Evaluation of Tensile Bond Strength between Self-Adhesive Resin Cement and Surface-Pretreated Zirconia

Abstract

1. Introduction

2. Materials and Methods

2.1. Specimen Preparation

- Group 1: not treated;

- Group 2: air-abraded with 50-μm-sized alumina particles under a pressure of 0.1 MPa from a distance of 10 mm for 20 s and at incidence angles of 60–90°;

- Group 3: etched using Zircos-E HNO3/HF etching solution;

- Group 4: treated with ZirADD zirconia-nanoparticle coating.

2.2. Bonding Procedure

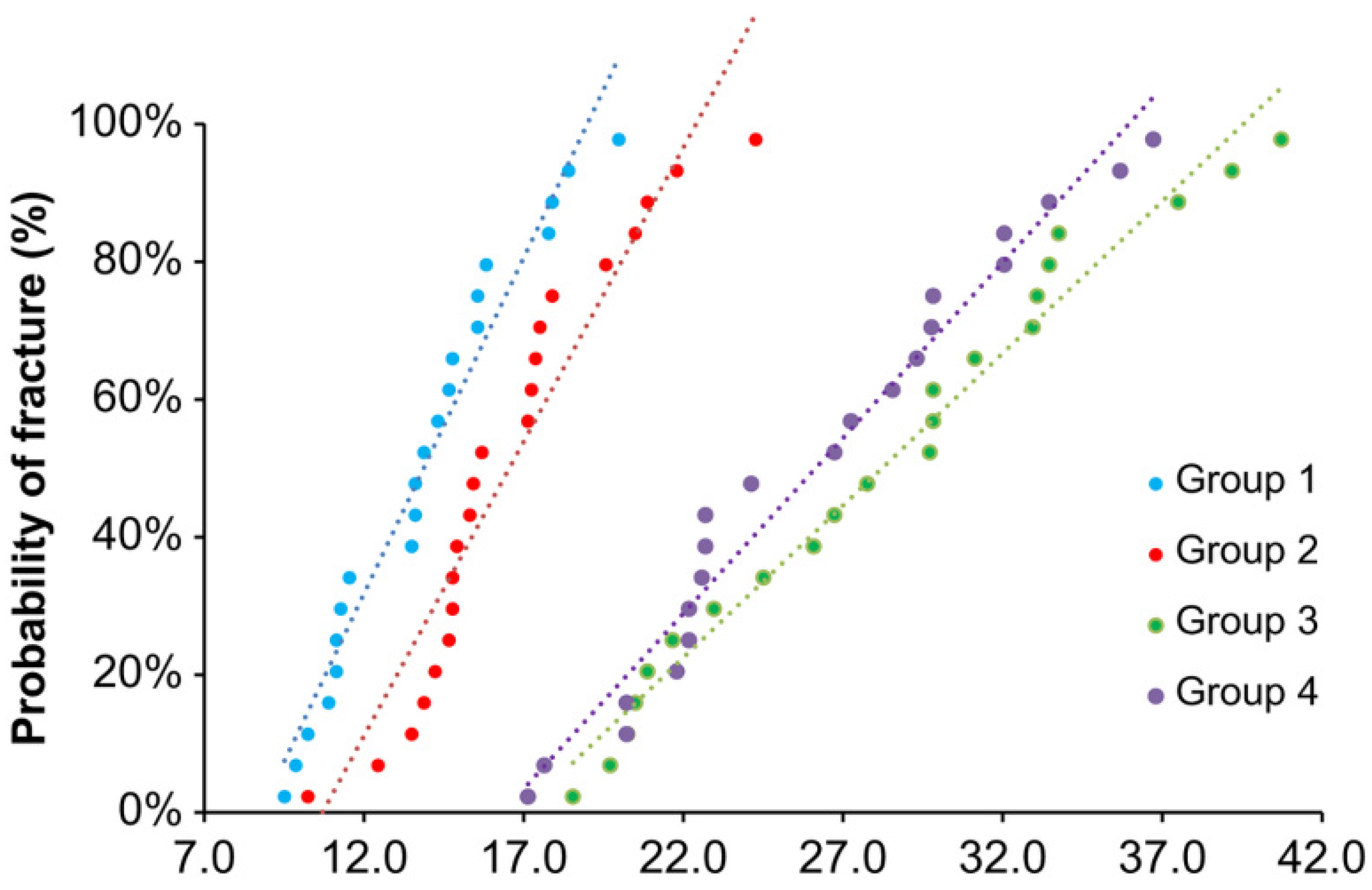

2.3. Tensile-Bond Test and Weibull Distribution

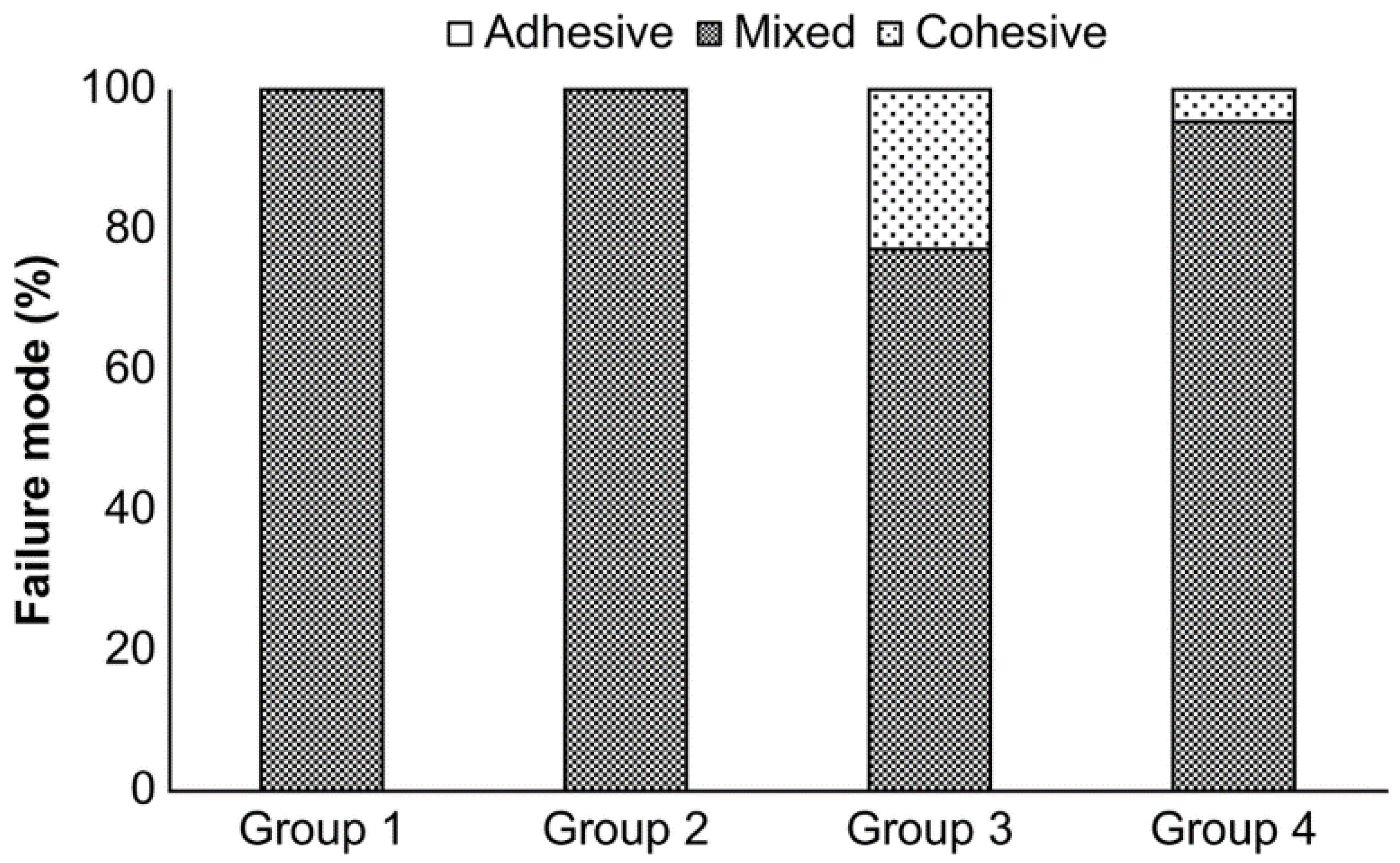

2.4. Failure-Mode Evaluation

2.5. Scanning Electron Microscopy (SEM) Analysis

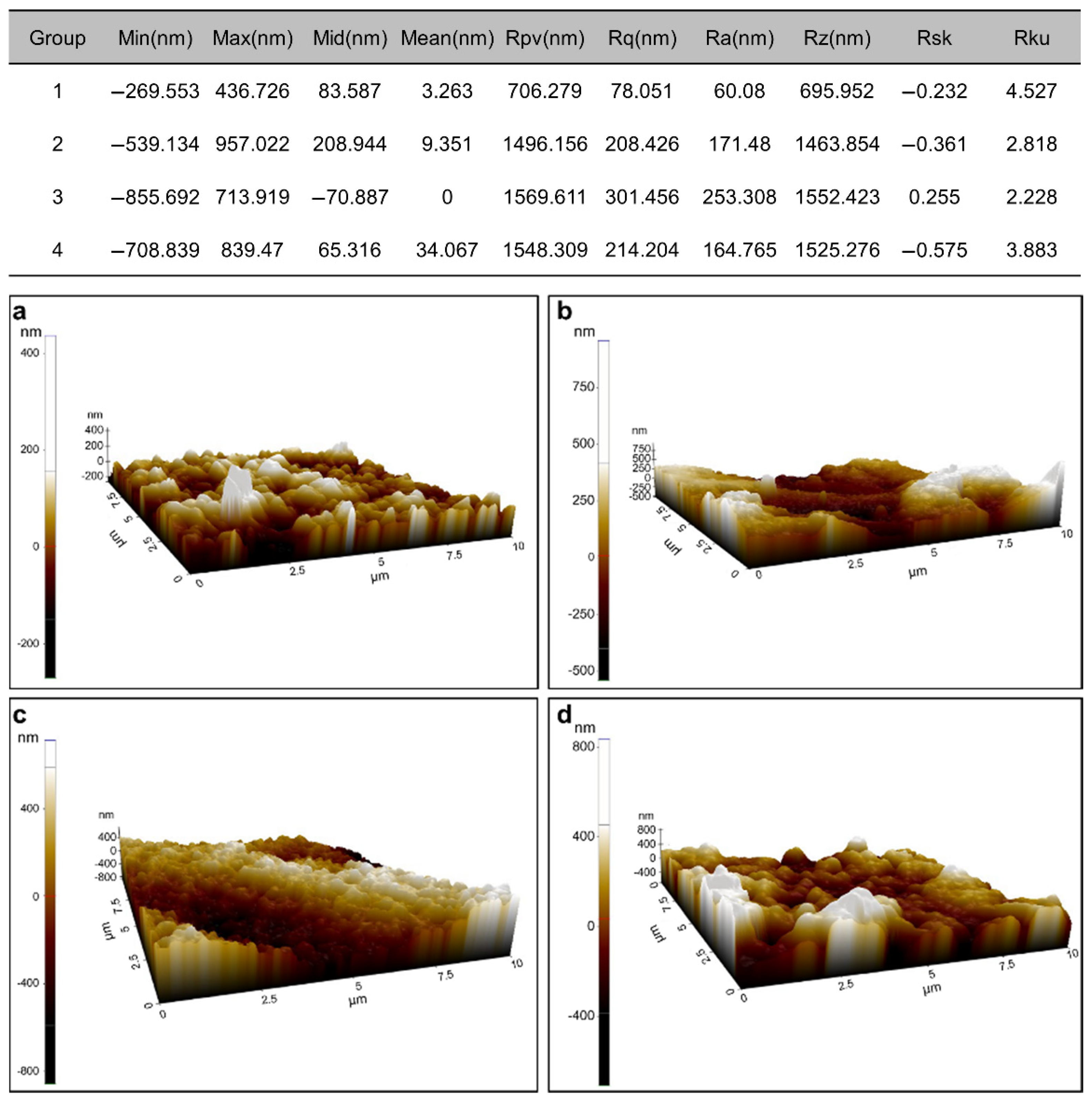

2.6. Atomic Force Microscopy (AFM) Analysis

2.7. Statistical Analysis

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pjetursson, B.E.; Sailer, I.; Makarov, N.A.; Zwahlen, M.; Thoma, D.S. All-Ceramic or Metal-Ceramic Tooth-Supported Fixed Dental Prostheses (FDPs)? A Systematic Review of the Survival and Complication Rates. Part II: Multiple-Unit FDPs. Dent. Mater. 2015, 31, 624–639. [Google Scholar] [CrossRef]

- Rinke, S.; Wehle, J.; Schulz, X.; Bürgers, R.; Rödiger, M. Prospective Evaluation of Posterior Fixed Zirconia Dental Prostheses: 10-Year Clinical Results. Int. J. Prosthodont. 2018, 31, 35–42. [Google Scholar] [CrossRef]

- Pontevedra, P.; Lopez-Suarez, C.; Pelaez, J.; Garcia-Serdio, S.; Suarez, M.J. Prospective Clinical Evaluation of Posterior Monolithic Zirconia Fixed Partial Dentures Using a Complete Digital Workflow: Two-Year Follow-Up. J. Prosthodont. 2021, 30, 298–304. [Google Scholar] [CrossRef]

- Solá-Ruiz, M.F.; Baixauli-López, M.; Roig-Vanaclocha, A.; Amengual-Lorenzo, J.; Agustín-Panadero, R. Prospective Study of Monolithic Zirconia Crowns: Clinical Behavior and Survival Rate at a 5-Year Follow-Up. J. Prosthodont. Res. 2021, 65, 284–290. [Google Scholar] [CrossRef]

- Ahmed, W.M.; Abdallah, M.-N.; McCullagh, A.P.; Wyatt, C.C.L.; Troczynski, T.; Carvalho, R.M. Marginal Discrepancies of Monolithic Zirconia Crowns: The Influence of Preparation Designs and Sintering Techniques: Marginal Fit of Full-Contoured Zirconia Crowns. J. Prosthodont. 2019, 28, 288–298. [Google Scholar] [CrossRef]

- Tekin, Y.H.; Hayran, Y. Fracture Resistance and Marginal Fit of the Zirconia Crowns with Varied Occlusal Thickness. J. Adv. Prosthodont. 2020, 12, 283–290. [Google Scholar] [CrossRef]

- Konstantinidis, I.; Trikka, D.; Gasparatos, S.; Mitsias, M. Clinical Outcomes of Monolithic Zirconia Crowns with CAD/CAM Technology. A 1-Year Follow-Up Prospective Clinical Study of 65 Patients. Int. J. Environ. Res. Public Health 2018, 15, 2523. [Google Scholar] [CrossRef]

- Abduo, J.; Lyons, K.; Swain, M. Fit of Zirconia Fixed Partial Denture: A Systematic Review. J. Oral Rehabil. 2010, 37, 866–876. [Google Scholar] [CrossRef]

- Daou, E.E.; Baba, N.Z. Evaluation of Marginal and Internal Fit of Presintered Co-Cr and Zirconia Three-Unit Fixed Dental Prosthesis Compared to Cast Co-Cr. J. Prosthodont. 2020, 29, 792–799. [Google Scholar] [CrossRef]

- Kelly, J.R. Clinically Relevant Approach to Failure Testing of All-Ceramic Restorations. J. Prosthet. Dent. 1999, 81, 652–661. [Google Scholar] [CrossRef]

- Dong, X.D.; Darvell, B.W. Stress Distribution and Failure Mode of Dental Ceramic Structures under Hertzian Indentation. Dent. Mater. 2003, 19, 542–551. [Google Scholar] [CrossRef]

- Kurtoglu, C.; Uysal, H.; Mamedov, A. Influence of Layer Thickness on Stress Distribution in Ceramic-Cement-Dentin Multilayer Systems. Dent. Mater. J. 2008, 27, 626–632. [Google Scholar] [CrossRef] [PubMed]

- Campos, F.; Valandro, L.; Feitosa, S.; Kleverlaan, C.; Feilzer, A.; de Jager, N.; Bottino, M. Adhesive Cementation Promotes Higher Fatigue Resistance to Zirconia Crowns. Oper. Dent. 2017, 42, 215–224. [Google Scholar] [CrossRef] [PubMed]

- Kamposiora, P.; Papavasiliou, G.; Bayne, S.C.; Felton, D.A. Predictions of Cement Microfracture under Crowns Using 3D-FEA. J Prosthodont. 2000, 9, 201–209. [Google Scholar] [CrossRef]

- Thammajaruk, P.; Inokoshi, M.; Chong, S.; Guazzato, M. Bonding of Composite Cements to Zirconia: A Systematic Review and Meta-Analysis of in Vitro Studies. J. Mech. Behav. Biomed. Mater. 2018, 80, 258–268. [Google Scholar] [CrossRef]

- Scaminaci Russo, D.; Cinelli, F.; Sarti, C.; Giachetti, L. Adhesion to Zirconia: A Systematic Review of Current Conditioning Methods and Bonding Materials. Dent. J. 2019, 7, 74. [Google Scholar] [CrossRef]

- Tsuchimoto, Y.; Yoshida, Y.; Mine, A.; Nakamura, M.; Nishiyama, N.; Van Meerbeek, B.; Suzuki, K.; Kuboki, T. Effect of 4-MET- and 10-MDP-Based Primers on Resin Bonding to Titanium. Dent. Mater. J. 2006, 25, 120–124. [Google Scholar] [CrossRef][Green Version]

- Magne, P.; Paranhos, M.P.G.; Burnett, L.H. New Zirconia Primer Improves Bond Strength of Resin-Based Cements. Dent. Mater. 2010, 26, 345–352. [Google Scholar] [CrossRef]

- Koizumi, H.; Nakayama, D.; Komine, F.; Blatz, M.B.; Matsumura, H. Bonding of Resin-Based Luting Cements to Zirconia With and Without the Use of Ceramic Priming Agents. J. Adhes. Dent. 2012, 14, 385–392. [Google Scholar] [CrossRef]

- Go, E.; Shin, Y.; Park, J. Evaluation of the Microshear Bond Strength of MDP-Containing and Non–MDP-Containing Self-Adhesive Resin Cement on Zirconia Restoration. Oper. Dent. 2019, 44, 379–385. [Google Scholar] [CrossRef]

- Gunge, H.; Ogino, Y.; Kihara, M.; Tsukiyama, Y.; Koyano, K. Retrospective Clinical Evaluation of Posterior Monolithic Zirconia Restorations after 1 to 3.5 Years of Clinical Service. J. Oral Sci. 2018, 60, 154–158. [Google Scholar] [CrossRef] [PubMed]

- Sriamporn, T.; Thamrongananskul, N.; Busabok, C.; Poolthong, S.; Uo, M.; Tagami, J. Dental Zirconia Can Be Etched by Hydrofluoric Acid. Dent. Mater. J. 2014, 33, 79–85. [Google Scholar] [CrossRef] [PubMed]

- Smielak, B.; Klimek, L. Effect of Hydrofluoric Acid Concentration and Etching Duration on Select Surface Roughness Parameters for Zirconia. J. Prosthet. Dent. 2015, 113, 596–602. [Google Scholar] [CrossRef] [PubMed]

- Chai, J.; Chu, F.C.S.; Chow, T.W. Effect of Surface Treatment on Shear Bond Strength of Zirconia to Human Dentin: Bond Strength between Zirconia-Based Ceramics and Dentin. J. Prosthodont. 2011, 20, 173–179. [Google Scholar] [CrossRef] [PubMed]

- Elsaka, S.E. Influence of Surface Treatments on the Bond Strength of Resin Cements to Monolithic Zirconia. J. Adhes. Dent. 2016, 18, 387–395. [Google Scholar] [CrossRef]

- Anand, S.; Ebenezar, A.V.R.; Anand, N.; Rajkumar, K.; Mahalaxmi, S.; Srinivasan, N. Microshear Bond Strength Evaluation of Surface Pretreated Zirconia Ceramics Bonded to Dentin. Eur. J. Dent. 2015, 9, 224–227. [Google Scholar] [CrossRef]

- Zhang, Y.; Pajares, A.; Lawn, B.R. Fatigue and Damage Tolerance of Y-TZP Ceramics in Layered Biomechanical Systems. J. Biomed. Mater. Res. 2004, 71B, 166–171. [Google Scholar] [CrossRef]

- Guazzato, M.; Quach, L.; Albakry, M.; Swain, M.V. Influence of Surface and Heat Treatments on the Flexural Strength of Y-TZP Dental Ceramic. J. Dent. 2005, 33, 9–18. [Google Scholar] [CrossRef]

- Uo, M.; Sjögren, G.; Sundh, A.; Goto, M.; Watari, F.; Bergman, M. Effect of Surface Condition of Dental Zirconia Ceramic (Denzir) on Bonding. Dent. Mater. J. 2006, 25, 626–631. [Google Scholar] [CrossRef]

- Cho, J.H.; Kim, S.J.; Shim, J.S.; Lee, K.-W. Effect of Zirconia Surface Treatment Using Nitric Acid-Hydrofluoric Acid on the Shear Bond Strengths of Resin Cements. J. Adv. Prosthodont. 2017, 9, 77–84. [Google Scholar] [CrossRef]

- Jo, Y.-B.; Ahn, J.-J.; Lee, S.-H.; Park, T.; Huh, J.-B. The Effect of ZrO2 Slurry Application to the Pre-Sintered Zirconia Surface on Bonding Strength. Implantology 2020, 24, 76–82. [Google Scholar] [CrossRef]

- Otani, A.; Amaral, M.; May, L.G.; Cesar, P.F.; Valandro, L.F. A Critical Evaluation of Bond Strength Tests for the Assessment of Bonding to Y-TZP. Dent. Mater. 2015, 31, 648–656. [Google Scholar] [CrossRef] [PubMed]

- de Souza, G.; Hennig, D.; Aggarwal, A.; Tam, L.E. The Use of MDP-Based Materials for Bonding to Zirconia. J. Prosthet. Dent. 2014, 112, 895–902. [Google Scholar] [CrossRef] [PubMed]

- Özcan, M.; Melo, R.M.; Souza, R.O.A.; Machado, J.P.B.; Felipe Valandro, L.; Botttino, M.A. Effect of Air-Particle Abrasion Protocols on the Biaxial Flexural Strength, Surface Characteristics and Phase Transformation of Zirconia after Cyclic Loading. J. Mech. Behav. Biomed. Mater. 2013, 20, 19–28. [Google Scholar] [CrossRef]

- Iwaya, Y.; Machigashira, M.; Kanbara, K.; Miyamoto, M.; Noguchi, K.; Izumi, Y.; Ban, S. Surface Properties and Biocompatibility of Acid-Etched Titanium. Dent. Mater. J. 2008, 27, 415–421. [Google Scholar] [CrossRef]

- Vallet-Regí, M.; Colilla, M.; Izquierdo-Barba, I.; Manzano, M. Mesoporous Silica Nanoparticles for Drug Delivery: Current Insights. Molecules 2017, 23, 47. [Google Scholar] [CrossRef]

- Wang, J.; Liu, X.; Milcovich, G.; Chen, T.Y.; Durack, E.; Mallen, S.; Ruan, Y.; Weng, X.; Hudson, S.P. Co-reductive fabrication of carbon nanodots with high quantum yield for bioimaging of bacteria. Beilstein J. Nanotechnol. 2018, 9, 137–145. [Google Scholar] [CrossRef]

- Jun, I.-K.; Koh, Y.-H.; Song, J.-H.; Lee, S.-H.; Kim, H.-E. Improved Compressive Strength of Reticulated Porous Zirconia Using Carbon Coated Polymeric Sponge as Novel Template. Mater. Lett. 2006, 60, 2507–2510. [Google Scholar] [CrossRef]

- Mazzitelli, C.; Maravic, T.; Sebold, M.; Checchi, V.; Josic, U.; Breschi, L.; Mazzoni, A. Effect of Shelf-Life of a Universal Adhesive to Dentin. Int. J. Adhes. Adhes. 2020, 102, 102673. [Google Scholar] [CrossRef]

- Yang, B.; Barloi, A.; Kern, M. Influence of Air-Abrasion on Zirconia Ceramic Bonding Using an Adhesive Composite Resin. Dent. Mater. 2010, 26, 44–50. [Google Scholar] [CrossRef]

- Shahin, R.; Kern, M. Effect of Air-Abrasion on the Retention of Zirconia Ceramic Crowns Luted with Different Cements before and after Artificial Aging. Dent. Mater. 2010, 26, 922–928. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Hong, G.; Wu, Y.-H.; Endo, K.; Han, J.-M.; Kumamoto, H.; Wada, T.; Kato, H.; Gao, P.; Sasaki, K. A Novel Method of Surface Modification by Electrochemical Deoxidation: Effect on Surface Characteristics and Initial Bioactivity of Zirconia: Surface Modification of Zirconia by ECD. J. Biomed. Mater. Res. 2017, 105, 2641–2652. [Google Scholar] [CrossRef] [PubMed]

- Heikkinen, T.T.; Matinlinna, J.P.; Vallittu, P.K.; Lassila, L.V.J. Long Term Water Storage Deteriorates Bonding of Composite Resin to Alumina and Zirconia Short Communication. Open Dent. J. 2013, 7, 123–125. [Google Scholar] [CrossRef] [PubMed]

- Noda, Y.; Nakajima, M.; Takahashi, M.; Mamanee, T.; Hosaka, K.; Takagaki, T.; Ikeda, M.; Foxton, R.M.; Tagami, J. The Effect of Five Kinds of Surface Treatment Agents on the Bond Strength to Various Ceramics with Thermocycle Aging. Dent. Mater. J. 2017, 36, 755–761. [Google Scholar] [CrossRef] [PubMed]

| Product | Manufacturer | Composition |

|---|---|---|

| ZirClean cleaning agent | Bisco Inc., Schaumburg, IL, USA | Zirconium oxide, water, polyethylene glycol, potassium hydroxide, pigments, additives |

| Theracem resin cement | Bisco Inc., Schaumburg, IL, USA | Calcium base filler, silanated non-reactive fillers, methacrylate monomers containing phosphoric acid groups, methacrylate monomers, ytterbium fluoride, initiators (chemical and light) |

| Zircos-E etching solution | M&C Dental, Seoul, Korea | Hydrofluoric acid and nitric acid |

| ZirADD zirconia-nanoparticle coating | PNUADD, Busan, Korea | Distilled water, nano-sized zirconia powder, carbon powder, dispersive agent, binder |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, M.; Kim, R.H.; Lee, S.C.; Lee, T.K.; Hayashi, M.; Yu, B.; Jo, D.-W. Evaluation of Tensile Bond Strength between Self-Adhesive Resin Cement and Surface-Pretreated Zirconia. Materials 2022, 15, 3089. https://doi.org/10.3390/ma15093089

Kim M, Kim RH, Lee SC, Lee TK, Hayashi M, Yu B, Jo D-W. Evaluation of Tensile Bond Strength between Self-Adhesive Resin Cement and Surface-Pretreated Zirconia. Materials. 2022; 15(9):3089. https://doi.org/10.3390/ma15093089

Chicago/Turabian StyleKim, Mijoo, Reuben H. Kim, Samuel C. Lee, Thomas K. Lee, Marc Hayashi, Bo Yu, and Deuk-Won Jo. 2022. "Evaluation of Tensile Bond Strength between Self-Adhesive Resin Cement and Surface-Pretreated Zirconia" Materials 15, no. 9: 3089. https://doi.org/10.3390/ma15093089

APA StyleKim, M., Kim, R. H., Lee, S. C., Lee, T. K., Hayashi, M., Yu, B., & Jo, D.-W. (2022). Evaluation of Tensile Bond Strength between Self-Adhesive Resin Cement and Surface-Pretreated Zirconia. Materials, 15(9), 3089. https://doi.org/10.3390/ma15093089