Reinforcement of Calcareous Sands by Stimulation of Native Microorganisms Induced Mineralization

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Biostimulation

2.2.1. Single-Factor Test

2.2.2. PB Test Design and Screening of Key Components

2.2.3. CCD Response Surface Analysis

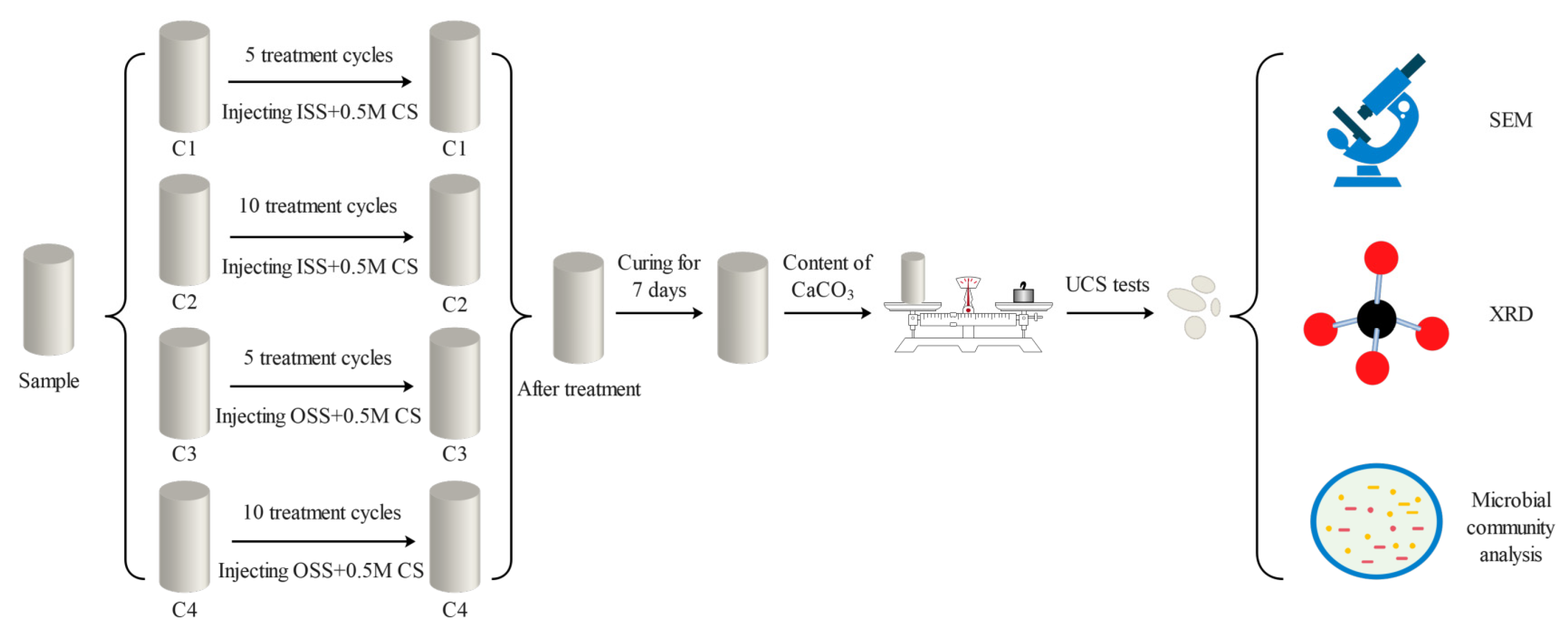

2.3. Biomineralization Scheme

2.3.1. Sample Preparation

2.3.2. Biomineralization Scheme and Parameter Setting

2.4. Evaluation of the Biomineralization Effect

2.4.1. Urease Activity

2.4.2. Determination of Calcium Carbonate Content

2.4.3. UCS Test

2.4.4. SEM and XRD Analysis

2.4.5. Microbial Community Analysis

3. Results and Discussion

3.1. Optimal Stimulation

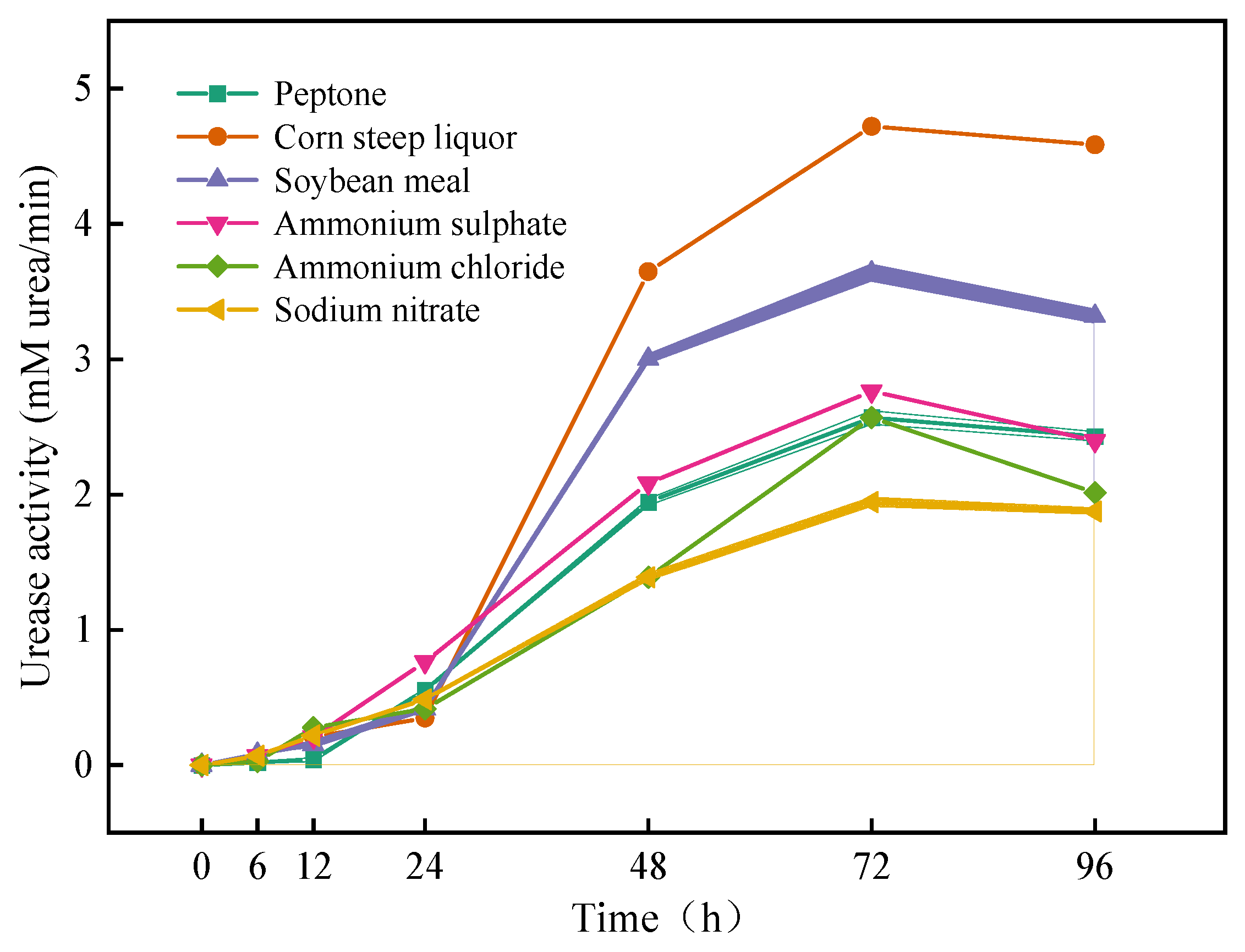

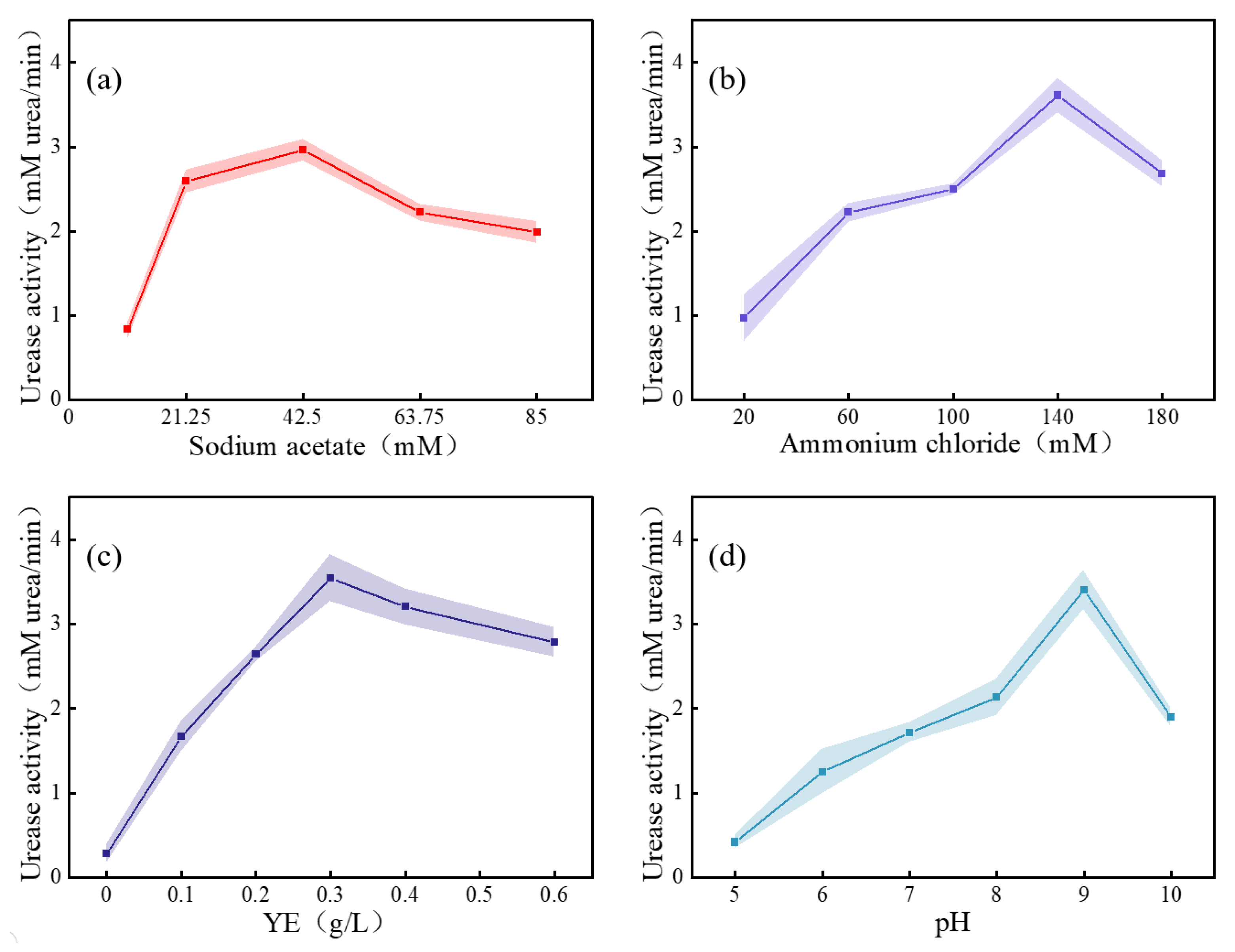

3.1.1. Single-Factor Test

3.1.2. Results of PB Design

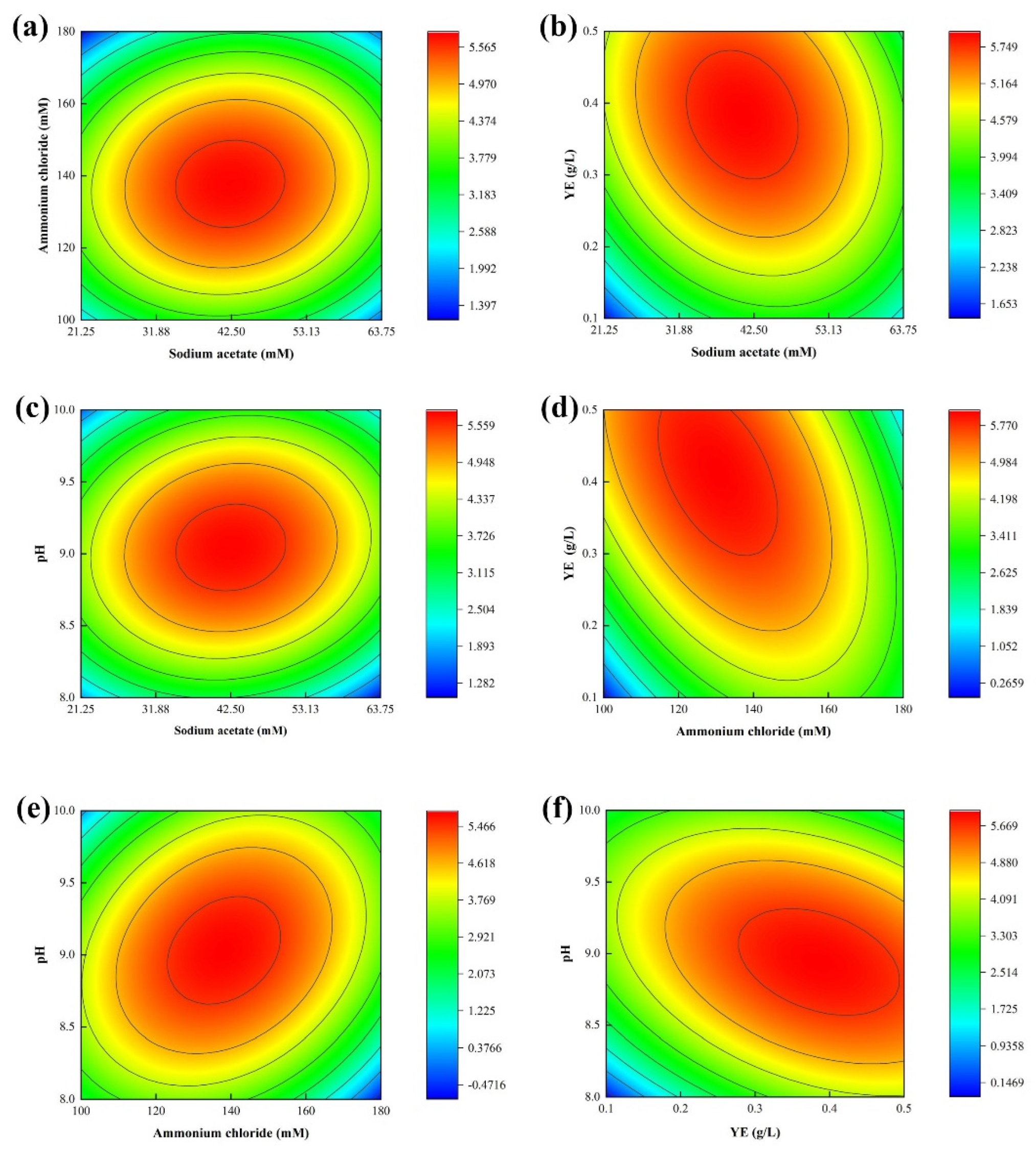

3.1.3. CCD Response Surface Analysis

3.2. Urease Activity

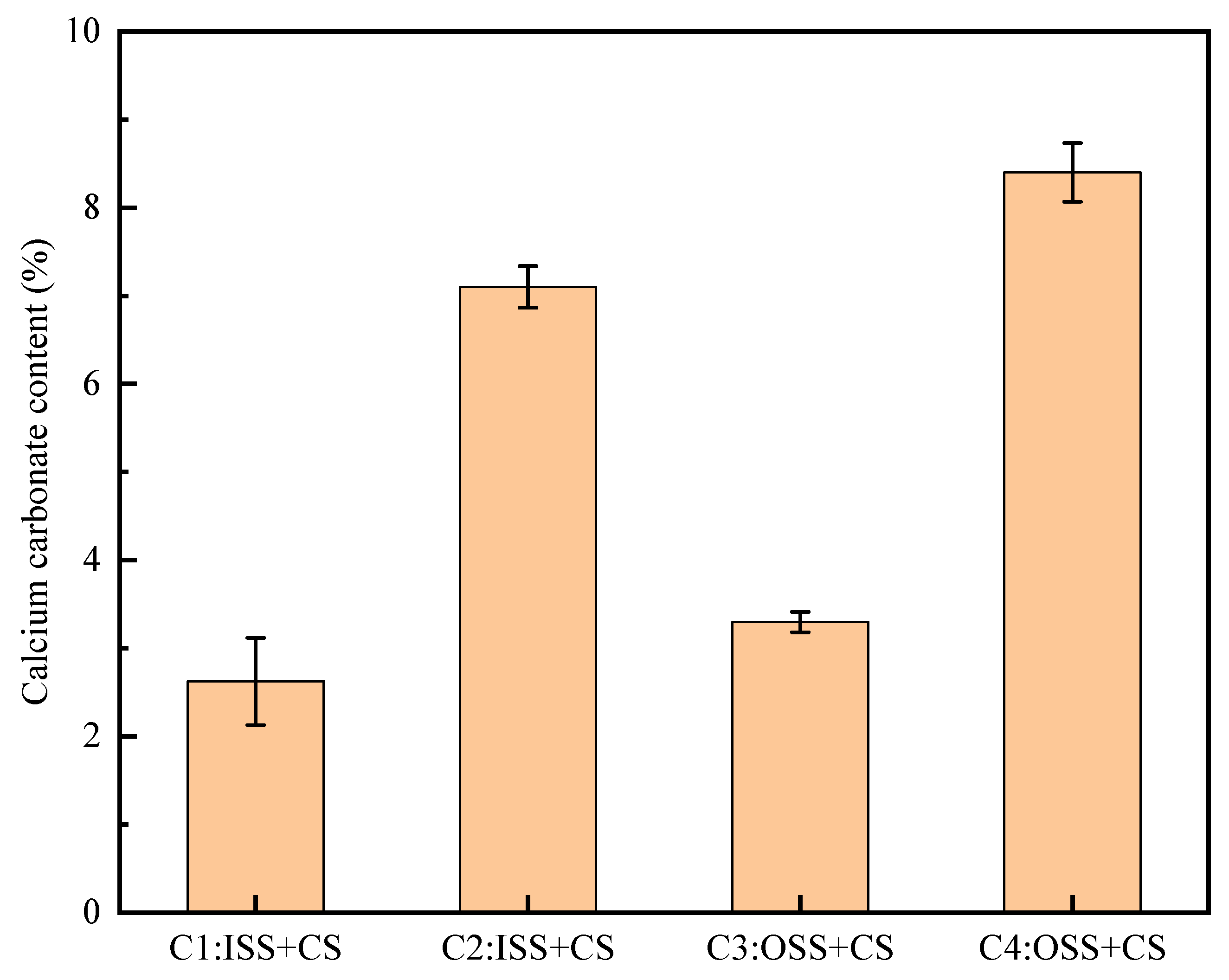

3.3. Calcium Carbonate Content

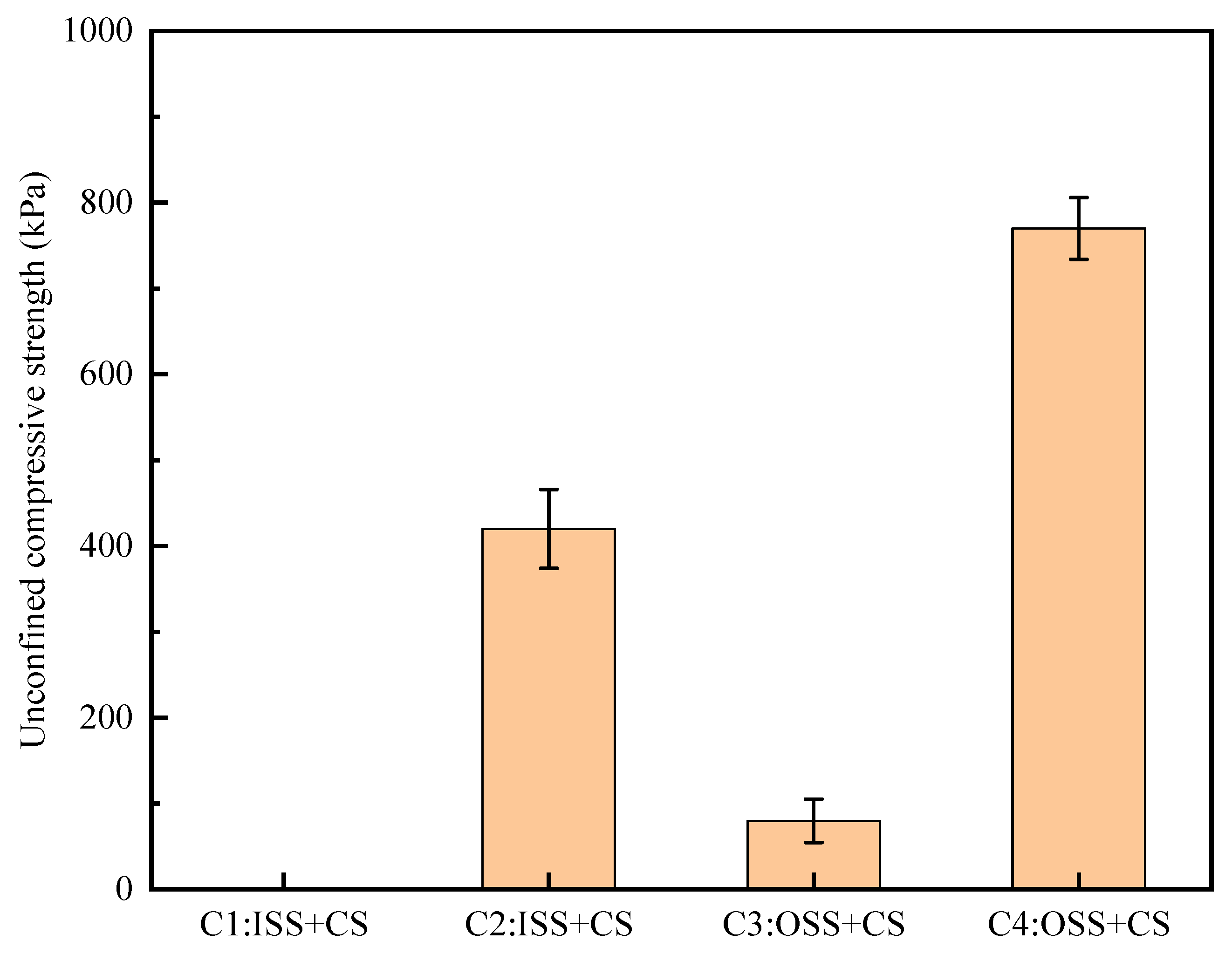

3.4. UCS Test and Analysis

3.5. SEM Test Results and Analysis

3.6. XRD Results and Analysis

3.7. Results of Microbial Community Analysis

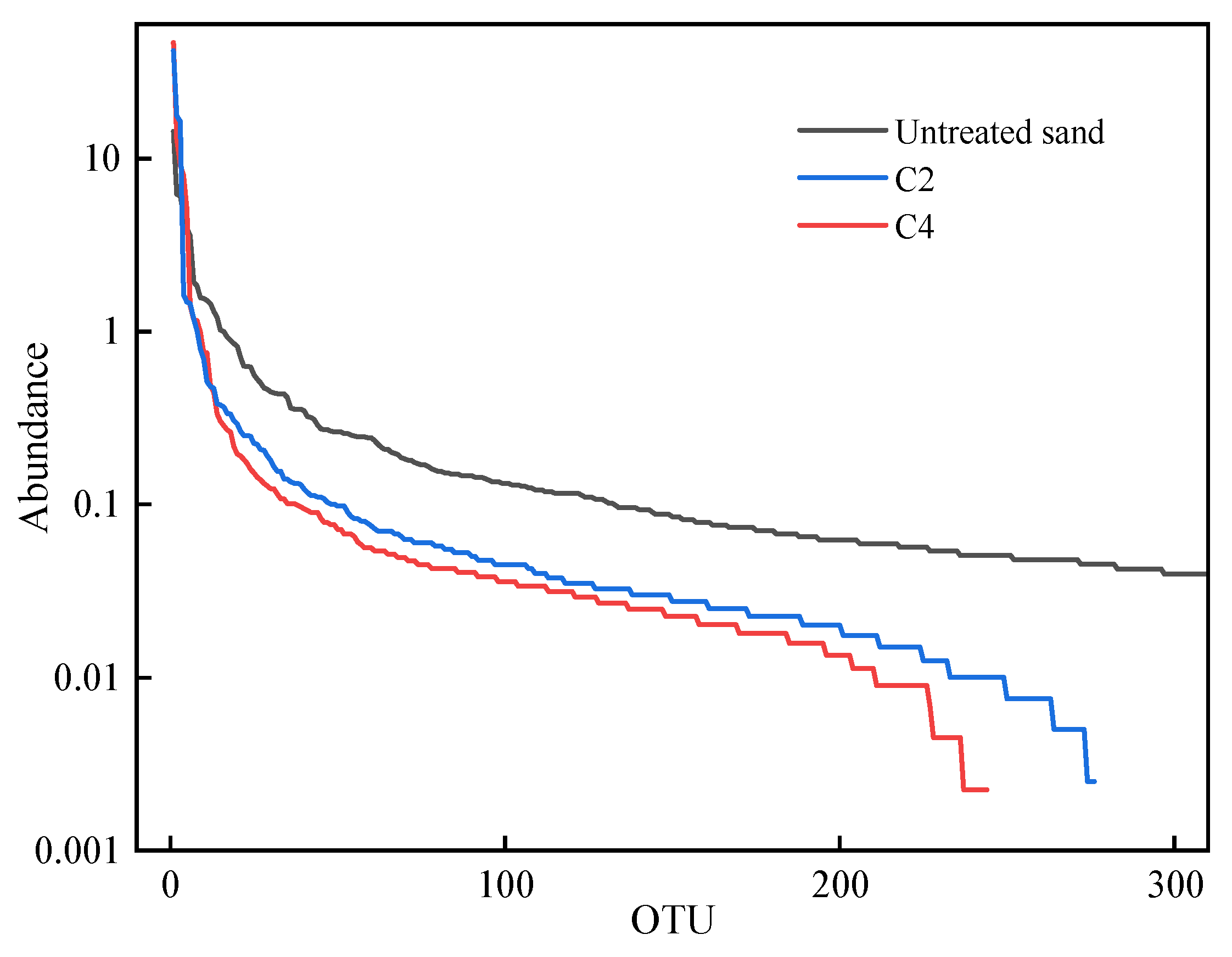

3.7.1. Rank Abundance Curve

3.7.2. Microbial Relative Abundance Analysis

4. Conclusions

- Using response surface methodology, stimulation solutions were optimized based on the urease activity of indigenous microorganisms in calcareous sand. The following components and concentrations were obtained for the optimal stimulation solution: sodium acetate (38.00 mM), ammonium chloride (124.24 mM), yeast extract (0.46 g/L), urea (333 mM), and nickel chloride (0.01 mM); the pH value was 8.75.

- The comparison of test results showed that the urease activity reached 6.2270 mM urea/min with the optimal stimulation solution. In the actual test, the urease activity reached 6.1891 mM urea/min, which was 71% higher than that of the initial stimulation solution. In mineralization tests, calcareous sand columns treated with the optimal stimulation regimen showed increased calcium carbonate precipitation. The high urease activity mineralization scheme and multiple cycles of treatment could effectively improve the UCS. The UCS of the calcareous sand column treated by the optimal stimulation scheme was significantly higher than that of the initial stimulation scheme, and the maximum reached 770 kPa.

- The SEM and XRD analysis results showed that mineralization products formed between the calcareous sand particles and on their surfaces. Calcium carbonate obtained from biomineralization precipitated as calcite. The appearance of calcite and cementation between particles greatly improved the mechanical properties of calcareous sand.

- Microbial community analysis showed that the stimulation scheme screened the microorganisms in the calcareous sand. Making urease-producing microorganisms the dominant species improved the urease-producing ability and total urease activity; ultimately, the mineralization rate of calcareous sands could be increased. The level of change in the microbial community was a strong basis for the successful reinforcement of calcareous sand by stimulating native urease-producing microorganisms.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhu, C.; Chen, H.; Meng, Q.; Wang, R. Microscopic characterization of intra-pore structures of calcareous sands. Rock Soil Mech. 2014, 35, 1831–1836. [Google Scholar] [CrossRef]

- Zhang, Q.; Ye, W.; Liu, Z.; Wang, Q.; Chen, Y. Advances in soil cementation by biologically induced calcium carbonate precipitation. Rock Soil Mech. 2022, 43, 345–357. [Google Scholar]

- Whiffin, V.S.; van Paassen, L.A.; Harkes, M.P. Microbial carbonate precipitation as a soil improvement technique. Geomicrobiol. J. 2007, 24, 417–423. [Google Scholar] [CrossRef]

- Burbank, M.B.; Weaver, T.J.; Green, T.L.; Williams, B.C.; Crawford, R.L. Precipitation of Calcite by Indigenous Microorganisms to Strengthen Liquefiable Soils. Geomicrobiol. J. 2011, 28, 301–312. [Google Scholar] [CrossRef]

- Cheng, L.; Cord-Ruwisch, R.; Shahin, M.A. Cementation of sand soil by microbially induced calcite precipitation at various degrees of saturation. Can. Geotech. J. 2013, 50, 81–90. [Google Scholar] [CrossRef]

- DeJong, J.T.; Fritzges, M.B.; Nusslein, K. Microbially induced cementation to control sand response to undrained shear. J. Geotech. Geoenvironmental Eng. 2006, 132, 1381–1392. [Google Scholar] [CrossRef]

- Liu, H.; Xiao, P.; Xiao, Y.; Wang, J.; Chen, Y.; Chu, J. Dynamic behaviors of MICP-treated calcareous sand in cyclic tests. Chin. J. Geotech. Eng. 2018, 40, 38–45. [Google Scholar] [CrossRef]

- Zhang, X.; Chen, Y.; Zhang, Z.; Ding, X.; Xu, S.; Liu, H.; Wang, Z. Performance evaluation of liquefaction resistance of a MICP-treated calcareous sandy foundation using shake table tests. Chin. J. Geotech. Eng. 2020, 42, 1023–1031. [Google Scholar] [CrossRef]

- Jiang, N.J.; Yoshioka, H.; Yamamoto, K.; Soga, K. Ureolytic activities of a urease-producing bacterium and purified urease enzyme in the anoxic condition: Implication for subseafloor sand production control by microbially induced carbonate precipitation (MICP). Ecol. Eng. 2016, 90, 96–104. [Google Scholar] [CrossRef]

- Kirkland, C.M.; Thane, A.; Hiebert, R.; Hyatt, R.; Kirksey, J.; Cunningham, A.B.; Phillips, A.J. Addressing wellbore integrity and thief zone permeability using microbially-induced calcium carbonate precipitation (MICP): A field demonstration. J. Pet. Sci. Eng. 2020, 190, 107060. [Google Scholar] [CrossRef]

- Wu, J.; Wang, X.B.; Wang, H.F.; Zeng, R.J. Microbially induced calcium carbonate precipitation driven by ureolysis to enhance oil recovery. RSC Adv. 2017, 7, 37382–37391. [Google Scholar] [CrossRef]

- Liu, S.; Dong, B.; Yu, J.; Cai, Y. Evaluation of Biostimulation Efficacy on the Reinforcement of Calcareous Sand. J. Test. Eval. 2021, 49, 4181–4200. [Google Scholar] [CrossRef]

- San Pablo, A.C.M.; Lee, M.; Graddy, C.M.R.; Kolbus, C.M.; Khan, M.; Zamani, A.; Nelson, D.C. Meter-Scale Biocementation Experiments to Advance Process Control and Reduce Impacts: Examining Spatial Control, Ammonium By-Product Removal, and Chemical Reductions. J. Geotech. Geoenvironmental Eng. 2020, 146, 04020125. [Google Scholar] [CrossRef]

- Gomez, M.G.; Anderson, C.M.; Graddy, C.M.R.; DeJong, J.T.; Nelson, D.C.; Ginn, T.R. Large-Scale Comparison of Bioaugmentation and Biostimulation Approaches for Biocementation of Sands. J. Geotech. Geoenviron. Eng. 2017, 143, 04016124. [Google Scholar] [CrossRef]

- Mahanty, B.; Kim, S.; Kim, C.G. Assessment of a Biostimulated or Bioaugmented Calcification System with Bacillus pasteurii in a Simulated Soil Environment. Microb. Ecol. 2012, 65, 679–688. [Google Scholar] [CrossRef]

- Islam, M.T.; Chittoori, B.C.S.; Burbank, M. Evaluating the Applicability of Biostimulated Calcium Carbonate Precipitation to Stabilize Clayey Soils. J. Mater. Civ. Eng. 2020, 32, 04019369. [Google Scholar] [CrossRef]

- Raveh-Amit, H.; Tsesarsky, M. Biostimulation in Desert Soils for Microbial-Induced Calcite Precipitation. Appl. Sci. 2020, 10, 2905. [Google Scholar] [CrossRef]

- Dhami, N.K.; Alsubhi, W.R.; Watkin, E.; Mukherjee, A. Bacterial Community Dynamicsand Biocement Formationduring Stimulation and Augmentation: Implications for Soil Consolidaton. Front. Microbiol. 2017, 8, 1267. [Google Scholar] [CrossRef]

- Gomez, M.G.; Anderson, C.M.; Dejong, J.T.; Nelson, D.C.; Lau, X.H. Stimulating In Situ Soil Bacteria for Bio-Cementation of Sands. In Proceedings of the Geo-Congress 2014, Atlanta, Georgia, 23–26 February 2014. [Google Scholar] [CrossRef]

- Gomez, M.G.; Graddy, C.M.R.; DeJong, J.T.; Nelson, D.C.; Tsesarsky, M. Stimulation of Native Microorganisms for Biocementation in Samples Recovered from Field-Scale Treatment Depths. J. Geotech. Geoenviron. Eng. 2018, 144, 04017098. [Google Scholar] [CrossRef]

- Kiasari, M.A.; Pakbaz, M.S.; Ghezelbash, G.R. Comparison of Effects of Different Nutrients on Stimulating Indigenous Soil Bacteria for Biocementation. J. Mater. Civ. Eng. 2019, 31. [Google Scholar] [CrossRef]

- Gat, D.; Ronen, Z.; Tsesarsky, M. Soil Bacteria Population Dynamics Following Stimulation for Ureolytic Microbial-Induced CaCO3 Precipitation. Environ. Sci. Technol. 2016, 50, 616–624. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.J.; Han, X.L.; Jiang, N.J.; Wang, J.; Feng, J. The effect of enrichment media on the stimulation of native ureolytic bacteria in calcareous sand. Int. J. Environ. Sci. Technol. 2020, 17, 1795–1808. [Google Scholar] [CrossRef]

- Ministry of Water Resources of the People’s Republic of China (WMR). Specification of Soil Test, SL 237-1999; China Water and Power Press: Beijing, China, 1999. [Google Scholar]

- Zarastvand, M.R.; Asadijafari, M.H.; Talebitooti, R. Acoustic wave transmission characteristics of stiffened composite shell systems with double curvature. Compos. Struct. 2022, 292, 115688. [Google Scholar] [CrossRef]

- Whiffin, V.S. Microbial CaCO3 Precipitation for the Production of Biocement. Ph.D. Thesis, Murdoch University, Perth, Australia, 2004. [Google Scholar]

- Deng, X.; Zhou, H.; Qu, X.N.; Long, J.; Peng, P.Q.; Hou, H.B.; Li, K.L.; Zhang, P.; Liao, B.H. Optimization of Cd(II) removal from aqueous solution with modified corn straw biochar using Plackett-Burman design and response surface methodology. Desalination Water Treat. 2017, 70, 210–219. [Google Scholar] [CrossRef]

- Miao, L.; Wu, L.; Sun, X.; Li, X.; Zhang, J. Method for solidifying desert sands with enzyme-catalysed mineralization. Land Degrad. Dev. 2020, 31, 1317–1324. [Google Scholar] [CrossRef]

- Chu, J.; Ivanov, V.; Naeimi, M.; Stabnikov, V.; Liu, H.L. Optimization of calcium-based bioclogging and biocementation of sand. Acta Geotech. 2013, 9, 277–285. [Google Scholar] [CrossRef]

- Okyay, T.O.; Rodrigues, D.F. Optimized carbonate micro-particle production by Sporosarcina pasteurii using response surface methodology. Ecol. Eng. 2014, 62, 168–174. [Google Scholar] [CrossRef]

- Al-Salloum, Y.; Abbas, H.; Sheikh, Q.I.; Hadi, S.; Alsayed, S.; Almusallam, T. Effect of some biotic factors on microbially-induced calcite precipitation in cement mortar. Saudi J. Biol. Sci. 2017, 24, 286–294. [Google Scholar] [CrossRef]

- Lin, H.; Suleiman, M.T.; Brown, D.G. Investigation of pore-scale CaCO3 distributions and their effects on stiffness and permeability of sands treated by microbially induced carbonate precipitation (MICP). Soils Found. 2020, 60, 944–961. [Google Scholar] [CrossRef]

- Al Qabany, A.; Soga, K. Effect of chemical treatment used in MICP on engineering properties of cemented soils. Geotechnique 2013, 63, 331–339. [Google Scholar] [CrossRef]

- Li, B. Geotechnical Properties of Biocement Treated Sand and Clay. Ph.D. Thesis, Nanyang Technological University, Singapore, 2015. [Google Scholar] [CrossRef]

- Stabnikov, V.; Jian, C.; Ivanov, V.; Li, Y. Halotolerant, alkaliphilic urease-producing bacteria from different climate zones and their application for biocementation of sand. World J. Microbiol. Biotechnol. 2013, 29, 1453–1460. [Google Scholar] [CrossRef] [PubMed]

- Ahenkorah, I.; Rahman, M.M.; Karim, M.R.; Teasdale, P.R. Optimization of Enzyme Induced Carbonate Precipitation (EICP) as a Ground Improvement Technique. In Proceedings of the Geo-Congress 2020, Minneapolis, MN, USA, 25–28 February 2020; pp. 552–561. [Google Scholar] [CrossRef]

- Van Paassen, L.A.; Daza, C.M.; Staal, M.; Sorokin, D.Y.; van der Zon, W.; van Loosdrecht, M.C.M. Potential soil reinforcement by biological denitrification. Ecol. Eng. 2010, 36, 168–175. [Google Scholar] [CrossRef]

- Van Paassen, L.A.; Harkes, M.P.; Van Zwieten, G.A.; Van Der Zon, W.H.; Van Der Star, W.R.L.; Van Loosdrecht, M.C.M. Scale up of BioGrout: A biological ground reinforcement method. In Proceedings of the 17th International Conference on Soil Mechanics and Geotechnical Engineering: The Academia and Practice of Geotechnical Engineering, Alexandria, Egypt, 5–9 October 2009; pp. 2328–2333. [Google Scholar] [CrossRef]

- Liu, H.; Xiao, P.; Xiao, Y.; Chu, J. State-of-the-art review of biogeotechnology and its engineering applications. J. Civ. Environ. Eng. 2019, 41, 1–14. [Google Scholar] [CrossRef]

- Gu, Z.; Chen, Q.; Wang, L.; Niu, S.; Zheng, J.; Yang, M.; Yan, Y. Morphological Changes of Calcium Carbonate and Mechanical Properties of Samples during Microbially Induced Carbonate Precipitation (MICP). Materials 2022, 15, 7754. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Li, M.; Tao, X.; Zhang, S.; He, J.; Zhu, L.; Wen, K. The Effect of Nucleating Agents on Enzyme-Induced Carbonate Precipitation and Corresponding Microscopic Mechanisms. Materials 2022, 15, 5814. [Google Scholar] [CrossRef] [PubMed]

- DeJong, J.T.; Mortensen, B.M.; Martinez, B.C.; Nelson, D.C. Bio-mediated soil improvement. Ecol. Eng. 2010, 36, 197–210. [Google Scholar] [CrossRef]

- Rowshanbakht, K.; Khamehchiyan, M.; Sajedi, R.H.; Nikudel, M.R. Effect of injected bacterial suspension volume and relative density on carbonate precipitation resulting from microbial treatment. Ecol. Eng. 2016, 89, 49–55. [Google Scholar] [CrossRef]

- Wang, L.; Liu, S. Mechanism of Sand Cementation with an Efficient Method of Microbial-Induced Calcite Precipitation. Materials 2021, 14, 5631. [Google Scholar] [CrossRef]

- Liu, S.; Yu, J.; Zeng, W.; Peng, X.; Cai, Y.; Tu, B. Repair effect of tabia cracks with microbially induced carbonate precipitation. Chin. J. Rock Mech. Eng. 2020, 39, 191–204. [Google Scholar] [CrossRef]

- Chittoori, B.C.S.; Pathak, A.; Burbank, M.; Islam, M.T. Application of Bio-Stimulated Calcite Precipitation to Stabilize Expansive Soils: Field Trials. Geo-Congress 2020, 2020, 111–120. [Google Scholar] [CrossRef]

- Dhami, N.K.; Mukherjee, A.; Reddy, M.S. Micrographical, minerological and nano -mechanical characterisation of microbial carbonates from urease and carbonic anhydrase producing bacteria. Ecol. Eng. 2016, 94, 443–454. [Google Scholar] [CrossRef]

- Bai, Y.; Chang, Y.; Liang, J.; Chen, C.; Qu, J. Treatment of groundwater containing Mn(II), Fe(II), As(III) and Sb(III) by bioaugmented quartz-sand filters. Water Res. 2016, 106, 126–134. [Google Scholar] [CrossRef] [PubMed]

- Park, S.C.; Baik, K.S.; Kim, M.S.; Chun, J.; Seong, C.N. Nocardioides dokdonensis sp nov., an actinomycete isolated from sand sediment. Int. J. Syst. Evol. Microbiol. 2008, 58, 2619–2623. [Google Scholar] [CrossRef] [PubMed]

| d10 | d30 | d60 | Cu | Cc |

|---|---|---|---|---|

| 0.281 mm | 0.385 mm | 0.592 mm | 2.107 | 0.891 |

| Factor | Level | |

|---|---|---|

| −1 | +1 | |

| Molasses (g/L) | 3.5 | 5.2 |

| Sodium acetate (mM) | 42.5 | 63.75 |

| Corn steep liquor (g/L) | 5 | 7.5 |

| Soybean meal (g/L) | 5 | 7.5 |

| Ammonium sulfate (mM) | 35 | 53 |

| Ammonium chloride (mM) | 100 | 151 |

| Nickel chloride (mM) | 0.01 | 0.015 |

| Urea (mM) | 333 | 500 |

| YE (g/L) | 0.2 | 0.3 |

| pH | 7.0 | 9.0 |

| Number | A | B | C | D | E | F | G | H | I | J | UA |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 1 | −1 | 1 | −1 | −1 | −1 | 1 | 1 | 1 | −1 | 1.19 |

| 2 | 1 | 1 | −1 | 1 | −1 | −1 | −1 | 1 | 1 | 1 | 3.06 |

| 3 | −1 | 1 | 1 | −1 | 1 | −1 | −1 | −1 | 1 | 1 | 4.43 |

| 4 | 1 | −1 | 1 | 1 | −1 | 1 | −1 | −1 | −1 | 1 | 4.93 |

| 5 | 1 | 1 | −1 | 1 | 1 | −1 | 1 | −1 | −1 | −1 | 0.35 |

| 6 | 1 | 1 | 1 | −1 | 1 | 1 | −1 | 1 | −1 | −1 | 1.46 |

| 7 | −1 | 1 | 1 | 1 | −1 | 1 | 1 | −1 | 1 | −1 | 2.29 |

| 8 | −1 | −1 | 1 | 1 | 1 | −1 | 1 | 1 | −1 | 1 | 2.64 |

| 9 | −1 | −1 | −1 | 1 | 1 | 1 | −1 | 1 | 1 | −1 | 2.36 |

| 10 | 1 | −1 | −1 | −1 | 1 | 1 | 1 | −1 | 1 | 1 | 5.90 |

| 11 | −1 | 1 | −1 | −1 | −1 | 1 | 1 | 1 | −1 | 1 | 3.68 |

| 12 | −1 | −1 | −1 | −1 | −1 | −1 | −1 | −1 | −1 | −1 | 1.39 |

| Item | Effect | p Value | Estimated Coefficient |

|---|---|---|---|

| Molasses | 0.0167 | 0.705 | 0.0083 |

| Sodium acetate | −0.5233 | 0.040 | −0.2617 |

| Corn steep liquor | 0.0333 | 0.500 | 0.0167 |

| Soybean meal | −0.4033 | 0.052 | −0.2017 |

| Ammonium sulfate | 0.1000 | 0.205 | 0.0500 |

| Ammonium chloride | 1.2600 | 0.017 | 0.6300 |

| Nickel chloride | −0.2633 | 0.080 | −0.1317 |

| Urea | −0.8167 | 0.026 | −0.4083 |

| YE | 0.7967 | 0.027 | 0.3983 |

| pH | 2.6000 | 0.008 | 1.3000 |

| Model | 0.026 | ||

| R2 > 99% | |||

| Factor | Level | ||||

|---|---|---|---|---|---|

| −2 | −1 | 0 | 1 | 2 | |

| Sodium acetate (mM) | 21.25 | 31.88 | 42.5 | 53.13 | 63.75 |

| Ammonium chloride (mM) | 100 | 120 | 140 | 160 | 180 |

| YE (g/L) | 0.1 | 0.2 | 0.3 | 0.4 | 0.5 |

| pH | 8 | 8.5 | 9 | 9.5 | 10 |

| Source | df | Sum of Squares | Mean Square | F Value | p Value Prob > F |

|---|---|---|---|---|---|

| Model | 14 | 34.7283 | 2.4806 | 23.63 | <0.0001 |

| A | 1 | 0.0012 | 0.0012 | 0.01 | 0.917 |

| B | 1 | 0.4085 | 0.4085 | 3.89 | 0.066 |

| C | 1 | 5.1328 | 5.1328 | 48.90 | <0.0001 |

| D | 1 | 0.2707 | 0.2707 | 2.58 | 0.128 |

| A2 | 1 | 5.1562 | 5.1562 | 49.12 | <0.0001 |

| A2 | 1 | 10.6015 | 10.6015 | 101.00 | <0.0001 |

| C2 | 1 | 2.5502 | 2.5502 | 24.30 | <0.0001 |

| D2 | 1 | 11.0546 | 11.0546 | 105.32 | <0.0001 |

| AB | 1 | 0.0814 | 0.0814 | 0.78 | 0.392 |

| AC | 1 | 0.3460 | 0.3460 | 3.30 | 0.088 |

| AD | 1 | 0.1442 | 0.1442 | 1.37 | 0.258 |

| BC | 1 | 2.4704 | 5.4704 | 23.54 | <0.0001 |

| BD | 1 | 1.5234 | 1.5234 | 14.51 | 0.0023 |

| CD | 1 | 1.3439 | 1.3439 | 12.80 | 0.003 |

| Misfit term | 0.244 | ||||

| Pure error | 6 | 0.4198 | |||

| Cor total | 30 | 36.4077 | |||

| R2 = 95.39% | R2(adj.) = 91.35% | ||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shen, G.; Liu, S.; He, Y.; Pan, M.; Yu, J.; Cai, Y. Reinforcement of Calcareous Sands by Stimulation of Native Microorganisms Induced Mineralization. Materials 2023, 16, 251. https://doi.org/10.3390/ma16010251

Shen G, Liu S, He Y, Pan M, Yu J, Cai Y. Reinforcement of Calcareous Sands by Stimulation of Native Microorganisms Induced Mineralization. Materials. 2023; 16(1):251. https://doi.org/10.3390/ma16010251

Chicago/Turabian StyleShen, Gangqiang, Shiyu Liu, Yuhan He, Muzhi Pan, Jin Yu, and Yanyan Cai. 2023. "Reinforcement of Calcareous Sands by Stimulation of Native Microorganisms Induced Mineralization" Materials 16, no. 1: 251. https://doi.org/10.3390/ma16010251

APA StyleShen, G., Liu, S., He, Y., Pan, M., Yu, J., & Cai, Y. (2023). Reinforcement of Calcareous Sands by Stimulation of Native Microorganisms Induced Mineralization. Materials, 16(1), 251. https://doi.org/10.3390/ma16010251