Tensile Test Coupled with an EBSD Study of a GH4169 Ring Rolled Product

Abstract

:1. Introduction

2. Materials and Test Method

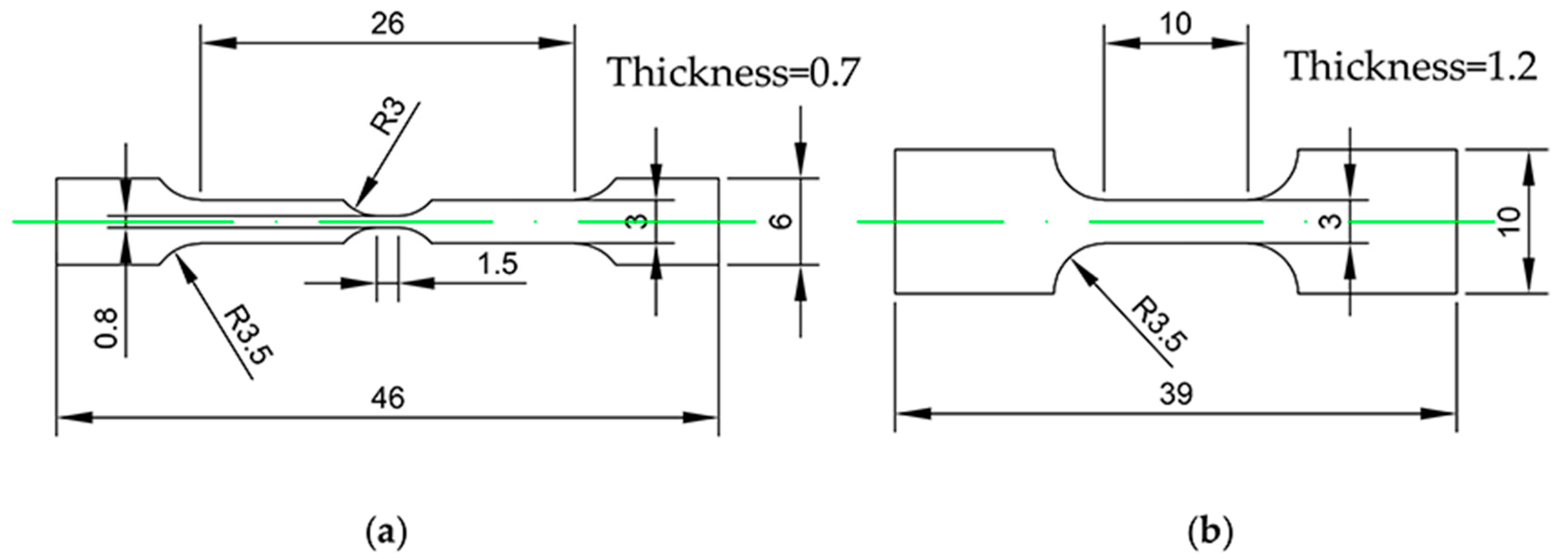

2.1. Specimen Preparation

2.2. Test Method

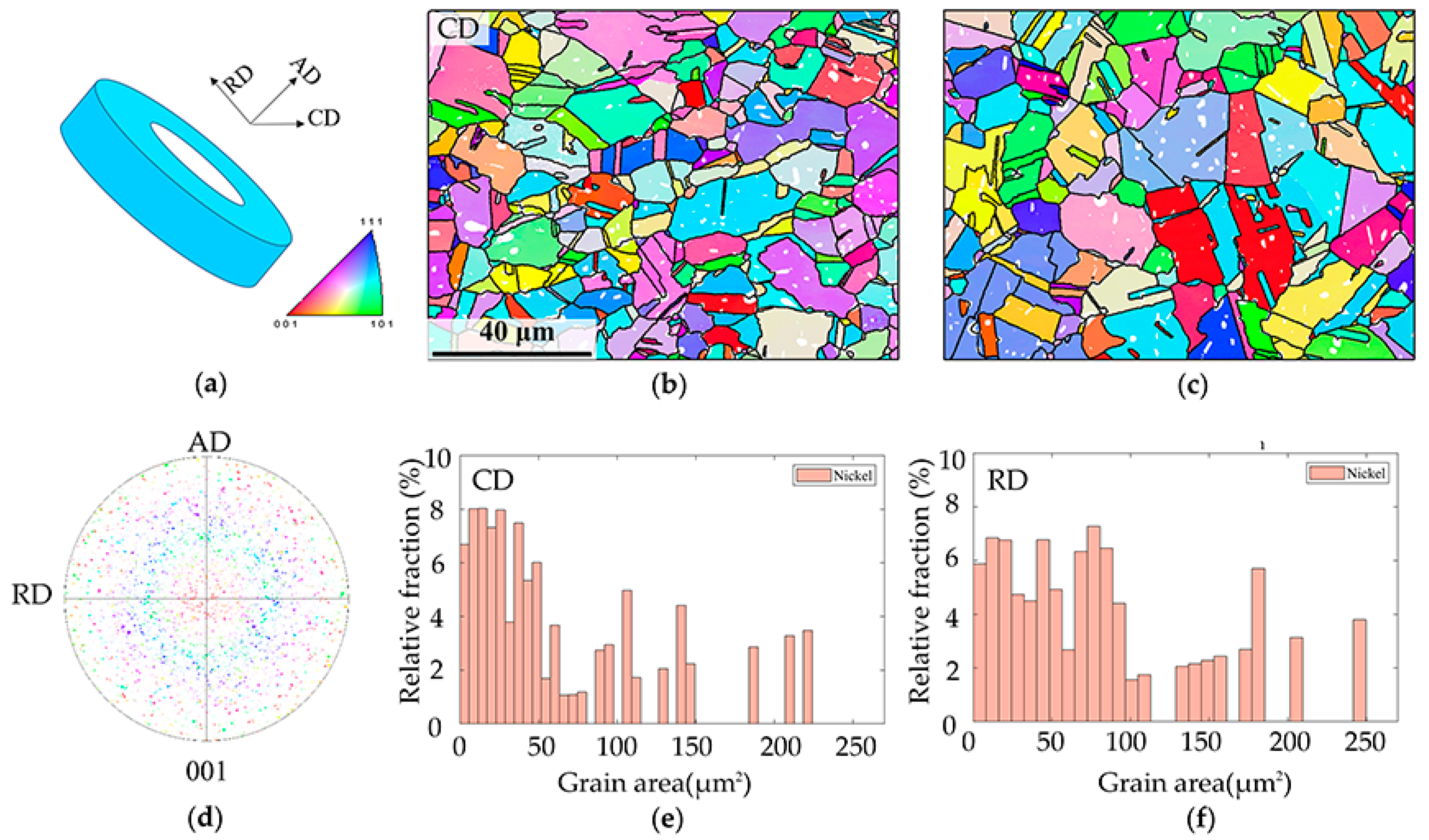

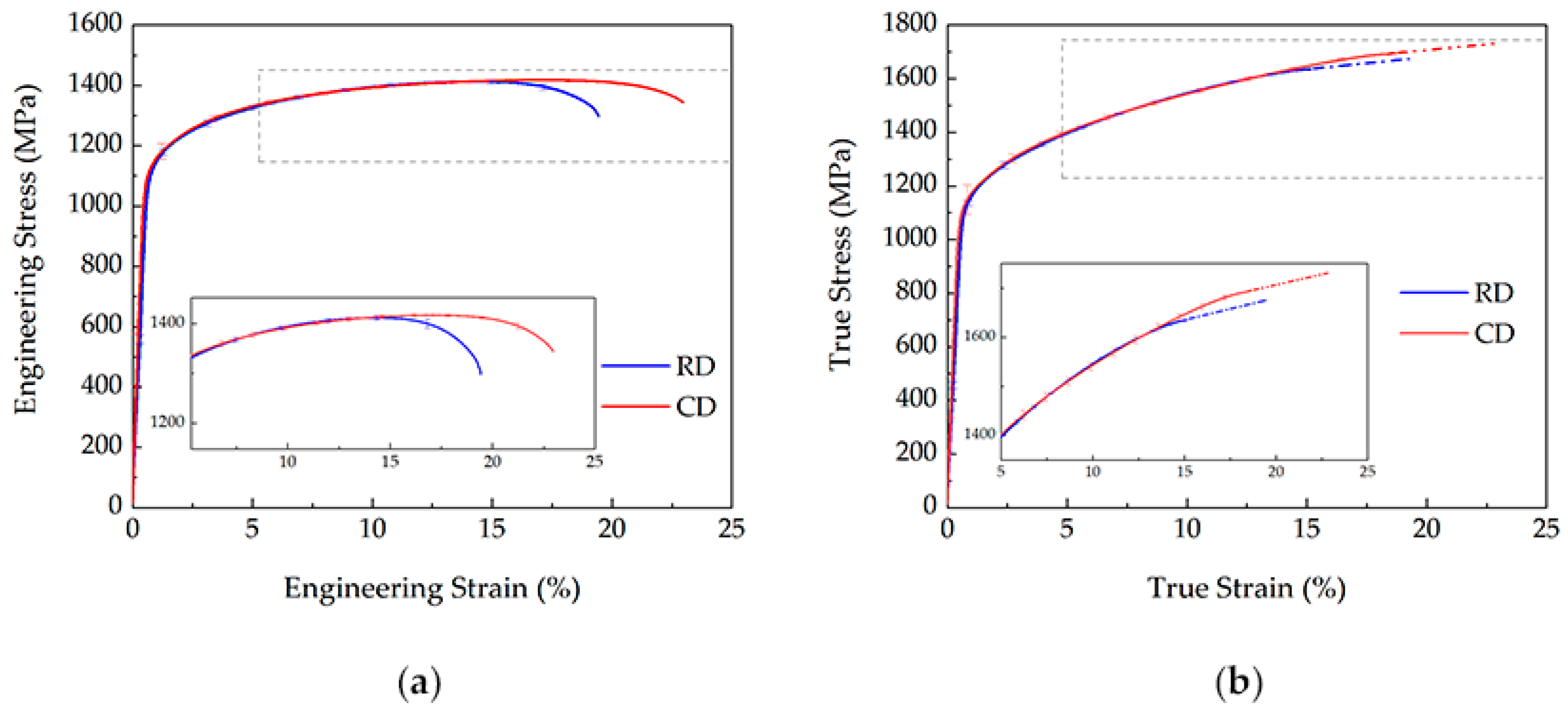

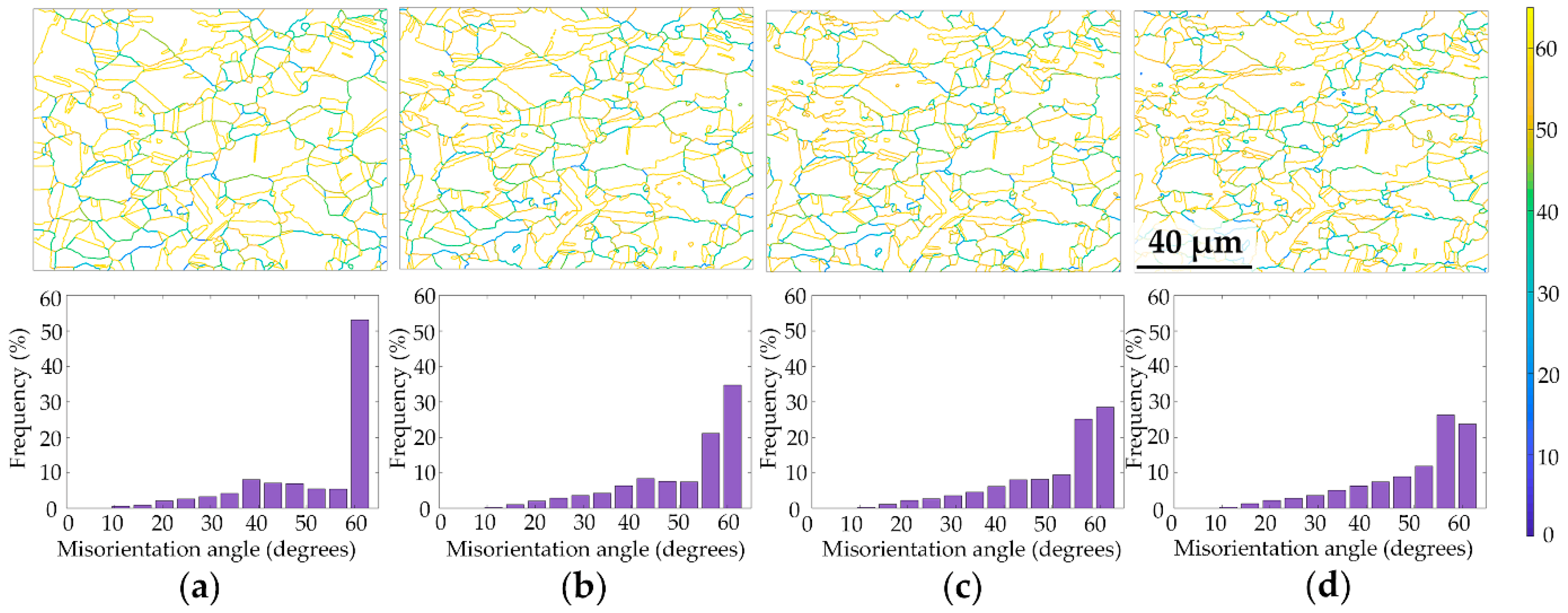

3. Result and Discussion

4. Conclusions

- The microstructure of the ring-rolled GH4169 alloy is evenly distributed in CD and RD directions, and the orientation distribution is random. In addition, the microstructure in both directions presents a large number of twin characteristics;

- The tensile properties along the circumferential direction and radial direction show a close stress–strain curve in the conventional tensile tests. The ultimate tensile strength (UTS) values in RD and CD are 1422 and 1418 MPa, respectively, and the elongation (EL) values are 18.64 and 22.92%, respectively;

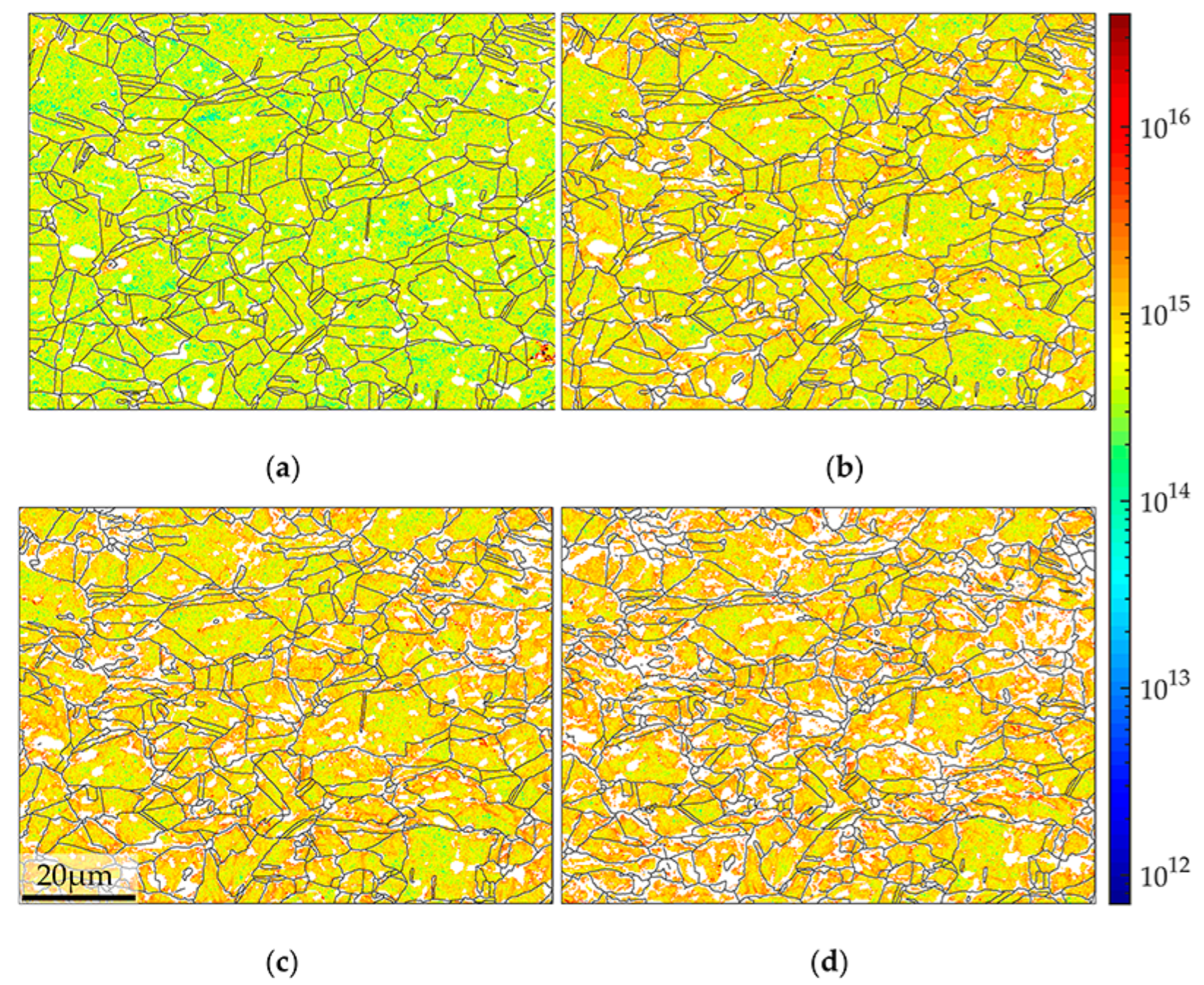

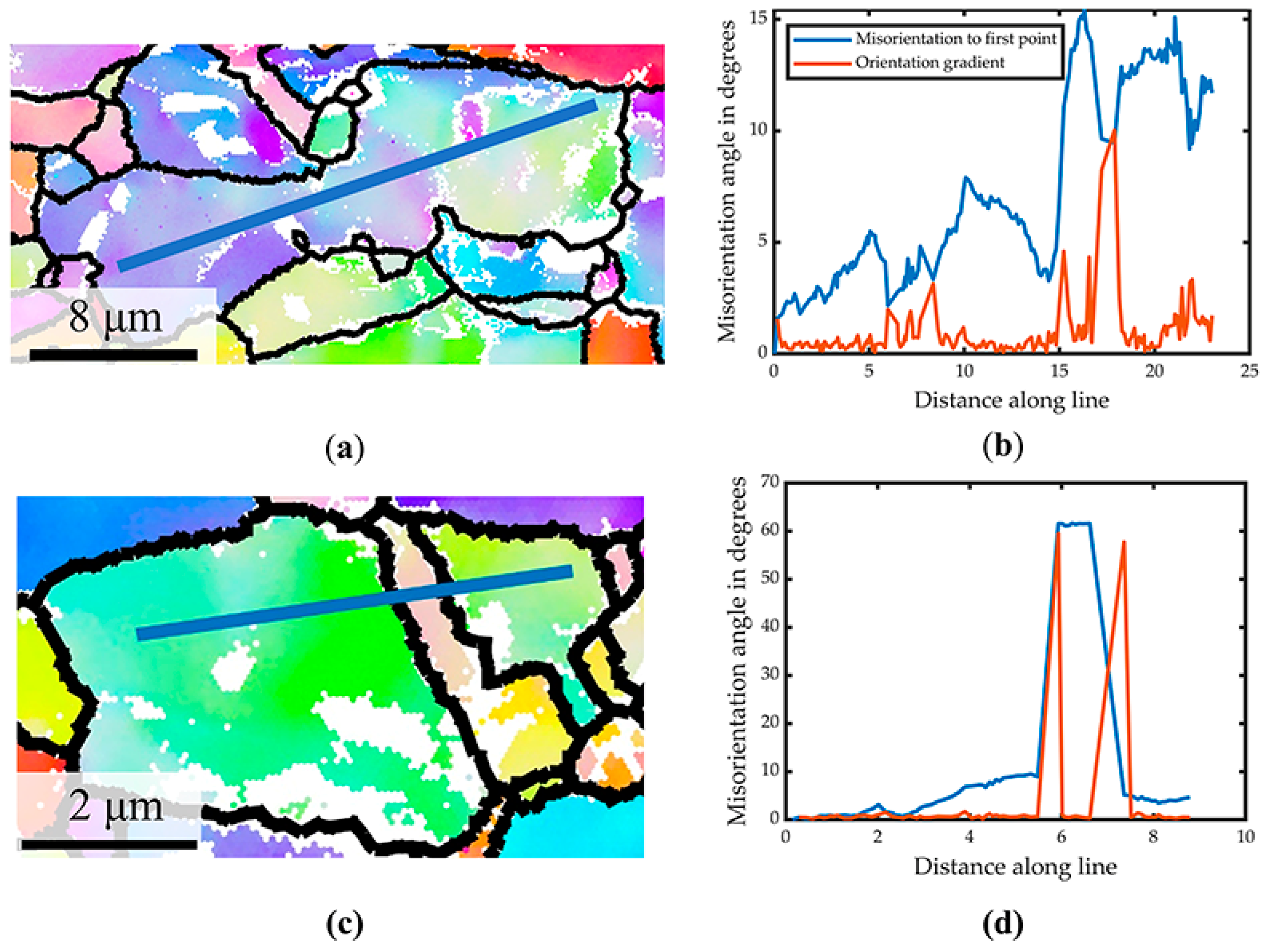

- During the in situ tensile test, low-angle grain boundaries show a tendency to distribute in regions neighboring grains with relatively small sizes;

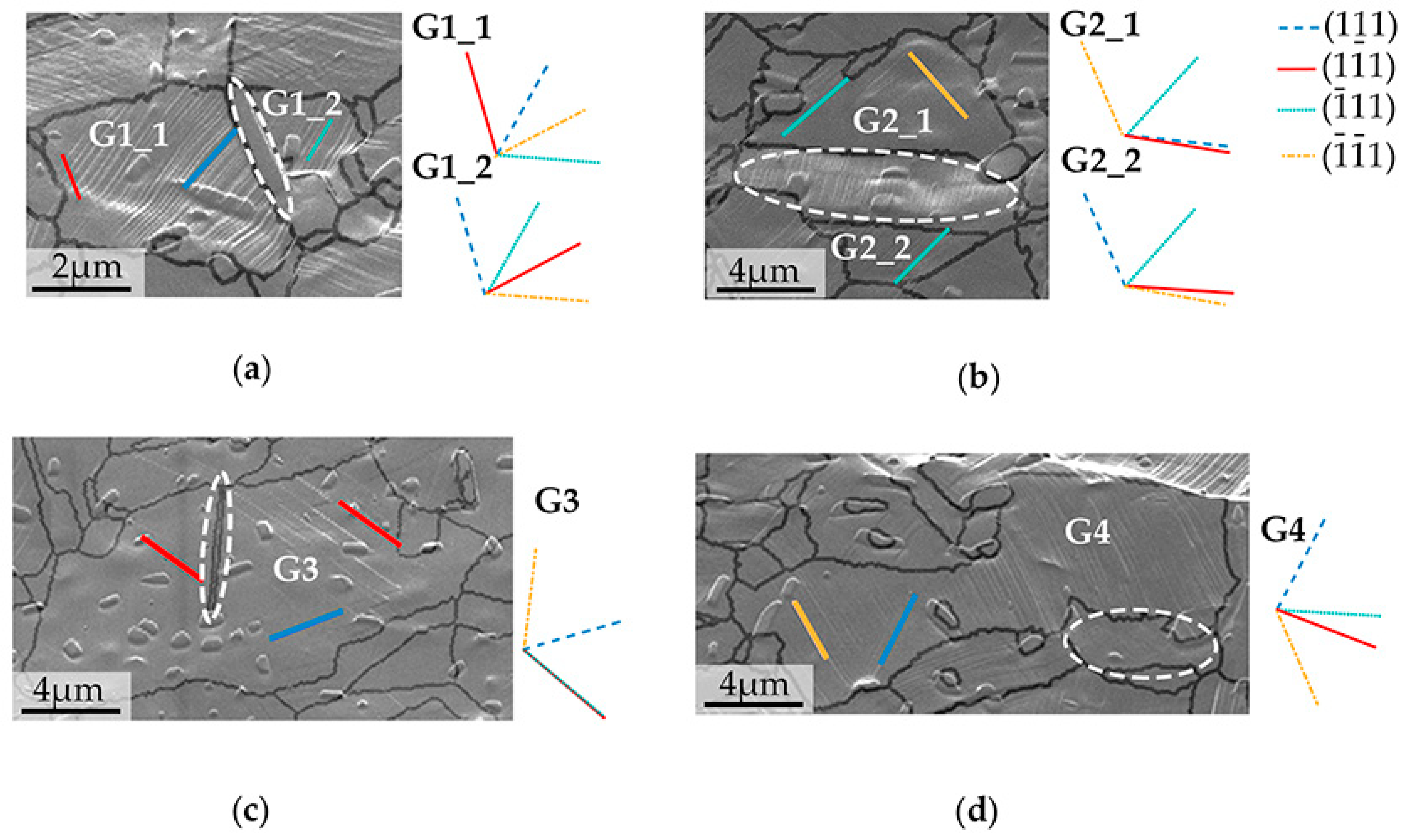

- In the grain interior, the traces of most grains show good agreement with Schmid’s law. Several traces of grains featuring twins disobey the Schmid’s law. The interplay between secondary phase and slip system activation is less important compared to twins, which promote or hinder the slip system activation. The behavior of the slip system further influenced the rotation activity of the grains. Further study should focus mainly on the interactions between the matrix and the twins.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Geng, P.; Qin, G.; Ma, H.; Zhou, J.; Ma, N. Linear Friction Welding of Dissimilar Ni-Based Superalloys: Microstructure Evolution and Thermo-Mechanical Interaction. J. Mater. Res. Technol. 2021, 11, 633–649. [Google Scholar] [CrossRef]

- Guo, J. The Current Situation of Application and Development of Superalloys in The Fields of Energy Industry. Acta Metall. Sin. 2010, 46, 513–527. [Google Scholar] [CrossRef]

- Yin, Q.; Liu, Z.; Wang, B.; Song, Q.; Cai, Y. Recent Progress of Machinability and Surface Integrity for Mechanical Machining Inconel 718: A Review. Int. J. Adv. Manuf. Technol. 2020, 109, 215–245. [Google Scholar] [CrossRef]

- Williams, J.C.; Starke, E.A. Progress in Structural Materials for Aerospace Systems11The Golden Jubilee Issue—Selected Topics in Materials Science and Engineering: Past, Present and Future, Edited by S. Suresh. Acta Mater. 2003, 51, 5775–5799. [Google Scholar] [CrossRef]

- He, H.; Yi, Y.; Huang, S.; Zhang, Y. An Improved Process for Grain Refinement of Large 2219 Al Alloy Rings and Its Influence on Mechanical Properties. J. Mater. Sci. Technol. 2019, 35, 55–63. [Google Scholar] [CrossRef]

- Guenther, S.; Schwich, G.; Hirt, G. Investigation of Bond Formation Behaviour in Composite Ring Rolling. J. Mater. Process. Technol. 2020, 275, 116364. [Google Scholar] [CrossRef]

- Jiang, H.; Shan, D.; Guo, B.; Zong, Y. Effect of Fibrous Macrostructure on Mechanical Properties, Anisotropy and Fracture Mechanism of Roller Bearing Ring. Mater. Sci. Eng. A 2021, 816, 141311. [Google Scholar] [CrossRef]

- Qi, H.; Qin, F.; Li, Y.; Chen, H.; Liu, C.; Qi, H. Effect of Feed Rate on Texture Evolution of 42CrMo Casting Blank During Hot Ring Rolling. In Forming the Future; Daehn, G., Cao, J., Kinsey, B., Tekkaya, E., Vivek, A., Yoshida, Y., Eds.; Springer: Cham, Switzerland, 2021; pp. 2507–2519. [Google Scholar]

- Hua, L.; Pan, L.; Lan, J. Researches on the Ring Stiffness Condition in Radial–Axial Ring Rolling. J. Mater. Process. Technol. 2009, 209, 2570–2575. [Google Scholar] [CrossRef]

- Han, X.; Hua, L.; Zhou, G.; Wang, X.; Lu, B. An Innovative Eccentric Ring Rolling Method for Fabricating Eccentric Rings. Int. J. Mech. Sci. 2017, 120, 120–135. [Google Scholar] [CrossRef]

- Qian, D.; He, Y.; Wang, F.; Chen, Y.; Lu, X. Microstructure and Mechanical Properties of M50 Steel by Combining Cold Rolling with Austempering. Metals 2020, 10, 381. [Google Scholar] [CrossRef] [Green Version]

- Lv, N.; Liu, D.; Hu, Y.; Yang, Y.; Wang, J. Multi-Objective Optimization of Parametric Design for Profile Ring Rolling Process Based on Residual Stress Control. Int. J. Adv. Manuf. Technol. 2022, 119, 6613–6631. [Google Scholar] [CrossRef]

- Zayadi, H.; Parvizi, A.; Farahmand, H.R.; Rahmatabadi, D. Investigation of Ring Rolling Key Parameters for Decreasing Geometrical Ring Defects by 3D Finite Element and Experiments. Arab. J. Sci. Eng. 2021, 46, 12105–12115. [Google Scholar] [CrossRef]

- Yeom, J.T.; Kim, J.H.; Park, N.K.; Choi, S.S.; Lee, C.S. Ring-Rolling Design for a Large-Scale Ring Product of Ti–6Al–4V Alloy. J. Mater. Process. Technol. 2007, 187–188, 747–751. [Google Scholar] [CrossRef]

- Cleaver, C.; Allwood, J. Incremental Profile Ring Rolling with Axial and Circumferential Constraints. CIRP Ann. 2017, 66, 285–288. [Google Scholar] [CrossRef] [Green Version]

- Lv, N.; Liu, D.; Yang, Y.; Wang, J. Studying the Residual Stress Homogenization and Relief in Aerospace Rolling Ring of GH4169 Alloy Using Ageing Treatment. Int. J. Adv. Manuf. Technol. 2021, 112, 3415–3429. [Google Scholar] [CrossRef]

- Jia, R.; Zeng, W.; Zhao, Z.; Zhang, P.; Xu, J.; Wang, Q. In-Situ Investigation on the Deformation Mechanism of Duplex Microstructure of a near α Titanium Alloy. J. Alloys Compd. 2022, 893, 162184. [Google Scholar] [CrossRef]

- Borkar, H.; Seifeddine, S.; Jarfors, A.E.W. In-Situ EBSD Study of Deformation Behavior of Al–Si–Cu Alloys during Tensile Testing. Mater. Des. 2015, 84, 36–47. [Google Scholar] [CrossRef]

- Zhang, W.; Lu, J.; Wang, J.; Sang, L.; Ma, J.; Zhang, Y.; Zhang, Z. In-Situ EBSD Study of Deformation Behavior of Inconel 740H Alloy at High-Temperature Tensile Loading. J. Alloys Compd. 2020, 820, 153424. [Google Scholar] [CrossRef]

- Britton, T.B.; Jiang, J.; Guo, Y.; Vilalta-Clemente, A.; Wallis, D.; Hansen, L.N.; Winkelmann, A.; Wilkinson, A.J. Tutorial: Crystal Orientations and EBSD—Or Which Way Is Up? Mater. Charact. 2016, 117, 113–126. [Google Scholar] [CrossRef] [Green Version]

- Xia, Y.; Miao, K.; Wu, H.; Geng, L.; Xu, C.; Ku, C.-S.; Fan, G. Superior Strength-Ductility Synergy of Layered Aluminum under Uniaxial Tensile Loading: The Roles of Local Stress State and Local Strain State. Int. J. Plast. 2022, 152, 103240. [Google Scholar] [CrossRef]

- Gao, Y.; Ding, Y.; Ma, Y.; Chen, J.; Wang, X.; Xu, J. Evolution of Annealing Twins in Inconel 625 Alloy during Tensile Loading. Mater. Sci. Eng. A 2022, 831, 142188. [Google Scholar] [CrossRef]

- Chen, P.; Mao, S.C.; Liu, Y.; Wang, F.; Zhang, Y.F.; Zhang, Z.; Han, X.D. In-Situ EBSD Study of the Active Slip Systems and Lattice Rotation Behavior of Surface Grains in Aluminum Alloy during Tensile Deformation. Mater. Sci. Eng. A 2013, 580, 114–124. [Google Scholar] [CrossRef]

- Li, Z.; Wen, Z.; Gu, S.; Pei, H.; Gao, H.; Mao, Q. In-Situ Observation of Crack Initiation and Propagation in Ni-Based Superalloy with Film Cooling Holes during Tensile Test. J. Alloys Compd. 2019, 793, 65–76. [Google Scholar] [CrossRef]

- Singh, J.; Kim, M.-S.; Kaushik, L.; Kang, J.-H.; Kim, D.; Martin, E.; Choi, S.-H. Twinning-Detwinning Behavior of E-Form Mg Alloy Sheets during in-Plane Reverse Loading. Int. J. Plast. 2020, 127, 102637. [Google Scholar] [CrossRef]

- Nautiyal, P.; Boesl, B.; Agarwal, A. Test Methods for In-Situ Mechanical Characterization. In In-Situ Mechanics of Materials: Principles, Tools, Techniques and Applications; Nautiyal, P., Boesl, B., Agarwal, A., Eds.; Springer: Cham, Switzerland, 2020; pp. 75–112. ISBN 978-3-030-43320-8. [Google Scholar]

- Sang, L.; Lu, J.; Wang, J.; Ullah, R.; Sun, X.; Zhang, Y.; Zhang, Z. In-Situ SEM Study of Temperature-Dependent Tensile Behavior of Inconel 718 Superalloy. J. Mater. Sci. 2021, 56, 16097–16112. [Google Scholar] [CrossRef]

- Bachmann, F.; Hielscher, R.; Schaeben, H. Texture Analysis with MTEX—Free and Open Source Software Toolbox. Solid State Phenom. 2010, 160, 63–68. [Google Scholar] [CrossRef] [Green Version]

- Lavogiez, C.; Dancette, S.; Cazottes, S.; Le Bourlot, C.; Maire, E. In Situ Analysis of Plasticity and Damage Nucleation in a Ti-6Al-4V Alloy and Laser Weld. Mater. Charact. 2018, 146, 81–90. [Google Scholar] [CrossRef]

- Jiang, H.; Song, Y.; Wu, Y.; Shan, D.; Zong, Y. Macrostructure, Microstructure and Mechanical Properties Evolution during 8Cr4Mo4V Steel Roller Bearing Inner Ring Forging Process. Mater. Sci. Eng. A 2020, 798, 140196. [Google Scholar] [CrossRef]

- Jiang, H.; Wu, Y.; Gong, X.; Shan, D.; Zong, Y. Control of Flow Lines during the Forging Process of Bearing Outer Rings with a Deviated Groove. Int. J. Adv. Manuf. Technol. 2020, 106, 753–764. [Google Scholar] [CrossRef]

- Wilkinson, A.J.; Meaden, G.; Dingley, D.J. High Resolution Mapping of Strains and Rotations Using Electron Backscatter Diffraction. Mater. Sci. Technol. 2006, 22, 1271–1278. [Google Scholar] [CrossRef] [Green Version]

- Arsenlis, A.; Parks, D.M. Crystallographic Aspects of Geometrically-Necessary and Statistically-Stored Dislocation Density. Acta Mater. 1999, 47, 1597–1611. [Google Scholar] [CrossRef]

- Pantleon, W. Resolving the Geometrically Necessary Dislocation Content by Conventional Electron Backscattering Diffraction. Scr. Mater. 2008, 58, 994–997. [Google Scholar] [CrossRef]

- Yoo, Y.S.J.; Lim, H.; Emery, J.; Kacher, J. Relating Microstructure to Defect Behavior in AA6061 Using a Combined Computational and Multiscale Electron Microscopy Approach. Acta Mater. 2019, 174, 81–91. [Google Scholar] [CrossRef]

- Nye, J.F. Some Geometrical Relations in Dislocated Crystals. Acta Metall. 1953, 1, 153–162. [Google Scholar] [CrossRef]

- Bieler, T.R.; Eisenlohr, P.; Roters, F.; Kumar, D.; Mason, D.E.; Crimp, M.A.; Raabe, D. The Role of Heterogeneous Deformation on Damage Nucleation at Grain Boundaries in Single Phase Metals. Int. J. Plast. 2009, 25, 1655–1683. [Google Scholar] [CrossRef]

- Chen, Z.; Daly, S.H. Active Slip System Identification in Polycrystalline Metals by Digital Image Correlation (DIC). Exp. Mech. 2017, 57, 115–127. [Google Scholar] [CrossRef]

| Grains of Interest | Slip System | Schmid Factor | Grains of Interest | Slip System | Schmid Factor |

|---|---|---|---|---|---|

| G1_1 | (111) [01] | 0.4523 | G2_1 | (11) [01] | 0.4564 |

| (111) [10] | 0.4028 | (11) [0] | 0.4040 | ||

| (11) [0] | 0.3351 | (1) [011] | 0.3805 | ||

| G1_2 | (11) [101] | 0.4517 | G2_2 | (11) [0] | 0.4587 |

| (11) [0] | 0.4028 | (11) [101] | 0.4002 | ||

| (111) [10] | 0.3328 | (111) [10] | 0.3857 | ||

| G3 | (11) [110] | 0.4037 | G4 | (1) [0] | 0.4448 |

| (11) [01] | 0.3710 | (111) [10] | 0.4350 | ||

| (111) [01] | 0.2520 | (1) [011] | 0.3759 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, H.; Niu, H.; Wu, H.; Li, R.; Fan, G. Tensile Test Coupled with an EBSD Study of a GH4169 Ring Rolled Product. Materials 2022, 15, 2891. https://doi.org/10.3390/ma15082891

Wang H, Niu H, Wu H, Li R, Fan G. Tensile Test Coupled with an EBSD Study of a GH4169 Ring Rolled Product. Materials. 2022; 15(8):2891. https://doi.org/10.3390/ma15082891

Chicago/Turabian StyleWang, Hao, Haoyi Niu, Hao Wu, Rengeng Li, and Guohua Fan. 2022. "Tensile Test Coupled with an EBSD Study of a GH4169 Ring Rolled Product" Materials 15, no. 8: 2891. https://doi.org/10.3390/ma15082891

APA StyleWang, H., Niu, H., Wu, H., Li, R., & Fan, G. (2022). Tensile Test Coupled with an EBSD Study of a GH4169 Ring Rolled Product. Materials, 15(8), 2891. https://doi.org/10.3390/ma15082891