Tensile Strength of Class F Fly Ash and Fly Ash with Bentonite Addition as a Material for Earth Structures

Abstract

:1. Introduction

2. Materials and Methods

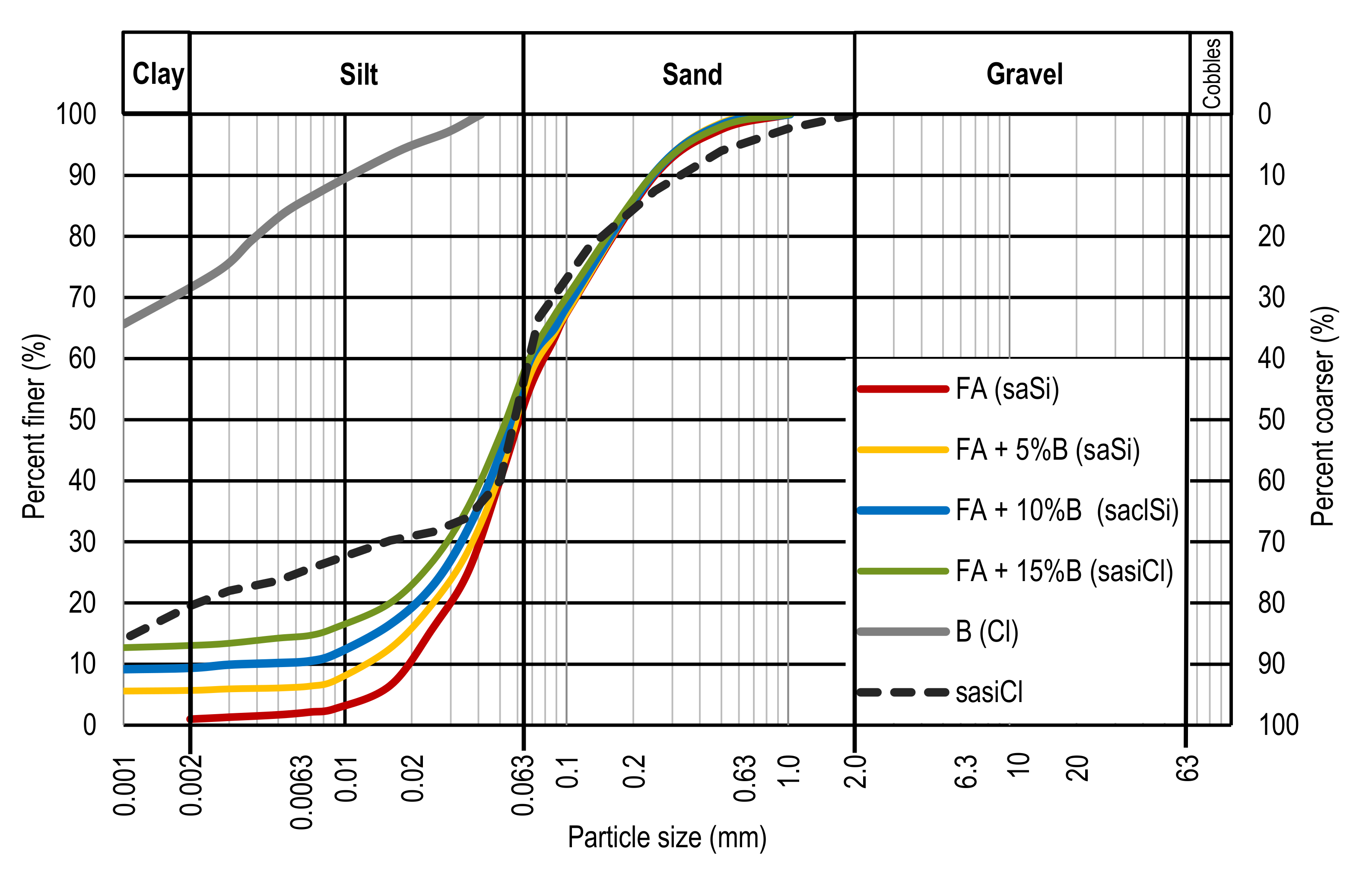

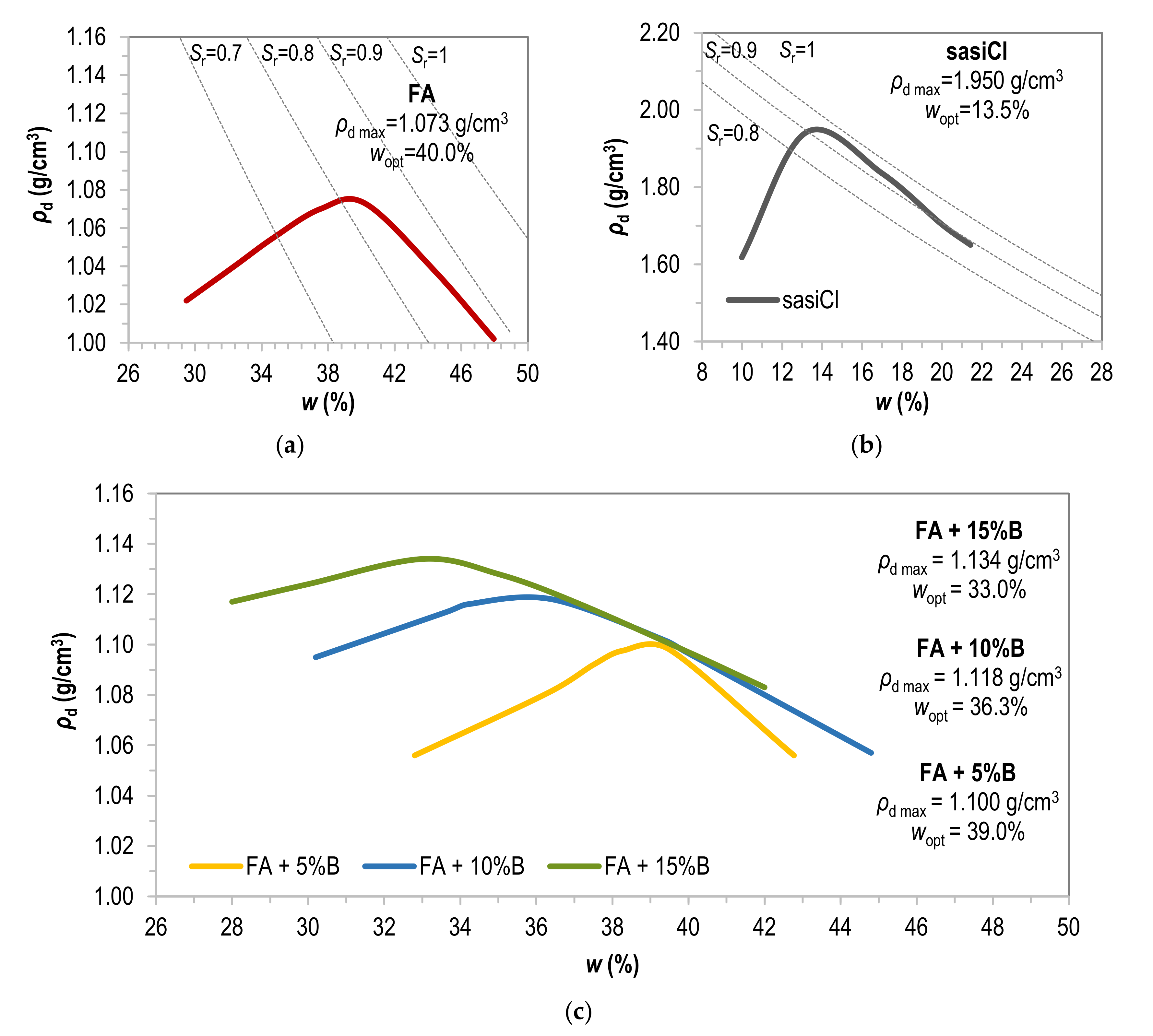

2.1. Materials

2.2. Methods

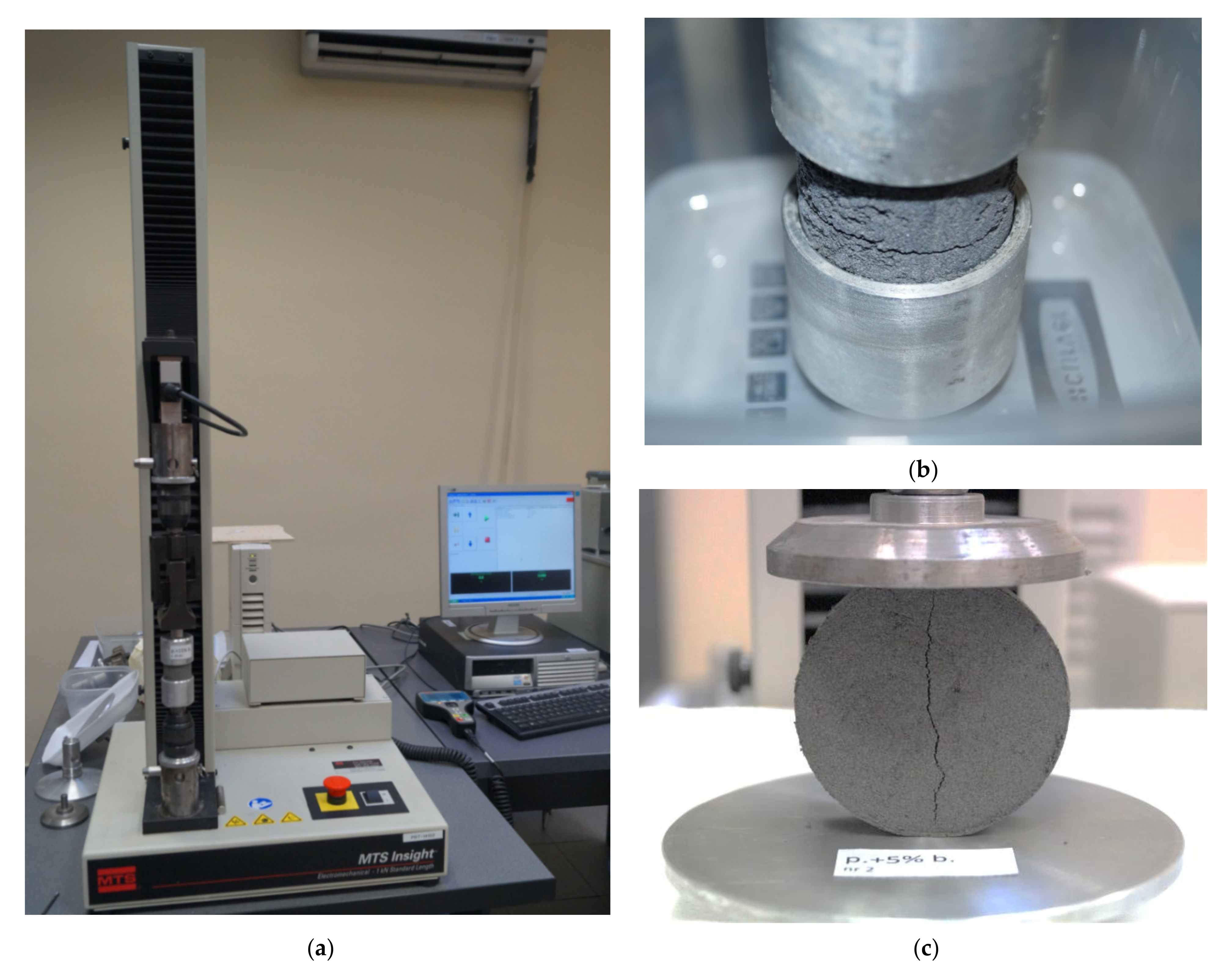

2.2.1. Direct Method

2.2.2. Indirect Method

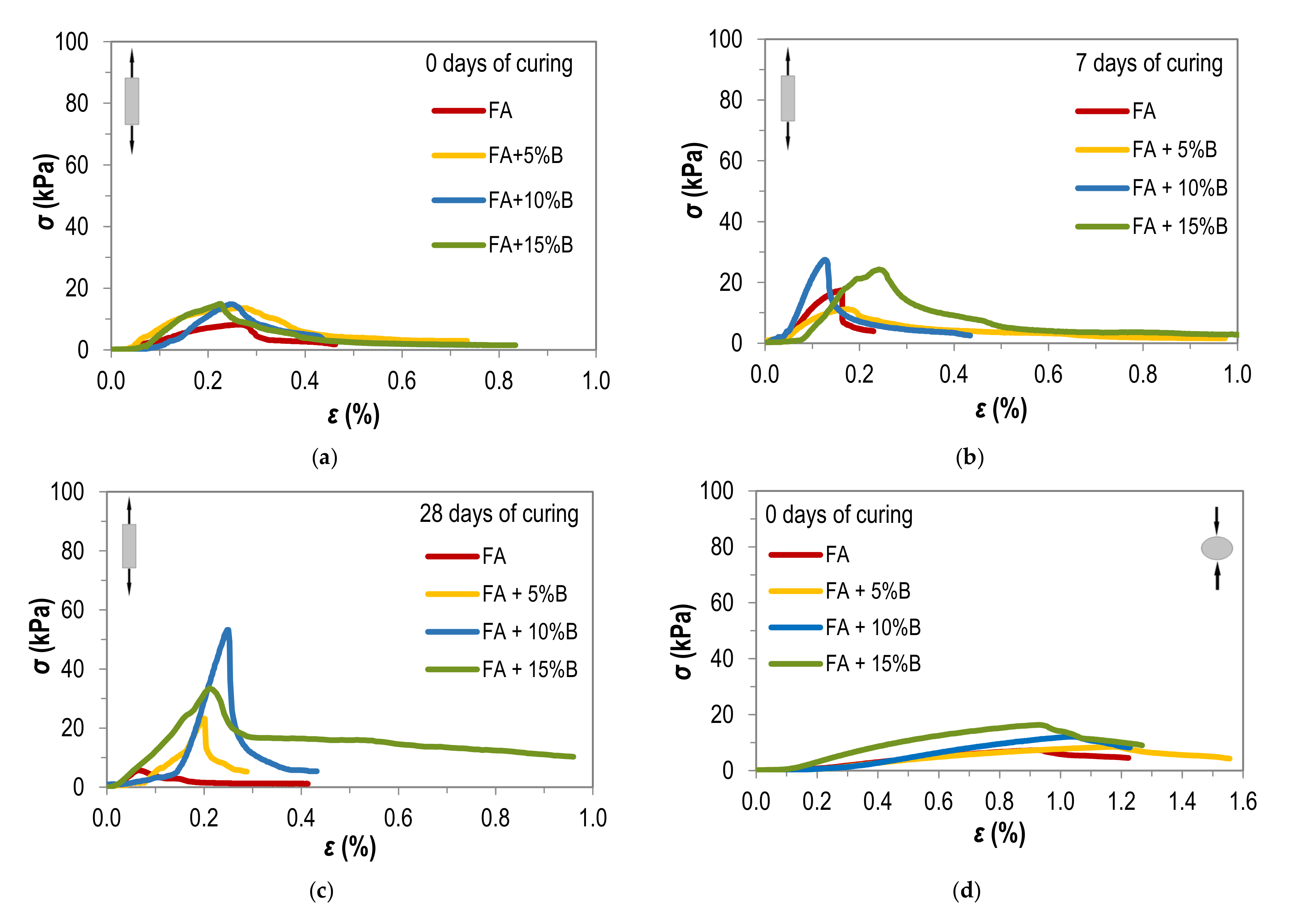

3. Results and Discussion

4. Conclusions

- (1)

- Bentonite considerably influences the tensile strength of fly ash, established by both direct and indirect (Brazilian) methods. The addition of 10% bentonite enhances the tensile strength of fly ash compacted by the standard Proctor method at optimum moisture content, tested by the Brazilian method, by more than 10 times.

- (2)

- Raising the bentonite content to 15% increases the strain recorded at sample fracture, while the strength increase remains the same or decreases. Addition of bentonite increases the relative strain of the sample in proportion to the percentage of the additive. The value of relative strain during cracking in the fly ash sample with 15% addition of bentonite was established as: 1.4% with the Brazilian method and 0.6% with the direct method.

- (3)

- The tensile strength values obtained by means of the Brazilian method are comparable or higher than the direct method, which is especially apparent at higher values of destructive forces. Results of the Brazilian test may overestimate the tensile strength of tested granular materials.

- (4)

- The curing time of the fly ash with various bentonite additions affects the tensile strength tested by direct and indirect methods. The lowest values of the tensile strength are obtained for the samples tested directly after compaction, the highest—after 28 days of cure.

- (5)

- The tested cohesive soil, sandy silty clay (sasiCl) shows a maximum value of tensile stress at higher relative strain—about four times—than fly ash with bentonite addition tested by the direct method. In the case of the indirect test method, the relative strain while achieving maximum tensile strength is comparable between cohesive soil and fly ash with bentonite additions. The values of maximum tensile strength are comparable for tested clay and the fly ash improved by 10–15% of bentonite addition after 28 days of curing.

- (6)

- According to the results obtained from the tensile tests, it can be assumed that the addition of 10% bentonite in the case of fly ash allows to obtain optimal values of tensile strength. Increasing the bentonite addition to the fly ash to 15% slightly increases the tensile strength.

- (7)

- The tests carried out and presented in the paper have shown that different tensile strength values can be obtained depending on the method. This suggests that the test conditions (methods) should be always indicated or described with the presented value of the tensile strength of the soil.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Vaniček, I. The importance of tensile strength in geotechnical engineering. Acta Geotech. Slov. 2013, 1, 5–17. [Google Scholar]

- Zabielska-Adamska, K. Laboratory compaction of fly ash and fly ash with cement additions. J. Hazard. Mater. 2008, 151, 481–489. [Google Scholar] [CrossRef] [PubMed]

- Lu, N.; Wu, B.; Tan, C.P. Tensile strength characteristics of unsaturated sands. J. Geotech. Geoenvironmental Eng. 2007, 133, 144–154. [Google Scholar] [CrossRef]

- Plé, O.; Lê, T.N.H. Effect of polypropylene fiber-reinforcement on the mechanical behavior of silty clay. Geotext. Geomembr. 2012, 32, 111–116. [Google Scholar] [CrossRef]

- Zabielska-Adamska, K.; Wasil, M. Tensile strength of fly ash as a barrier layer. In Proceedings of the 19th International Conference on Soil Mechanics and Geotechnical Engineering ICSMGE 2017, Seoul, Korea, 17–22 September 2017; pp. 3215–3218. [Google Scholar]

- Eisele, T.C.; Kawatra, S.K.; Nofal, A. Tensile properties of class c fly-ash as a foundry core binder. Miner. Process. Extr. Met. Rev. 2004, 25, 279–286. [Google Scholar] [CrossRef]

- Araki, H.; Koseki, J.; Sato, T. Tensile strength of compacted rammed earth materials. Soils Found. 2016, 56, 189–204. [Google Scholar] [CrossRef]

- Li, Y.; Guan, F.; Su, H.; Aydin, A.; Beroya-Eitner, M.A.; Zachert, H. A new direct tension test method for soils and soft rocks. Geotech. Test. J. 2020, 43, 1317–1334. [Google Scholar] [CrossRef]

- Wang, R.; Li, Y.; Lv, D.; Zhao, W.; Zhang, C.; Zachert, H.; Eichhoff, G.; Beroya-Eitner, M.A. Comparison of test methods for determining the tensile strength of soil and weak rocks. Front. Earth Sci. 2022, 10, 835851. [Google Scholar] [CrossRef]

- Tamrakar, S.B.; Toyosawa, Y.; Mitachi, T.; Itoh, K. Tensile strength of compacted and saturated soils using newly developed tensile strength measuring apparatus. Soils Found. 2005, 45, 103–110. [Google Scholar] [CrossRef] [Green Version]

- Chakrabarti, S.; Kodikara, J. Direct tensile failure of cementitiously stabilized crushed rock materials. Can. Geotech. J. 2007, 44, 231–240. [Google Scholar] [CrossRef]

- Stirling, R.A.; Hughes, P.; Davie, C.T.; Glendinning, S. Tensile behaviour of unsaturated compacted clay soils—A direct assessment method. Appl. Clay Sci. 2015, 112, 123–133. [Google Scholar] [CrossRef] [Green Version]

- Divya, P.V.; Viswanadham, B.V.S.; Gourc, J.P. Influence of geomembrane on the deformation behaviour of clay-based landfill covers. Geotext. Geomembranes 2012, 34, 158–171. [Google Scholar] [CrossRef]

- Mollamahmutoğlu, M.; Yilmaz, Y. Potential use of fly ash and bentonite mixture as liner or cover at waste disposal areas. Environ. Earth Sci. 2001, 40, 1316–1324. [Google Scholar] [CrossRef]

- Akin, I.D.; Likos, W.J. Brazilian tensile strength testing of compacted clay. Geotech. Test. J. 2017, 40, 608–617. [Google Scholar] [CrossRef]

- Zabielska-Adamska, K.; Wasil, M. Tensile Strength of Barrier Material. In Proceedings of the Environmental Engineering, 10th International Conference, Vilnius, Lithuania, 27–28 April 2017. [Google Scholar] [CrossRef]

- Li, D.; Wong, L.N.Y. The Brazilian disc test for rock mechanic applications: Review and new insights. Rock Mech. Rock Eng. 2012, 46, 269–287. [Google Scholar] [CrossRef]

- Plé, O.; Manicacci, A.; Gourc, J.P.; Camp, S. Flexural behavior of a clay layer: Experimental and numerical study. Can. Geotech. J. 2012, 49, 485–493. [Google Scholar] [CrossRef]

- Camp, S.; Gourc, J.P.; Plé, O. Landfill clay barrier subjected to cracking: Multi-scale analysis of bending tests. Appl. Clay Sci. 2010, 48, 384–392. [Google Scholar] [CrossRef]

- Trabelsi, H.; Romero, E.; Jamei, M. Tensile strength during drying of remoulded and compacted clay: The role of fabric and water retention. Appl. Clay Sci. 2018, 162, 57–68. [Google Scholar] [CrossRef]

- He, S.; Wang, X.; Bai, H.; Xu, Z.; Ma, D. Effect of fiber dispersion, content and aspect ratio on tensile strength of PP fiber reinforced soil. J. Mater. Res. Technol. 2021, 15, 1613–1621. [Google Scholar] [CrossRef]

- Ghosh, A.; Subbarao, C. Tensile strength bearing ratio and slake durability of class f fly ash stabilized with lime and gypsum. J. Mater. Civ. Eng. 2006, 18, 18–27. [Google Scholar] [CrossRef]

- Zabielska-Adamska, K. Shear strength parameters of compacted fly ash–HDPE geomembrane interfaces. Geotext. Geomembranes 2006, 24, 91–102. [Google Scholar] [CrossRef]

- Wasil, M. Effect of bentonite addition on the properties of fly ash as a material for landfill sealing layers. Appl. Sci. 2020, 10, 1488. [Google Scholar] [CrossRef] [Green Version]

- Zabielska-Adamska, K. Hydraulic conductivity of fly ash as a barrier material: Some problems in determination. Environ. Earth Sci. 2020, 79, 321. [Google Scholar] [CrossRef]

- ASTM C618-19; Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. ASTM International: Conshohocken, PA, USA, 2019.

- EN ISO 14688-1:2017; Geotechnical Investigation and Testing—Identification and Classification of Soil—Part 1: Identifica-tion and Description. International Organization for Standardization: Geneva, Switzerland, 2017.

- ASTM D3967-08; Standard Test Method for Splitting Tensile Strength of Intact rock Core Specimens. ASTM International: Conshohocken, PA, USA, 2008.

- Tang, C.-S.; Pei, X.-J.; Wang, D.-Y.; Shi, B.; Li, J. Tensile strength of compacted clayey soil. J. Geotech. Geoenvironmental Eng. 2015, 141, 04014122. [Google Scholar] [CrossRef]

- Ibarra, S.Y.; McKyes, E.; Broughton, R.S. Measurement of tensile strength of unsaturated sandy loam soil. Soil Tillage Res. 2005, 81, 15–23. [Google Scholar] [CrossRef]

- Wang, J.-J.; Zhu, J.-G.; Chiu, C.F.; Zhang, H. Experimental study on fracture toughness and tensile strength of a clay. Eng. Geol. 2007, 94, 65–75. [Google Scholar] [CrossRef]

| Designation | Content (%) |

|---|---|

| Si as SiO2 | 46.42 |

| Al as Al2O3 | 21.01 |

| Fe as Fe2O3 | 6.27 |

| Ca as CaO | 3.12 |

| Mg as MgO | 0.87 |

| S as SO3 | 0.68 |

| P as P2O5 | 0.092 |

| Ti as TiO2 | 1.4 |

| Mn as Mn3O4 | 0.070 |

| Na as Na2O | 0.48978 |

| K as K2O | 0.63535 |

| C as a loss of ignition | 8.23 |

| Material | D50 (mm) | ρs (g/cm3) | Ss (m2/g) |

|---|---|---|---|

| FA | 0.061 | 2.18 | 21.01 |

| FA + 5%B | 0.059 | 2.18 | 42.24 |

| FA + 10%B | 0.056 | 2.22 | 57.90 |

| FA + 15%B | 0.054 | 2.24 | 67.73 |

| sasiCl | 0.058 | 2.68 | 102.58 |

| B | – | 2.45 | 506.84 |

| Material | Days of Curing | Method | Number of Samples (pcs.) | Range of σ (kPa) | Mean σ (kPa) | Range of ε (%) | Method | Number of Samples (pcs.) | Range of σ (kPa) | Mean σ (kPa) | Range of ε (%) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| FA | 0 | Direct | 2 | 8.15–8.55 | 8.35 | 0.3–0.5 | Indirect | 2 | 6.86–7.32 | 7.09 | 0.9 |

| FA + 5%B | 2 | 13.26–13.56 | 13.41 | 0.3–0.4 | 2 | 6.39–8.45 | 7.42 | 1.0–1.2 | |||

| FA + 10%B | 4 | 5.80–14.83 | 10.71 | 0.2–0.3 | 2 | 10.10–12.11 | 11.10 | 0.9–1.0 | |||

| FA + 15%B | 3 | 9.73–15.92 | 13.43 | 0.2–0.4 | 2 | 12.99–16.34 | 14.66 | 1.0 | |||

| FA | 7 | 2 | 10.71–17.39 | 14.05 | 0.1–0.2 | 2 | 10.98–11.65 | 11.32 | 0.7–1.0 | ||

| FA + 5%B | 4 | 11.20–24.95 | 16.08 | 0.1–0.6 | 2 | 21.96–22.78 | 22.37 | 0.6–0.7 | |||

| FA + 10%B | 3 | 11.30–27.41 | 20.27 | 0.1–0.3 | 2 | 27.42–28.07 | 28.20 | 0.7–0.8 | |||

| FA + 15%B | 2 | 23.78–24.27 | 24.02 | 0.2–0.3 | 2 | 36.60–40.83 | 38.72 | 0.7–0.8 | |||

| FA | 28 | 2 | 4.13–5.80 | 4.96 | 0.1 | 2 | 7.22–8.14 | 7.68 | 0.3–0.4 | ||

| FA + 5%B | 3 | 12.97–24.36 | 20.24 | 0.1–0.3 | 4 | 20.67–47.63 | 35.91 | 0.7–1.2 | |||

| FA + 10%B | 3 | 27.50–53.25 | 37.17 | 0.2–0.5 | 4 | 56.39–97.32 | 79.43 | 0.8–0.9 | |||

| FA + 15%B | 3 | 16.31–33.50 | 22.30 | 0.2–0.4 | 4 | 64.95–90.00 | 80.82 | 0.9–1.4 |

| Test Method | Curing Time (Days) | R2 | Adjusted R2 | Standard Error of Estimation | F-Test | Statistical Relevance |

|---|---|---|---|---|---|---|

| Direct | 0 | 0.1043 | 0.0228 | 2.9994 | 1.2803 | irrelevant |

| 7 | 0.3625 | 0.3045 | 5.0850 | 6.2545 | relevant | |

| 28 | 0.2514 | 0.1834 | 12.0791 | 3.6942 | irrelevant | |

| Indirect | 0 | 0.8628 | 0.8514 | 1.2652 | 75.4958 | relevant |

| 7 | 0.9742 | 0.9721 | 1.5667 | 453.7332 | relevant | |

| 28 | 0.7524 | 0.7318 | 16.2163 | 36.4687 | relevant |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wasil, M.; Zabielska-Adamska, K. Tensile Strength of Class F Fly Ash and Fly Ash with Bentonite Addition as a Material for Earth Structures. Materials 2022, 15, 2887. https://doi.org/10.3390/ma15082887

Wasil M, Zabielska-Adamska K. Tensile Strength of Class F Fly Ash and Fly Ash with Bentonite Addition as a Material for Earth Structures. Materials. 2022; 15(8):2887. https://doi.org/10.3390/ma15082887

Chicago/Turabian StyleWasil, Mariola, and Katarzyna Zabielska-Adamska. 2022. "Tensile Strength of Class F Fly Ash and Fly Ash with Bentonite Addition as a Material for Earth Structures" Materials 15, no. 8: 2887. https://doi.org/10.3390/ma15082887

APA StyleWasil, M., & Zabielska-Adamska, K. (2022). Tensile Strength of Class F Fly Ash and Fly Ash with Bentonite Addition as a Material for Earth Structures. Materials, 15(8), 2887. https://doi.org/10.3390/ma15082887