Stressing State Analysis of Partially Prestressed Concrete Beams with High Strength Reinforcement Based on NSF Method

Abstract

:1. Introduction

2. Method and Theory of Structural Stress State

2.1. Numerical Description of the Structural Stressing State

2.2. Application of Mann–Kendall Criterion

3. Experimental Introduction

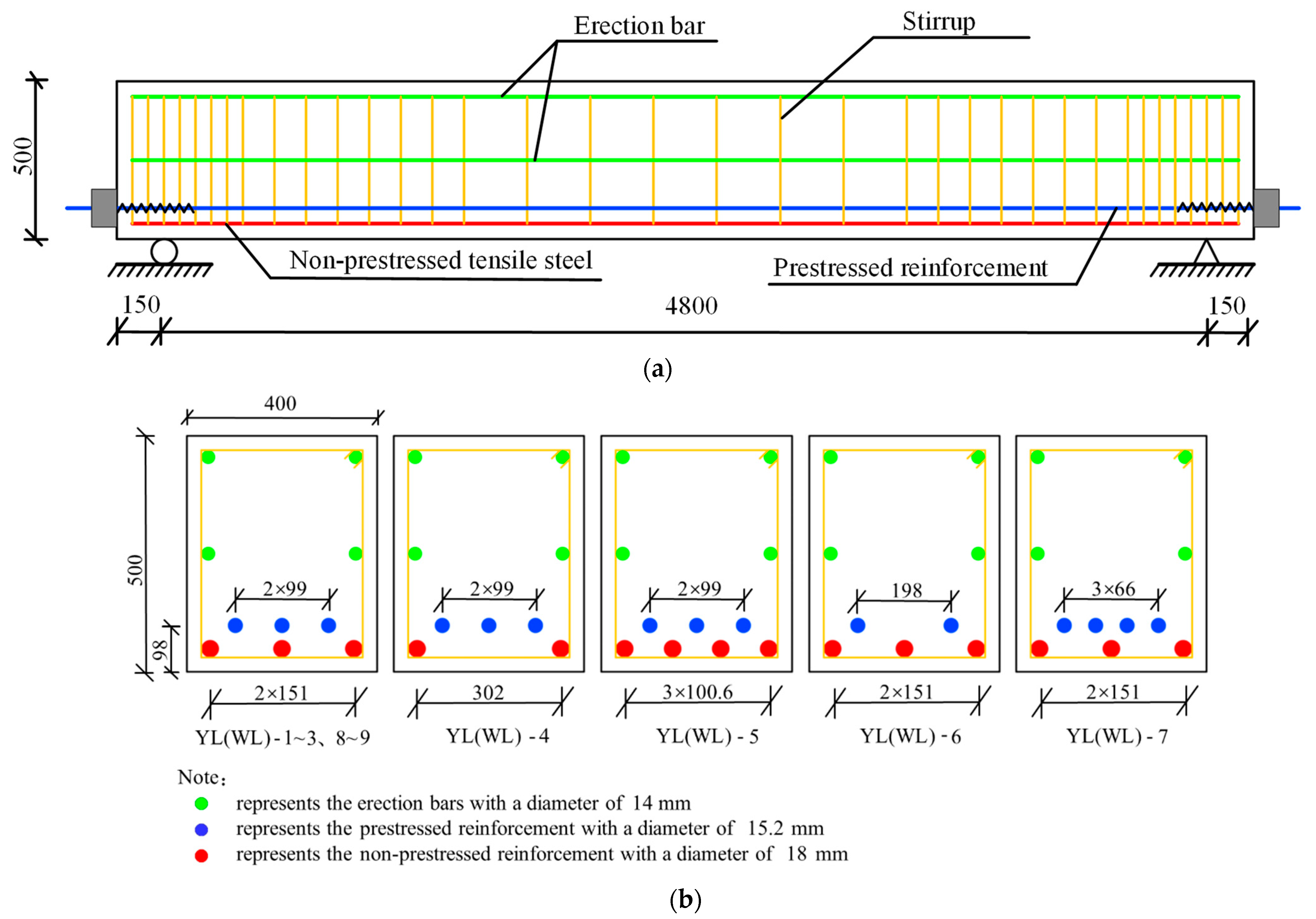

3.1. Design and Fabrication of the Test Beam

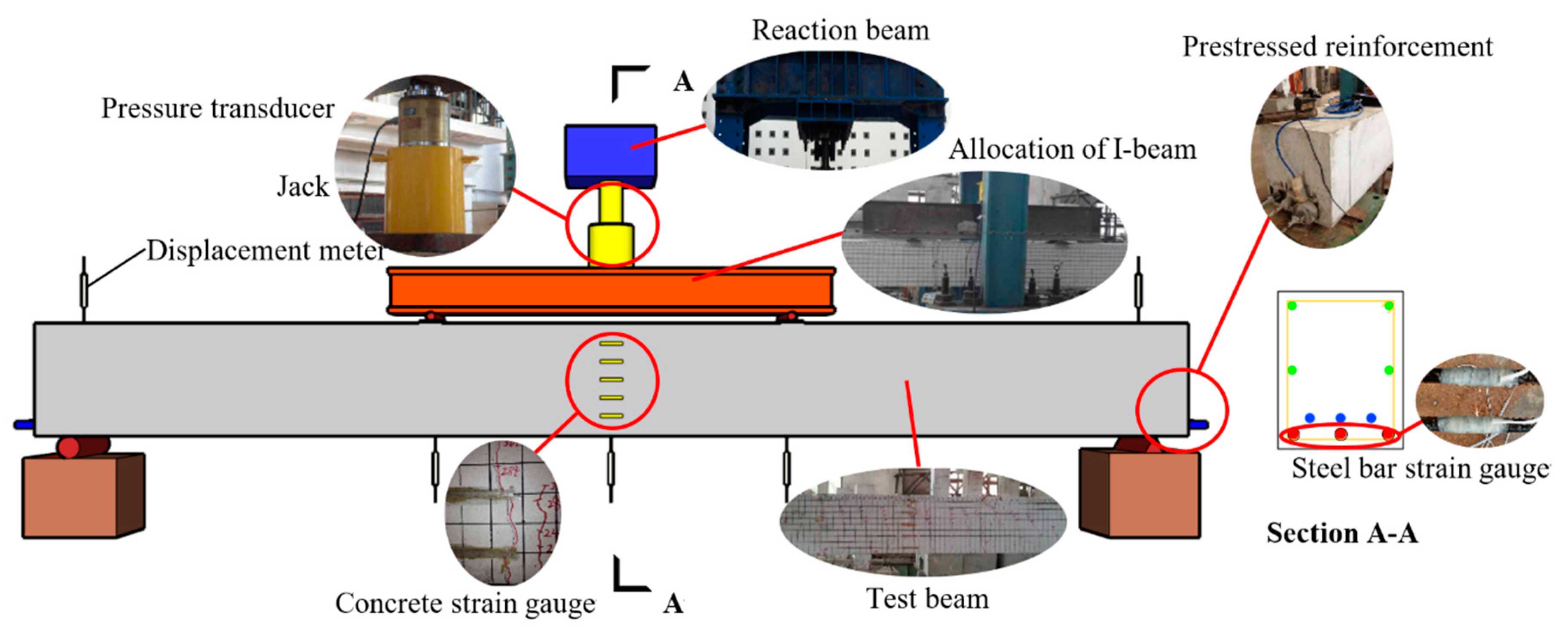

3.2. Arrangement of Measuring Points and Loading Scheme

4. Stress State Analysis of the Test Beam

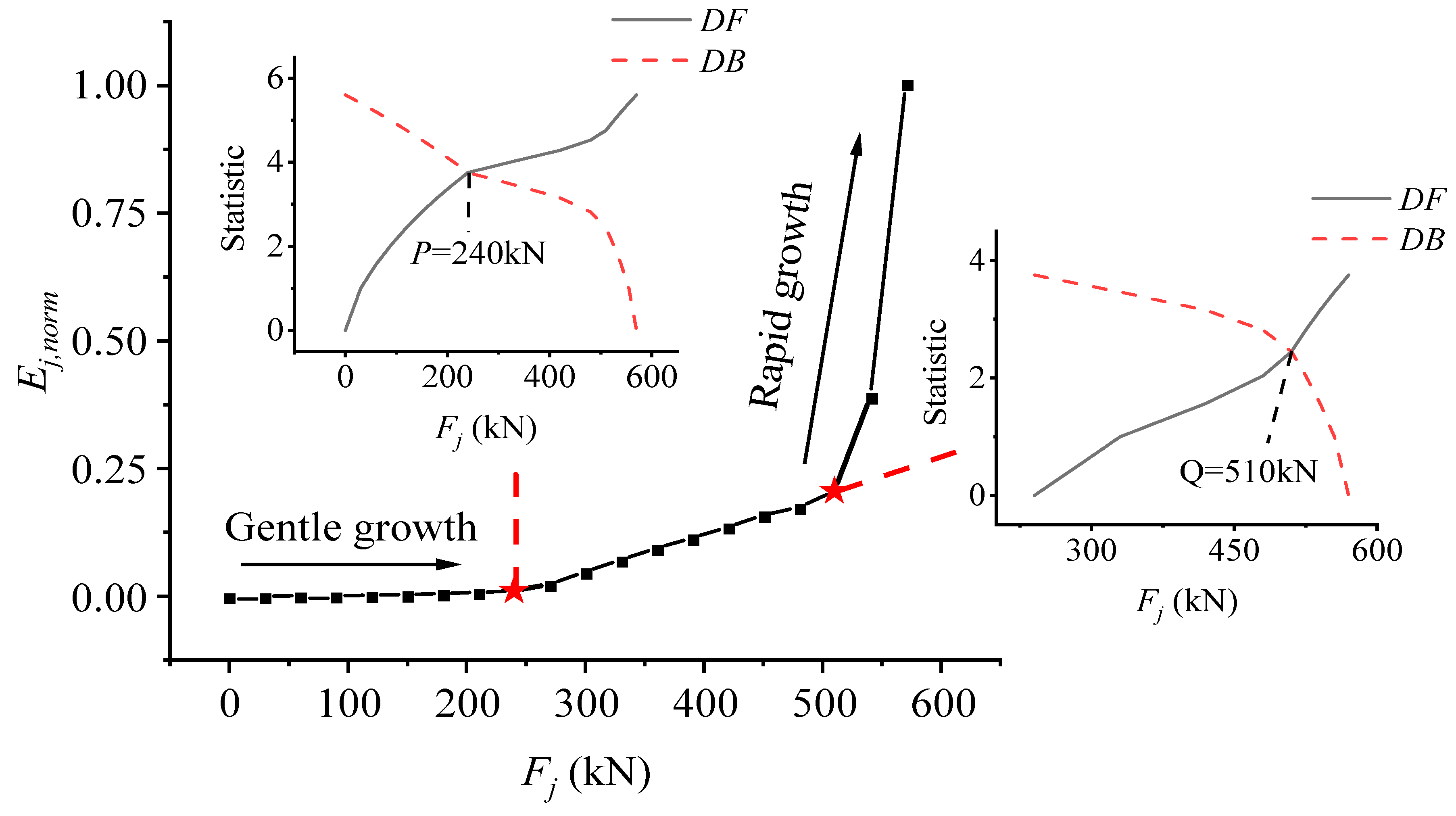

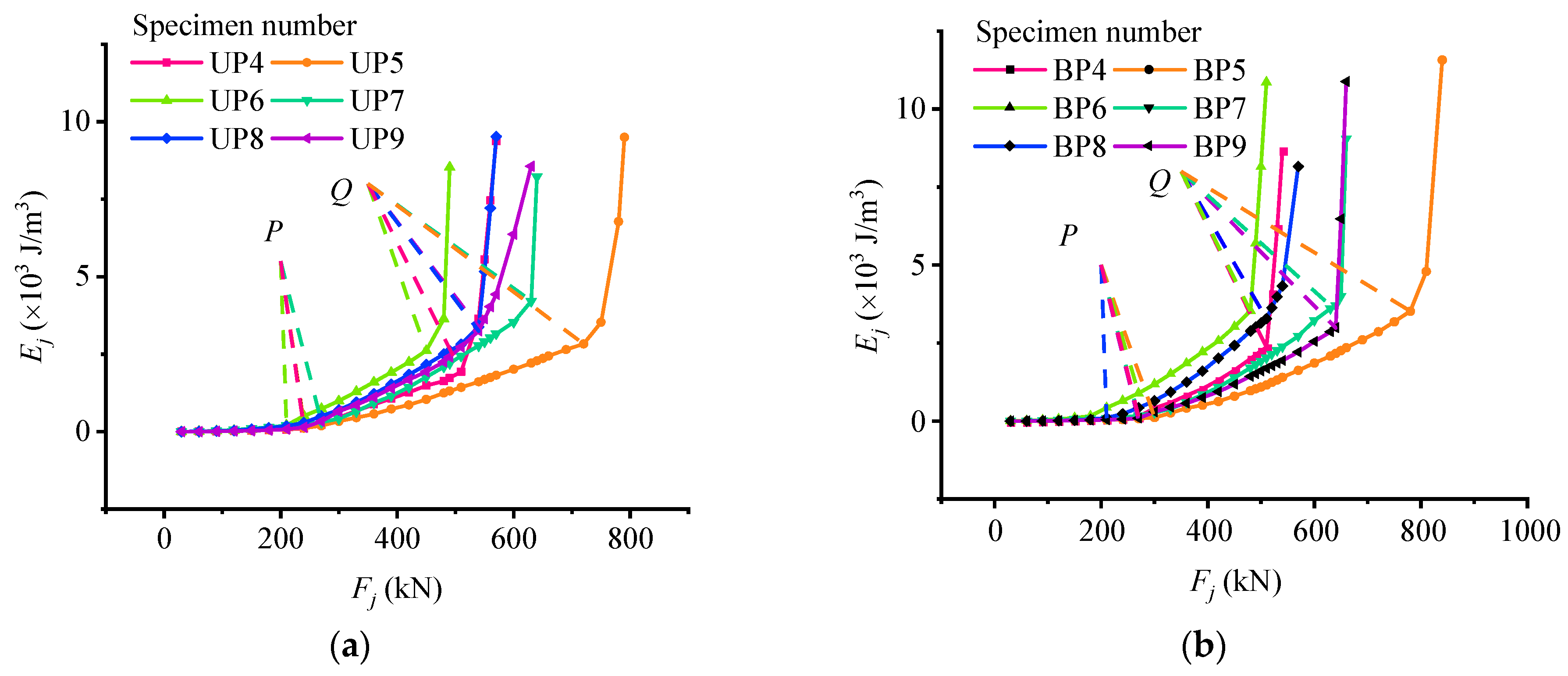

4.1. Ej, norm-Fj Curves and Failure Loads of Test Beams

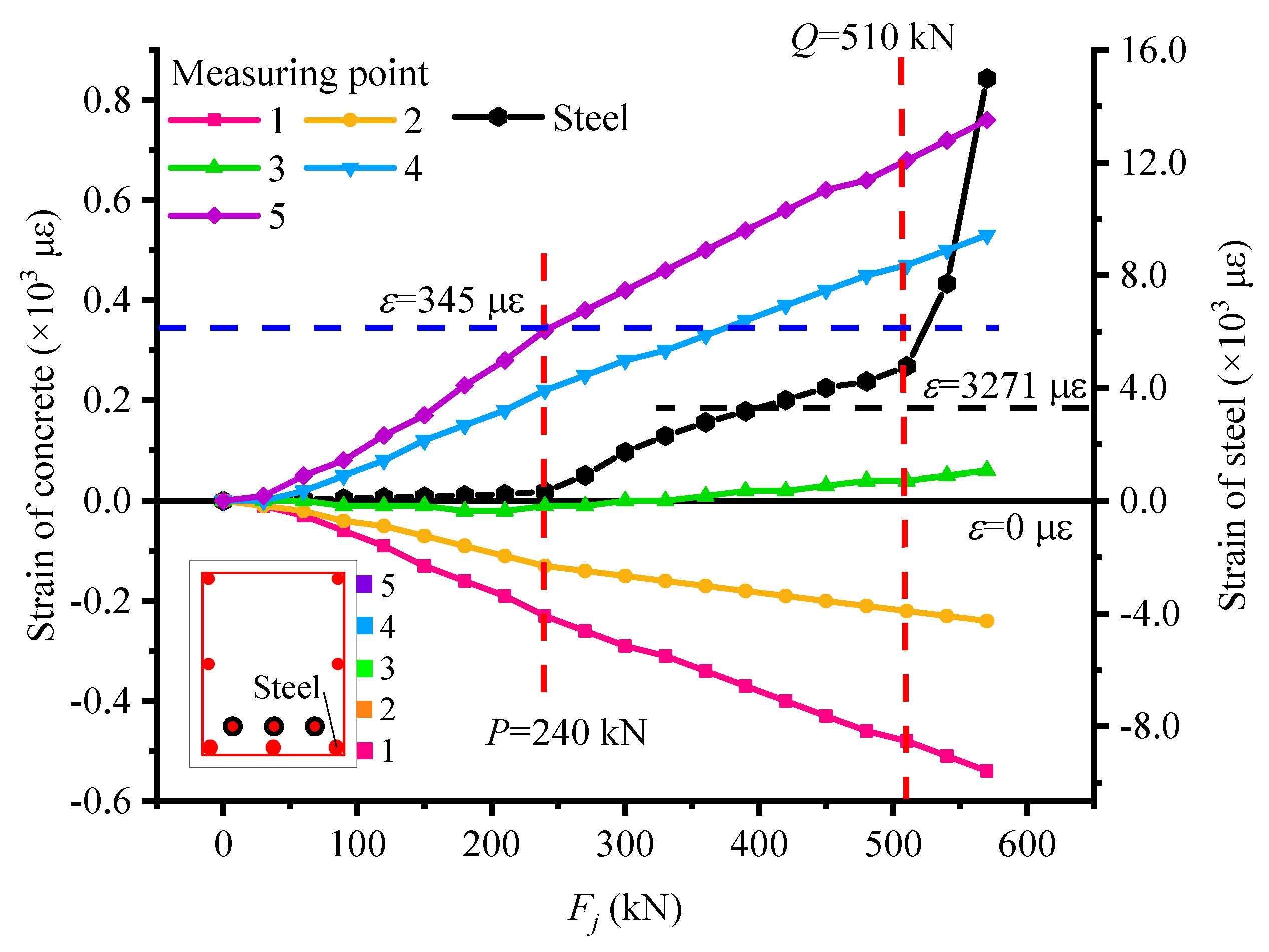

4.2. Reflection of Structural Stressing State Characteristics of Test Beam in Strain

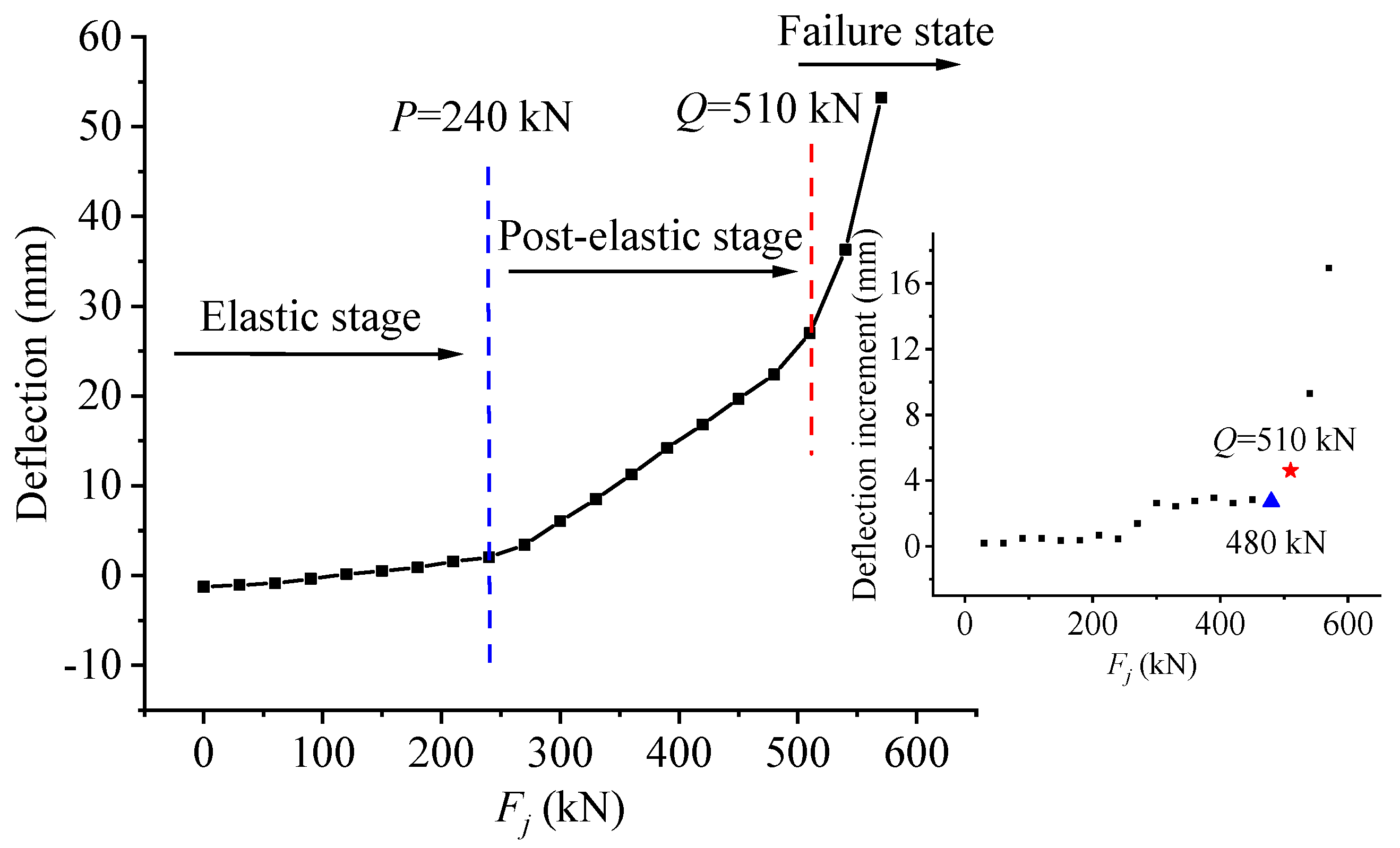

4.3. Reflection of Stress State Characteristics of Test Beam in Deflection

5. Analysis of Stress State of Test Beams with Different Design Parameters

5.1. Strain Energy Analysis of Test Beam Section under Different Working Conditions

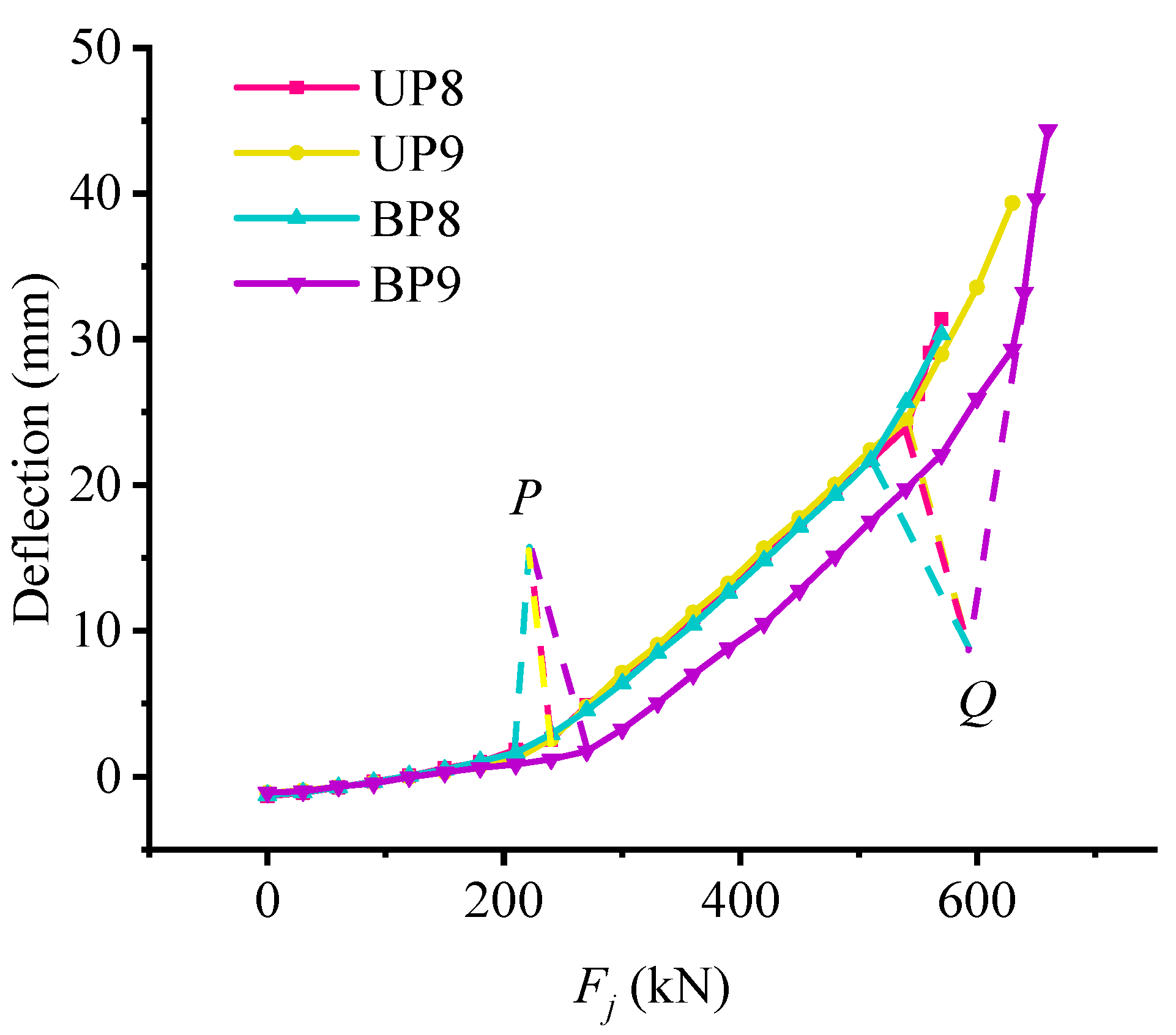

5.2. Analysis of Deflection Influencing Factors

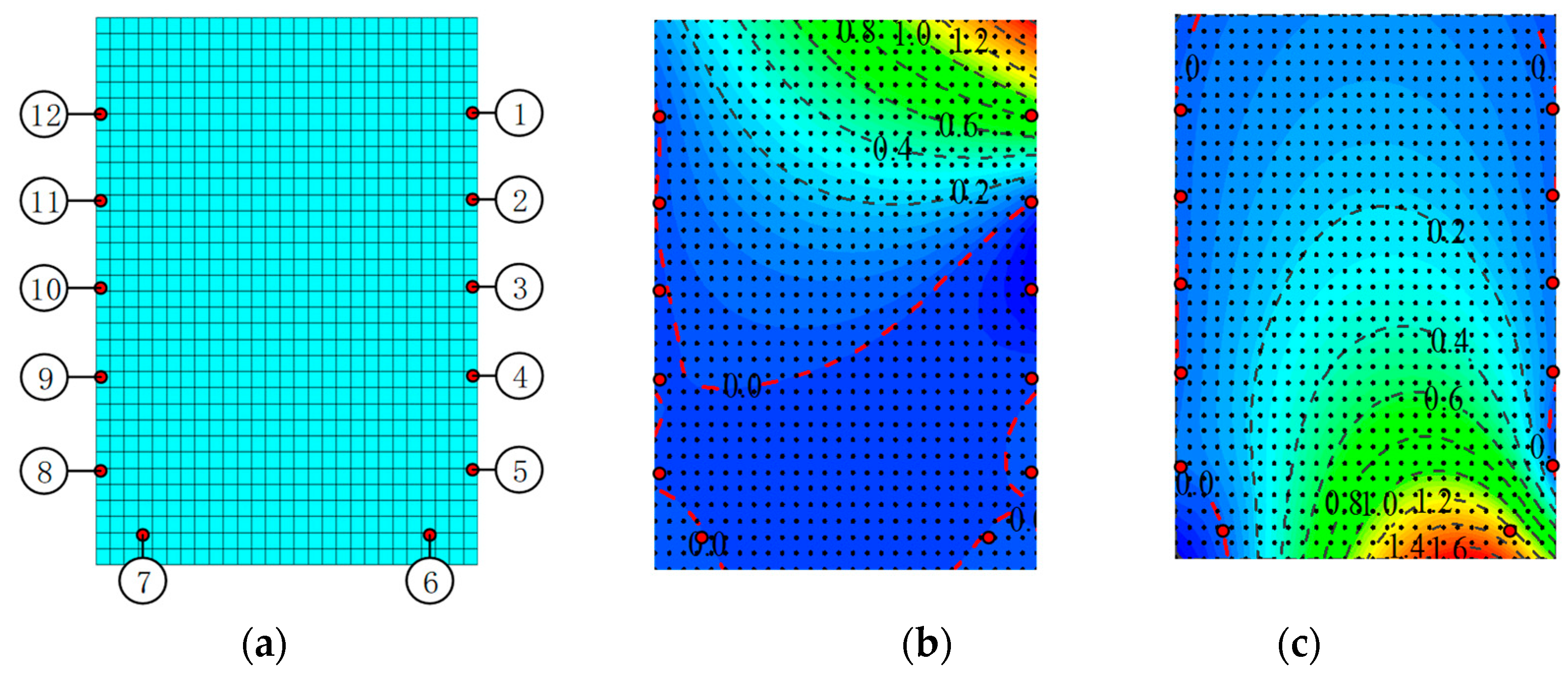

6. Strain State Analysis Based on Strain Interpolation

6.1. Strain Field Interpolation Method Based on NSF Method

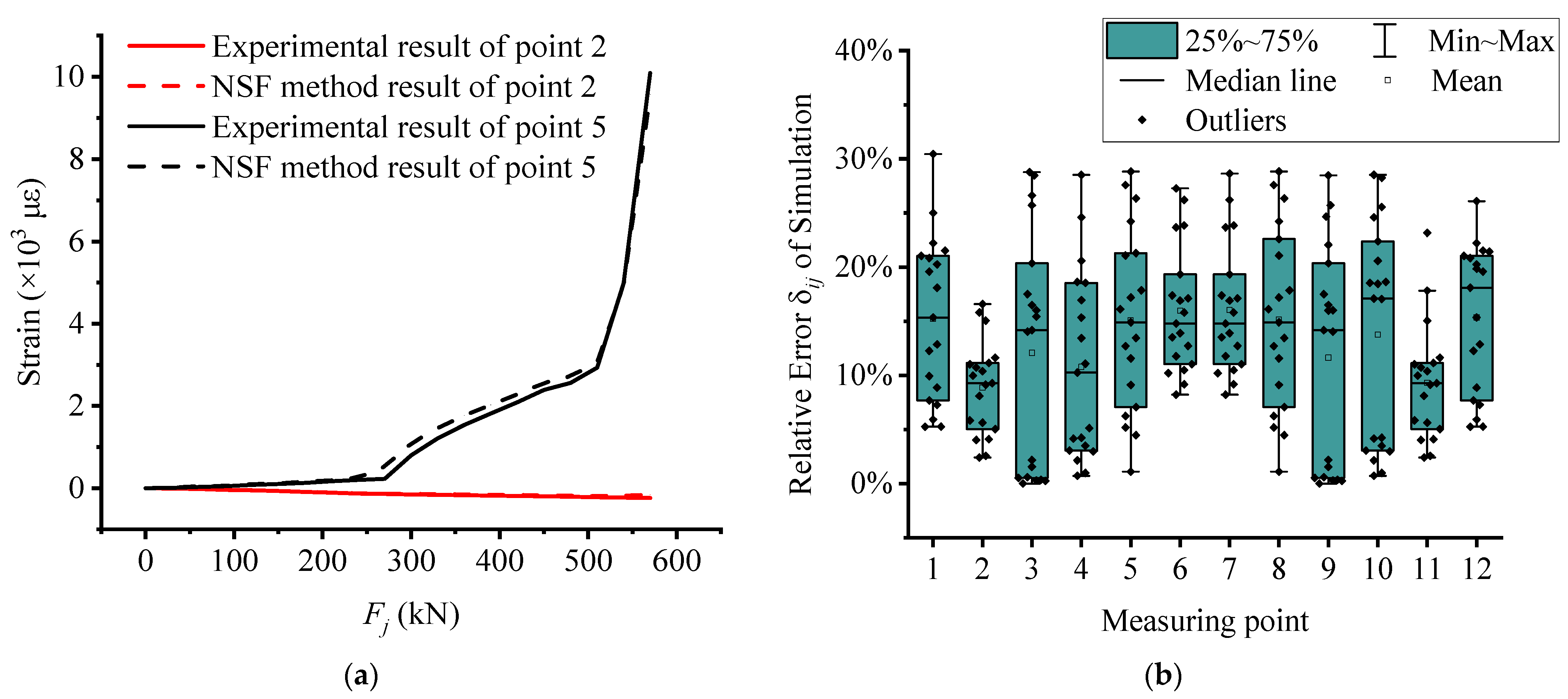

6.2. Error Analysis of the NSF Method

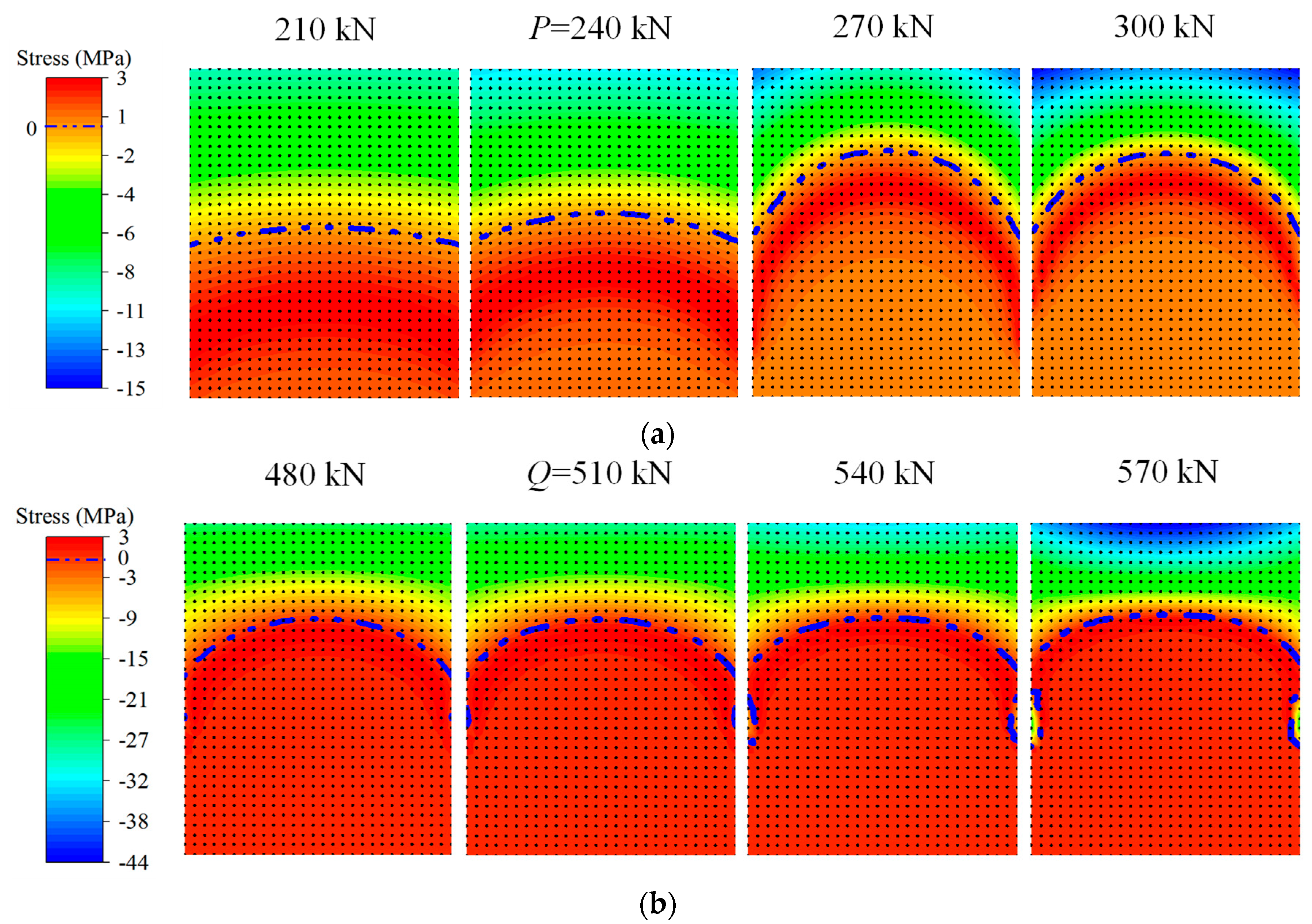

6.3. Analysis of Strain Field/Stress Field

6.4. Analysis of Internal Forces Calculated by the NSF Method

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Eij | the GSED value of the i-th point under the j-th load |

| εij | the strain value of this point |

| Ej | the GSED and value of each point under the action of the j-th load |

| Emax | the maximum GSED and value in the whole process |

| Ej, norm | all measuring points reflect the stress state of the structure under each load step Fj |

| φs | stands for steel strand |

| Df | Diameter of non-prestressed reinforcement |

| fy | The measured yield strength of non-prestressed reinforcement |

| fst | The measured value of ultimate strength of non-prestressed reinforcement |

| Es | The elastic modulus of non-prestressed reinforcement |

| Dn | Diameter of prestressed steel bar |

| fpy | Tensile strength of prestressed steel bars |

| Ep | Modulus of elasticity of prestressed steel bars |

| fcu | Compressive strength of concrete cube test block |

| ft | Axial tensile strength of concrete |

| Ec | Elastic modulus of concrete |

| ft,r | the representative value of uniaxial tensile strength of concrete |

| αt | the parameter of the descending section of the stress-strain curve of concrete under uniaxial tension |

| εt,r | the peak tensile strain of concrete corresponding to the representative value of uniaxial tensile strength |

| dt | represents the damage evolution parameter of concrete under uniaxial tension |

| fc,r | the representative value of uniaxial compressive strength of concrete |

| αc | the parameter of the descending section of the stress-strain curve of concrete under uniaxial compression |

| εc,r | the peak tensile strain of concrete corresponding to the representative value of uniaxial compressive strength |

| dc | represents the damage evolution parameter of concrete under uniaxial compression |

References

- Yao, X.; Zhang, Y.; Guan, J.; Li, L.; Liu, H.; Han, R.; Xi, J. Experimental study and reliability analysis of flexural capacity of RC beams reinforced with 600 MPa grade steel. Adv. Civ. Eng. 2020, 2020, 8899630. [Google Scholar] [CrossRef]

- Su, J.; Li, Z.-X.; Dhakal, R.P.; Li, C.; Wang, F. Comparative study on seismic vulnerability of RC bridge piers reinforced with normal and high-strength steel bars. Structures 2021, 29, 1562–1581. [Google Scholar] [CrossRef]

- Narayanan, R.S. Eurocode 2: Design Of Concrete Structures—Part 2: Concrete Bridges; Springer: Berlin/Heidelberg, Germany, 2014. [Google Scholar]

- Japanese Industrial Standards Committee, Standards Board, Technical Committee on Iron and Steel. Steel Bars for Concrete Reinforcement; Japanese Standards Association: Tokyo, Japan, 2004. [Google Scholar]

- ACI Committee 318. Building Code Requirement for Structural Concrete and Commentary; American Concrete Insitute: Farmington Hills, MI, USA, 2011. [Google Scholar]

- Department of Standards and Norms, Ministry of Housing and Urban Rural Development of China. Technical Guide for Application of High Strength Reinforcement; China Construction Industry Press: Beijing, China, 2013. [Google Scholar]

- Qin, J.G.; Lu, F.Y.; Lin, Y.L.; Wen, X.J.; Zu Liang, M. Dynamic Tensile Behaviour and Full Field Strain Measurement of High Strength Steel. Appl. Mech. Mater. 2013, 275, 1859–1865. [Google Scholar] [CrossRef]

- Elices, M.; Perez-Guerrero, M.; Iordachescu, M.; Valiente, A. Valiente. Fracture toughness of high-strength steel bars. Eng. Fract. Mech. 2017, 170, 119–129. [Google Scholar] [CrossRef]

- Han, Q.; Hu, M.; Xu, K.; Du, X. Hysteretic behavior and modelling of ultra-high-strength steel bar including buckling. Bull. Earthq. Eng. 2019, 17, 5265–5289. [Google Scholar] [CrossRef]

- Shahrooz, B.M.; Reis, J.M.; Wells, E.L.; Miller, R.A.; Harries, K.A.; Russell, H.G. Flexural Members with High-Strength Reinforcement: Behavior and Code Implications. J. Bridge Eng. 2014, 19, 04014003. [Google Scholar] [CrossRef]

- Hung, C.C.; Chueh, C.Y. Cyclic behavior of UHPFRC flexural members reinforced with high-strength steel rebar. Eng. Struct. 2016, 122, 108–120. [Google Scholar] [CrossRef]

- Kim, C.; Kim, S.; Kim, K.-H.; Shin, D.; Haroon, M.; Lee, J.-Y. Torsional Behavior of Reinforced Concrete Beams with High-Strength Steel Bars. ACI Struct. J. 2019, 116, 251–263. [Google Scholar] [CrossRef]

- Anggraini, R. Flexural capacity of concerete beams reinforced with high-strength steel bars under monotonic loading. Geomate J. 2021, 20, 173–180. [Google Scholar]

- de Dios Garay, J.; Lubell, A.S. Behavior of Concrete deep beams with high strength reinforcement. In Proceedings of the Structures Congress 2008: Crossing Borders, Vancouver, BC, Canada, 24–26 April 2008. [Google Scholar]

- Hassan, T.K.; Mantawy, A.; Soliman, J.; Sherif, A.; Rizkalla, S.H. Bond Characteristics and Shear Behavior of Concrete Beams Reinforced with High-Strength Steel Reinforcement. Adv. Struct. Eng. 2012, 15, 303–318. [Google Scholar] [CrossRef]

- Hadi, M. Helically reinforced HSC beams reinforced with high strength steel. Int. J. Mater. Prod. Tech. 2005, 23, 138–148. [Google Scholar] [CrossRef]

- Hwang, H.J.; Park, H.G.; Choi, W.S.; Chung, L.; Kim, J.K. Cyclic Loading Test for Beam-Column Connections with 600 MPa (87 ksi) Beam Flexural Reinforcing Bars. ACI Struct. J. 2014, 111, 913–924. [Google Scholar] [CrossRef]

- Jang, S.J.; Jeong, G.Y.; Kim, S.W.; Yun, H.D.; Chun, Y.S. Effect of Reinforcement Layout on Structural Performance of Reinforced Concrete Coupling Beams with High-strength Steel Bar. J. Korea Inst. Struct. Maint. Insp. 2017, 21, 95–102. [Google Scholar]

- Devine, R.D.; Barbachyn, S.M.; Thrall, A.; Kurama, Y.C. Experimental Evaluation of Deep Beams with High-Strength Concrete and High-Strength Reinforcing Bar. ACI Struct. J. 2018, 115, 1023–1036. [Google Scholar] [CrossRef]

- Matthew, S.S.; Sami, H.R.; Paul, Z. Behavior of high-performance steel as shear reinforcement for concrete beams. ACI Struct. J. 2009, 35, 171–177. [Google Scholar]

- Ahmad, S.; Bahij, S.; Al-Osta, M.A.; Adekunle, S.K.; Al-Dulaijan, S.U. Shear Behavior of Ultra-High-Performance Concrete (UHPC) Beams Reinforced with High-Strength Steel Bars. ACI Struct. J. 2019, 116, 3–14. [Google Scholar] [CrossRef]

- Chen, M.; Li, Z.H.; Wu, J.F.; Wang, J.H. Shear behaviour and diagonal crack checking of shale ceramsite lightweight aggregate concrete beams with high-strength steel bars. Constr. Build. Mater. 2020, 249, 118730. [Google Scholar] [CrossRef]

- Feng, J.; Wang, S.; Meloni, M.; Zhang, Q.; Yang, J.; Cai, J. Seismic Behavior of RC Beam Column Joints with 600 MPa High Strength Steel Bars. App. Sci. 2020, 10, 4684. [Google Scholar] [CrossRef]

- Zhou, G.C.; Rafiq, M.Y.; Bugmann, G.; Easterbrook, D. A cellular automata model for predicting the failure pattern of laterally loaded masonry wall panels. J. Comput. Civ. Eng. 2009, 20, 400–409. [Google Scholar] [CrossRef] [Green Version]

- Zhou, G.C.; Pan, D.; Xu, X.; Rafiq, M.Y. Innovative ANN Technique for Predicting Failure/Cracking Load of Masonry Wall Panel under Lateral Load. J. Comput. Civ. Eng. 2010, 24, 377–387. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhou, G.C.; Xiong, Y.; Rafiq, M.Y. Techniques for Predicting Cracking Pattern of Masonry Wallet Using Artificial Neural Networks and Cellular Automata. J. Comput. Civ. Eng. 2010, 24, 161–172. [Google Scholar] [CrossRef]

- Huang, Y.X.; Zhang, Y.; Zhang, M.; Zhou, G.C. Method for Predicting the Failure Load of Masonry Wall Panels Based on Generalized Strain-Energy Density. J. Eng. Mech. 2014, 140, 04014061. [Google Scholar] [CrossRef]

- Mann, H.B. Nonparametric tests against trend. Econometrica 1945, 13, 245–259. [Google Scholar] [CrossRef]

- Kendall, M.G. Rank Correlation Methods. Brit. J. Psychol. 1990, 25, 86–91. [Google Scholar] [CrossRef]

- Li, Q. Study on mechanical behavior of partially prestressed concrete beams with 600MPa non prestressed reinforcement. Ph.D. Thesis, Hebei University of Technology, Tianjing, China, 2017. [Google Scholar]

- China Academy of Building Sciences; CSCEC International Construction Co. Standard for Test Methods of Concrete Structures; China Construction Industry Press: Beijing, China, 2012. [Google Scholar]

- Shi, J.; Yang, K.K.; Zheng, K.K.; Shen, J.Y.; Zhou, G.G.; Huang, Y. An investigation into working behavior characteristics of parabolic CFST arches applying structural stressing state theory. J. Civ. Eng. Manag. 2019, 25, 215–227. [Google Scholar] [CrossRef] [Green Version]

- Shi, J.; Zheng, K.K.; Tan, Y.Q.; Yang, K.K.; Zhou, G.C. Response simulating interpolation methods for expanding experimental data based on numerical shape functions. Comput. Struct. 2019, 218, 1–8. [Google Scholar] [CrossRef]

| Member Number | Concrete Strength Grade | Quantity of Prestressed Reinforcement | Non-Prestressed Tensile Reinforcement | |

|---|---|---|---|---|

| Number | Steel Strength (MPa) | |||

| BP1/UP1 | C40 | 3 | 3 | 400 |

| BP2/UP2 | C50 | 3 | 3 | 500 |

| BP3/UP3 | C50 | 3 | 3 | 600 |

| BP4/UP4 | C50 | 3 | 2 | 600 |

| BP5/UP5 | C50 | 3 | 4 | 600 |

| BP6/UP6 | C50 | 2 | 3 | 600 |

| BP7/UP7 | C50 | 4 | 3 | 600 |

| BP8/UP8 | C40 | 3 | 3 | 600 |

| BP9/UP9 | C60 | 3 | 3 | 600 |

| Steel Type | Df (mm) | fy (MPa) | fst (MPa) | Es (GPa) |

|---|---|---|---|---|

| 400 MPa | 18 | 439 | 613 | 200 |

| 500 MPa | 18 | 552 | 711 | 200 |

| 600 MPa | 18 | 654 | 824 | 200 |

| Batch | Dn (mm) | fpy (MPa) | Ep (GPa) |

|---|---|---|---|

| 1 | 15 | 1885 | 190 |

| 2 | 15 | 1885 | 195 |

| 3 | 15 | 1864 | 197 |

| Specification | ≥1860 | 195 |

| Concrete Strength Grade | fcu (MPa) | ft (MPa) | Ec (GPa) |

|---|---|---|---|

| C40 | 47.3 | 2.9 | 34 |

| C50 | 54.2 | 3.0 | 35 |

| C60 | 67.4 | 3.3 | 36 |

| Member Number | Characteristic Load P (kN) | Characteristic Load Q (kN) | Member Number | Characteristic Load P (kN) | Characteristic Load Q (kN) |

|---|---|---|---|---|---|

| UP4 | 240 | 510 | BP4 | 270 | 510 |

| UP5 | 240 | 720 | BP5 | 300 | 780 |

| UP6 | 210 | 480 | BP6 | 270 | 480 |

| UP7 | 270 | 630 | BP7 | 270 | 630 |

| UP8 | 240 | 540 | BP8 | 210 | 510 |

| UP9 | 240 | 540 | BP9 | 270 | 640 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yuan, J.; Xu, F.; Du, H.; Yu, S.; Sun, G. Stressing State Analysis of Partially Prestressed Concrete Beams with High Strength Reinforcement Based on NSF Method. Materials 2022, 15, 3377. https://doi.org/10.3390/ma15093377

Yuan J, Xu F, Du H, Yu S, Sun G. Stressing State Analysis of Partially Prestressed Concrete Beams with High Strength Reinforcement Based on NSF Method. Materials. 2022; 15(9):3377. https://doi.org/10.3390/ma15093377

Chicago/Turabian StyleYuan, Jian, Feng Xu, Heng Du, Suhui Yu, and Guorui Sun. 2022. "Stressing State Analysis of Partially Prestressed Concrete Beams with High Strength Reinforcement Based on NSF Method" Materials 15, no. 9: 3377. https://doi.org/10.3390/ma15093377

APA StyleYuan, J., Xu, F., Du, H., Yu, S., & Sun, G. (2022). Stressing State Analysis of Partially Prestressed Concrete Beams with High Strength Reinforcement Based on NSF Method. Materials, 15(9), 3377. https://doi.org/10.3390/ma15093377