In-Service Delaminations in FRP Structures under Operational Loading Conditions: Are Current Fracture Testing and Analysis on Coupons Sufficient for Capturing the Essential Effects for Reliable Predictions?

Abstract

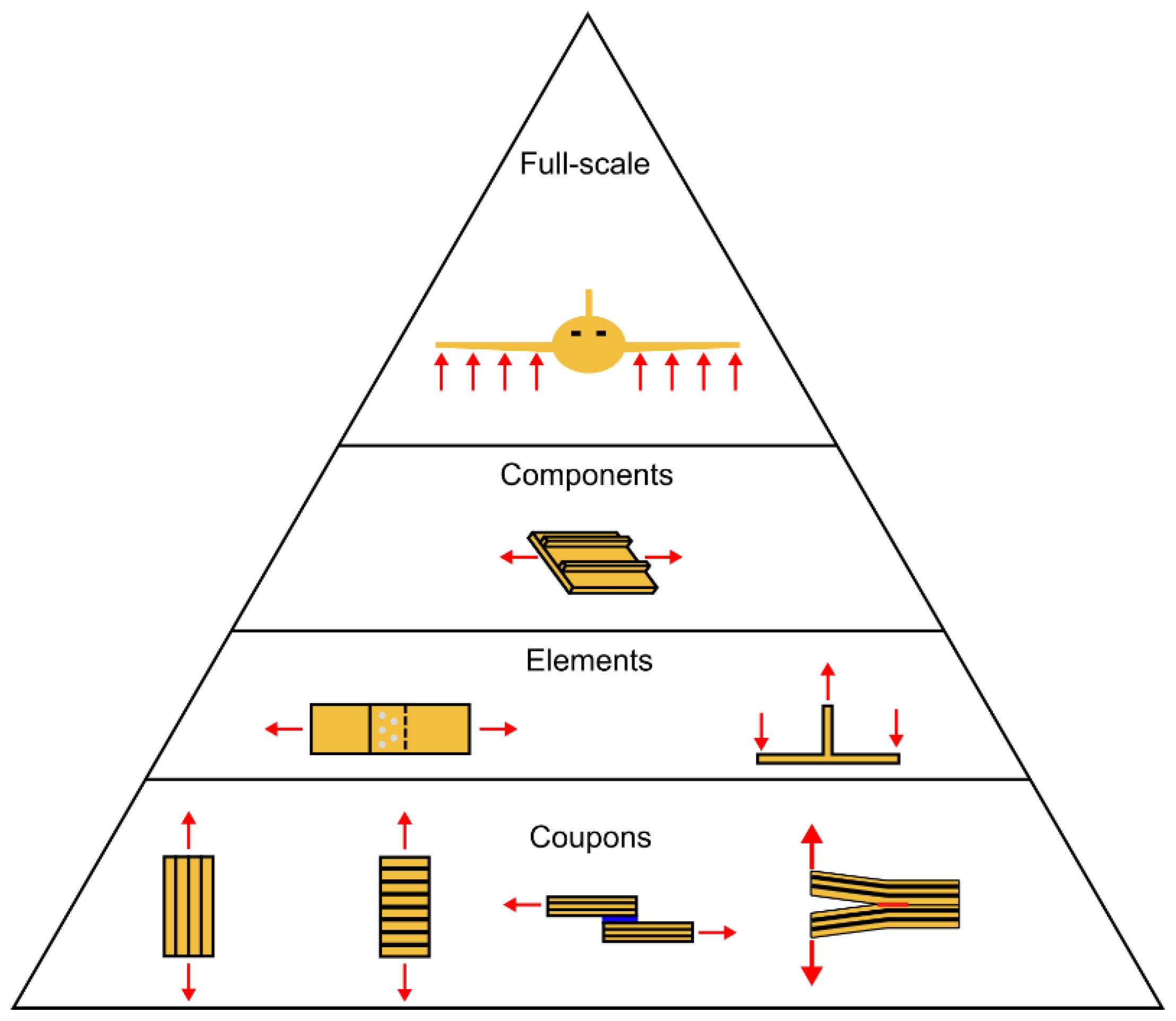

1. Introduction

2. Materials and Methodology

3. Relevant Issues and Discussion

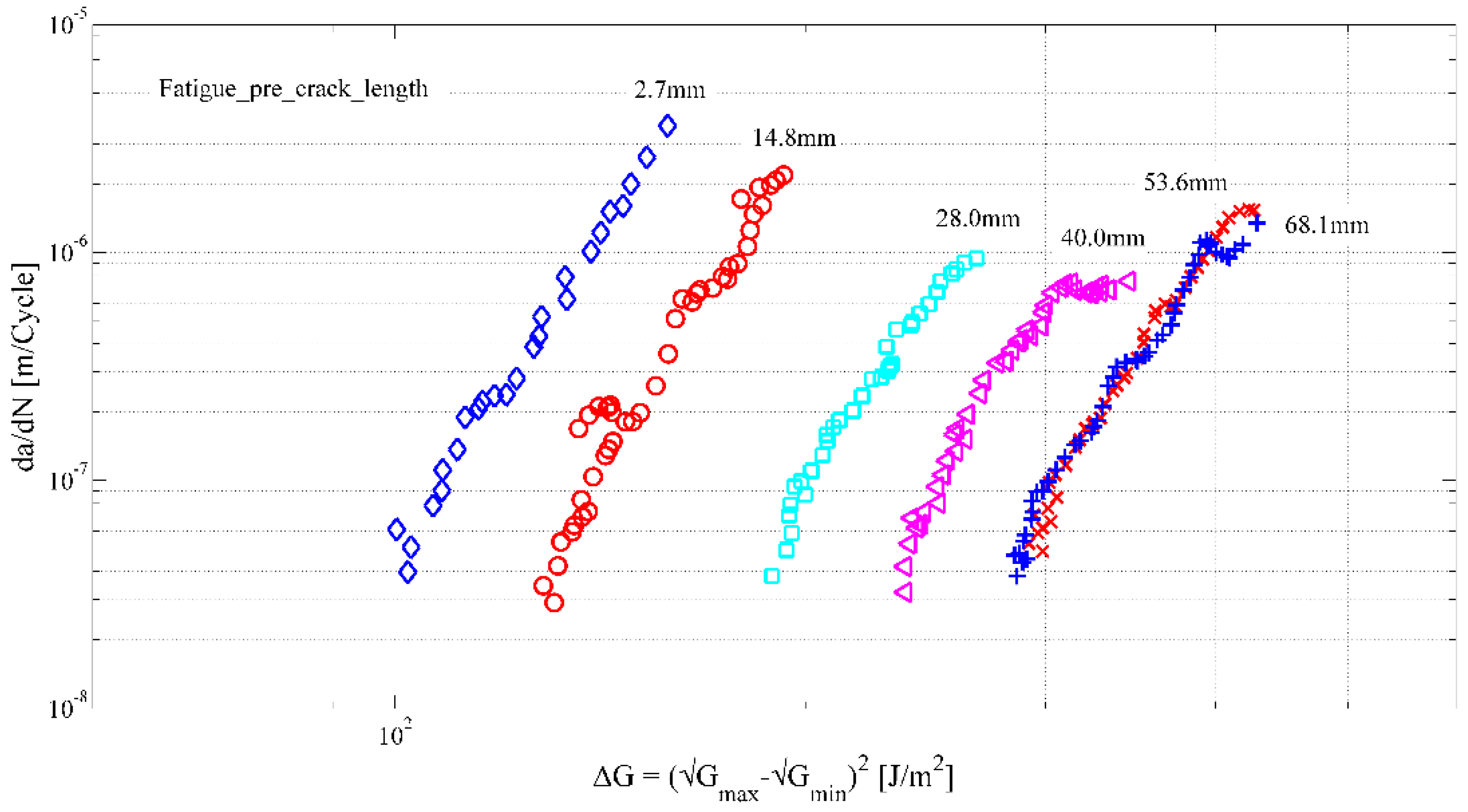

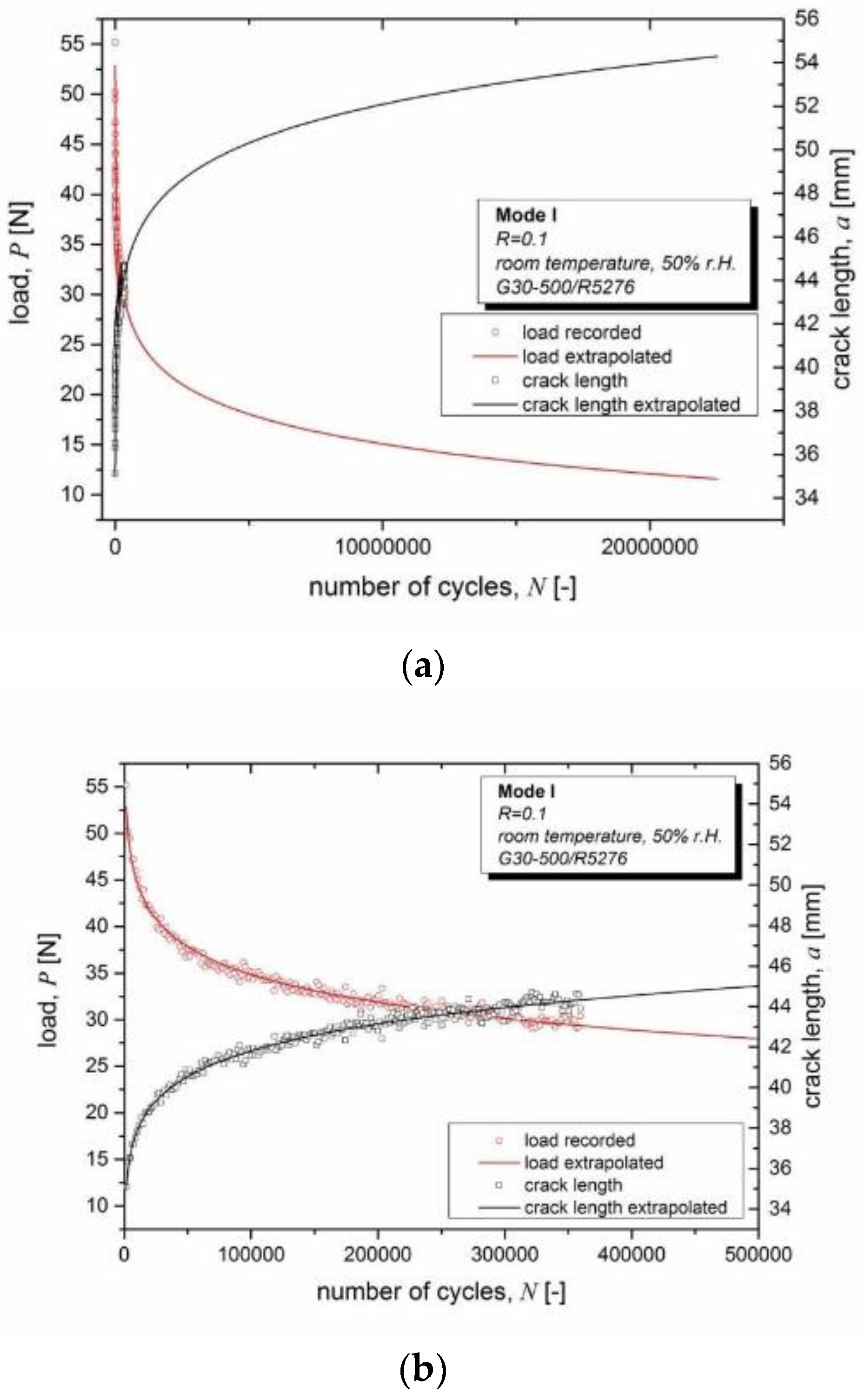

3.1. Accounting for Fibre Bridging Effects

3.1.1. The Fibre Bridging Phenomenon

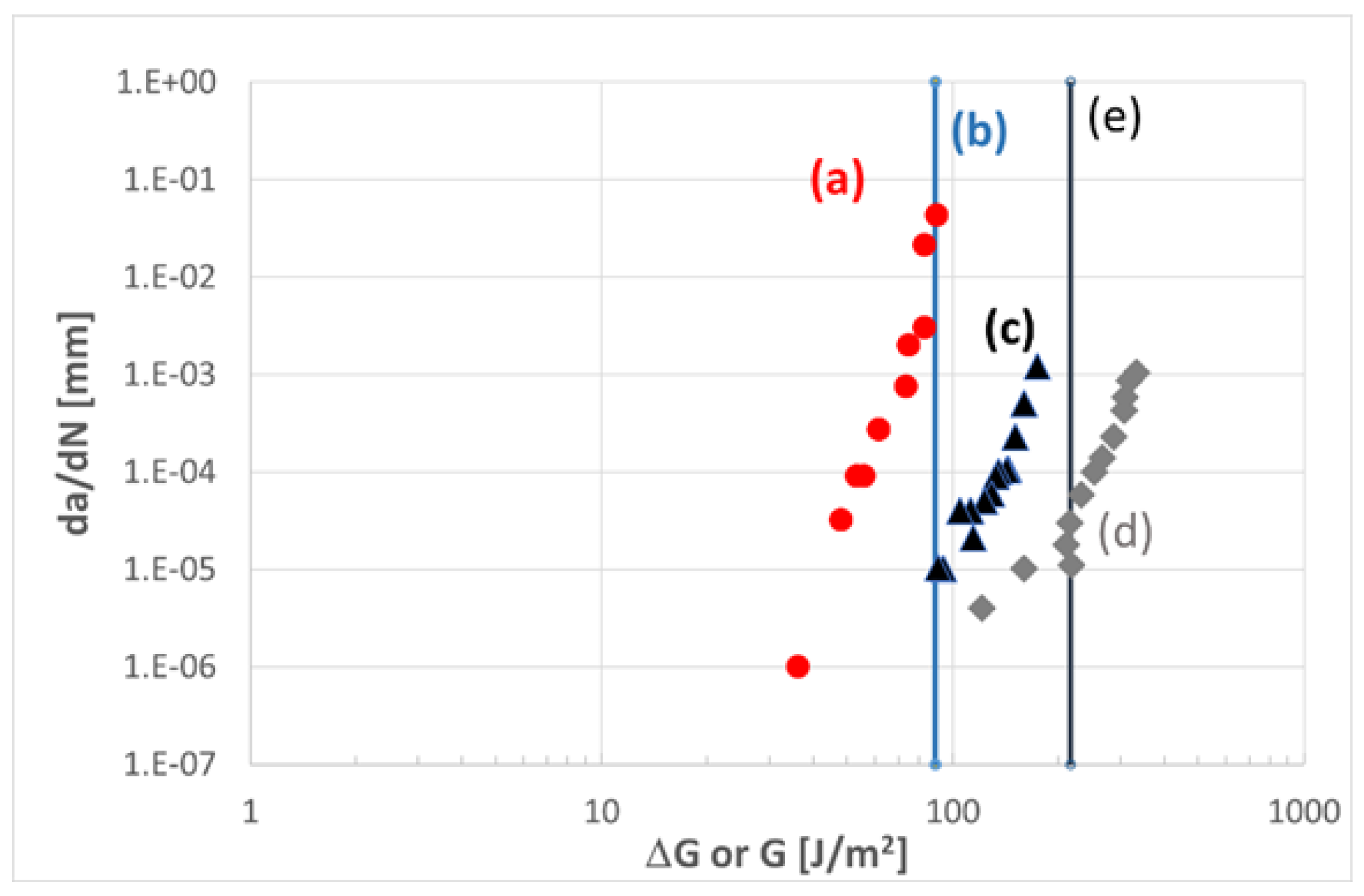

3.1.2. Evaluating the Zero-Bridging Curve

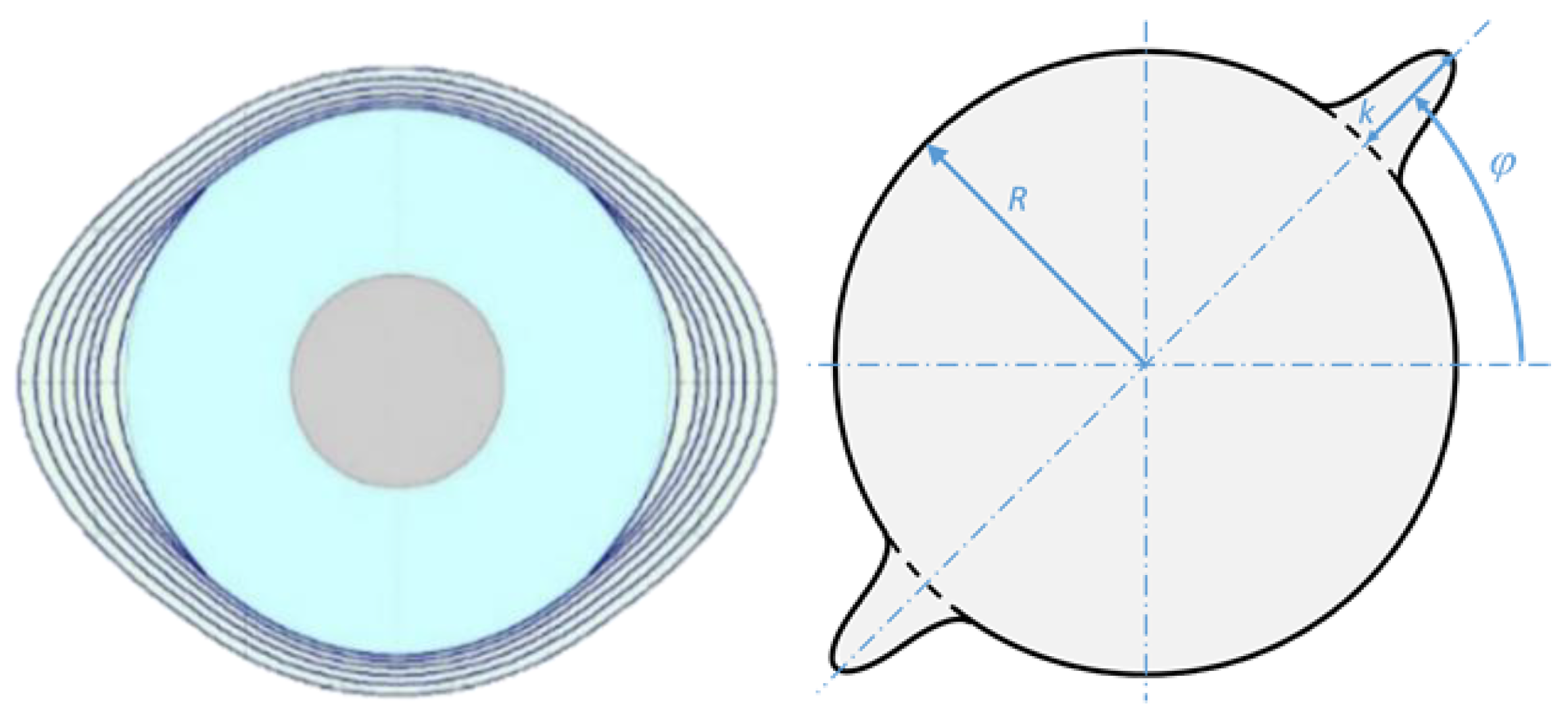

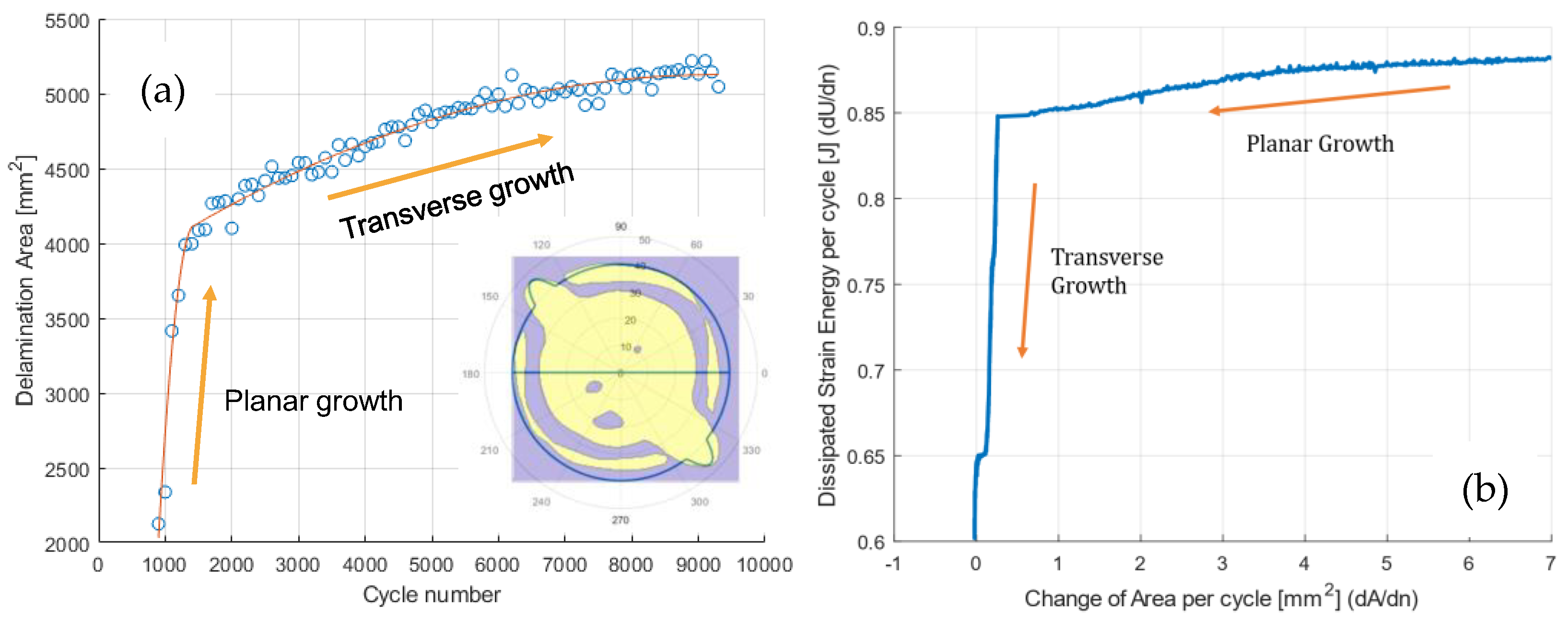

3.2. Two-Dimensional Delamination Propagation versus That in Standard Beam Specimens

3.3. Multidirectional Laminates and Multiple Delaminations in Composite Testing

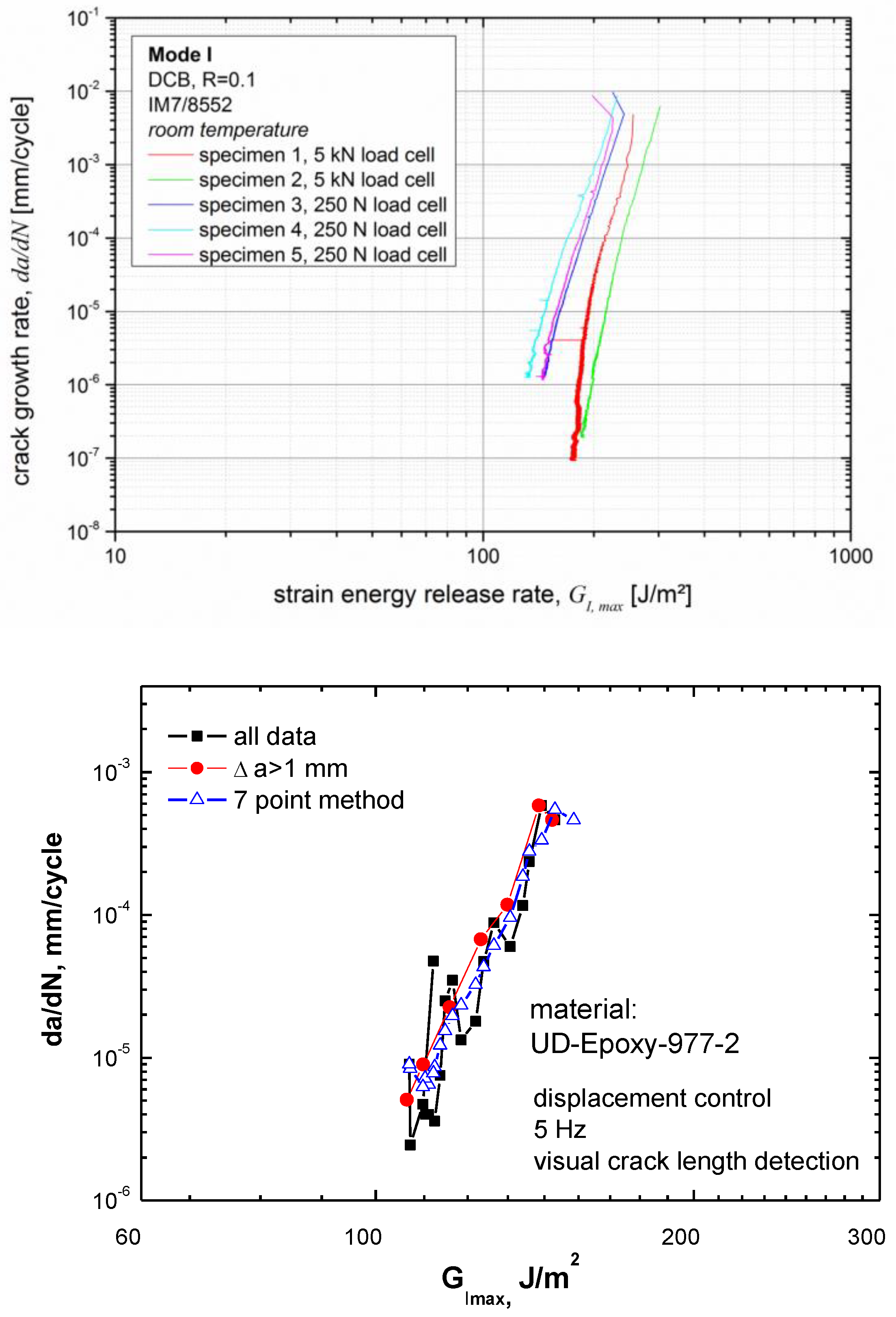

3.4. Scatter and Sources of Scatter in Testing and Modelling

3.5. Issues with Prediction of FRP Delamination Resistance Behaviour in Service Environments

3.6. FRP Delamination Initiation and Propagation versus Neat Matrix Polymer Toughness

3.7. Perspectives for CFRP Composite Structural Design Approaches: Smarter Testing and Beyond

4. Summary, Conclusions and Outlook

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Brunner, A.J.; Blackman, B.R.K.; Davies, P. A Status Report on Delamination Resistance Testing of Polymer-Matrix Composites. Eng. Fract. Mech. 2008, 75, 2779–2794. [Google Scholar] [CrossRef]

- Shrivastava, R.; Singh, K.K. Interlaminar Fracture Toughness Characterization of Laminated Composites: A Review. Polym. Rev. 2020, 60, 542–593. [Google Scholar] [CrossRef]

- Sharafi, S.; Santare, M.H.; Gerdes, J.; Advani, S.G. A Review of Factors that Influence the Fracture Toughness of Extrusion-Based Additively Manufactured Polymer and Polymer Composites. Addit. Manuf. 2021, 38, 101830. [Google Scholar] [CrossRef]

- Jones, R.; Kinloch, A.J.; Michopoulos, J.G.; Brunner, A.J.; Phan, N. Delamination Growth in Polymer-Matrix Fibre Composites and the Use of Fracture Mechanics Data for Material Characterisation and Life Prediction. Compos. Struct. 2017, 180, 316–333. [Google Scholar] [CrossRef]

- Murri, G.B.; O’Brien, T.K.; Rousseau, C.Q. Fatigue life methodology for tapered Composite flexbeam laminates. In Proceedings of the American Helicopter Society 53rd Annual Forum, Virginia Beach, VA, USA, 29 April–1 May 1997. [Google Scholar]

- Jones, R.; Stelzer, S.; Brunner, A.J. Mode I, II and Mixed Mode I/II Delamination Growth in Composites. Compos. Struct. 2014, 110, 317–324. [Google Scholar] [CrossRef]

- Pascoe, J.A. Slow-Growth Damage Tolerance for Fatigue after Impact in FRP Composites: Why Current Research Won’t Get Us There. Theor. Appl. Fract. Mech. 2021, 116, 103127. [Google Scholar] [CrossRef]

- Davies, P.; Blackman, B.R.K.; Brunner, A.J. Standard Test Methods for Delamination Resistance of Composite Materials: Current Status. Appl. Compos. Mater. 1998, 5, 345–364. [Google Scholar] [CrossRef]

- Brunner, A.J. Fracture Mechanics of Polymer Composites in Aerospace Applications. In Polymer Composites in the Aerospace Industry; Woodhead Publishing Limited: Cambridge, UK, 2019; pp. 195–252. ISBN 9780081026793. [Google Scholar]

- Mega, M.; Dolev, O.; Banks-Sills, L. Fracture Toughness Resistance Curves for a Delamination in CFRP MD Laminate Composites, Part I: Nearly Mode II Deformation. Theor. Appl. Fract. Mech. 2022, 119, 103335. [Google Scholar] [CrossRef]

- Gong, Y.; Chen, X.; Tao, J.; Zhao, L.; Zhang, J.; Hu, N. A Simple Procedure for Determining the Mode I Bridging Stress of Composite DCB Laminates without Measuring the Crack Opening Displacement. Compos. Struct. 2020, 243, 112147. [Google Scholar] [CrossRef]

- Cameselle-Molares, A.; Vassilopoulos, A.P.; Keller, T. Experimental Investigation of Two-Dimensional Delamination in GFRP Laminates. Eng. Fract. Mech. 2018, 203, 152–171. [Google Scholar] [CrossRef]

- Cameselle-Molares, A.; Vassilopoulos, A.P.; Keller, T. Two-Dimensional Fatigue Debonding in GFRP/Balsa Sandwich Panels. Int. J. Fatigue 2019, 125, 72–84. [Google Scholar] [CrossRef]

- Alderliesten, R.; den Ouden, H.J. Do standard delamination tests relate to planar delamination growth? In Proceedings of the 20th European Conference on Composite Materials, Lausanne, Switzerland, 26–30 June 2022. [Google Scholar]

- Choi, N.S.; Kinloch, A.J.; Williams, J.G. Delamination Fracture of Multidirectional Carbon-Fiber/Epoxy Composites under Mode I, Mode II and Mixed-Mode I/II Loading. J. Compos. Mater. 1999, 33, 73–100. [Google Scholar] [CrossRef]

- Peng, L.; Zhang, J.; Zhao, L.; Bao, R.; Yang, H.; Fei, B. Mode I Delamination Growth of Multidirectional Composite Laminates under Fatigue Loading. J. Compos. Mater. 2011, 45, 1077–1090. [Google Scholar] [CrossRef]

- Khudiakova, A.; Brunner, A.J.; Wolfahrt, M.; Wettemann, T.; Godec, D.; Pinter, G. On the Investigation of Quasi-Static Crack Resistance of Thermoplastic Tape Layered Composites with Multiple Delaminations: Approaches for Quantification. Compos. Part A Appl. Sci. Manuf. 2021, 149, 106484. [Google Scholar] [CrossRef]

- Khudiakova, A.; Brunner, A.J.; Wolfahrt, M.; Pinter, G. Quantification Approaches for Fatigue Crack Resistance of Thermoplastic Tape Layered Composites with Multiple Delaminations. Materials 2021, 14, 1476. [Google Scholar] [CrossRef] [PubMed]

- Gong, Y.; Zhang, B.; Hallett, S.R. Delamination Migration in Multidirectional Composite Laminates under Mode I Quasi-Static and Fatigue Loading. Compos. Struct. 2018, 189, 160–176. [Google Scholar] [CrossRef]

- Davies, P.; Sims, G.D.; Blackman, B.R.K.; Brunner, A.J.; Kageyama, K.; Hojo, M.; Tanaka, K.; Murri, G.; Rousseau, C.; Gieseke, B.; et al. Comparison of Test Configurations for Determination of Mode II Interlaminar Fracture Toughness Results from International Collaborative Test Programme. Plast. Rubber Compos. 1999, 28, 432–437. [Google Scholar] [CrossRef]

- Brunner, A.J. Fracture Mechanics Testing of Fiber-Reinforced Polymer Composites: The Effects of the “Human Factor” on Repeatability and Reproducibility of Test Data. Eng. Fract. Mech. 2022, 264, 108340. [Google Scholar] [CrossRef]

- Federal Aviation Administration. Advisory Circular AC20-107B: Composite Aircraft Structure; Federal Aviation Administration: Washington, DC, USA, 2010.

- Khan, R.; Alderliesten, R.; Badshah, S.; Khattak, M.A.; Khan, M.S.; Benedictus, R. Experimental Investigation of the Microscopic Damage Development at Mode i Fatigue Delamination Tips in Carbon/Epoxy Laminates. J. Teknol. 2016, 78, 33–40. [Google Scholar] [CrossRef][Green Version]

- Blondeau, C.; Pappas, G.; Botsis, J. Influence of Ply-Angle on Fracture in Antisymmetric Interfaces of CFRP Laminates. Compos. Struct. 2019, 216, 464–476. [Google Scholar] [CrossRef]

- Blondeau, C.; Pappas, G.A.; Botsis, J. Crack Propagation in CFRP Laminates under Mode I Monotonic and Fatigue Loads: A Methodological Study. Compos. Struct. 2021, 256, 113002. [Google Scholar] [CrossRef]

- Yao, L.; Sun, Y.; Alderliesten, R.C.; Benedictus, R.; Zhao, M. Fibre Bridging Effect on the Paris Relation for Mode I Fatigue Delamination Growth in Composites with Consideration of Interface Configuration. Compos. Struct. 2017, 159, 471–478. [Google Scholar] [CrossRef]

- Alderliesten, R. Fatigue Delamination of Composite Materials—Approach to Exclude Large Scale Fibre Bridging. IOP Conf. Ser. Mater. Sci. Eng. 2018, 388, 012002. [Google Scholar] [CrossRef]

- ISO 15024:2001; Fibre-Reinforced Plastic Composites—Determination of Mode I Interlaminar Fracture Toughness, GIC, for Unidirectionally Reinforced Material. International Organization for Standardization: Geneva, Switzerland, 2001; p. 30.

- ASTM D5528-13; Standard Test Method for Mode I Interlaminar Fracture Toughness of Unidirectional Fiber-Reinforced Polymer Matrix Composites. ASTM International: West Conshohocken, PA, USA, 2013.

- Khan, R.; Alderliesten, R.; Yao, L.; Benedictus, R. Crack Closure and Fibre Bridging during Delamination Growth in Carbon Fibre/Epoxy Laminates under Mode I Fatigue Loading. Compos. Part A Appl. Sci. Manuf. 2014, 67, 201–211. [Google Scholar] [CrossRef]

- Jones, R.; Peng, D.; Singh Raman, R.K.; Kinloch, A.J.; Michopoulos, J. Thoughts on Two Approaches for Accounting for the Scatter in Fatigue Delamination Growth Curves. Compos. Struct. 2021, 258, 113175. [Google Scholar] [CrossRef]

- Pappas, G.A.; Botsis, J. Towards a Geometry Independent Traction-Separation and Angle Relation Due to Large Scale Bridging in DCB Configuration. Compos. Sci. Technol. 2020, 197, 108172. [Google Scholar] [CrossRef]

- Sørensen, B.F.; Jacobsen, T.K. Crack Growth in Composites Applicability of R-Curves and Bridging Laws. Plast. Rubber Compos. 2000, 29, 119–133. [Google Scholar] [CrossRef]

- Sørensen, B.F.; Gamstedt, E.K.; Østergaard, R.C.; Goutianos, S. Micromechanical Model of Cross-over Fibre Bridging—Prediction of Mixed Mode Bridging Laws. Mech. Mater. 2008, 40, 220–234. [Google Scholar] [CrossRef]

- Goutianos, S.; Sørensen, B.F. The Application of J Integral to Measure Cohesive Laws under Large-Scale Yielding. Eng. Fract. Mech. 2016, 155, 145–165. [Google Scholar] [CrossRef]

- Yao, L.; Sun, Y.; Zhao, M.; Alderliesten, R.C.; Benedictus, R. Stress Ratio Dependence of Fibre Bridging Significance in Mode I Fatigue Delamination Growth of Composite Laminates. Compos. Part A Appl. Sci. Manuf. 2017, 95, 65–74. [Google Scholar] [CrossRef]

- Donough, M.J.; Gunnion, A.J.; Orifici, A.C.; Wang, C.H. Scaling Parameter for Fatigue Delamination Growth in Composites under Varying Load Ratios. Compos. Sci. Technol. 2015, 120, 39–48. [Google Scholar] [CrossRef]

- Yao, L.; Alderliesten, R.C.; Jones, R.; Kinloch, A.J. Delamination Fatigue Growth in Polymer-Matrix Fibre Composites: A Methodology for Determining the Design and Lifing Allowables. Compos. Struct. 2018, 196, 8–20. [Google Scholar] [CrossRef]

- Hojo, M.; Aoki, T. Characterization of fatigue R-curves based on GMAX-constant delamination tests in CF/PEEK laminates. In Proceedings of the 20th International Conference on Composite Materials, Copenhagen, Denmark, 19–24 July 2015; paper No. 2116. pp. 1–8. [Google Scholar]

- Jensen, S.M.; Martos, M.J.; Lindgaard, E.; Bak, B.L.V. Inverse Parameter Identification of N-Segmented Multilinear Cohesive Laws Using Parametric Finite Element Modeling. Compos. Struct. 2019, 225, 111074. [Google Scholar] [CrossRef]

- Jensen, S.M.; Bak, B.L.V.; Bender, J.J.; Carreras, L.; Lindgaard, E. Transient Delamination Growth in GFRP Laminates with Fibre Bridging under Variable Amplitude Loading in G-Control. Compos. Part B Eng. 2021, 225, 109296. [Google Scholar] [CrossRef]

- Jensen, S.M.; Bak, B.L.V.; Bender, J.J.; Lindgaard, E. Transition-Behaviours in Fatigue-Driven Delamination of GFRP Laminates Following Step Changes in Block Amplitude Loading. Int. J. Fatigue 2021, 144, 106045. [Google Scholar] [CrossRef]

- Nilsson, K.F.; Asp, L.E.; Alpman, J.E.; Nystedt, L. Delamination Buckling and Growth for Delaminations at Different Depths in a Slender Composite Panel. Int. J. Solids Struct. 2001, 38, 3039–3071. [Google Scholar] [CrossRef]

- Amaral, L.; Yao, L.; Alderliesten, R.; Benedictus, R. The Relation between the Strain Energy Release in Fatigue and Quasi-Static Crack Growth. Eng. Fract. Mech. 2015, 145, 86–97. [Google Scholar] [CrossRef]

- Köllner, A.; Forsbach, F.; Völlmecke, C. Delamination Buckling in Composite Plates: An Analytical Approach to Predict Delamination Growth BT. In New Achievements in Continuum Mechanics and Thermodynamics: A Tribute to Wolfgang H. Müller; In Abali, B.E., Altenbach, H., dell’Isola, F., Eremeyev, V.A., Öchsner, A., Eds.; Springer International Publishing: Cham, Switzerland, 2019; pp. 241–255. ISBN 978-3-030-13307-8. [Google Scholar]

- Van der Panne, M. Effect of Different Fibre Orientations at the Interface on Fatigue Delamination Growth. Master’s Thesis, Delft University of Technology, Delft, The Netherlands, 2022. Available online: https://resolver.tudelft.nl/uuid:0ff76d38-2a0e-440c-a5b6-74c887e32a64 (accessed on 22 December 2022).

- Van der Panne, M.; Pascoe, J.-A. Fatigue Delamination Growth—Is UD Testing Enough? In Proceedings of the 23rd European Conference on Facture—ECF 23, Funchal, Portugal, 27 June–1 July 2022. [Google Scholar]

- Den Ouden, H.J. Investigating Planar Delamination Behavior in Carbon Fiber Reinforced Polymer Panels. Master’s Thesis, Delft University of Technology, Delft, The Netherlands, 2020. Available online: https://resolver.tudelft.nl/uuid:e47a4a61-c2ff-45bc-994b-ed6bdd2d47ac (accessed on 22 December 2022).

- Pichler, N.; Herráez, M.; Botsis, J. Mixed-Mode Fracture Response of Anti-Symmetric Laminates: Experiments and Modelling. Compos. Part B Eng. 2020, 197, 108089. [Google Scholar] [CrossRef]

- Mollenhauer, D.H.; Baril-Gosselin, S.; Iarve, E.; Li, C.; Rapking, D.; Zhou, E.; Braginsky, M. Mode I Fracture Specimens Exhibiting Oscillatory Crack Migration. In Proceedings of the ECCM18—18th European Conference on Composite Materials, Athens, Greece, 24–28 June 2018. [Google Scholar]

- Singh, S.; Greenhalgh, E. Micromechanisms of interlaminar fracture in carbon-epoxy composites at multidirectional ply interfaces. In Proceedings of the 4th International Conference on the Deformation and Fracture of Composites (DFC-4), Manchester, UK, 24–27 March 1997. [Google Scholar]

- Peng, L.; Xu, J.; Zhang, J.; Zhao, L. Mixed Mode Delamination Growth of Multidirectional Composite Laminates under Fatigue Loading. Eng. Fract. Mech. 2012, 96, 676–686. [Google Scholar] [CrossRef]

- Chocron, T.; Banks-Sills, L. Nearly Mode I Fracture Toughness and Fatigue Delamination Propagation in a Multidirectional Laminate Fabricated by a Wet-Layup. Phys. Mesomech. 2019, 22, 107–140. [Google Scholar] [CrossRef]

- Banks-Sills, L.; Simon, I.; Chocron, T. Multi-Directional Composite Laminates: Fatigue Delamination Propagation in Mode I—A Comparison. Int. J. Fract. 2019, 219, 175–185. [Google Scholar] [CrossRef]

- Zhao, L.; Gong, Y.; Zhang, J.; Wang, Y.; Lu, Z.; Peng, L.; Hu, N. A Novel Interpretation of Fatigue Delamination Growth Behavior in CFRP Multidirectional Laminates. Compos. Sci. Technol. 2016, 133, 79–88. [Google Scholar] [CrossRef]

- Gong, Y.; Zhao, L.; Zhang, J.; Hu, N. Crack Closure in the Fatigue Delamination of Composite Multidirectional DCB Laminates with Large-Scale Fiber Bridging. Compos. Struct. 2020, 244, 112220. [Google Scholar] [CrossRef]

- Rask, M.; Sørensen, B.F. Determination of the J Integral for Laminated Double Cantilever Beam Specimens: The Curvature Approach. Eng. Fract. Mech. 2012, 96, 37–48. [Google Scholar] [CrossRef]

- Brunner, A.J.; Blackman, B.R.K.; Williams, J.G. Calculating a Damage Parameter and Bridging Stress from GIC Delamination Tests on Fibre Composites. Compos. Sci. Technol. 2006, 66, 785–795. [Google Scholar] [CrossRef]

- Goutianos, S.; Sørensen, B.F. Fracture Resistance Enhancement of Layered Structures by Multiple Cracks. Eng. Fract. Mech. 2016, 151, 92–108. [Google Scholar] [CrossRef]

- Yang, Y. A Numerical Study of Damage Mechanisms in the CAI of Laminated Composites for Aerospace Applications. Ph.D. Thesis, University of Nottingham, Nottingham, UK, 2016. [Google Scholar]

- Trabal, G.G.; Bak, B.L.V.; Chen, B.; Jensen, S.M.; Lindgaard, E. Delamination Toughening of Composite Laminates Using Weakening or Toughening Interlaminar Patches to Initiate Multiple Delaminations: A Numerical Study. Eng. Fract. Mech. 2022, 273, 108730. [Google Scholar] [CrossRef]

- Herráez, M.; Pichler, N.; Botsis, J. Improving Delamination Resistance through Tailored Defects. Compos. Struct. 2020, 247, 112422. [Google Scholar] [CrossRef]

- Sun, X.C.; Hallett, S.R. Failure Mechanisms and Damage Evolution of Laminated Composites under Compression after Impact (CAI): Experimental and Numerical Study. Compos. Part A Appl. Sci. Manuf. 2018, 104, 41–59. [Google Scholar] [CrossRef]

- Yang, Y.; Li, S. CAI Damage Mechanism Characterisation. In Proceedings of the 20th International Conference on Composite Materials, Copenhagen, Denmark, 19–24 July 2015; pp. 19–24. [Google Scholar]

- Davies, P.; Moulin, C.; Kausch, H.H.; Fischer, M. Measurement of GIc and GIIc in Carbon/Epoxy Composites. Compos. Sci. Technol. 1990, 39, 193–205. [Google Scholar] [CrossRef]

- Davies, P.; Kausch, H.H.; Williams, J.G.; Kinloch, A.J.; Charalambides, M.N.; Pavan, A.; Moore, D.R.; Prediger, R.; Robinson, I.; Burgoyne, N.; et al. Round-Robin Interlaminar Fracture Testing of Carbon-Fibre-Reinforced Epoxy and PEEK Composites. Compos. Sci. Technol. 1992, 43, 129–136. [Google Scholar] [CrossRef]

- O’Brien, K.R.; Martin, R.H. Round Robin Testing for Mode I Interlaminar Fracture Toughness of Composite Materials. J. Compos. Technol. Res. 1993, 15, 269–281. [Google Scholar] [CrossRef]

- Stelzer, S.; Brunner, A.J.; Argüelles, A.; Murphy, N.; Pinter, G. Mode I Delamination Fatigue Crack Growth in Unidirectional Fiber Reinforced Composites: Development of a Standardized Test Procedure. Compos. Sci. Technol. 2012, 72, 1102–1107. [Google Scholar] [CrossRef]

- Stelzer, S.; Brunner, A.J.; Argüelles, A.; Murphy, N.; Cano, G.M.; Pinter, G. Mode I Delamination Fatigue Crack Growth in Unidirectional Fiber Reinforced Composites: Results from ESIS TC4 Round-Robins. Eng. Fract. Mech. 2014, 116, 92–107. [Google Scholar] [CrossRef]

- Davies, P. Round Robin Analysis of GIc Interlaminar Fracture Test. Appl. Compos. Mater. 1996, 3, 135–140. [Google Scholar] [CrossRef]

- Brunner, A.J.; Murphy, N.; Pinter, G. Development of a Standardized Procedure for the Characterization of Interlaminar Delamination Propagation in Advanced Composites under Fatigue Mode I Loading Conditions. Eng. Fract. Mech. 2009, 76, 2678–2689. [Google Scholar] [CrossRef]

- ASTM E647-13; Standard Test Method for Measurement of Fatigue Crack Growth Rates. ASTM International: West Conshohocken, PA, USA, 2015.

- Mejlej, V.G.; Osorio, D.; Vietor, T. An Improved Fatigue Failure Model for Multidirectional Fiber-Reinforced Composite Laminates under Any Stress Ratios of Cyclic Loading. Procedia CIRP 2017, 66, 27–32. [Google Scholar] [CrossRef]

- Samareh-Mousavi, S.S.; Mandegarian, S.; Taheri-Behrooz, F. A Nonlinear FE Analysis to Model Progressive Fatigue Damage of Cross-Ply Laminates under Pin-Loaded Conditions. Int. J. Fatigue 2019, 119, 290–301. [Google Scholar] [CrossRef]

- Brod, M.; Dean, A.; Rolfes, R. Numerical Life Prediction of Unidirectional Fiber Composites under Block Loading Conditions Using a Progressive Fatigue Damage Model. Int. J. Fatigue 2021, 147, 106159. [Google Scholar] [CrossRef]

- Hohe, J.; Gall, M.; Fliegener, S.; Hamid, Z.M.A. A Continuum Damage Mechanics Model for Fatigue and Degradation of Fiber Reinforced Materials. J. Compos. Mater. 2020, 54, 2837–2852. [Google Scholar] [CrossRef]

- Engelstad, S.P.; Clay, S.B. Comparison of Composite Damage Growth Tools for Fatigue Behavior of Notched Composite Laminates. J. Compos. Mater. 2017, 51, 2227–2249. [Google Scholar] [CrossRef]

- ISO 9080:2012; Plastics Piping and Ducting Systems—Determination of the Long-Term Hydrostatic Strength of Thermoplastics Materials in Pipe Form by Extrapolation. International Organization for Standardization: Geneva, Switzerland, 2012.

- Pinter, G.; Lang, R.W.; Haager, M. A Test Concept for Lifetime Prediction of Polyethylene Pressure Pipes. Mon. Chem. 2007, 138, 347–355. [Google Scholar] [CrossRef]

- Lang, R.W.; Stern, A.; Doerner, G. Prediction Models for Thermoplastics Pipes under Internal Pressure. Angew. Makromol. Chem. 1997, 247, 131–145. [Google Scholar] [CrossRef]

- Frank, A.; Arbeiter, F.J.; Berger, I.J.; Hutař, P.; Náhlík, L.; Pinter, G. Fracture Mechanics Lifetime Prediction of Polyethylene Pipes. J. Pipeline Syst. Eng. Pract. 2019, 10, 04018030. [Google Scholar] [CrossRef]

- Miyano, Y.; Nakada, M. Accelerated Testing Methodology for Durability of CFRP. Compos. Part B Eng. 2020, 191, 107977. [Google Scholar] [CrossRef]

- Hadid, M.; Guerira, B.; Bahri, M.; Zouani, K. The Creep Master Curve Construction for the Polyamide 6 by the Stepped Isostress Method. Mater. Res. Innov. 2014, 18, S6-336–S6-339. [Google Scholar] [CrossRef]

- Tanks, J.; Rader, K.; Sharp, S.; Sakai, T. Accelerated Creep and Creep-Rupture Testing of Transverse Unidirectional Carbon/Epoxy Lamina Based on the Stepped Isostress Method. Compos. Struct. 2017, 159, 455–462. [Google Scholar] [CrossRef]

- Panella, F.W.; Pirinu, A. Fatigue and Damage Analysis on Aeronautical CFRP Elements under Tension and Bending Loads: Two Cases of Study. Int. J. Fatigue 2021, 152, 106403. [Google Scholar] [CrossRef]

- Chisholm, S.A.; Castro, J.F.; Chapman, B.D.; Karayev, K.Z.; Gunther, A.J.; Kabir, M.H. Smarter Testing through simulation for efficient design and attainment of regulatory compliance. In ICAF 2019—Structural Integrity in the Age of Additive Manufacturing, Proceedings of the 30th Symposium of the International Committee on Aeronautical Fatigue, Krakow, Poland, 2–7 June 2019; Springer International Publishing: Cham, Switzerland, 2020; pp. 292–307. [Google Scholar]

- Pochiraju, K.V.; Tandon, G.P.; Schoeppner, G.A. Long-Term Durability of Polymeric Matrix Composites, 1st ed.; Springer: New York, NY, USA, 2012. [Google Scholar]

- Davies, P. Environmental Degradation of Composites for Marine Structures: New Materials and New Applications. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2016, 374, 20150272. [Google Scholar] [CrossRef]

- Starkova, O.; Gagani, A.I.; Karl, C.W.; Rocha, I.B.C.M.; Burlakovs, J.; Krauklis, A.E. Modelling of Environmental Ageing of Polymers and Polymer Composites—Durability Prediction Methods. Polymers 2022, 14, 907. [Google Scholar] [CrossRef]

- Riahinezhad, M.; Hallman, M.; Masson, J.F. Critical Review of Polymeric Building Envelope Materials: Degradation, Durability and Service Life Prediction. Buildings 2021, 11, 299. [Google Scholar] [CrossRef]

- Voicu, R. CFRP Composite Behaviour under Extreme Environment Exposure. Mater. Plast. 2016, 53, 465–469. [Google Scholar]

- Edwards, D.L.; Tighe, A.P.; Van Eesbeek, M.; Kimoto, Y.; De Groh, K.K. Overview of the Natural Space Environment and ESA, JAXA, and NASA Materials Flight Experiments. MRS Bull. 2010, 35, 25–34. [Google Scholar] [CrossRef]

- Feraboli, P.; Miller, M. Damage Resistance and Tolerance of Carbon/Epoxy Composite Coupons Subjected to Simulated Lightning Strike. Compos. Part A Appl. Sci. Manuf. 2009, 40, 954–967. [Google Scholar] [CrossRef]

- Wang, Y. Multiphysics Analysis of Lightning Strike Damage in Laminated Carbon/Glass Fiber Reinforced Polymer Matrix Composite Materials: A Review of Problem Formulation and Computational Modeling. Compos. Part A Appl. Sci. Manuf. 2017, 101, 543–553. [Google Scholar] [CrossRef]

- Hohe, J.; Neubrand, A.; Fliegener, S.; Beckmann, C.; Schober, M.; Weiss, K.P.; Appel, S. Performance of Fiber Reinforced Materials under Cryogenic Conditions—A Review. Compos. Part A Appl. Sci. Manuf. 2021, 141, 106226. [Google Scholar] [CrossRef]

- Johnson, W.S.; Pavlick, M.M.; Oliver, M.S. Determination of Interlaminar Toughness of IM7/977-2 Composites at Temperature Extremes and Different Thicknesses; Georgia Institute of Technology: Atlanta, GA, USA, 2005. [Google Scholar]

- Surendra Kumar, M.; Sharma, N.; Ray, B.C. Microstructural and Mechanical Aspects of Carbon/Epoxy Composites at Liquid Nitrogen Temperature. J. Reinf. Plast. Compos. 2009, 28, 2013–2023. [Google Scholar] [CrossRef]

- Davidson, B.D.; Kumar, M.; Soffa, M.A. Influence of Mode Ratio and Hygrothermal Condition on the Delamination Toughness of a Thermoplastic Particulate Interlayered Carbon/Epoxy Composite. Compos. Part A Appl. Sci. Manuf. 2009, 40, 67–79. [Google Scholar] [CrossRef]

- Murray, B.R.; Doyle, A.; Feerick, P.J.; Semprimoschnig, C.O.A.; Leen, S.B.; Ó Brádaigh, C.M. Rotational Moulding of Peek Polymer Liners with Carbon Fibre/Peek over Tape-Placement for Space Cryogenic Fuel Tanks. Mater. Des. 2017, 132, 567–581. [Google Scholar] [CrossRef]

- Hooper, S.J.; Subramanian, R. Effects of water and jet fuel absorption on mode i and mode ii delamination of graphite/epoxy. In Composite Materials: Fatigue and Fracture; ASTM STP 1156; American Society for Testing and Materials: Philadelphia, PA, USA, 1993; Volume 4, pp. 318–340. [Google Scholar]

- Landry, B.; LaPlante, G.; LeBlanc, L.R. Environmental Effects on Mode II Fatigue Delamination Growth in an Aerospace Grade Carbon/Epoxy Composite. Compos. Part A Appl. Sci. Manuf. 2012, 43, 475–485. [Google Scholar] [CrossRef]

- Moutsompegka, E.; Tserpes, K.I.; Polydoropoulou, P.; Tornow, C.; Schlag, M.; Brune, K.; Mayer, B.; Pantelakis, S. Experimental Study of the Effect of Pre-Bond Contamination with de-Icing Fluid and Ageing on the Fracture Toughness of Composite Bonded Joints. Fatigue Fract. Eng. Mater. Struct. 2017, 40, 1581–1591. [Google Scholar] [CrossRef]

- Yavas, D.; Shang, X.; Bastawros, A.F. Mode-I Fracture Toughness and Surface Morphology Evolution for Contaminated Adhesively Bonded Composite Structures. Compos. Struct. 2018, 203, 513–522. [Google Scholar] [CrossRef]

- Leblanc, L.R.; LaPlante, G. Experimental Investigation and Finite Element Modeling of Mixed-Mode Delamination in a Moisture-Exposed Carbon/Epoxy Composite. Compos. Part A Appl. Sci. Manuf. 2016, 81, 202–213. [Google Scholar] [CrossRef]

- Kumar, A.; Sharma, K.; Dixit, A.R. Carbon Nanotube- and Graphene-Reinforced Multiphase Polymeric Composites: Review on Their Properties and Applications. J. Mater. Sci. 2020, 55, 2682–2724. [Google Scholar] [CrossRef]

- Arvind, J.; Reby Roy, K.E.; Kasthoori, M.S.; Kasthoori Nath, A.J. Enhancement of Fracture Toughness and Reduced Brittle Characteristics of Modified CFRP Composites by Incorporating Synergism Effect between PC/ABS Blend with DGEBA Resin Systems. Polym. Technol. Mater. 2022, 61, 1845–1856. [Google Scholar] [CrossRef]

- Yadav, A.; Nayak, B.A.; Fulmali, A.O.; Prusty, R.K. Synergetic Impact of Both Fiber Surface Grafting and Matrix Modification by Carbon Nanotubes and Functionalized Carbon Nanotubes on the Flexural Behavior of Carbon Fiber Reinforced Polymer Composites: An Assessment at Cryo-, Room-, and Elevated- in Situ T. J. Appl. Polym. Sci. 2022, 139, e53104. [Google Scholar] [CrossRef]

- Zhou, J.; Zhang, C.; Cheng, C.; Wang, M.; Yang, Z.; Yang, Y.; Yang, H.; Yu, M. Synergetic Improvement of Interlaminar Fracture Toughness in Carbon Fiber/Epoxy Composites Interleaved with PES/PEK-C Hybrid Nanofiber Veils. Adv. Fiber Mater. 2022, 4, 1081–1093. [Google Scholar] [CrossRef]

- Farooq, U.; Teuwen, J.; Dransfeld, C. Toughening of Epoxy Systems with Interpenetrating Polymer Network (IPN): A Review. Polymers 2020, 12, 1908. [Google Scholar] [CrossRef]

- Ramírez, F.M.G.; de Moura, M.F.S.F.; Moreira, R.D.F.; Silva, F.G.A. A Review on the Environmental Degradation Effects on Fatigue Behaviour of Adhesively Bonded Joints. Fatigue Fract. Eng. Mater. Struct. 2020, 43, 1307–1326. [Google Scholar] [CrossRef]

- Tserpes, K.; Barroso-Caro, A.; Carraro, P.A.; Beber, V.C.; Floros, I.; Gamon, W.; Kozłowski, M.; Santandrea, F.; Shahverdi, M.; Skejić, D.; et al. A Review on Failure Theories and Simulation Models for Adhesive Joints. J. Adhes. 2021, 98, 1855–1915. [Google Scholar] [CrossRef]

- Burda, I.; Barbezat, M.; Brunner, A.J. The Effect of Nano- and Micron-Scale Filler Modified Epoxy Matrix on Glass-Fiber Reinforced Polymer Insulator Component Behavior. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2021, 235, 1287–1301. [Google Scholar] [CrossRef]

- Hache, F.; Renaud, A.; Caous, D.; Wahl, J.C.; Mallarino, S. Experimental Study of Interactions between Water Aging and Cyclic Behavior of Composites. AIAA J. 2021, 59, 1880–1883. [Google Scholar] [CrossRef]

- Rocha, I.B.C.M.; Raijmaekers, S.; Nijssen, R.P.L.; van der Meer, F.P.; Sluys, L.J. Hygrothermal Ageing Behaviour of a Glass/Epoxy Composite Used in Wind Turbine Blades. Compos. Struct. 2017, 174, 110–122. [Google Scholar] [CrossRef]

- Attukur Nandagopal, R.; Chai, G.B.; Narasimalu, S. Influence of Stress Ratio and Stress Concentration on the Fatigue Behaviour of Hygrothermal Aged Multidirectional CFRP Composite Laminate. Int. J. Fatigue 2020, 137, 105651. [Google Scholar] [CrossRef]

- Malpot, A.; Touchard, F.; Bergamo, S. An Investigation of the Influence of Moisture on Fatigue Damage Mechanisms in a Woven Glass-Fibre-Reinforced PA66 Composite Using Acoustic Emission and Infrared Thermography. Compos. Part B Eng. 2017, 130, 11–20. [Google Scholar] [CrossRef]

- Brunner, A.J. Correlation between acoustic emission signals and delaminations in carbon fiber reinforced polymer matrix composites: A new look at mode i fracture test data. In Proceedings of the 32nd European Conference on Acoustic Emission Testing, Prague, Czech Republic, 7–9 September 2016; pp. 297–304. [Google Scholar]

- O’Brien, T.K. Composite Interlaminar Shear Fracture Toughness, GIIc: Shear Measurement or Sheer Myth? In Composite Materials: Fatigue and Fracture; ASTM STP 1330; Bucinell, R.B., Ed.; American Society for Testing and Materials: Philadelphia, PA, USA, 1998; Volume 7, pp. 3–18. [Google Scholar]

- Battisti, A.; Esqué-de los Ojos, D.; Ghisleni, R.; Brunner, A.J. Single Fiber Push-out Characterization of Interfacial Properties of Hierarchical CNT-Carbon Fiber Composites Prepared by Electrophoretic Deposition. Compos. Sci. Technol. 2014, 95, 121–127. [Google Scholar] [CrossRef]

- Hsieh, T.H.; Kinloch, A.J.; Masania, K.; Sohn Lee, J.; Taylor, A.C.; Sprenger, S. The Toughness of Epoxy Polymers and Fibre Composites Modified with Rubber Microparticles and Silica Nanoparticles. J. Mater. Sci. 2010, 45, 1193–1210. [Google Scholar] [CrossRef]

- Fischer, F.; Beier, U.; Wolff-Fabris, F.; Altstädt, V. Toughened High Performance Epoxy Resin System for Aerospace Applications. Sci. Eng. Compos. Mater. 2011, 18, 209–215. [Google Scholar] [CrossRef]

- Hexcel. HexFlow RTM6-2 Product Data Sheet (Global Version); Hexcel: Stamford, CT, USA, 2018. [Google Scholar]

- Shiino, M.Y.; Alderliesten, R.C.; Pitanga, M.Y.; Cioffi, M.O.H. Fatigue Crack Growth Rate in Mode I of a Carbon Fiber 5HS Weave Composite Laminate Processed via RTM. Adv. Mater. Res. 2014, 891–892, 172–177. [Google Scholar] [CrossRef]

- Wu, Z.; Yi, X.S.; Wilkinson, A. Interlaminar Fracture Toughness of Carbon Fibre/RTM6-2 Composites Toughened with Thermoplastic-Coated Fabric Reinforcement. Compos. Part B Eng. 2017, 130, 192–199. [Google Scholar] [CrossRef]

- Brunner, A.J. Can Simple Estimates from Neat Polymers Provide Safe Fatigue Fracture Design Limits for Fiber-Reinforced Polymer Matrix Composites? Procedia Struct. Integr. 2022, 42C, 1660–1667. [Google Scholar]

- Carolan, D.; Ivankovic, A.; Kinloch, A.J.; Sprenger, S.; Taylor, A.C. Toughened Carbon Fibre-Reinforced Polymer Composites with Nanoparticle-Modified Epoxy Matrices. J. Mater. Sci. 2017, 52, 1767–1788. [Google Scholar] [CrossRef]

- Jones, S.A.; Tomlinson, R.A. Investigating Mixed-Mode (I/II) Fracture in Epoxies Using Digital Image Correlation: Composite GIIc Performance from Resin Measurements. Eng. Fract. Mech. 2015, 149, 368–374. [Google Scholar] [CrossRef]

- Wickramasinghe, S.; Do, T.; Tran, P. FDM-Based 3D Printing of Polymer and Associated Composite: A Review on Mechanical Properties, Defects and Treatments. Polymers 2020, 12, 1529. [Google Scholar] [CrossRef] [PubMed]

- Plocher, J.; Mencattelli, L.; Narducci, F.; Pinho, S. Learning from Nature: Bio-Inspiration for Damage-Tolerant High-Performance Fibre-Reinforced Composites. Compos. Sci. Technol. 2021, 208, 108669. [Google Scholar] [CrossRef]

- Radzuan, N.A.M.; Sulong, A.B.; Verma, A.; Muhamad, N. Layup Sequence and Interfacial Bonding of Additively Manufactured Polymeric Composite: A Brief Review. Nanotechnol. Rev. 2021, 10, 1853–1872. [Google Scholar] [CrossRef]

- Shanmugam, V.; Rajendran, D.J.J.; Babu, K.; Rajendran, S.; Veerasimman, A.; Marimuthu, U.; Singh, S.; Das, O.; Neisiany, R.E.; Hedenqvist, M.S.; et al. The Mechanical Testing and Performance Analysis of Polymer-Fibre Composites Prepared through the Additive Manufacturing. Polym. Test. 2021, 93, 106925. [Google Scholar] [CrossRef]

- Patterson, A.E.; Chadha, C.; Jasiuk, I.M.; Allison, J.T. Fracture Testing of Polymer Materials Processed via Fused Filament Fabrication: A Survey of Materials, Methods, and Design Applications. Prog. Addit. Manuf. 2021, 6, 765–780. [Google Scholar] [CrossRef]

- Kaddour, A.S.; Hinton, M.J. Maturity of 3D Failure Criteria for Fibre-Reinforced Composites: Comparison between Theories and Experiments: Part B of WWFE-II. J. Compos. Mater. 2013, 47, 925–966. [Google Scholar] [CrossRef]

- Breite, C.; Melnikov, A.; Turon, A.; de Morais, A.B.; Le Bourlot, C.; Maire, E.; Schöberl, E.; Otero, F.; Mesquita, F.; Sinclair, I.; et al. Detailed Experimental Validation and Benchmarking of Six Models for Longitudinal Tensile Failure of Unidirectional Composites. Compos. Struct. 2022, 279, 114828. [Google Scholar] [CrossRef]

- Breite, C.; Melnikov, A.; Turon, A.; Morais, A.B.D.; Otero, F.; Mesquita, F.; Costa, J.; Mayugo, A.; Guerrero, J.M.; Gorbatikh, L.; et al. Blind Benchmarking of Seven Longitudinal Tensile Failure Models for Two Virtual Unidirectional Composites. Compos. Sci. Technol. 2020, 202, 108555. [Google Scholar] [CrossRef]

- Alderliesten, R.C. How Proper Similitude Can Improve Our Understanding of Crack Closure and Plasticity in Fatigue. Int. J. Fatigue 2016, 82, 263–273. [Google Scholar] [CrossRef]

- Patro, S.; Mahapatra, T.R.; Dash, S.; Kishore Murty, V. Artificial intelligence techniques for fault assessment in laminated composite structure: A review. In Proceedings of the 3rd International Conference on Design and Manufacturing Aspects for Sustainable Energy (ICMED-ICMPC 2021), Hyderabad, India, 24–26 September 2021; Volume 309, p. 01083. [Google Scholar]

- Allegri, G. Modelling Fatigue Delamination Growth in Fibre-Reinforced Composites: Power-Law Equations or Artificial Neural Networks? Mater. Des. 2018, 155, 59–70. [Google Scholar] [CrossRef]

- Menges, A.; Kannenberg, F.; Zechmeister, C. Computational Co-Design of Fibrous Architecture. Archit. Intell. 2022, 1, 6. [Google Scholar] [CrossRef]

- Qiu, C.; Han, Y.; Shanmugam, L.; Zhao, Y.; Dong, S.; Du, S.; Yang, J. A Deep Learning-Based Composite Design Strategy for Efficient Selection of Material and Layup Sequences from a given Database. Compos. Sci. Technol. 2022, 230, 109154. [Google Scholar] [CrossRef]

- Bessa, M.A.; Pellegrino, S. Design of Ultra-Thin Shell Structures in the Stochastic Post-Buckling Range Using Bayesian Machine Learning and Optimization. Int. J. Solids Struct. 2018, 139–140, 174–188. [Google Scholar] [CrossRef]

- Kim, C.; Lee, J.; Yoo, J. Machine Learning-Combined Topology Optimization for Functionary Graded Composite Structure Design. Comput. Methods Appl. Mech. Eng. 2021, 387, 114158. [Google Scholar] [CrossRef]

| Load Condition | Average Error (%) |

|---|---|

| Open-hole tension | |

| [0/45/90/-45]2S (200 kcycles) | 16 |

| [60/0/-60]3S (300 kcycles) | 74 |

| [30/60/90/-60/-30]2S (300 kcycles) | 26 |

| Open-hole compression | |

| [0/45/90/-45]2S (200 kcylces) | 15 |

| [60/0/-60]3S (300 kcycles) | 69 |

| [30/60/90/-60/-30]2S (300 kcycles) | 39 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brunner, A.J.; Alderliesten, R.; Pascoe, J.-A. In-Service Delaminations in FRP Structures under Operational Loading Conditions: Are Current Fracture Testing and Analysis on Coupons Sufficient for Capturing the Essential Effects for Reliable Predictions? Materials 2023, 16, 248. https://doi.org/10.3390/ma16010248

Brunner AJ, Alderliesten R, Pascoe J-A. In-Service Delaminations in FRP Structures under Operational Loading Conditions: Are Current Fracture Testing and Analysis on Coupons Sufficient for Capturing the Essential Effects for Reliable Predictions? Materials. 2023; 16(1):248. https://doi.org/10.3390/ma16010248

Chicago/Turabian StyleBrunner, Andreas J., René Alderliesten, and John-Alan Pascoe. 2023. "In-Service Delaminations in FRP Structures under Operational Loading Conditions: Are Current Fracture Testing and Analysis on Coupons Sufficient for Capturing the Essential Effects for Reliable Predictions?" Materials 16, no. 1: 248. https://doi.org/10.3390/ma16010248

APA StyleBrunner, A. J., Alderliesten, R., & Pascoe, J.-A. (2023). In-Service Delaminations in FRP Structures under Operational Loading Conditions: Are Current Fracture Testing and Analysis on Coupons Sufficient for Capturing the Essential Effects for Reliable Predictions? Materials, 16(1), 248. https://doi.org/10.3390/ma16010248