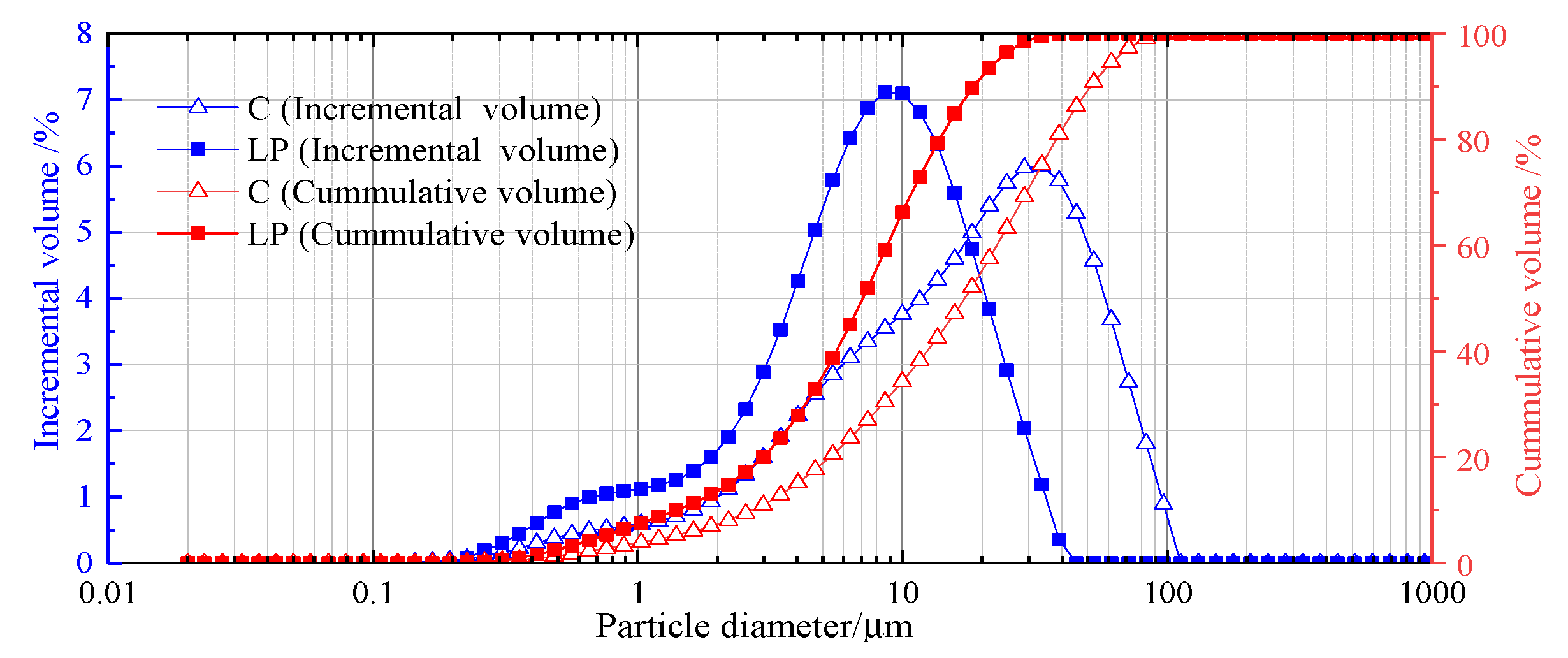

Figure 1.

Particle size distribution of powders.

Figure 1.

Particle size distribution of powders.

Figure 2.

Anton Paar MCR 102 rheometer.

Figure 2.

Anton Paar MCR 102 rheometer.

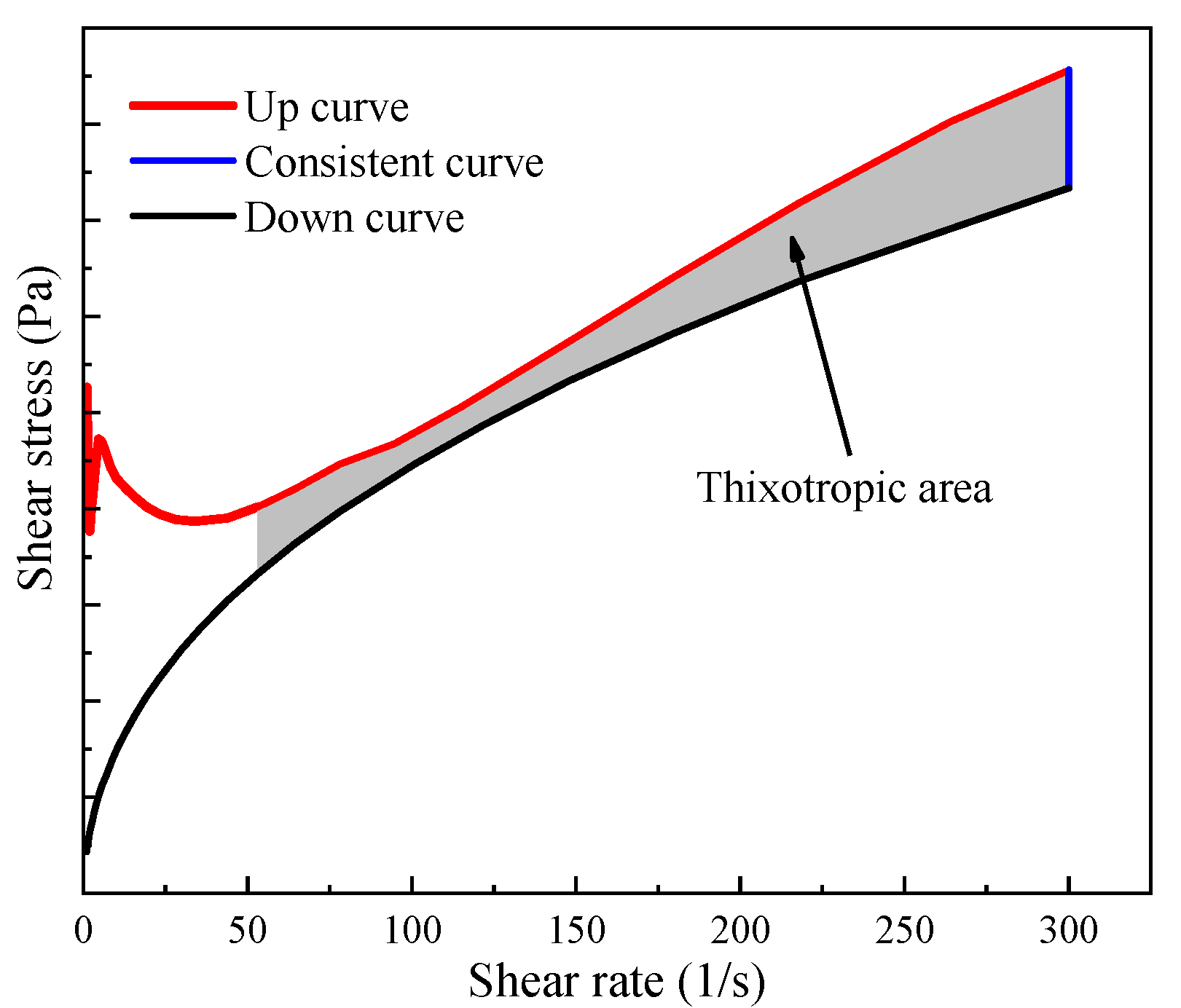

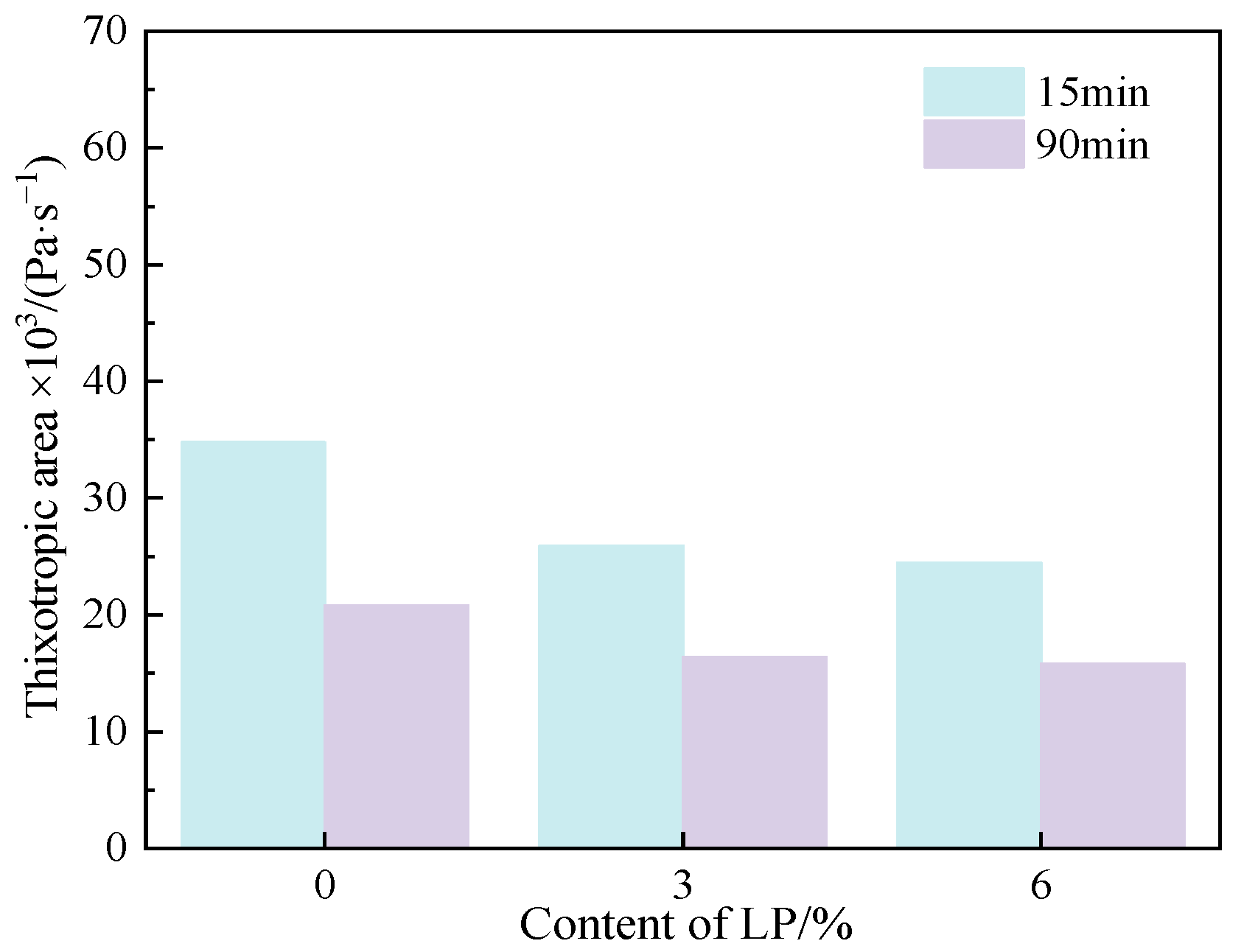

Figure 3.

Thixotropic area of all pastes.

Figure 3.

Thixotropic area of all pastes.

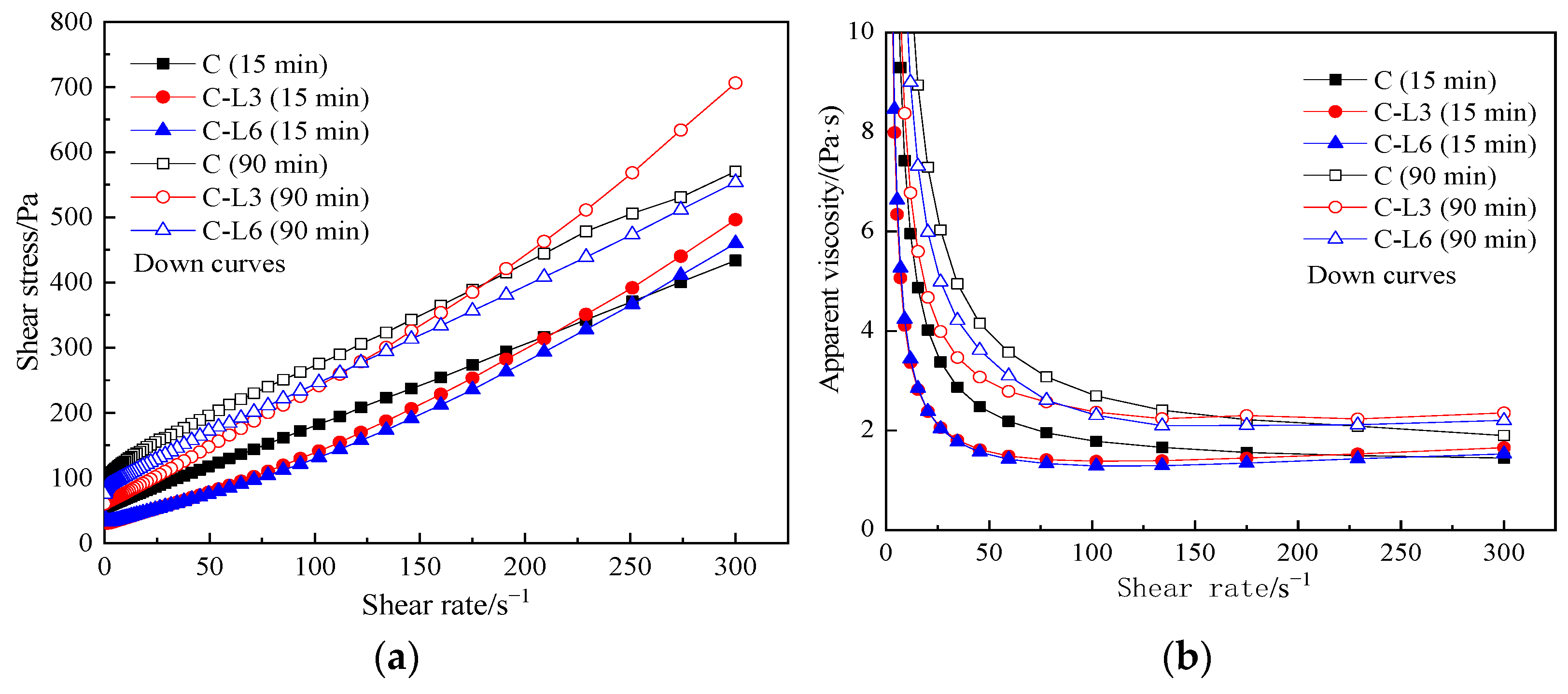

Figure 4.

Rheological curves of C-LP paste. (a) shear stress vs. shear rate, (b) apparent viscosity vs. shear rate.

Figure 4.

Rheological curves of C-LP paste. (a) shear stress vs. shear rate, (b) apparent viscosity vs. shear rate.

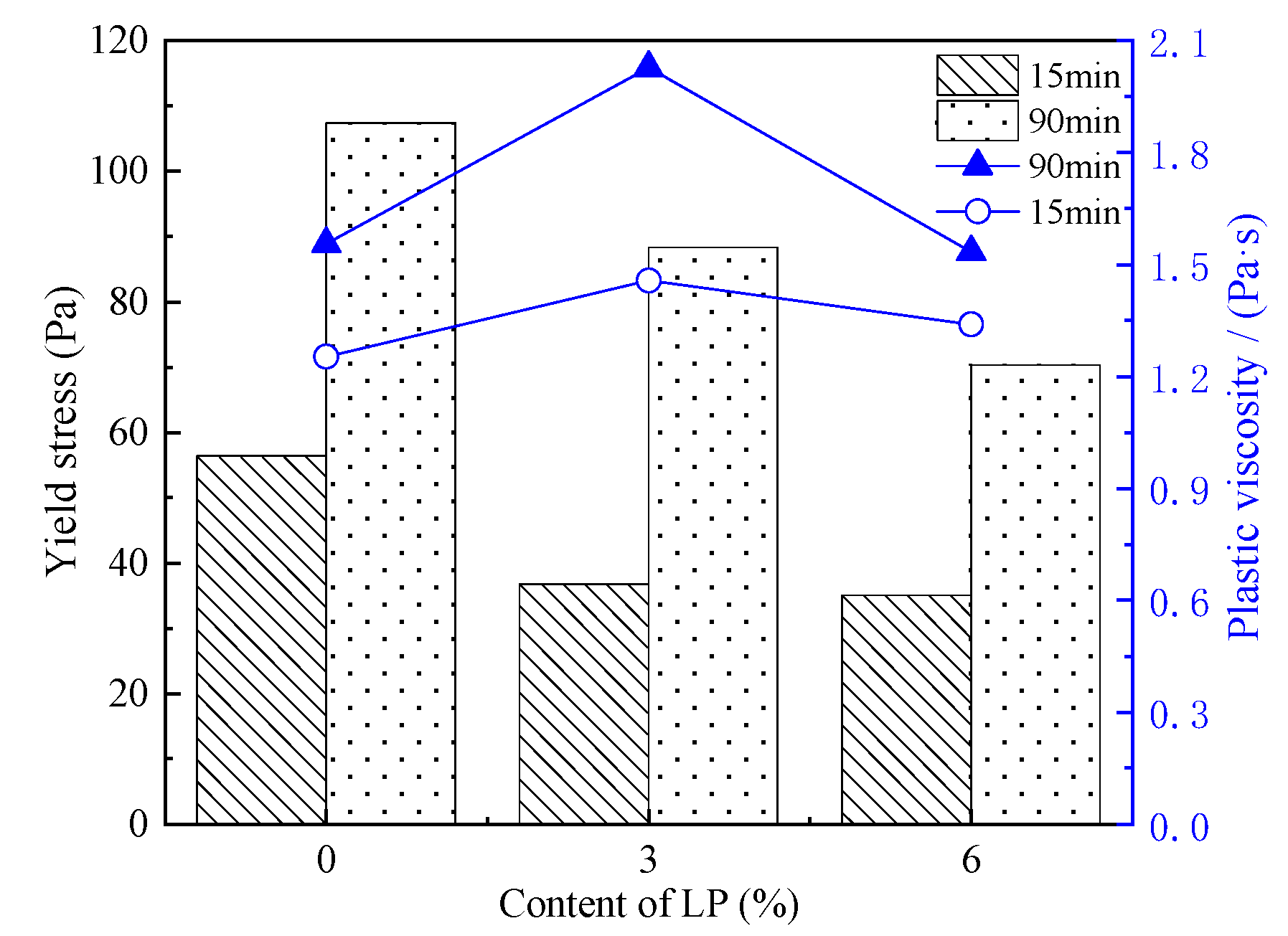

Figure 5.

Yield stress and plastic viscosity of C-LP pastes.

Figure 5.

Yield stress and plastic viscosity of C-LP pastes.

Figure 6.

Thixotropic area of C-LP pastes.

Figure 6.

Thixotropic area of C-LP pastes.

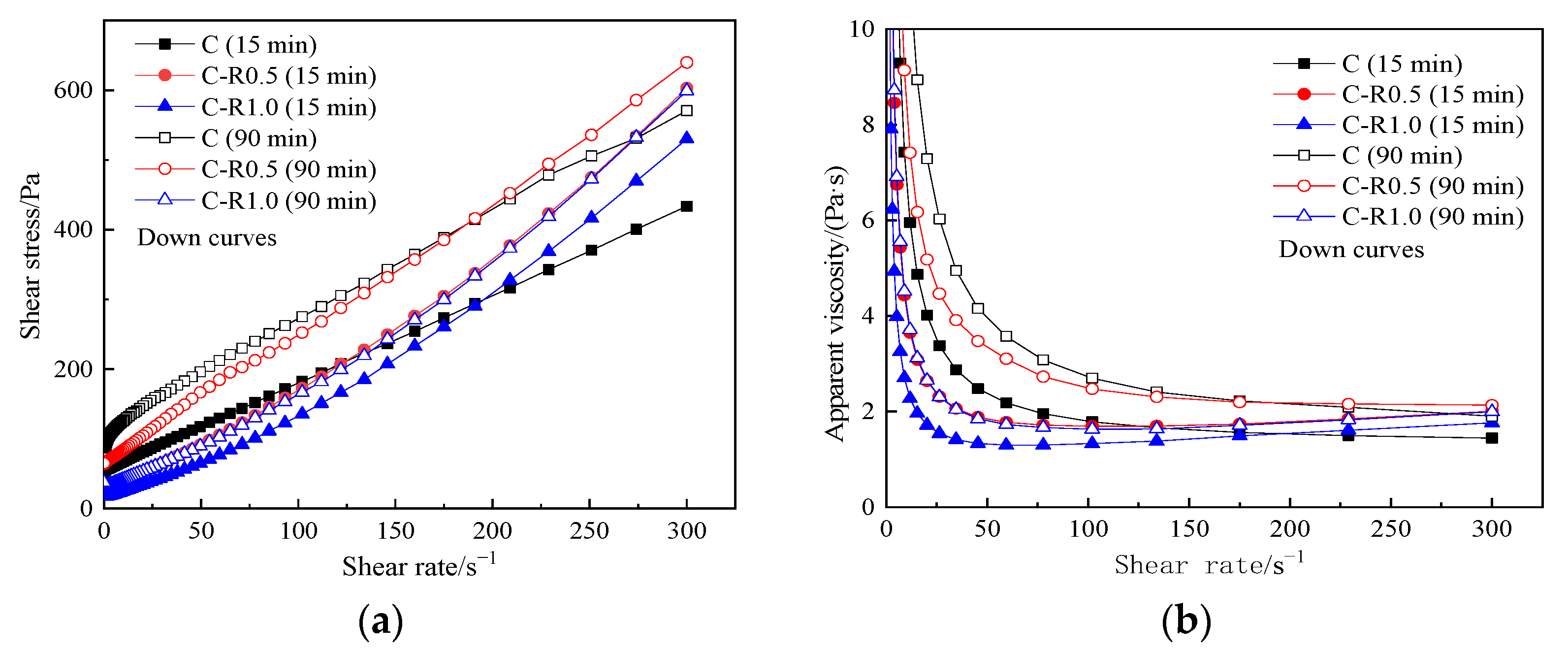

Figure 7.

Rheological curves of C-RPP pastes. (a) shear stress vs. shear rate, (b) apparent viscosity vs. shear rate.

Figure 7.

Rheological curves of C-RPP pastes. (a) shear stress vs. shear rate, (b) apparent viscosity vs. shear rate.

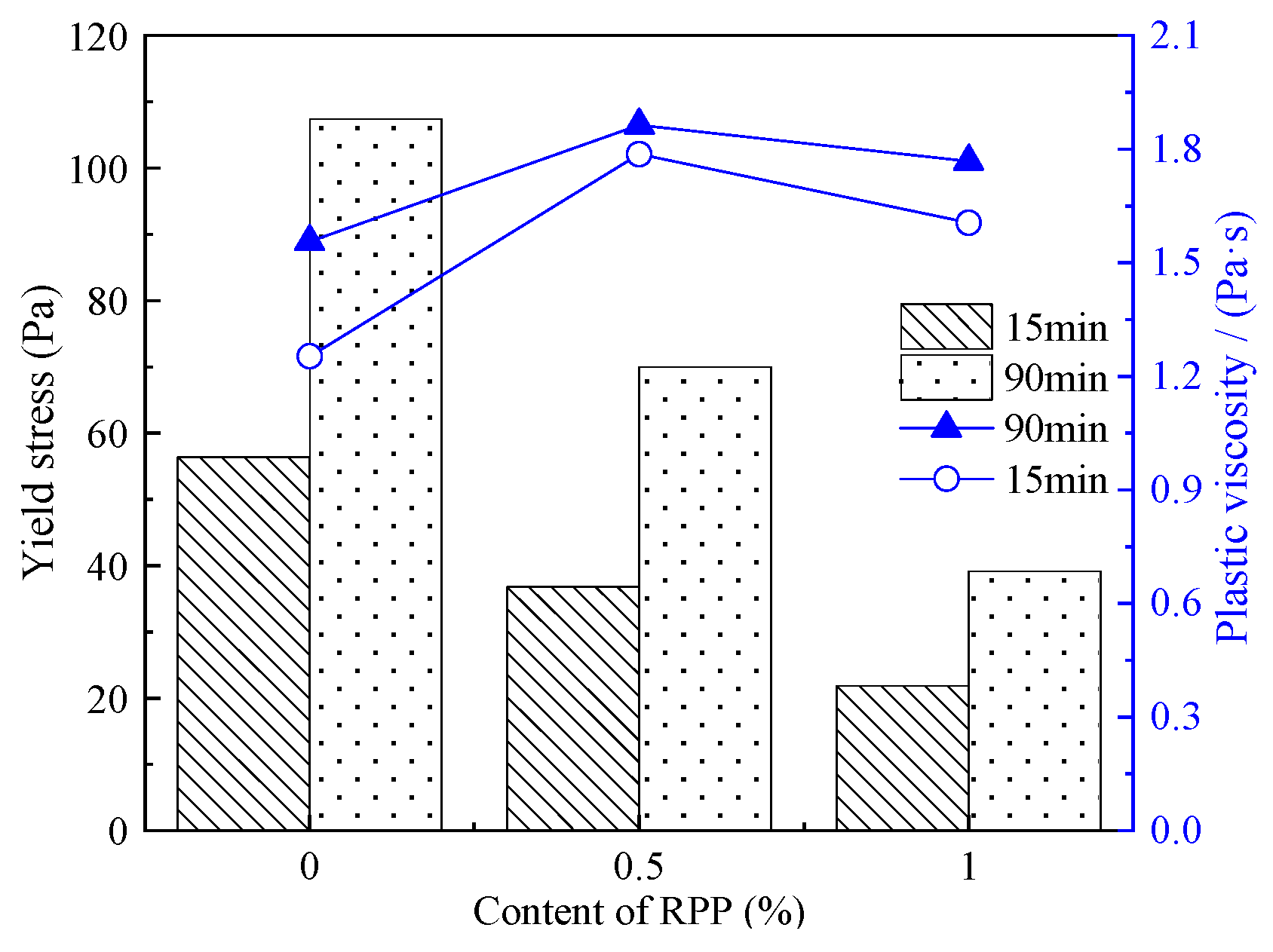

Figure 8.

Yield stress and plastic viscosity of C-RPP pastes.

Figure 8.

Yield stress and plastic viscosity of C-RPP pastes.

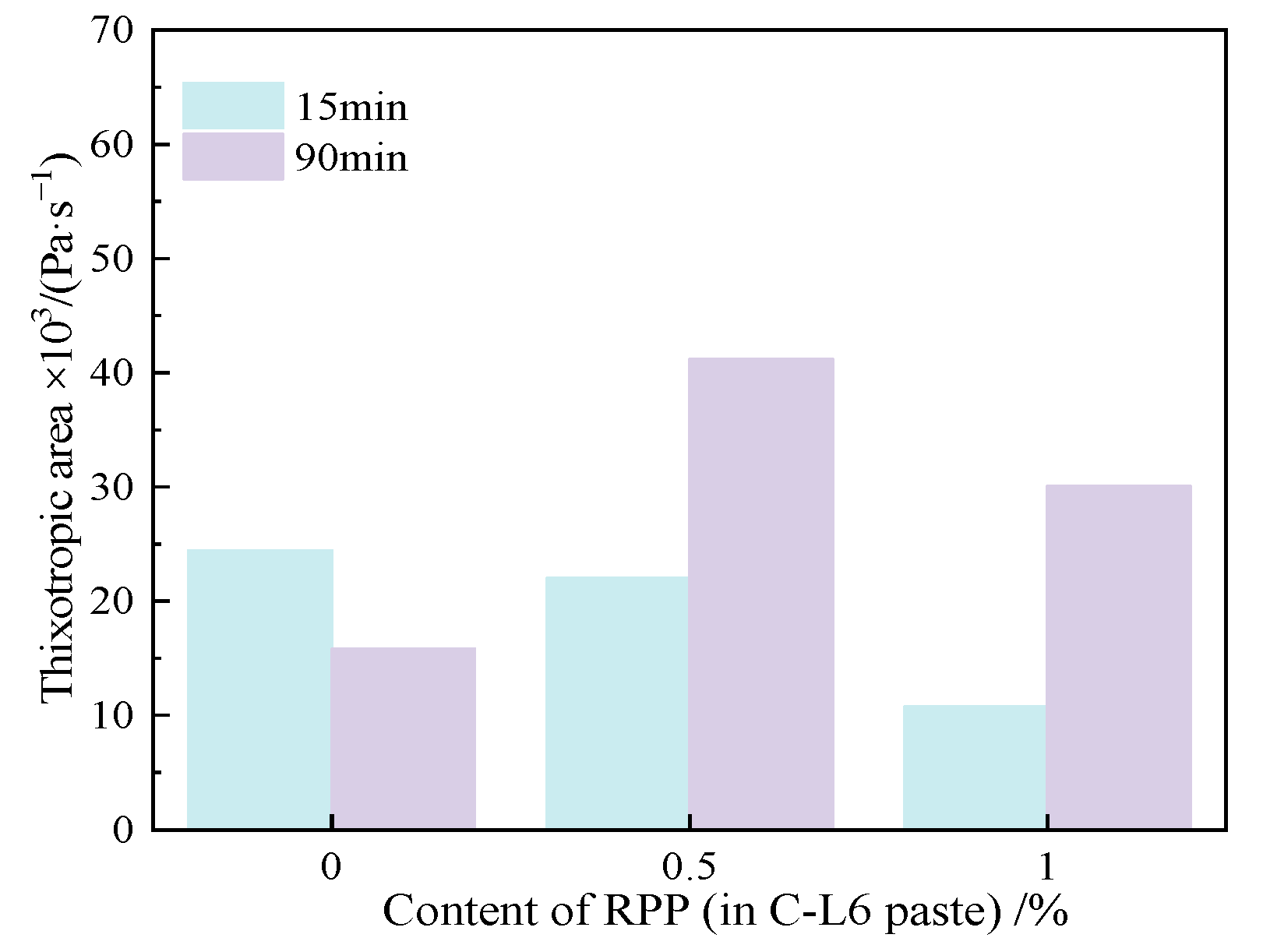

Figure 9.

Thixotropic area of C-RPP pastes.

Figure 9.

Thixotropic area of C-RPP pastes.

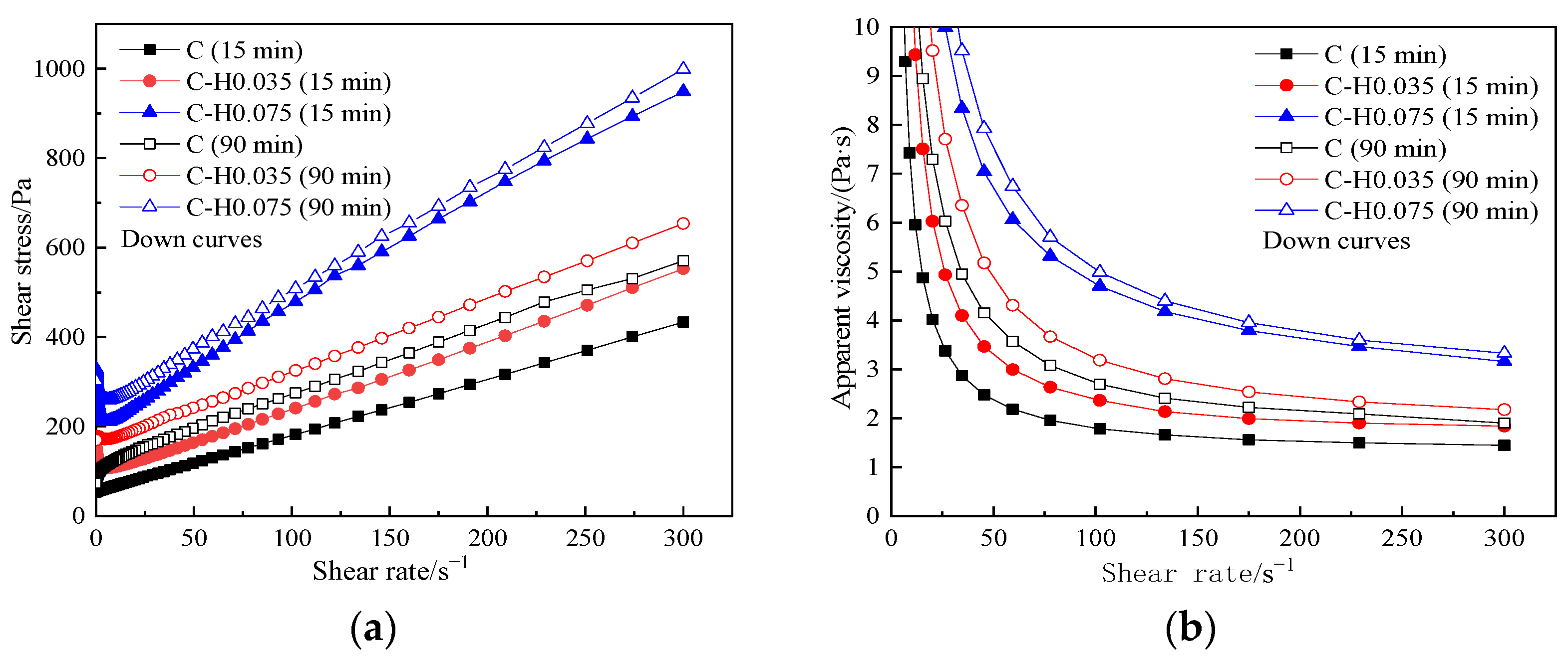

Figure 10.

Rheological curves of C-HPMC pastes. (a) shear stress vs. shear rate, (b) apparent viscosity vs. shear rate.

Figure 10.

Rheological curves of C-HPMC pastes. (a) shear stress vs. shear rate, (b) apparent viscosity vs. shear rate.

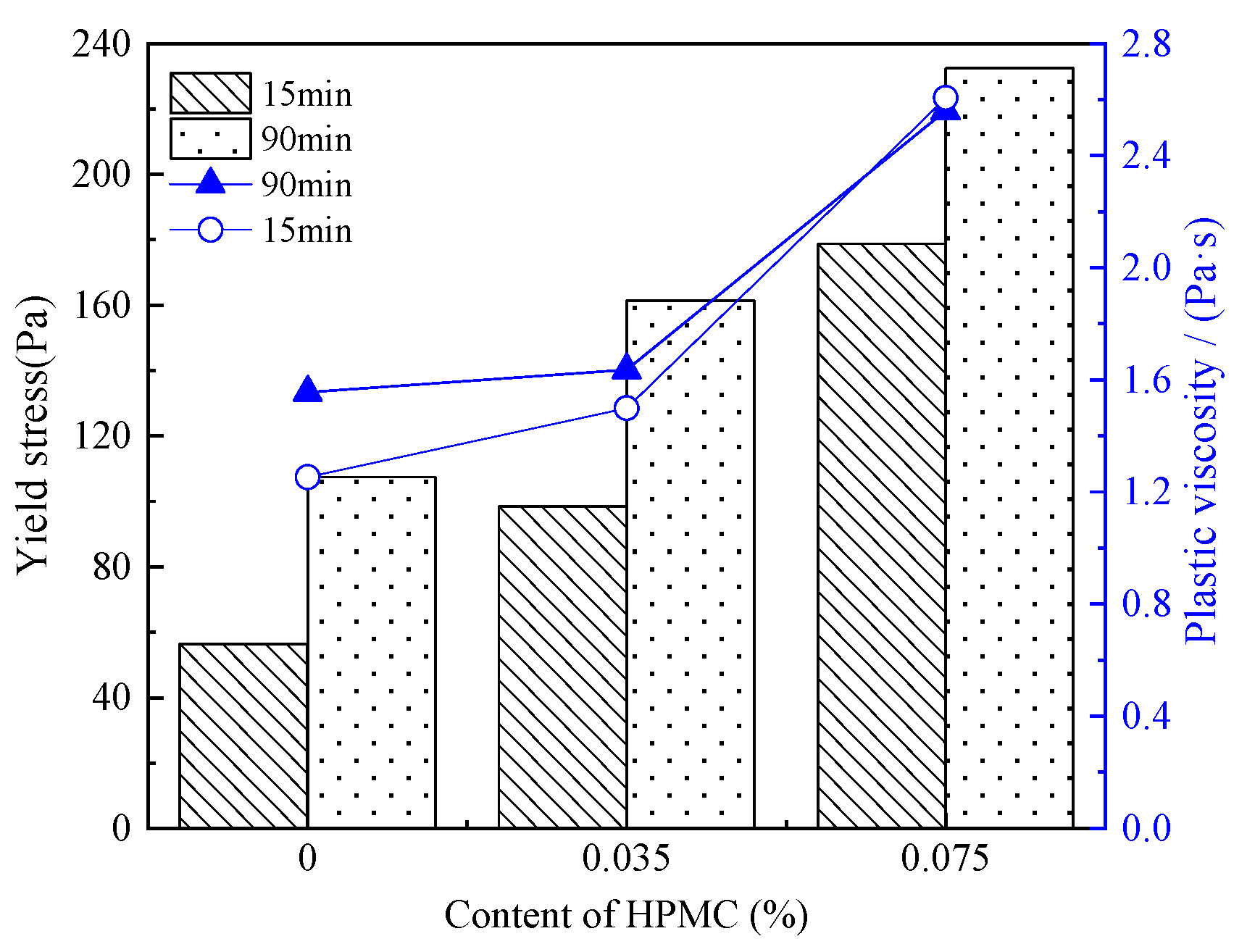

Figure 11.

Yield stress and plastic viscosity of C-HPMC pastes.

Figure 11.

Yield stress and plastic viscosity of C-HPMC pastes.

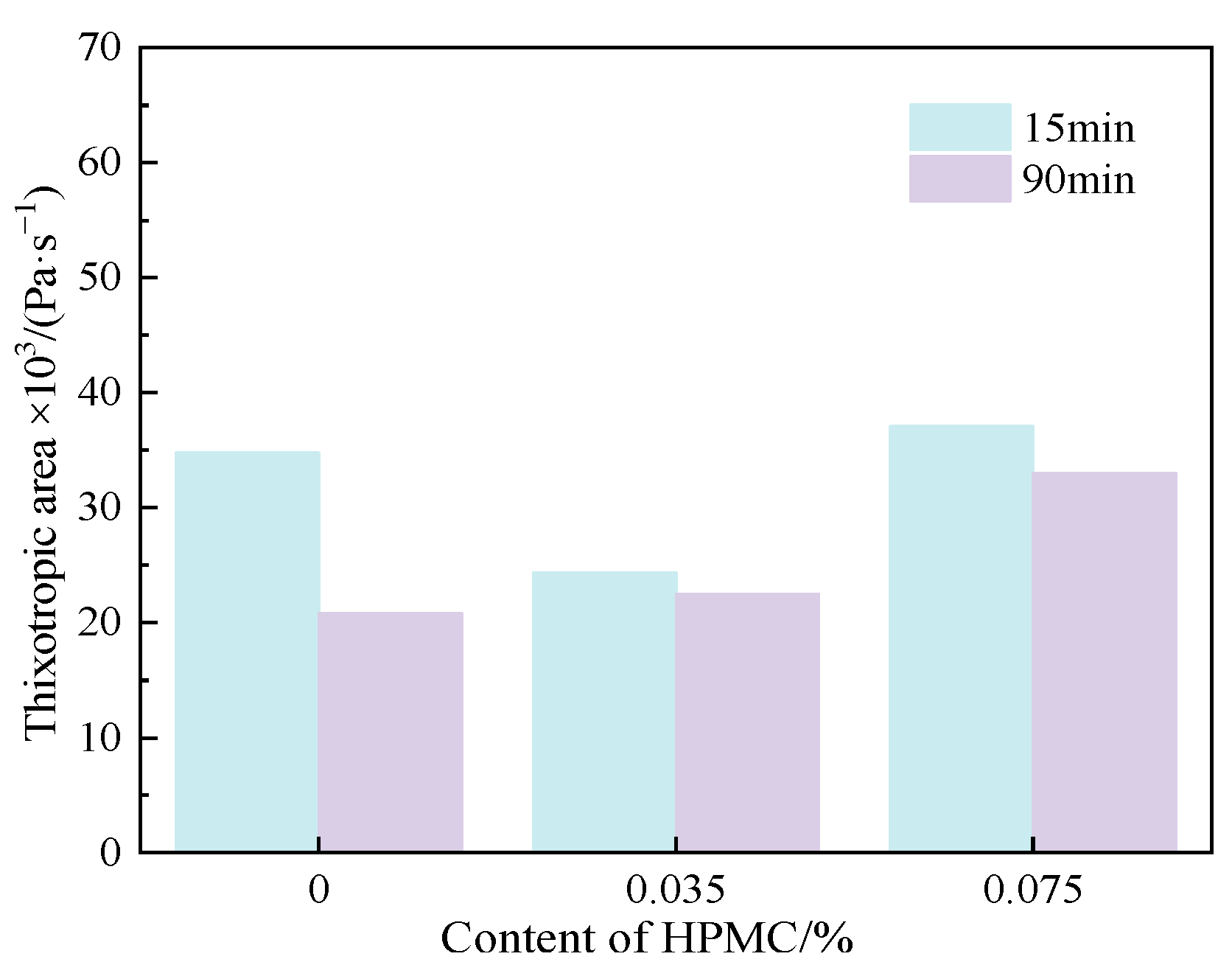

Figure 12.

Thixotropic area of C-HPMC pastes.

Figure 12.

Thixotropic area of C-HPMC pastes.

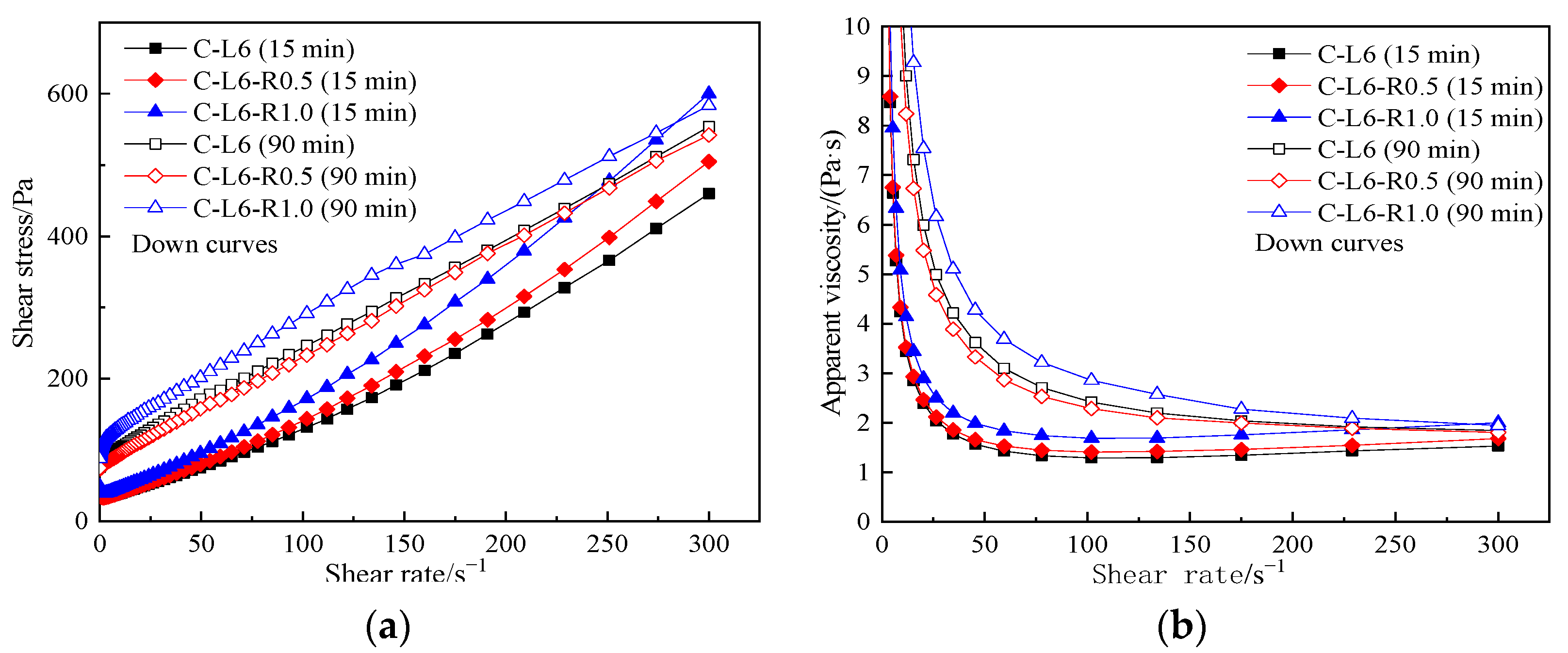

Figure 13.

Rheological curves of C-L6-RPP pastes. (a) shear stress vs. shear rate, (b)apparent viscosity vs. shear rate.

Figure 13.

Rheological curves of C-L6-RPP pastes. (a) shear stress vs. shear rate, (b)apparent viscosity vs. shear rate.

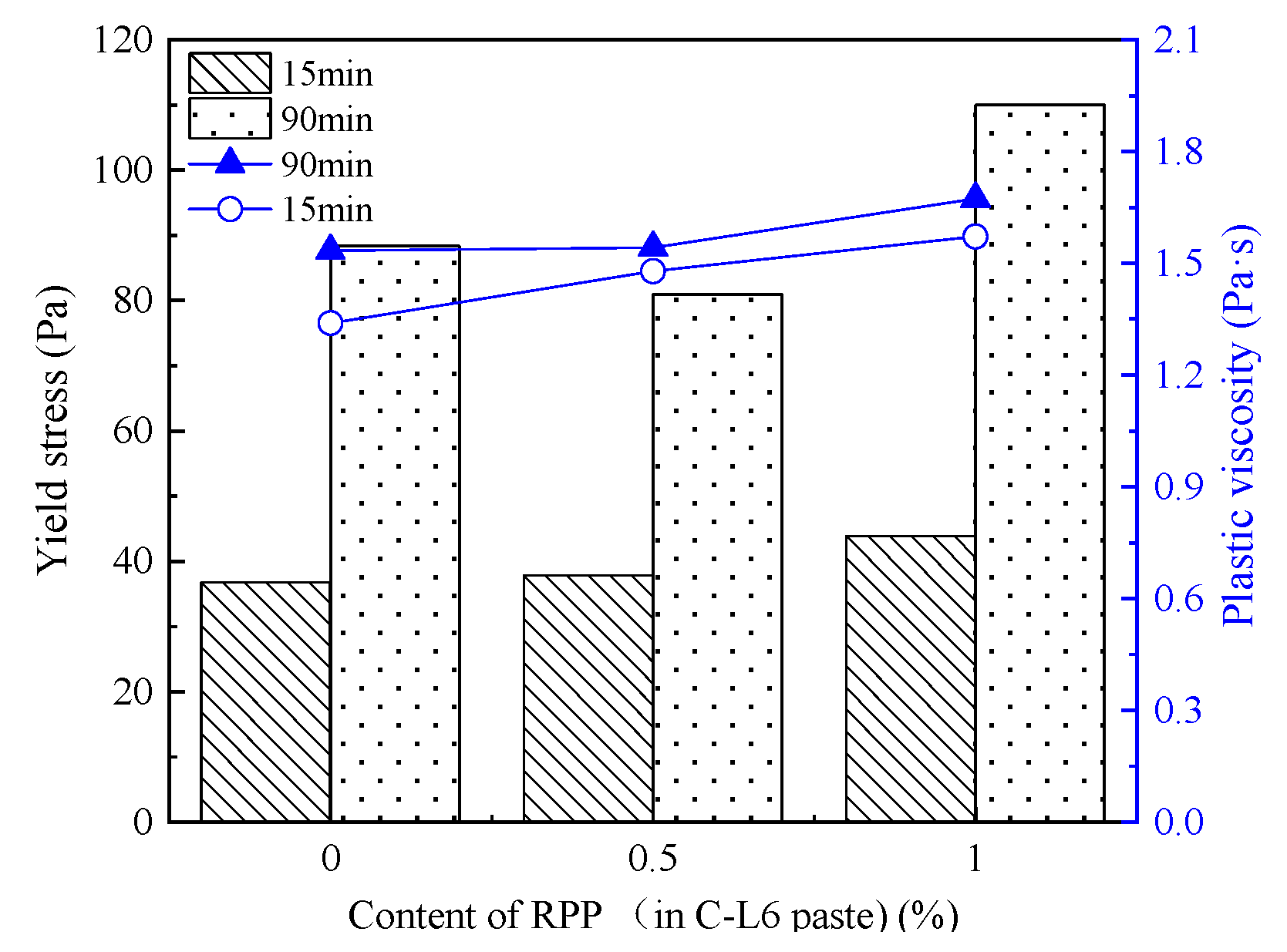

Figure 14.

Yield stress and plastic viscosity of C-L6-RPP pastes.

Figure 14.

Yield stress and plastic viscosity of C-L6-RPP pastes.

Figure 15.

Thixotropic area of C-L6-RPP pastes.

Figure 15.

Thixotropic area of C-L6-RPP pastes.

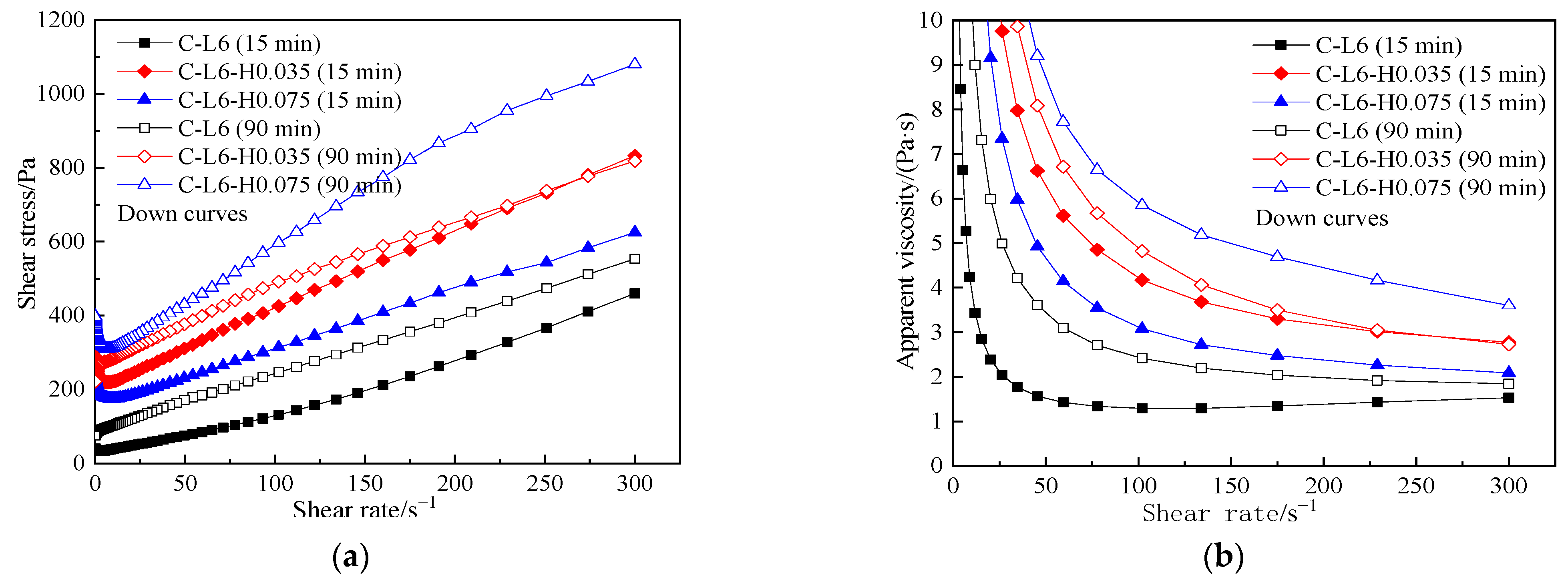

Figure 16.

Rheological curves of C-L6-HPMC pastes. (a) shear stress vs. shear rate, (b) apparent viscosity vs. shear rate.

Figure 16.

Rheological curves of C-L6-HPMC pastes. (a) shear stress vs. shear rate, (b) apparent viscosity vs. shear rate.

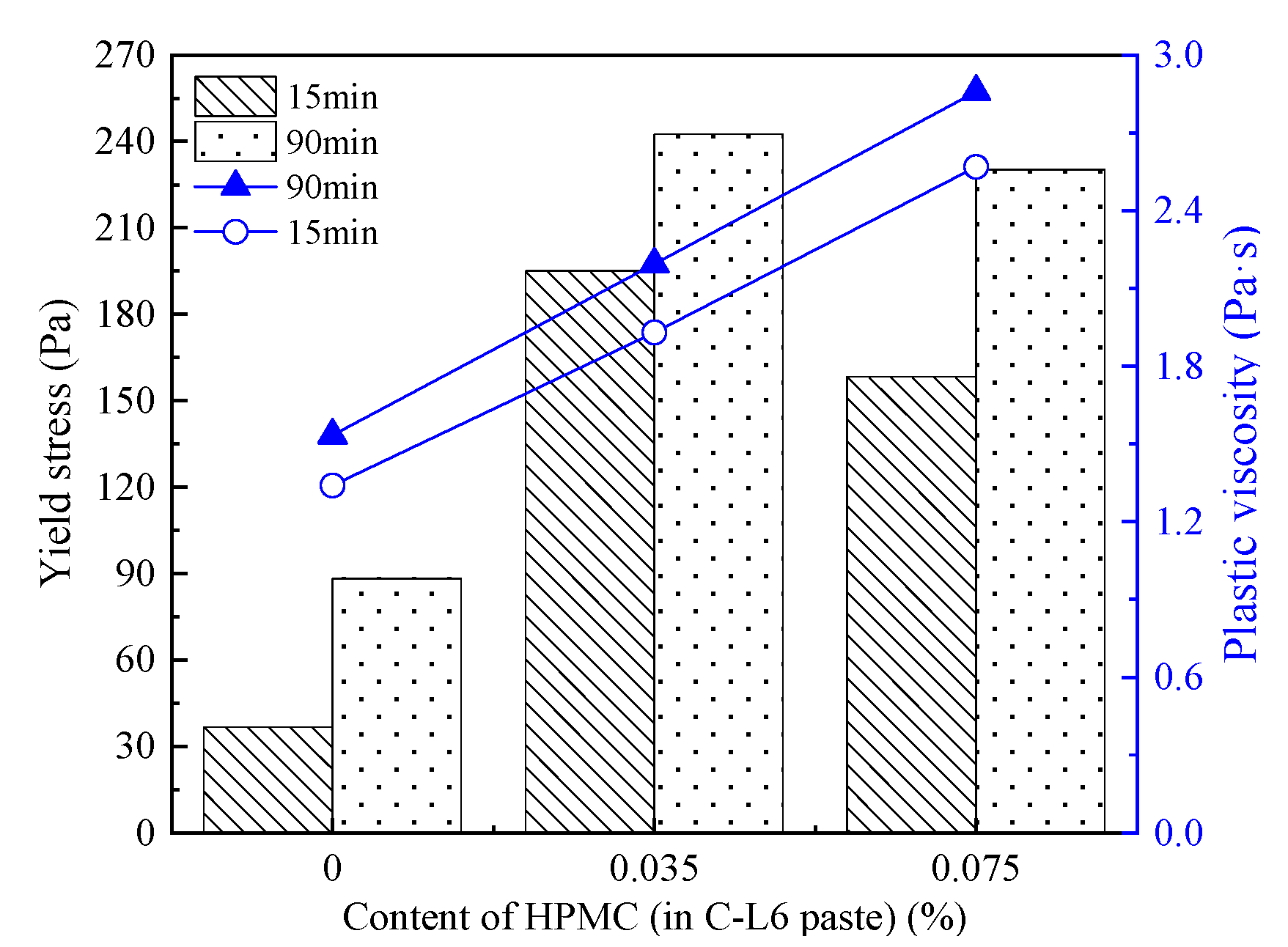

Figure 17.

Yield stress and plastic viscosity of C-L6-HPMC pastes.

Figure 17.

Yield stress and plastic viscosity of C-L6-HPMC pastes.

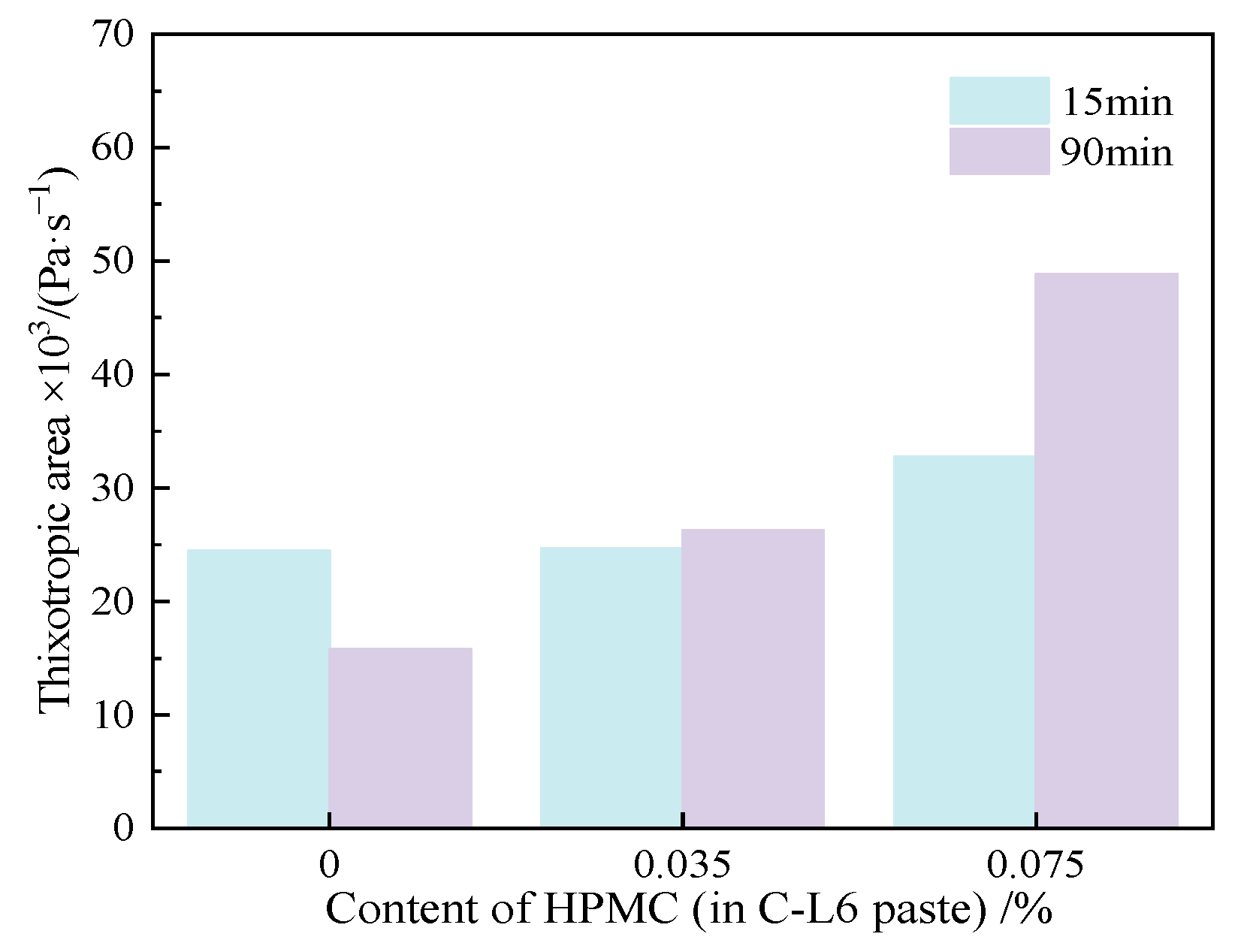

Figure 18.

Thixotropic area of C-L6-HPMC pastes.

Figure 18.

Thixotropic area of C-L6-HPMC pastes.

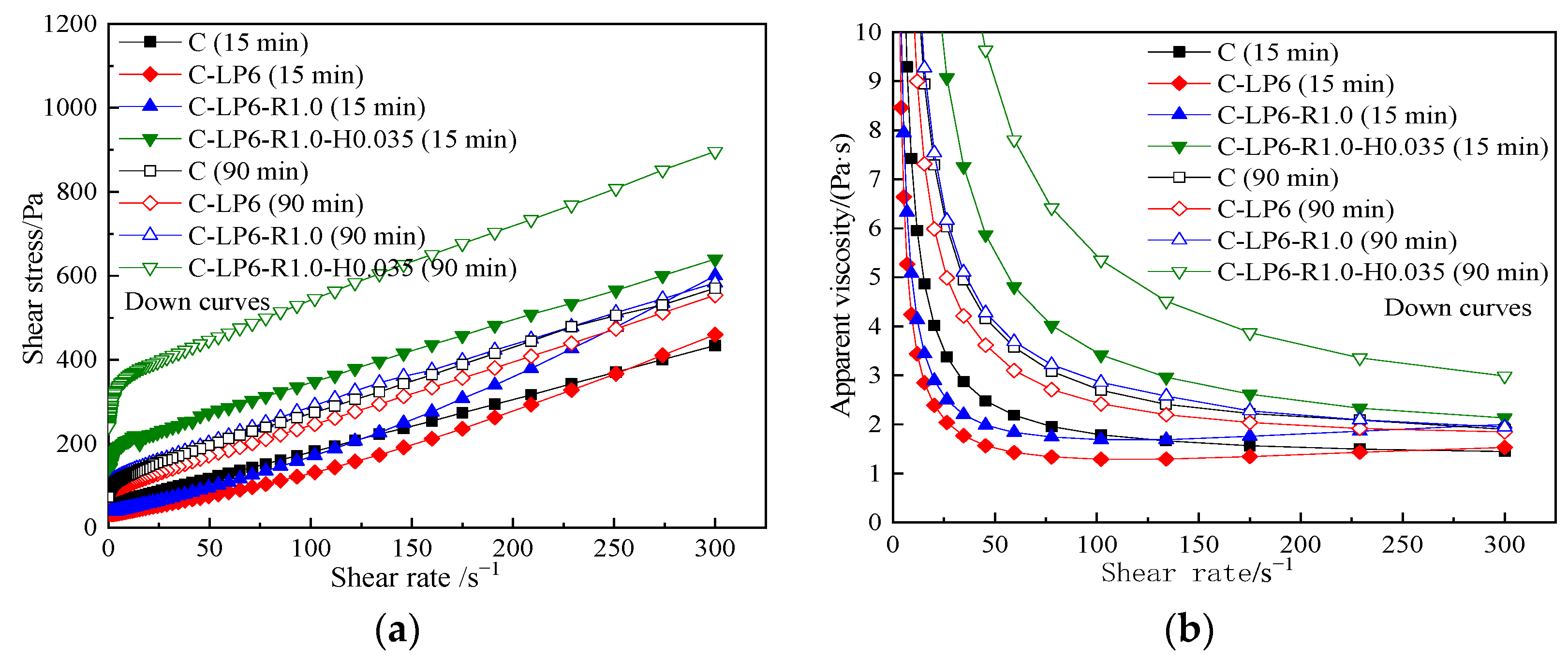

Figure 19.

Rheological curves of C-L6-RPP-HPMC pastes. (a) shear stress vs. shear rate, (b) apparent viscosity vs. shear rate.

Figure 19.

Rheological curves of C-L6-RPP-HPMC pastes. (a) shear stress vs. shear rate, (b) apparent viscosity vs. shear rate.

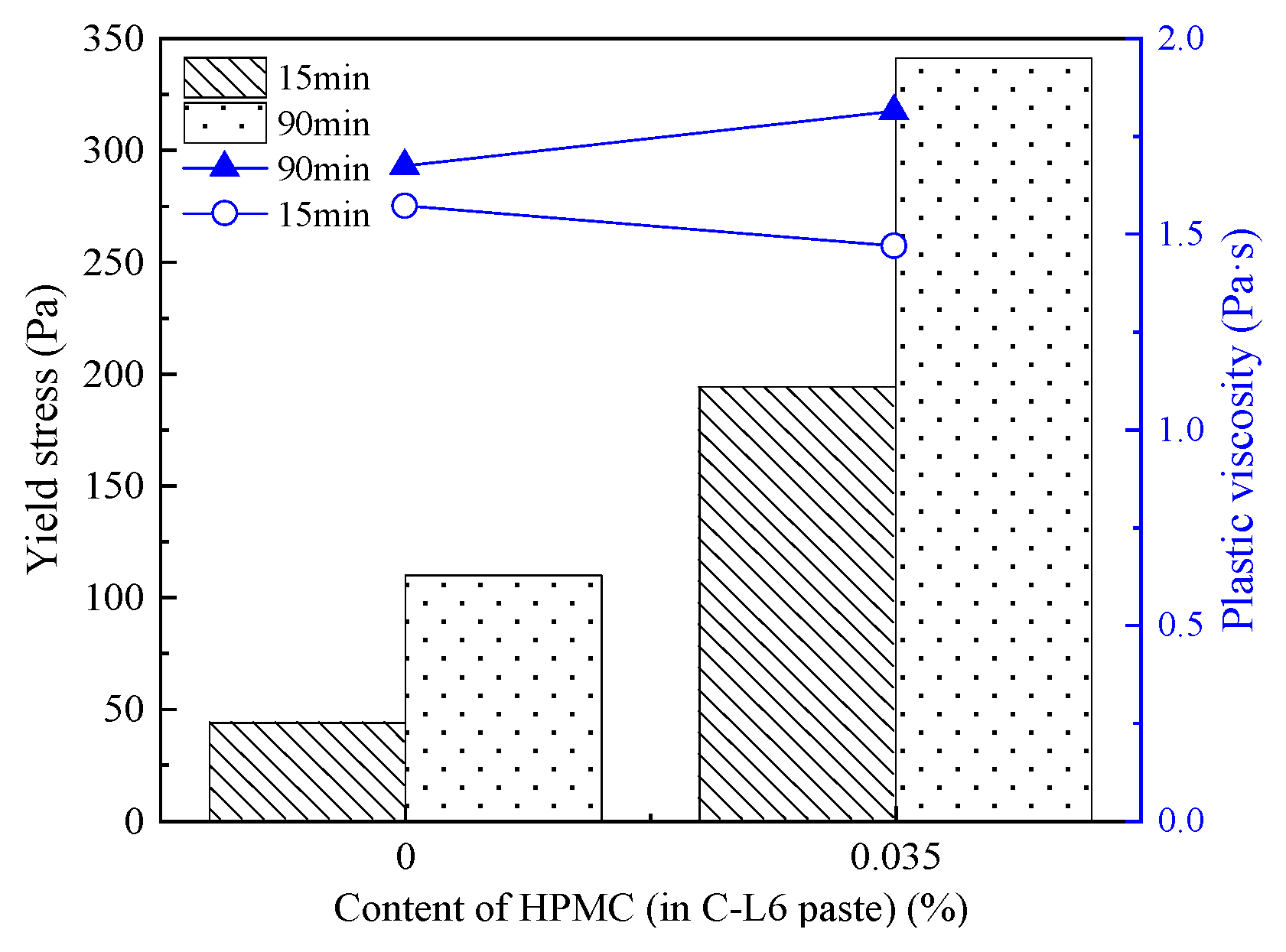

Figure 20.

Yield stress and plastic viscosity of C-L6-R1.0-HPMC pastes.

Figure 20.

Yield stress and plastic viscosity of C-L6-R1.0-HPMC pastes.

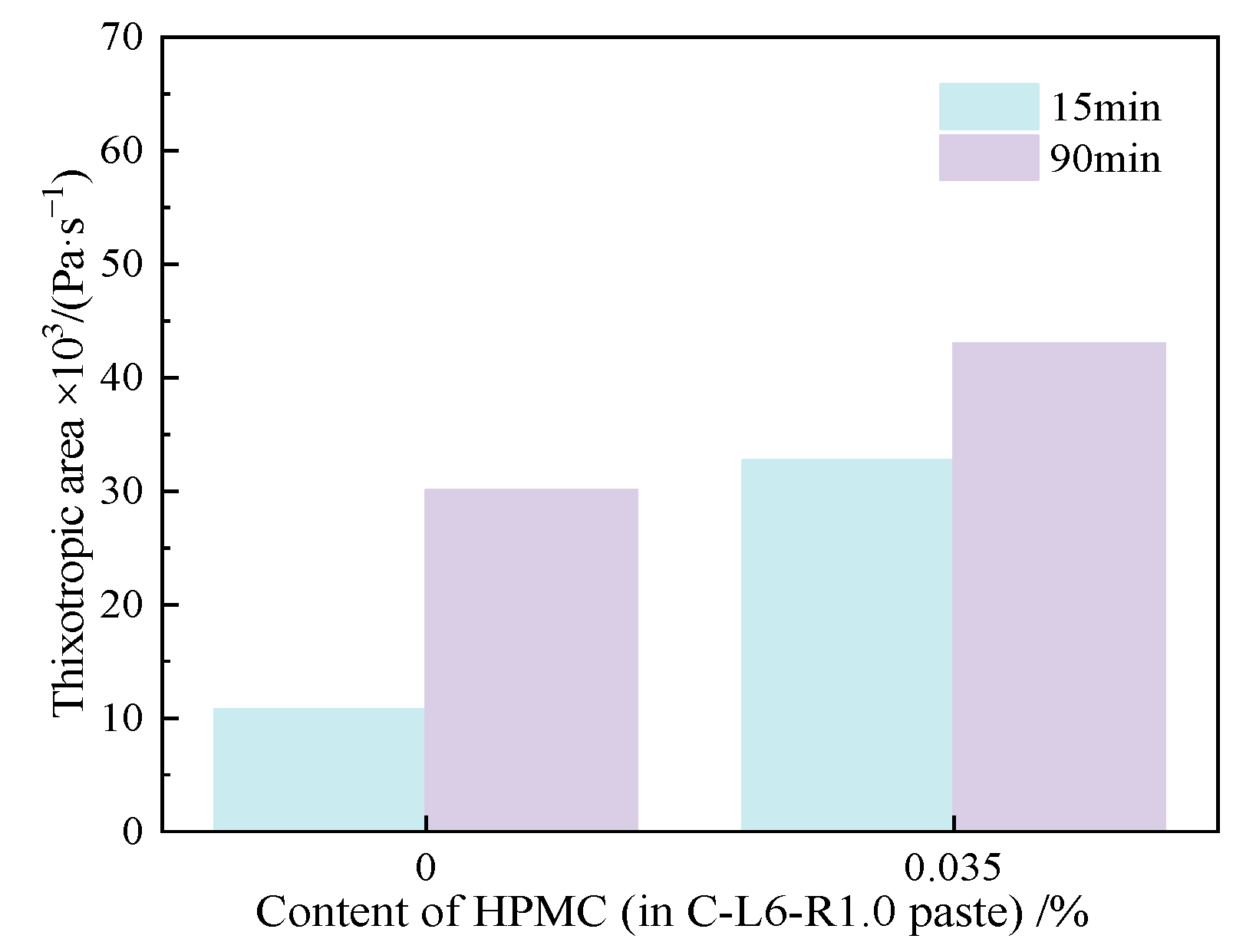

Figure 21.

Thixotropic area of C-L6-RPP-R1.0-HPMC pastes.

Figure 21.

Thixotropic area of C-L6-RPP-R1.0-HPMC pastes.

Figure 22.

Thermogravimetric/differential thermogravimetry curves for 3 d of different pastes. (a) DTA curves, (b) TG curves.

Figure 22.

Thermogravimetric/differential thermogravimetry curves for 3 d of different pastes. (a) DTA curves, (b) TG curves.

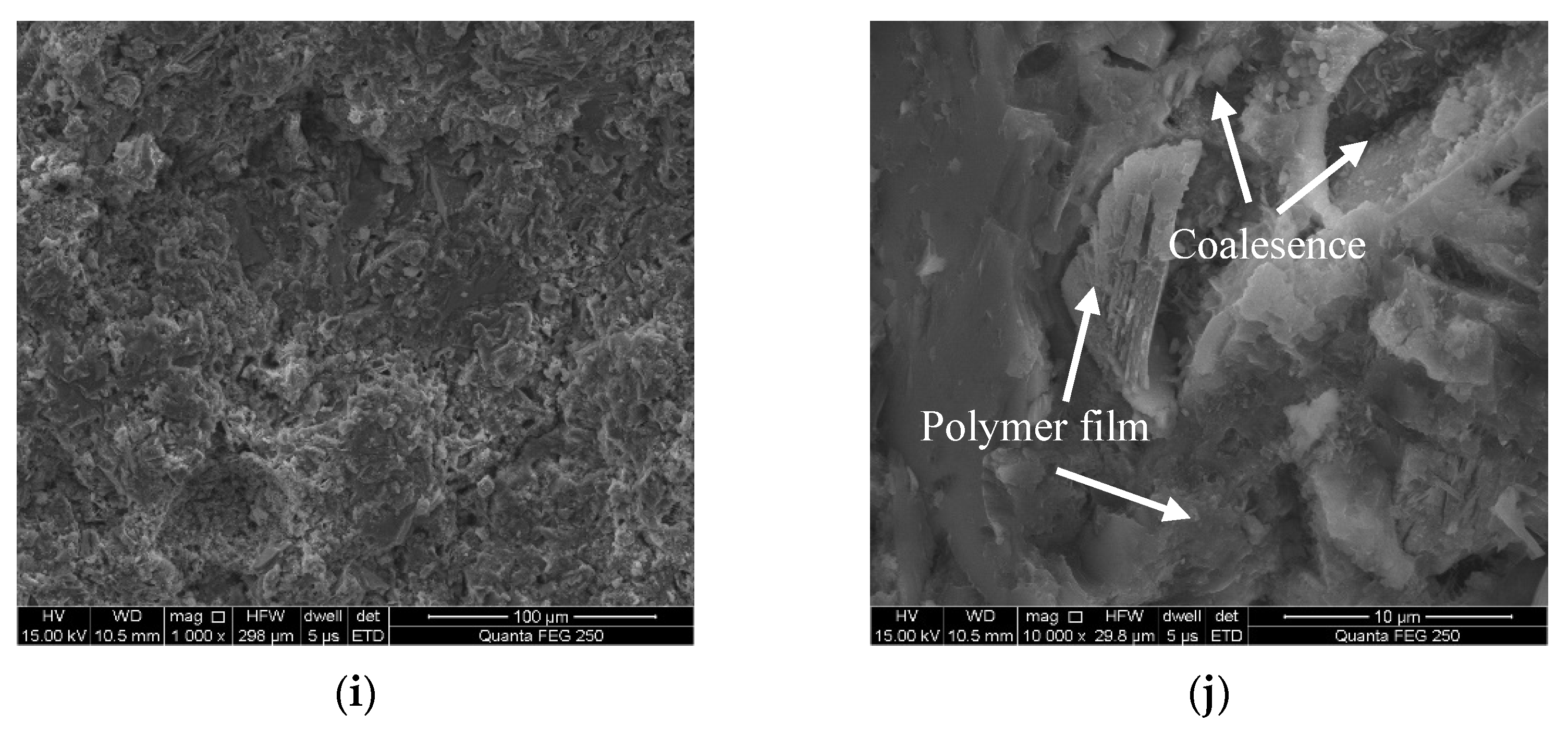

Figure 23.

Microstructure of different pastes cured for 3 d. (a) Cement paste (Magnified 2000 times), (b) Cement paste (Magnified 10,000 times), (c) C-L6(Magnified 2000 times), (d) C-L6(Magnified 10,000 times), (e) C-R1.0(Magnified 2000 times), (f) C-R1.0 (Magnified 10,000 times), (g) C-H0.075 (Magnified 2000 times), (h) C-H0.075 (Magnified 10,000 times), (i) C-L6-R1.0-H0.035 (Magnified 2000 times), (j) C-L6-R1.0-H0.035 (Magnified 10,000 times).

Figure 23.

Microstructure of different pastes cured for 3 d. (a) Cement paste (Magnified 2000 times), (b) Cement paste (Magnified 10,000 times), (c) C-L6(Magnified 2000 times), (d) C-L6(Magnified 10,000 times), (e) C-R1.0(Magnified 2000 times), (f) C-R1.0 (Magnified 10,000 times), (g) C-H0.075 (Magnified 2000 times), (h) C-H0.075 (Magnified 10,000 times), (i) C-L6-R1.0-H0.035 (Magnified 2000 times), (j) C-L6-R1.0-H0.035 (Magnified 10,000 times).

Table 1.

Chemical composition of cement (w/%).

Table 1.

Chemical composition of cement (w/%).

| | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 |

|---|

| PC | 20.95 | 5.19 | 3.83 | 64.29 | 1.85 | 2.95 |

Table 2.

Mineral composition of cement (w/%).

Table 2.

Mineral composition of cement (w/%).

| | C3S | C2S | C3A | C4AF |

|---|

| PC | 59.38 | 15.59 | 7.28 | 11.64 |

Table 3.

Physical properties of cement.

Table 3.

Physical properties of cement.

Fineness

0.08/% | Specific Surface Area/(m2/kg) | Density

/(g/cm3) | Standard Consistency/% | Setting Time/min | Flexural Strength/MPa | Compressive Strength/MPa |

|---|

| Initial | Final | 3d | 3d |

|---|

| 0.5 | 346 | 3.12 | 24.60 | 96 | 158 | 6.5 | 28.0 |

Table 4.

Medium particle size and specific surface area of cement and limestone powder.

Table 4.

Medium particle size and specific surface area of cement and limestone powder.

| Material | | Specific Surface Area/(m2·kg−1) |

|---|

| C | 17.194 | 345 |

| LP | 7.077 | 1104 |

Table 5.

Mix proportion of cement compound paste.

Table 5.

Mix proportion of cement compound paste.

| NO. | Sample | Mix Proportion/g | |

|---|

| C | LP | RPP | HPMC | SP | W |

|---|

| 1 | C | 500 | 0 | 0 | 0 | 0.85 | 160 |

| 2 | C-L3 | 485 | 15 | 0 | 0 |

| 3 | C-L6 | 470 | 30 | 0 | 0 |

| 4 | C-R0.5 | 500 | 0 | 2.5 | 0 |

| 5 | C-R1.0 | 500 | 0 | 5.0 | 0 |

| 6 | C-H0.035 | 500 | 0 | 0 | 0.175 |

| 7 | C-H0.075 | 500 | 0 | 0 | 0.375 |

| 8 | C-L6-R0.5 | 470 | 30 | 2.5 | 0 |

| 9 | C-L6-R1.0 | 470 | 30 | 5 | 0 |

| 10 | C-L6-H0.035 | 470 | 30 | 0 | 0.175 |

| 11 | C-L6-H0.075 | 470 | 30 | 0 | 0.375 |

| 12 | C-L6-R1.0-H0.035 | 470 | 30 | 5 | 0.175 |

Table 6.

Rheological parameters of C-LP pastes.

Table 6.

Rheological parameters of C-LP pastes.

| NO. | Resting Time (min) | | | | |

|---|

| C | 15 min | 56.4 | 1.253 | 1.001 | 0.9999 |

| 90 min | 107.4 | 1.555 | 0.794 | 0.9951 |

| C-L3 | 15 min | 36.8 | 1.057 | 1.323 | 0.9995 |

| 90 min | 88.3 | 1.154 | 1.154 | 0.9987 |

| C-L6 | 15 min | 35.1 | 1.340 | 1.353 | 0.9993 |

| 90 min | 70.3 | 1.533 | 0.932 | 0.9989 |

Table 7.

Rheological parameters of C-RPP pastes.

Table 7.

Rheological parameters of C-RPP pastes.

| NO. | Resting Time (min) | | | | |

|---|

| C | 15 min | 56.4 | 1.253 | 1.001 | 0.9999 |

| 90 min | 107.4 | 1.555 | 0.794 | 0.9951 |

| C-R0.5 | 15 min | 36.8 | 1.787 | 1.293 | 0.9994 |

| 90 min | 70.0 | 1.863 | 0.998 | 0.9992 |

| C-R1.0 | 15 min | 21.8 | 1.605 | 1.361 | 0.9998 |

| 90 min | 39.1 | 1.768 | 1.336 | 0.9994 |

Table 8.

Rheological parameters of C-HPMC pastes.

Table 8.

Rheological parameters of C-HPMC pastes.

| NO. | Resting Time (min) | | | | |

|---|

| C | 15 min | 56.4 | 1.253 | 1.001 | 0.9999 |

| 90 min | 107.4 | 1.555 | 0.794 | 0.9951 |

| C-H0.035 | 15 min | 98.5 | 1.500 | 1.303 | 0.9755 |

| 90 min | 161.5 | 1.636 | 1.082 | 0.9988 |

| C- H0.075 | 15 min | 178.8 | 2.607 | 0.739 | 0.9455 |

| 90 min | 232.5 | 2.561 | 0.697 | 0.9873 |

Table 9.

Rheological parameters of C-L6-RPP pastes.

Table 9.

Rheological parameters of C-L6-RPP pastes.

| NO. | Resting Time (min) | | | | |

|---|

| C-L6 | 15 min | 36.8 | 1.340 | 1.353 | 0.9993 |

| 90 min | 88.3 | 1.533 | 0.932 | 0.9989 |

| C-L6-R0.5 | 15 min | 37.8 | 1.478 | 1.347 | 0.9992 |

| 90 min | 81.0 | 1.541 | 0.985 | 0.9996 |

| C-L6-R1.0 | 15 min | 43.9 | 1.572 | 1.339 | 0.9993 |

| 90 min | 110.0 | 1.673 | 0.825 | 0.9977 |

Table 10.

Rheological parameters of C-L6-HPMC pastes.

Table 10.

Rheological parameters of C-L6-HPMC pastes.

| NO. | Resting Time (min) | | | | |

|---|

| C-L6 | 15 min | 36.8 | 1.340 | 1.353 | 0.9993 |

| 90 min | 88.3 | 1.533 | 0.932 | 0.9989 |

| C-L6-H0.035 | 15 min | 195.0 | 1.930 | 0.944 | 0.9698 |

| 90 min | 242.5 | 3.593 | 0.797 | 0.9963 |

| C-L6-H0.075 | 15 min | 158.3 | 2.568 | 1.027 | 0.9466 |

| 90 min | 230.2 | 2.858 | 0.862 | 0.9633 |

Table 11.

Rheological parameters of C-L6-RPP-HPMC pastes.

Table 11.

Rheological parameters of C-L6-RPP-HPMC pastes.

| NO. | Resting Time (min) | | | | |

|---|

| C | 15 min | 56.4 | 1.253 | 1.001 | 0.9999 |

| 90 min | 107.4 | 1.555 | 0.794 | 0.9951 |

| C-L6 | 15 min | 36.8 | 1.340 | 1.353 | 0.9993 |

| 90 min | 88.3 | 1.533 | 0.932 | 0.9989 |

| C-L6-R1.0 | 15 min | 43.9 | 1.572 | 1.339 | 0.9993 |

| 90 min | 110.0 | 1.673 | 0.825 | 0.9977 |

| C-L6-R1.0-H0.035 | 15 min | 194.2 | 1.469 | 0.998 | 0.9952 |

| 90 min | 341.3 | 1.813 | 0.985 | 0.9859 |