Abstract

MnZn ferrite homogeneous fibers were synthesized via a simple solvothermal method and they were used as a reinforcing phase to prepare homogeneous-fiber-reinforced MnZn ferrite materials. The effects of MnZn ferrite homogeneous fibers (0 wt% to 4 wt%) doping on the microstructure, magnetic, and mechanical properties of MnZn ferrite materials were studied systematically. The results showed that MnZn ferrite homogeneous fibers exhibited high purity, good crystallinity, and smooth 1D fibrous structures, which were homogeneous with MnZn ferrite materials. Simultaneously, a certain content of MnZn ferrite homogeneous fibers helped MnZn ferrite materials exhibit more uniform and compact crystal structures, less porosity, and fewer grain boundaries. In addition, the homogeneous-fiber-reinforced MnZn ferrite materials possessed superior magnetic and mechanical properties such as higher effective permeability, lower magnetic loss, and higher Vickers hardness compared to ordinary MnZn ferrite materials. In addition, the magnetic and mechanical properties of homogeneous-fiber-reinforced MnZn ferrite materials first increased and then gradually decreased as the homogeneous fiber content increased from 0 wt% to 4 wt%. The best magnetic and mechanical properties of materials were obtained as the fiber content was about 2 wt%.

1. Introduction

MnZn ferrite is an important member of the soft magnetic materials, which has been widely used in network communication, information storage, automatic control, medical diagnosis, and various apparatuses from household appliances to scientific equipment [1,2,3]. Moreover, it has superior characteristics such as high magnetic permeability, high electrical resistivity, high stability, large magnetic induction, and low magnetic loss [4,5,6]. Thus, it is crucial to develop MnZn ferrite exhibiting better performances with the rapid development of modern science and technology.

After decades of studies, it is well known that doping a small amount of oxides is one of the most effective strategies for improving the performances of MnZn ferrite. Common oxides doped in MnZn ferrite have been systematically researched and can be divided into three types: First, dopants such as SiO2 [7], CaO [8], and HfO2 [9] tend to change the chemical compositions and further adjust the resistivity of grain boundaries. The first kind of dopants can enhance the resistivity and lower the loss of MnZn ferrite, but the segregation of the above cations at the grain boundaries may bring down the initial permeability of the material due to magnetic dilution. Second, soluble oxides involving TiO2 [10], SnO2 [11], NiO [12], and Co2O3 [13] are easy to dissolve into the lattices and alter the performance. The second kind of dopants can effectively adjust the intrinsic magnetic properties of MnZn ferrite. However, they may also reduce partial magnetic properties of the material. Third, dopants with low melting points such as V2O5 [14], Bi2O3 [15], and MoO3 [16] can modify the microstructure of the MnZn ferrite during the process of sintering. The third kind of dopants is critical for improving the permeability and reducing the loss of MnZn ferrite. Larger amounts of non-magnetic dopants will damage the microstructure and reduce the properties of the material. Accordingly, it can be found that the addition of the above dopants can improve some performances of MnZn ferrite, but often lead to the deterioration of other performances. Therefore, the MnZn ferrite homogeneous-fiber- and particle-co-reinforced structure is proposed to prepare the MnZn ferrite with excellent microstructure, magnetic, and mechanical properties.

In this work, MnZn ferrite homogenous fibers synthesized by the solvothermal method were used as the reinforcing phase to prepare homogeneous-fiber-reinforced MnZn ferrite materials. The microstructure, phase composition, magnetic, and mechanical properties of materials were characterized by scanning electron microscopy (SEM), X-ray diffraction (XRD), an LCR meter, a magnetic automatic test device, and a hardness tester. Furthermore, the effect of homogeneous fiber content (0 wt% to 4 wt%) on the homogeneous-fiber-reinforced MnZn ferrite materials was investigated in detail.

2. Experimental Details

2.1. Synthesis of MnZn Ferrite Homogenous Fibers

MnSO4·4H2O (≥99%), ZnSO4·7H2O (≥99%), FeSO4·7H2O (≥99%), H2C2O4 (≥98%), ethylene glycol (EG, ≥99%), and deionized water were used as raw materials. In a typical process, 0.5 mmol MnSO4·4H2O, 0.5 mmol ZnSO4·7H2O, and 2 mmol FeSO4·7H2O were dissolved in a mixture of EG and deionized water with a volume of 30 mL (EG:water = 3:1). Then, 3 mmol H2C2O4 was added into the above mixture under continuous stirring for 60 min. Subsequently, the obtained mixture was transferred into a Para polyphenyl-lined autoclave of 50 mL capacity and heated at 120 °C for 24 h. After that, the products were centrifuged to separate solids, washed with ethanol and deionized water for several times, and dried in an oven at 80 °C for 12 h. Finally, the as-prepared precursor fibers were annealed in air atmosphere at 500 °C for 2 h. The MnZn ferrite homogenous fibers, as a nominal composition of Mn0.5Zn0.5Fe2O4, were collected by the solvothermal method.

2.2. Synthesis of Homogeneous-Fiber-Reinforced MnZn Ferrites

MnO (≥99%), ZnO (≥99%), Fe2O3 (≥99%), and MnZn ferrite homogenous fibers (Mn0.5Zn0.5Fe2O4, made by our laboratory) were used as raw materials. The preparation process was as follows: First, MnO, ZnO, and Fe2O3 were evenly mixed for 120 min at a speed of 300 r/min in the planetary mill. After that, the evenly mixed powders were dried at 90 °C for 10 h in the oven. Subsequently, the dried powders were pre-sintered at 850 °C for 2.5 h in an air atmosphere and cooled to room temperature. Next, the pre-sintered materials were evenly mixed for 120 min at a speed of 300 r/min, and then dried at 90 °C for 10 h. Additionally, the dried materials were mixed with 0.85 wt% polyvinyl alcohol for granulation, followed by 50 mesh screening to obtain the MnZn ferrite powders. Then, the as-prepared MnZn ferrite homogenous fibers of 1 wt%, 2 wt%, 3 wt%, and 4 wt%, together with MnZn ferrite powders, were evenly mixed and dried to obtain the 1 wt%, 2 wt%, 3 wt%, and 4 wt% homogeneous-fiber-reinforced MnZn ferrite composite powders. After that, the composite powders were pressed into toroidal shapes with the dimensions of OD (outer diameter) 20 mm, ID (inner diameter) 10 mm, and h (height) 8 mm under an external load of 350 MPa for 15 min. Finally, the annular samples were sintered at 1280 °C for 6 h in a Blank equilibrium atmosphere-controlled sintering system to obtain the required 1 wt%, 2 wt%, 3 wt%, and 4 wt% homogeneous-fiber-reinforced MnZn ferrite samples. In addition, the ordinary MnZn ferrite sample was prepared with 0 wt% MnZn ferrite homogeneous fibers by the above preparation process.

2.3. Characterizations

The surface morphology of the samples was characterized by SEM (Supra 35VP, ZEISS, Jena, Germany). The phase composition and crystallographic structure of the samples were analyzed by XRD (D8 Advance, Bruker, Karlsruhe, Germany) over the 2θ range of 10° and 80° with Cu Kα irradiation (λ = 0.15418 nm) at 40 kV and 40 mA. The LCR meter (IM3570A988-06, HIOKI E.E. CORPORATION, Hioki, Japan) was used to measure the effective permeability of the samples at room temperature with a frequency range of 10 kHz to 1000 kHz. The magnetic automatic test device (MATS-3000SA, Hunan Linkjoin Technology Co., Ltd., Loudi, China) was used to measure the magnetic loss of the samples at room temperature in the frequency range from 10 kHz to 1000 kHz. The Vickers hardness of the samples was determined on a hardness tester (HV-1000ZDT, Shanghai Jvjing Precision Instrument Manufacturing Co., Ltd., Shanghai, China). The load was 200 g and the loading time was 15 s.

3. Results and Discussion

3.1. Characterization of the MnZn Ferrite Homogeneous Fibers

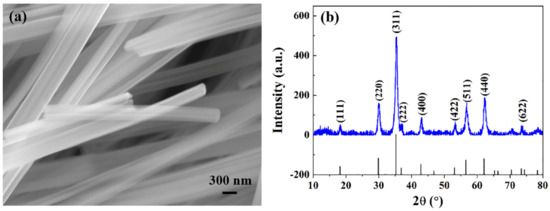

The general SEM image of the as-prepared MnZn ferrite homogeneous fibers is shown in Figure 1a. It can be seen that the typical MnZn ferrite homogeneous fibers exhibited a 1D fibrous structure with a large aspect ratio and had a smooth surface area. The XRD pattern of the corresponding MnZn ferrite homogeneous fibers is shown in Figure 1b. It can be observed that the major diffraction peaks appearing at 18.1°, 29.8°, 35.1°, 36.7°, 42.6°, 52.9°, 56.3°, 61.8°, and 73.3° were assigned to the (111), (220), (311), (222), (400), (422), (511), (440), and (622) planes, respectively, and matched well with the standard powder diffraction data of MnZn ferrite, which indicated the high purity and good crystallinity of MnZn ferrite homogeneous fibers. In addition, the MnZn ferrite homogeneous fibers had the same chemical composition as the MnZn ferrites. Therefore, it can be known that the MnZn ferrite homogeneous fibers prepared by the solvothermal method had high purity, good crystallinity, and smooth 1D fibrous structures, which were homogeneous with MnZn ferrites.

Figure 1.

(a,b) SEM image and XRD spectrum of the MnZn ferrite homogeneous fibers.

3.2. Microstructure Characterization Analysis of MnZn Ferrite

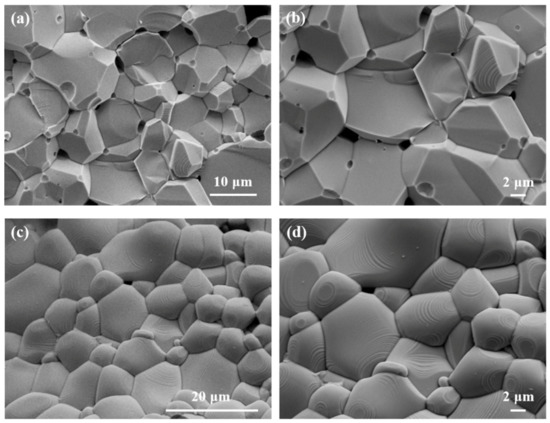

The SEM images of typical MnZn ferrite samples are shown in Figure 2. Figure 2a,b display a cross-sectional morphology of ordinary MnZn ferrite with 0 wt% MnZn ferrite homogeneous fibers. Figure 2c,d reveal a representative cross-sectional morphology of homogeneous-fiber-reinforced MnZn ferrite with 2 wt% MnZn ferrite homogeneous fibers. It can be clearly seen from Figure 2a,b that the 0 wt% ordinary MnZn ferrite sample had a relatively good crystal structure, while there were small pores between the grains of the sample. With the introduction of MnZn ferrite homogenous fibers, it can be noticed from Figure 2c,d that the 2 wt% homogeneous-fiber-reinforced MnZn ferrite sample had a more uniform and compact crystal structure. Meanwhile, the sample exhibited less porosity and fewer grain boundaries.

Figure 2.

SEM images of typical MnZn ferrite samples. (a,b) 0 wt% ordinary MnZn ferrite; (c,d) 2 wt% homogeneous-fiber-reinforced MnZn ferrite.

This was because the introduction of MnZn ferrite homogenous fibers took the bridge between the grains, which could induce grain crystallization and promote the homogeneity of the materials. In addition, the nanoscale MnZn ferrite homogeneous fibers with finer grain size than the MnZn ferrite particles could make the composite powders rearrange at the low-temperature sintering stage, and the homogeneous fibers can be filled into the small pores between the grains, gradually eliminating the pores and grain boundaries of materials. Thus, the homogeneous-fiber-reinforced MnZn ferrite exhibited a better microstructure compared with the ordinary MnZn ferrite.

3.3. Magnetic Properties Analysis of the Homogeneous Fiber Reinforced MnZn Ferrite

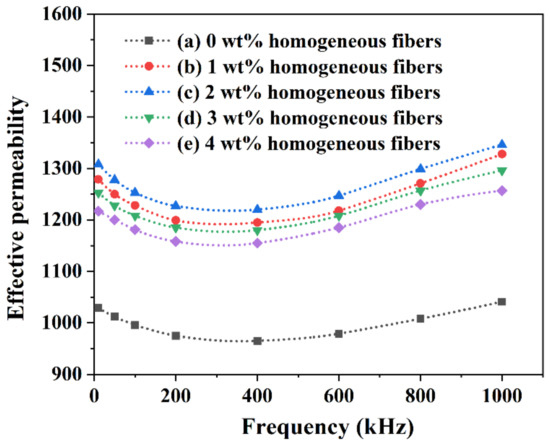

To understand the function of MnZn ferrite homogeneous fibers on the magnetic properties of the homogeneous-fiber-reinforced MnZn ferrites, the effective permeability and magnetic loss of the homogeneous-fiber-reinforced MnZn ferrite samples prepared with different fiber contents (0 wt% to 4 wt%) were measured by an LCR meter and magnetic automatic test device, respectively. The effective permeability of the homogeneous-fiber-reinforced MnZn ferrite samples with different fiber contents (0 wt% to 4 wt%) versus frequency at room temperature is shown in Figure 3. It can be seen that the effective permeability of all samples first decreased and then gradually increased with the increase in the frequency range from 10 kHz to 1000 kHz. At the same frequency, the effective permeability of the 1 wt%, 2 wt%, 3 wt%, and 4 wt% homogeneous-fiber-reinforced MnZn ferrite samples was higher than that of the ordinary MnZn ferrite sample with 0 wt% homogeneous fibers. In addition, it can be found that the effective permeability of the homogeneous-fiber-reinforced MnZn ferrite samples increased with the increase in fiber content as the content of MnZn ferrite homogeneous fibers was less than 2 wt%, and then gradually decreased with the increase in fiber content as the fiber content was larger than 2 wt%. The effective permeability reached a maximum as the fiber content was 2 wt%.

Figure 3.

Effective permeability of the homogeneous-fiber-reinforced MnZn ferrite samples versus frequency at room temperature: (a) 0 wt%, (b) 1 wt%, (c) 2 wt%, (d) 3 wt%, and (e) 4 wt%.

It can be known that the internal grain size and grain interface structure of MnZn ferrite materials affected the dynamic balance during the magnetization process [17]. The permeability was directly proportional to the average grain sizes and inversely proportional to the number of grain boundaries and pores [18]. Ordinary MnZn ferrite with 0 wt% homogeneous fibers had more pores and grain boundaries than the homogeneous-fiber-reinforced MnZn ferrites, so the effective permeability was relatively low. As the homogeneous fiber content increased, the crystal grains gradually grew and became uniform, so the pores were gradually eliminated and the effective permeability gradually increased. When the homogeneous fiber content exceeded 2 wt%, owing to the fact that the fibers deposited at grain boundaries and impeded domain wall motion, the permeability decreased.

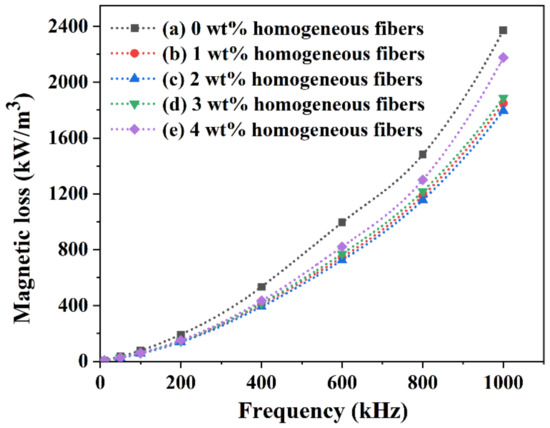

Figure 4 shows the magnetic loss of the homogeneous-fiber-reinforced MnZn ferrite samples with different fiber contents (0 wt% to 4 wt%) versus frequency at room temperature. It can be found that the magnetic loss of all samples increased gradually with the increase in frequency. At the same frequency, the magnetic loss of the homogeneous-fiber-reinforced MnZn ferrite samples with the fiber content from 1 wt% to 4 wt% was lower than that of the ordinary MnZn ferrite sample with 0 wt% homogeneous fibers. In addition, the magnetic loss of the homogeneous-fiber-reinforced MnZn ferrite samples first decreased and then gradually increased with the rise in the homogeneous fiber contents from 1 wt% to 4 wt%. The minimum magnetic loss was obtained as the fiber content was 2 wt%.

Figure 4.

Magnetic loss of the homogeneous-fiber-reinforced MnZn ferrite samples versus frequency at room temperature: (a) 0 wt%, (b) 1 wt%, (c) 2 wt%, (d) 3 wt%, and (e) 4 wt%.

The cause of this phenomenon was that the MnZn ferrite with 2 wt% homogeneous fibers had a uniform and compact crystal structure, which could effectively restrain the interaction between magnetic particles and greatly reduce the magnetic loss. Thus, a certain content of MnZn ferrite homogenous fibers was beneficial to improve the magnetic properties of MnZn ferrite materials. Meanwhile, the homogeneous-fiber-reinforced MnZn ferrite materials exhibited the best magnetic properties as the fiber content was about 2 wt%.

3.4. Mechanical Properties Analysis of the Homogeneous-Fiber-Reinforced MnZn Ferrite

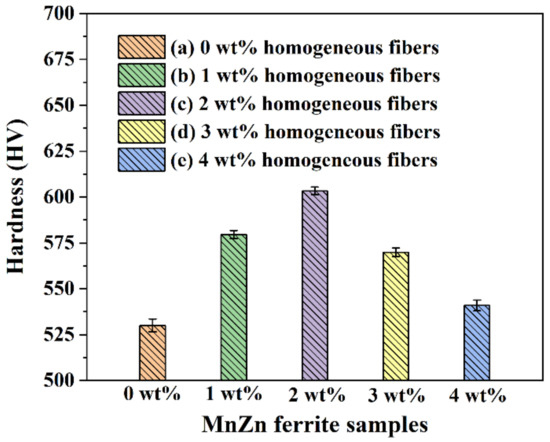

To study the impact of the MnZn ferrite homogeneous fibers on the mechanical properties of the homogeneous-fiber-reinforced MnZn ferrites, the Vickers hardness of the homogeneous-fiber-reinforced MnZn ferrite samples synthesized with different fiber contents (0 wt% to 4 wt%) was measured by the hardness tester. Figure 5 shows the Vickers hardness of the homogeneous-fiber-reinforced MnZn ferrite samples with different fiber contents (0 wt% to 4 wt%). Meanwhile, the Vickers hardness values for seven groups of repetitive tests of the homogeneous-fiber-reinforced MnZn ferrite samples with different fiber contents (0 wt% to 4 wt%) are shown in Table 1. As we can see, the average Vickers hardness values of 0 wt%, 1 wt%, 2 wt%, 3 wt%, and 4 wt% homogeneous-fiber-reinforced MnZn ferrite samples were 530.1, 579.6, 603.3, 585.1, and 540.9 HV, respectively. The corresponding standard deviations of the samples were 3.49, 2.16, 2.06, 3.06, and 2.96 HV. It can be seen that the deviations in Vickers hardness for the samples were within a certain range. The results indicated that the 1 wt%, 2 wt%, 3 wt%, and 4 wt% homogeneous-fiber-reinforced MnZn ferrite samples had a much higher Vickers hardness than the 0 wt% ordinary MnZn ferrite sample. At the same time, the Vickers hardness of the corresponding homogeneous-fiber-reinforced MnZn ferrite samples first increased and then gradually decreased with the increase in homogeneous fiber contents from 1 wt% to 4 wt%. In addition, the maximum Vickers hardness was obtained as the fiber content was 2 wt%, which was consistent with the test results of magnetic properties.

Figure 5.

Vickers hardness of homogeneous-fiber-reinforced MnZn ferrite samples with different fiber contents: (a) 0 wt%, (b) 1 wt%, (c) 2 wt%, (d) 3 wt%, and (e) 4 wt%.

Table 1.

Vickers hardness values for seven repetitions of homogeneous-fiber-reinforced MnZn ferrite samples with different fiber contents: (a) 0 wt%, (b) 1 wt%, (c) 2 wt%, (d) 3 wt%, and (e) 4 wt%.

It is known that good crystal structure is the guarantee of materials with high magnetic and mechanical properties. For the homogeneous-fiber-reinforced MnZn ferrite materials, the MnZn ferrite homogeneous fibers were used as the reinforcing phase to construct a co-reinforced structure of homogeneous fibers and particles. In this co-reinforced structure, the homogeneous fibers could effectively weaken the damage caused by stress concentration, so the particles could improve the microregional stress distribution of materials [19,20]. In the crystallization process, the added homogeneous fibers could bridge between the original particles, providing more paths for the diffusion of atoms during sintering, strengthening the reaction and crystallization kinetic conditions. In addition, the addition of fibers had an impact on the movement of dislocations on the matrix. The fibers were obstacles for the dislocation movement, and internal stresses also occurred. Therefore, the hardness of MnZn ferrite materials increased. More importantly, the MnZn ferrite homogeneous fibers had the same chemical composition, perfect lattice matching, and good surface wettability with the MnZn ferrite particles [21,22]. It can completely overcome the problem of unstable interface structures between heterogeneous fibers and particles, due to their different thermal conductivity, thermal expansion coefficient, elastic modulus, and Poisson’s ratio. Accordingly, the strength and stability of homogeneous-fiber-reinforced MnZn ferrite materials were enhanced. Thus, doping a certain content of MnZn ferrite homogenous fibers gave an optimized crystal structure of MnZn ferrite materials, improving the strength and stability of materials. Meanwhile, homogeneous-fiber-reinforced MnZn ferrite materials exhibited the best mechanical properties as the fiber content was about 2 wt%.

4. Conclusions

In this paper, we put forward a MnZn ferrite homogeneous-fiber- and particle-co-reinforced structure and revealed the effect of MnZn ferrite homogeneous fibers (0 wt% to 4 wt%) doping on the microstructures as well as magnetic and mechanical characteristics of MnZn ferrite materials. The result showed that MnZn ferrite homogeneous fibers prepared via the solvothermal method exhibited high purity, good crystallinity, and smooth 1D fibrous structures, which were homogeneous with MnZn ferrite materials. In addition, the homogeneous-fiber-reinforced MnZn ferrite materials had a denser crystal structure, less porosity, and fewer grain boundaries, exhibiting excellent properties of high permeability, low magnetic loss, and high Vickers hardness in comparison to 0 wt% ordinary MnZn ferrite materials. Simultaneously, the magnetic and mechanical properties of the homogeneous-fiber-reinforced MnZn ferrites first increased and then gradually decreased with the rise in the homogeneous fiber contents from 1 wt% to 4 wt%. The optimal content of the homogeneous fibers was around 2 wt%.

Author Contributions

Conceptualization, Z.D. and Y.S.; methodology, Y.S. and F.L.; validation, Y.S., F.L. and Z.D.; formal analysis, Y.S.; investigation, Y.S.; resources, Z.D.; data curation, Y.S.; writing—original draft preparation, Y.S.; writing—review and editing, Y.S., F.L. and Z.D.; visualization, Y.S.; supervision, F.L. and Z.D.; project administration, Z.D; funding acquisition, Z.D. All authors have read and agreed to the published version of the manuscript.

Funding

The work was supported by the National Natural Science Foundation of China Youth Fund “Homogeneous fiber and strong magnetic field control the axial crystallization and performance of large aspect ratio MnZn ferrite” (51907186), the STS Regional Key Project of the Chinese Academy of Sciences “Induction heating key magnetic permeability preparation and industrialization technology development” (KFJ-STS-QYZD-142), and the Beijing Municipal Science and Technology Commission Huairou Science City Special Project “Induction heating key permeable magnet preparation and industrial application” (Z201100008420008).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Wang, S.-F.; Chiang, Y.-J.; Hsu, Y.-F.; Chen, C.-H. Effects of additives on the loss characteristics of Mn-Zn ferrite. J. Magn. Magn. Mater. 2014, 365, 119–125. [Google Scholar] [CrossRef]

- Wu, G.H.; Yu, Z.; Sun, K.; Guo, R.D.; Zhang, H.Y.; Jiang, X.N.; Wu, C.J.; Lan, Z.W. Ultra-low core losses at high frequencies and temperatures in MnZn ferrites with nano-BaTiO3 additives. J. Alloy. Compd. 2020, 821, 153573. [Google Scholar] [CrossRef]

- Wang, X.Y.; Yi, S.B.; Wu, C.; Bai, G.H.; Yan, M. Correlating the microstructure and magnetic properties of MnZn power ferrites via Co2O3 and MoO3 co-doping for MHz applications. J. Magn. Magn. Mater. 2021, 538, 168324. [Google Scholar] [CrossRef]

- Petrescu, L.-G.; Petrescu, M.-C.; Ioniță, V.; Cazacu, E.; Constantinescu, C.-D. Magnetic properties of manganese-zinc soft ferrite ceramic for high frequency applications. Materials 2019, 12, 3173. [Google Scholar] [CrossRef] [PubMed]

- Yi, S.B.; Bai, G.H.; Wang, X.Y.; Zhang, X.F.; Hussain, A.; Jin, J.Y.; Yan, M. Development of high-temperature high-permeability MnZn power ferrites for MHz application by Nb2O5 and TiO2 co-dopin. Ceram. Int. 2020, 46, 8935–8941. [Google Scholar] [CrossRef]

- Fang, X.G.; Ma, D.Y.; Sun, B.W.; Xu, X.P.; Quan, W.; Xiao, Z.S.; Zhai, Y.Y. A high-performance magnetic shield with MnZn ferrite and Mu-metal film combination for atomic sensors. Materials 2022, 15, 6680. [Google Scholar] [CrossRef]

- Nie, J.H.; Li, H.H.; Feng, Z.K.; He, H.H. The effect of nano-SiO2 on the magnetic properties of the low power loss manganese-zinc ferrites. J. Magn. Magn. Mater. 2003, 265, 172–175. [Google Scholar] [CrossRef]

- Žnidaršič, A.; Drofenik, M. High-resistivity grain boundaries in CaO-doped MnZn ferrites for high-frequency power application. J. Am. Ceram. Soc. 1999, 82, 359–365. [Google Scholar] [CrossRef]

- Guo, R.D.; Yang, X.F.; Sun, K.; Li, K.W.; Yu, Z.; Wu, G.H.; Zhang, X.F.; Jiang, X.N.; Lan, Z.W. Temperature characteristics of core losses for HfO2 doped manganese-zinc ferrites. J. Magn. Magn. Mater. 2019, 491, 165554. [Google Scholar] [CrossRef]

- Zaspalis, V.T.; Eleftheriou, E. The effect of TiO2 on the magnetic power losses and electrical resistivity of polycrystalline MnZn-ferrites. J. Phys. D Appl. Phys. 2005, 38, 2156. [Google Scholar] [CrossRef]

- Huang, A.P.; He, H.H.; Feng, Z.K. Effects of SnO2 addition on the magnetic properties of manganese zinc ferrites. J. Magn. Magn. Mater. 2006, 301, 331–335. [Google Scholar]

- Sun, K.; Lan, Z.W.; Yu, Z.; Li, L.Z.; Ji, H.N.; Xu, Z.Y. Effects of NiO addition on the structural, microstructural and electromagnetic properties of manganese-zinc ferrite. Mater. Chem. Phys. 2009, 113, 797–802. [Google Scholar] [CrossRef]

- Hussain, A.; Bai, G.H.; Huo, H.X.; Yi, S.B.; Wang, X.Y.; Fan, X.Y.; Yan, M. Co2O3 and SnO2 doped MnZn ferrites for applications at 3–5 MHz frequencies. Ceram. Int. 2019, 45, 12544–12549. [Google Scholar] [CrossRef]

- Chen, S.H.; Chang, S.C.; Tsay, C.Y.; Liu, K.S.; Lin, I.N. Improvement on magnetic power loss of MnZn-ferrite materials by V2O5 and Nb2O5 co-doping. J. Eur. Ceram. Soc. 2001, 21, 1931–1935. [Google Scholar] [CrossRef]

- Andrei, P.; Caltun, O.F.; Papusoi, C.; Stancu, A.; Feder, M. Losses and magnetic properties of Bi2O3 doped MnZn ferrites. J. Magn. Magn. Mater. 1999, 196, 362–364. [Google Scholar] [CrossRef]

- Gu, M.; Liu, G.Q. Effects of MoO3 and TiO2 additions on the magnetic properties of manganese-zinc power ferrites. J. Alloy. Compd. 2009, 475, 356–360. [Google Scholar] [CrossRef]

- Matsuo, Y.; Ono, K.; Hashimoto, T.; Nakao, F. Magnetic properties and mechanical strength of MnZn ferrite. IEEE Trans. Magn. 2001, 37, 2369–2372. [Google Scholar] [CrossRef]

- Luo, F.; Duan, Z.X.; Zhang, Y.Y.; Shang, Y.J. Influence of microstructure optimization on magnetic and thermal properties of MnZn ferrite. J. Mater. Sci. Mater. Electron. 2021, 21, 15633–15642. [Google Scholar] [CrossRef]

- Wang, H.L.; Wang, C.A.; Chen, D.L.; Xu, H.L.; Lu, H.X.; Zhang, R.; Feng, L. Preparation and characterization of ZrB2-SiC ultra-high temperature ceramics by microwave sintering. Front. Mater. Sci. China 2010, 4, 276–280. [Google Scholar] [CrossRef]

- Ma, F.C.; Lu, S.Y.; Liu, P.; Li, W.; Liu, X.K.; Chen, X.H.; Zhang, K.; Pan, D. Evolution of strength and fibers orientation of a short-fibers reinforced Ti-matrix composite after extrusion. Mater. Des. 2017, 126, 297–304. [Google Scholar] [CrossRef]

- Gu, M.; Liu, G.Q.; Wang, W. Study of Mn3O4 doping to improve the magnetic properties of MnZn ferrites. Mater. Sci. Eng. B 2009, 158, 35–39. [Google Scholar] [CrossRef]

- Choi, M.S.; Kang, S.-T.; Lee, B.Y.; Koh, K.-T.; Ryu, G.-S. Improvement in predicting the post-cracking tensile behavior of ultra-high performance cementitious composites based on fiber orientation distribution. Materials 2016, 9, 829. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).