Investigation of the Flexural Behavior of Preloaded and Pre-Cracked Reinforced Concrete Beams Strengthened with CFRP Plates

Abstract

1. Introduction

2. Materials and Methods

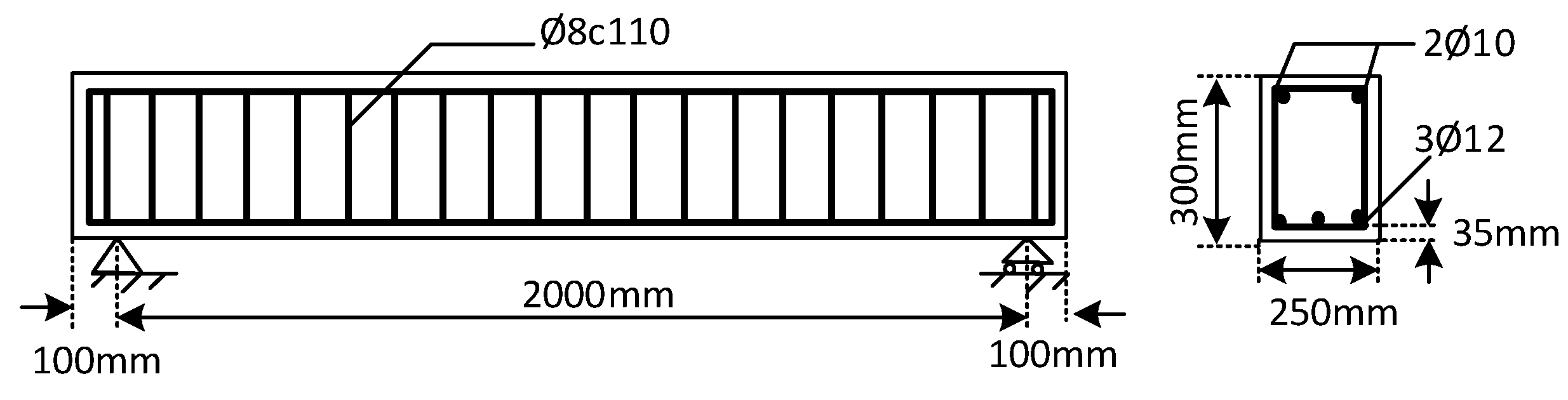

2.1. Preparation of Reinforced Concrete Beams

2.2. Properties of Materials

2.2.1. Concrete and Steel Reinforcement

2.2.2. CFRP Plates (CarboDur S512) and Epoxy Adhesive

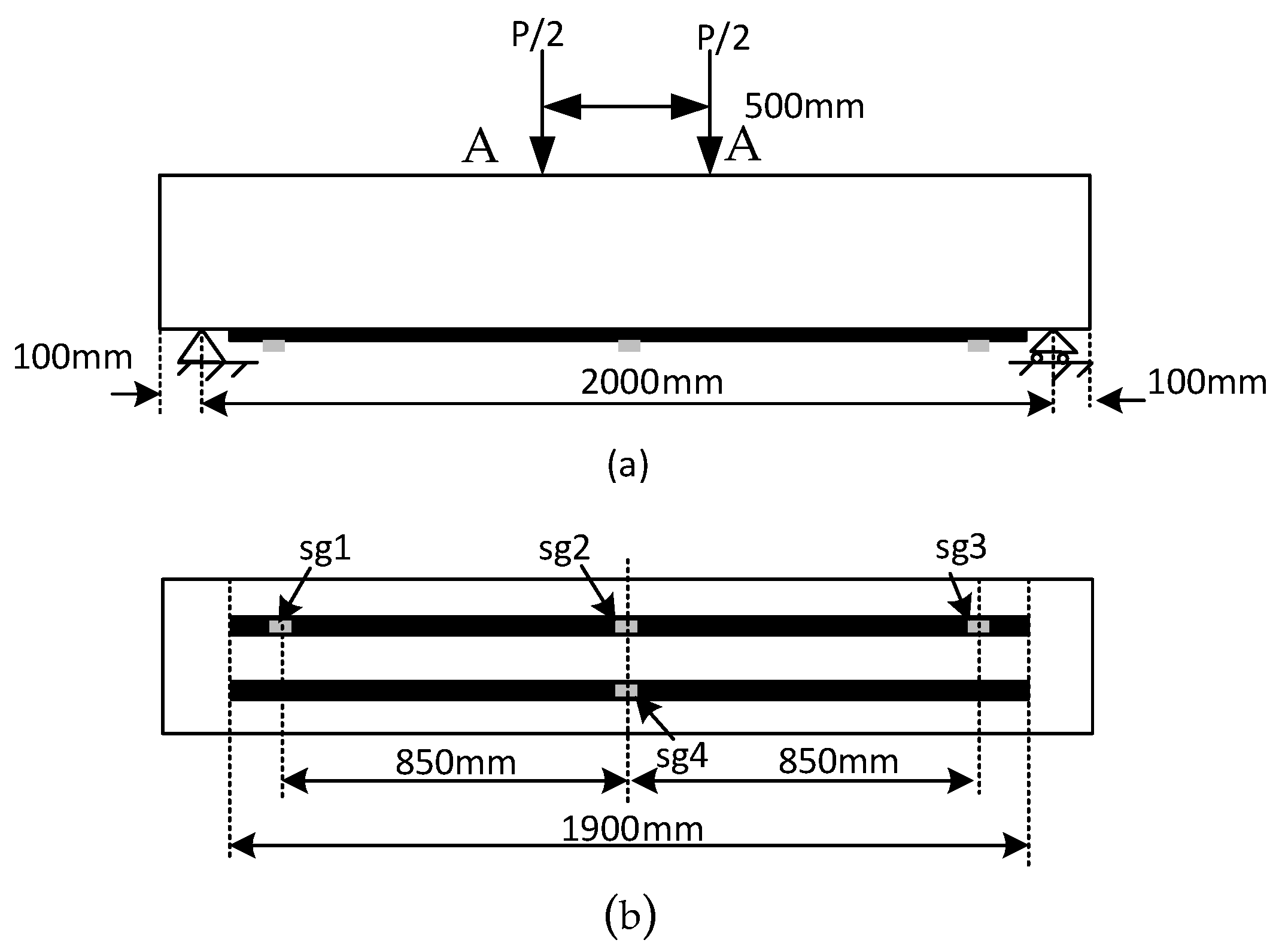

2.3. Test Set Up and Instrumentation

2.4. Testing Procedure

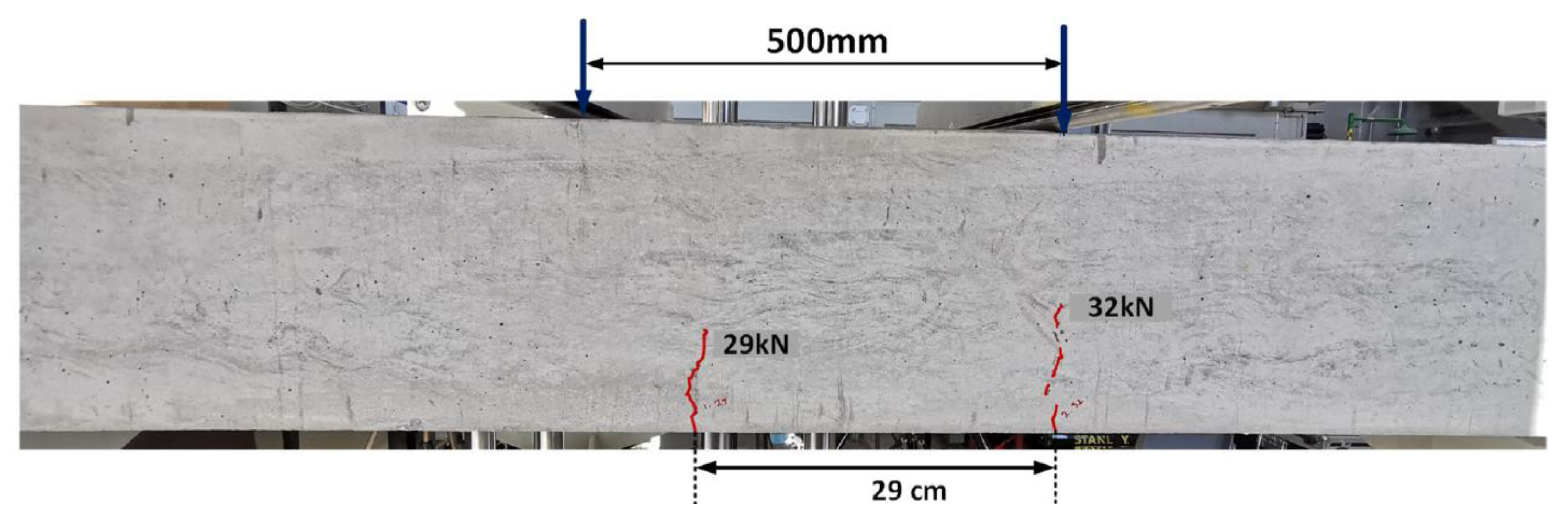

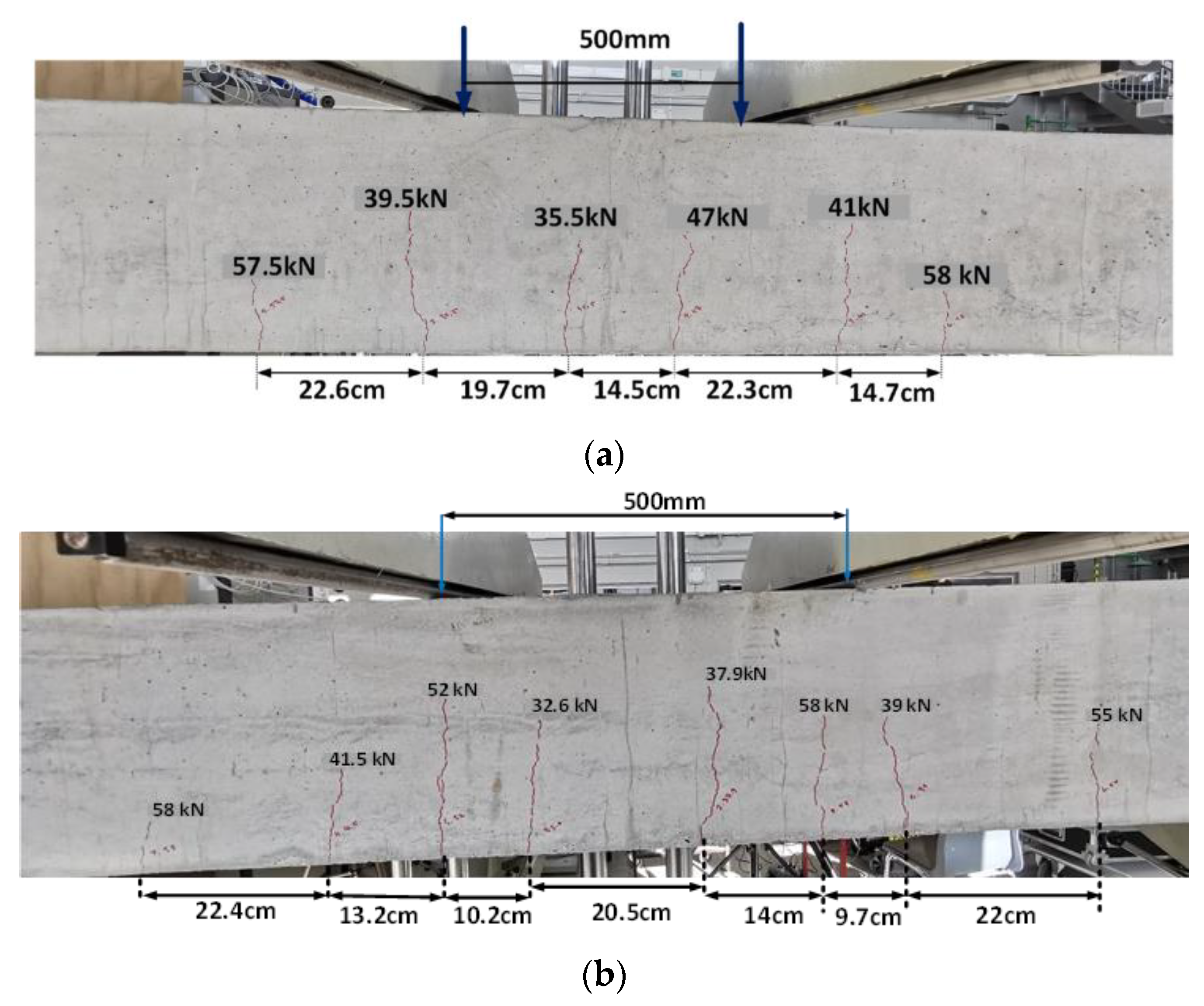

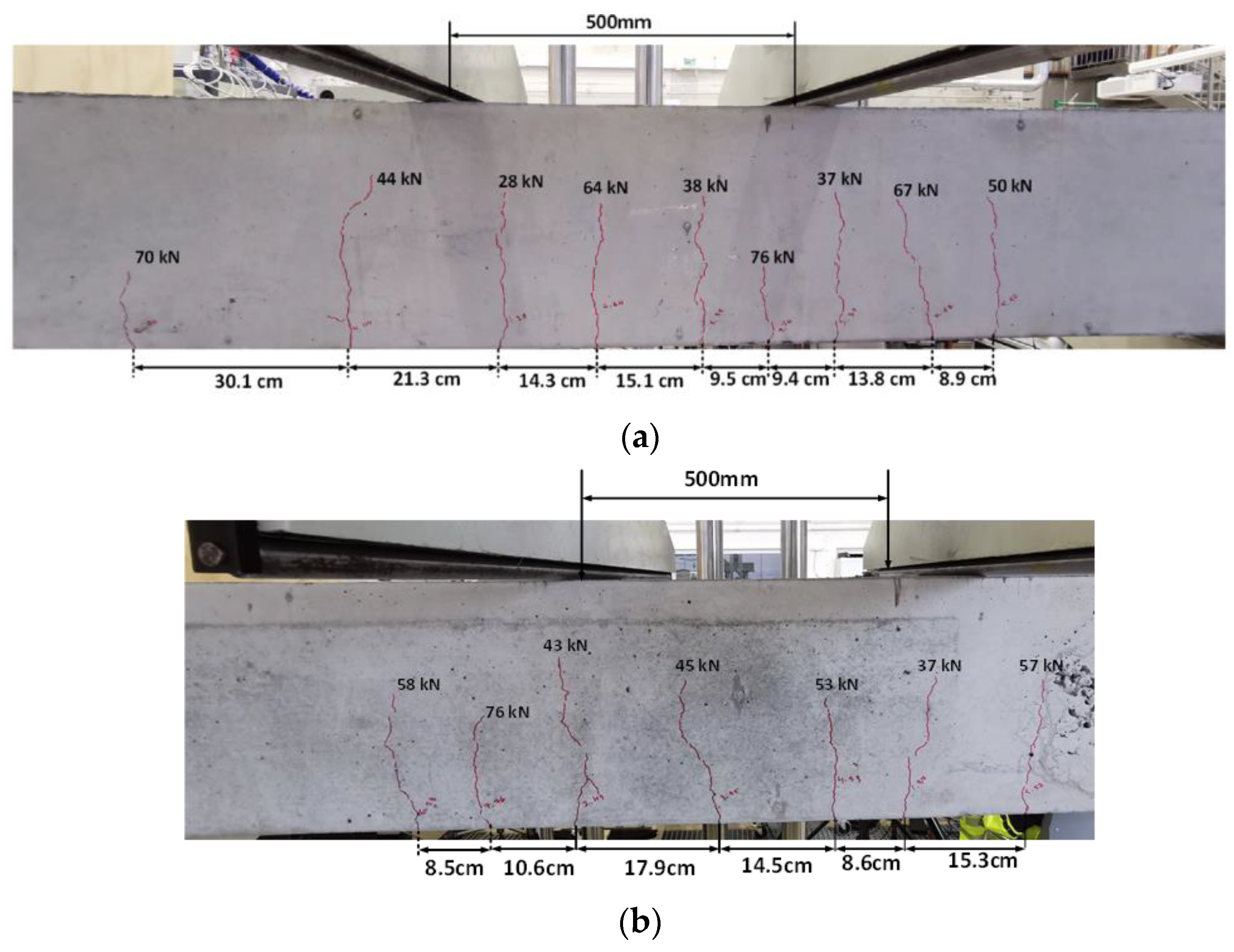

Crack Formation during Preloading Prior to Pasting CFRP Plates

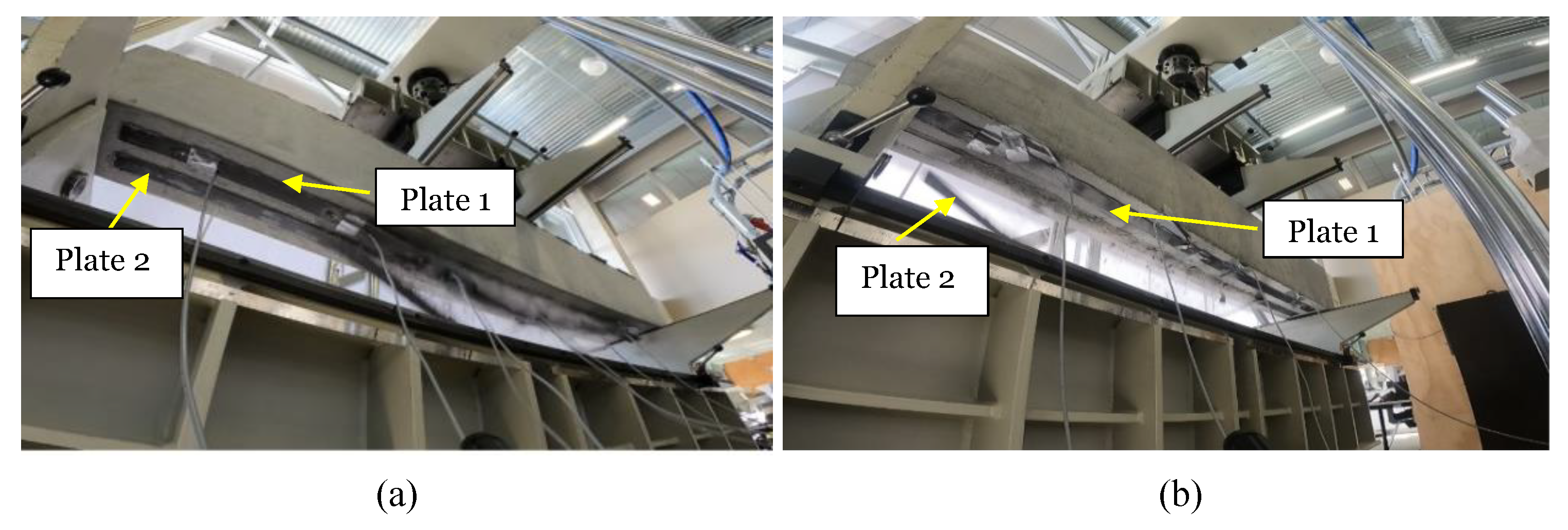

2.5. CFRP Plate Inspection Prior to Testing

3. Discussion of the Results of the Experiment

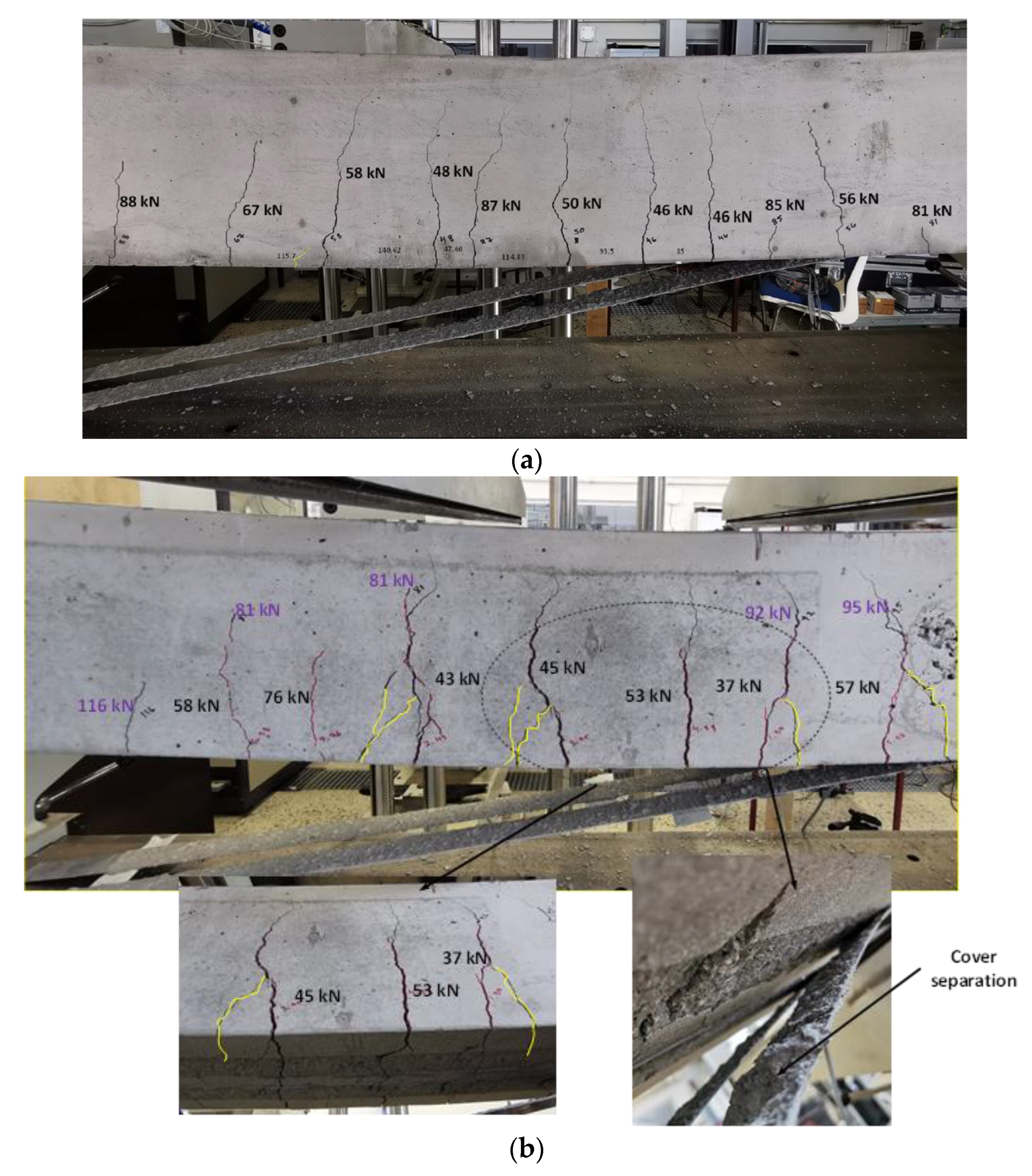

3.1. Cracking Behavior

3.2. Failure Modes during Four-Point Bending Test

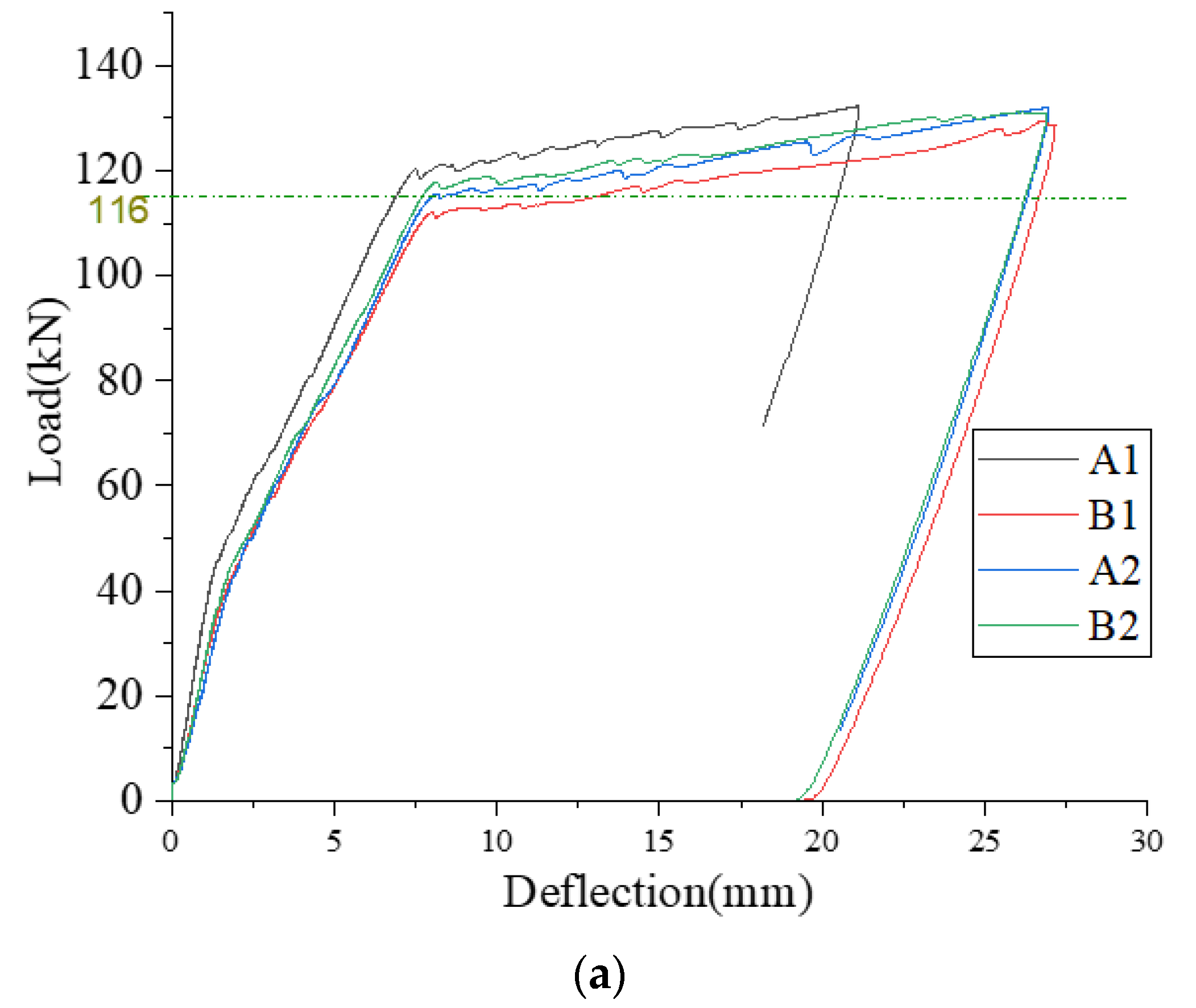

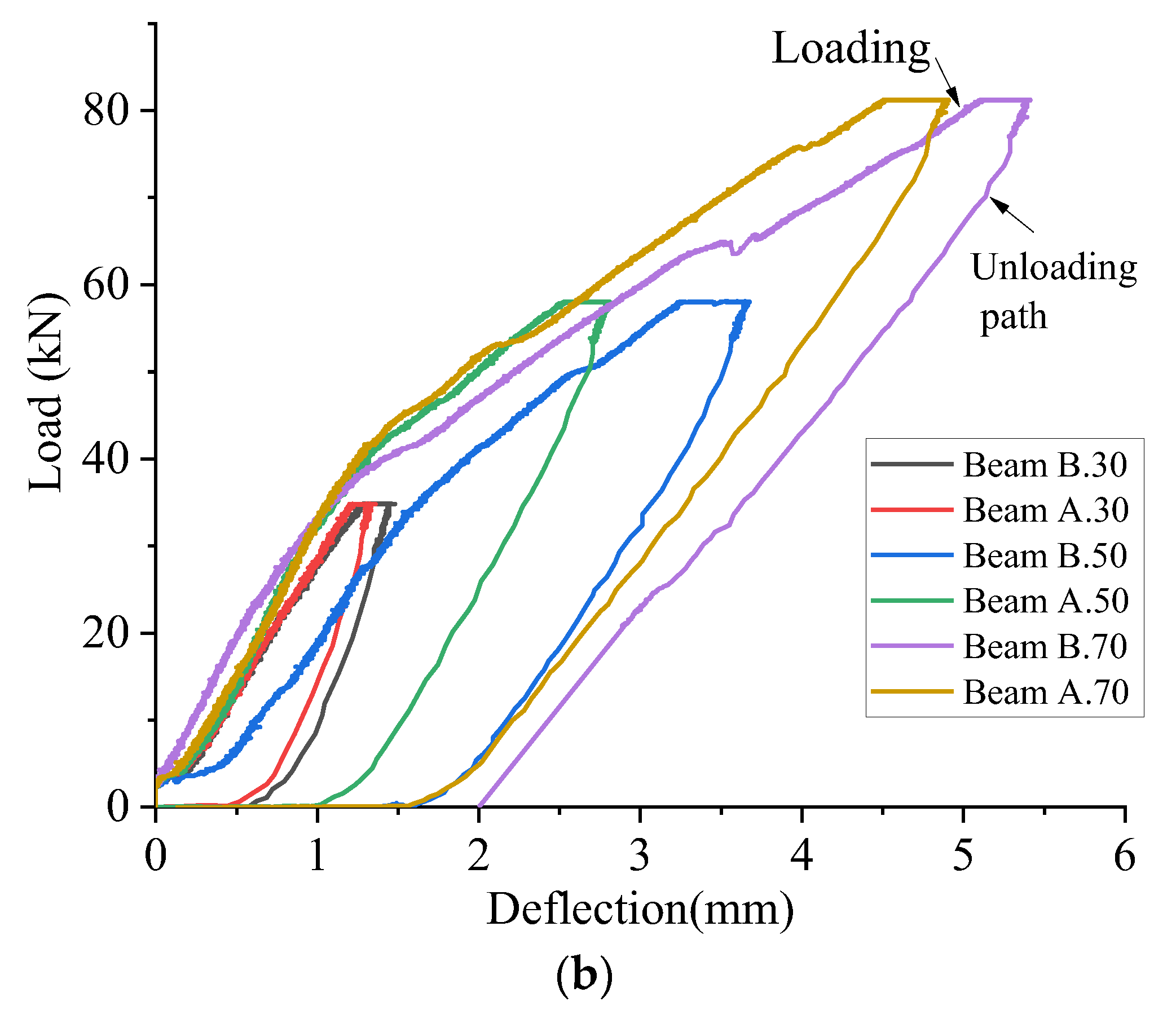

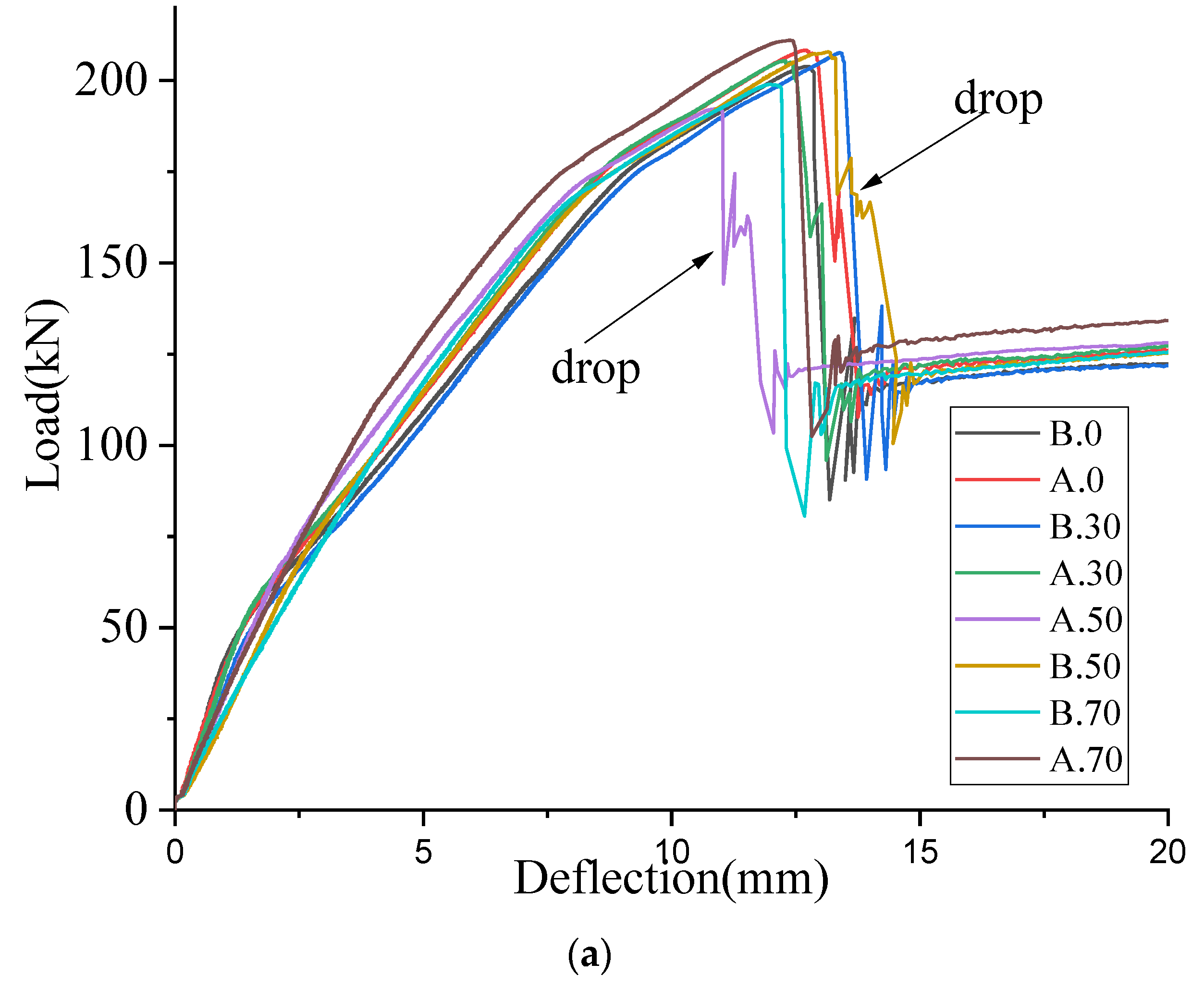

3.3. Load vs. Deflection Behavior of Strengthened Beams with and without Preload

3.4. Experimental Ultimate Bending Moment

3.5. Comparison of Experimental Ultimate Bending Moment with Theoretical Flexural Capacity

- the Euler–Bernoulli theory of plane sections is applicable [28];

- the strain in the reinforcement bonded with concrete, whether in tension or in compression, is the same as that in the surrounding concrete [28];

- the tensile strength of the concrete is neglected [28];

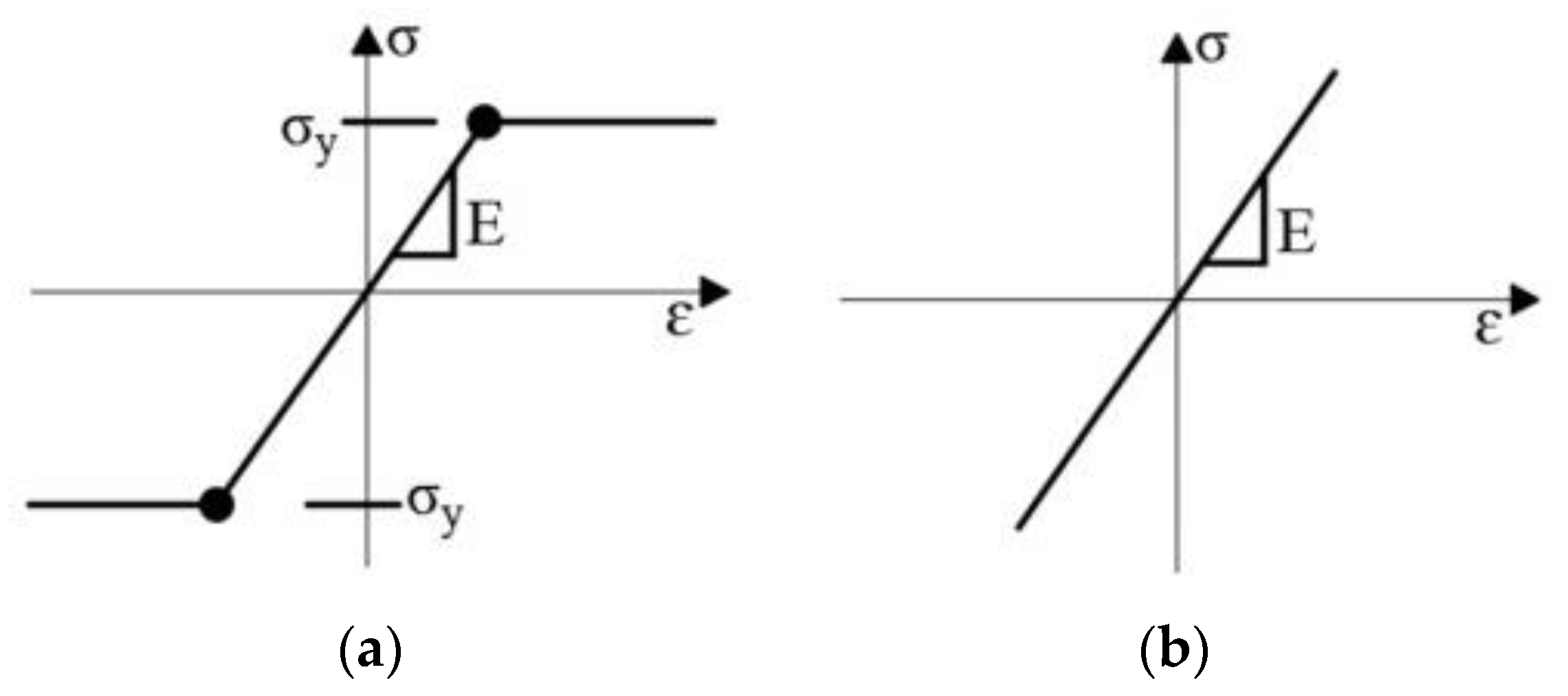

- the stresses in the reinforcing steel are determined on the basis of a bilinear stress-strain relation with a horizontal top branch [28];

- the FRP stress-strain relationship is linear until the ultimate strains occur [29];

- three possible failure modes of RC beam strengthened in flexure with the CFRP strips are considered: concrete crushing in compression zone, CFRP strip debonding and CFRP strip rupture;

- the ultimate strains in the FRP material due to the possibility of debonding are determined based on the assumptions of the Italian standard [30];

- the ultimate strains in the FRP material due to the possibility of breaking are determined using the material factor [29] and the strain correlation factor.

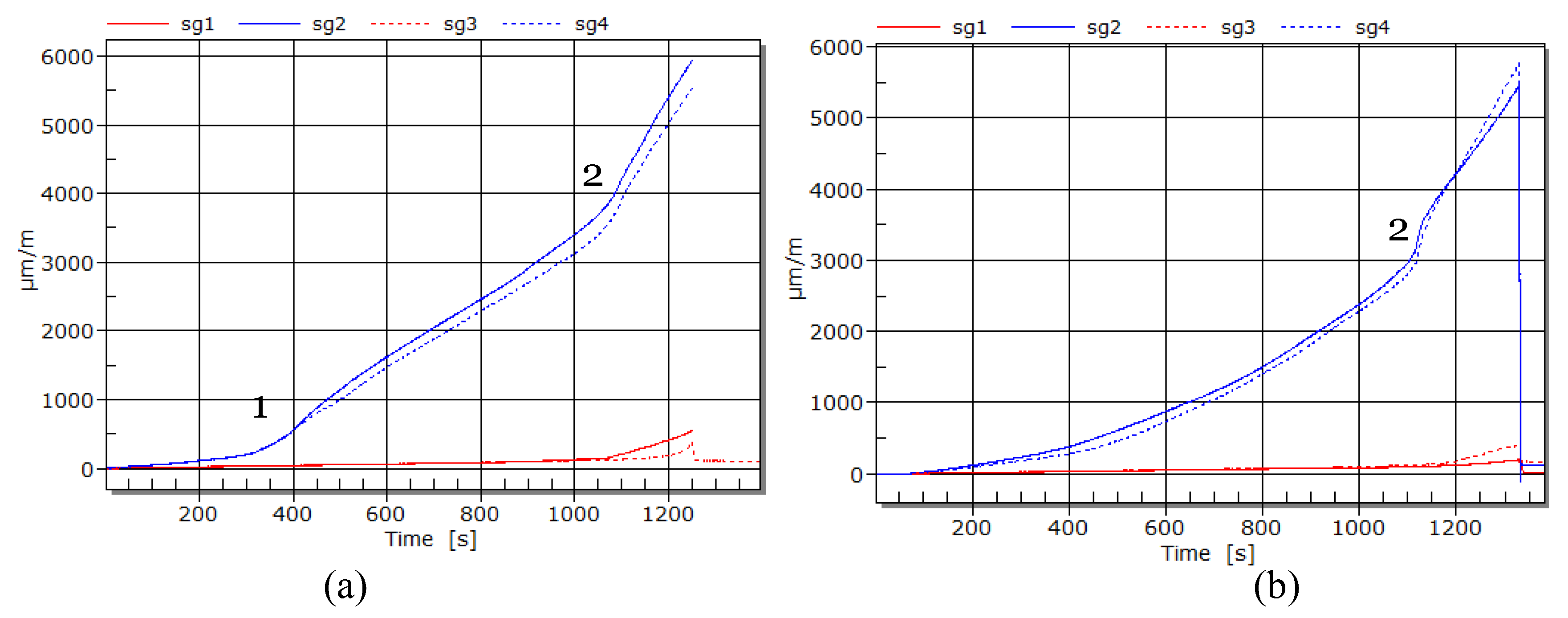

3.6. Strain Development in CRFP Plates at 0% vs. 70% Preload Levels

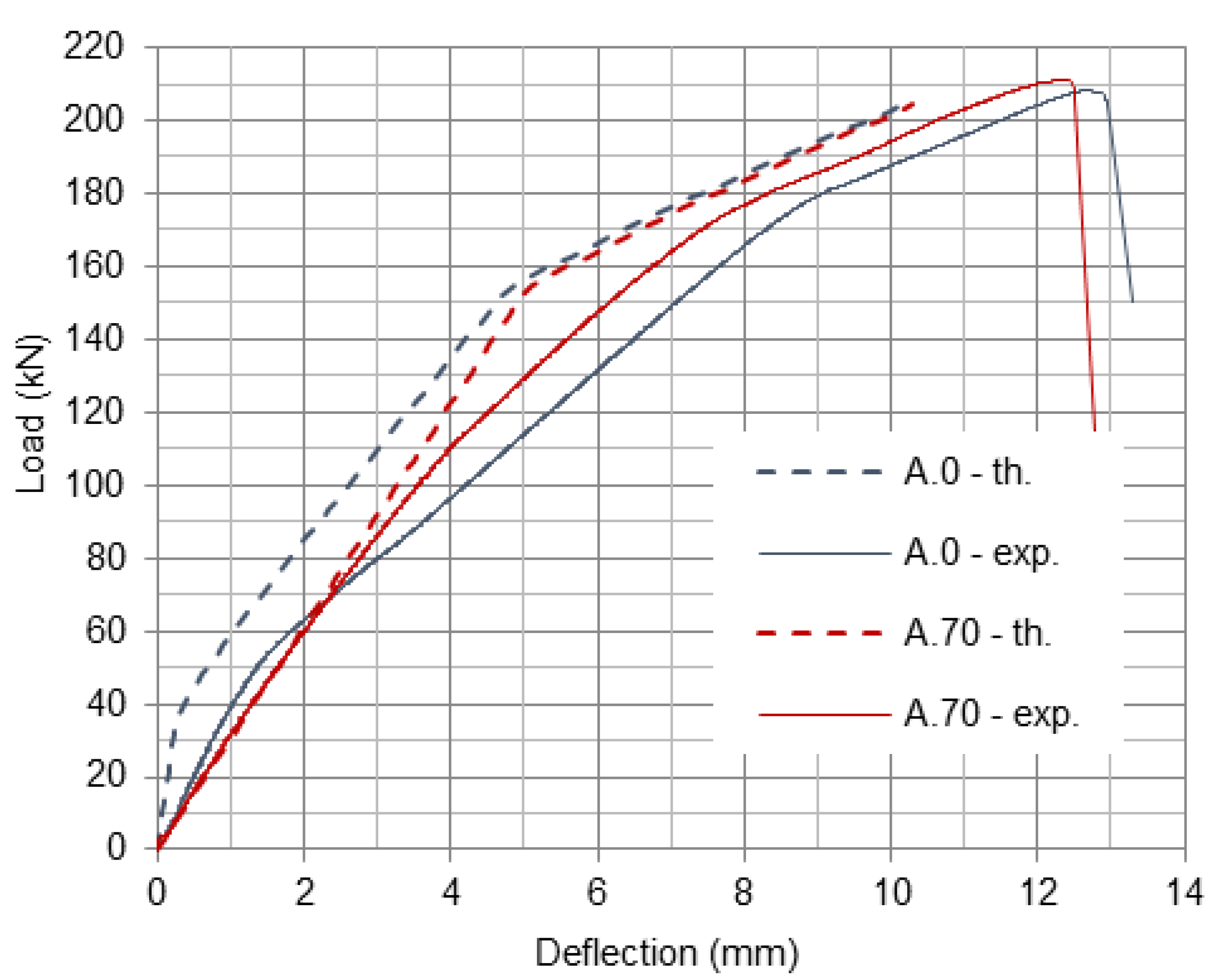

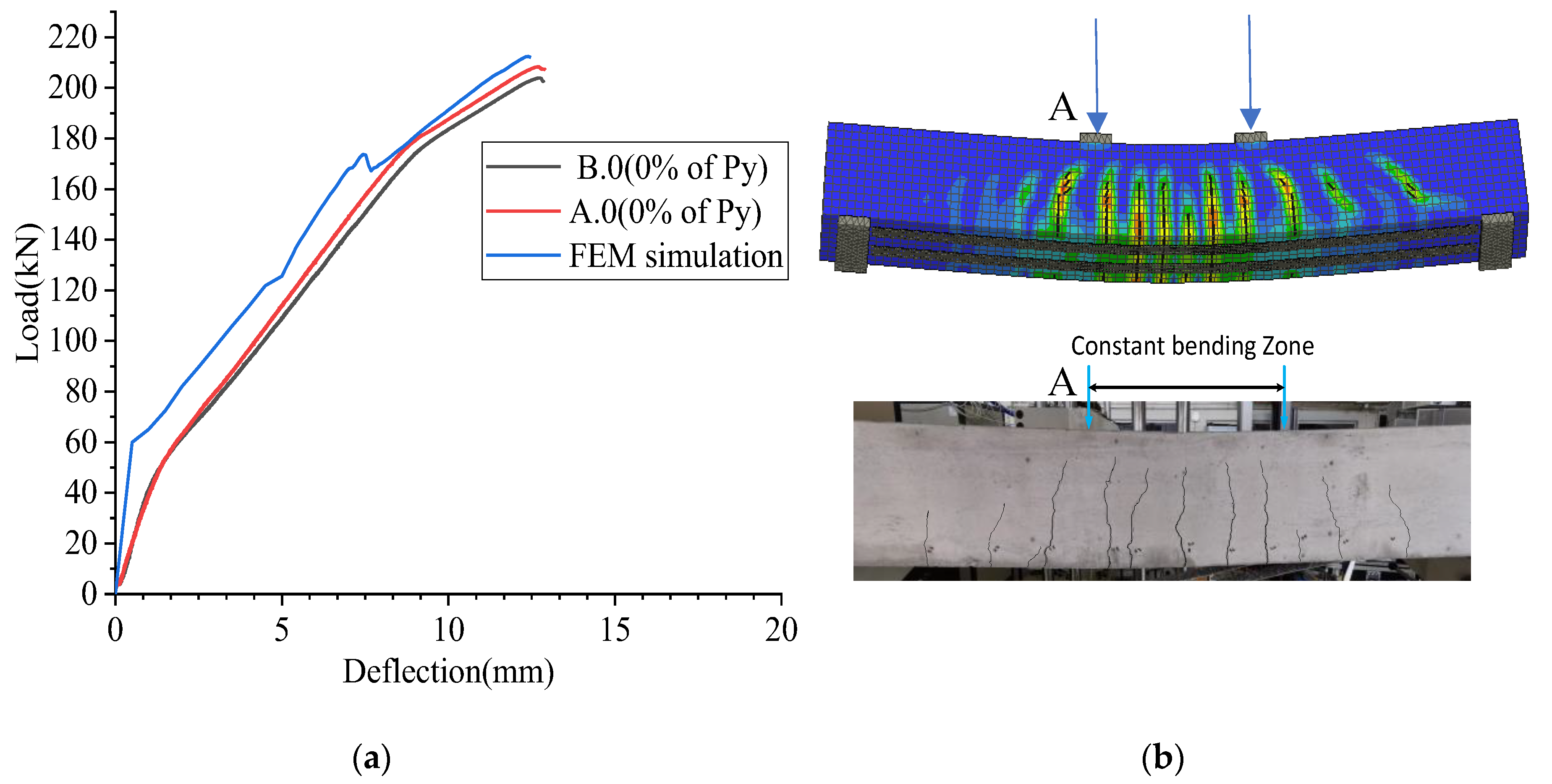

3.7. Verification of the Load vs. Deflection Behavior Using FEM Simulation

4. Conclusions

- The first crack formation is delayed in strengthened beams without preloading, compared to strengthened beams with preload conditions.

- The strengthened beams without preload level (0%) and with preload levels (30%, 50% and 70%) indicated similar failure mode. The failure happened by widening the flexural cracks, leading to breaks in the bond between the CFRP plates and concrete, and then, delamination, starting at middle of the beam and then at the ends of the CRP plates. Hence, the failure mode is similar to IFC debonding, leading to plate end debonding or complete debonding of the plates. In addition, based on the quality of the bond between the CFRP plates and concrete, debonding of two plates in a beam happened simultaneously or one plate prior to the other plate.

- Cover separation is not a dominant failure mode in strengthened beams without a preload condition and 30% preloaded beams. However, when increasing preload level from 50% to 70%, slight cover separation is observed at the proximity of wide crack openings.

- When increasing the preload level from 0% to 70%, during failure, wide diagonal cracks (secondary cracks) occurred.

- The initial cracking stage, post cracking stage and post-yielding stage are clearly observed in strengthened beams without preload levels or a 30% preload level, whereas only a post-yielding stage is clearly observed in the 50% and 70% preload conditions. There is no significant difference in tangent stiffness in 0% preload and 30% preload, during the initial cracking stage. However, the tangent stiffness is reduced when the preload level is increased from 30% to 70%.

- There is no significant decrease in the experimental ultimate bending moment, while increasing preload level from 0% to 70%.

- The experimental ultimate bending moment gives good agreement with the theoretical ultimate bending moment, estimated based on the CFRP strain limit given in CNR standard [30].

- The analytical and FEM simulation load-deflection curves give a good agreement with experimental flexural behavior of CFRP strengthened RC beams.

- A capacity increase between 70% and 80%, compared to the un-strengthened member. The test result demonstrates the vast potential of capacity enhancement that can be attained by externally bonded CFRP.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Junaid, M.T.; Karzad, A.S.; Elbana, A.; Altoubat, S. Experimental study on shear response of GFRP reinforced concrete beams strengthened with externally bonded CFRP sheets. Structures 2022, 35, 1295–1307. [Google Scholar] [CrossRef]

- Hamrat, M.; Bouziadi, F.; Boulekbache, B.; Daouadji, T.H.; Chergui, S.; Labed, A.; Amziane, S. Experimental and numerical investigation on the deflection behavior of pre-cracked and repaired reinforced concrete beams with fiber-reinforced polymer. Constr. Build. Mater. 2020, 249, 118745. [Google Scholar] [CrossRef]

- Xiang, Y.; Fang, Z.; Fang, Y. Single and multiple impact behavior of CFRP cables under pretension. Constr. Build. Mater. 2017, 140, 521–533. [Google Scholar] [CrossRef]

- Huang, B.-T.; Wang, Y.-T.; Wu, J.-Q.; Yu, J.; Dai, J.-G.; Leung, C.K. Effect of fiber content on mechanical performance and cracking characteristics of ultra-high-performance seawater sea-sand concrete (UHP-SSC). Adv. Struct. Eng. 2020, 24, 1182–1195. [Google Scholar] [CrossRef]

- Huang, B.-T.; Li, Q.-H.; Xu, S.-L.; Liu, W.; Wang, H.-T. Fatigue deformation behavior and fiber failure mechanism of ultra-high toughness cementitious composites in compression. Mater. Des. 2018, 157, 457–468. [Google Scholar] [CrossRef]

- Helal, K.; Yehia, S.; Hawileh, R.; Abdalla, J. Performance of preloaded CFRP-strengthened fiber reinforced concrete beams. Compos. Struct. 2020, 244, 112262. [Google Scholar] [CrossRef]

- Arduini, M.; Nanni, A. Behavior of precracked RC beams strengthened with carbon FRP sheets. J. Compos. Constr. 1997, 1, 63–70. [Google Scholar] [CrossRef]

- Zhang, A.-H.; Jin, W.-L.; Li, G.-B. Behavior of preloaded RC beams strengthened with CFRP laminates. J. Zhejiang Univ. A 2006, 7, 436–444. [Google Scholar] [CrossRef]

- Li, G.; Zhang, A.; Guo, Y. Effect of preload level on flexural load-carrying capacity of RC beams strengthened by externally bonded FRP sheets. Open Civ. Eng. J. 2015, 9, 426–434. [Google Scholar] [CrossRef]

- Fayyadh, M.M.; Razak, H.A. Assessment of effectiveness of CFRP repaired RC beams under different damage levels based on flexural stiffness. Constr. Build. Mater. 2012, 37, 125–134. [Google Scholar] [CrossRef]

- Wang, T.-w.; Chang, Y. Experimental research on the flexural behavior of RC beams strengthened by NSM CFRP sheets. J. Wuhan Univ. Technol. 2009, 31, 111–115. [Google Scholar]

- Wu, Z.; Shao, Y.; Iwashita, K.; Sakamoto, K. Strengthening of preloaded RC beams using hybrid carbon sheets. J. Compos. Constr. 2007, 11, 299–307. [Google Scholar] [CrossRef]

- Benjeddou, O.; Ben Ouezdou, M.; Bedday, A. Damaged RC beams repaired by bonding of CFRP laminates. Constr. Build. Mater. 2007, 21, 1301–1310. [Google Scholar] [CrossRef]

- Nawaz, W.; Elchalakani, M.; Karrech, A.; Yehia, S.; Yang, B.; Youssf, O. Flexural behavior of all lightweight reinforced concrete beams externally strengthened with CFRP sheets. Constr. Build. Mater. 2022, 327, 126966. [Google Scholar] [CrossRef]

- Al-Fakih, A.; Hashim, M.H.M.; Alyousef, R.; Mutafi, A.; Sabah, S.H.A.; Tafsirojjaman, T. Cracking behavior of sea sand RC beam bonded externally with CFRP plate. Structures 2021, 33, 1578–1589. [Google Scholar] [CrossRef]

- Shin, Y.S.; Lee, C. Flexural behavior of reinforced concrete beams strengthened with carbon fiber-reinforced polymer laminates at different levels of sustaining load. ACI Struct. J. 2003, 100, 231–239. [Google Scholar]

- Teng, J.; Smith, S.; Yao, J.; Chen, J. Intermediate crack-induced debonding in RC beams and slabs. Constr. Build. Mater. 2003, 17, 447–462. [Google Scholar] [CrossRef]

- Richardson, T.; Fam, A. Modulus effect of bonded CFRP laminates used for repairing preyield and postyield cracked concrete beams. J. Compos. Constr. 2014, 18, 04013054. [Google Scholar] [CrossRef]

- Jian-He, X.; Yong-Chang, G.; Yi-Feng, L.; Gong-Fa, C. Experimental study on flexural behaviour of pre-damaged reinforced concrete beams strengthened with CFRP. Mater. Plast. 2014, 51, 370–375. [Google Scholar]

- Sika®. SiKa CarboDur S512, Product Datasheet. Available online: https://gbr.sika.com/dms/getdocument.get/02772e0b-de83-3f22-8d08-71f4352432ce/SikaCarboDurS_en_GB_(09-2017)_5_1.pdf (accessed on 8 January 2021).

- Sika®. Sikadur®-30, Product Datasheet. Available online: https://nor.sika.com/dms/getdocument.get/1c080076-b5fd-3700-b3af-e059547c9744/PDB_Sikadur-30.pdf (accessed on 6 January 2021).

- Choi, W.; Yun, H.-D. Non-destructive evaluation (NDE) of composites: Use of acoustic emission (AE) techniques. In Non-Destructive Evaluation (NDE) of Polymer Matrix Composites; Elsevier: Amsterdam, The Netherlands, 2013; pp. 557–573. [Google Scholar]

- Sika®. Method Statement Sika CarboDur System. Available online: https://lva.sika.com/dms/getdocument.get/4c3e3d96-acee-3cb6-b83e-14b4b91e3bc4/MS_Carbodur_2013.pdf (accessed on 5 January 2021).

- Graneland, E.G. Flexural Behavior of Cracked Reinforced Concrete Beams with Externally Bonded CFRP Plates. Master’s Thesis, University of Stavanger, Stavanger, Norway, 10 July 2021. [Google Scholar]

- Gao, B.; Leung, C.K.; Kim, J.-K. Prediction of concrete cover separation failure for RC beams strengthened with CFRP strips. Eng. Struct. 2005, 27, 177–189. [Google Scholar] [CrossRef]

- Wu, H.-C.; Eamon, C.D. Strengthening of Concrete Structures Using Fiber Reinforced Polymers (FRP): Design, Construction and Practical Applications; Woodhead Publishing: Duxford, UK, 2017. [Google Scholar]

- Piątek, B. New Technology of Strengthening Reinforced Concrete Structures by Tensioned CFRP Strips. Ph.D. Thesis, Rzeszów University of Technology, Rzeszów, Poland, 2017. [Google Scholar]

- EN 1992; Design of Concrete Structures—Part 1-1: General Rules and Rules for Buildings. CEN: Brussels, Belgium, 2018.

- FIB. Externally Bonded FRP Reinforcement for RC Structures; Bulletin 14; Fédération Internationale du Béton: Lausanne, Switzerland, 2001. [Google Scholar]

- CNR-DT 200/2004; Guide for the Design and Construction of Externally Bonded FRP Systems for Strengthening Existing Structure. Materials, RC and PC Structures, Masonry Structures. Italian Research Council: Rome, Italy, 2004.

- Pellegrino, C.; Modena, C. Flexural Strengthening of Real-Scale RC and PRC Beams with End-Anchored Pretensioned FRP Laminates. ACI Struct. J. 2009, 106, 319–328. [Google Scholar]

- ACI 440.2R-17; Guide for the Design and Construction of Externally Bonded FRP Systems for Strengthening Concrete Structures. ACI: Farmington Hills, MI, USA, 2017.

- Jumaat, M.Z.; Rahman, M.; Alam, M.; Rahman, M. Premature failures in plate bonded strengthened RC beams with an emphasis on premature shear: A review. Int. J. Phys. Sci. 2011, 6, 156–168. [Google Scholar]

- Cervenka, V. Computer simulation of failure of concrete structures for practice. In 1st fib Congress, Osaka, Japan, October 2002; Cervenka Consulting: Prague, Czech Republic, 2002. [Google Scholar]

- Cervenka, V.; Jendele, L.; Cervenka, J. ATENA Program Documentation: Part 1: Theory. Prague, Czech Republic. 2021. Available online: https://www.cervenka.cz/assets/files/atena-pdf/ATENA_Theory.pdf (accessed on 2 February 2021).

- Gholamhoseini, A. Experimental and finite element study of ultimate strength of continuous composite concrete slabs with steel decking. Int. J. Adv. Struct. Eng. 2018, 10, 85–97. [Google Scholar] [CrossRef]

| Material | Quantity (kg m−3) |

|---|---|

| Standard cement FA | 309 |

| Sand (0/2 mm) Sand (0/8 mm) | 306 909 |

| Gravel(8/16 mm) | 675 |

| Silica | 11 |

| Fly ash | 20 |

| Water | 131 |

| Admixtures Dynamon SX-23 Mapeair 25 1:19 | 2.21 0.34 |

| CarboDur S512 | Mean Value | 5% Fractile-Value | 95% Fractile-Value |

|---|---|---|---|

| Modulus of Elasticity | 170 GPa | 165 GPa | 180 GPa |

| Tensile strength | 3100 MPa | 3000 MPa | 3600 MPa |

| Strain at break | Minimum value: 1.8% | ||

| Property | Value |

|---|---|

| Modules of Elasticity in compression | 9600 N/mm2 (at 2 °CC) |

| Tensile Modulus of Elasticity | 11,200 N/mm2 (+2 °CC) |

| Shrinkage | 0.04% |

| Thermal coefficient of expansion | 2.5 × 10−5 pe °C (temperature range: −20 °C to +40 °C) |

| Tensile strength (7 days curing) | 26 N/mm2–29 N/mm2(+15 °C +35 °C) |

| Density | 1.65 kg/L ± 0.1 kg/L |

| Bond Condition | ||

|---|---|---|

| Beam | Bond Quality | Comment |

| A.0, B.0, A.30 | Good (No defects detected by visual inspection) | Excess adhesive pressed out on both sides of the plates. |

| B.30 | Generally good bond quality | One location with void in adhesive layer. [d~2 mm] |

| A.50 | Poor bond quality | Four locations with relatively deep voids [d~4–9 mm] |

| B.50 | Potentially compromised bond quality | Three locations with relatively deep voids [d~3–6 mm] |

| A.70 | Generally good bond | Two locations with void in adhesive layer [d~1–2 mm] |

| B.70 | Generally good bond | Two locations with void in adhesive layer [d~2–3 mm] |

| Preload | Beam | Pmax.ex (kN) | Py (kN) | MR.exp (kN.m) | Increase of MR.exp 1 (%) | Decrease of Average MR.exp 2 (%) | Max Mid Span Strain (µm/m) | Strain Decrease (%) | |

|---|---|---|---|---|---|---|---|---|---|

| 0%_U * | A1 | - | 120 | 44 (avg) | - | - | - | - | |

| B2 | - | 117 | - | - | - | - | - | ||

| A2 | - | 112 | - | - | - | - | - | ||

| B1 | - | 115 | - | - | - | - | - | ||

| 0%_S * | A.0 | 208.4 | - | 79 | 78 | - | 5948 | - | 1.03 |

| B.0 | 203.9 | - | 77 | 74 | 6408 | - | 1.01 | ||

| 30%_S * | A.30 | 205.4 | - | 78 | 75 | 0 | 5731 | 7% | 1.02 |

| B.30 | 207.6 | - | 79 | 77 | - | 1.03 | |||

| 50%_S * | A.50 | 192.4 | - | 73 | 64 | 7 | 4925 | 20% | 0.95 |

| B.50 | 207.8 | - | 79 | 77 | - | 1.03 | |||

| 70%_S * | A.70 | 211.1 | - | 80 | 80 | 1 | 5763 | 7% | 1.04 |

| B.70 | 199 | - | 76 | 70 | 5610 | - | 0.99 |

| Properties | Value |

|---|---|

| Mean cylindrical compressive strength (fc) (MPa) | 49 |

| Modulus of elasticity (Ec) (GPa) | 35 |

| Poisson’s ratio (υ) | 0.2 |

| Mean tensile strength (ft) (MPa) | 3.3 |

| Fracture energy (Gf) (N/m) | 147 |

| Fixed crack | 1 |

| Plastic strain (εcp) | 0.0009528 |

| Onset of crushing (fcu) (MPa) | 7.35 |

| Critical compressive displacement (wd) (m) | 0.0005 |

| Density (γ) (MN/m3) | 0.024 |

| Thermal expansion (α) (C0–1) | 0.000012 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Samarakoon, S.M.S.M.K.; Piatek, B.; De Silva, G.H.M.J.S. Investigation of the Flexural Behavior of Preloaded and Pre-Cracked Reinforced Concrete Beams Strengthened with CFRP Plates. Materials 2023, 16, 22. https://doi.org/10.3390/ma16010022

Samarakoon SMSMK, Piatek B, De Silva GHMJS. Investigation of the Flexural Behavior of Preloaded and Pre-Cracked Reinforced Concrete Beams Strengthened with CFRP Plates. Materials. 2023; 16(1):22. https://doi.org/10.3390/ma16010022

Chicago/Turabian StyleSamarakoon, S. M. Samindi M. K., Bartosz Piatek, and G. H. M. J. Subashi De Silva. 2023. "Investigation of the Flexural Behavior of Preloaded and Pre-Cracked Reinforced Concrete Beams Strengthened with CFRP Plates" Materials 16, no. 1: 22. https://doi.org/10.3390/ma16010022

APA StyleSamarakoon, S. M. S. M. K., Piatek, B., & De Silva, G. H. M. J. S. (2023). Investigation of the Flexural Behavior of Preloaded and Pre-Cracked Reinforced Concrete Beams Strengthened with CFRP Plates. Materials, 16(1), 22. https://doi.org/10.3390/ma16010022