Low-Power Laser Powder Bed Fusion Processing of Scalmalloy®

Abstract

:1. Introduction

2. Materials and Methods

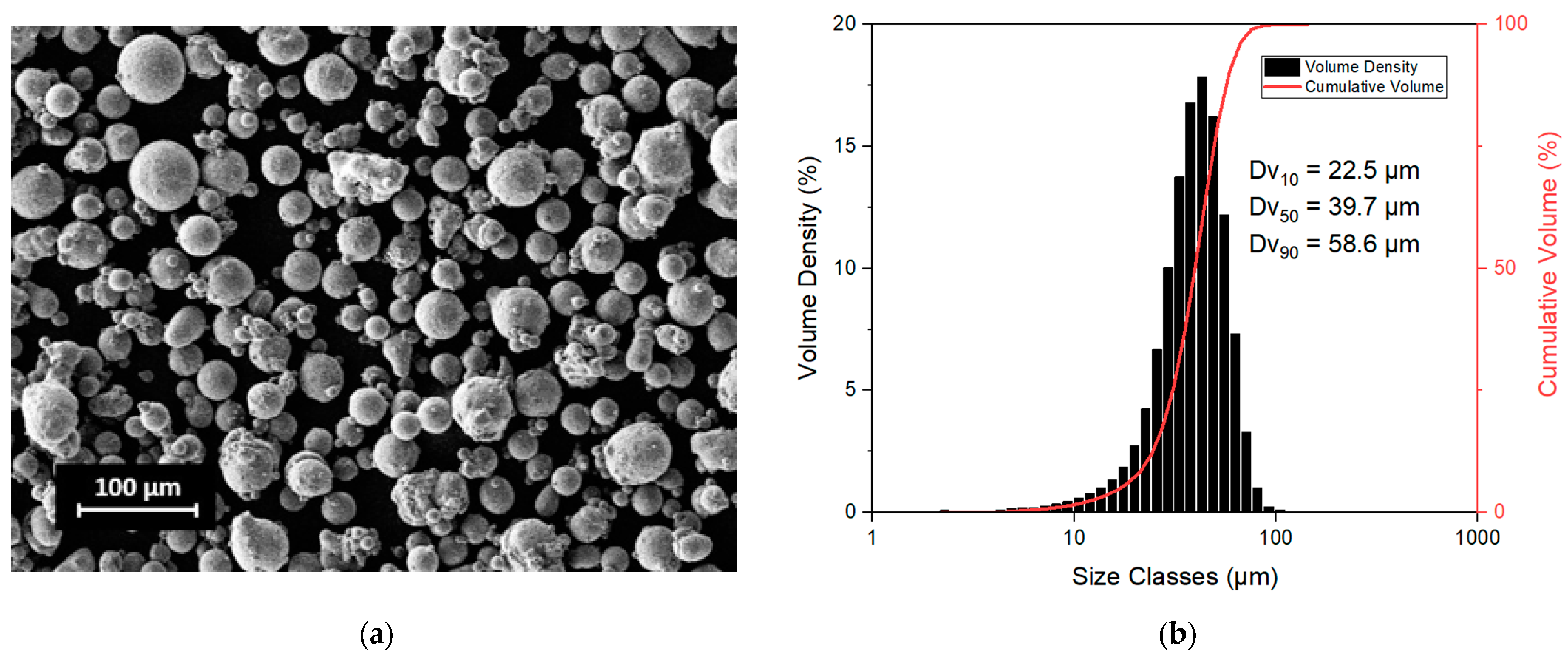

2.1. Materials

2.2. Production of LPBF Samples

2.3. Characterization

3. Results

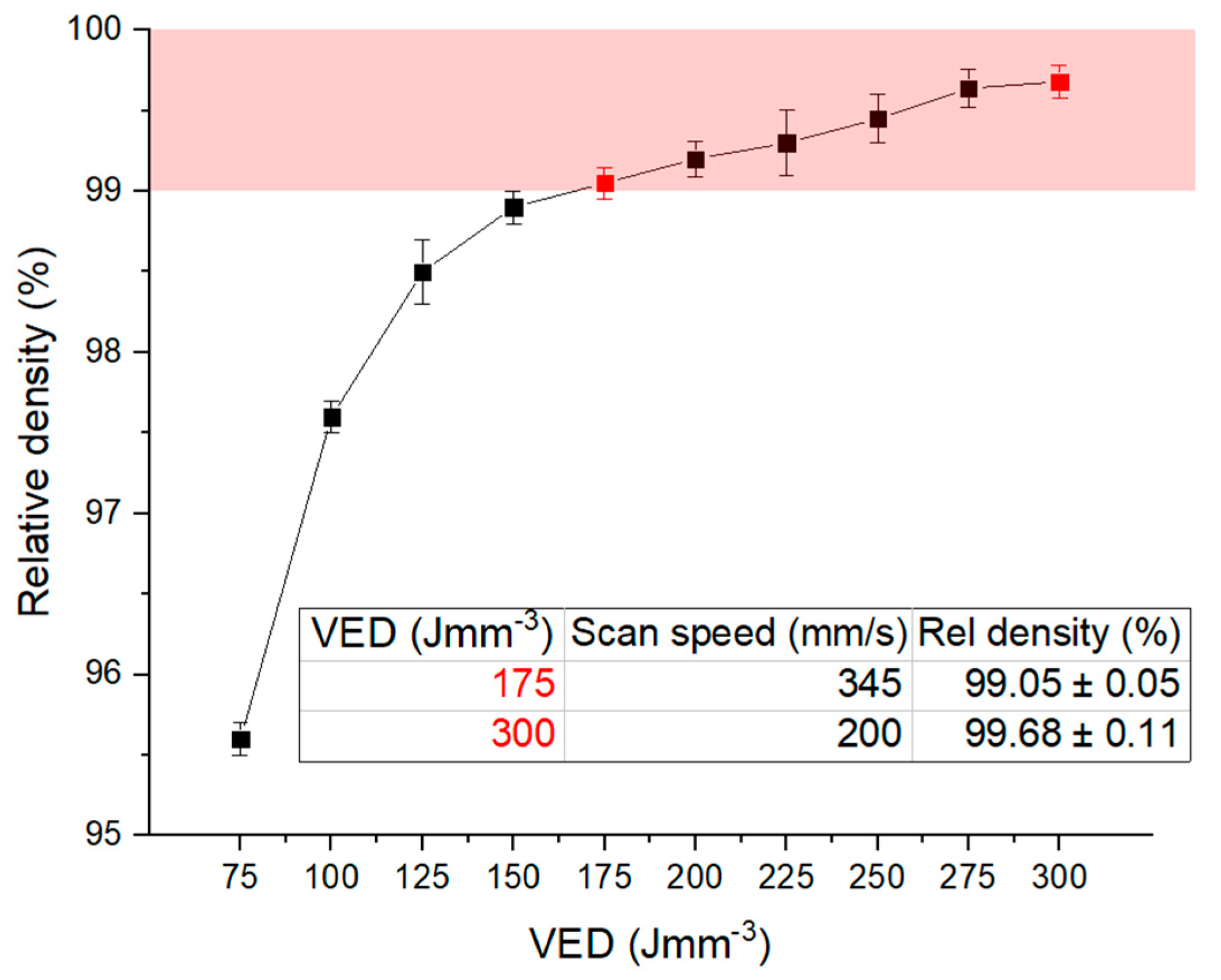

3.1. LPBF Process Parameter Window

3.2. Phase Identification

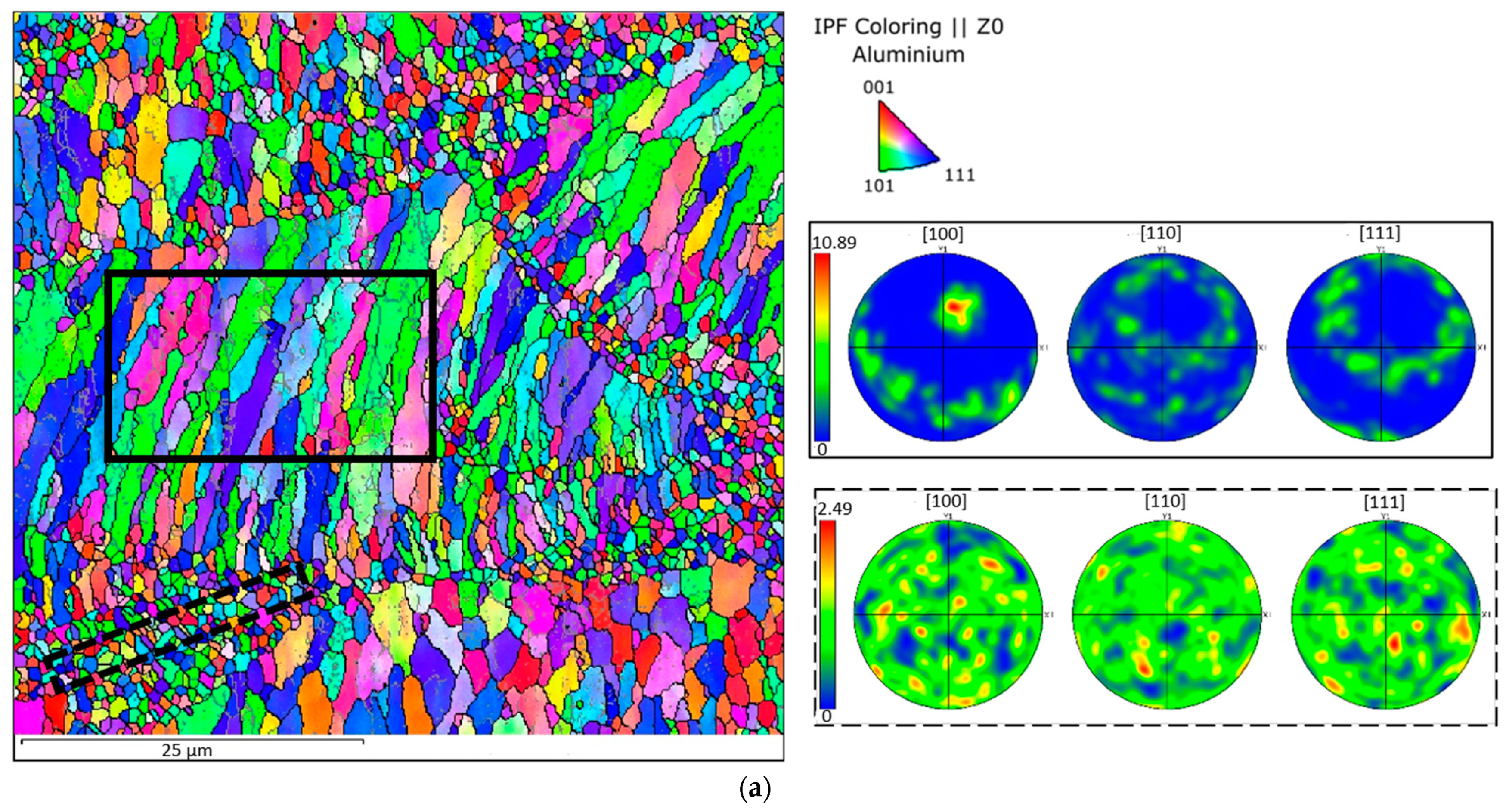

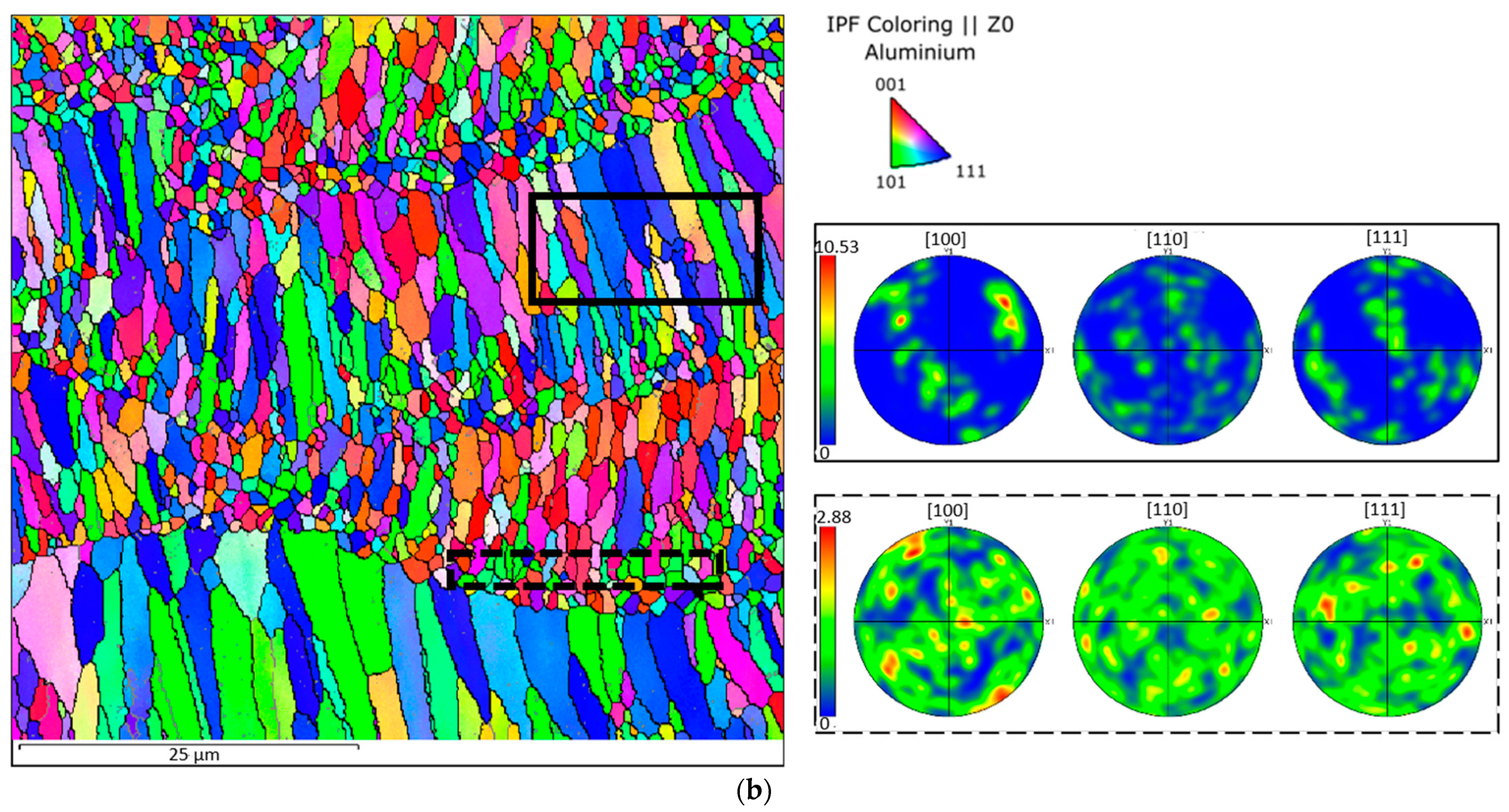

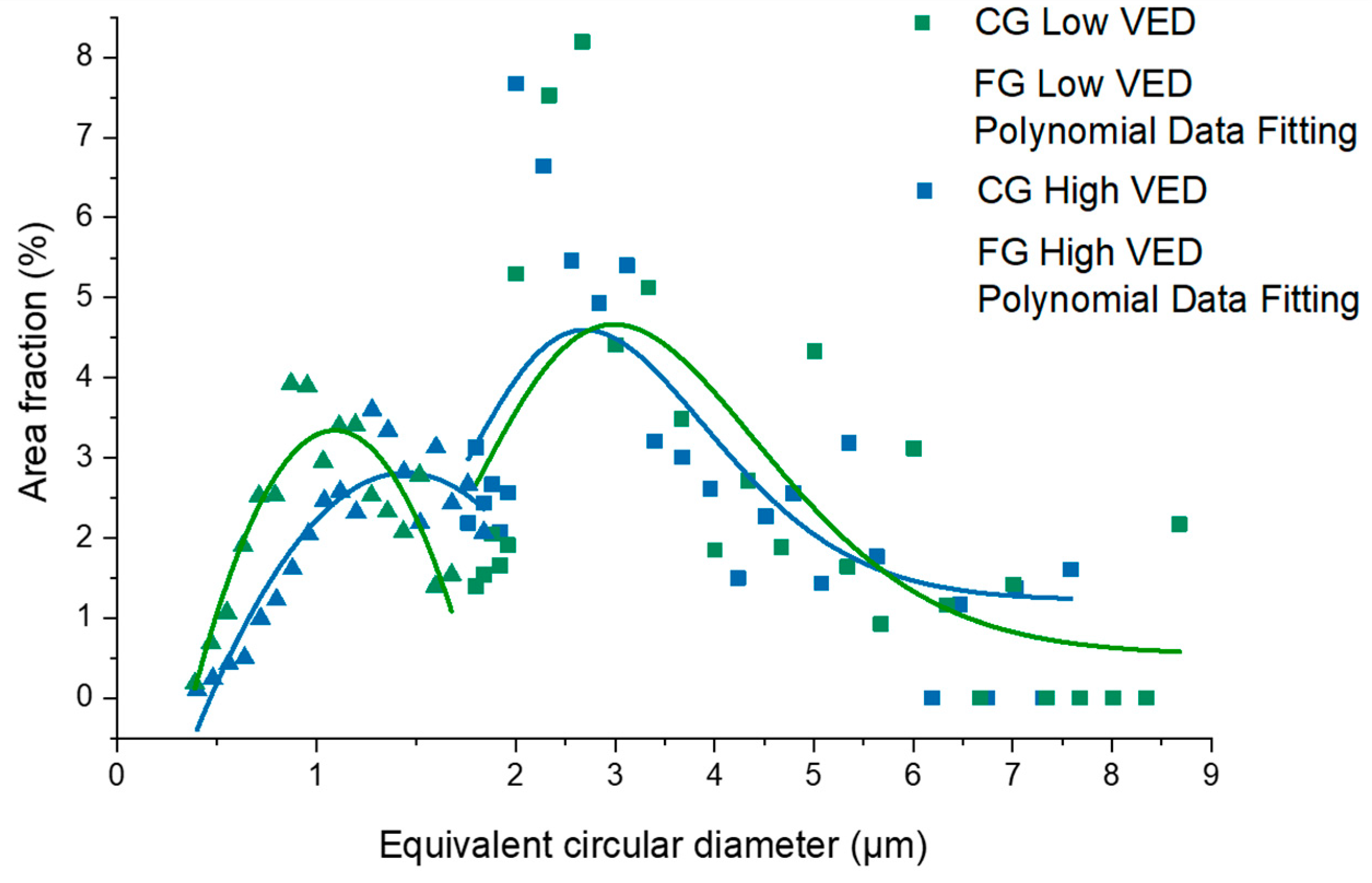

3.3. As-Built Microstructure

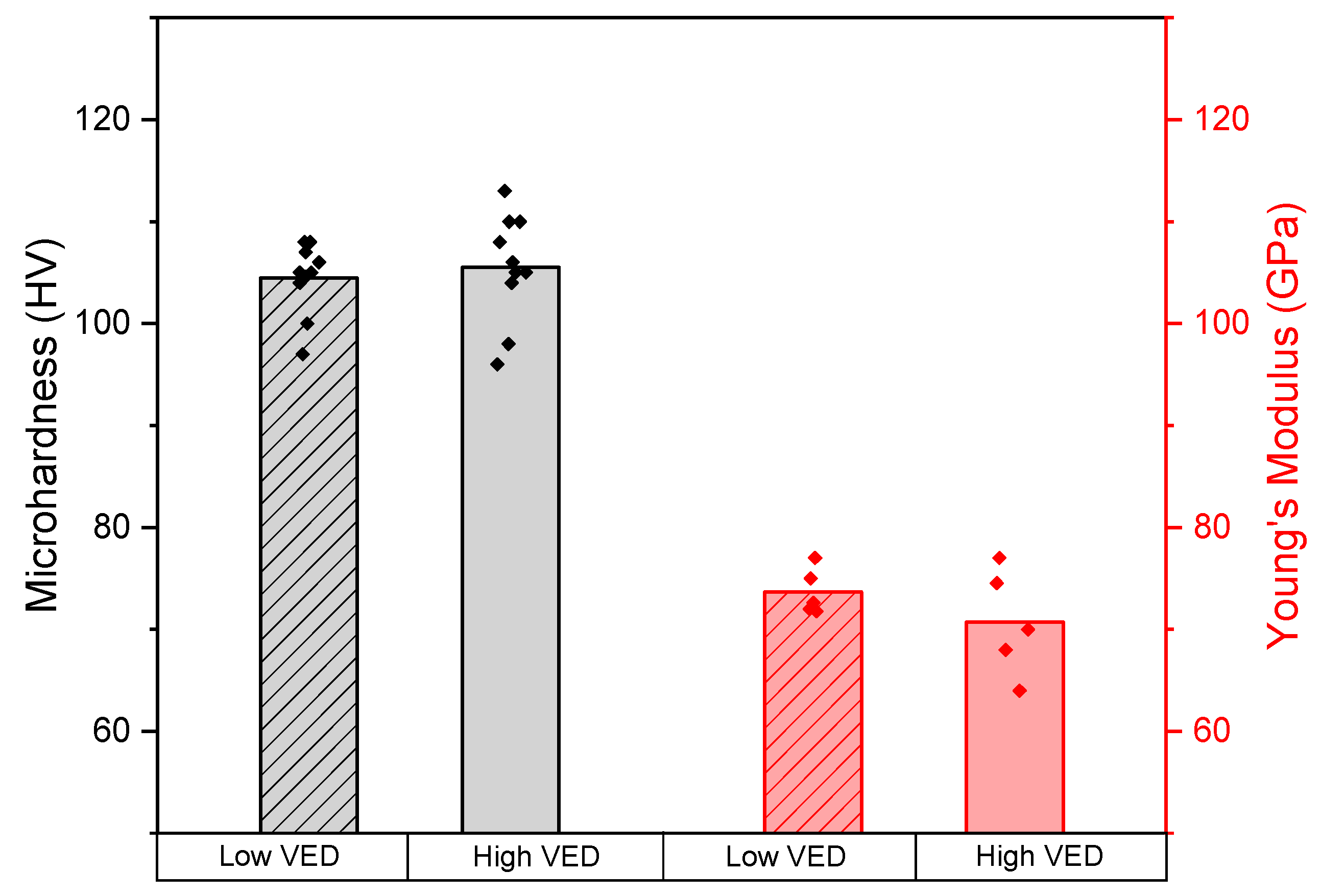

3.4. As-Built Mechanical Properties

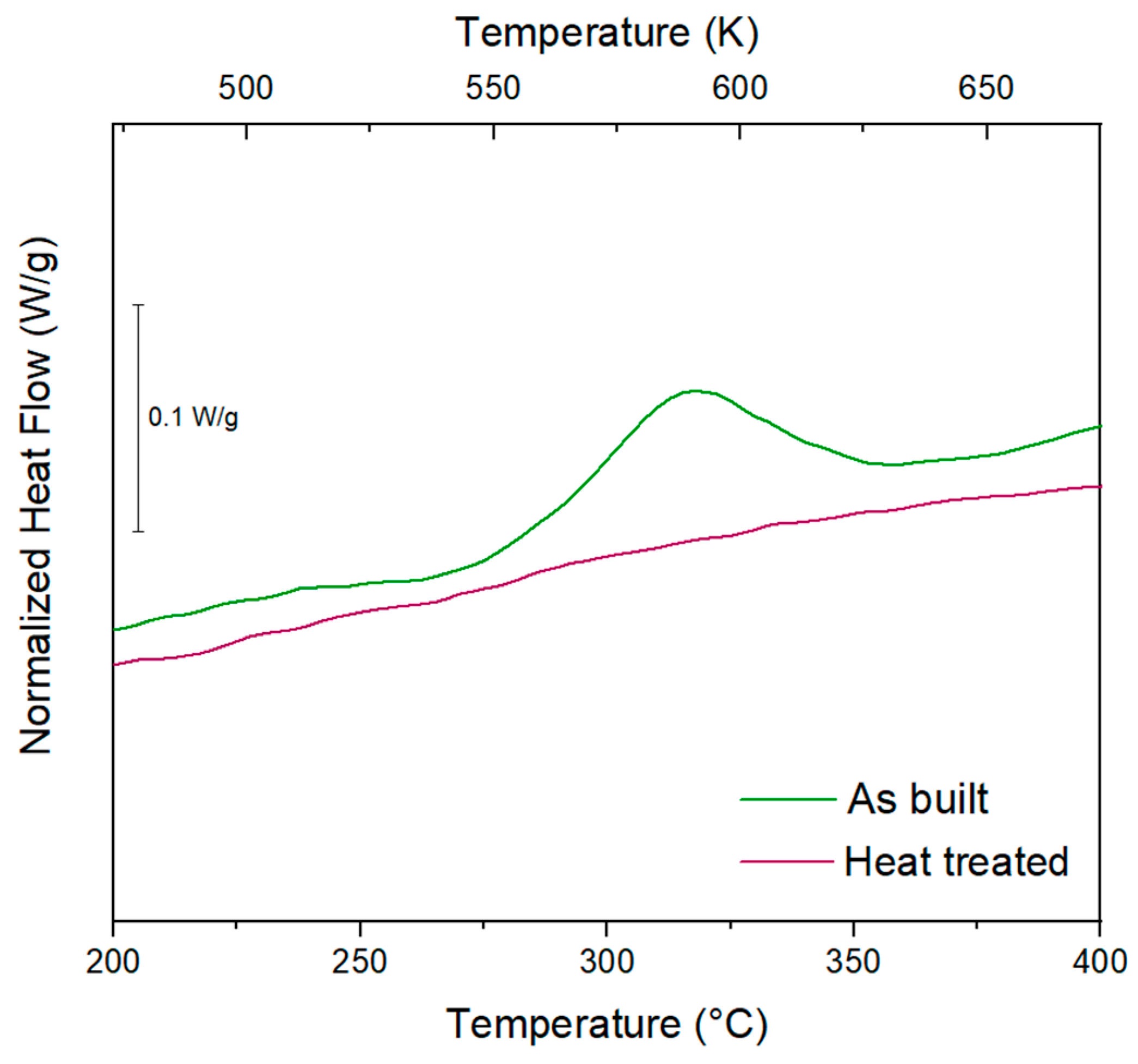

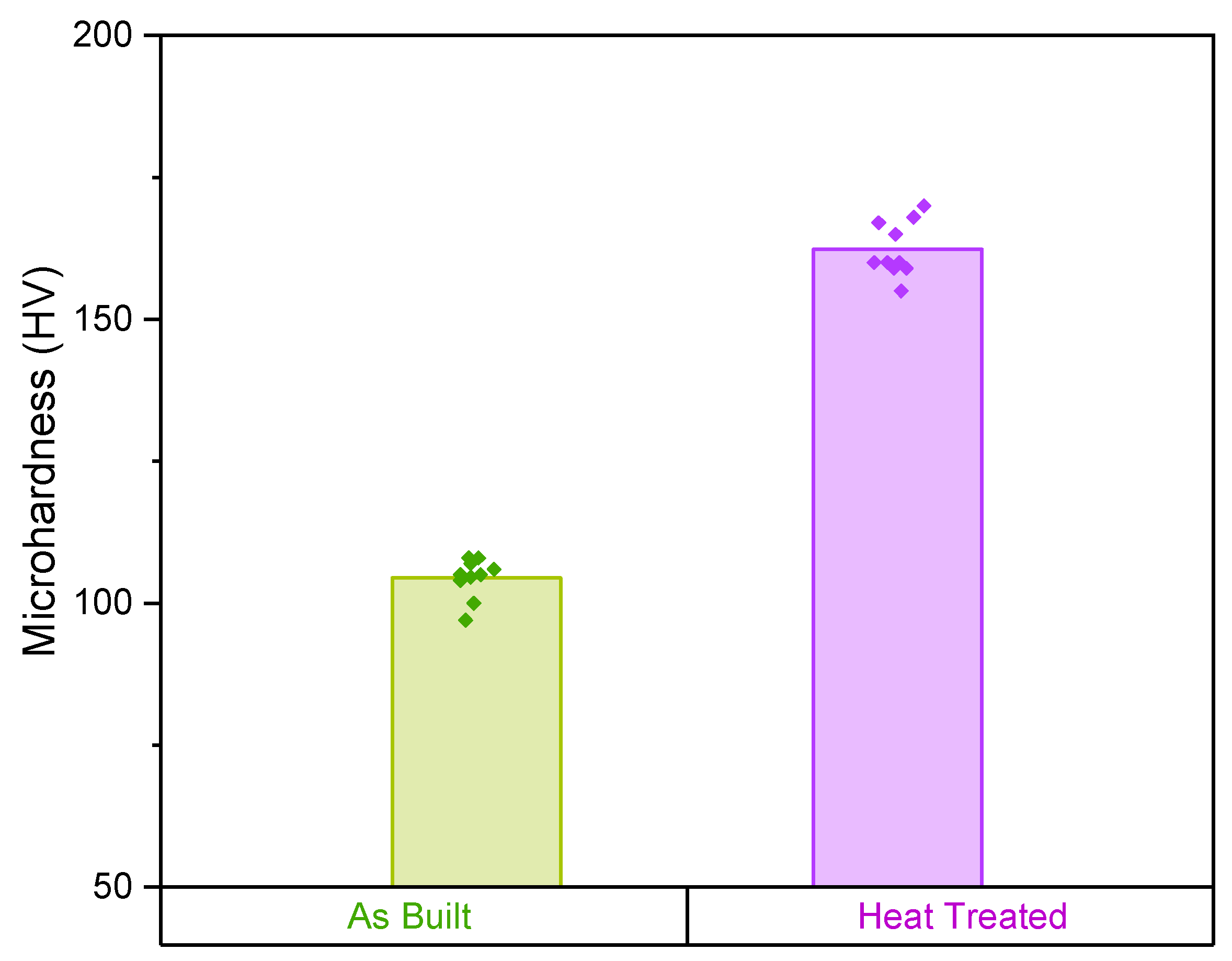

3.5. Heat Treatment Effect

4. Discussion

5. Conclusions

- An exponential increase in densification level from 95.6 to 99.7% was observed by increasing the volumetric energy density. Above 175 Jmm−3, however, there was a relative density stabilisation with values above 99%.

- EBSD analyses revealed a similar preferential growing direction in the CG zone for both VED conditions, showing an orientation parallel to the build direction. However, a general finer microstructure was observed for the low-VED sample.

- The mechanical investigations led to an identical mean microhardness value of 105 HV for each processing condition and a slightly higher Young’s modulus value for the low-VED sample (74 GPa).

- The comparison of DSC signals between the as-built and the heat-treated conditions permitted us to verify the effectiveness of the heat treatment conducted at 325 °C for 4 h. An exothermic peak centred at 312 °C and related to the Al3(Sc, Zr) formation was detected only for the as-built sample. Therefore, the disappearance of the latter for the heat-treated sample suggested the accomplishment of precipitation reactions.

- Despite the EBSD analysis, a fairly marked grain size change was highlighted after the heat treatment; the growth was controlled by the inoculating action of precipitates. In addition, an impressive improvement in mechanical properties was noticed after the heat treatment with an increase in microhardness of more than 50%.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive manufacturing of metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Bartkowiak, K.; Ullrich, S.; Frick, T.; Schmidt, M. New developments of laser processing aluminium alloys via additive manufacturing technique. Phys. Procedia 2011, 12, 393–401. [Google Scholar] [CrossRef] [Green Version]

- Fiocchi, J.; Tuissi, A.; Biffi, C. Heat treatment of aluminium alloys produced by laser powder bed fusion: A review. Mater. Des. 2021, 204, 109651. [Google Scholar] [CrossRef]

- Olakanmi, E.O.T.; Cochrane, R.F.; Dalgarno, K.W. A review on selective laser sintering/melting (SLS/SLM) of aluminium alloy powders: Processing, microstructure, and properties. Prog. Mater. Sci. 2015, 74, 401–477. [Google Scholar] [CrossRef]

- Aversa, A.; Marchese, G.; Saboori, A.; Bassini, E.; Manfredi, D.; Biamino, S.; Ugues, D.; Fino, P.; Lombardi, M. New aluminium alloys specifically designed for laser powder bed fusion: A review. Materials 2019, 12, 1007. [Google Scholar] [CrossRef] [Green Version]

- Zhang, H.; Gu, D.; Yang, J.; Dai, D.; Zhao, T.; Hong, C.; Gasser, A.; Poprawe, R. Selective laser melting of rare earth element Sc modified aluminum alloy: Thermodynamics of precipitation behavior and its influence on mechanical properties. Addit. Manuf. 2018, 23, 1–12. [Google Scholar] [CrossRef]

- Zakharov, V.V. Effect of scandium on the structure and properties of aluminum alloys. Met. Sci. Heat Treat. 2003, 45, 246–253. [Google Scholar] [CrossRef]

- Spierings, A.B.; Dawson, K.; Voegtlin, M.; Palm, F.; Uggowitzer, P.J. Microstructure and mechanical properties of as-processed scandium-modified aluminium using selective laser melting. Cirp Ann. 2016, 65, 213–216. [Google Scholar] [CrossRef]

- Davydov, V.G.; Elagin, V.I.; Zakharov, V.V.; Rostoval, D. Alloying aluminum alloys with scandium and zirconium additives. Met. Sci. Heat Treat. 1996, 38, 347–352. [Google Scholar] [CrossRef]

- Fuller, C.B.; Seidman, D.N.; Dunand, D.C. Mechanical properties of Al (Sc, Zr) alloys at ambient and elevated temperatures. Acta Mater. 2003, 51, 4803–4814. [Google Scholar] [CrossRef]

- Sutcliffe, C.; Fox, P. Manufacture of Metal Articles. WO2013179017A1, 5 December 2013. [Google Scholar]

- Sébastien, B.; Florence, M.; Gilles, P.; Guillaume, L.; Maxime, G.; Sébastien, E. Additive manufacturing of Scalmalloy® satellite parts. In Proceedings of the 8th European Conference For Aeronautics And Space Sciences (Eucass), Madrid, Spain, 1–4 July 2019. [Google Scholar]

- Spierings, A.B.; Dawson, K.; Uggowitzer, P.J.; Wegener, K. Influence of SLM scan-speed on microstructure, precipitation of Al3Sc particles and mechanical properties in Sc-and Zr-modified Al-Mg alloys. Mater. Des. 2018, 140, 134–143. [Google Scholar] [CrossRef]

- Spierings, A.B.; Dawson, K.; Heeling, T.; Uggowitzer, P.J.; Schäublin, R.; Palm, F.; Wegener, K. Microstructural features of Sc-and Zr-modified Al-Mg alloys processed by selective laser melting. Mater. Des. 2017, 115, 52–63. [Google Scholar] [CrossRef]

- Schmidtke, K.; Palm, F.; Hawkins, A.; Emmelmann, C. Process and mechanical properties: Applicability of a scandium modified Al-alloy for laser additive manufacturing. Phys. Procedia 2011, 12, 369–374. [Google Scholar] [CrossRef] [Green Version]

- Spierings, A.; Dawson, K.; Kern, K.; Palm, F.; Wegener, K. SLM-processed Sc-and Zr-modified Al-Mg alloy: Mechanical properties and microstructural effects of heat treatment. Mater. Sci. Eng. A 2017, 701, 264–273. [Google Scholar] [CrossRef]

- Lasagni, F.; Galleguillos, C.; Herrera, M.; Santaolaya, J.; Hervás, D.; González, S.; Periñán, A. On the processability and mechanical behavior of Al–Mg–Sc alloy for PBF-LB. Prog. Addit. Manuf. 2022, 7, 29–39. [Google Scholar] [CrossRef]

- Shi, Y.; Rometsch, P.; Yang, K.; Palm, F.; Wu, X. Characterisation of a novel Sc and Zr modified Al–Mg alloy fabricated by selective laser melting. Mater. Lett. 2017, 196, 347–350. [Google Scholar] [CrossRef]

- Li, R.; Wang, M.; Yuan, T.; Song, B.; Chen, C.; Zhou, K.; Cao, P. Selective laser melting of a novel Sc and Zr modified Al-6.2 Mg alloy: Processing, microstructure, and properties. Powder Technol. 2017, 319, 117–128. [Google Scholar] [CrossRef]

- Vlach, M.; Stulikova, I.; Smola, B.; Kekule, T.; Kudrnova, H.; Danis, S.; Gemma, R.; Ocenasek, V.; Malek, J.; Tanprayoon, D.; et al. Precipitation in cold-rolled Al–Sc–Zr and Al–Mn–Sc–Zr alloys prepared by powder metallurgy. Mater. Charact. 2013, 86, 59–68. [Google Scholar] [CrossRef]

- Li, R.; Chen, H.; Zhu, H.; Wang, M.; Chen, C.; Yuan, T. Effect of aging treatment on the microstructure and mechanical properties of Al-3.02 Mg-0.2 Sc-0.1 Zr alloy printed by selective laser melting. Mater. Des. 2019, 168, 107668. [Google Scholar] [CrossRef]

- Spierings, A.; Dawson, K.; Dumitraschkewitz, P.; Pogatscher, S.; Wegener, K. Microstructure characterization of SLM-processed Al-Mg-Sc-Zr alloy in the heat treated and HIPed condition. Addit. Manuf. 2018, 20, 173–181. [Google Scholar] [CrossRef]

- Weingarten, C.; Buchbinder, D.; Pirch, N.; Meiners, W.; Wissenbach, K.; Poprawe, R. Formation and reduction of hydrogen porosity during selective laser melting of AlSi10Mg. J. Mater. Processing Technol. 2015, 221, 112–120. [Google Scholar] [CrossRef]

- Royset, J.; Ryum, N. Kinetics and mechanisms of precipitation in an Al–0.2 wt.% Sc alloy. Mater. Sci. Eng. A 2005, 396, 409–422. [Google Scholar] [CrossRef]

- Hosseiny, N.; Shabani, A.; Toroghinejad, M.R. Effect of bimodal microstructure on texture evolution and mechanical properties of 1050 Al alloy processed through severe plastic deformation and subsequent annealing. Mater. Sci. Eng. A 2021, 820, 141580. [Google Scholar] [CrossRef]

- Zhu, L.; Lu, J. Modelling the plastic deformation of nanostructured metals with bimodal grain size distribution. Int. J. Plast. 2012, 30, 166–184. [Google Scholar] [CrossRef]

- Wang, Y.; Ma, E. Three strategies to achieve uniform tensile deformation in a nanostructured metal. Acta Mater. 2004, 52, 1699–1709. [Google Scholar] [CrossRef]

- Arora, H.S.; Ayyagari, A.; Saini, J.; Selvam, K.; Riyadh, S.; Pole, M.; Grewal, H.S.; Mukherjee, S. High Tensile Ductility and Strength in Dual-phase Bimodal Steel through Stationary Friction Stir Processing. Sci. Rep. 2019, 9, 1972. [Google Scholar] [CrossRef] [PubMed]

- Kok, Y.; Tan, X.; Wang, P.; Nai, M.; Loh, N.; Liu, E.; Tor, S.B. Anisotropy and heterogeneity of microstructure and mechanical properties in metal additive manufacturing: A critical review. Mater. Des. 2018, 139, 565–586. [Google Scholar] [CrossRef]

- Ashby, M.F.; Shercliff, H.; Cebon, D. Materiali: Dalla Scienza alla Progettazione Ingegneristica; CEA: Bassano del Grappa, Italy, 2009. [Google Scholar]

- Booth-Morrison, C.; Seidman, D.N.; Dunand, D.C. Effect of Er additions on ambient and high-temperature strength of precipitation-strengthened Al–Zr–Sc–Si alloys. Acta Mater. 2012, 60, 3643–3654. [Google Scholar] [CrossRef]

- Zhang, H.-M.; Zha, M.; Jia, H.-L.; Tian, T.; Zhang, X.-H.; Wang, C.; Ma, P.-K.; Gao, D.; Wang, H.-Y. Influences of the Al3Sc particle content on the evolution of bimodal grain structure and mechanical properties of Al–Mg–Sc alloys processed by hard-plate rolling. Mater. Sci. Eng. A 2021, 802, 140451. [Google Scholar] [CrossRef]

- Smith, W.F.; Hashemi, J. Scienza e Tecnologia dei Materiali; Connect; McGraw-Hill: New York, NY, USA, 2016. [Google Scholar]

| Element (wt%) | Mg | Sc | Mn | Zr | Fe | Si | Other Elements |

|---|---|---|---|---|---|---|---|

| Scalmalloy® | 4.77 | 0.78 | 0.51 | 0.27 | 0.12 | 0.06 | <0.3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Martucci, A.; Aversa, A.; Manfredi, D.; Bondioli, F.; Biamino, S.; Ugues, D.; Lombardi, M.; Fino, P. Low-Power Laser Powder Bed Fusion Processing of Scalmalloy®. Materials 2022, 15, 3123. https://doi.org/10.3390/ma15093123

Martucci A, Aversa A, Manfredi D, Bondioli F, Biamino S, Ugues D, Lombardi M, Fino P. Low-Power Laser Powder Bed Fusion Processing of Scalmalloy®. Materials. 2022; 15(9):3123. https://doi.org/10.3390/ma15093123

Chicago/Turabian StyleMartucci, Alessandra, Alberta Aversa, Diego Manfredi, Federica Bondioli, Sara Biamino, Daniele Ugues, Mariangela Lombardi, and Paolo Fino. 2022. "Low-Power Laser Powder Bed Fusion Processing of Scalmalloy®" Materials 15, no. 9: 3123. https://doi.org/10.3390/ma15093123

APA StyleMartucci, A., Aversa, A., Manfredi, D., Bondioli, F., Biamino, S., Ugues, D., Lombardi, M., & Fino, P. (2022). Low-Power Laser Powder Bed Fusion Processing of Scalmalloy®. Materials, 15(9), 3123. https://doi.org/10.3390/ma15093123