Experimental and Numerical Study on Uniaxial Compression Failure of Concrete Confined by Nylon Ties

Abstract

:1. Introduction

2. Laboratory Tests

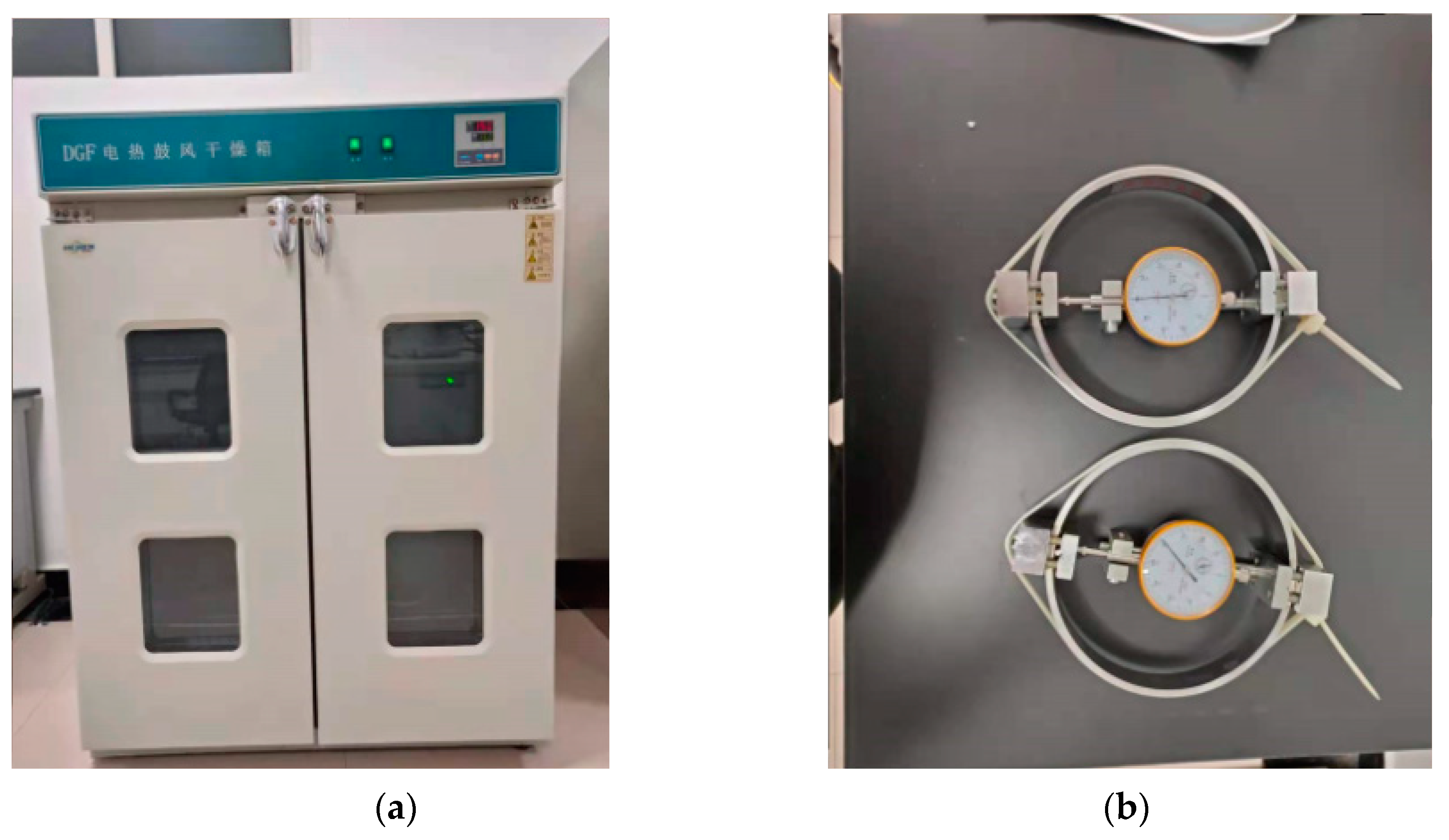

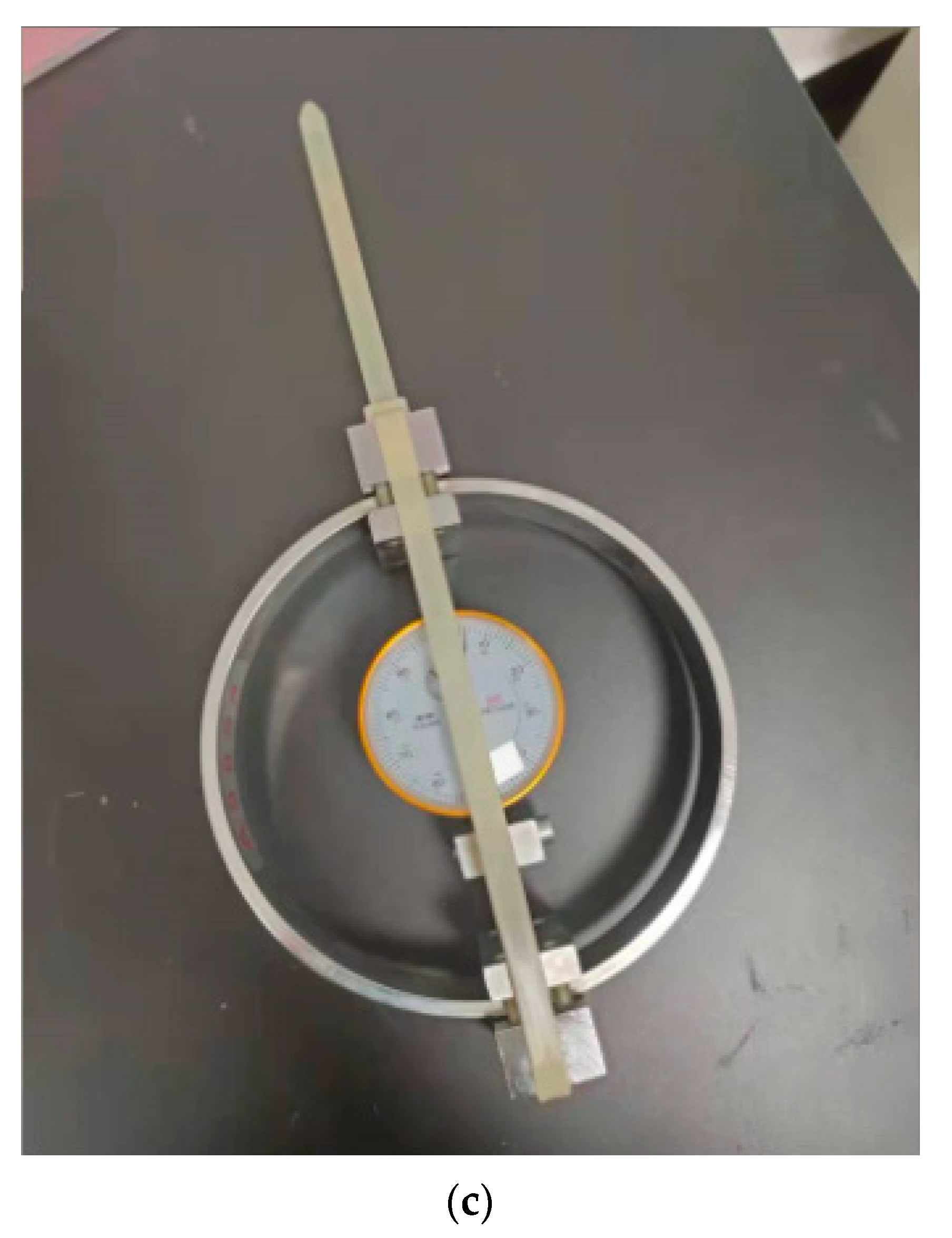

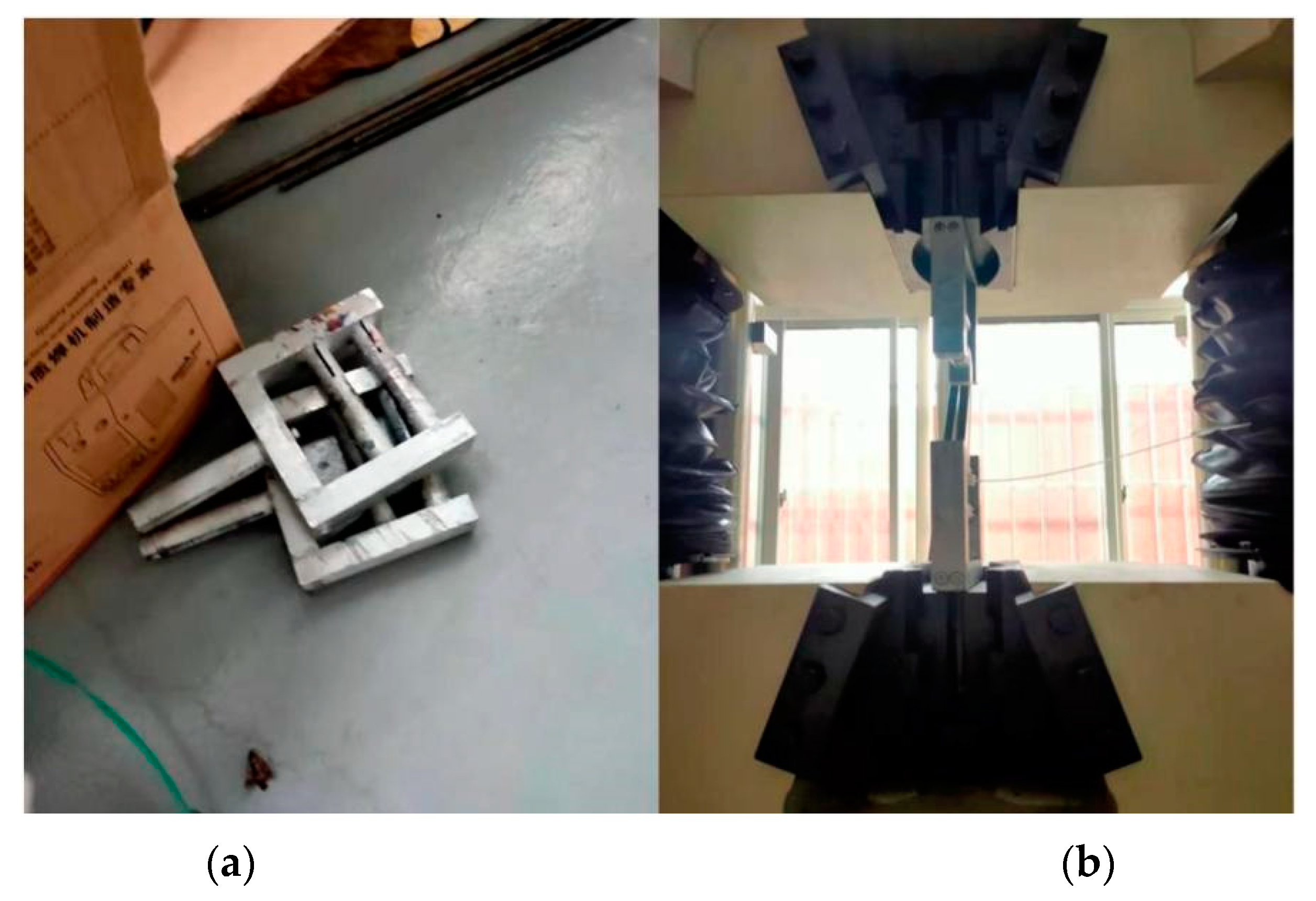

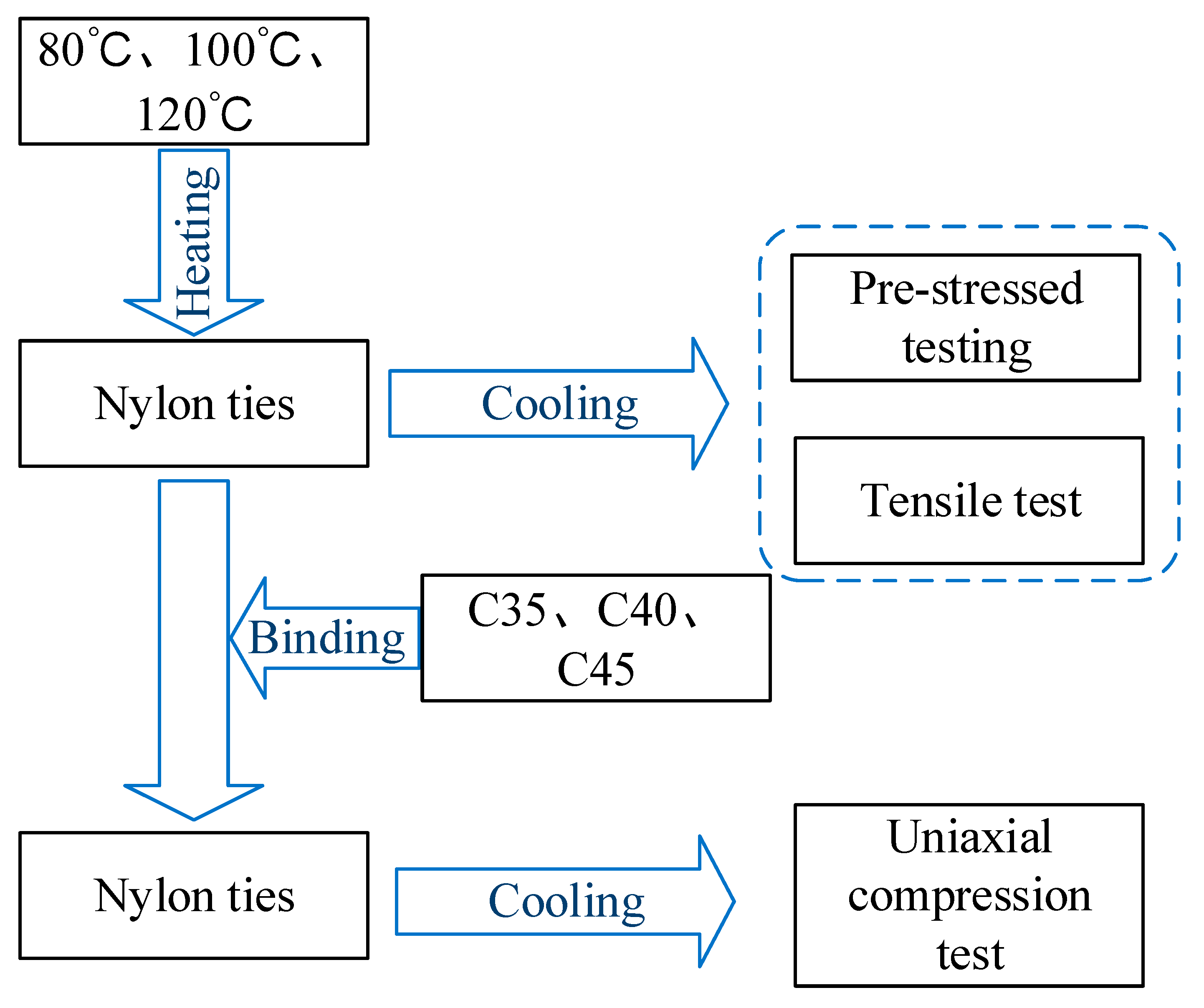

2.1. Experimental Study on Mechanical Properties of Nylon Ties

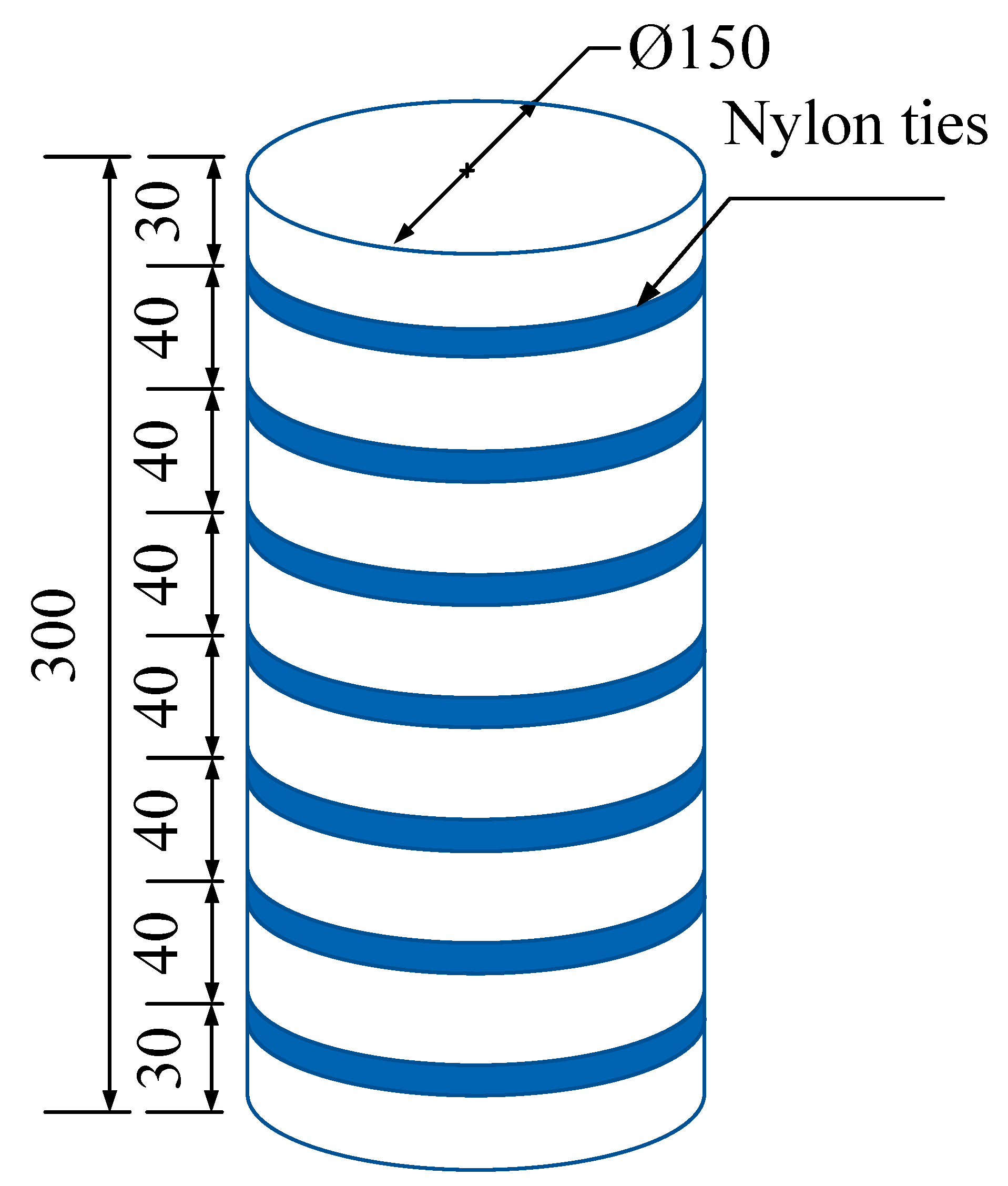

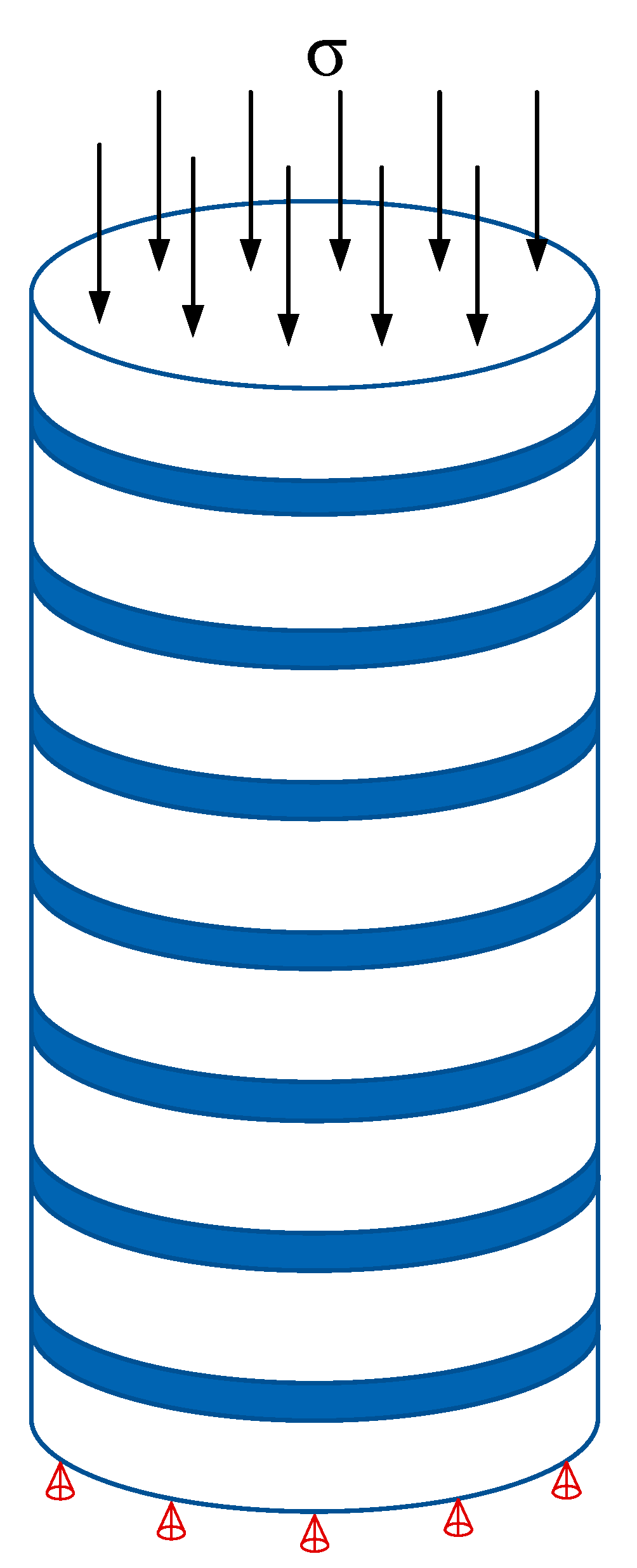

2.2. Uniaxial Compression Test

3. Establishment of Finite Element Model

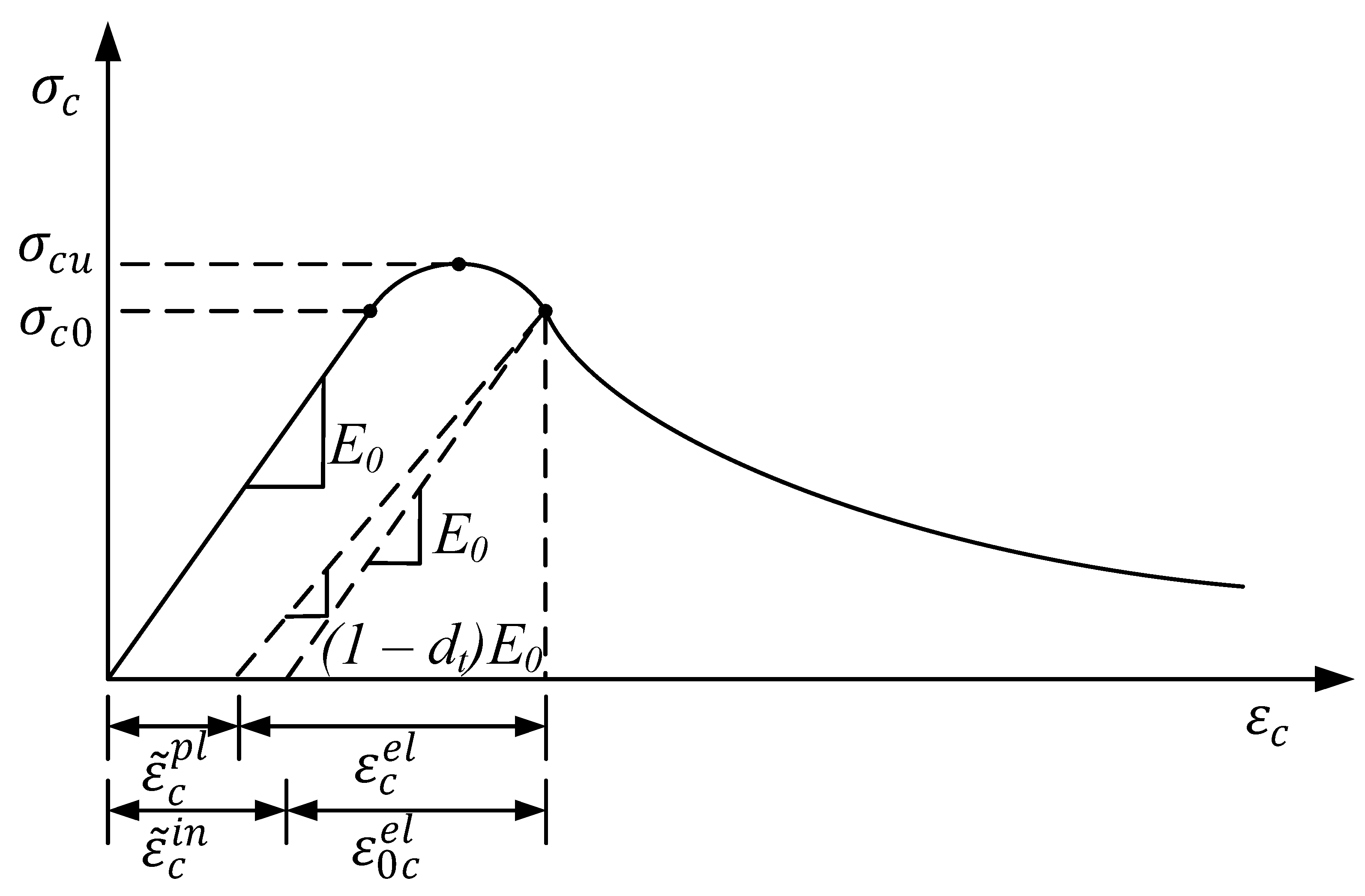

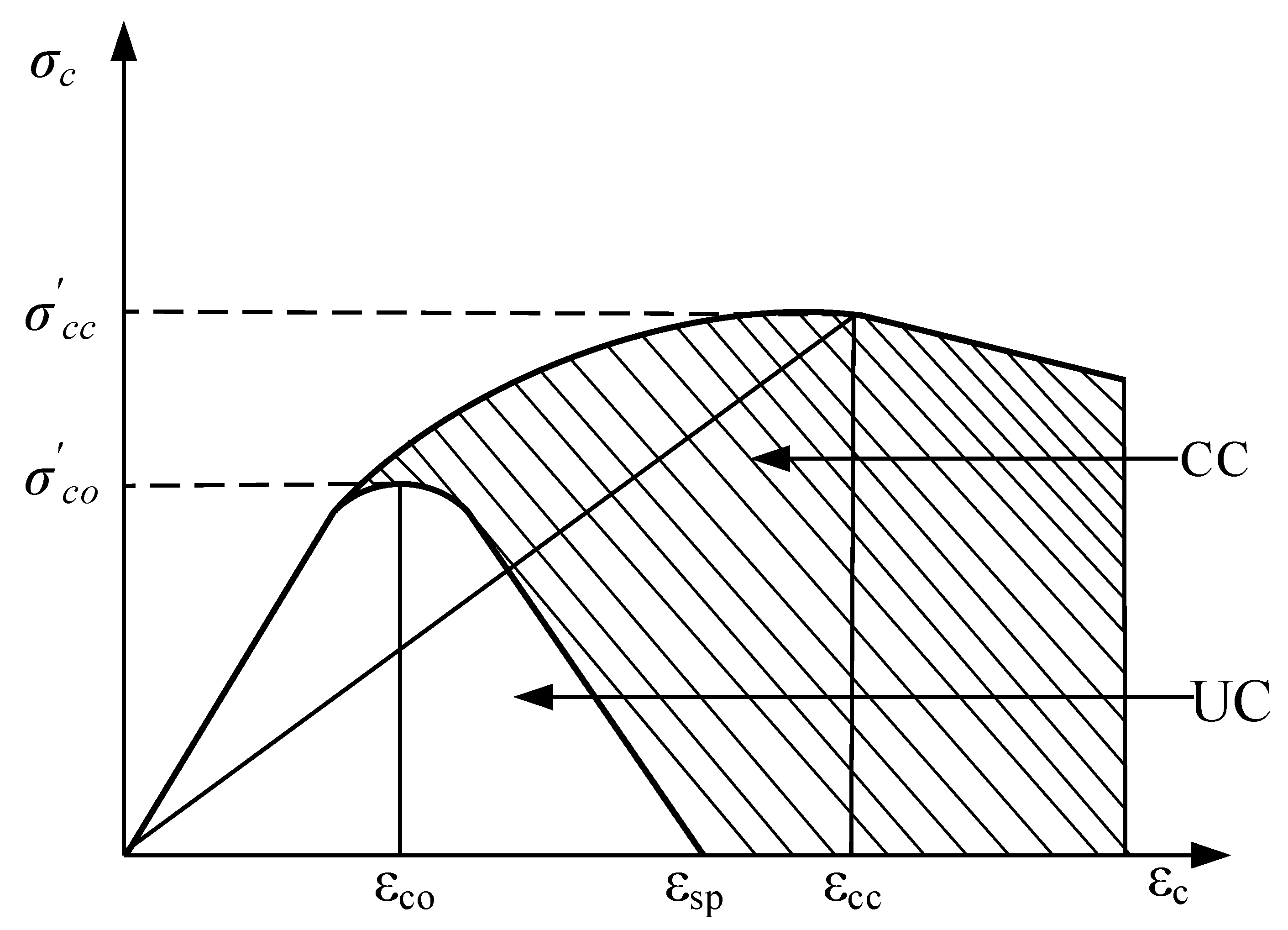

3.1. Damage Plastic Model of Concrete

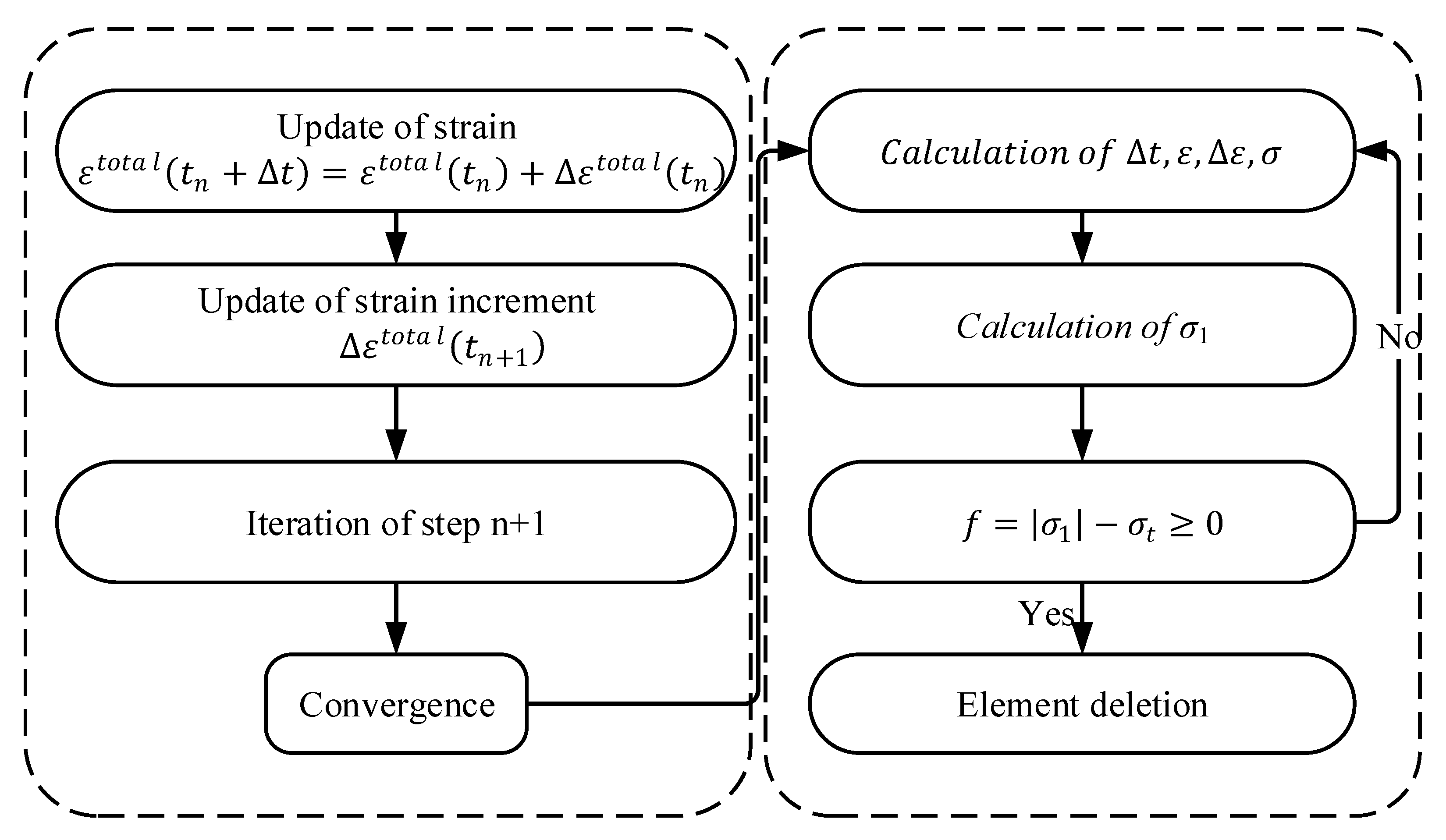

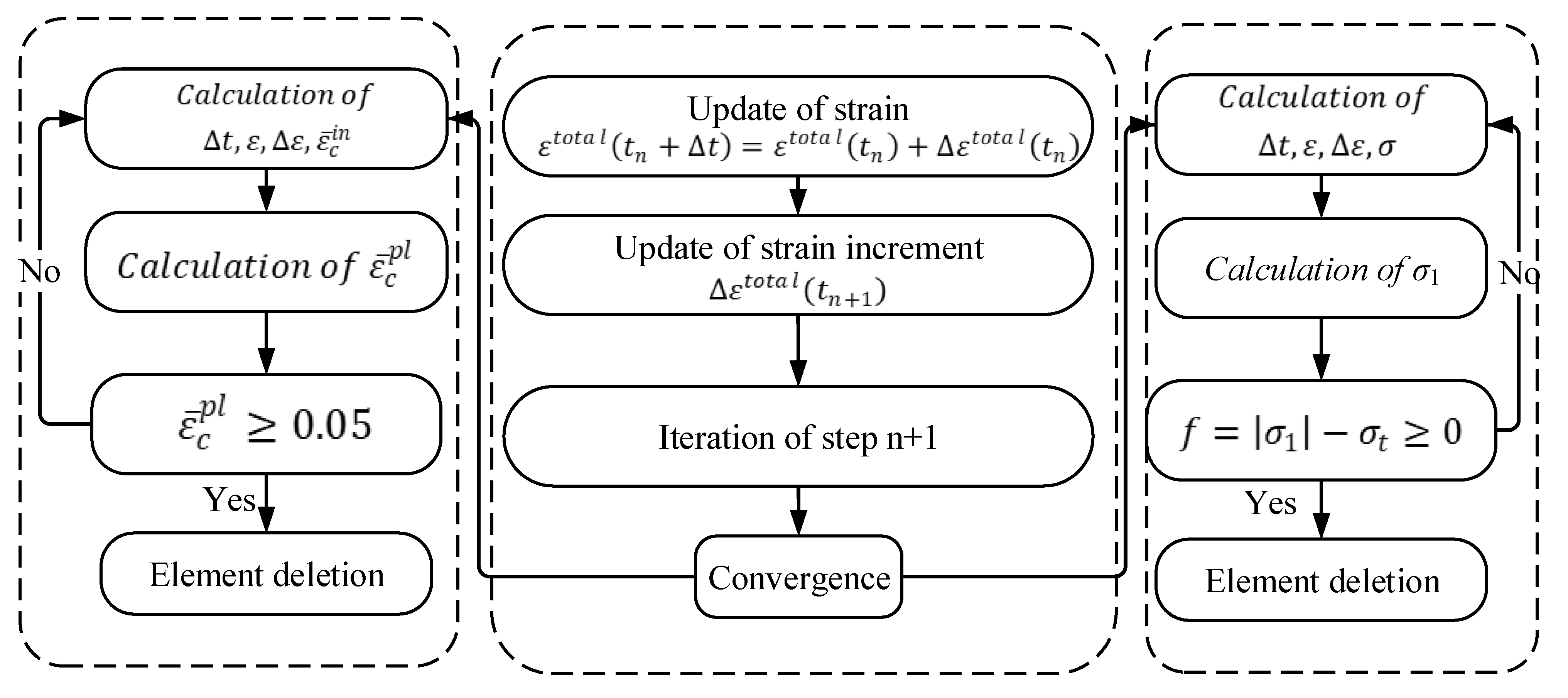

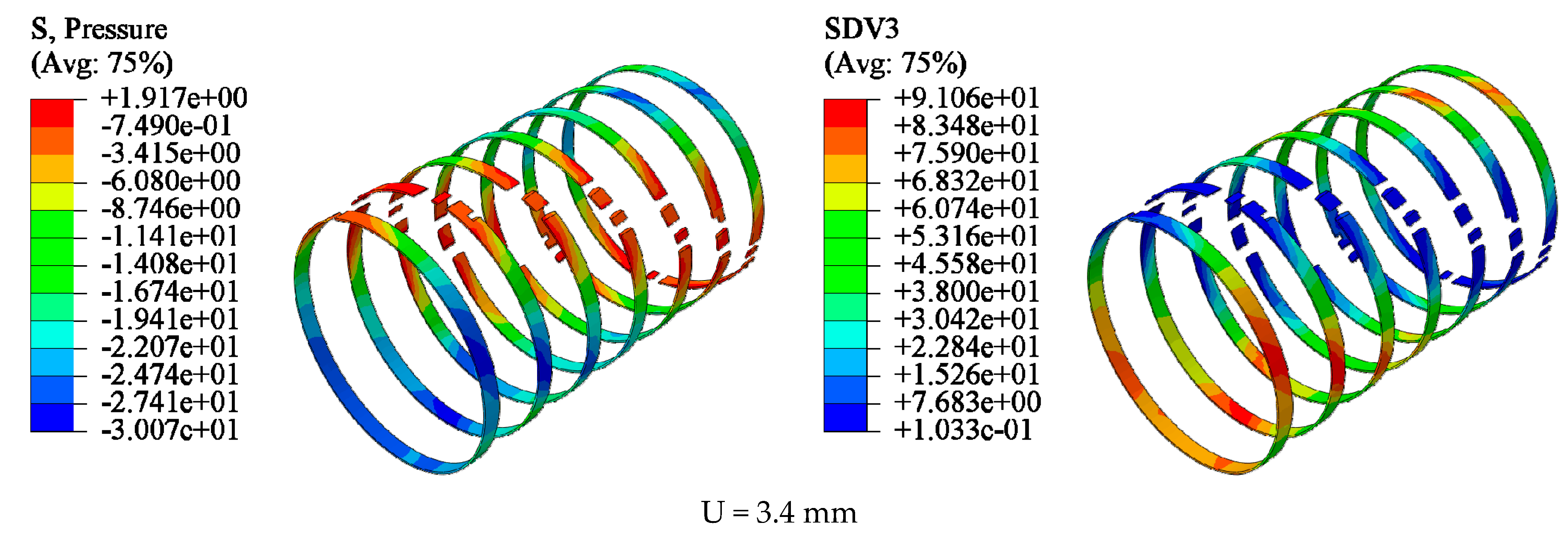

3.2. Failure Model of Nylon Ties

4. Experimental Results

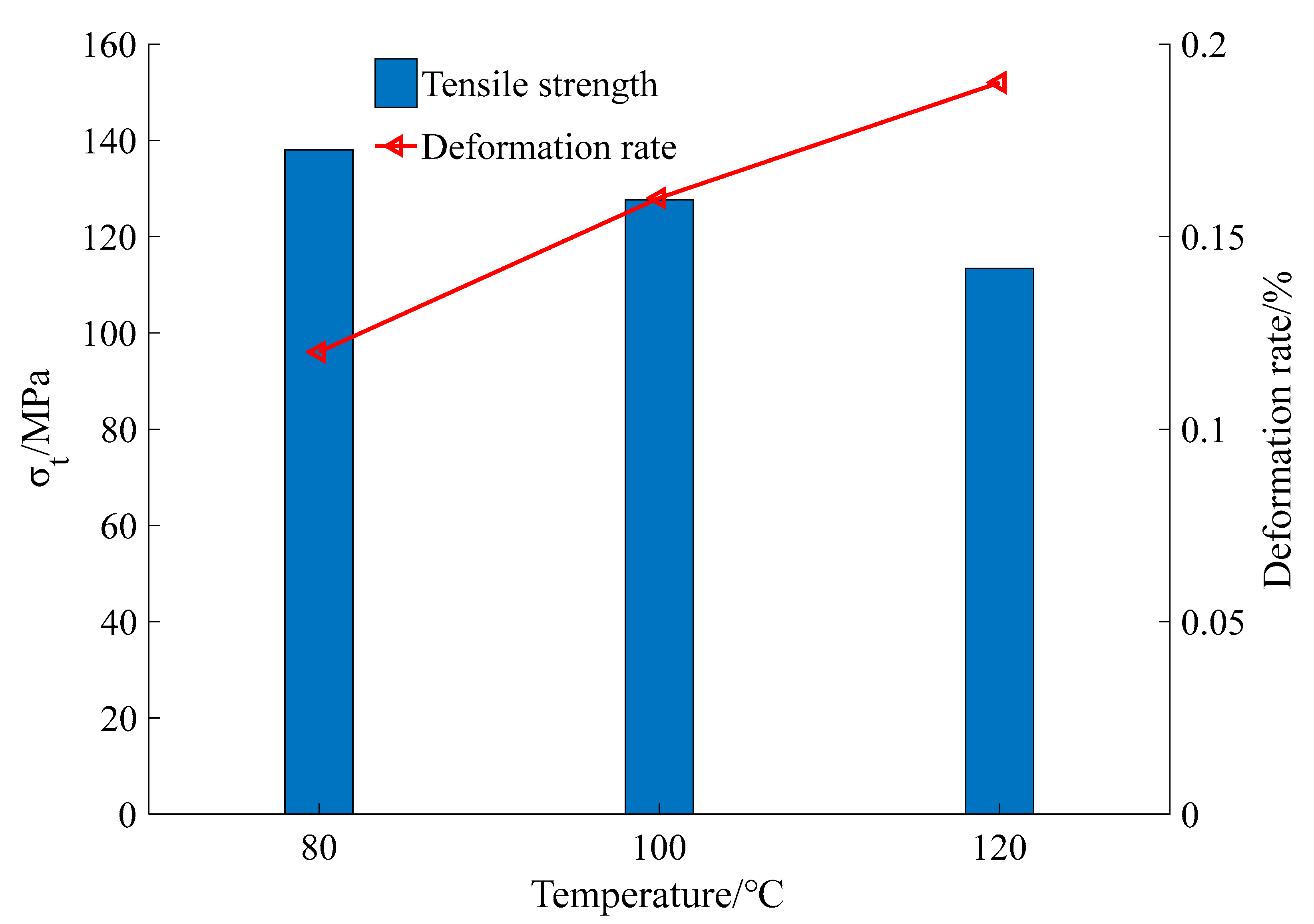

4.1. Analysis of Mechanical Properties of Nylon Ties

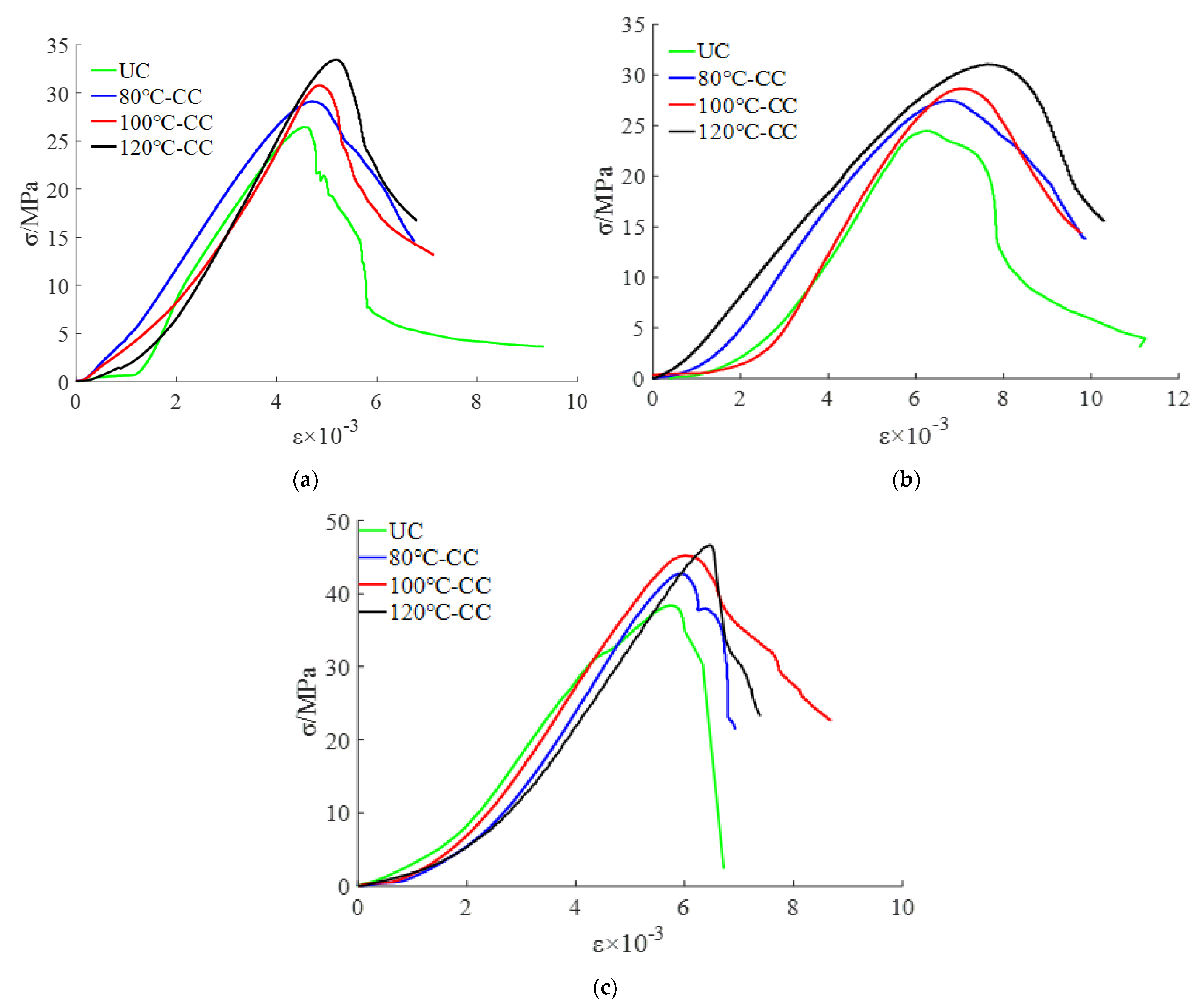

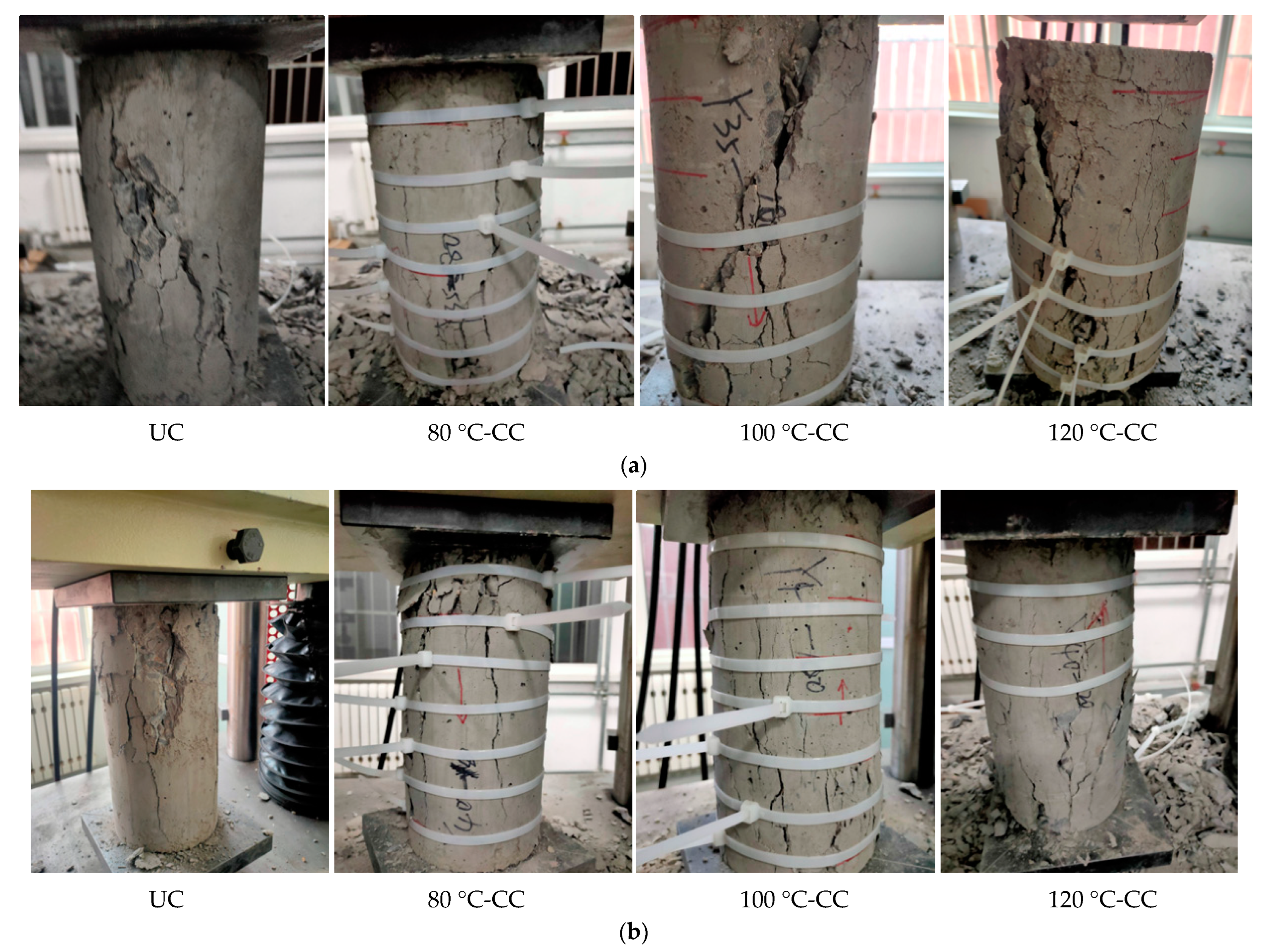

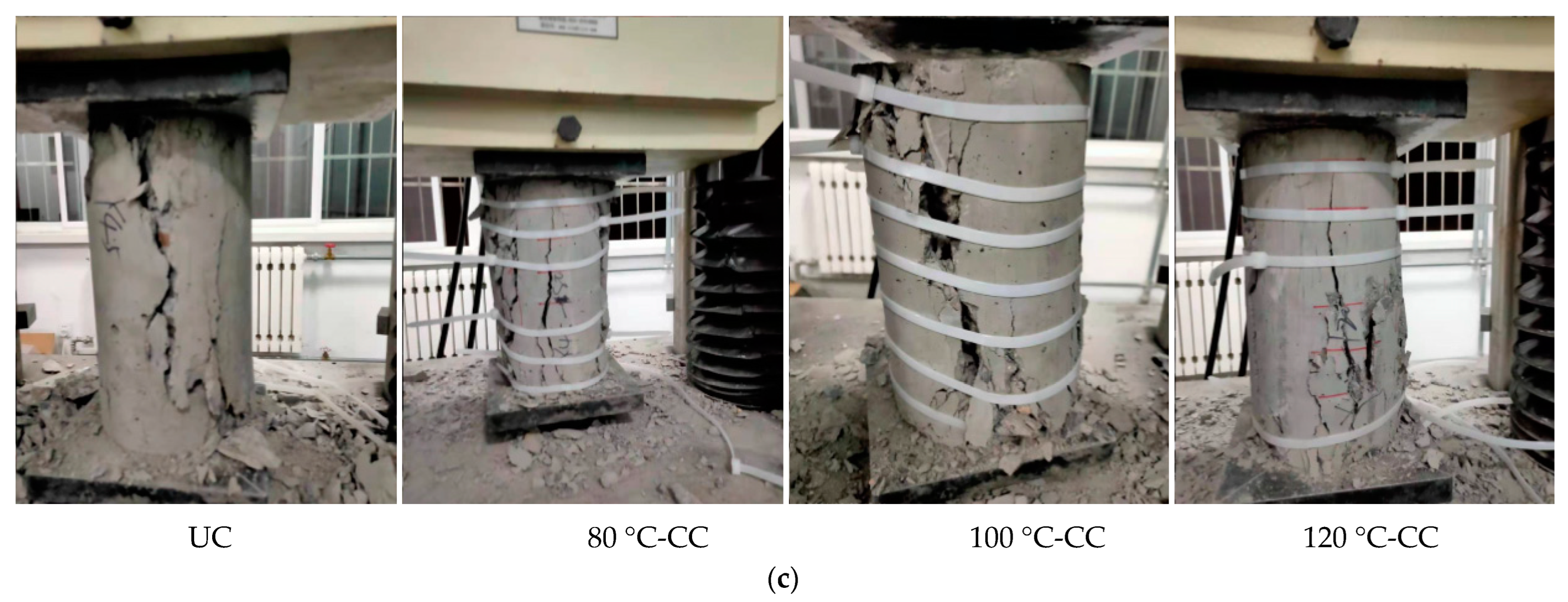

4.2. Analysis of Confined Concrete under Uniaxial Compression

5. Numerical Results

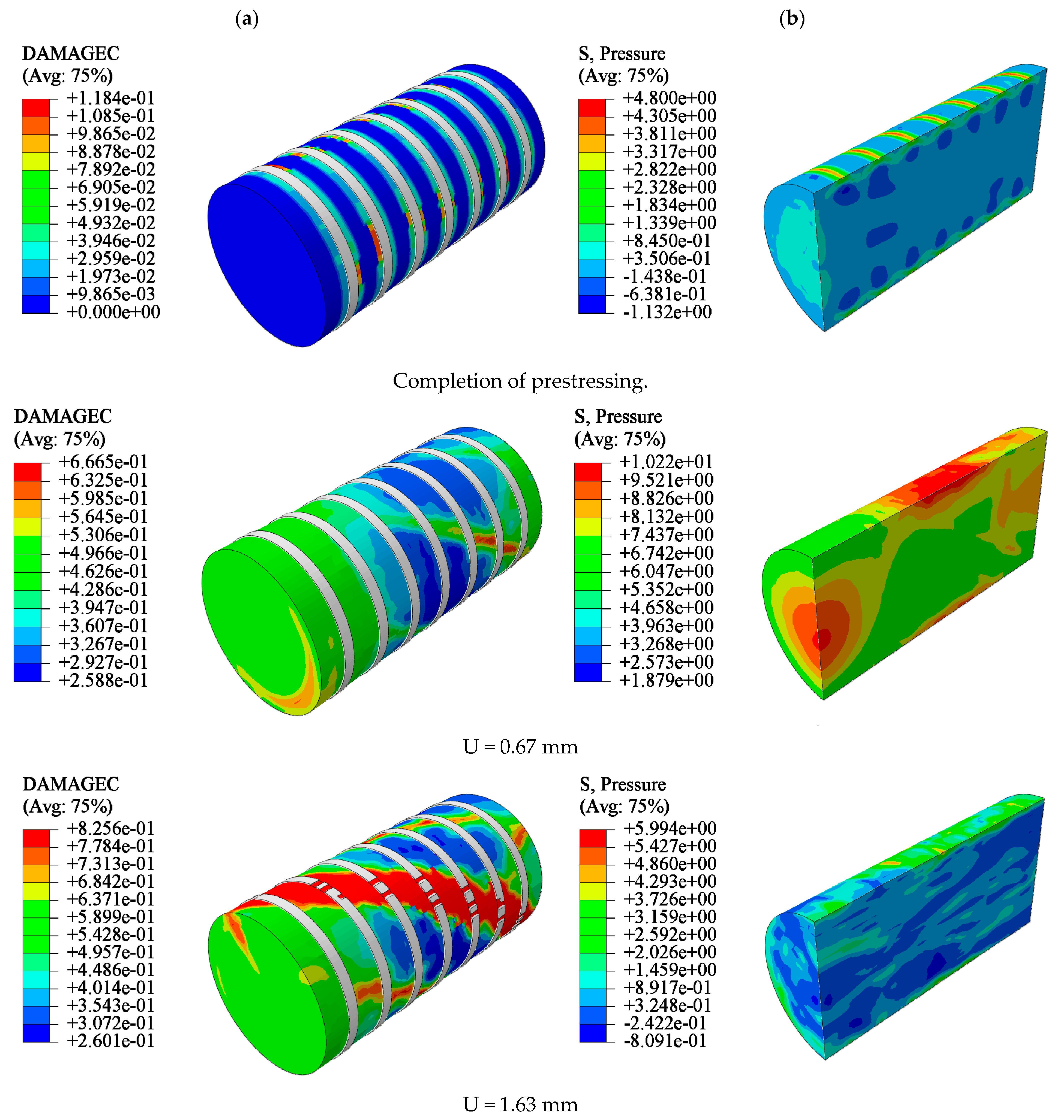

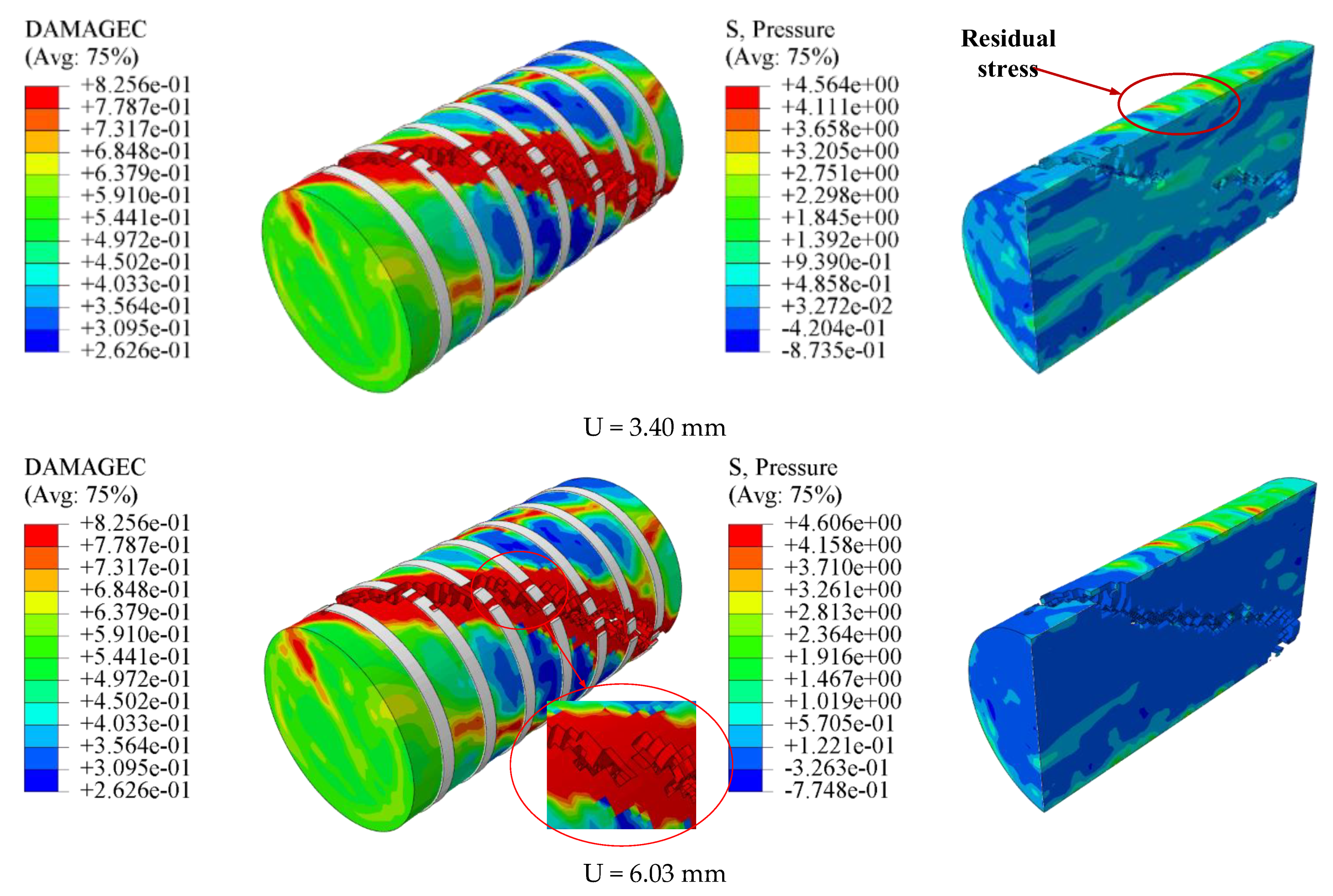

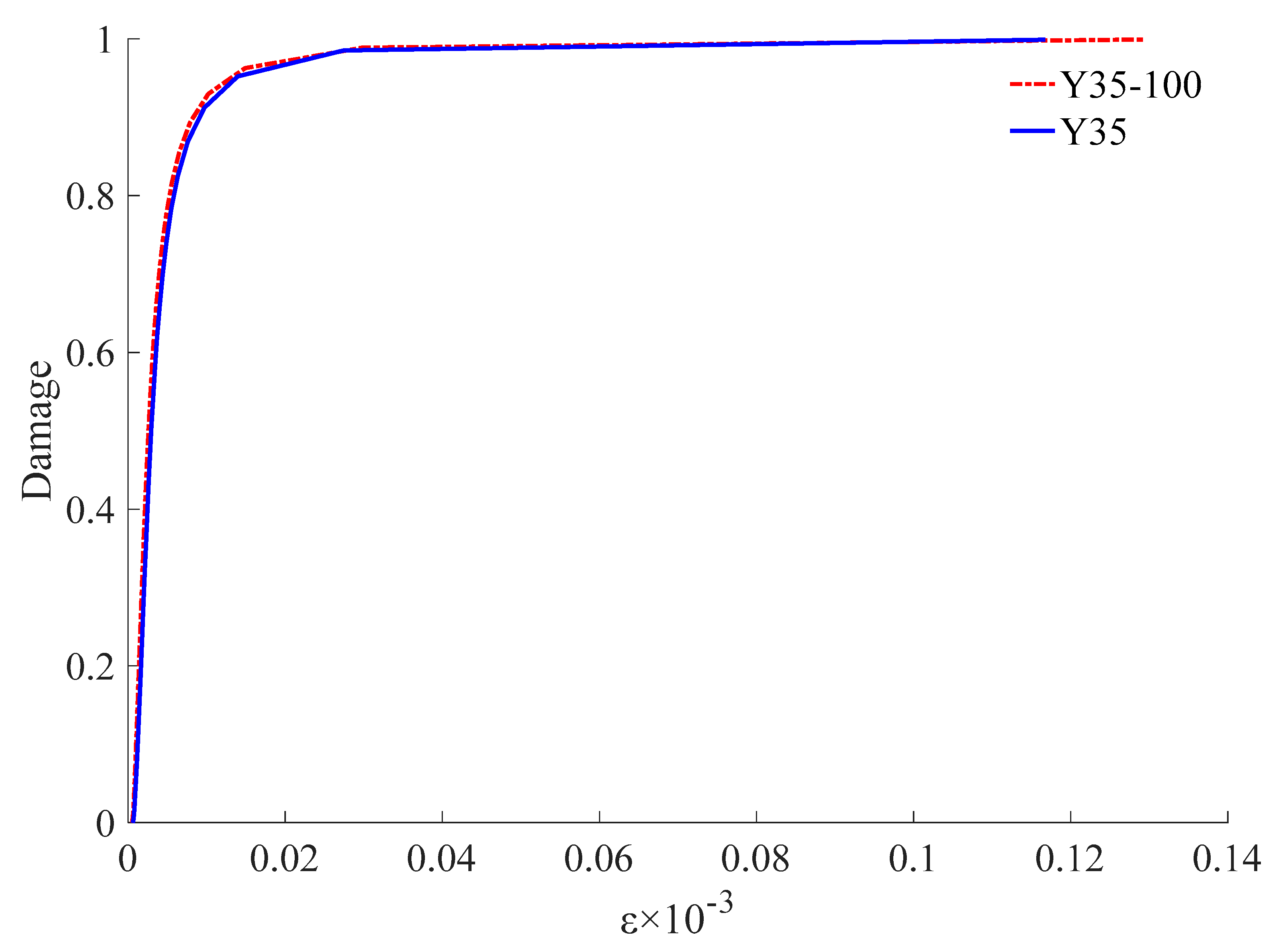

5.1. Analysis of Damage Evolution Law of UC

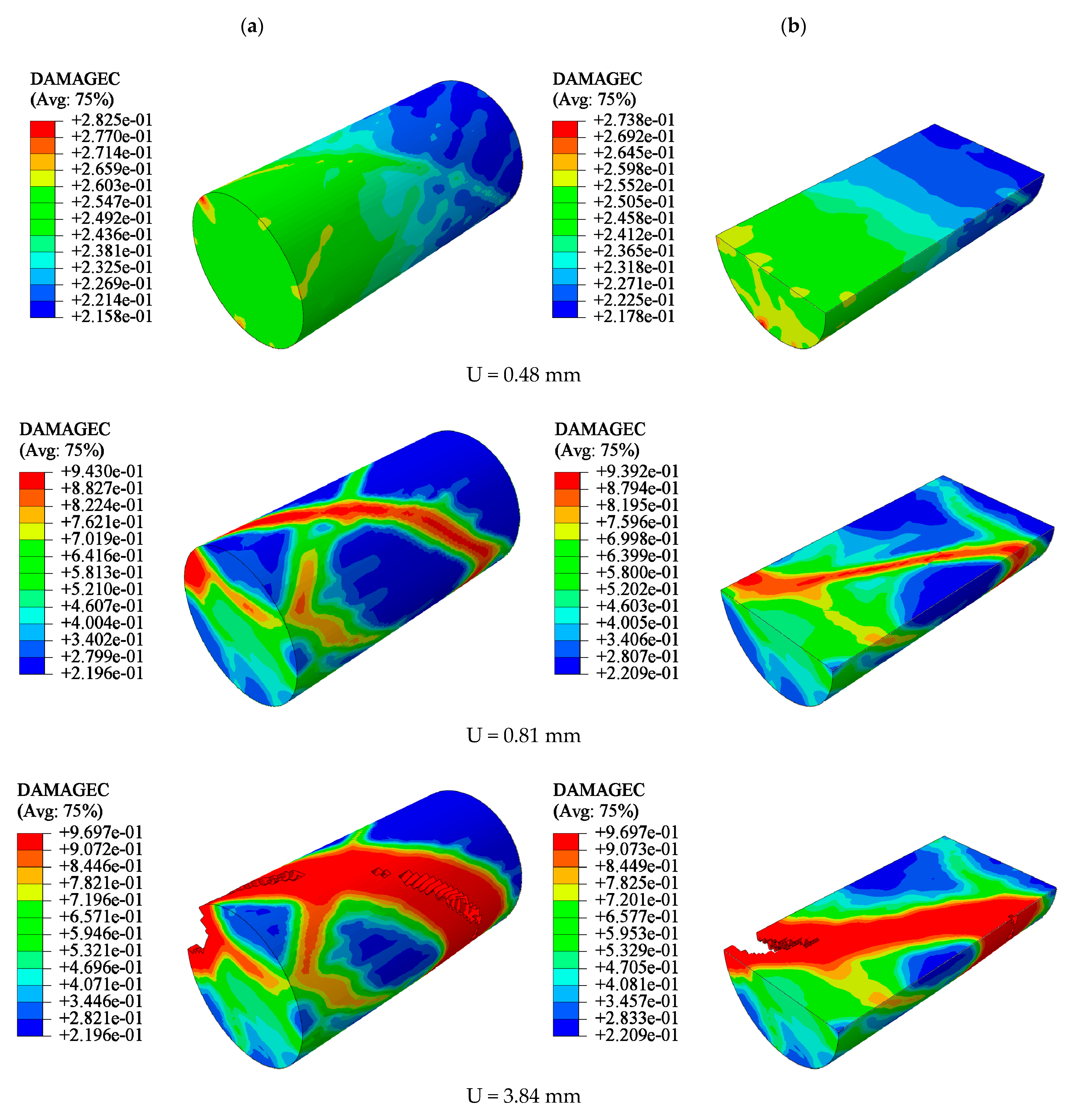

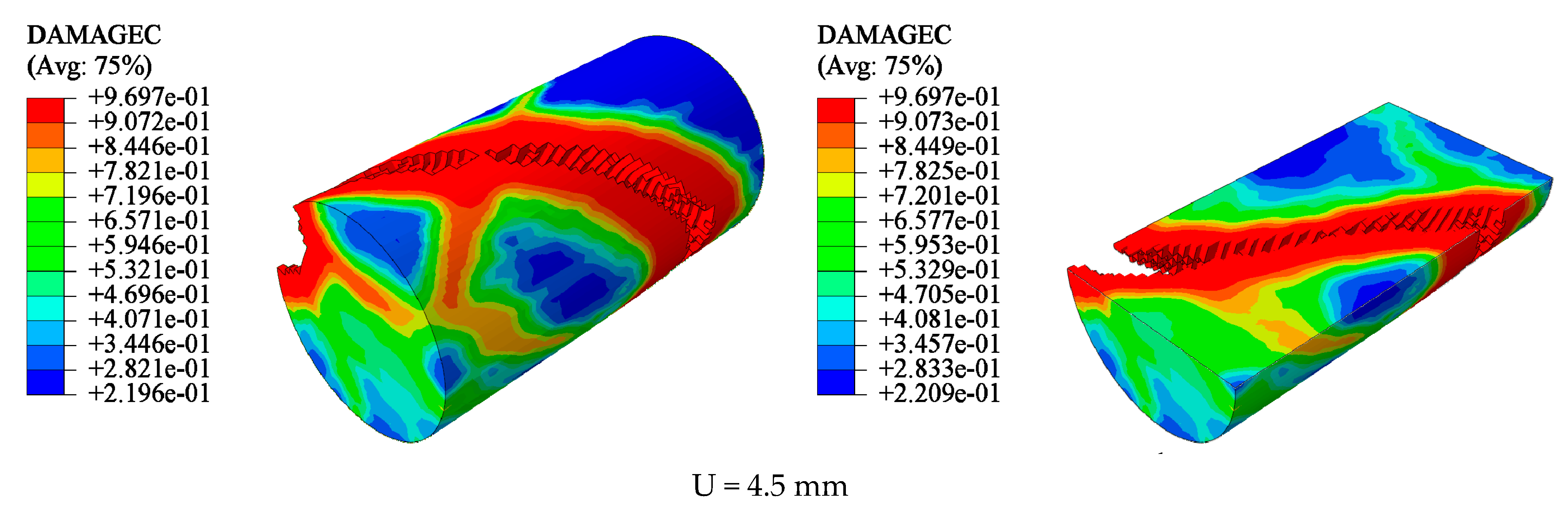

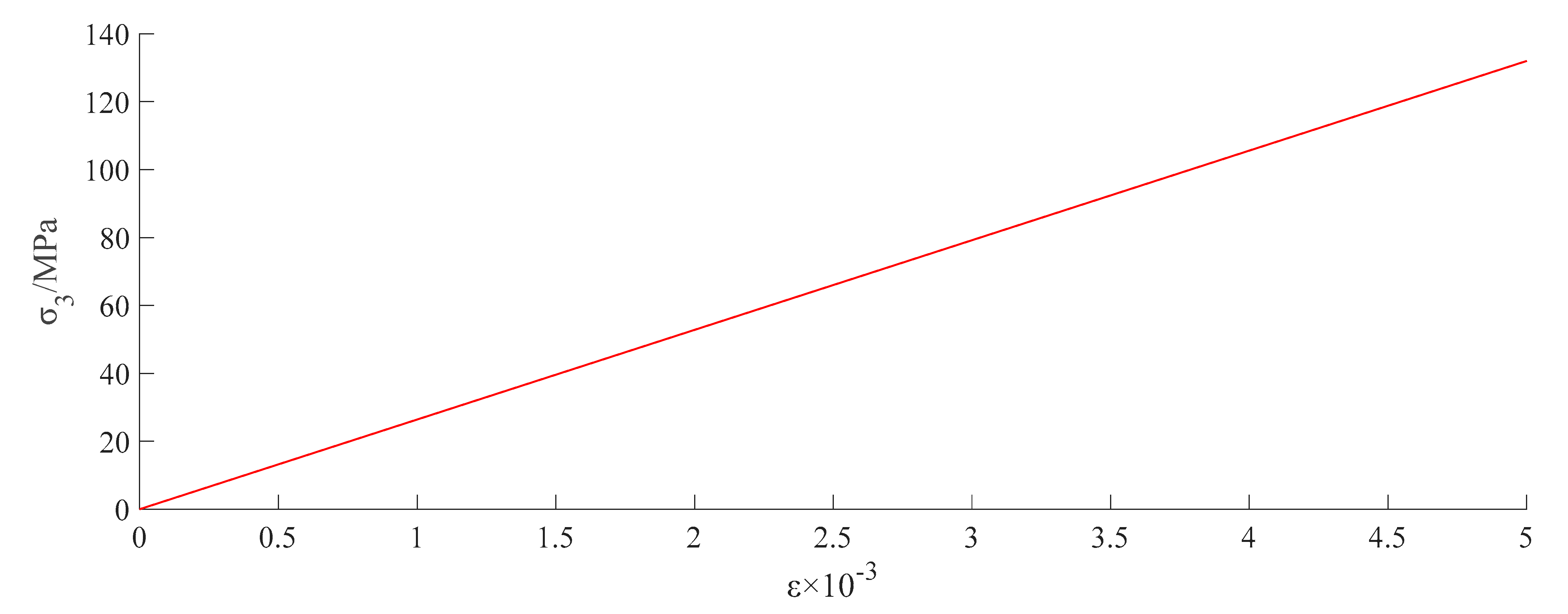

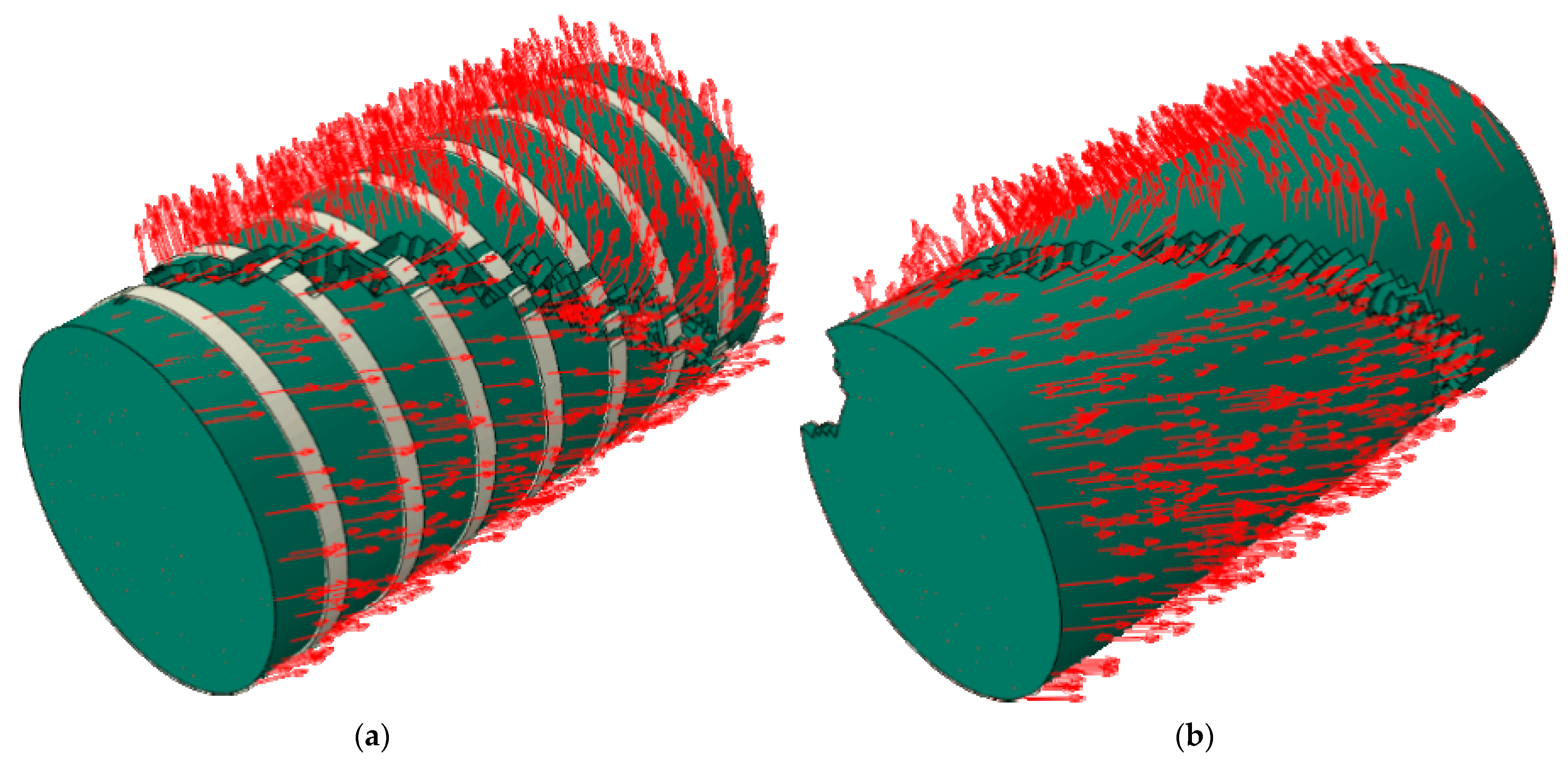

5.2. Analysis of Damage Evolution Law of CC

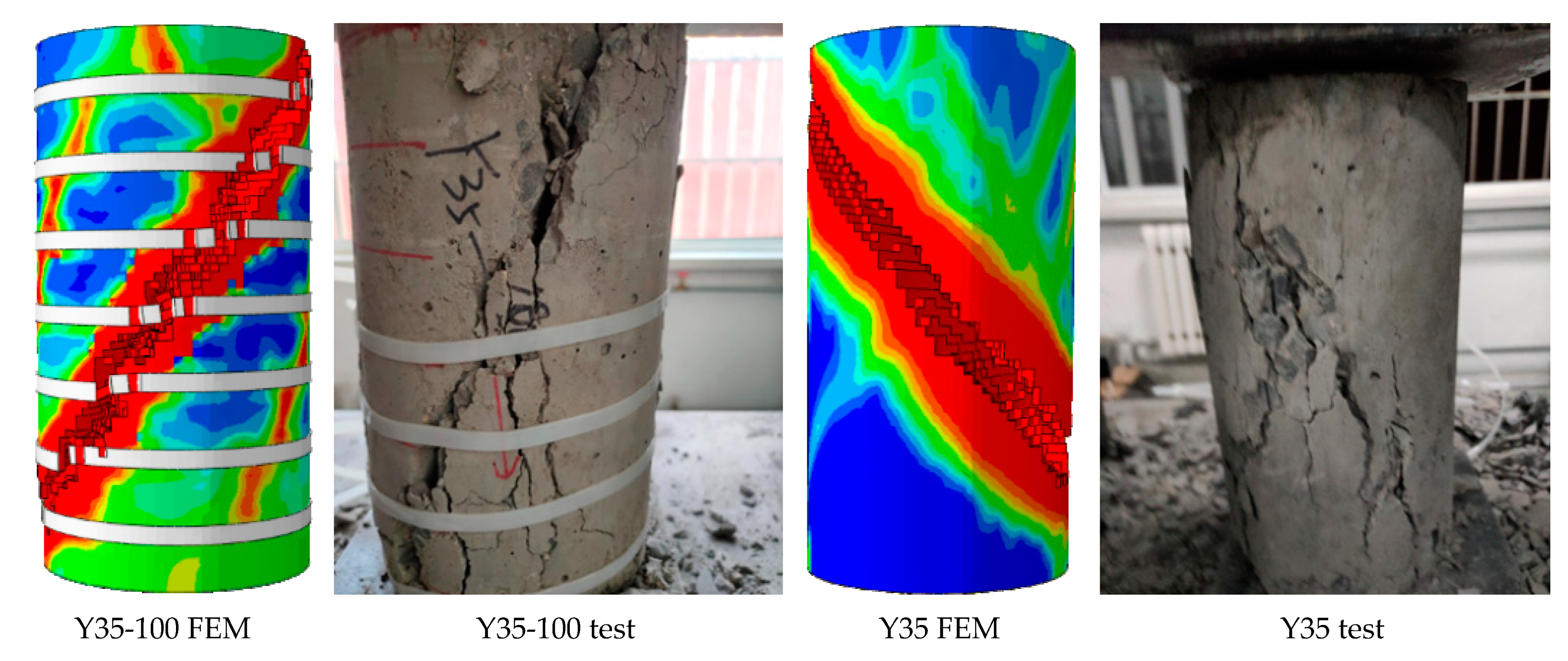

5.3. Comparison of Concrete Cylinder Test and Numerical Simulation Results

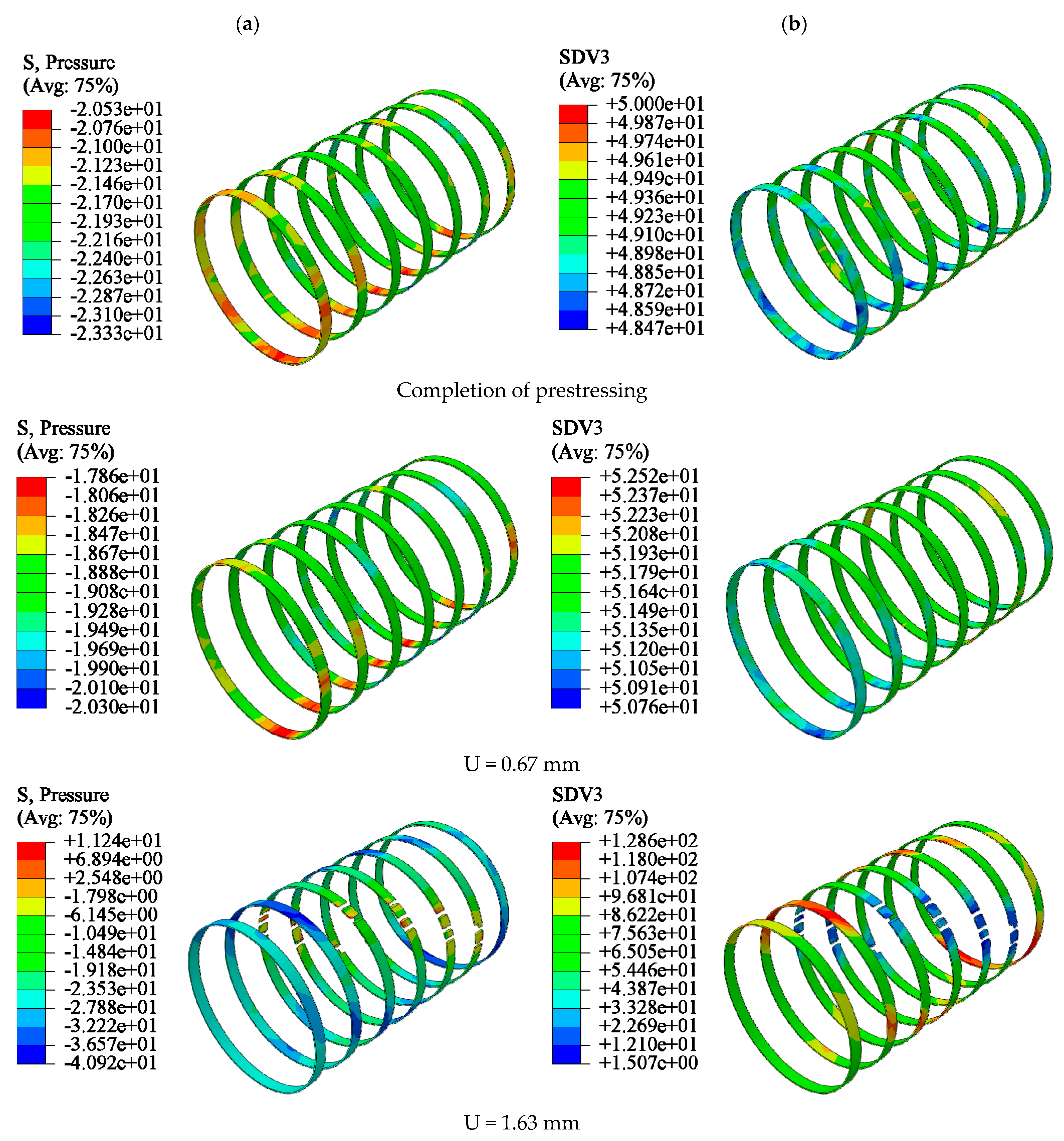

5.4. Damage Analysis of Nylon Ties

6. Conclusions

- The tensile strength of the nylon ties decreased with increasing temperature, but the preload caused by the cold shrinkage of the ties increased. After high temperature cooling at 80 °C, 100 °C, and 120 °C, the tensile strengths of the tie were 138 MPa, 127.64 MPa, and 113.41 MPa, respectively, and the average pre-tightening forces generated by the ties were 27.82 kPa, 33.33 kPa, and 44.29 kPa, respectively.

- The prestress produced by nylon ties with different heating temperatures owing to the decrease in temperature can enhance the bearing capacity, compressive strength, and initial elastic modulus of CCs; the higher the heating temperature, the higher the prestress and the more evident the restraint effect. Compared with the UC, the compressive strength of specimens with 80 °C, 100 °C, and 120 °C confinement schemes increased by 9.46%, 15.73%, and 20.06%, respectively.

- The finite element software ABAQUS was used to establish the damage-failure model of the CC. The damage laws of confined CCs under uniaxial compression were analyzed from the aspects of maximum principal strain, equivalent plastic strain, and compression damage, which can effectively improve the ductility and elastic modulus of members. At the initial loading stage, the prestress applied by the ties effectively inhibited the volume expansion of the concrete, and the lateral pressure on the ties increased slowly. With the increase in load, the effect of the prestressed restraint decreased, and the growth rate of the lateral force of the tie belts accelerated. Combined with the results of the numerical simulation and test, the reliability of the damage model was verified, providing a theoretical reference for the study of the damage law of engineering reinforcements.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Garden, H.; Hollaway, L. An experimental study of the failure modes of reinforced concrete beams strengthened with prestressed carbon composite plates. Compos. Part B Eng. 1998, 29, 411–424. [Google Scholar] [CrossRef]

- Bakis, C.E.; Bank, L.C.; Brown, V.L.; Cosenza, E.; Davalos, J.F.; Lesko, J.J.; Machida, A.; Rizkalla, S.H.; Triantafillou, T.C. Fiber-Reinforced Polymer Composites for Construction—State-of-the-Art Review. J. Compos. Constr. 2002, 6, 73–87. [Google Scholar] [CrossRef] [Green Version]

- Liu, C.; Wang, X.; Shi, J.; Liu, L.; Wu, Z. Experimental study on the flexural behavior of RC beams strengthened with prestressed BFRP laminates. Eng Struct. 2021, 233, 111801. [Google Scholar] [CrossRef]

- Komurlu, E.; Kesimal, A. An Experimental Study on Reinforcing Rock Columns Using Heated Polymeric Ties. Rock Mech. Rock Eng. 2015, 49, 1995–2003. [Google Scholar] [CrossRef]

- Bai, Y.-L.; Mei, S.-J.; Li, P.; Xu, J. Cyclic stress-strain model for large-rupture strain fiber-reinforced polymer (LRS FRP)-confined concrete. J. Build. Eng. 2021, 42, 102459. [Google Scholar] [CrossRef]

- Zhang, P.; Lv, X.; Liu, Y.; Zou, X.; Li, Y.; Wang, J.; Sheikh, S.A. Novel fiber reinforced polymers (FRP)-ultrahigh performance concrete (UHPC) hybrid beams with improved shear performance. Constr. Build. Mater. 2021, 286, 122720. [Google Scholar] [CrossRef]

- Nepomuceno, E.; Sena-Cruz, J.; Correia, L.; D’Antino, T. Review on the bond behavior and durability of FRP bars to concrete. Constr. Build. Mater. 2021, 287, 123042. [Google Scholar] [CrossRef]

- Raheem, M.M.; Rasheed, H.A. Development of an objective model to predict shear capacity of FRP U-wrap anchors. Compos. Struct. 2021, 265, 113762. [Google Scholar] [CrossRef]

- Kim, Y.; Hwang, G.; Jeon, J. A volume-porous conductive electrode by hexagonal close packing of phenolic resin-based carbon spheres. Mater. Lett. 2019, 254, 301–304. [Google Scholar] [CrossRef]

- Tang, K.; Zhang, A.; Ge, T.; Liu, X.; Tang, X.; Li, Y. Research progress on modification of phenolic resin. Mater. Today Commun. 2020, 26, 101879. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, H.; Eberhardt, T.L.; Gu, Q.; Pan, H. Preparation of carboxylated lignin-based epoxy resin with excellent mechanical properties. Eur. Polym. J. 2021, 150, 110389. [Google Scholar] [CrossRef]

- Ma, C.; Sánchez-Rodríguez, D.; Kamo, T. A comprehensive study on the oxidative pyrolysis of epoxy resin from fiber/epoxy composites: Product characteristics and kinetics. J. Hazard. Mater. 2021, 412, 125329. [Google Scholar] [CrossRef]

- Gan, L.; Xiao, Z.; Pan, H.; Xu, W.; Wang, Y.; Wang, X. Efficiently production of micron-sized polyethylene terephthalate (PET) powder from waste polyester fibre by physicochemical method. Adv. Powder Technol. 2021, 32, 630–636. [Google Scholar] [CrossRef]

- Zhou, L.; Wu, L.; Qin, P.; Li, B.-G. Synthesis and properties of long chain polyesters from biobased 1,5-pentanediol and aliphatic α,ω-diacids with 10–16 carbon atoms. Polym. Degrad. Stab. 2021, 187, 109546. [Google Scholar] [CrossRef]

- Komurlu, E.; Kesimal, A. Using sprayed polymer as tunnel support. In Proceedings of the 7th Asian Rock Mechanics Symposium, Seoul, Korea, 15–19 October 2012. [Google Scholar]

- Xu, N. Toughening Modification Study of Polyamide 66 (PA66) at a Low Temperature. Master’s Thesis, Liaoning University, Shenyang, China, 2016. [Google Scholar]

- Tran, T.K.; Tran, N.T.; Kim, D.J. Enhancing impact resistance of hybrid ultra-high-performance fiber-reinforced concretes through strategic use of polyamide fibers. Constr. Build. Mater. 2020, 271, 121562. [Google Scholar] [CrossRef]

- Qiao, Y.; Chakravarthula, S.; Deliwala, J. Flexural strength of polyamide 6 intercalated/exfoliated cements. Mater. Sci. Eng. A 2005, 404, 270–273. [Google Scholar] [CrossRef]

- Horgnies, M.; Gutiérrez-González, S.; Rodríguez, A.; Calderón, V. Effects of the use of polyamide powder wastes on the microstructure and macroscopic properties of masonry mortars. Cem. Concr. Comp. 2014, 52, 64–72. [Google Scholar] [CrossRef]

- Singh, R.; Kumar, R.; Ranjan, N.; Penna, R.; Fraternali, F. On the recyclability of polyamide for sustainable composite structures in civil engineering. Compos. Struct. 2018, 184, 704–713. [Google Scholar] [CrossRef]

- Moghaddam, H.; Samadi, M.; Pilakoutas, K.; Mohebbi, S. Axial compressive behavior of concrete actively confined by metal strips; part A: Experimental study. Mater. Struct. 2010, 43, 1369–1381. [Google Scholar] [CrossRef]

- Gholampour, A.; Pour, A.F.; Hassanli, R.; Ozbakkaloglu, T. Behavior of Actively Confined Rubberized Concrete under Cyclic Axial Compression. J. Struct. Eng. 2019, 145, 04019131. [Google Scholar] [CrossRef]

- Rong, C.; Shi, Q. Analysis constitutive models for actively and passively confined concrete. Compos. Struct. 2020, 256, 113009. [Google Scholar] [CrossRef]

- Mohammadi, M.; Wu, Y.-F. Modified plastic-damage model for passively confined concrete based on triaxial tests. Compos. Part B Eng. 2018, 159, 211–223. [Google Scholar] [CrossRef]

- Moghaddam, H.; Samadi, M.; Pilakoutas, K. Compressive behavior of concrete actively confined by metal strips, part B: Analysis. Mater. Struct. 2010, 43, 1383–1396. [Google Scholar] [CrossRef]

- Li, C.L. Study on the Actively Confined Mechanism of Circular Concrete Columns Strengthened with Lateral Pre-Tensioned FRP. Master’s Thesis, Beijing Jiaotong University, Beijing, China, 2013. [Google Scholar]

- Hibbitt, K.; Karlssorn, B.; Sorensen, P. Abaqus/Standard User Subroutines Reference Manual; The Pennsylvania State University: State College, PA, USA, 2010. [Google Scholar]

- Mander, J.B.; Priestley, M.J.N.; Park, R. Theoretical Stress-Strain Model for Confined Concrete. J. Struct. Eng. 1988, 114, 1804–1826. [Google Scholar] [CrossRef] [Green Version]

- Sun, H.; Yang, Y.; Ju, Y.; Zhang, Q.; Peng, R. Numerical analysis of deformation, failure and energy release mechanisms of fractured coal rock under unloading conditions, China. J. China Coal Soc. 2014, 39, 258–272. [Google Scholar]

| Concrete Strength | Number | Heating Temperature of Nylon Ties (Deviation: ±1 °C) | Binding Space of Nylon Ties | Specimen Size |

|---|---|---|---|---|

| C35 | Y35-120 | 120 °C | 40 mm | ϕ150 mm × 300 mm |

| Y35-100 | 100 °C | 40 mm | ϕ150 mm × 300 mm | |

| Y35-80 | 80 °C | 40 mm | ϕ150 mm × 300 mm | |

| Y35 | - | - | ϕ150 mm × 300 mm | |

| C40 | Y40-120 | 120 °C | 40 mm | ϕ150 mm × 300 mm |

| Y40-100 | 100 °C | 40 mm | ϕ150 mm × 300 mm | |

| Y40-80 | 80 °C | 40 mm | ϕ150 mm × 300 mm | |

| Y40 | - | - | ϕ150 mm × 300 mm | |

| C45 | Y45-120 | 120 °C | 40 mm | ϕ150 mm × 300 mm |

| Y45-100 | 100 °C | 40 mm | ϕ150 mm × 300 mm | |

| Y45-80 | 80 °C | 40 mm | ϕ150 mm × 300 mm | |

| Y45 | - | - | ϕ150 mm × 300 mm |

| Performance of Nylon Ties | |||

|---|---|---|---|

| Physical properties | Density | 1.14 kg/m3 | |

| Glass transition temperature | 55–58 °C | ||

| Deformation rate | 80 °C | 0.10% | |

| 100 °C | 0.15% | ||

| 120 °C | 0.19% | ||

| Mechanical properties | Tensile strength | 80 °C | 138 MPa |

| 100 °C | 127.64 MPa | ||

| 120 °C | 113.41 MPa | ||

| Coefficient of linear expansion | 1.14 × 10−5/°C | ||

| Heat resistance [16] | Melting point | 252–265 °C | |

| Embrittlement temperature | −30 °C | ||

| Continuous deformation resistance temperature | 80–120 °C | ||

| Specific heat capacity | 1700 J/(kg·K) | ||

| Time | Heated Temperature of Nylon Ties | ||

|---|---|---|---|

| 80 °C | 100 °C | 120 °C | |

| 1 min | 26.07 | 37.27 | 42.59 |

| 2 min | 35.43 | 48.62 | 57.34 |

| 4 min | 44.37 | 52.14 | 66.52 |

| 8 min | 44.41 | 52.19 | 66.68 |

| 16 min | 44.41 | 52.19 | 66.68 |

| Time | Heated Temperature of Nylon Ties | ||

|---|---|---|---|

| 80 °C | 100 °C | 120 °C | |

| 1 min | 7.89 | 11.76 | 14.06 |

| 2 min | 9.43 | 12.94 | 16.12 |

| 4 min | 11.10 | 14.31 | 17.76 |

| 8 min | 11.24 | 14.46 | 17.89 |

| 16 min | 11.24 | 14.46 | 17.89 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Shang, S.; Zhou, H.; Jiang, C.; Huai, H.; Xu, Z. Experimental and Numerical Study on Uniaxial Compression Failure of Concrete Confined by Nylon Ties. Materials 2022, 15, 2975. https://doi.org/10.3390/ma15092975

Wang H, Shang S, Zhou H, Jiang C, Huai H, Xu Z. Experimental and Numerical Study on Uniaxial Compression Failure of Concrete Confined by Nylon Ties. Materials. 2022; 15(9):2975. https://doi.org/10.3390/ma15092975

Chicago/Turabian StyleWang, Hui, Shichang Shang, Hang Zhou, Cheng Jiang, Hongyuan Huai, and Zhichao Xu. 2022. "Experimental and Numerical Study on Uniaxial Compression Failure of Concrete Confined by Nylon Ties" Materials 15, no. 9: 2975. https://doi.org/10.3390/ma15092975

APA StyleWang, H., Shang, S., Zhou, H., Jiang, C., Huai, H., & Xu, Z. (2022). Experimental and Numerical Study on Uniaxial Compression Failure of Concrete Confined by Nylon Ties. Materials, 15(9), 2975. https://doi.org/10.3390/ma15092975