- and macro-properties of cementitious materials. Constr. Build. Mater. 2015, 106, 102–114. [Google Scholar] [CrossRef]

- Zhao, L.; Guo, X.L.; Ge, C.; Li, Q.; Guo, L.P.; Shu, X.; Liu, J.P. Investigation of the effectiveness of PC@GO on the reinforcement for cement composites. Constr. Build. Mater. 2016, 113, 470–478. [Google Scholar] [CrossRef]

- Murugan, M.; Santhanam, M.; Gupta, S.S.; Pradeep, T.; Shah, S.P. Influence of 2D rGO nanosheets on the properties of OPC paste. Cem. Concr. Compos. 2016, 70, 48–59. [Google Scholar] [CrossRef]

- Metaxa, Z.S. Exfoliated graphene nanoplatelet cement-based nanocomposites as piezoresistive sensors: Influence of nanoreinforcement lateral size on monitoring capability. Ciência Tecnol. Mater. 2016, 28, 73–79. [Google Scholar] [CrossRef]

- Bhojaraju, C.; Mousavi, S.S.; Ouellet-Plamondon, C.M. Influence of GGBFS on corrosion resistance of cementitious composites containing graphene and graphene oxide. Cem. Concr. Compos. 2023, 135, 104836. [Google Scholar] [CrossRef]

- Lu, C.; Lu, Z.; Li, Z.; Leung, C.K. Effect of graphene oxide on the mechanical behavior of strain hardening cementitious composites. Constr. Build. Mater. 2016, 120, 457–464. [Google Scholar] [CrossRef]

- Kiamahalleh, M.V.; Gholampour, A.; Tran, D.N.; Ozbakkaloglu, T.; Losic, D. Physiochemical and mechanical properties of reduced graphene oxide–cement mortar composites: Effect of reduced graphene oxide particle size. Constr. Build. Mater. 2020, 250, 118832. [Google Scholar] [CrossRef]

- Reddy, P.V.R.K.; Prasad, D.R. Investigation on the impact of graphene oxide on microstructure and mechanical behaviour of concrete. J. Build. Pathol. Rehabilitation 2022, 7, 30. [Google Scholar] [CrossRef]

- Jyothimol, P.; Hazeena, R.; Issac, M.T.; Mathiazhagan, A. Effect of reduced graphene oxide on the mechanical properties of concrete. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Kerala, India, 11–13 December 2020; Volume 491, p. 012038. [Google Scholar] [CrossRef]

- Du, H.J.; Gao, H.J.; Jacey, S.; Pang, S.D. Improvement in concrete resistance against water and chloride ingress by adding graphene nanoplatelet. Cem. Concr. Res. 2016, 83, 114–123. [Google Scholar] [CrossRef]

- Bai, S.Y.; Jiang, L.H.; Xu, N.; Jin, M.; Jiang, S.B. Enhancement of mechanical and electrical properties of graphene/cement composite due to improved dispersion of graphene by addition of silica fume. Constr. Build. Mater. 2018, 164, 433–441. [Google Scholar] [CrossRef]

- Li, G.; Yuan, J.B.; Zhang, Y.H.; Zhang, N.; Liew, K.M. Microstructure and mechanical performance of graphene reinforced cementitious composites. Compos. Part A Appl. Sci. Manuf. 2018, 114, 188–195. [Google Scholar] [CrossRef]

- e Silva, R.A.; Guetti, P.D.C.; da Luz, M.S.; Rouxinol, F.; Gelamo, R.V. Enhanced properties of cement mortars with multilayer graphene nanoparticles. Constr. Build. Mater. 2017, 149, 378–385. [Google Scholar] [CrossRef]

- Han, B.G.; Zheng, Q.F.; Sun, S.W.; Dong, S.F.; Zhang, L.Q.; Yu, X.; Ou, J.P. Enhancing mechanisms of multi-layer graphenes to cementitious composites. Compos. Part A Appl. Sci. Manuf. 2017, 101, 143–150. [Google Scholar] [CrossRef]

- Cao, M.-L.; Zhang, H.-X.; Zhang, C. Effect of graphene on mechanical properties of cement mortars. J. Central South Univ. 2016, 23, 919–925. [Google Scholar] [CrossRef]

- Manjunatha, M.; Dinesh, S.; Balaji, K. Influence of PVC waste powder and silica fume on strength and microstructure properties of concrete: An experimental study. Case Stud. Constr. Mater. 2021, 15, e00610. [Google Scholar] [CrossRef]

- Manjunatha, M.; Seth, D.; Balaji, K.V.G.D.; Bharath, A. Engineering properties and environmental impact assessment of green concrete prepared with PVC waste powder: A step towards sustainable approach. Case Stud. Constr. Mater. 2022, 17, e01404. [Google Scholar] [CrossRef]

- Zhang, Q.; Liu, B.; Xiaom, K.; Ekberg, C.; Zhang, S.G. Preparation and hydration of industrial solid waste—Cement blends: A review. Int. J. Miner. Metall. Mater. 2022, 29, 2106–2116. [Google Scholar] [CrossRef]

- Misri, Z.; Ibrahim, M.H.W.; Awal, A.S.M.A.; Desa, M.S.M.; Ghadzali, N.S. Review on factors influencing thermal conductivity of concrete incorporating various type of waste materials. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Langkawi, Malaysia, 4–5 December 2017; Volume 140, p. 012141. [Google Scholar] [CrossRef]

- Duan, Y.J.; Sun, J.H.; Dun, C.Y.; Guo, Y.; Ma, X.X.; Yang, M.J. Mix Design and Strength Properties of Full Iron Tailings Concrete. In Proceedings of the 8th Annual International Conference on Material Science and Engineering (ICMSE2020), Guiyang, Guizhou, China, 14–15 August 2020; Volume 1637, p. 012028. [Google Scholar] [CrossRef]

- Huang, D.W.; Sun, R.J.; Wei, S.S.; Wang, Y.Y.; Hu, Y.Z.; Ge, Z. Comprehensive utilization of iron tailings in China. IOP Conf. Ser. Earth Environ. Sci. 2018, 199, 042055. [Google Scholar] [CrossRef]

- Tian, Z.-X.; Zhao, Z.-H.; Dai, C.-Q.; Liu, S.-J. Experimental Study on the Properties of Concrete Mixed with Iron Ore Tailings. Adv. Mater. Sci. Eng. 2016, 2016, 1–9. [Google Scholar] [CrossRef]

- Zhang, N.; Tang, B.W.; Liu, X.M. Cementitious activity of iron ore tailing and its utilization in cementitious materials, bricks and concrete. Constr. Build. Mater. 2021, 288, 123022. [Google Scholar] [CrossRef]

- Ling, G.; Shui, Z.H.; Gao, X.; Sun, T.; Yu, R.; Li, X.S. Utilizing Iron Ore Tailing as Cementitious Material for Eco-Friendly Design of Ultra-High Performance Concrete (UHPC). Materials 2021, 14, 1829. [Google Scholar] [CrossRef]

- Zhang, Z.Q.; Zhang, Z.L.; Yin, S.N.; Yu, L.W. Utilization of Iron Tailings Sand as an Environmentally Friendly Alternative to Natural River Sand in High-Strength Concrete: Shrinkage Characterization and Mitigation Strategies. Materials 2020, 13, 5614. [Google Scholar] [CrossRef] [PubMed]

- Atta, K.F.; Kumar, S.S.; Daryoush, H.; Alireza, M. Utilisation of iron ore tailings as aggregates in concrete. Cogent Eng. 2015, 2, 1083137. [Google Scholar] [CrossRef]

- Zhao, Y.Q.; Gu, X.W.; Qiu, J.P.; Zhang, W.F.; Li, X.H. Study on the Utilization of Iron Tailings in Ultra-High-Performance Concrete: Fresh Properties and Compressive Behaviors. Materials 2021, 14, 4807. [Google Scholar] [CrossRef] [PubMed]

- Huang, X.Y.; Ranade, R.; Ni, W.; Li, V.C. Development of green engineered cementitious composites using iron ore tailings as aggregates. Constr. Build. Mater. 2013, 44, 757–764. [Google Scholar] [CrossRef]

- Zhang, J.L.; Zhang, N.; Yuan, J.B.; Zhao, J.H.; Zhang, J.C.; Zhang, Y.H. Mortar Designed from Red Mud with Iron Tailings and Moulded by 3D Printing. Bull. Environ. Contam. Toxicol. 2022, 109, 95–100. [Google Scholar] [CrossRef]

- GB/T 17671-1999; Method of Testing Cements-Determination of Strength. Standards Press of China: Beijing, China, 1999.

- Song, S.; Zhang, N.; Yuan, J.B.; Zhang, Y.H. New attempt to produce red mud-iron tailing based alkali-activated mortar: Performance and microstructural characteristics. J. Build. Eng. 2021, 43, 103222. [Google Scholar] [CrossRef]

- Li, X.J.; Zhang, N.; Yuan, J.B.; Wang, X.K.; Zhang, Y.H.; Chen, F.X.; Zhang, Y.H. Preparation and microstructural characterization of a novel 3D printable building material composed of copper tailings and iron tailings. Constr. Build. Mater. 2020, 249, 118779. [Google Scholar] [CrossRef]

- Haque, E.; Islam, M.M.; Pourazadi, E.; Hassan, M.; Faisal, S.N.; Roy, A.K.; Konstantinov, K.; Harris, A.T.; Minett, A.I.; Gomes, V.G. Nitrogen doped graphene via thermal treatment of composite solid precursors as a high performance supercapacitor. RSC Adv. 2015, 5, 30679–30686. [Google Scholar] [CrossRef]

- Bianco, G.V.; Losurdo, M.; Giangregorio, M.M.; Capezzuto, P.; Bruno, G. Exploring and rationalising effective n-doping of large area CVD-graphene by NH3. Phys. Chem. Chem. Phys. 2013, 16, 3632–3639. [Google Scholar] [CrossRef]

- Gu, X.W.; Zhang, W.F.; Zhang, X.L.; Li, X.H.; Qiu, J.P. Hydration characteristics investigation of iron tailings blended ultra high performance concrete: The effects of mechanical activation and iron tailings content. J. Build. Eng. 2021, 45, 103459. [Google Scholar] [CrossRef]

- Zhao, S.J.; Fan, J.J.; Sun, W. Utilization of iron ore tailings as fine aggregate in ultra-high performance concrete. Constr. Build. Mater. 2013, 50, 540–548. [Google Scholar] [CrossRef]

- Ugama, T.I.; Ejeh, S.P.; Amartey, D.Y. Effect of iron ore tailing on the properties of concrete. Civ. Environ. Res. 2014, 6, 7. [Google Scholar]

- Ahmad, J.; Zaid, O.; Shahzaib, M.; Abdullah, M.U.; Ullah, A.; Ullah, R. Mechanical properties of sustainable concrete modified by adding marble slurry as cement substitution. AIMS Mater. Sci. 2021, 8, 343–358. [Google Scholar] [CrossRef]

- Wu, R.D.; Zhang, Y.Y.; Zhang, G.T.; An, S.H. Enhancement effect and mechanism of iron tailings powder on concrete strength. J. Build. Eng. 2022, 57, 104954. [Google Scholar] [CrossRef]

- Li, C.; Zhang, N.; Zhang, J.C.; Song, S.; Zhang, Y.H. C-A-S-H Gel and Pore Structure Characteristics of Alkali-Activated Red Mud–Iron Tailings Cementitious Mortar. Materials 2021, 15, 112. [Google Scholar] [CrossRef]

- Li, H.Y.; Guan, X.M.; Zhang, X.Y.; Ge, P.; Hu, X.X.; Zou, D.H. Influence of superfine ettringite on the properties of sulphoaluminate cement-based grouting materials. Constr. Build. Mater. 2018, 166, 723–731. [Google Scholar] [CrossRef]

- Alkhateb, H.; Al-Ostaz, A.; Cheng, A.H.-D.; Li, X.B. Materials Genome for Graphene-Cement Nanocomposites. J. Nanomechanics Micromechanics 2013, 3, 67–77. [Google Scholar] [CrossRef]

- Zhou, J.W.; Yao, L.M.; Wang, Y.F.; Zhao, W.Q.; Gu, J.H. Study on the Adsorption Properties of Iron Tailings for GO. Coatings 2021, 11, 768. [Google Scholar] [CrossRef]

| Matrix | Type/Dosage (wt.%) | w/b | Increase in Flexural Strength (%)/Age | Increase in Compressive Strength (%)/Age | Ref. |

|---|---|---|---|---|---|

| Paste | GO/0.05 | 0.29 | 69.4/7 days | 66.4/7 days | [28] |

| Paste | GO/0.022 | 0.42 | 26.7/3 days | 27.6/3 days | [32] |

| Paste | rGO/0.02 | 0.32 | 70.0/7 days | 22.0/28 days | [33] |

| Paste | GNPs/0.15 | 0.30 | 27.5/28 days | 49.4/28 days | [34] |

| Paste | GNPs/0.06 | 0.35 | 22.2/7 days | 16.7/7 days | [35] |

| Mortar | GO/0.08 | 0.20 | 80.6/8 days | – | [36] |

| Mortar | rGO/0.10 | 0.485 | – | 57.5/7 days | [37] |

| Mortar | GNPs/0.10 | 0.54 | – | 19.9/28 days | [31] |

| Concrete | GO/0.10 | 0.50 | ~13.0/7 days | ~47.0/7 days | [38] |

| Concrete | rGO/0.05 | 0.43 | 36.0/28 days | 113.0/3 days | [39] |

| Concrete | GNPs/2.50 | 0.47 | – | Almost unchanged/28 days | [40] |

| Materials | SiO2 | CaO | MgO | Al2O3 | SO3 | Fe2O3 |

|---|---|---|---|---|---|---|

| Ordinary Portland cement | 24.85 | 48.38 | 4.39 | 10.88 | 2.95 | 2.68 |

| Belite cement | 16.85 | 48.71 | 2.40 | 14.88 | 11.95 | 1.47 |

| Sample | Iron Ore Tailings/(wt.%) | Portland Cement/(wt.%) | Belite Cement/(wt.%) | Polycarboxylate Superplasticizer/(wt.%) | Graphene/(wt.%) |

|---|---|---|---|---|---|

| XB0 | 50 | 40 | 10 | 0.1 | 0.00 |

| XB1 | 50 | 40 | 10 | 0.1 | 0.01 |

| XB2 | 50 | 40 | 10 | 0.1 | 0.02 |

| XB3 | 50 | 40 | 10 | 0.1 | 0.03 |

| XB4 | 50 | 40 | 10 | 0.1 | 0.04 |

| XB5 | 50 | 40 | 10 | 0.1 | 0.05 |

| Matrix | L/S | Aggregate | Flexural Strength (MPa)/Age | Compressive Strength (MPa)/Age | Ref. |

|---|---|---|---|---|---|

| Mortar | 0.18 | Iron ore tailings | 6.32/7 days | 32.14/7 days | [61] |

| Mortar | 0.20 | Iron ore tailings/copper tailings | 6.80/3 days | 27.6/3 days | [62] |

| Element | Atomic/% | Weight/% |

|---|---|---|

| C | 91.02 | 88.38 |

| O | 8.98 | 11.62 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xiao, H.; Zhang, N.; Li, G.; Zhang, Y.; Wang, Y.; Wang, Y.; Zhang, Y. Graphene-Iron Ore Tailings–Based Cementitious Composites with High Early Flexural Strength. Materials 2023, 16, 327. https://doi.org/10.3390/ma16010327

Xiao H, Zhang N, Li G, Zhang Y, Wang Y, Wang Y, Zhang Y. Graphene-Iron Ore Tailings–Based Cementitious Composites with High Early Flexural Strength. Materials. 2023; 16(1):327. https://doi.org/10.3390/ma16010327

Chicago/Turabian StyleXiao, Huiteng, Na Zhang, Gen Li, Youpeng Zhang, Yidi Wang, Yu Wang, and Yihe Zhang. 2023. "Graphene-Iron Ore Tailings–Based Cementitious Composites with High Early Flexural Strength" Materials 16, no. 1: 327. https://doi.org/10.3390/ma16010327

APA StyleXiao, H., Zhang, N., Li, G., Zhang, Y., Wang, Y., Wang, Y., & Zhang, Y. (2023). Graphene-Iron Ore Tailings–Based Cementitious Composites with High Early Flexural Strength. Materials, 16(1), 327. https://doi.org/10.3390/ma16010327