Effect of Al and La Doping on the Structure and Magnetostrictive Properties of Fe73Ga27 Alloy

Abstract

1. Introduction

2. Materials and Methods

3. Results

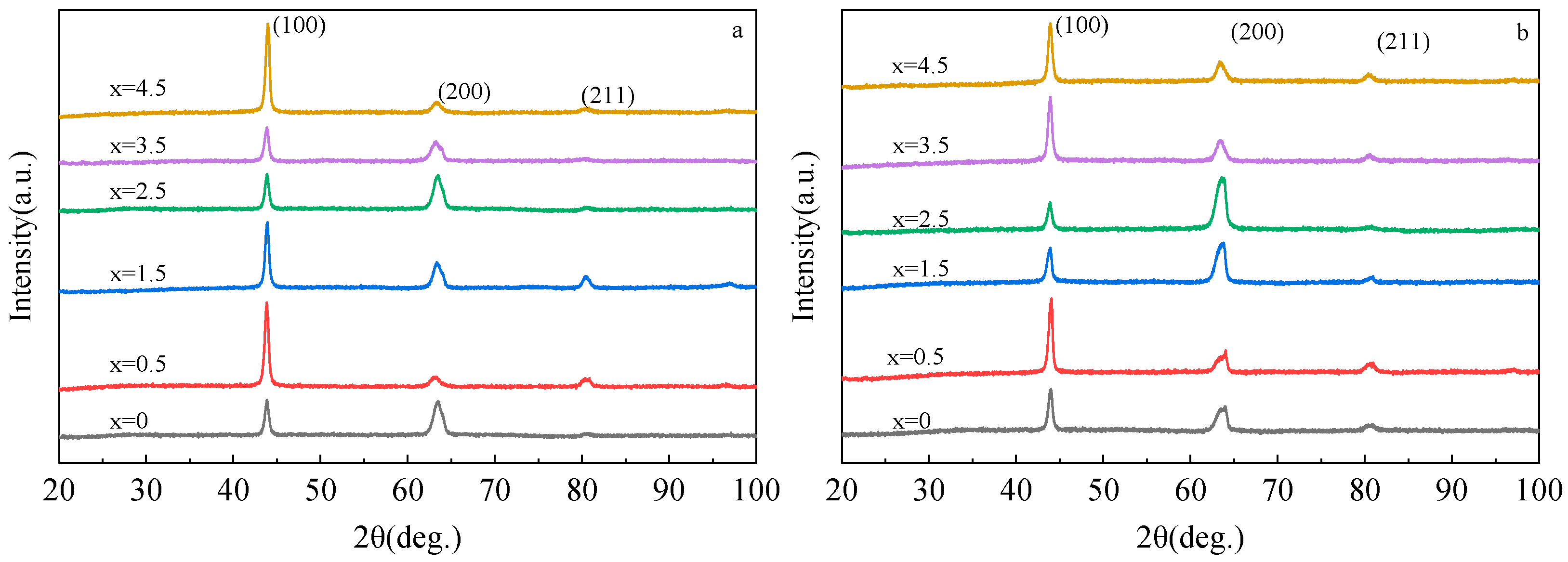

3.1. XRD Analysis

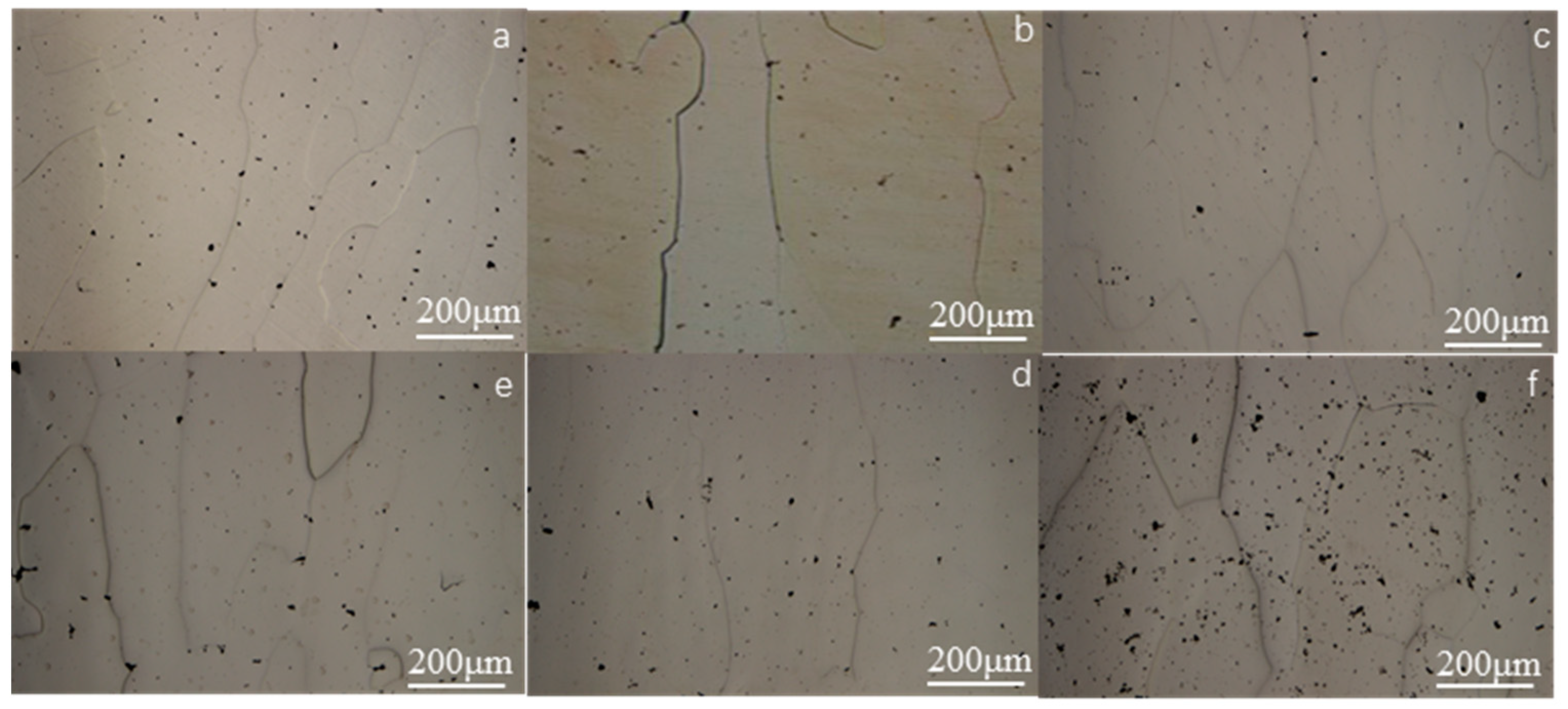

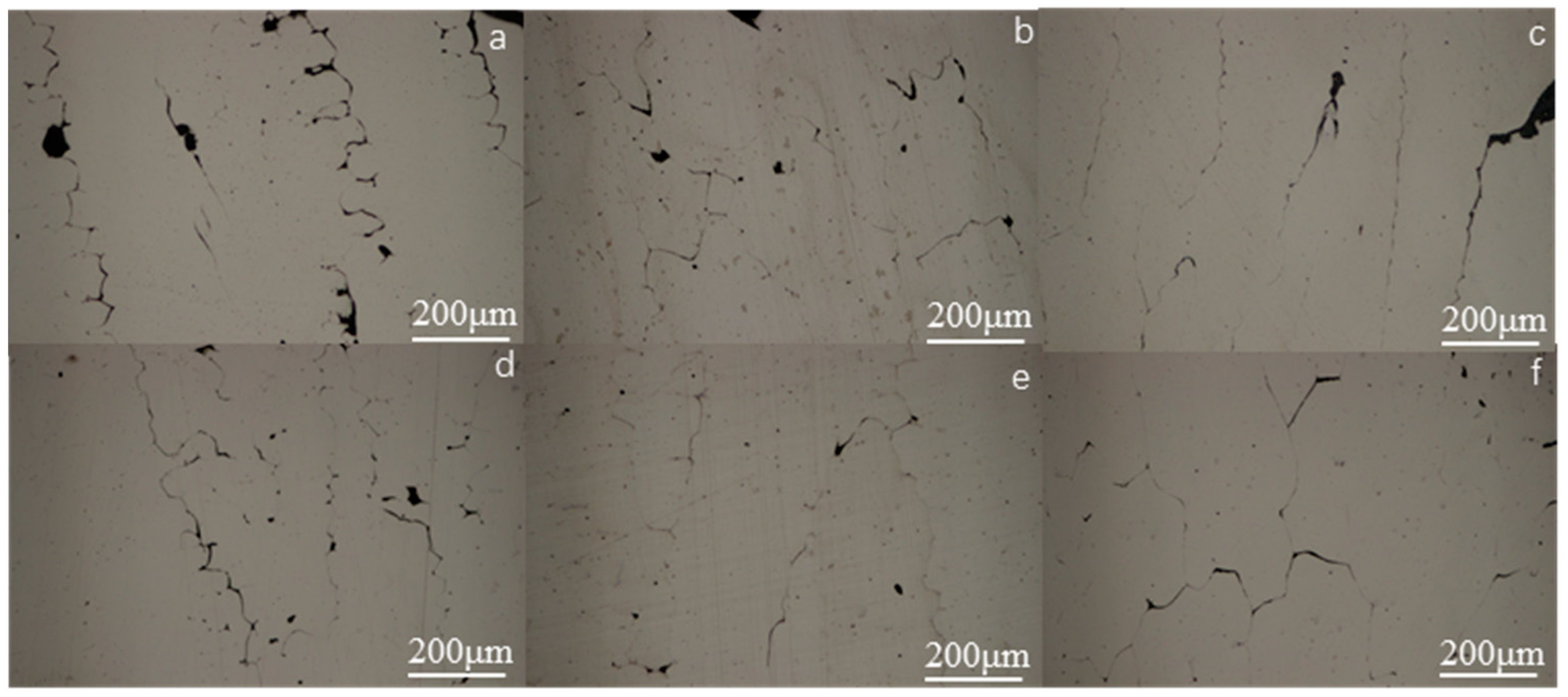

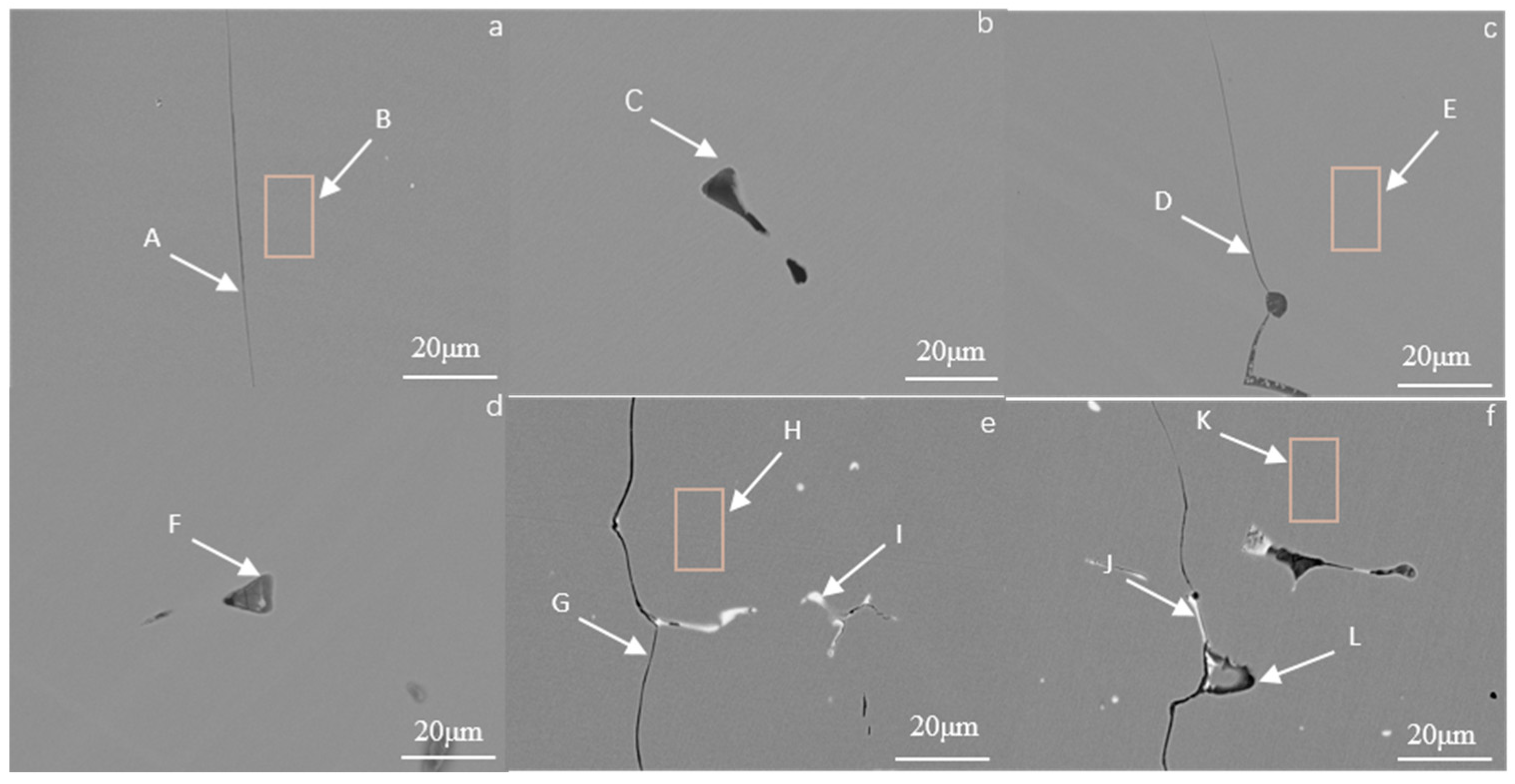

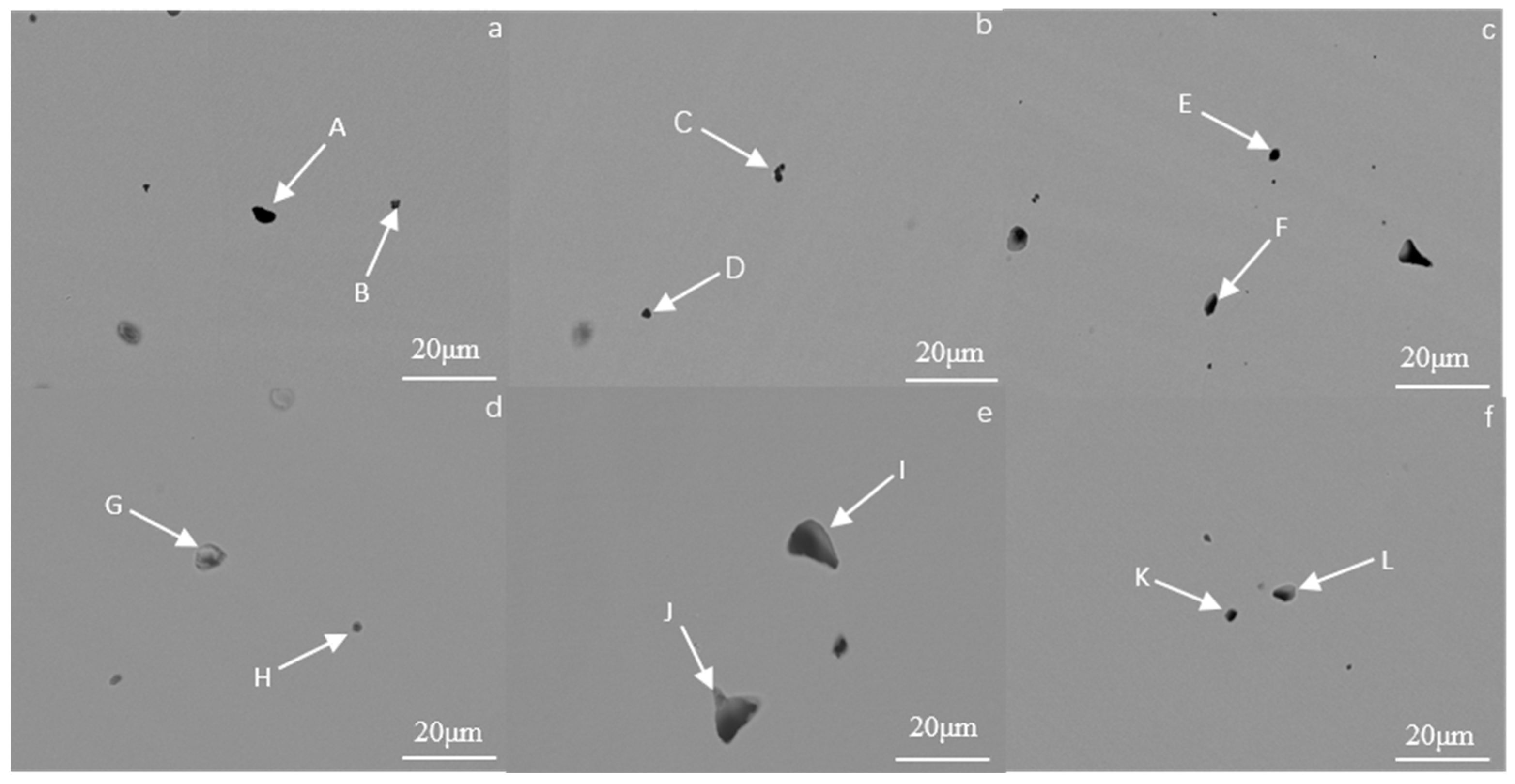

3.2. Analysis of Alloy Structure and Morphology

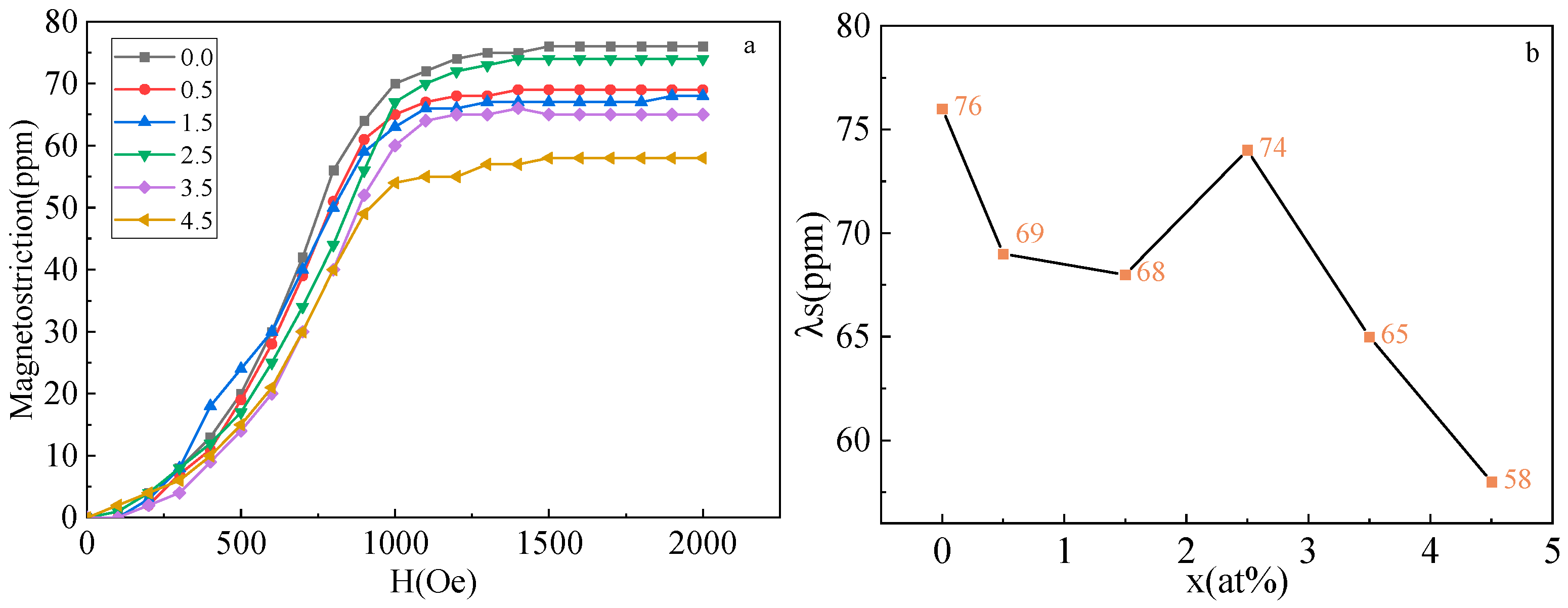

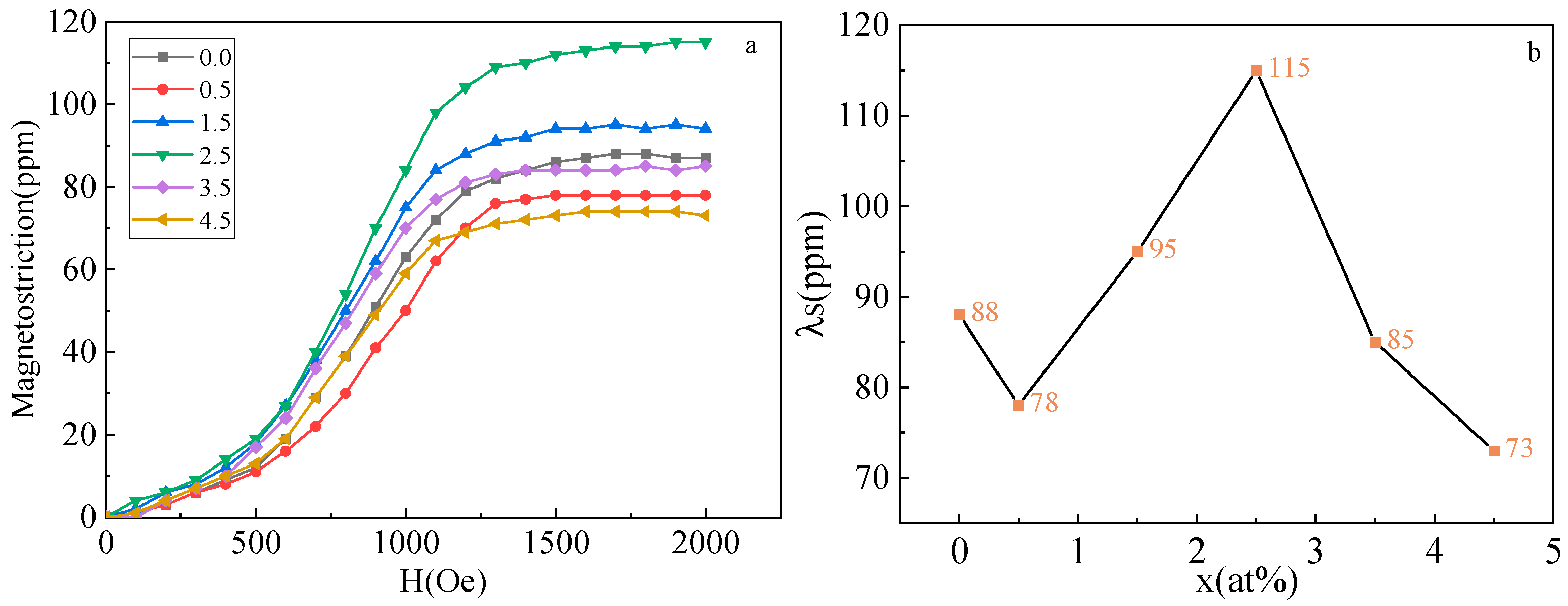

3.3. Magnetostriction Properties

3.4. Microhardness

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Clark, A.E. Ferromagnetic Materials; North-Holland: Amsterdam, The Netherlands, 1980. [Google Scholar]

- Liu, H.F.; Lim, C.W.; Gao, S.Z.; Zhao, J. Effects analysis of bias and excitation conditions on power output of an environmental vibration energy harvesting device using Fe-Ga slice. Mechatronics 2019, 57, 20. [Google Scholar] [CrossRef]

- Flatau, A.B.; Stadler, B.J.H.; Park, J.; Reddy, K.S.M.; Chaitany, P.R.D.; Mudivarthi, C.; van Ordera, M. Magnetostrictive Fe-Ga Nanowires for Actuation and Sensing Applications; Woodhead Publishing: Sawston, UK, 2020; p. 737. [Google Scholar]

- Qiao, R.H.; Gou, J.M.; Yang, T.Z.; Zhang, Y.; Liu, F.; Hu, S.; Ma, T. Enhanced damping capacity of ferromagnetic Fe-Ga alloys by introducing structural defects. J. Mater. Sci. Technol. 2021, 84, 173. [Google Scholar] [CrossRef]

- Wang, N.J.; Liu, Y.; Zhang, H.W.; Chen, X.; Li, Y. Fabrication, magnetostriction properties and applications of Tb-Dy-Fe alloys: A review. China Foundry 2016, 13, 75. [Google Scholar] [CrossRef]

- Clark, A.E.; Wun-Fogle, M. Restorff, J.B.; Dennis, K.W.; Lograsso, T.A.; McCallum, R.W. Temperature dependence of the magnetic anisotropy and magnetostriction of Fe100−xGax (x = 8.6, 16.6, 28.5). J. Appl. Phys. 2005, 97, 10M316. [Google Scholar] [CrossRef]

- Xu, S.F. Study on the Physical Properties of Fe-Ga Magnetostrictive Alloys; Jilin University: Changchun, China, 2008. [Google Scholar]

- Li, H. Effect of Ce and Tb Doping on Magnetostrictive Properties of Fe-Ga-Al Alloy; Inner Mongol University of Technology: Hohhot, China, 2021. [Google Scholar]

- Srisukhumbowornchai, N.; Guruswamy, S. Large magnetostriction in directionally solidified Fe-Ga and Fe-Ga-A1 alloys. J. Appl. Phys. 2001, 90, 5680–5688. [Google Scholar] [CrossRef]

- Han, Z.Y.; Gao, X.S.; Zhang, M.C.; Zhou, S. <110>Pressure effect of magnetostrictive strain in axially oriented polycrystalline Fe-Ga alloy. In Proceedings of the 2002 China Materials Conference, Beijing, China, 1 October 2002; pp. 375–379. [Google Scholar]

- Yu, Q.G.; Jiang, L.P.; Zhang, G.R.; Hao, H.B.; Wu, S.X.; Zhao, Z.Q. Effect of Tb on the magnetostrictive properties of Fe83Ga17 alloy. Rare Earth 2010, 31, 21–24. [Google Scholar]

- Jiang, L.; Zhang, G.; Yang, J.; Hao, H.; Wu, S.; Zhao, Z. Research on microstructure and magnetostriction of Fe83Ga17Dyx alloys. J. Rare Earths 2010, 28, 409–412. [Google Scholar] [CrossRef]

- Meng, C.Z.; Wu, Y.; Jiang, C.B. Design of high ductility FeGa magnetostrictive alloys: Tb doping and directional solidification. Mater. Des. 2017, 130, 183–189. [Google Scholar] [CrossRef]

- Yao, Z.Q.; Zhao, Z.Q.; Jiang, L.P.; Hao, H.B.; Wu, S.X.; Zhang, G.R.; Yang, J.D. Effect of rare earth Ce addition on microstructure and magnetostrictive properties of Fe83Ga17 alloy. Acta Metall. Sin. 2013, 49, 87–91. [Google Scholar] [CrossRef]

- Clark, A.E.; Hathaway, K.B.; Wun-Fogle, M.; Restorff, J.B.; Lograsso, T.A.; Keppens, V.; Petculescu, G.; Taylor, R.A. Extraordinary magnetoelasticity and lattice softening in bcc Fe-Ga alloys. J. Appl. Phys. 2003, 93, 8621–8623. [Google Scholar] [CrossRef]

- Ning, S.Q. Effect of A1 on Microstructure and Magnetostrictive Strain of Fe81Gal9 Alloy; Inner Mongol University of Technology: Hohhot, China, 2015. [Google Scholar]

- Yao, Z.; Tian, X.; Jiang, L.; Hao, H.; Zhang, G.; Wu, S.; Zhao, Z.; Gerile, N. Influences of rare earth element Ce-doping and melt-spinning on microstructure and magnetostriction of Fe83Ga17 alloy. J. Alloy. Compd. 2015, 42, 431–435. [Google Scholar] [CrossRef]

- Li, J.X.; Gao, X.S.; Zhu, J. Effect of atomic vacancies on magnetostrictive properties of directionally solidified Fe-Ga alloys. Chin. J. Rare Met. 2017, 41, 155–162. [Google Scholar]

- Xu, H.J. Fundamentals of Materials Science, 1st ed.; Beijing University of Technology Press: Beijing, China, 2001; p. 56. [Google Scholar]

- Cheng, S.; Das, B.; Wun-Fogle, M.; Lubitz, P.; Clark, A. Structure of melt-spun Fe-Ga-based magnetostrictive alloys. IEEE Trans. Magn. 2002, 38, 2838–2840. [Google Scholar] [CrossRef]

- Gong, P.; Jiang, L.P.; Yan, W.J.; Zhao, Z.Q. Effect of Y on microstructure and magnetostrictive properties of as-cast Fe81Ga19 alloy. Chin. Rare Earths 2016, 37, 91–95. [Google Scholar]

- Zhang, M.C.; Jiang, H.L.; Gao, X.X.; Zhu, J.; Zhou, S.Z. Magnetostriction and microstructure of rolled Fe83Ga17Er0.4 alloy. Chin. J. Rare Met. 2016, 37, 75–79. [Google Scholar]

- Cui, Z.X. Metallogy and Heat Treatment, 1st ed.; China Machine Press: Beijing, China, 1989; p. 54. [Google Scholar]

- Clark, A.E.; Wun-Fogle, M.; Restorff, J.B.; Lograsso, T.A. Effect of quenching on the magnetostriction of Fe1-xGax. IEEE Trans. Magn. 2001, 37, 2678–2680. [Google Scholar] [CrossRef]

- Liu, G.Z. Effect of Adding the Third Group of Elements (C, B, Al, Cu) on Phase Structure and Magnetostrictive Properties of Fe-Ga Alloy; Lanzhou University of Technology: Lanzhou, China, 2010. [Google Scholar]

- Yao, T. Study on the Influence of Adding Co and Tb Elements on the Structure and Magnetic Properties of Fe-Ga Alloy; Inner Mongol University of Technology: Hohhot, China, 2021. [Google Scholar]

- Wang, R.; Tian, X.; Yao, Z.Q.; Zhao, X.; Hao, H.B.; Tian, R.N.; Ou, Z.Q.; Zhao, X.T. Effects of trace rare earth elements Tb and La doping on the structure and magnetostrictive properties of Fe-Al alloy. Chin. Rare Earths 2020, 41, 24–31. [Google Scholar]

- Yan, S.W.; Mou, X.; Qi, Y.; Xu, L.H.; Zhang, H.P. Research progress on mechanical properties strengthening of Fe-Ga magnetostrictive alloy. Iron Steel 2022, 57, 79–90. [Google Scholar]

| Types of Alloys | Fe73Ga27−xAlx | (Fe73Ga27−xAlx)99.9La0.1 | ||

|---|---|---|---|---|

| x(%) | a(Å) | I200/I110(%) | a(Å) | I200/I110(%) |

| 0 | 2.9251 | 83.8 | 2.9142 | 42.8 |

| 0.5 | 2.9263 | 9.3 | 2.9155 | 22.1 |

| 1.5 | 2.9289 | 33.1 | 2.9157 | 89.0 |

| 2.5 | 2.9203 | 80.4 | 2.9132 | 140.77 |

| 3.5 | 2.9215 | 46.7 | 2.9184 | 28.6 |

| 4.5 | 2.9243 | 10.0 | 2.9226 | 26.9 |

| Micro-Zones | Fe73Ga27−xAlx | Micro-Zones | (Fe73Ga27−xAlx)99.9La0.1 | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Fe | Ga | Al | Fe | Ga | Al | La | ||||

| x = 0 | A | 69.33 | 30.67 | 0 | x = 0 | G | 50.39 | 39.65 | 0 | 9.96 |

| B | 73.87 | 26.13 | 0 | H | 75.25 | 24.69 | 0 | 0.06 | ||

| C | 77.56 | 22.44 | 0 | I | 36.92 | 47.78 | 0 | 15.30 | ||

| x = 2.5 | D | 72.02 | 27.52 | 0.46 | x = 2.5 | J | 74.99 | 23.87 | 1.10 | 0.05 |

| E | 72.22 | 27.06 | 0.72 | K | 74.77 | 23.99 | 2.19 | 0.06 | ||

| F | 80.06 | 18.52 | 1.42 | L | 17.68 | 58.13 | 0.44 | 23.75 | ||

| Micro-Zones | Fe73Ga27−xAlx | Micro-Zones | Fe73Ga27−xAlx | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Fe | Ga | Al | Fe | Ga | Al | ||||

| x = 0 | A | 83.45 | 16.55 | 0 | x = 2.5 | G | 71.75 | 26.71 | 1.53 |

| B | 73.87 | 26.13 | 0 | H | 71.94 | 25.95 | 2.11 | ||

| x = 0.5 | C | 29.81 | 10.30 | 59.89 | x = 3.5 | I | 77.77 | 22.10 | 0.13 |

| D | 30.39 | 9.16 | 60.45 | J | 78.24 | 21.76 | 0 | ||

| x = 1.5 | E | 76.82 | 23.18 | 0 | x = 4.5 | K | 34.25 | 10.07 | 55.68 |

| F | 77.08 | 22.92 | 0 | L | 72.54 | 24.81 | 2.65 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Du, J.; Gong, P.; Li, X.; Ning, S.; Song, W.; Wang, Y.; Hao, H. Effect of Al and La Doping on the Structure and Magnetostrictive Properties of Fe73Ga27 Alloy. Materials 2023, 16, 12. https://doi.org/10.3390/ma16010012

Du J, Gong P, Li X, Ning S, Song W, Wang Y, Hao H. Effect of Al and La Doping on the Structure and Magnetostrictive Properties of Fe73Ga27 Alloy. Materials. 2023; 16(1):12. https://doi.org/10.3390/ma16010012

Chicago/Turabian StyleDu, Jinchao, Pei Gong, Xiao Li, Shaoqi Ning, Wei Song, Yuan Wang, and Hongbo Hao. 2023. "Effect of Al and La Doping on the Structure and Magnetostrictive Properties of Fe73Ga27 Alloy" Materials 16, no. 1: 12. https://doi.org/10.3390/ma16010012

APA StyleDu, J., Gong, P., Li, X., Ning, S., Song, W., Wang, Y., & Hao, H. (2023). Effect of Al and La Doping on the Structure and Magnetostrictive Properties of Fe73Ga27 Alloy. Materials, 16(1), 12. https://doi.org/10.3390/ma16010012